489ccbafd3b3ecb9ddc8a343129cc3c2.ppt

- Количество слайдов: 22

Use of Modern Technologies for Better Boiling House Efficiency by Mohammad Awais Qureshi Advisor Shakarganj Mills Limited

Industry Scenario History of Sugar Industry Operation Levels Non-Sharing of Technical Data Lack of Critical Analysis Long Term Vision

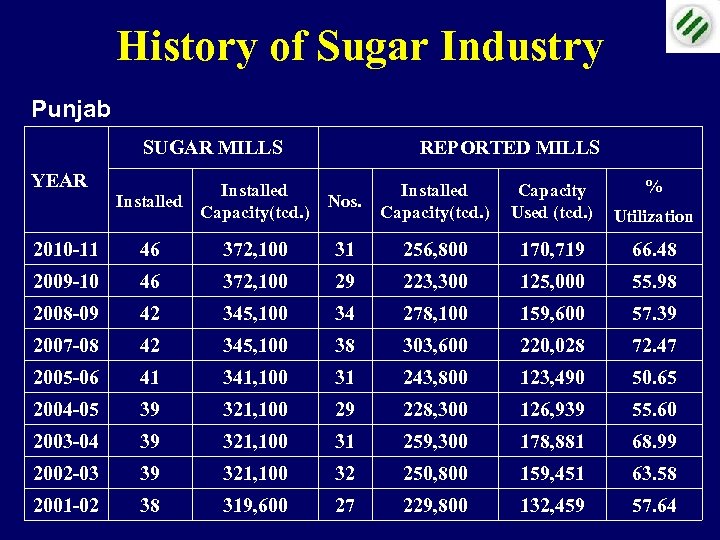

History of Sugar Industry Punjab SUGAR MILLS YEAR REPORTED MILLS % Installed Capacity(tcd. ) Nos. Installed Capacity(tcd. ) Capacity Used (tcd. ) Utilization 2010 -11 46 372, 100 31 256, 800 170, 719 66. 48 2009 -10 46 372, 100 29 223, 300 125, 000 55. 98 2008 -09 42 345, 100 34 278, 100 159, 600 57. 39 2007 -08 42 345, 100 38 303, 600 220, 028 72. 47 2005 -06 41 341, 100 31 243, 800 123, 490 50. 65 2004 -05 39 321, 100 29 228, 300 126, 939 55. 60 2003 -04 39 321, 100 31 259, 300 178, 881 68. 99 2002 -03 39 321, 100 32 250, 800 159, 451 63. 58 2001 -02 38 319, 600 27 229, 800 132, 459 57. 64

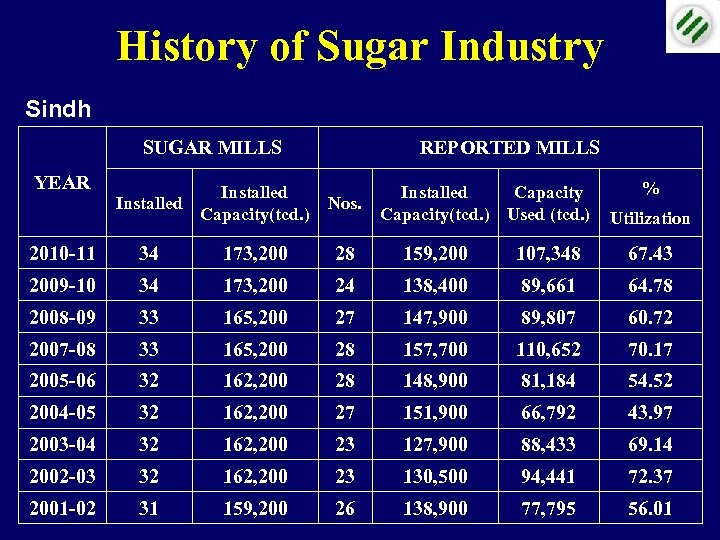

History of Sugar Industry Sindh SUGAR MILLS YEAR Installed Capacity(tcd. ) REPORTED MILLS Nos. Installed Capacity(tcd. ) Used (tcd. ) % Utilization 2010 -11 34 173, 200 28 159, 200 107, 348 67. 43 2009 -10 34 173, 200 24 138, 400 89, 661 64. 78 2008 -09 33 165, 200 27 147, 900 89, 807 60. 72 2007 -08 33 165, 200 28 157, 700 110, 652 70. 17 2005 -06 32 162, 200 28 148, 900 81, 184 54. 52 2004 -05 32 162, 200 27 151, 900 66, 792 43. 97 2003 -04 32 162, 200 23 127, 900 88, 433 69. 14 2002 -03 32 162, 200 23 130, 500 94, 441 72. 37 2001 -02 31 159, 200 26 138, 900 77, 795 56. 01

