ae8f876bdf3ffc427a9379d331169b4e.ppt

- Количество слайдов: 52

Using the Time Twin Process to Improve Quality and Reduce Costs in High Deposition Welding of Thick Section Aluminium Mike Ludwig Market Segment Manager Shipbuilding & Power Generation Fronius USA - Welding Division 1 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Using the Time Twin Process to Improve Quality and Reduce Costs in High Deposition Welding of Thick Section Aluminium Mike Ludwig Market Segment Manager Shipbuilding & Power Generation Fronius USA - Welding Division 1 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Outline / Introduction / Technical Requirements / Approach / Results / Conclusions 2 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Outline / Introduction / Technical Requirements / Approach / Results / Conclusions 2 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Acknowledgements / Work done by Fronius International R&D Group / Contributors: / Christoph Kammerhuber, International Shipbuilding Segment Manager / Stephen Egerland, International Pipeline/Offshore Segment Manager 3 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Acknowledgements / Work done by Fronius International R&D Group / Contributors: / Christoph Kammerhuber, International Shipbuilding Segment Manager / Stephen Egerland, International Pipeline/Offshore Segment Manager 3 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Liquefied Natural Gas (LNG) / Increasing importance of Natural Gas in Energy Sector / Storage a/o transport over long distances / Significant volume reduction by liquefaction / Approximately 1/600 of the original volume at temperatures of approx. – 162°C / Different methods to transport LNG 4 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Liquefied Natural Gas (LNG) / Increasing importance of Natural Gas in Energy Sector / Storage a/o transport over long distances / Significant volume reduction by liquefaction / Approximately 1/600 of the original volume at temperatures of approx. – 162°C / Different methods to transport LNG 4 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

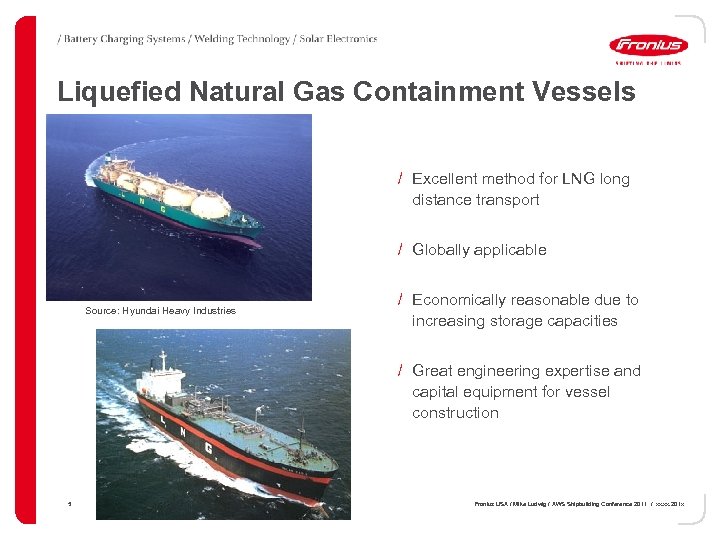

Liquefied Natural Gas Containment Vessels (LNG) / Excellent method for LNG long distance transport / Globally applicable Source: Hyundai Heavy Industries / Economically reasonable due to increasing storage capacities / Great engineering expertise and capital equipment for vessel construction 5 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Liquefied Natural Gas Containment Vessels (LNG) / Excellent method for LNG long distance transport / Globally applicable Source: Hyundai Heavy Industries / Economically reasonable due to increasing storage capacities / Great engineering expertise and capital equipment for vessel construction 5 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

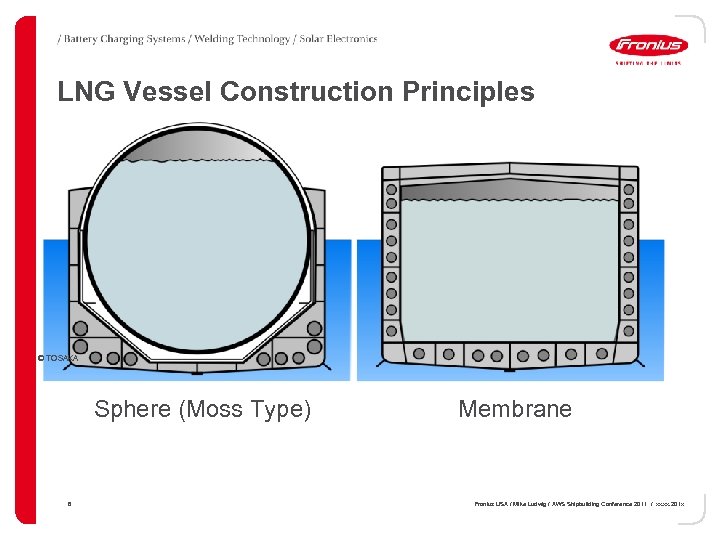

LNG Vessel Construction Principles © TOSAKA Sphere (Moss Type) 6 Membrane Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

LNG Vessel Construction Principles © TOSAKA Sphere (Moss Type) 6 Membrane Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

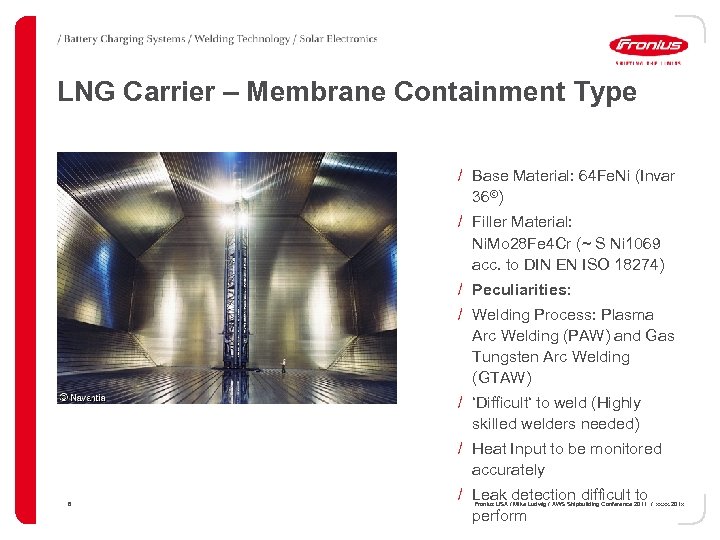

LNG Carrier – Membrane Containment Type / Base Material: 64 Fe. Ni (Invar 36©) / Filler Material: Ni. Mo 28 Fe 4 Cr (~ S Ni 1069 acc. to DIN EN ISO 18274) / Peculiarities: / Welding Process: Plasma Arc Welding (PAW) and Gas Tungsten Arc Welding (GTAW) / ‘Difficult‘ to weld (Highly skilled welders needed) / Heat Input to be monitored accurately 8 / Leak detection difficult to perform Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

LNG Carrier – Membrane Containment Type / Base Material: 64 Fe. Ni (Invar 36©) / Filler Material: Ni. Mo 28 Fe 4 Cr (~ S Ni 1069 acc. to DIN EN ISO 18274) / Peculiarities: / Welding Process: Plasma Arc Welding (PAW) and Gas Tungsten Arc Welding (GTAW) / ‘Difficult‘ to weld (Highly skilled welders needed) / Heat Input to be monitored accurately 8 / Leak detection difficult to perform Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

