19f46f6fbd85bcc0c02e21f988cd61eb.ppt

- Количество слайдов: 53

US CMS Silicon Tracker Project US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 1

US CMS Silicon Tracker Project US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 1

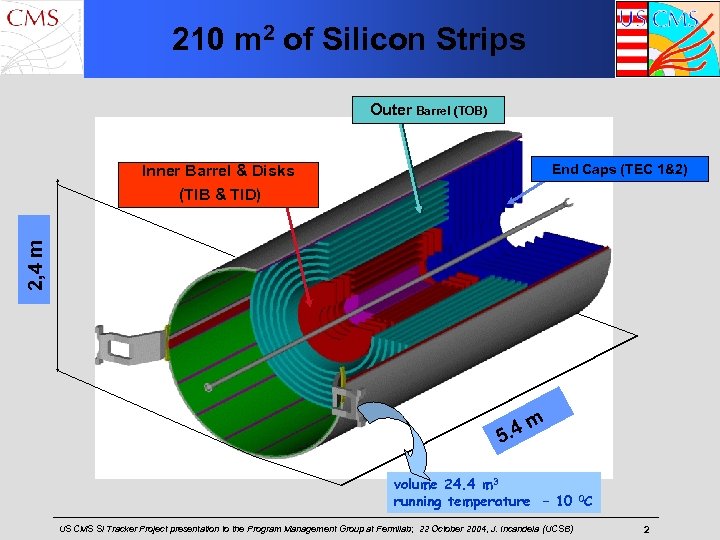

210 m 2 of Silicon Strips Outer Barrel (TOB) End Caps (TEC 1&2) 2, 4 m Inner Barrel & Disks (TIB & TID) . 4 5 m volume 24. 4 m 3 running temperature – 10 0 C US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 2

210 m 2 of Silicon Strips Outer Barrel (TOB) End Caps (TEC 1&2) 2, 4 m Inner Barrel & Disks (TIB & TID) . 4 5 m volume 24. 4 m 3 running temperature – 10 0 C US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 2

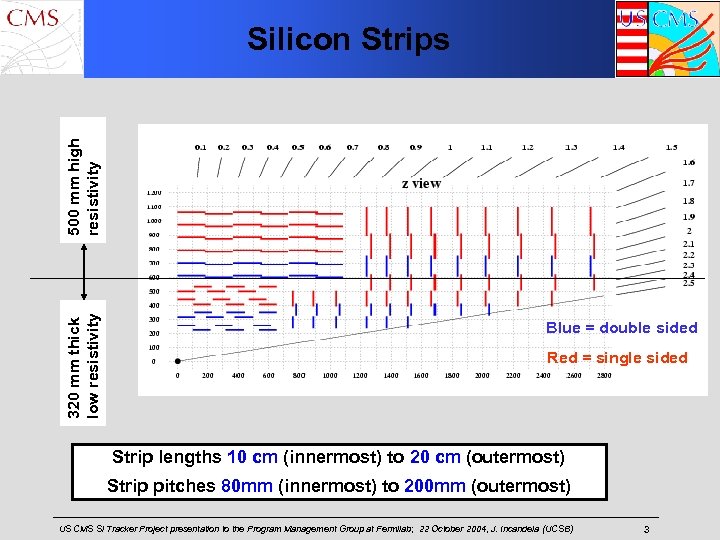

320 mm thick low resistivity 500 mm high resistivity Silicon Strips Blue = double sided Red = single sided Strip lengths 10 cm (innermost) to 20 cm (outermost) Strip pitches 80 mm (innermost) to 200 mm (outermost) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 3

320 mm thick low resistivity 500 mm high resistivity Silicon Strips Blue = double sided Red = single sided Strip lengths 10 cm (innermost) to 20 cm (outermost) Strip pitches 80 mm (innermost) to 200 mm (outermost) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 3

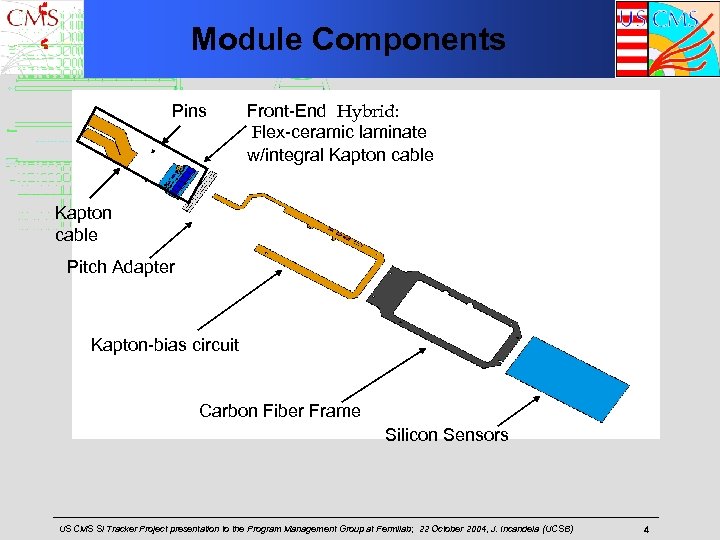

Module Components Pins Front-End Hybrid: Flex-ceramic laminate w/integral Kapton cable Pitch Adapter Kapton-bias circuit Carbon Fiber Frame Silicon Sensors US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 4

Module Components Pins Front-End Hybrid: Flex-ceramic laminate w/integral Kapton cable Pitch Adapter Kapton-bias circuit Carbon Fiber Frame Silicon Sensors US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 4

