7ac262b0f1788b25724492c60dcccabe.ppt

- Количество слайдов: 11

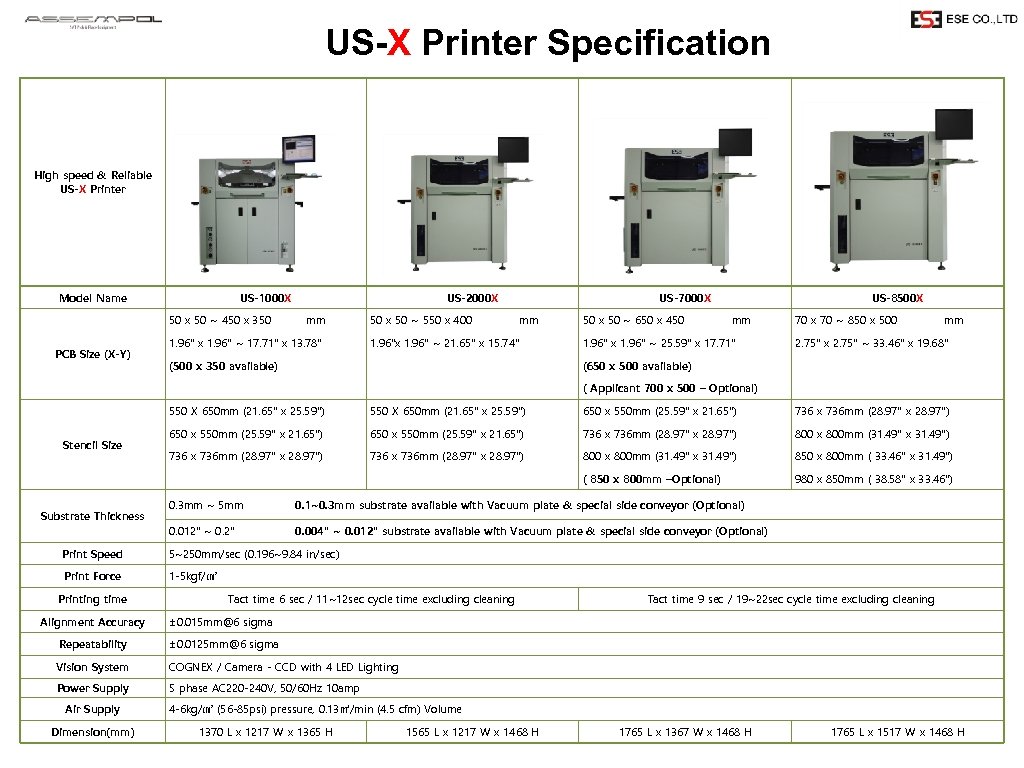

US-X Printer Specification High speed & Reliable US-X Printer Model Name US-1000 X 50 x 50 ~ 450 x 350 PCB Size (X-Y) US-2000 X mm 1. 96" x 1. 96" ~ 17. 71" x 13. 78" (500 x 350 available) 50 x 50 ~ 550 x 400 mm 1. 96"x 1. 96" ~ 21. 65" x 15. 74" US-7000 X 50 x 50 ~ 650 x 450 US-8500 X mm 1. 96" x 1. 96" ~ 25. 59" x 17. 71" (650 x 500 available) ( Applicant 700 x 500 – Optional) 70 x 70 ~ 850 x 500 mm 2. 75" x 2. 75" ~ 33. 46" x 19. 68" 550 X 650 mm (21. 65" x 25. 59") Stencil Size 550 X 650 mm (21. 65" x 25. 59") 650 x 550 mm (25. 59" x 21. 65") 736 x 736 mm (28. 97" x 28. 97") 800 x 800 mm (31. 49" x 31. 49") 736 x 736 mm (28. 97" x 28. 97") 800 x 800 mm (31. 49" x 31. 49") 850 x 800 mm ( 33. 46" x 31. 49") ( 850 x 800 mm –Optional) 980 x 850 mm ( 38. 58" x 33. 46") 0. 3 mm ~ 5 mm 0. 1~0. 3 mm substrate available with Vacuum plate & special side conveyor (Optional) 0. 012" ~ 0. 2" Substrate Thickness 0. 004" ~ 0. 012" substrate available with Vacuum plate & special side conveyor (Optional) Print Speed 5~250 mm/sec (0. 196~9. 84 in/sec) Print Force 1 -5 kgf/㎠ Printing time Tact time 6 sec / 11~12 sec cycle time excluding cleaning Alignment Accuracy ± 0. 015 mm@6 sigma Repeatability ± 0. 0125 mm@6 sigma Vision System Power Supply Tact time 9 sec / 19~22 sec cycle time excluding cleaning Air Supply Dimension(mm) COGNEX / Camera - CCD with 4 LED Lighting S phase AC 220 -240 V, 50/60 Hz 10 amp 4 -6 kg/㎠ (56 -85 psi) pressure, 0. 13㎥/min (4. 5 cfm) Volume 1370 L x 1217 W x 1365 H 1565 L x 1217 W x 1468 H 1765 L x 1367 W x 1468 H 1765 L x 1517 W x 1468 H