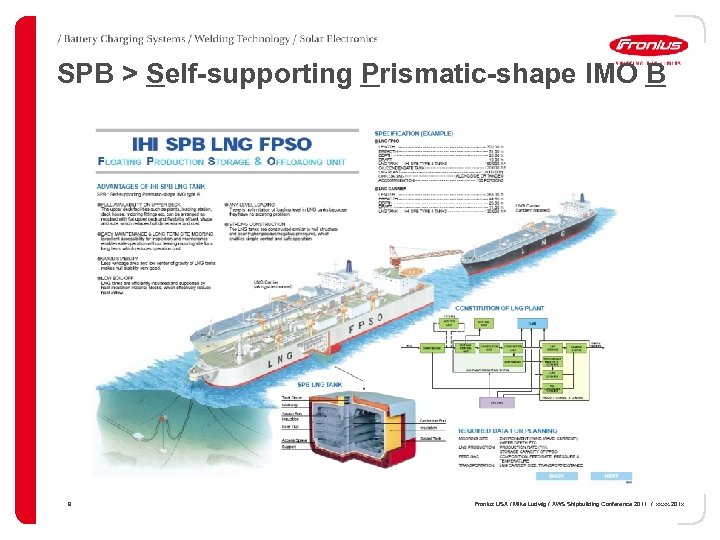

SPB > Self-supporting Prismatic-shape IMO B 9 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

SPB > Self-supporting Prismatic-shape IMO B 9 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

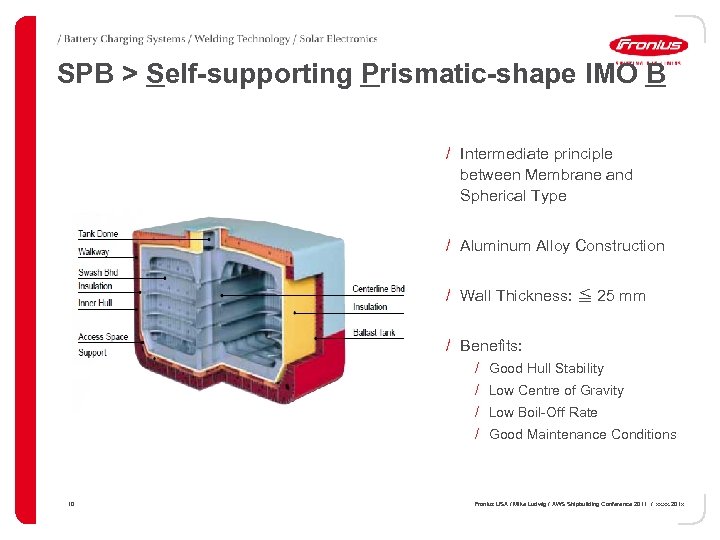

SPB > Self-supporting Prismatic-shape IMO B / Intermediate principle between Membrane and Spherical Type / Aluminum Alloy Construction / Wall Thickness: ≦ 25 mm / Benefits: / Good Hull Stability / Low Centre of Gravity / Low Boil-Off Rate / Good Maintenance Conditions 10 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

SPB > Self-supporting Prismatic-shape IMO B / Intermediate principle between Membrane and Spherical Type / Aluminum Alloy Construction / Wall Thickness: ≦ 25 mm / Benefits: / Good Hull Stability / Low Centre of Gravity / Low Boil-Off Rate / Good Maintenance Conditions 10 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

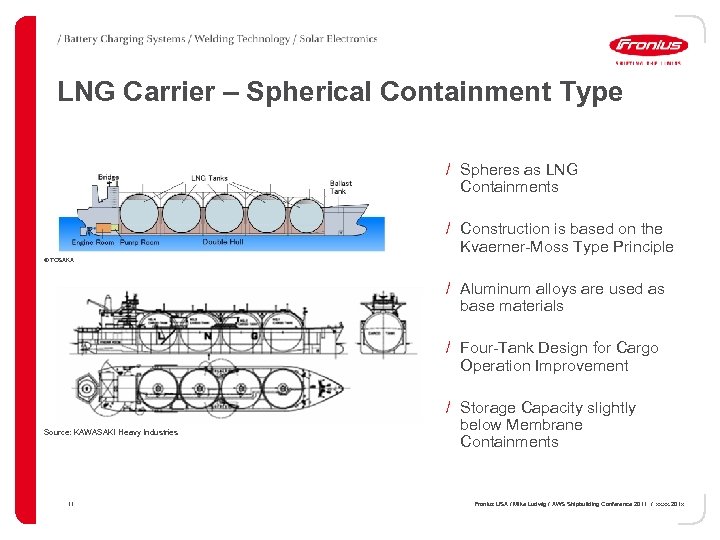

LNG Carrier – Spherical Containment Type / Spheres as LNG Containments / Construction is based on the Kvaerner-Moss Type Principle © TOSAKA / Aluminum alloys are used as base materials / Four-Tank Design for Cargo Operation Improvement Source: KAWASAKI Heavy Industries 11 / Storage Capacity slightly below Membrane Containments Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

LNG Carrier – Spherical Containment Type / Spheres as LNG Containments / Construction is based on the Kvaerner-Moss Type Principle © TOSAKA / Aluminum alloys are used as base materials / Four-Tank Design for Cargo Operation Improvement Source: KAWASAKI Heavy Industries 11 / Storage Capacity slightly below Membrane Containments Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

LNG Sphere Containment Construction / Benefits: / Manufacturing may occur separately to hull-construction / Increased use of semi-automated welding processes / Higher production rates Source: KAWASAKI Heavy Industries 12 / Improved test and repair conditions Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

LNG Sphere Containment Construction / Benefits: / Manufacturing may occur separately to hull-construction / Increased use of semi-automated welding processes / Higher production rates Source: KAWASAKI Heavy Industries 12 / Improved test and repair conditions Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Outline / Introduction / Technical Requirements / Approach / Results / Conclusion 13 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Outline / Introduction / Technical Requirements / Approach / Results / Conclusion 13 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

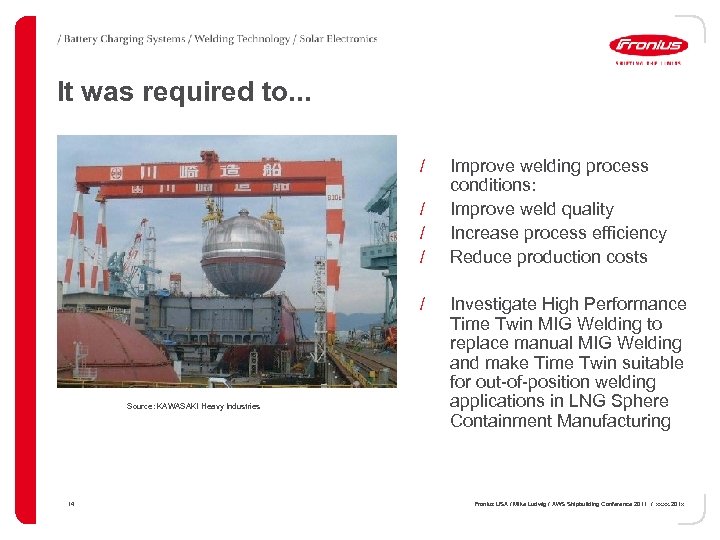

It was required to. . . / / / Source: KAWASAKI Heavy Industries 14 Improve welding process conditions: Improve weld quality Increase process efficiency Reduce production costs Investigate High Performance Time Twin MIG Welding to replace manual MIG Welding and make Time Twin suitable for out-of-position welding applications in LNG Sphere Containment Manufacturing Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

It was required to. . . / / / Source: KAWASAKI Heavy Industries 14 Improve welding process conditions: Improve weld quality Increase process efficiency Reduce production costs Investigate High Performance Time Twin MIG Welding to replace manual MIG Welding and make Time Twin suitable for out-of-position welding applications in LNG Sphere Containment Manufacturing Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Project Goals: / To investigate and evaluate the welding of thick section Aluminium using the MIG single wire & Twin Time (Tandem) welding process in common welding positions and under common welding process conditions / To develop and design a special Single & Tandem Torch for the welding in reduced weld preparation on thick section Aluminium 15 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Project Goals: / To investigate and evaluate the welding of thick section Aluminium using the MIG single wire & Twin Time (Tandem) welding process in common welding positions and under common welding process conditions / To develop and design a special Single & Tandem Torch for the welding in reduced weld preparation on thick section Aluminium 15 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Outline / Introduction / Technical Requirements / Approach / Results / Conclusion 16 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Outline / Introduction / Technical Requirements / Approach / Results / Conclusion 16 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