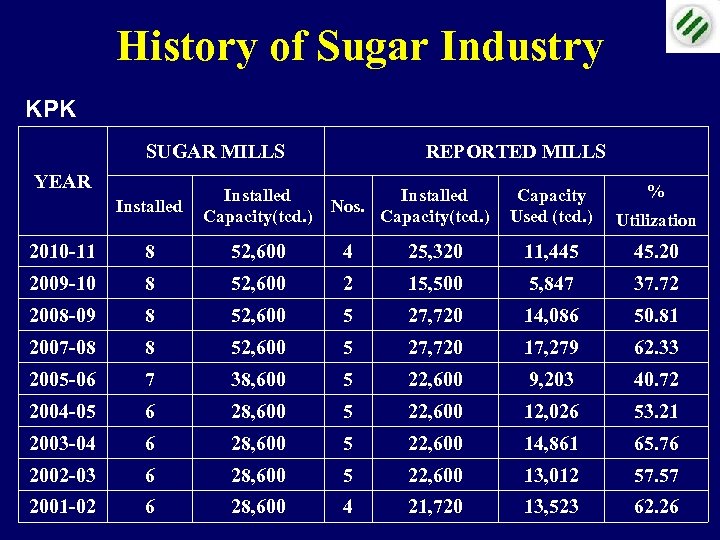

History of Sugar Industry KPK SUGAR MILLS YEAR REPORTED MILLS % Installed Capacity(tcd. ) Nos. Installed Capacity(tcd. ) Capacity Used (tcd. ) Utilization 2010 -11 8 52, 600 4 25, 320 11, 445 45. 20 2009 -10 8 52, 600 2 15, 500 5, 847 37. 72 2008 -09 8 52, 600 5 27, 720 14, 086 50. 81 2007 -08 8 52, 600 5 27, 720 17, 279 62. 33 2005 -06 7 38, 600 5 22, 600 9, 203 40. 72 2004 -05 6 28, 600 5 22, 600 12, 026 53. 21 2003 -04 6 28, 600 5 22, 600 14, 861 65. 76 2002 -03 6 28, 600 5 22, 600 13, 012 57. 57 2001 -02 6 28, 600 4 21, 720 13, 523 62. 26

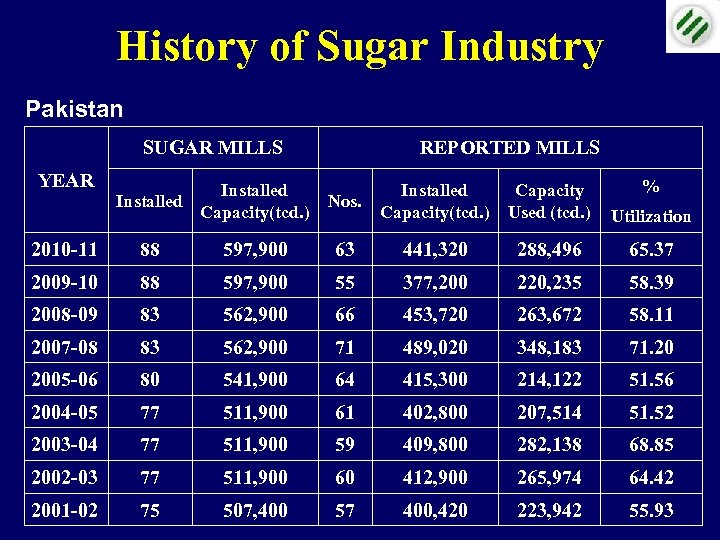

History of Sugar Industry Pakistan SUGAR MILLS YEAR REPORTED MILLS % Installed Capacity(tcd. ) Nos. Installed Capacity(tcd. ) Capacity Used (tcd. ) Utilization 2010 -11 88 597, 900 63 441, 320 288, 496 65. 37 2009 -10 88 597, 900 55 377, 200 220, 235 58. 39 2008 -09 83 562, 900 66 453, 720 263, 672 58. 11 2007 -08 83 562, 900 71 489, 020 348, 183 71. 20 2005 -06 80 541, 900 64 415, 300 214, 122 51. 56 2004 -05 77 511, 900 61 402, 800 207, 514 51. 52 2003 -04 77 511, 900 59 409, 800 282, 138 68. 85 2002 -03 77 511, 900 60 412, 900 265, 974 64. 42 2001 -02 75 507, 400 57 400, 420 223, 942 55. 93

Efficiency Avenues Clarification Evaporation Crystallization Centrifugation Cooling Crystallizers Energy Management Sanitation

Efficiency Avenues Clarification The basic need revolves around proper instrumentation and control of parameters. basic