US-X Printer Specification High speed & Reliable US-X Printer Model Name US-1000 X 50 x 50 ~ 450 x 350 PCB Size (X-Y) US-2000 X mm 1. 96" x 1. 96" ~ 17. 71" x 13. 78" (500 x 350 available) 50 x 50 ~ 550 x 400 mm 1. 96"x 1. 96" ~ 21. 65" x 15. 74" US-7000 X 50 x 50 ~ 650 x 450 US-8500 X mm 1. 96" x 1. 96" ~ 25. 59" x 17. 71" (650 x 500 available) ( Applicant 700 x 500 – Optional) 70 x 70 ~ 850 x 500 mm 2. 75" x 2. 75" ~ 33. 46" x 19. 68" 550 X 650 mm (21. 65" x 25. 59") Stencil Size 550 X 650 mm (21. 65" x 25. 59") 650 x 550 mm (25. 59" x 21. 65") 736 x 736 mm (28. 97" x 28. 97") 800 x 800 mm (31. 49" x 31. 49") 736 x 736 mm (28. 97" x 28. 97") 800 x 800 mm (31. 49" x 31. 49") 850 x 800 mm ( 33. 46" x 31. 49") ( 850 x 800 mm –Optional) 980 x 850 mm ( 38. 58" x 33. 46") 0. 3 mm ~ 5 mm 0. 1~0. 3 mm substrate available with Vacuum plate & special side conveyor (Optional) 0. 012" ~ 0. 2" Substrate Thickness 0. 004" ~ 0. 012" substrate available with Vacuum plate & special side conveyor (Optional) Print Speed 5~250 mm/sec (0. 196~9. 84 in/sec) Print Force 1 -5 kgf/㎠ Printing time Tact time 6 sec / 11~12 sec cycle time excluding cleaning Alignment Accuracy ± 0. 015 mm@6 sigma Repeatability ± 0. 0125 mm@6 sigma Vision System Power Supply Tact time 9 sec / 19~22 sec cycle time excluding cleaning Air Supply Dimension(mm) COGNEX / Camera - CCD with 4 LED Lighting S phase AC 220 -240 V, 50/60 Hz 10 amp 4 -6 kg/㎠ (56 -85 psi) pressure, 0. 13㎥/min (4. 5 cfm) Volume 1370 L x 1217 W x 1365 H 1565 L x 1217 W x 1468 H 1765 L x 1367 W x 1468 H 1765 L x 1517 W x 1468 H