From where we got started. . . / Traditional manual MIG Welding / Push-Pull Torches required / Usual wire diameters (1. 6 mm) / CV Spray Arc / Highly Skilled Welders / Quality limitations 17 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

From where we got started. . . / Traditional manual MIG Welding / Push-Pull Torches required / Usual wire diameters (1. 6 mm) / CV Spray Arc / Highly Skilled Welders / Quality limitations 17 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Equipment for single wire MIG welding trials Robacta Drive Torch RCU 5000 i 18 TPS 7200/9000 Welding System Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Equipment for single wire MIG welding trials Robacta Drive Torch RCU 5000 i 18 TPS 7200/9000 Welding System Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

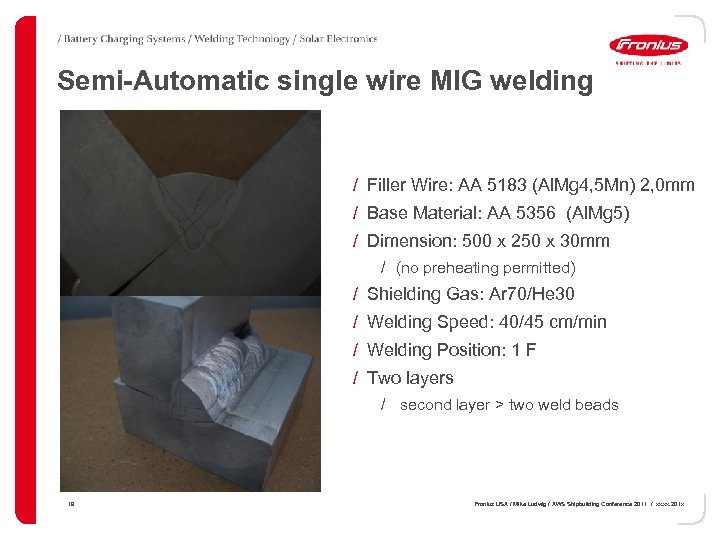

Semi-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 0 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 250 x 30 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 40/45 cm/min / Welding Position: 1 F / Two layers / second layer > two weld beads 19 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Semi-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 0 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 250 x 30 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 40/45 cm/min / Welding Position: 1 F / Two layers / second layer > two weld beads 19 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

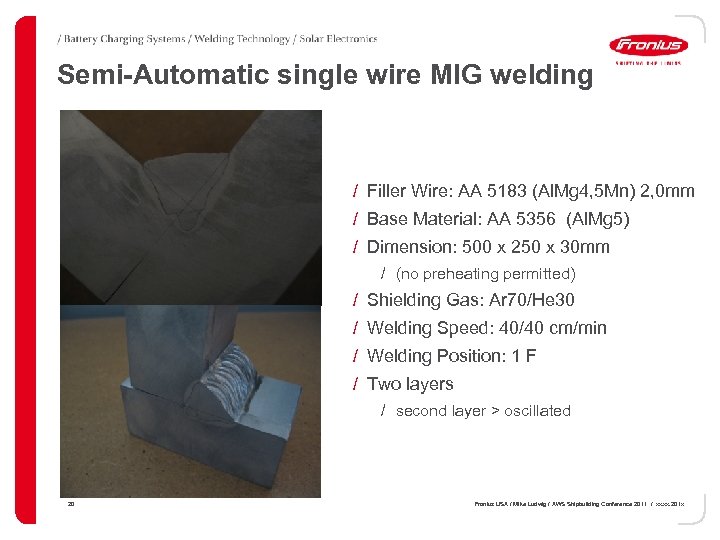

Semi-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 0 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 250 x 30 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 40/40 cm/min / Welding Position: 1 F / Two layers / second layer > oscillated 20 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Semi-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 0 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 250 x 30 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 40/40 cm/min / Welding Position: 1 F / Two layers / second layer > oscillated 20 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

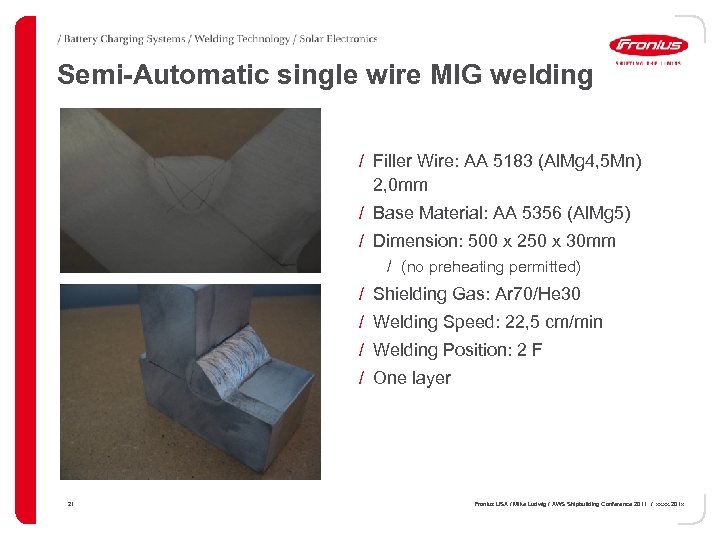

Semi-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 0 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 250 x 30 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 22, 5 cm/min / Welding Position: 2 F / One layer 21 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Semi-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 0 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 250 x 30 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 22, 5 cm/min / Welding Position: 2 F / One layer 21 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

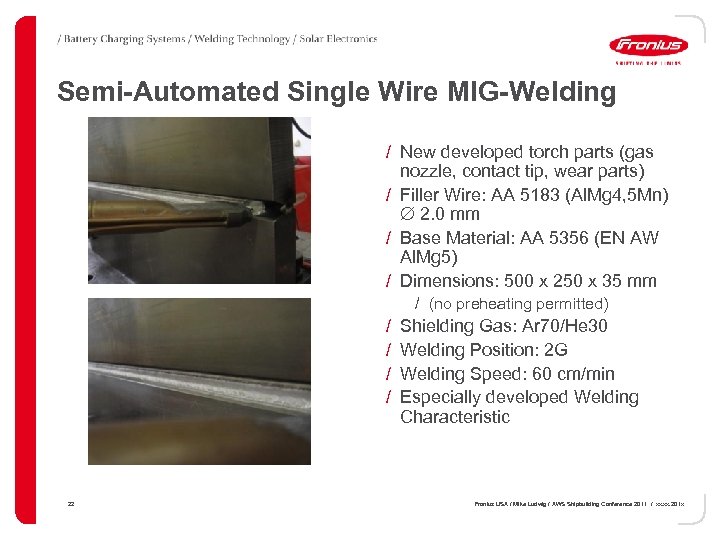

Semi-Automated Single Wire MIG-Welding / New developed torch parts (gas nozzle, contact tip, wear parts) / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2. 0 mm / Base Material: AA 5356 (EN AW Al. Mg 5) / Dimensions: 500 x 250 x 35 mm / (no preheating permitted) / / 22 Shielding Gas: Ar 70/He 30 Welding Position: 2 G Welding Speed: 60 cm/min Especially developed Welding Characteristic Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Semi-Automated Single Wire MIG-Welding / New developed torch parts (gas nozzle, contact tip, wear parts) / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2. 0 mm / Base Material: AA 5356 (EN AW Al. Mg 5) / Dimensions: 500 x 250 x 35 mm / (no preheating permitted) / / 22 Shielding Gas: Ar 70/He 30 Welding Position: 2 G Welding Speed: 60 cm/min Especially developed Welding Characteristic Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Fully-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 1, 6 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 250 x 15 mm / (no preheating permitted) / Shielding Gas: 100% Ar. / Welding Speed: 25 cm/min / Welding Position: 2 F / One layer > oscillated 23 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Fully-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 1, 6 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 250 x 15 mm / (no preheating permitted) / Shielding Gas: 100% Ar. / Welding Speed: 25 cm/min / Welding Position: 2 F / One layer > oscillated 23 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