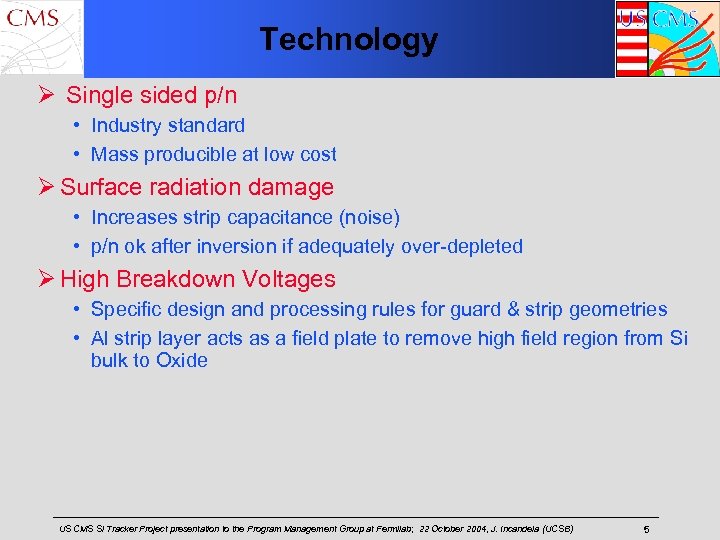

Technology Ø Single sided p/n • Industry standard • Mass producible at low cost Ø Surface radiation damage • Increases strip capacitance (noise) • p/n ok after inversion if adequately over-depleted Ø High Breakdown Voltages • Specific design and processing rules for guard & strip geometries • Al strip layer acts as a field plate to remove high field region from Si bulk to Oxide US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 5

Technology Ø Single sided p/n • Industry standard • Mass producible at low cost Ø Surface radiation damage • Increases strip capacitance (noise) • p/n ok after inversion if adequately over-depleted Ø High Breakdown Voltages • Specific design and processing rules for guard & strip geometries • Al strip layer acts as a field plate to remove high field region from Si bulk to Oxide US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 5

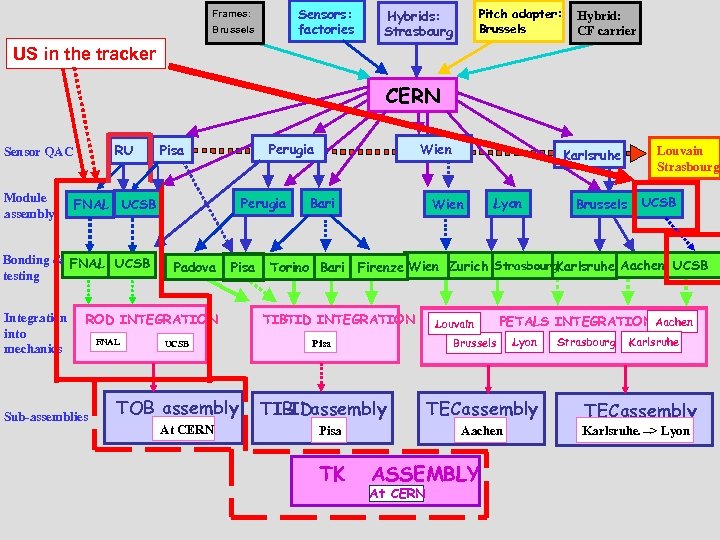

Sensors: factories Frames: Brussels Pitch adapter: Brussels Hybrids: Strasbourg Hybrid: CF carrier US in the tracker CERN RU Sensor QAC Module assembly Perugia FNAL UCSB Bonding & FNAL UCSB testing Integration into mechanics Perugia Pisa Padova Pisa ROD INTEGRATION Sub-assemblies Wien Bari Torino Bari Wien TIBTID INTEGRATION - TOB assembly TIBIDassembly Pisa TK Louvain Brussels UCSB PETALS INTEGRATION Aachen Brussels Pisa At CERN Lyon Louvain Strasbourg Firenze Wien Zurich Strasbourg. Karlsruhe Aachen UCSB FNAL Karlsruhe TECassembly Aachen ASSEMBLY At CERN Lyon Strasbourg Karlsruhe TECassembly Karlsruhe. --> Lyon

Sensors: factories Frames: Brussels Pitch adapter: Brussels Hybrids: Strasbourg Hybrid: CF carrier US in the tracker CERN RU Sensor QAC Module assembly Perugia FNAL UCSB Bonding & FNAL UCSB testing Integration into mechanics Perugia Pisa Padova Pisa ROD INTEGRATION Sub-assemblies Wien Bari Torino Bari Wien TIBTID INTEGRATION - TOB assembly TIBIDassembly Pisa TK Louvain Brussels UCSB PETALS INTEGRATION Aachen Brussels Pisa At CERN Lyon Louvain Strasbourg Firenze Wien Zurich Strasbourg. Karlsruhe Aachen UCSB FNAL Karlsruhe TECassembly Aachen ASSEMBLY At CERN Lyon Strasbourg Karlsruhe TECassembly Karlsruhe. --> Lyon

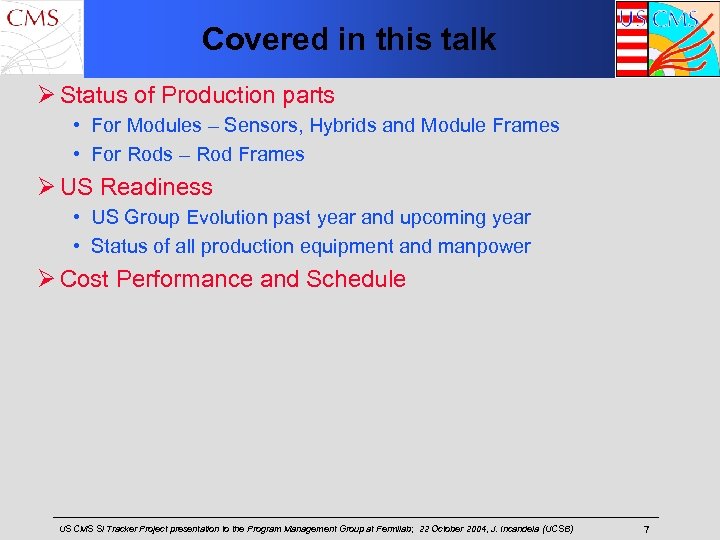

Covered in this talk Ø Status of Production parts • For Modules – Sensors, Hybrids and Module Frames • For Rods – Rod Frames Ø US Readiness • US Group Evolution past year and upcoming year • Status of all production equipment and manpower Ø Cost Performance and Schedule US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 7

