996bb36d85bd0815b1c11d1a7ef21e25.ppt

- Количество слайдов: 1

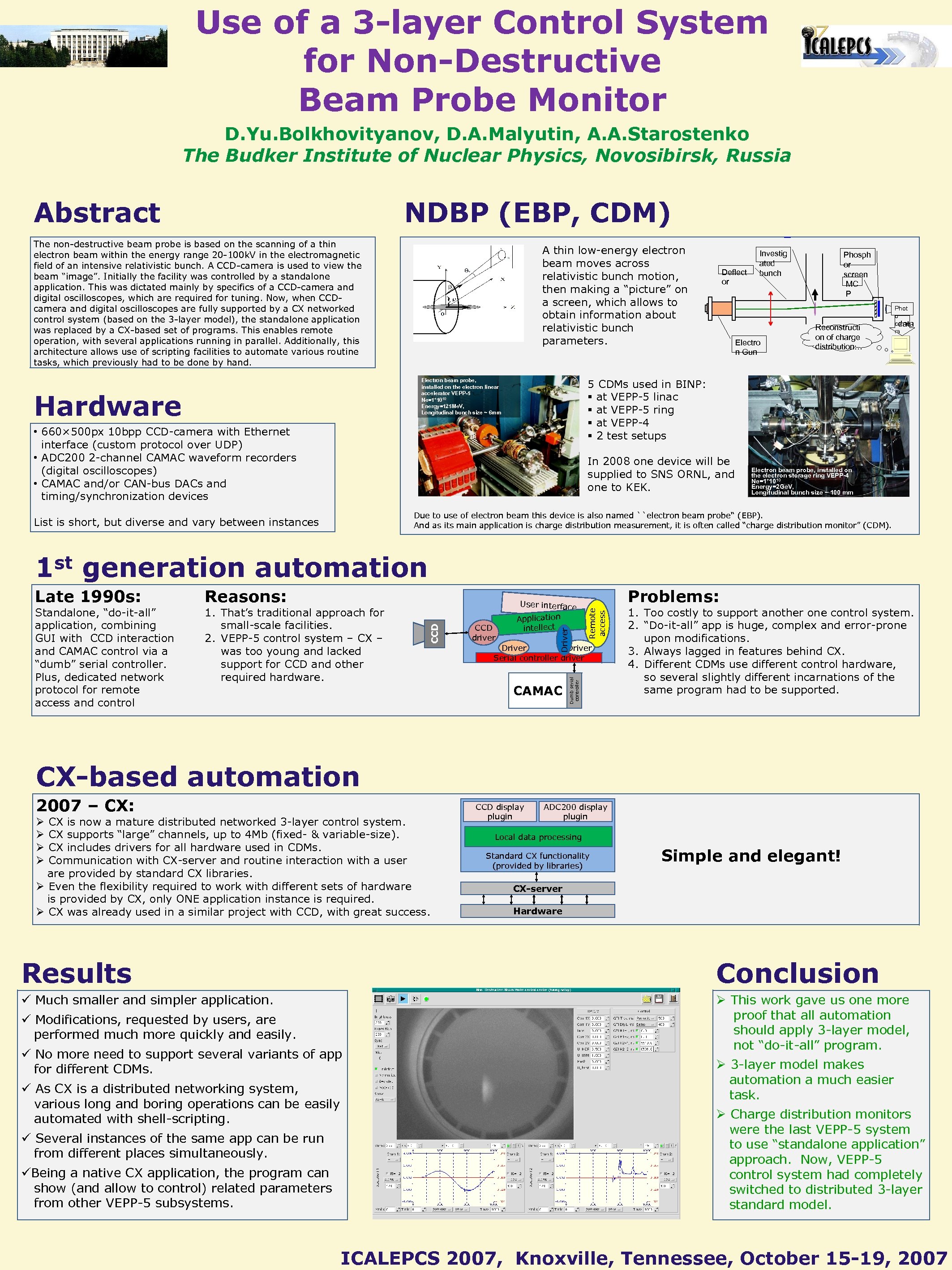

Use of a 3 -layer Control System for Non-Destructive Beam Probe Monitor D. Yu. Bolkhovityanov, D. A. Malyutin, A. A. Starostenko The Budker Institute of Nuclear Physics, Novosibirsk, Russia Abstract NDBP (EBP, CDM) The non-destructive beam probe is based on the scanning of a thin electron beam within the energy range 20 -100 k. V in the electromagnetic field of an intensive relativistic bunch. A CCD-camera is used to view the beam “image”. Initially the facility was controlled by a standalone application. This was dictated mainly by specifics of a CCD-camera and digital oscilloscopes, which are required for tuning. Now, when CCDcamera and digital oscilloscopes are fully supported by a CX networked control system (based on the 3 -layer model), the standalone application was replaced by a CX-based set of programs. This enables remote operation, with several applications running in parallel. Additionally, this architecture allows use of scripting facilities to automate various routine tasks, which previously had to be done by hand. A thin low-energy electron beam moves across relativistic bunch motion, then making a “picture” on a screen, which allows to obtain information about relativistic bunch parameters. • 660× 500 px 10 bpp CCD-camera with Ethernet interface (custom protocol over UDP) • ADC 200 2 -channel CAMAC waveform recorders (digital oscilloscopes) • CAMAC and/or CAN-bus DACs and timing/synchronization devices In 2008 one device will be supplied to SNS ORNL, and one to KEK. Reconstructi on of charge distribution… Phot o came data ra Electron beam probe, installed on the electron storage ring VEPP-4 Ne=1*1010 Energy=2 Ge. V, Longitudinal bunch size ~ 100 mm Due to use of electron beam this device is also named ``electron beam probe'‘ (EBP). And as its main application is charge distribution measurement, it is often called “charge distribution monitor” (CDM). List is short, but diverse and vary between instances generation automation CCD driver Problems: Remote access 1. That’s traditional approach for small-scale facilities. 2. VEPP-5 control system – CX – was too young and lacked support for CCD and other required hardware. User interface Application intellect Driver Serial controller driver CAMAC Dumb serial controller Standalone, “do-it-all” application, combining GUI with CCD interaction and CAMAC control via a “dumb” serial controller. Plus, dedicated network protocol for remote access and control Reasons: Driver Late 1990 s: CCD st 1 Electro n Gun Phosph or screen MC P 5 CDMs used in BINP: § at VEPP-5 linac § at VEPP-5 ring § at VEPP-4 § 2 test setups Electron beam probe, installed on the electron linear accelerator VEPP-5 Ne=1*1010 Energy=125 Me. V, Longitudinal bunch size ~ 6 mm Hardware Deflect or Investig ated bunch 1. Too costly to support another one control system. 2. “Do-it-all” app is huge, complex and error-prone upon modifications. 