6228c947442b422e047d4ad469fc5747.ppt

- Количество слайдов: 27

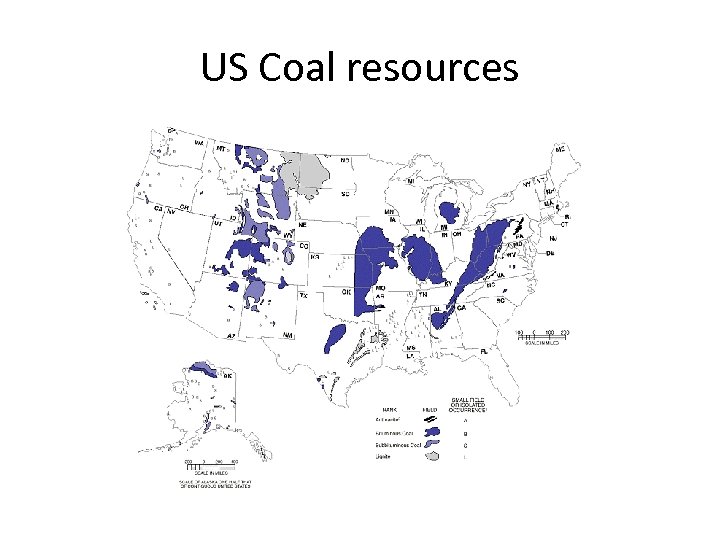

US Coal resources

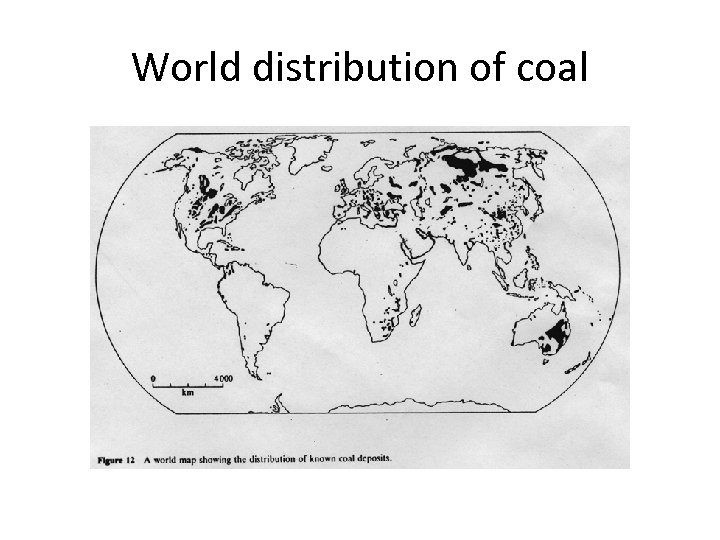

World distribution of coal

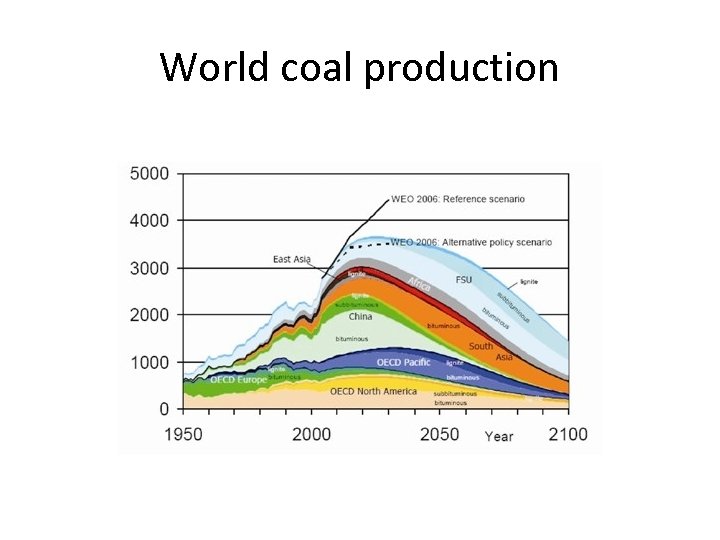

World coal production

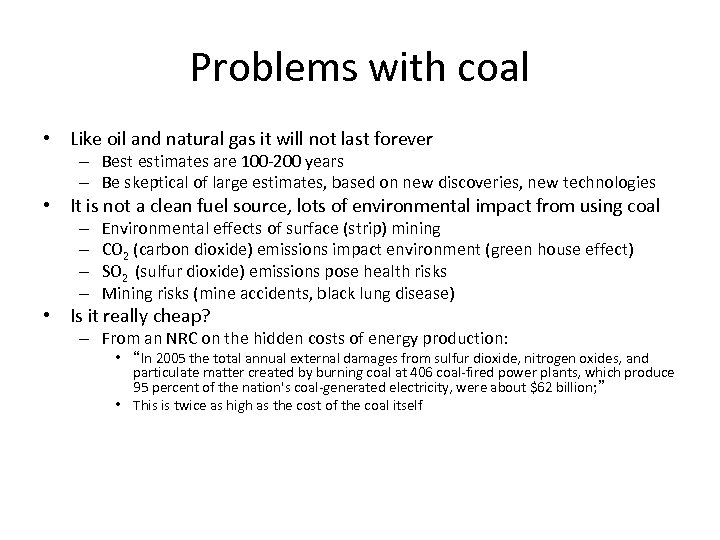

Problems with coal • Like oil and natural gas it will not last forever – Best estimates are 100 -200 years – Be skeptical of large estimates, based on new discoveries, new technologies • It is not a clean fuel source, lots of environmental impact from using coal – – Environmental effects of surface (strip) mining CO 2 (carbon dioxide) emissions impact environment (green house effect) SO 2 (sulfur dioxide) emissions pose health risks Mining risks (mine accidents, black lung disease) • Is it really cheap? – From an NRC on the hidden costs of energy production: • “In 2005 the total annual external damages from sulfur dioxide, nitrogen oxides, and particulate matter created by burning coal at 406 coal-fired power plants, which produce 95 percent of the nation's coal-generated electricity, were about $62 billion; ” • This is twice as high as the cost of the coal itself