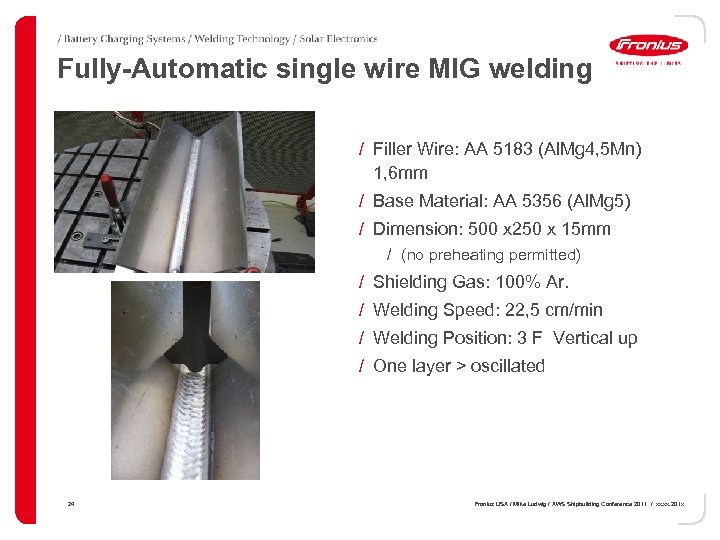

Fully-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 1, 6 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 250 x 15 mm / (no preheating permitted) / Shielding Gas: 100% Ar. / Welding Speed: 22, 5 cm/min / Welding Position: 3 F Vertical up / One layer > oscillated 24 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Fully-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 1, 6 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 250 x 15 mm / (no preheating permitted) / Shielding Gas: 100% Ar. / Welding Speed: 22, 5 cm/min / Welding Position: 3 F Vertical up / One layer > oscillated 24 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

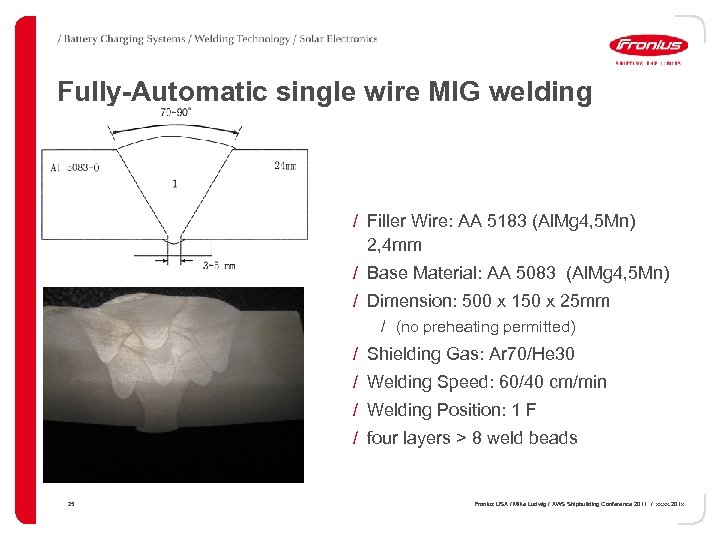

Fully-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 4 mm / Base Material: AA 5083 (Al. Mg 4, 5 Mn) / Dimension: 500 x 150 x 25 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 60/40 cm/min / Welding Position: 1 F / four layers > 8 weld beads 25 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Fully-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 4 mm / Base Material: AA 5083 (Al. Mg 4, 5 Mn) / Dimension: 500 x 150 x 25 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 60/40 cm/min / Welding Position: 1 F / four layers > 8 weld beads 25 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

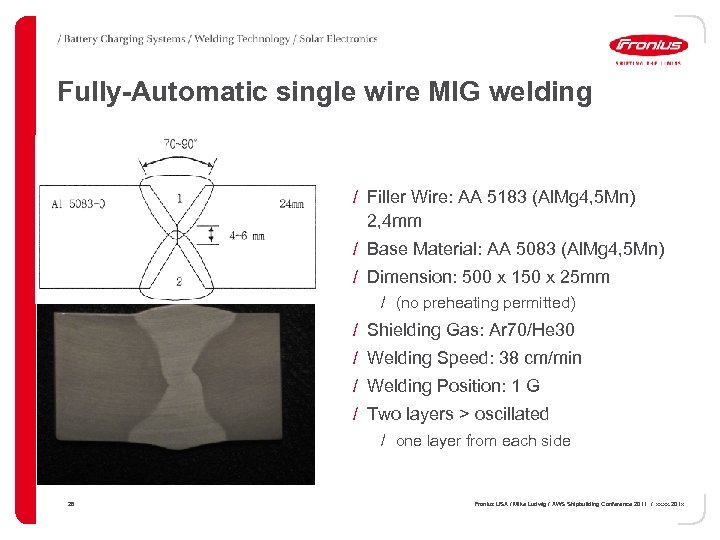

Fully-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 4 mm / Base Material: AA 5083 (Al. Mg 4, 5 Mn) / Dimension: 500 x 150 x 25 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 38 cm/min / Welding Position: 1 G / Two layers > oscillated / one layer from each side 26 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Fully-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 4 mm / Base Material: AA 5083 (Al. Mg 4, 5 Mn) / Dimension: 500 x 150 x 25 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 38 cm/min / Welding Position: 1 G / Two layers > oscillated / one layer from each side 26 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

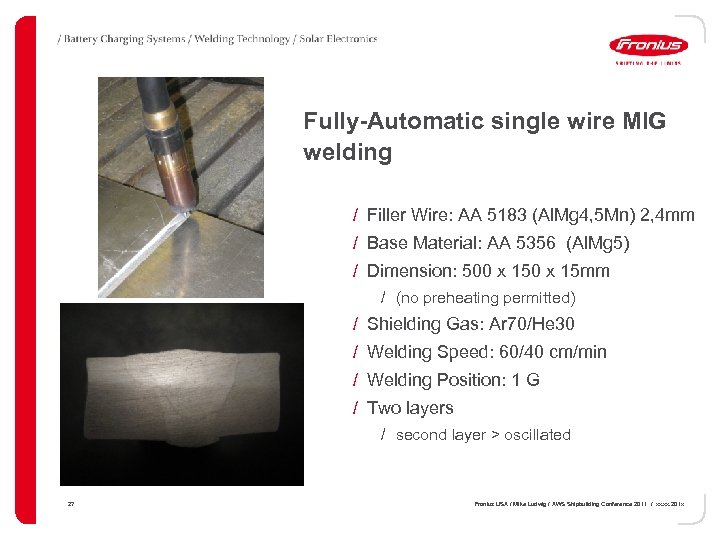

Fully-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 4 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 15 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 60/40 cm/min / Welding Position: 1 G / Two layers / second layer > oscillated 27 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Fully-Automatic single wire MIG welding / Filler Wire: AA 5183 (Al. Mg 4, 5 Mn) 2, 4 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 500 x 15 mm / (no preheating permitted) / Shielding Gas: Ar 70/He 30 / Welding Speed: 60/40 cm/min / Welding Position: 1 G / Two layers / second layer > oscillated 27 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

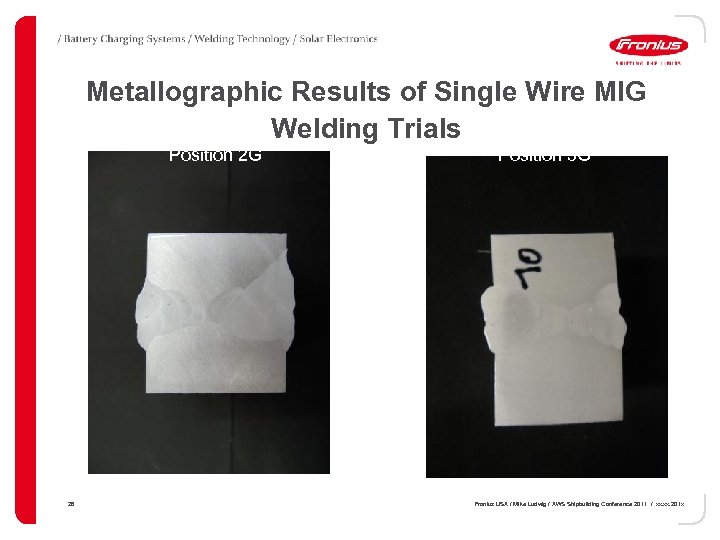

Metallographic Results of Single Wire MIG Welding Trials Position 2 G 28 Position 3 G Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Metallographic Results of Single Wire MIG Welding Trials Position 2 G 28 Position 3 G Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