3. Always lagged in features behind CX. 4. Different CDMs use different control hardware, so several slightly different incarnations of the same program had to be supported. CX-based automation 2007 – CX: CX is now a mature distributed networked 3 -layer control system. CX supports “large” channels, up to 4 Mb (fixed- & variable-size). CX includes drivers for all hardware used in CDMs. Communication with CX-server and routine interaction with a user are provided by standard CX libraries. Ø Even the flexibility required to work with different sets of hardware is provided by CX, only ONE application instance is required. Ø CX was already used in a similar project with CCD, with great success. Ø Ø CCD display plugin ADC 200 display plugin Local data processing Standard CX functionality (provided by libraries) Simple and elegant! CX-server Hardware Results Conclusion ü Much smaller and simpler application. Ø This work gave us one more proof that all automation should apply 3 -layer model, not “do-it-all” program. ü Modifications, requested by users, are performed much more quickly and easily. ü No more need to support several variants of app for different CDMs. ü As CX is a distributed networking system, various long and boring operations can be easily automated with shell-scripting. ü Several instances of the same app can be run from different places simultaneously. üBeing a native CX application, the program can show (and allow to control) related parameters from other VEPP-5 subsystems. Ø 3 -layer model makes automation a much easier task. Ø Charge distribution monitors were the last VEPP-5 system to use “standalone application” approach. Now, VEPP-5 control system had completely switched to distributed 3 -layer standard model. ICALEPCS 2007, Knoxville, Tennessee, October 15 -19, 2007

Use of a 3 -layer Control System for Non-Destructive Beam Probe Monitor D. Yu. Bolkhovityanov, D. A. Malyutin, A. A. Starostenko The Budker Institute of Nuclear Physics, Novosibirsk, Russia Abstract NDBP (EBP, CDM) The non-destructive beam probe is based on the scanning of a thin electron beam within the energy range 20 -100 k. V in the electromagnetic field of an intensive relativistic bunch. A CCD-camera is used to view the beam “image”. Initially the facility was controlled by a standalone application. This was dictated mainly by specifics of a CCD-camera and digital oscilloscopes, which are required for tuning. Now, when CCDcamera and digital oscilloscopes are fully supported by a CX networked control system (based on the 3 -layer model), the standalone application was replaced by a CX-based set of programs. This enables remote operation, with several applications running in parallel. Additionally, this architecture allows use of scripting facilities to automate various routine tasks, which previously had to be done by hand. A thin low-energy electron beam moves across relativistic bunch motion, then making a “picture” on a screen, which allows to obtain information about relativistic bunch parameters. • 660× 500 px 10 bpp CCD-camera with Ethernet interface (custom protocol over UDP) • ADC 200 2 -channel CAMAC waveform recorders (digital oscilloscopes) • CAMAC and/or CAN-bus DACs and timing/synchronization devices In 2008 one device will be supplied to SNS ORNL, and one to KEK. Reconstructi on of charge