Covered in this talk Ø Status of Production parts • For Modules – Sensors, Hybrids and Module Frames • For Rods – Rod Frames Ø US Readiness • US Group Evolution past year and upcoming year • Status of all production equipment and manpower Ø Cost Performance and Schedule US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 7

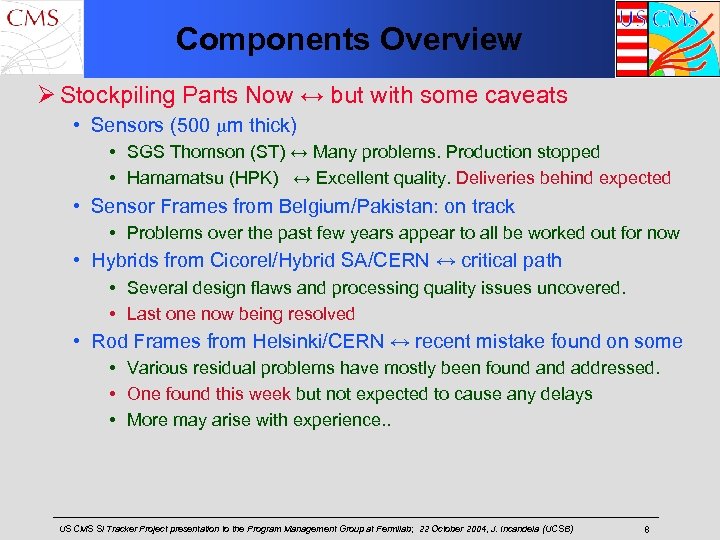

Components Overview Ø Stockpiling Parts Now ↔ but with some caveats • Sensors (500 mm thick) • SGS Thomson (ST) ↔ Many problems. Production stopped • Hamamatsu (HPK) ↔ Excellent quality. Deliveries behind expected • Sensor Frames from Belgium/Pakistan: on track • Problems over the past few years appear to all be worked out for now • Hybrids from Cicorel/Hybrid SA/CERN ↔ critical path • Several design flaws and processing quality issues uncovered. • Last one now being resolved • Rod Frames from Helsinki/CERN ↔ recent mistake found on some • Various residual problems have mostly been found addressed. • One found this week but not expected to cause any delays • More may arise with experience. . US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 8

Components Overview Ø Stockpiling Parts Now ↔ but with some caveats • Sensors (500 mm thick) • SGS Thomson (ST) ↔ Many problems. Production stopped • Hamamatsu (HPK) ↔ Excellent quality. Deliveries behind expected • Sensor Frames from Belgium/Pakistan: on track • Problems over the past few years appear to all be worked out for now • Hybrids from Cicorel/Hybrid SA/CERN ↔ critical path • Several design flaws and processing quality issues uncovered. • Last one now being resolved • Rod Frames from Helsinki/CERN ↔ recent mistake found on some • Various residual problems have mostly been found addressed. • One found this week but not expected to cause any delays • More may arise with experience. . US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 8

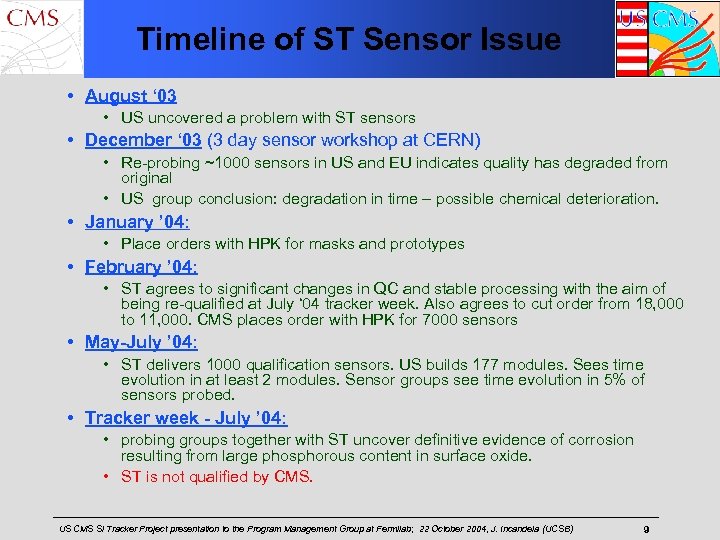

Timeline of ST Sensor Issue • August ‘ 03 • US uncovered a problem with ST sensors • December ‘ 03 (3 day sensor workshop at CERN) • Re-probing ~1000 sensors in US and EU indicates quality has degraded from original • US group conclusion: degradation in time – possible chemical deterioration. • January ’ 04: • Place orders with HPK for masks and prototypes • February ’ 04: • ST agrees to significant changes in QC and stable processing with the aim of being re-qualified at July ‘ 04 tracker week. Also agrees to cut order from 18, 000 to 11, 000. CMS places order with HPK for 7000 sensors • May-July ’ 04: • ST delivers 1000 qualification sensors. US builds 177 modules. Sees time evolution in at least 2 modules. Sensor groups see time evolution in 5% of sensors probed. • Tracker week - July ’ 04: • probing groups together with ST uncover definitive evidence of corrosion resulting from large phosphorous content in surface oxide. • ST is not qualified by CMS. US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 9

Timeline of ST Sensor Issue • August ‘ 03 • US uncovered a problem with ST sensors • December ‘ 03 (3 day sensor workshop at CERN) • Re-probing ~1000 sensors in US and EU indicates quality has degraded from original • US group conclusion: degradation in time – possible chemical deterioration. • January ’ 04: • Place orders with HPK for masks and prototypes • February ’ 04: • ST agrees to significant changes in QC and stable processing with the aim of being re-qualified at July ‘ 04 tracker week. Also agrees to cut order from 18, 000 to 11, 000. CMS places order with HPK for 7000 sensors • May-July ’ 04: • ST delivers 1000 qualification sensors. US builds 177 modules. Sees time evolution in at least 2 modules. Sensor groups see time evolution in 5% of sensors probed. • Tracker week - July ’ 04: • probing groups together with ST uncover definitive evidence of corrosion resulting from large phosphorous content in surface oxide. • ST is not qualified by CMS. US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 9