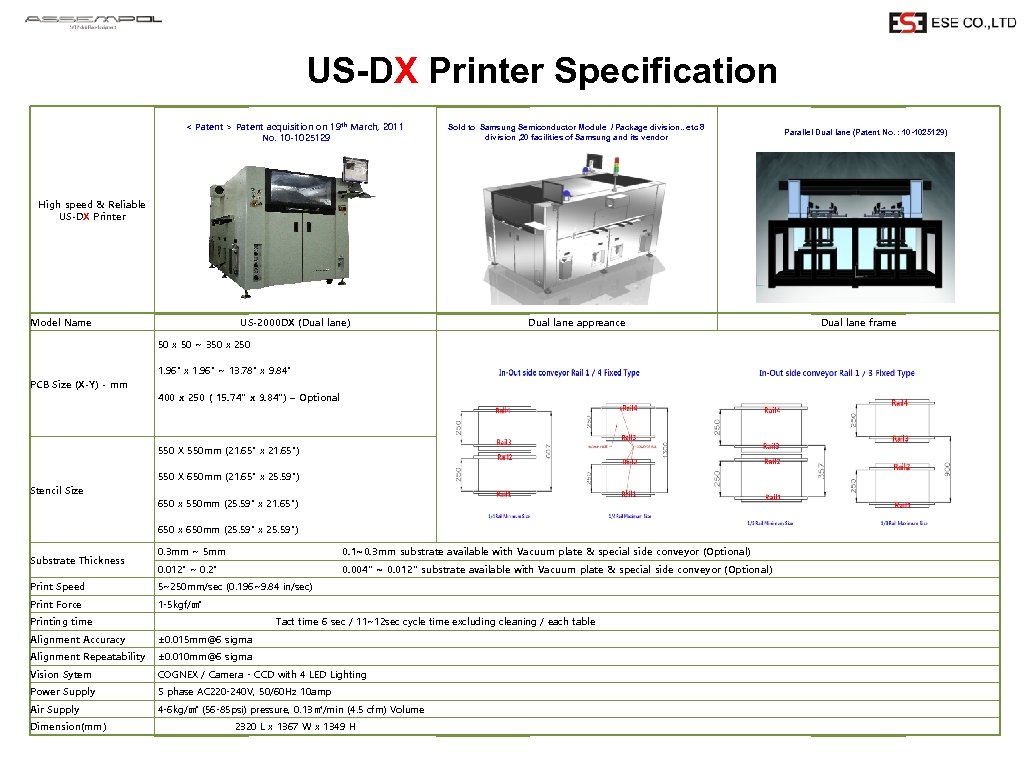

US-DX Printer Specification 19 th < Patent > Patent acquisition on No. 10 -1025129 March, 2011 Sold to Samsung Semiconductor Module / Package division. . etc 8 division , 20 facilities of Samsung and its vendor Parallel Dual lane (Patent No. : 10 -1025129) High speed & Reliable US-DX Printer Model Name US-2000 DX (Dual lane) Dual lane appreance 50 x 50 ~ 350 x 250 PCB Size (X-Y) - mm 1. 96" x 1. 96" ~ 13. 78" x 9. 84" 400 x 250 ( 15. 74" x 9. 84") – Optional 550 X 650 mm (21. 65" x 25. 59") 650 x 550 mm (25. 59" x 21. 65") 650 x 650 mm (25. 59" x 25. 59") Substrate Thickness 550 X 550 mm (21. 65" x 21. 65") Stencil Size Dual lane frame 0. 3 mm ~ 5 mm 0. 1~0. 3 mm substrate available with Vacuum plate & special side conveyor (Optional) 0. 012" ~ 0. 2" 0. 004" ~ 0. 012" substrate available with Vacuum plate & special side conveyor (Optional) Print Speed 5~250 mm/sec (0. 196~9. 84 in/sec) Print Force 1 -5 kgf/㎠ Printing time Tact time 6 sec / 11~12 sec cycle time excluding cleaning / each table Alignment Accuracy ± 0. 015 mm@6 sigma Alignment Repeatability ± 0. 010 mm@6 sigma Vision Sytem COGNEX / Camera - CCD with 4 LED Lighting Power Supply S phase AC 220 -240 V, 50/60 Hz 10 amp Air Supply 4 -6 kg/㎠ (56 -85 psi) pressure, 0. 13㎥/min (4. 5 cfm) Volume Dimension(mm) 2320 L x 1367 W x 1349 H

US-DX Printer Specification 19 th < Patent > Patent acquisition on No. 10 -1025129 March, 2011 Sold to Samsung Semiconductor Module / Package division. . etc 8 division , 20 facilities of Samsung and its vendor Parallel Dual lane (Patent No. : 10 -1025129) High speed & Reliable US-DX Printer Model Name US-2000 DX (Dual lane) Dual lane appreance 50 x 50 ~ 350 x 250 PCB Size (X-Y) - mm 1. 96" x 1. 96" ~ 13. 78" x 9. 84" 400 x 250 ( 15. 74" x 9. 84") – Optional 550 X 650 mm (21. 65" x 25. 59") 650 x 550 mm (25. 59" x 21. 65") 650 x 650 mm (25. 59" x 25. 59") Substrate Thickness 550 X 550 mm (21. 65" x 21. 65") Stencil Size Dual lane frame 0. 3 mm ~ 5 mm 0. 1~0. 3 mm substrate available with Vacuum plate & special side conveyor (Optional) 0. 012" ~ 0. 2" 0. 004" ~ 0. 012" substrate available with Vacuum plate & special side conveyor (Optional) Print Speed 5~250 mm/sec (0. 196~9. 84 in/sec) Print Force 1 -5 kgf/㎠ Printing time Tact time 6 sec / 11~12 sec cycle time excluding cleaning / each table Alignment Accuracy ± 0. 015 mm@6 sigma Alignment Repeatability ± 0. 010 mm@6 sigma Vision Sytem COGNEX / Camera - CCD with 4 LED Lighting Power Supply S phase AC 220 -240 V, 50/60 Hz 10 amp Air Supply 4 -6 kg/㎠ (56 -85 psi) pressure, 0. 13㎥/min (4. 5 cfm) Volume Dimension(mm) 2320 L x 1367 W x 1349 H