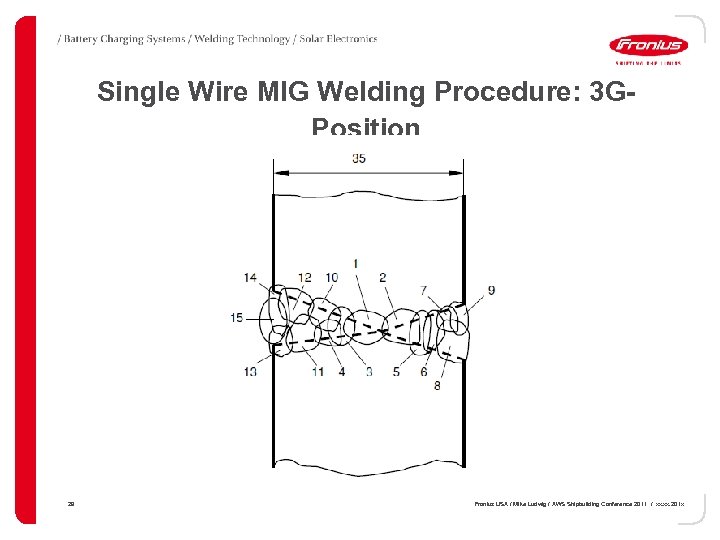

Single Wire MIG Welding Procedure: 3 GPosition 29 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Single Wire MIG Welding Procedure: 3 GPosition 29 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

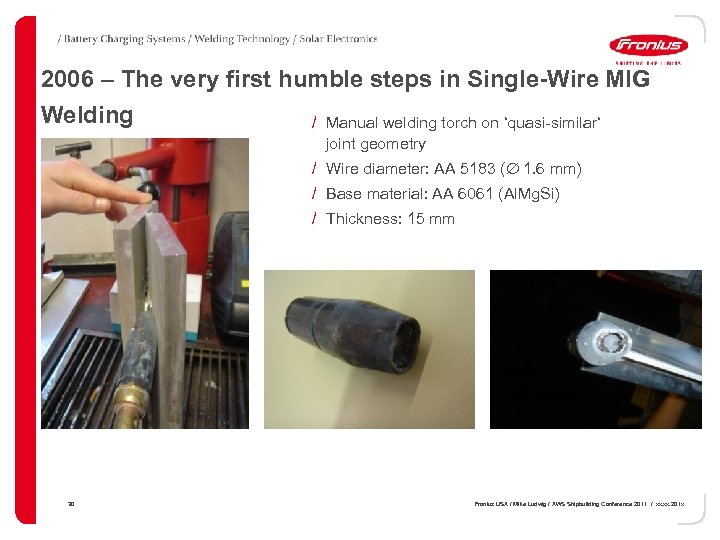

2006 – The very first humble steps in Single-Wire MIG Welding / Manual welding torch on ‘quasi-similar‘ joint geometry / Wire diameter: AA 5183 ( 1. 6 mm) / Base material: AA 6061 (Al. Mg. Si) / Thickness: 15 mm 30 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

2006 – The very first humble steps in Single-Wire MIG Welding / Manual welding torch on ‘quasi-similar‘ joint geometry / Wire diameter: AA 5183 ( 1. 6 mm) / Base material: AA 6061 (Al. Mg. Si) / Thickness: 15 mm 30 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

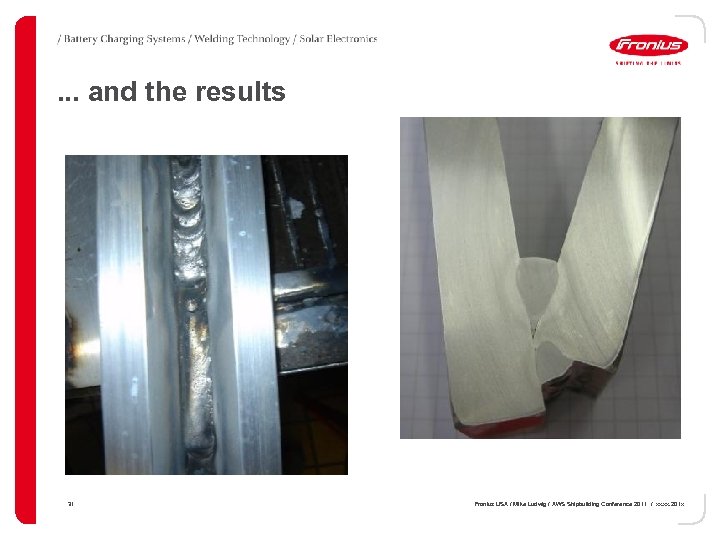

. . . and the results 31 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

. . . and the results 31 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

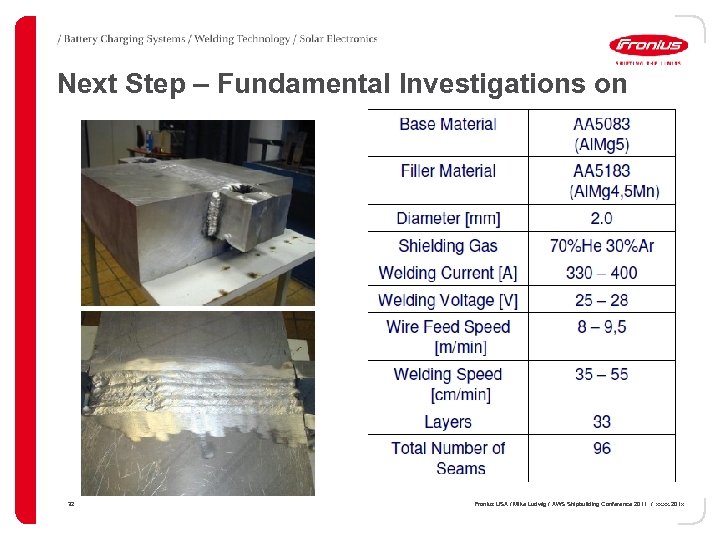

Next Step – Fundamental Investigations on Manual MIG 32 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Next Step – Fundamental Investigations on Manual MIG 32 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

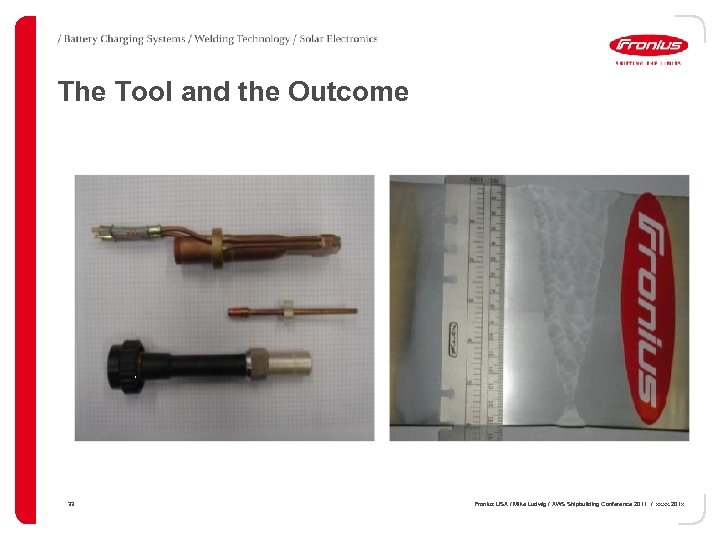

The Tool and the Outcome 33 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