Coal Liquefaction • Process of producing synthetic fuel from coal • Direct and indirect process to achieve this • Direct: – Carbonization- produces coal tar, oil, water vapor, synthetic gas and char (a solid residue). Produces fluids that are of low quality for fuel. – Hydrogenation –add H 2 to coal mixed with solvents and catalysts. No proven commercial value to the process • Indirect: Fischer-Tropsch process (coal gasification) – Coal is gasified into syngas, which is converted to gasoline ad diesel.

Coal gasification • Process of producing coal gas, which can be converted into gasoline and diesel fuel and Hydrogen. • Coal is heated and blown with oxygen and steam. Produces syngas, which can then be turned into gasoline as described on the previous slide. • Or syngas is fed into another reaction which produces H • Produces by-products which are environmentally damaging and need mitigation techniques • Produces more CO 2 than crude oil refinement-needs carbon sequestering technologies.

Non-conventional fossil fuels • Tar sands, shale gas and shale oil • Until recently, these were not considered as a viable large scale contributors to our energy needs • Technological advances and rising energy prices have brought shale oil and gas to the forefront as possible short term solutions

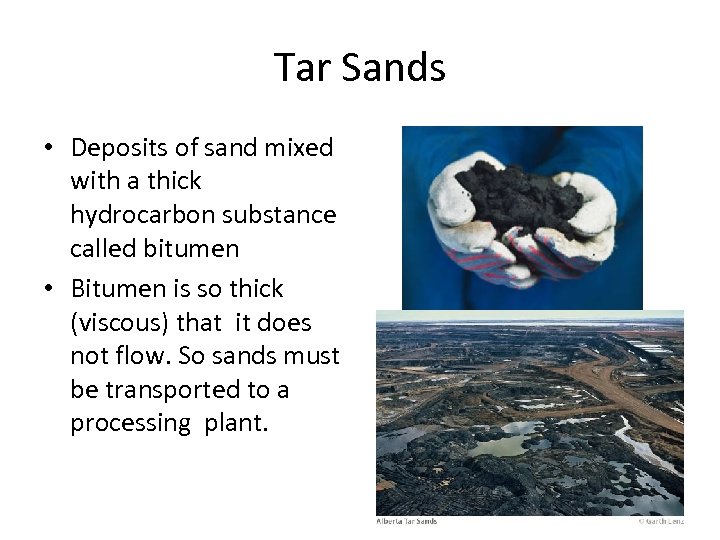

Tar Sands • Deposits of sand mixed with a thick hydrocarbon substance called bitumen • Bitumen is so thick (viscous) that it does not flow. So sands must be transported to a processing plant.