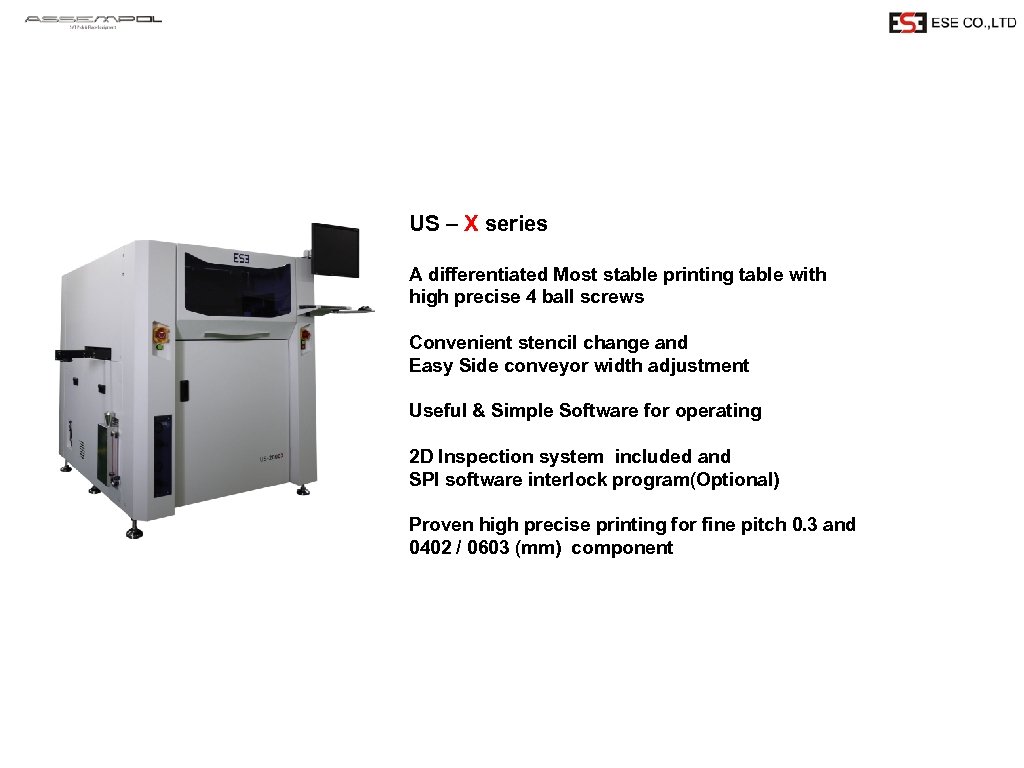

US – X series A differentiated Most stable printing table with high precise 4 ball screws Convenient stencil change and Easy Side conveyor width adjustment Useful & Simple Software for operating 2 D Inspection system included and SPI software interlock program(Optional) Proven high precise printing for fine pitch 0. 3 and 0402 / 0603 (mm) component

US – X series A differentiated Most stable printing table with high precise 4 ball screws Convenient stencil change and Easy Side conveyor width adjustment Useful & Simple Software for operating 2 D Inspection system included and SPI software interlock program(Optional) Proven high precise printing for fine pitch 0. 3 and 0402 / 0603 (mm) component

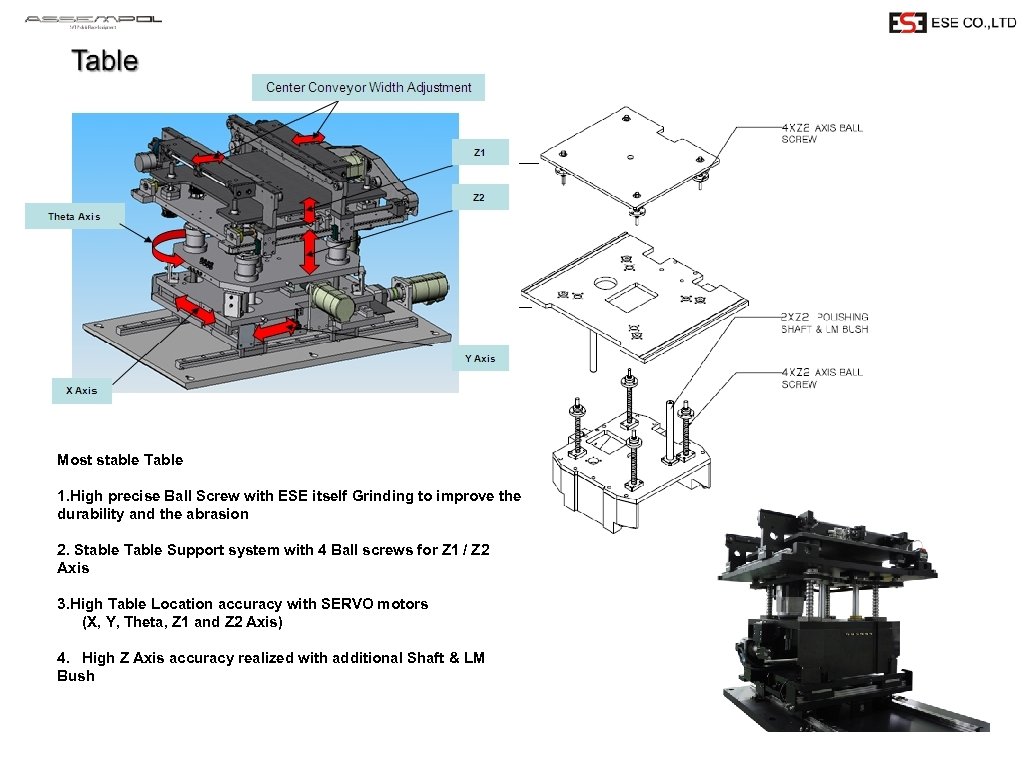

Most stable Table 1. High precise Ball Screw with ESE itself Grinding to improve the durability and the abrasion 2. Stable Table Support system with 4 Ball screws for Z 1 / Z 2 Axis 3. High Table Location accuracy with SERVO motors (X, Y, Theta, Z 1 and Z 2 Axis) 4. High Z Axis accuracy realized with additional Shaft & LM Bush

Most stable Table 1. High precise Ball Screw with ESE itself Grinding to improve the durability and the abrasion 2. Stable Table Support system with 4 Ball screws for Z 1 / Z 2 Axis 3. High Table Location accuracy with SERVO motors (X, Y, Theta, Z 1 and Z 2 Axis) 4. High Z Axis accuracy realized with additional Shaft & LM Bush