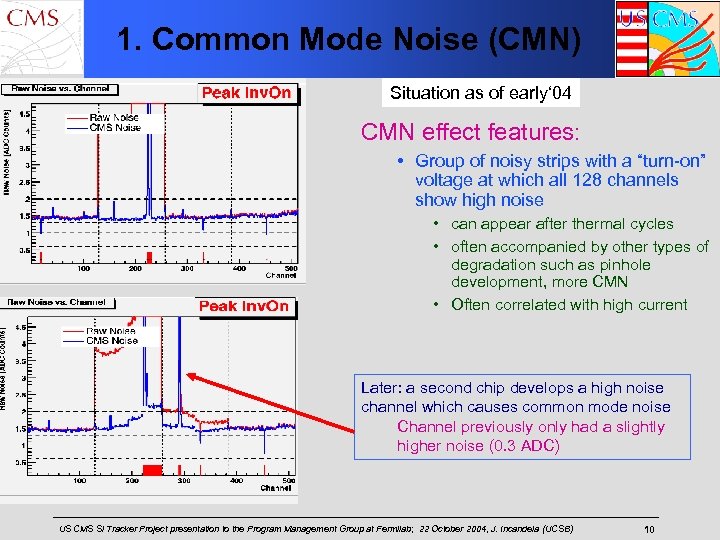

1. Common Mode Noise (CMN) Situation as of early‘ 04 CMN effect features: • Group of noisy strips with a “turn-on” voltage at which all 128 channels show high noise • can appear after thermal cycles • often accompanied by other types of degradation such as pinhole development, more CMN • Often correlated with high current Later: a second chip develops a high noise channel which causes common mode noise Channel previously only had a slightly higher noise (0. 3 ADC) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 10

1. Common Mode Noise (CMN) Situation as of early‘ 04 CMN effect features: • Group of noisy strips with a “turn-on” voltage at which all 128 channels show high noise • can appear after thermal cycles • often accompanied by other types of degradation such as pinhole development, more CMN • Often correlated with high current Later: a second chip develops a high noise channel which causes common mode noise Channel previously only had a slightly higher noise (0. 3 ADC) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 10

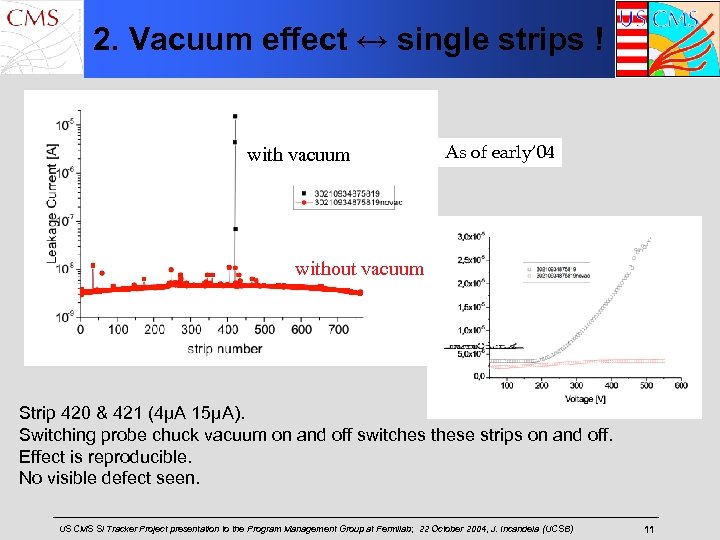

2. Vacuum effect ↔ single strips ! with vacuum As of early‘ 04 without vacuum Strip 420 & 421 (4µA 15µA). Switching probe chuck vacuum on and off switches these strips on and off. Effect is reproducible. No visible defect seen. US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 11

2. Vacuum effect ↔ single strips ! with vacuum As of early‘ 04 without vacuum Strip 420 & 421 (4µA 15µA). Switching probe chuck vacuum on and off switches these strips on and off. Effect is reproducible. No visible defect seen. US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 11

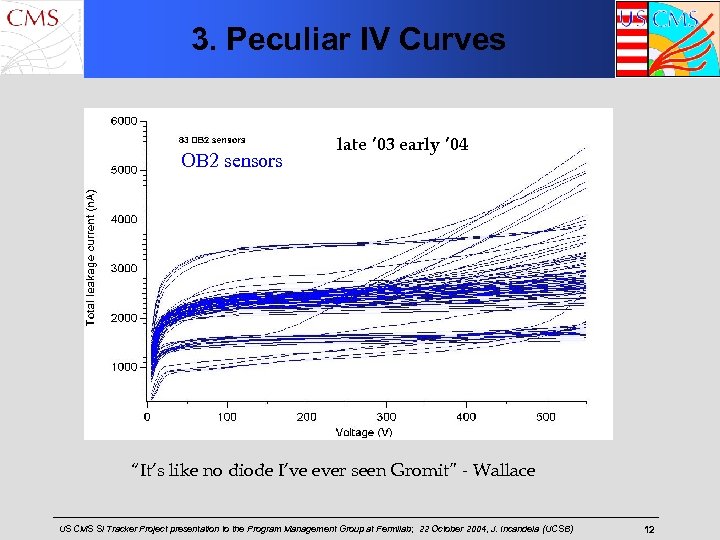

3. Peculiar IV Curves OB 2 sensors late ’ 03 early ’ 04 “It’s like no diode I’ve ever seen Gromit” - Wallace US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 12

3. Peculiar IV Curves OB 2 sensors late ’ 03 early ’ 04 “It’s like no diode I’ve ever seen Gromit” - Wallace US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 12