The Tool and the Outcome 33 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Outline / Introduction / Technical Requirements / Approach / Twin Welding / Conclusion 34 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Outline / Introduction / Technical Requirements / Approach / Twin Welding / Conclusion 34 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

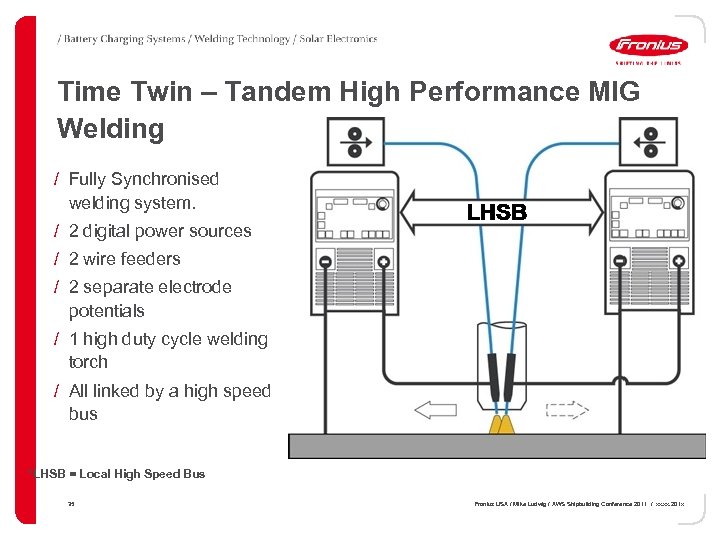

Time Twin – Tandem High Performance MIG Welding / Fully Synchronised welding system. / 2 digital power sources / 2 wire feeders / 2 separate electrode potentials / 1 high duty cycle welding torch / All linked by a high speed bus *LHSB = Local High Speed Bus 35 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Time Twin – Tandem High Performance MIG Welding / Fully Synchronised welding system. / 2 digital power sources / 2 wire feeders / 2 separate electrode potentials / 1 high duty cycle welding torch / All linked by a high speed bus *LHSB = Local High Speed Bus 35 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Equipment Time Twin Torch Tripod Unit Time Twin Welding System RCU 5000 i 36 Oscillation Unit Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Equipment Time Twin Torch Tripod Unit Time Twin Welding System RCU 5000 i 36 Oscillation Unit Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

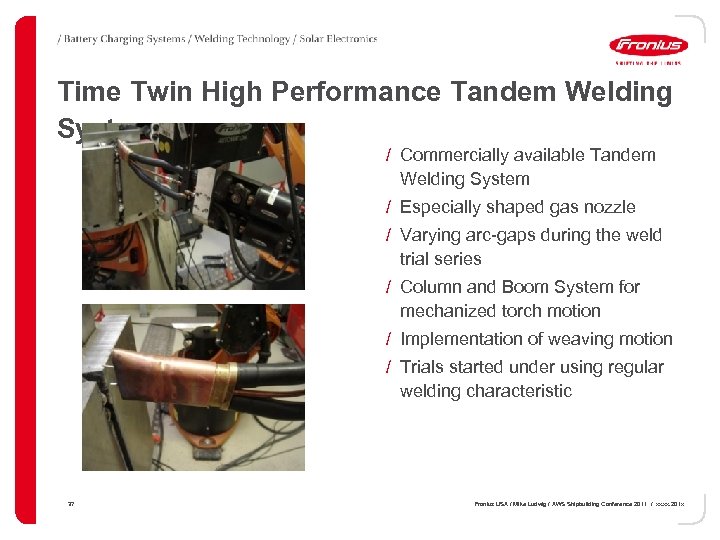

Time Twin High Performance Tandem Welding System / Commercially available Tandem Welding System / Especially shaped gas nozzle / Varying arc-gaps during the weld trial series / Column and Boom System for mechanized torch motion / Implementation of weaving motion / Trials started under using regular welding characteristic 37 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Time Twin High Performance Tandem Welding System / Commercially available Tandem Welding System / Especially shaped gas nozzle / Varying arc-gaps during the weld trial series / Column and Boom System for mechanized torch motion / Implementation of weaving motion / Trials started under using regular welding characteristic 37 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

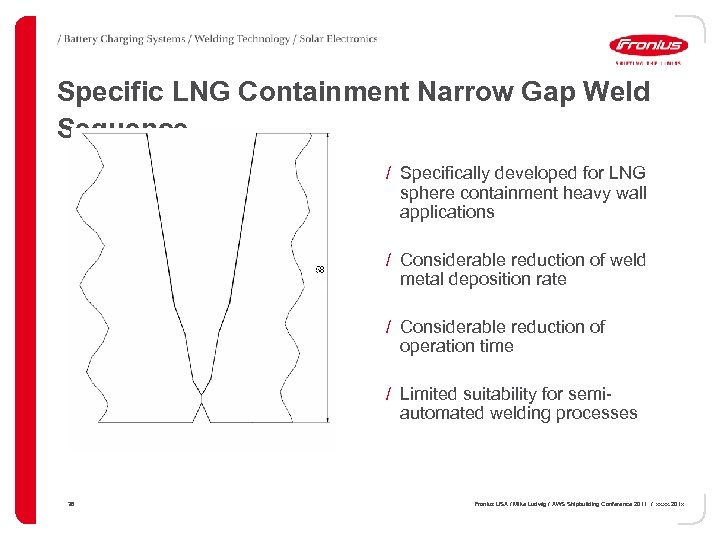

Specific LNG Containment Narrow Gap Weld Sequence / Specifically developed for LNG sphere containment heavy wall applications / Considerable reduction of weld metal deposition rate / Considerable reduction of operation time / Limited suitability for semiautomated welding processes 38 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Specific LNG Containment Narrow Gap Weld Sequence / Specifically developed for LNG sphere containment heavy wall applications / Considerable reduction of weld metal deposition rate / Considerable reduction of operation time / Limited suitability for semiautomated welding processes 38 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

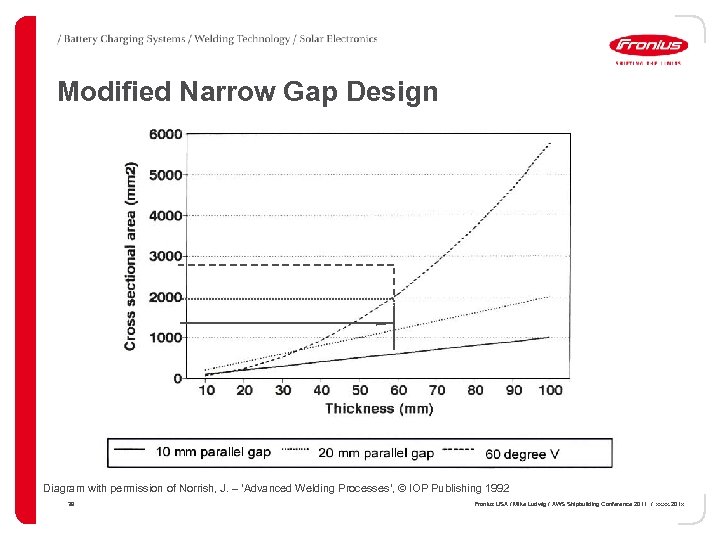

Modified Narrow Gap Design Diagram with permission of Norrish, J. – ‘Advanced Welding Processes‘, © IOP Publishing 1992 39 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Modified Narrow Gap Design Diagram with permission of Norrish, J. – ‘Advanced Welding Processes‘, © IOP Publishing 1992 39 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