distribution… Phot o came data ra Electron beam probe, installed on the electron storage ring VEPP-4 Ne=1*1010 Energy=2 Ge. V, Longitudinal bunch size ~ 100 mm Due to use of electron beam this device is also named ``electron beam probe'‘ (EBP). And as its main application is charge distribution measurement, it is often called “charge distribution monitor” (CDM). List is short, but diverse and vary between instances generation automation CCD driver Problems: Remote access 1. That’s traditional approach for small-scale facilities. 2. VEPP-5 control system – CX – was too young and lacked support for CCD and other required hardware. User interface Application intellect Driver Serial controller driver CAMAC Dumb serial controller Standalone, “do-it-all” application, combining GUI with CCD interaction and CAMAC control via a “dumb” serial controller. Plus, dedicated network protocol for remote access and control Reasons: Driver Late 1990 s: CCD st 1 Electro n Gun Phosph or screen MC P 5 CDMs used in BINP: § at VEPP-5 linac § at VEPP-5 ring § at VEPP-4 § 2 test setups Electron beam probe, installed on the electron linear accelerator VEPP-5 Ne=1*1010 Energy=125 Me. V, Longitudinal bunch size ~ 6 mm Hardware Deflect or Investig ated bunch 1. Too costly to support another one control system. 2. “Do-it-all” app is huge, complex and error-prone upon modifications. 3. Always lagged in features behind CX. 4. Different CDMs use different control hardware, so several slightly different incarnations of the same program had to be supported. CX-based automation 2007 – CX: CX is now a mature distributed networked 3 -layer control system. CX supports “large” channels, up to 4 Mb (fixed- & variable-size). CX includes drivers for all hardware used in CDMs. Communication with CX-server and routine interaction with a user are provided by standard CX libraries. Ø Even the flexibility required to work with different sets of hardware is provided by CX, only ONE application instance is required. Ø CX was already used in a similar project with CCD, with great success. Ø Ø CCD display plugin ADC 200 display plugin Local data processing Standard CX functionality (provided by libraries) Simple and elegant! CX-server Hardware Results Conclusion ü Much smaller and simpler application. Ø This work gave us one more proof that all automation should apply 3 -layer model, not “do-it-all” program. ü Modifications, requested by users, are performed much more quickly and easily. ü No more need to support several variants of app for different CDMs. ü As CX is a distributed networking system, various long and boring operations can be easily automated with shell-scripting. ü Several instances of the same app can be run from different places simultaneously. üBeing a native CX application, the program can show (and allow to control) related parameters from other VEPP-5 subsystems. Ø 3 -layer model makes automation a much easier task. Ø Charge distribution monitors were the last VEPP-5 system to use “standalone application” approach. Now, VEPP-5 control system had completely switched to distributed 3 -layer standard model. ICALEPCS 2007, Knoxville, Tennessee, October 15 -19, 2007