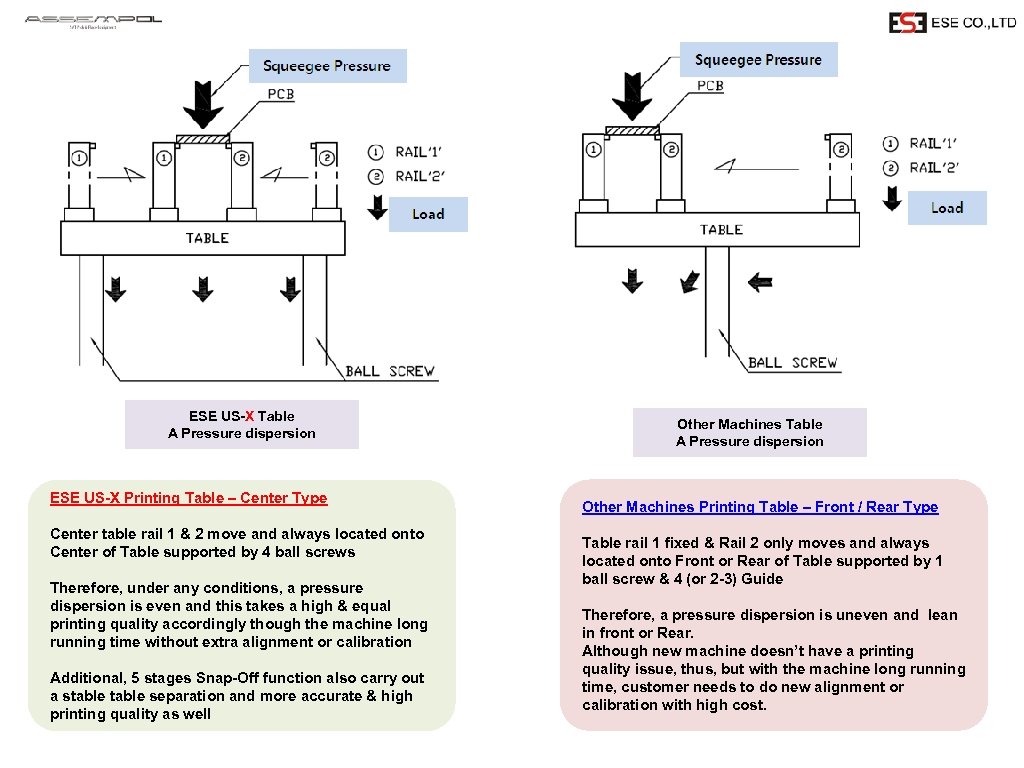

ESE US-X Table A Pressure dispersion ESE US-X Printing Table – Center Type Center table rail 1 & 2 move and always located onto Center of Table supported by 4 ball screws Therefore, under any conditions, a pressure dispersion is even and this takes a high & equal printing quality accordingly though the machine long running time without extra alignment or calibration Additional, 5 stages Snap-Off function also carry out a stable separation and more accurate & high printing quality as well Other Machines Table A Pressure dispersion Other Machines Printing Table – Front / Rear Type Table rail 1 fixed & Rail 2 only moves and always located onto Front or Rear of Table supported by 1 ball screw & 4 (or 2 -3) Guide Therefore, a pressure dispersion is uneven and lean in front or Rear. Although new machine doesn’t have a printing quality issue, thus, but with the machine long running time, customer needs to do new alignment or calibration with high cost.

ESE US-X Table A Pressure dispersion ESE US-X Printing Table – Center Type Center table rail 1 & 2 move and always located onto Center of Table supported by 4 ball screws Therefore, under any conditions, a pressure dispersion is even and this takes a high & equal printing quality accordingly though the machine long running time without extra alignment or calibration Additional, 5 stages Snap-Off function also carry out a stable separation and more accurate & high printing quality as well Other Machines Table A Pressure dispersion Other Machines Printing Table – Front / Rear Type Table rail 1 fixed & Rail 2 only moves and always located onto Front or Rear of Table supported by 1 ball screw & 4 (or 2 -3) Guide Therefore, a pressure dispersion is uneven and lean in front or Rear. Although new machine doesn’t have a printing quality issue, thus, but with the machine long running time, customer needs to do new alignment or calibration with high cost.