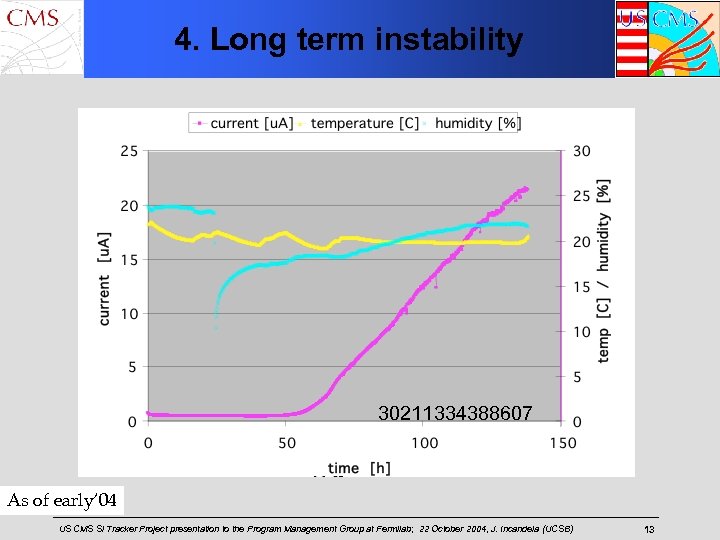

4. Long term instability 30211334388607 As of early‘ 04 US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 13

4. Long term instability 30211334388607 As of early‘ 04 US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 13

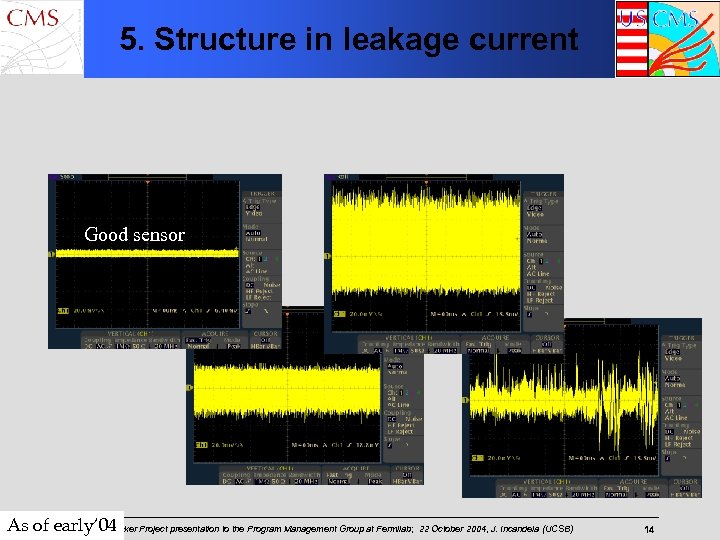

5. Structure in leakage current Good sensor As of early‘ 04 Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) US CMS Si Tracker 14

5. Structure in leakage current Good sensor As of early‘ 04 Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) US CMS Si Tracker 14

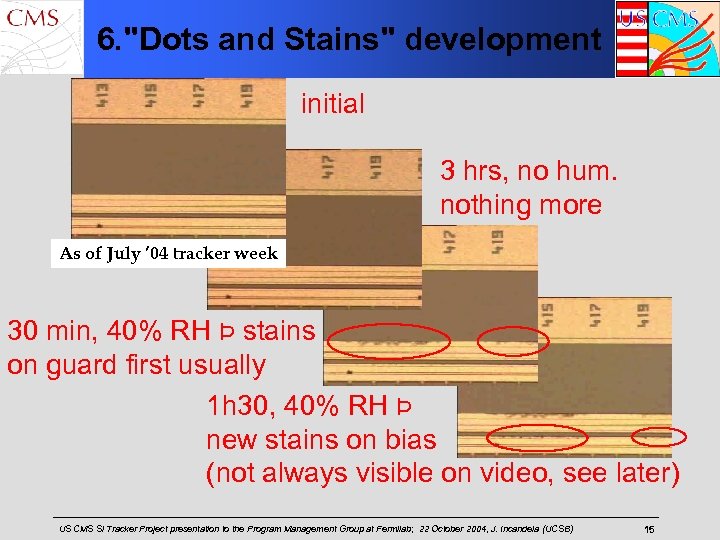

6. "Dots and Stains" development initial 3 hrs, no hum. nothing more As of July ’ 04 tracker week 30 min, 40% RH Þ stains on guard first usually 1 h 30, 40% RH Þ new stains on bias (not always visible on video, see later) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 15

6. "Dots and Stains" development initial 3 hrs, no hum. nothing more As of July ’ 04 tracker week 30 min, 40% RH Þ stains on guard first usually 1 h 30, 40% RH Þ new stains on bias (not always visible on video, see later) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 15

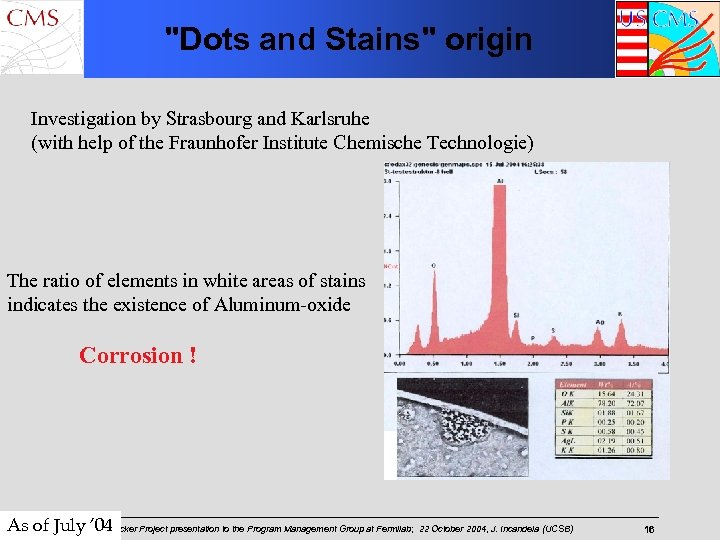

"Dots and Stains" origin Investigation by Strasbourg and Karlsruhe (with help of the Fraunhofer Institute Chemische Technologie) The ratio of elements in white areas of stains indicates the existence of Aluminum-oxide Corrosion ! As of July ’ 04 Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) US CMS Si Tracker 16