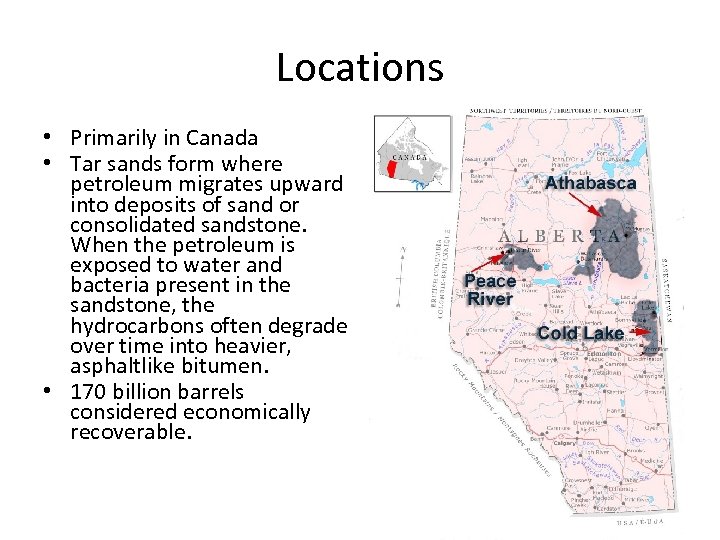

Locations • Primarily in Canada • Tar sands form where petroleum migrates upward into deposits of sand or consolidated sandstone. When the petroleum is exposed to water and bacteria present in the sandstone, the hydrocarbons often degrade over time into heavier, asphaltlike bitumen. • 170 billion barrels considered economically recoverable.

Tar sands processing • Tar sand is placed in rotating drums along with water and caustic soda that separates the water, soda and bitumen. • Bitumen is placed in a centrifuge and cracked into naptha, kerosene and heavy fuel oil • Requires a lot of water (about 3 barrels of water for one barrel of oil produced • Waste is stored on site in waste water ponds • Similar energy density to shale oil, much less than coal

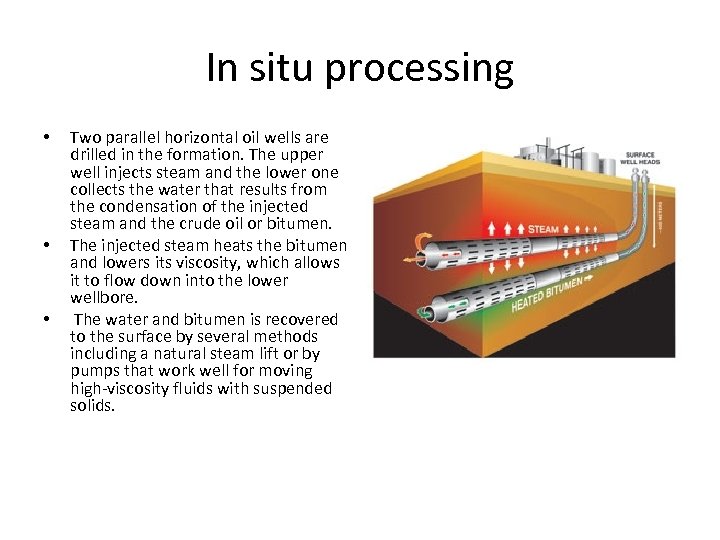

In situ processing • • • Two parallel horizontal oil wells are drilled in the formation. The upper well injects steam and the lower one collects the water that results from the condensation of the injected steam and the crude oil or bitumen. The injected steam heats the bitumen and lowers its viscosity, which allows it to flow down into the lower wellbore. The water and bitumen is recovered to the surface by several methods including a natural steam lift or by pumps that work well for moving high-viscosity fluids with suspended solids.