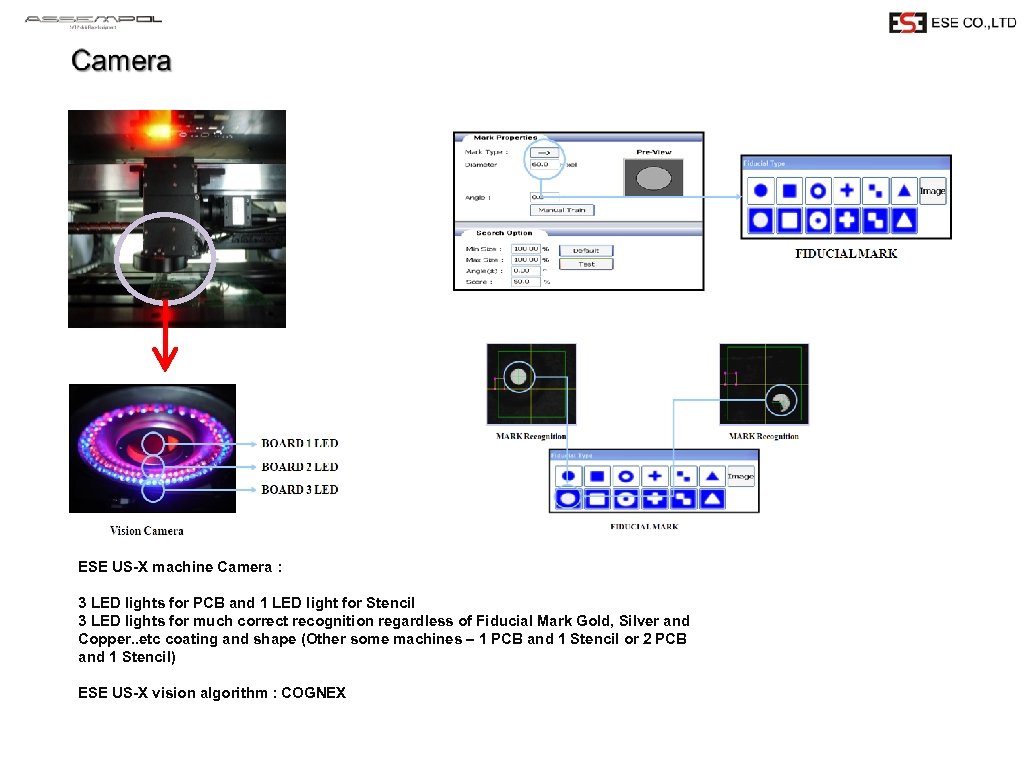

ESE US-X machine Camera : 3 LED lights for PCB and 1 LED light for Stencil 3 LED lights for much correct recognition regardless of Fiducial Mark Gold, Silver and Copper. . etc coating and shape (Other some machines – 1 PCB and 1 Stencil or 2 PCB and 1 Stencil) ESE US-X vision algorithm : COGNEX

ESE US-X machine Camera : 3 LED lights for PCB and 1 LED light for Stencil 3 LED lights for much correct recognition regardless of Fiducial Mark Gold, Silver and Copper. . etc coating and shape (Other some machines – 1 PCB and 1 Stencil or 2 PCB and 1 Stencil) ESE US-X vision algorithm : COGNEX

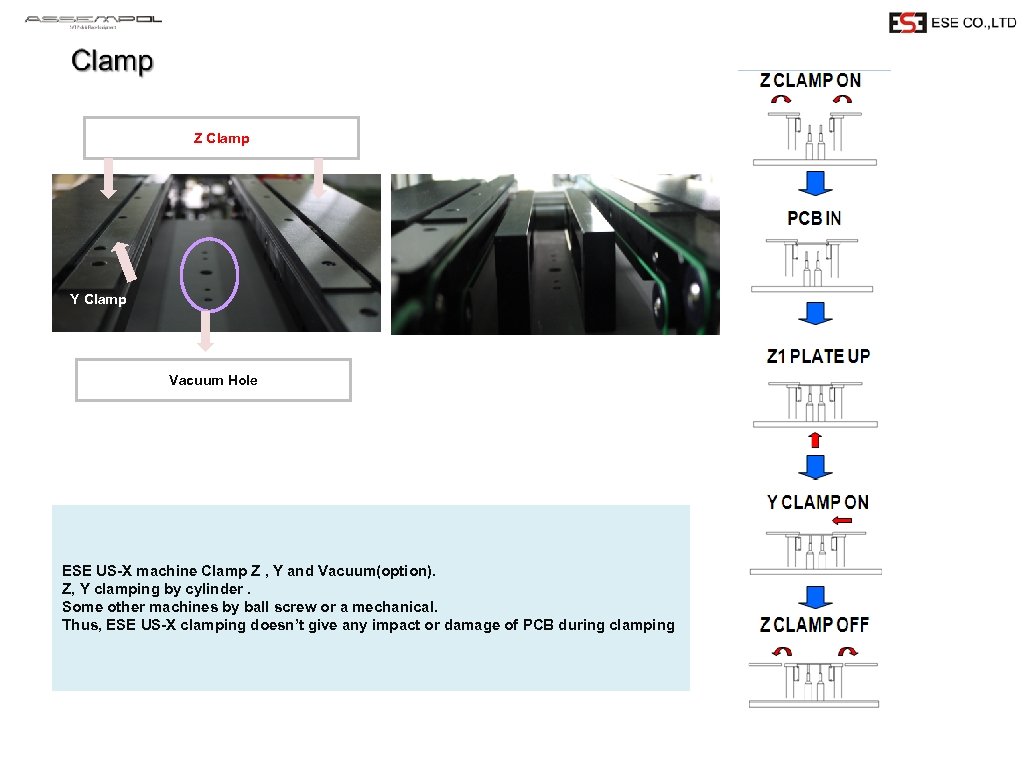

Z Clamp Y Clamp Vacuum Hole ESE US-X machine Clamp Z , Y and Vacuum(option). Z, Y clamping by cylinder. Some other machines by ball screw or a mechanical. Thus, ESE US-X clamping doesn’t give any impact or damage of PCB during clamping