"Dots and Stains" origin Investigation by Strasbourg and Karlsruhe (with help of the Fraunhofer Institute Chemische Technologie) The ratio of elements in white areas of stains indicates the existence of Aluminum-oxide Corrosion ! As of July ’ 04 Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) US CMS Si Tracker 16

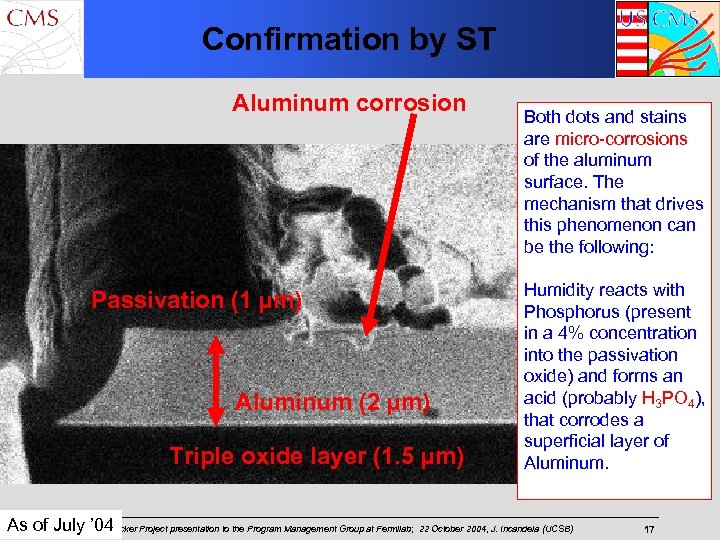

Confirmation by ST Aluminum corrosion Passivation (1 µm) Aluminum (2 µm) Triple oxide layer (1. 5 µm) Both dots and stains are micro-corrosions of the aluminum surface. The mechanism that drives this phenomenon can be the following: Humidity reacts with Phosphorus (present in a 4% concentration into the passivation oxide) and forms an acid (probably H 3 PO 4), that corrodes a superficial layer of Aluminum. As of July ’ 04 Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) US CMS Si Tracker 17

Confirmation by ST Aluminum corrosion Passivation (1 µm) Aluminum (2 µm) Triple oxide layer (1. 5 µm) Both dots and stains are micro-corrosions of the aluminum surface. The mechanism that drives this phenomenon can be the following: Humidity reacts with Phosphorus (present in a 4% concentration into the passivation oxide) and forms an acid (probably H 3 PO 4), that corrodes a superficial layer of Aluminum. As of July ’ 04 Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) US CMS Si Tracker 17

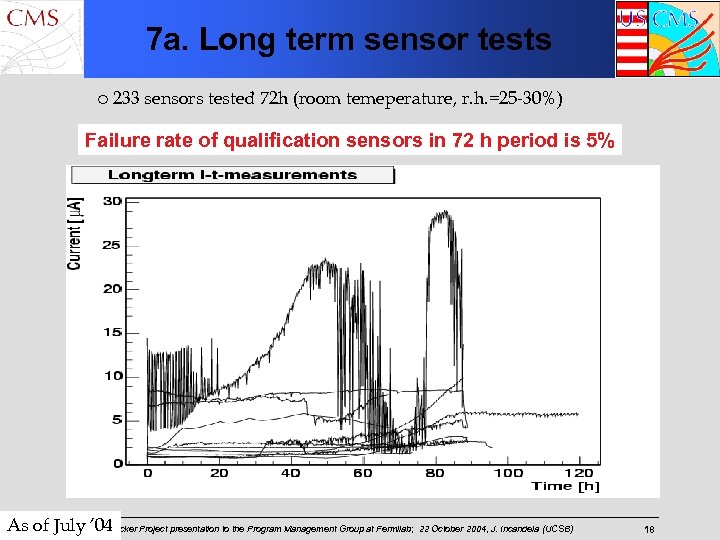

7 a. Long term sensor tests ¡ 233 sensors tested 72 h (room temeperature, r. h. =25 -30%) Failure rate of qualification sensors in 72 h period is 5% As of July ’ 04 Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) US CMS Si Tracker 18

7 a. Long term sensor tests ¡ 233 sensors tested 72 h (room temeperature, r. h. =25 -30%) Failure rate of qualification sensors in 72 h period is 5% As of July ’ 04 Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) US CMS Si Tracker 18

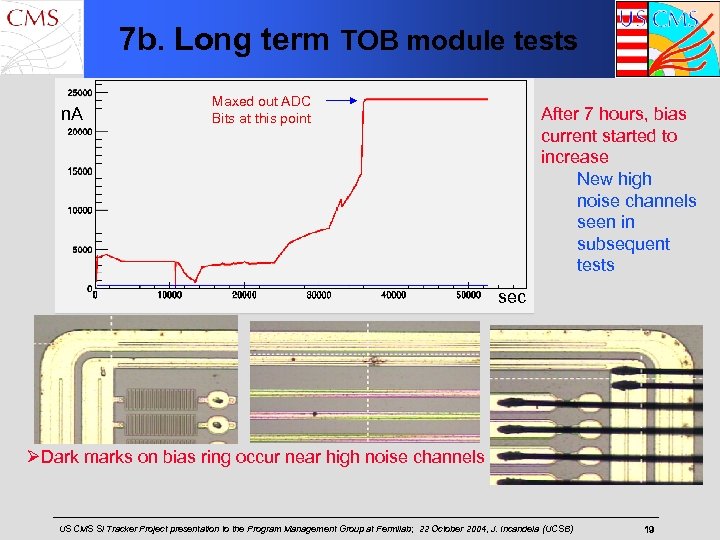

7 b. Long term TOB module tests n. A Maxed out ADC Bits at this point After 7 hours, bias current started to increase New high noise channels seen in subsequent tests sec ØDark marks on bias ring occur near high noise channels US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 19

7 b. Long term TOB module tests n. A Maxed out ADC Bits at this point After 7 hours, bias current started to increase New high noise channels seen in subsequent tests sec ØDark marks on bias ring occur near high noise channels US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 19