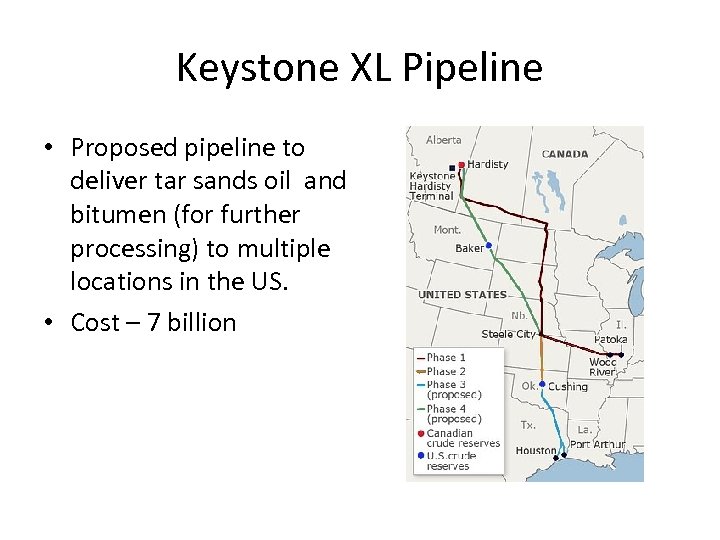

Keystone XL Pipeline • Proposed pipeline to deliver tar sands oil and bitumen (for further processing) to multiple locations in the US. • Cost – 7 billion

Concerns about Keystone XL • Portions cross known seismic regions • Crosses native American reservations – Concerns over damage to sacred sites – Contamination from leaks or from tars sands production itself • Leak or spill from any section would have environmental impacts • Overall tar sands usage produces more greenhouse gasses than conventional oil • Does not really address energy independence • How much will be kept in the US vs being exported? • If immediately approved, won’t effect prices at the pump until 2014 and there is no consensus on its impact on gas prices, though it will be smaller than 10 cents/gallon. • Compare to Trans. Alaska pipeline – 7 incidents in 35 years, 2 from sabotage(people putting holes in the pipeline), 1 from human error, 1 from earthquake(no leak), 3 from equipment failures

Shale oil vs oil shale • Shale Oil • The oil produced from oil shale • Oil Shale • Also called kerogen shale • Rocks that contain kerogen – Kerogen a solid mixture of organic compounds from which shale oil can be produced – Shale oil is a substitute for crude oil

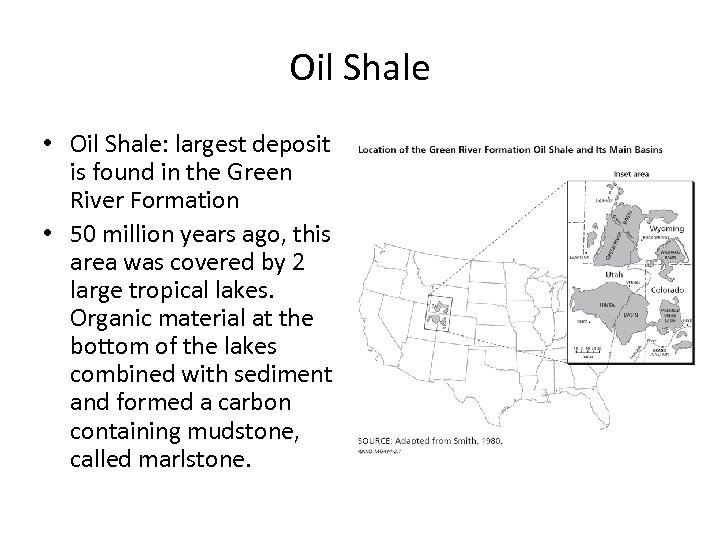

Oil Shale • Oil Shale: largest deposit is found in the Green River Formation • 50 million years ago, this area was covered by 2 large tropical lakes. Organic material at the bottom of the lakes combined with sediment and formed a carbon containing mudstone, called marlstone.