Z Clamp Y Clamp Vacuum Hole ESE US-X machine Clamp Z , Y and Vacuum(option). Z, Y clamping by cylinder. Some other machines by ball screw or a mechanical. Thus, ESE US-X clamping doesn’t give any impact or damage of PCB during clamping

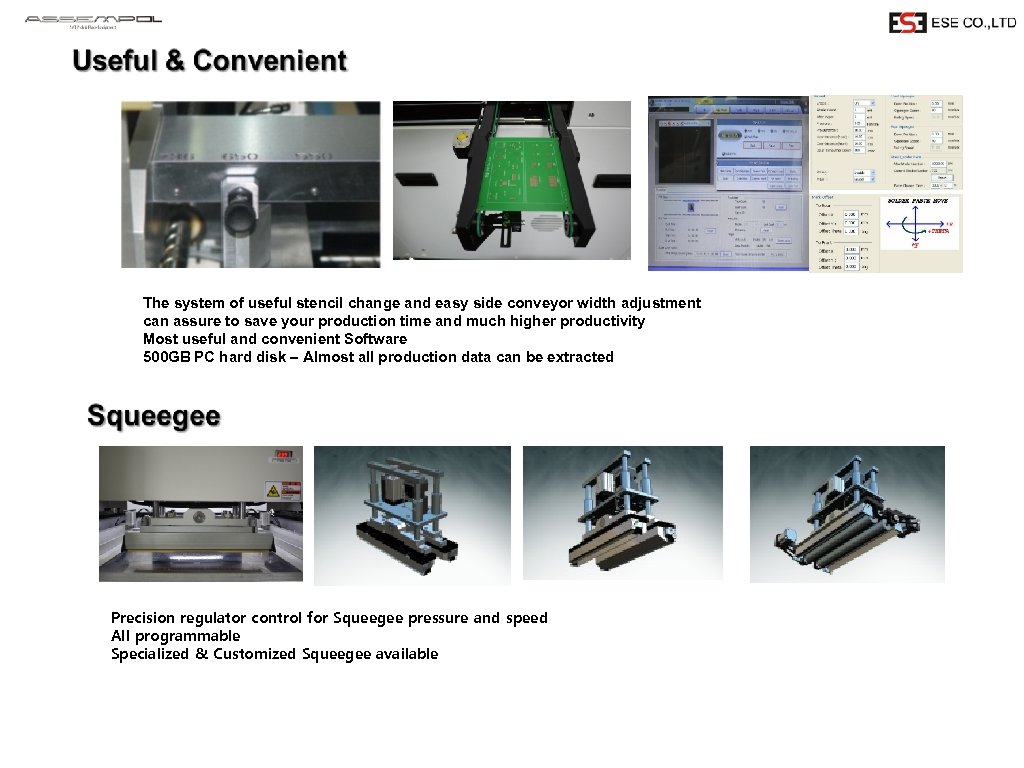

Y Clamp The system of useful stencil change and easy side conveyor width adjustment can assure to save your production time and much higher productivity Most useful and convenient Software 500 GB PC hard disk – Almost all production data can be extracted Precision regulator control for Squeegee pressure and speed All programmable Specialized & Customized Squeegee available

Y Clamp The system of useful stencil change and easy side conveyor width adjustment can assure to save your production time and much higher productivity Most useful and convenient Software 500 GB PC hard disk – Almost all production data can be extracted Precision regulator control for Squeegee pressure and speed All programmable Specialized & Customized Squeegee available