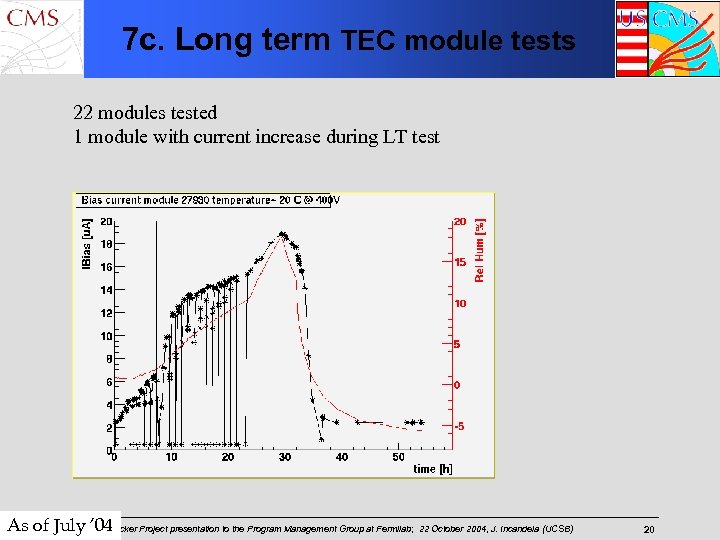

7 c. Long term TEC module tests 22 modules tested 1 module with current increase during LT test As of July ’ 04 Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) US CMS Si Tracker 20

7 c. Long term TEC module tests 22 modules tested 1 module with current increase during LT test As of July ’ 04 Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) US CMS Si Tracker 20

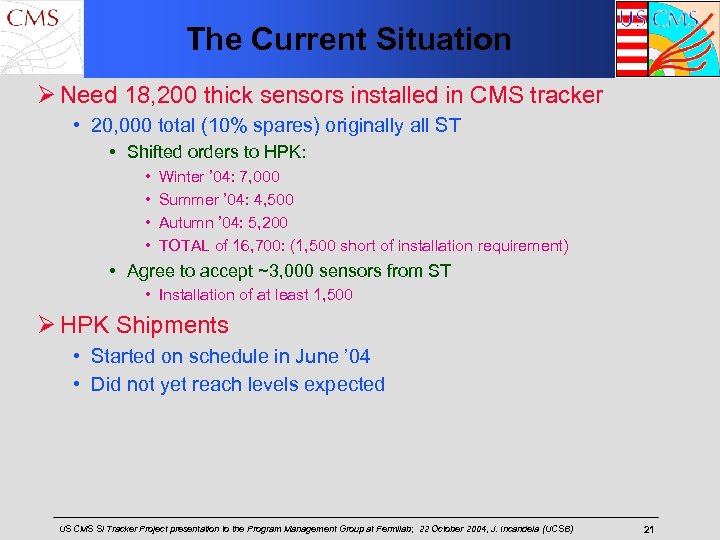

The Current Situation Ø Need 18, 200 thick sensors installed in CMS tracker • 20, 000 total (10% spares) originally all ST • Shifted orders to HPK: • • Winter ’ 04: 7, 000 Summer ’ 04: 4, 500 Autumn ’ 04: 5, 200 TOTAL of 16, 700: (1, 500 short of installation requirement) • Agree to accept ~3, 000 sensors from ST • Installation of at least 1, 500 Ø HPK Shipments • Started on schedule in June ’ 04 • Did not yet reach levels expected US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 21

The Current Situation Ø Need 18, 200 thick sensors installed in CMS tracker • 20, 000 total (10% spares) originally all ST • Shifted orders to HPK: • • Winter ’ 04: 7, 000 Summer ’ 04: 4, 500 Autumn ’ 04: 5, 200 TOTAL of 16, 700: (1, 500 short of installation requirement) • Agree to accept ~3, 000 sensors from ST • Installation of at least 1, 500 Ø HPK Shipments • Started on schedule in June ’ 04 • Did not yet reach levels expected US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 21

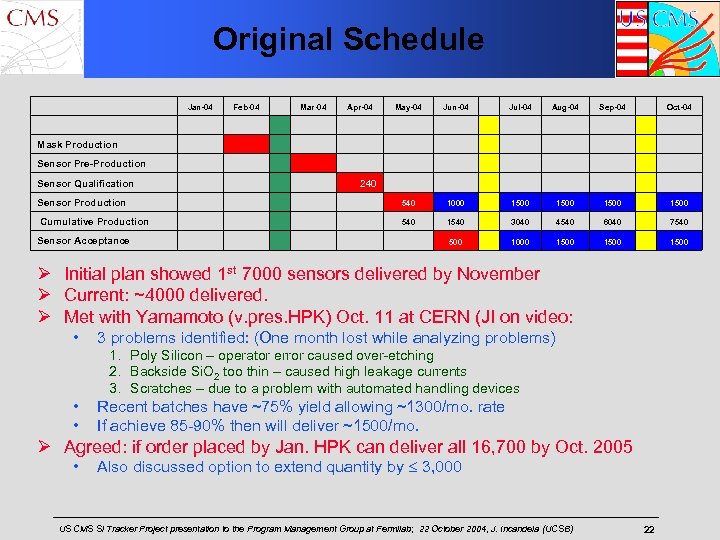

Original Schedule Jan-04 Feb-04 Mar-04 Apr-04 May-04 Jun-04 Jul-04 Aug-04 Sep-04 Oct-04 Mask Production Sensor Pre-Production Sensor Qualification Sensor Production 540 1000 1500 Cumulative Production 540 1540 3040 4540 6040 7540 Sensor Acceptance 500 1000 1500 240 Ø Initial plan showed 1 st 7000 sensors delivered by November Ø Current: ~4000 delivered. Ø Met with Yamamoto (v. pres. HPK) Oct. 11 at CERN (JI on video: • 3 problems identified: (One month lost while analyzing problems) 1. Poly Silicon – operator error caused over-etching 2. Backside Si. O 2 too thin – caused high leakage currents 3. Scratches – due to a problem with automated handling devices • • Recent batches have ~75% yield allowing ~1300/mo. rate If achieve 85 -90% then will deliver ~1500/mo. Ø Agreed: if order placed by Jan. HPK can deliver all 16, 700 by Oct. 2005 • Also discussed option to extend quantity by 3, 000 US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 22