Green River Formation

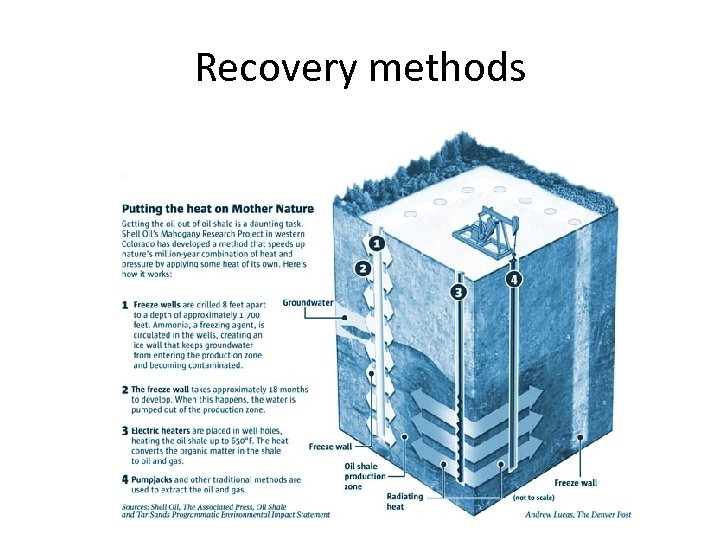

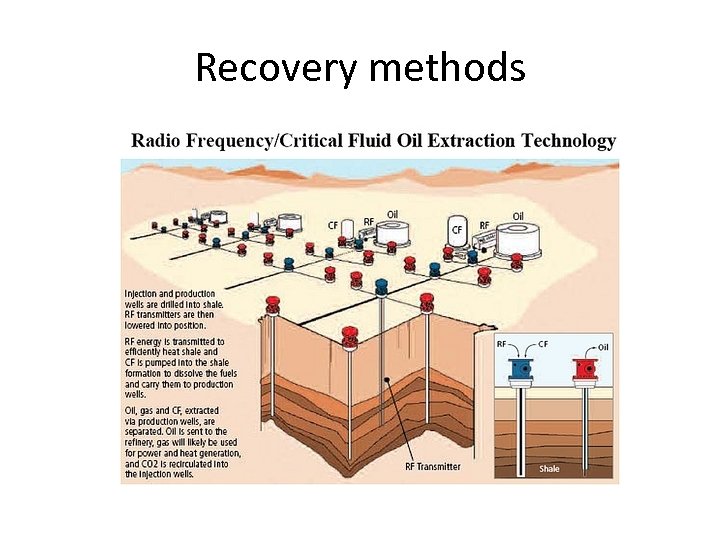

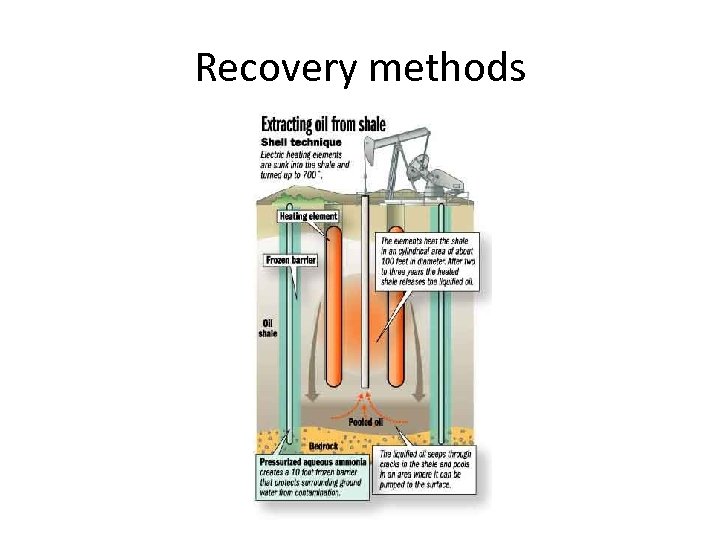

Recovery methods • Getting the oil is not easy, nor is it cheap, but it is becoming economically feasible. Same amount of coal produces much more energy. • Traditional removal process require heating (a process called retorting) of the shale to remove the hydrocarbons which expands the remaining shale by 35%. Need a deposit site to handle the waste • This process also requires lots of water, Green River formation is in a very dry part of the country. • In situ (on site) recovery methods are being developed to overcome these difficulties

Recovery methods

Recovery methods

Recovery methods

How much? • 0. 5 -1. 1 trillion barrels of technically recoverable oil shale oil in the US. (note that the word technically recoverable includes proved and unproved reserves) • Based on current demand, this would provide the US with enough oil for 400 years.