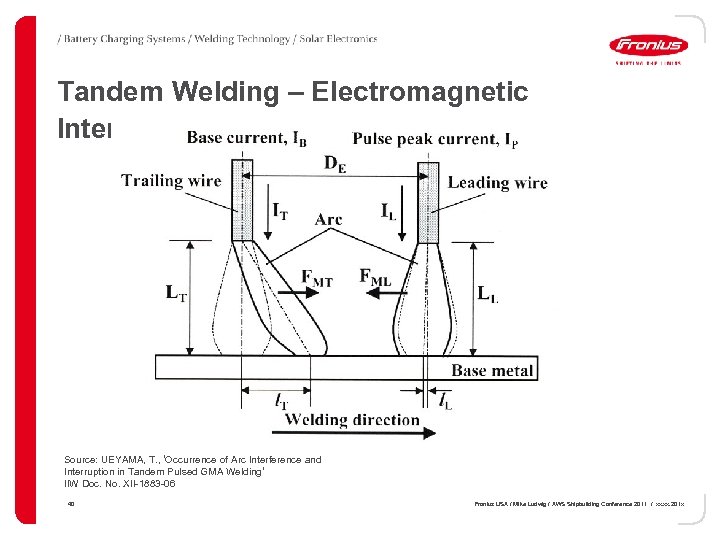

Tandem Welding – Electromagnetic Interferences Source: UEYAMA, T. , ‘Occurrence of Arc Interference and Interruption in Tandem Pulsed GMA Welding‘ IIW Doc. No. XII-1883 -06 40 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Tandem Welding – Electromagnetic Interferences Source: UEYAMA, T. , ‘Occurrence of Arc Interference and Interruption in Tandem Pulsed GMA Welding‘ IIW Doc. No. XII-1883 -06 40 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Electromagnetic Interference – A Closer View. . . 41 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Electromagnetic Interference – A Closer View. . . 41 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Improved Tandem MIG Welding Characteristic 42 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Improved Tandem MIG Welding Characteristic 42 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

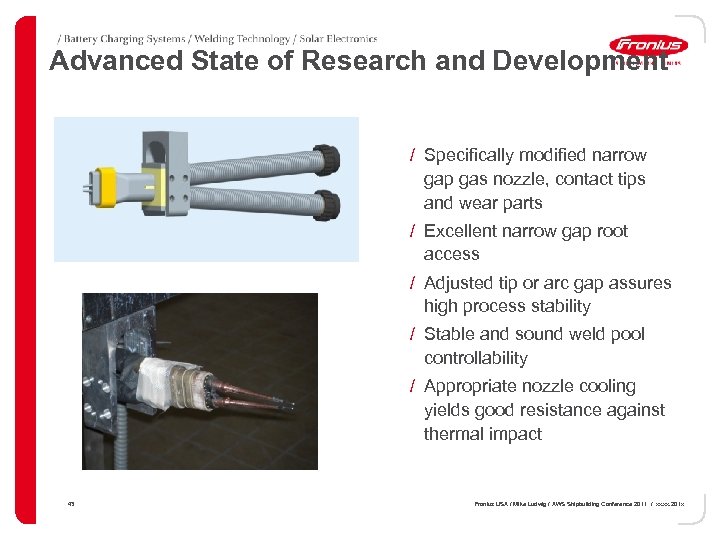

Advanced State of Research and Development / Specifically modified narrow gap gas nozzle, contact tips and wear parts / Excellent narrow gap root access / Adjusted tip or arc gap assures high process stability / Stable and sound weld pool controllability / Appropriate nozzle cooling yields good resistance against thermal impact 43 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Advanced State of Research and Development / Specifically modified narrow gap gas nozzle, contact tips and wear parts / Excellent narrow gap root access / Adjusted tip or arc gap assures high process stability / Stable and sound weld pool controllability / Appropriate nozzle cooling yields good resistance against thermal impact 43 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

New Developed Narrow Gap Tandem Torch 44 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

New Developed Narrow Gap Tandem Torch 44 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Time Twin Welding in 3 G Position 45 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Time Twin Welding in 3 G Position 45 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

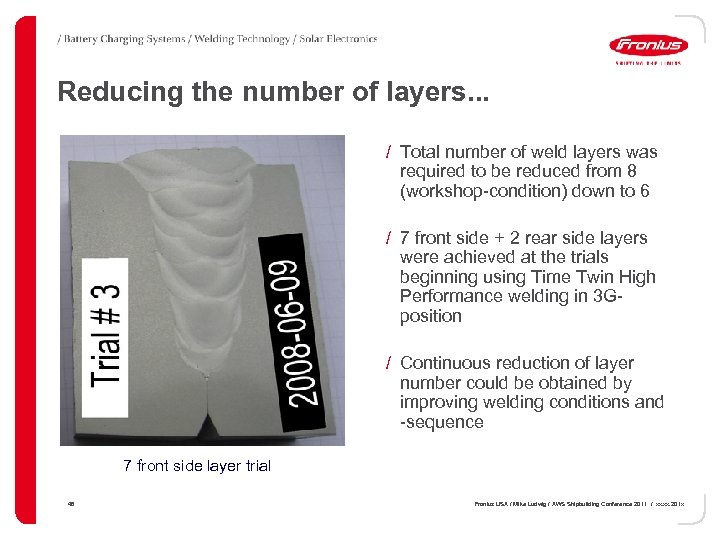

Reducing the number of layers. . . / Total number of weld layers was required to be reduced from 8 (workshop-condition) down to 6 / 7 front side + 2 rear side layers were achieved at the trials beginning using Time Twin High Performance welding in 3 Gposition / Continuous reduction of layer number could be obtained by improving welding conditions and -sequence 7 front side layer trial 46 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Reducing the number of layers. . . / Total number of weld layers was required to be reduced from 8 (workshop-condition) down to 6 / 7 front side + 2 rear side layers were achieved at the trials beginning using Time Twin High Performance welding in 3 Gposition / Continuous reduction of layer number could be obtained by improving welding conditions and -sequence 7 front side layer trial 46 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

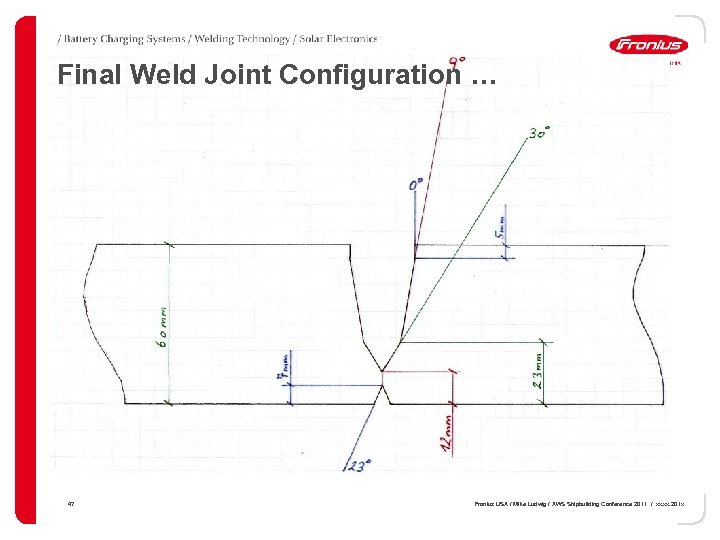

Final Weld Joint Configuration … 47 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Final Weld Joint Configuration … 47 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

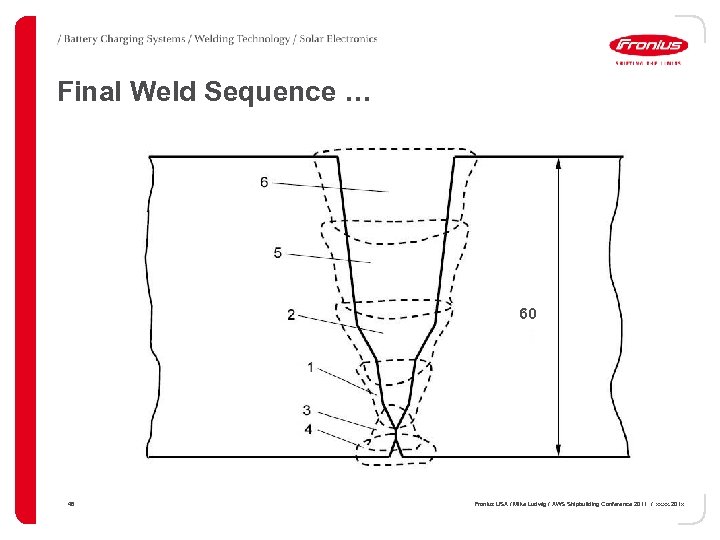

Final Weld Sequence … 60 48 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Final Weld Sequence … 60 48 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