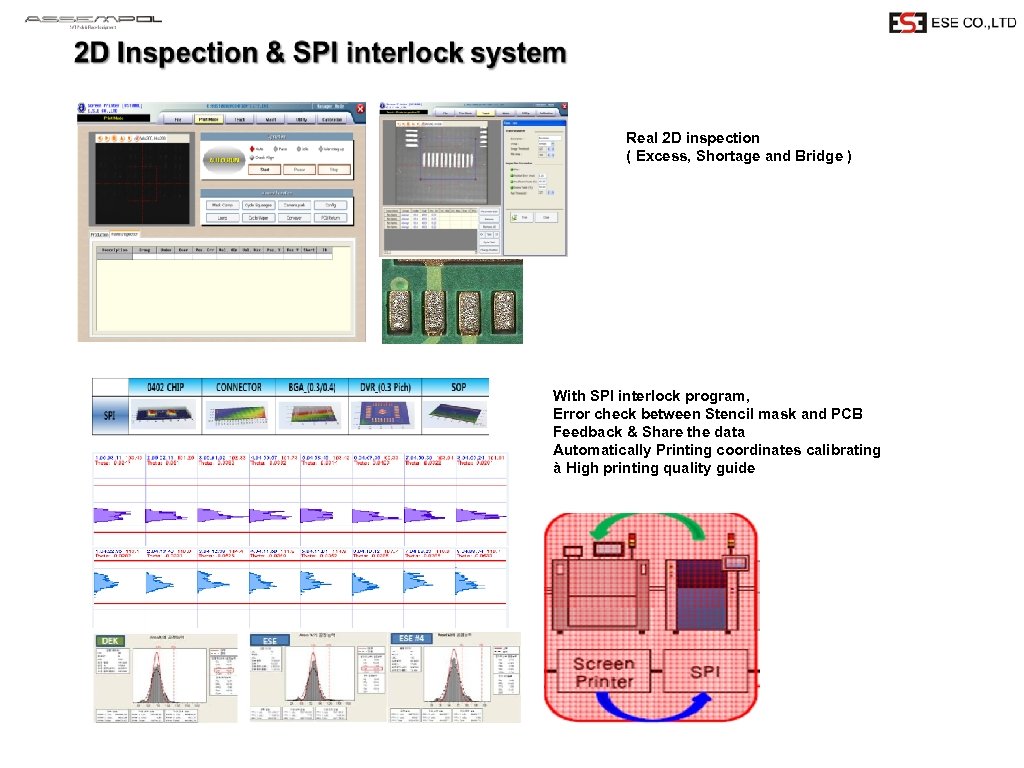

Real 2 D inspection ( Excess, Shortage and Bridge ) With SPI interlock program, Error check between Stencil mask and PCB Feedback & Share the data Automatically Printing coordinates calibrating à High printing quality guide

Real 2 D inspection ( Excess, Shortage and Bridge ) With SPI interlock program, Error check between Stencil mask and PCB Feedback & Share the data Automatically Printing coordinates calibrating à High printing quality guide

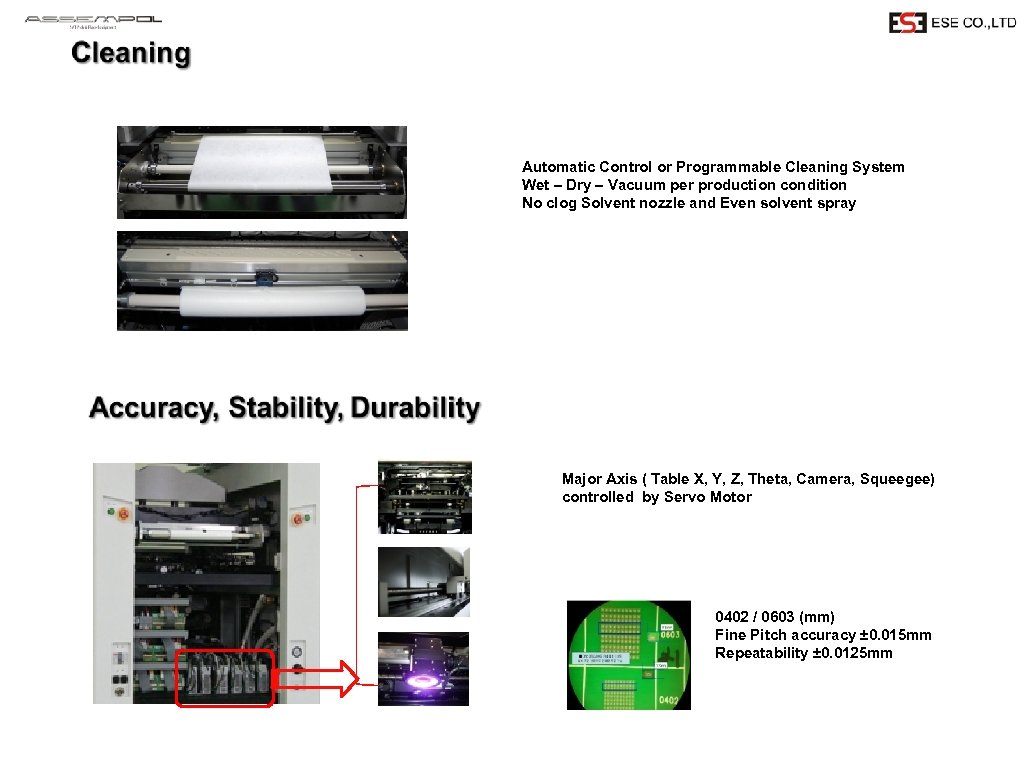

Automatic Control or Programmable Cleaning System Wet – Dry – Vacuum per production condition No clog Solvent nozzle and Even solvent spray Major Axis ( Table X, Y, Z, Theta, Camera, Squeegee) controlled by Servo Motor 0402 / 0603 (mm) Fine Pitch accuracy ± 0. 015 mm Repeatability ± 0. 0125 mm

Automatic Control or Programmable Cleaning System Wet – Dry – Vacuum per production condition No clog Solvent nozzle and Even solvent spray Major Axis ( Table X, Y, Z, Theta, Camera, Squeegee) controlled by Servo Motor 0402 / 0603 (mm) Fine Pitch accuracy ± 0. 015 mm Repeatability ± 0. 0125 mm