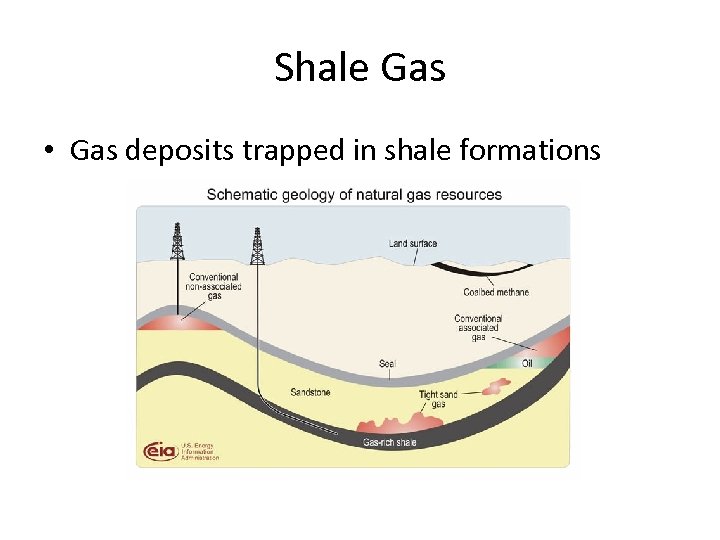

Shale Gas • Gas deposits trapped in shale formations

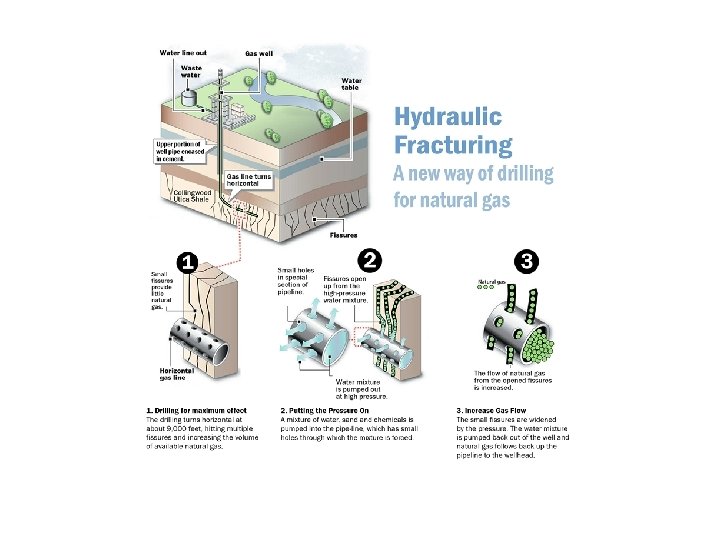

Fracking • Hydraulic Fracturing • A process which uses a high pressure liquid to create fractures or veins on rock to allow petroleum, natural gas or other substances to flow • Used as far back as 1860’s to extract oil in Pennsylvania, new York, West Virginia and Kentucky

Issues • Water useage –Fracking takes a large volume of water. The average well uses 3 -8 million gallons/week. • Many of the chemical additives used are toxic and known carcinogens-possibility exists of contaminating ground water supplies • Flowback – the fracking fluids are further contaminated as they flow back through the wells by naturally occurring minerals and possibly naturally occurring radioactive substances • Methane release-can cause explosions, can contaminate ground water and is a greenhouse gas • Earthquakes-the additional fluid can cause fault lines to slip more easily

Flaming Faucets? • http: //www. youtube. com/watch? v=Urnn. Q 17 SH_A

How much? • In the US, probably enough for about 100 years, at current rate of consumption • If we increase consumption, this number will go down. • Recovering methane from coal beds can offset the consumption increases a little

6228c947442b422e047d4ad469fc5747.ppt