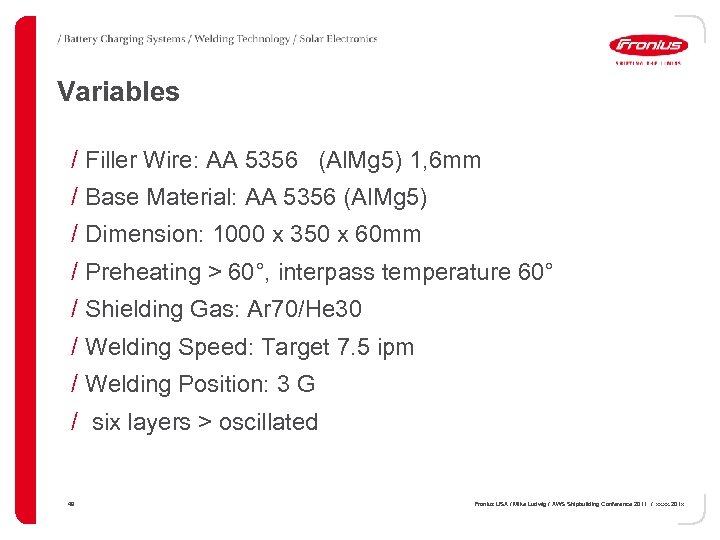

Variables / Filler Wire: AA 5356 (Al. Mg 5) 1, 6 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 1000 x 350 x 60 mm / Preheating > 60°, interpass temperature 60° / Shielding Gas: Ar 70/He 30 / Welding Speed: Target 7. 5 ipm / Welding Position: 3 G / six layers > oscillated 49 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Variables / Filler Wire: AA 5356 (Al. Mg 5) 1, 6 mm / Base Material: AA 5356 (Al. Mg 5) / Dimension: 1000 x 350 x 60 mm / Preheating > 60°, interpass temperature 60° / Shielding Gas: Ar 70/He 30 / Welding Speed: Target 7. 5 ipm / Welding Position: 3 G / six layers > oscillated 49 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

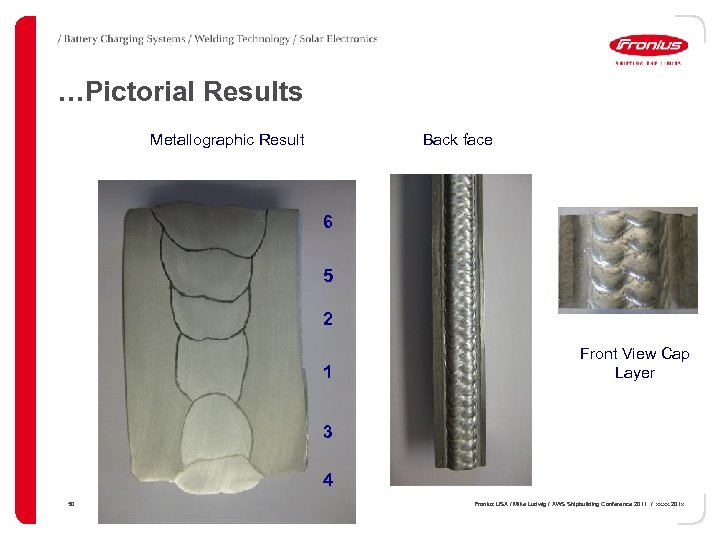

…Pictorial Results Metallographic Result Back face 6 5 2 1 Front View Cap Layer 3 4 50 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

…Pictorial Results Metallographic Result Back face 6 5 2 1 Front View Cap Layer 3 4 50 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

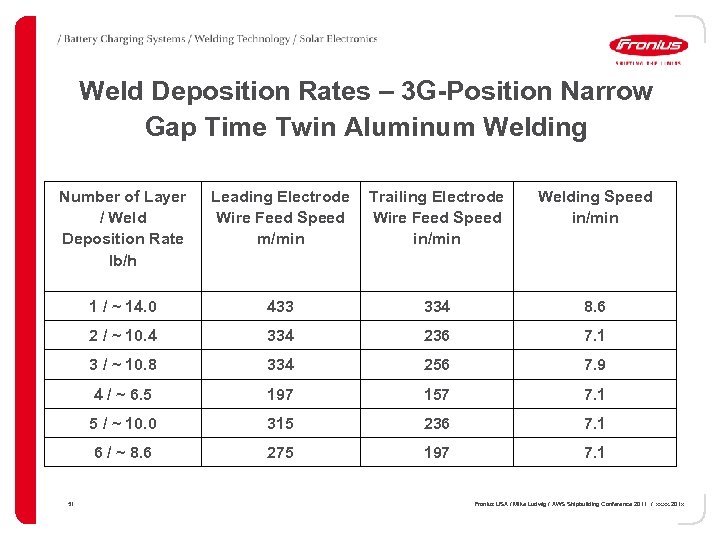

Weld Deposition Rates – 3 G-Position Narrow Gap Time Twin Aluminum Welding Number of Layer / Weld Deposition Rate lb/h Leading Electrode Wire Feed Speed m/min Trailing Electrode Wire Feed Speed in/min Welding Speed in/min 1 / ~ 14. 0 433 334 8. 6 2 / ~ 10. 4 334 236 7. 1 3 / ~ 10. 8 334 256 7. 9 4 / ~ 6. 5 197 157 7. 1 5 / ~ 10. 0 315 236 7. 1 6 / ~ 8. 6 275 197 7. 1 51 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Weld Deposition Rates – 3 G-Position Narrow Gap Time Twin Aluminum Welding Number of Layer / Weld Deposition Rate lb/h Leading Electrode Wire Feed Speed m/min Trailing Electrode Wire Feed Speed in/min Welding Speed in/min 1 / ~ 14. 0 433 334 8. 6 2 / ~ 10. 4 334 236 7. 1 3 / ~ 10. 8 334 256 7. 9 4 / ~ 6. 5 197 157 7. 1 5 / ~ 10. 0 315 236 7. 1 6 / ~ 8. 6 275 197 7. 1 51 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Conclusion / LNG aluminum alloy sphere manufacturing requires highest weld quality levels / Continuous increase in production rates requires a rise in welding process efficiency / Out-of-position single wire MIG GMAW has reached physical limits / Time Twin Tandem Welding was shifted towards being usable for out-of-position welding / Project requirements to improve quality and efficiency could be met entirely / Tailor-made welding power supply welding characteristics were used to cover the complete process range / Sophisticated welding torch engineering resolved joint design restrictions / Time Twin Process with narrow groove torch equipment proved excellent suitability for similar aluminum welding applications 52 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x

Conclusion / LNG aluminum alloy sphere manufacturing requires highest weld quality levels / Continuous increase in production rates requires a rise in welding process efficiency / Out-of-position single wire MIG GMAW has reached physical limits / Time Twin Tandem Welding was shifted towards being usable for out-of-position welding / Project requirements to improve quality and efficiency could be met entirely / Tailor-made welding power supply welding characteristics were used to cover the complete process range / Sophisticated welding torch engineering resolved joint design restrictions / Time Twin Process with narrow groove torch equipment proved excellent suitability for similar aluminum welding applications 52 Fronius USA / Mike Ludwig / AWS Shipbuilding Conference 2011 / xx. 201 x