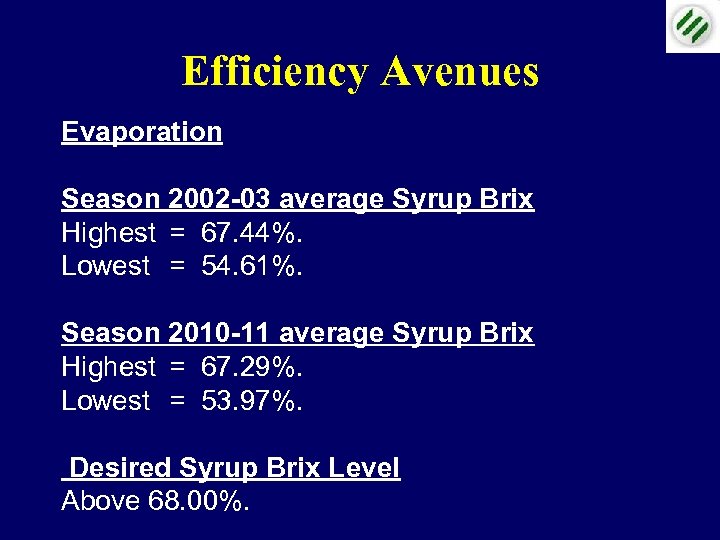

Efficiency Avenues Evaporation Season 2002 -03 average Syrup Brix Highest = 67. 44%. Lowest = 54. 61%. Season 2010 -11 average Syrup Brix Highest = 67. 29%. Lowest = 53. 97%. Desired Syrup Brix Level Above 68. 00%.

Efficiency Avenues Evaporation Efforts of Industry From Roberts to Kestner And falling films As an episode to improve efficiency Reduce condenser load Reduce steam consumption Extend capacity of Sugar Mills (6, 000 to 7, 000 tcd, Uttarpardesh, India)

Efficiency Avenues Crystallization Batch followed by Continuous Vacuum Pans are seen in the local Sugar Industry. Active operations did arrange gage-ts like mechanical circulators, Jiggers steam and above all vapors from the lower effect of evaporators. Recent development of V K Ts for raw sugar boiling has not found its way in the Country. Additional boiling needs

Efficiency Avenues Centrifugation Importance of equipment. Low grade continuous centrifugals. No appreciate able improvement for the last half a century. Static approach during half a century. (K 11 and K 12 rule this area) Operational parameters of raw station. (Pugmills, Wash Water and Temperature)

Efficiency Avenues Cooling Crystallizers U-type open crystallizers to Cassette Coolers. Introduction of vertical crystallizers. Development of vertical cooling crystallizers with provision of slowly lowering and lifting cooling blocks with hydraulic cylinders. Elimination of stirring operation.

Efficiency Avenues Energy Management Role of boiling house operations. Judicial use of vapours through recycling. Minimum use of water (during dilution, pan boiling and centrifugation) Recycling of surplus water in the factory. Steam consumption indicated by Mr. Sajid Naqvi Most of the Mills in Pakistan = 55– 57% Mills practicing steam saving measures = 50 -52% Mills having modern technologies = 42 -45% Modern Mills in other Countries = 35 -40%

Efficiency Avenues Sanitation This is a hidden corner in sugar industry, which if not given proper attention, can result in loosing efficiencies Sanitation both at mills and boiling house need proper attention.

Efficiency Expectations Role of operating department Build a team of dedicated & competent engineers. Chart down history of operations, critically analyzed, determine the ultimate goals and chalk out operational plans with in the resources / means available. Short term and long term goals are a must for any

Efficiency Expectations Difficulties to Technologists Quick turnover of the operational staff in noncontinuity of crushing rates do lead to in-efficiency and no proper Planning. Sharing of Technical Informations at Plant, National & International level, do help the managements in arriving at logical decisions

KISS Slogan Overriding considerations at all times should be 1. Low capital / operating costs and simplicity 2. KISS Slogan, Keep it simple, Stupid

Concluding Remarks This talk is just a bird eye view of better boiling house efficiencies. The learned speakers in their deliberations will throw detailed light on important avenues like evaporations, crystallizations and centrifugation etc. The purpose of Workshop can only be achieved if the experience of various delegates are shared in this forum.

Concluding Remarks The clarity of subject can only be achieved when a chance of thorough discussion is provided both to delegates and the speakers. In one of the International Workshop, we did listen from Mr. B. S. Purchase, Director of Sugar Research Institute, Darban, that no question is a silly question. There is always a hidden logic behind each question what ever comes to the mind must be posed to the speaker for the necessary clarifications.

THANKS

489ccbafd3b3ecb9ddc8a343129cc3c2.ppt