Original Schedule Jan-04 Feb-04 Mar-04 Apr-04 May-04 Jun-04 Jul-04 Aug-04 Sep-04 Oct-04 Mask Production Sensor Pre-Production Sensor Qualification Sensor Production 540 1000 1500 Cumulative Production 540 1540 3040 4540 6040 7540 Sensor Acceptance 500 1000 1500 240 Ø Initial plan showed 1 st 7000 sensors delivered by November Ø Current: ~4000 delivered. Ø Met with Yamamoto (v. pres. HPK) Oct. 11 at CERN (JI on video: • 3 problems identified: (One month lost while analyzing problems) 1. Poly Silicon – operator error caused over-etching 2. Backside Si. O 2 too thin – caused high leakage currents 3. Scratches – due to a problem with automated handling devices • • Recent batches have ~75% yield allowing ~1300/mo. rate If achieve 85 -90% then will deliver ~1500/mo. Ø Agreed: if order placed by Jan. HPK can deliver all 16, 700 by Oct. 2005 • Also discussed option to extend quantity by 3, 000 US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 22

Timeline of Hybrid Issues Ø Summer 2003 US finds broken cable traces • US reviews handling and studies alternative handling schemes • CERN finds breaks are widespread • Vendor says design is fatally flawed • New design implemented after only 2 months delay Ø Winter 2004 US finds strange failure mode in modules • US traces the problem to the hybrid • CERN responds instantaneously – halts all hybrid production • Find vias are not properly plated, with breaks occurring at unknown rate • US Halts production of TOB and TEC modules except for ST qualification • Many TEC & TIB modules already done in EU (small radius HPK thin sensor modules) • EU continues building Ø Summer 2004: Vendor bought out. • Management serious about solving this problem, with better resources. • 4 variations of design processed Ø Autumn 2004: QC Engineer at vendor - all trials are highly successful! • Week October 15 2004 CMS qualifies substrate • Week October 22 – CMS to qualify fully loaded hybrids US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 23

Timeline of Hybrid Issues Ø Summer 2003 US finds broken cable traces • US reviews handling and studies alternative handling schemes • CERN finds breaks are widespread • Vendor says design is fatally flawed • New design implemented after only 2 months delay Ø Winter 2004 US finds strange failure mode in modules • US traces the problem to the hybrid • CERN responds instantaneously – halts all hybrid production • Find vias are not properly plated, with breaks occurring at unknown rate • US Halts production of TOB and TEC modules except for ST qualification • Many TEC & TIB modules already done in EU (small radius HPK thin sensor modules) • EU continues building Ø Summer 2004: Vendor bought out. • Management serious about solving this problem, with better resources. • 4 variations of design processed Ø Autumn 2004: QC Engineer at vendor - all trials are highly successful! • Week October 15 2004 CMS qualifies substrate • Week October 22 – CMS to qualify fully loaded hybrids US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 23

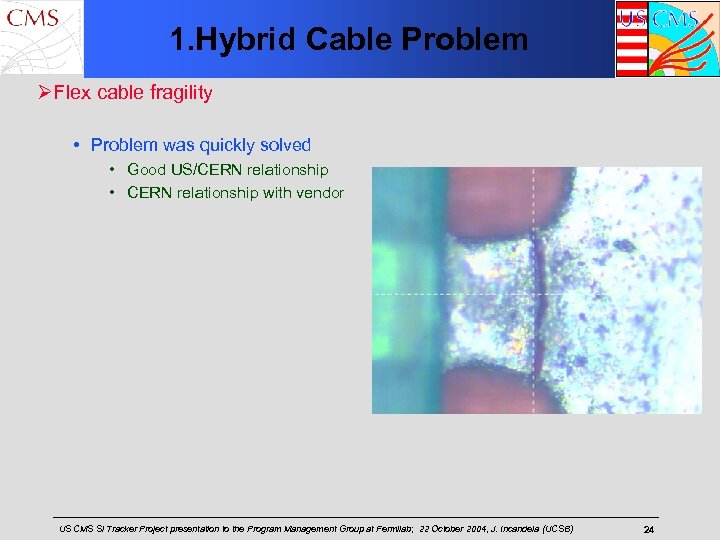

1. Hybrid Cable Problem ØFlex cable fragility • Problem was quickly solved • Good US/CERN relationship • CERN relationship with vendor US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 24

1. Hybrid Cable Problem ØFlex cable fragility • Problem was quickly solved • Good US/CERN relationship • CERN relationship with vendor US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 24

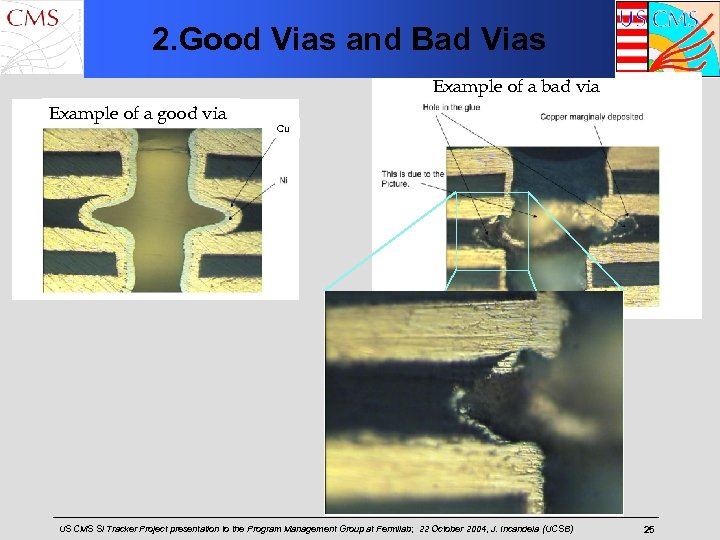

2. Good Vias and Bad Vias Example of a bad via Example of a good via Cu US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 25

2. Good Vias and Bad Vias Example of a bad via Example of a good via Cu US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 25

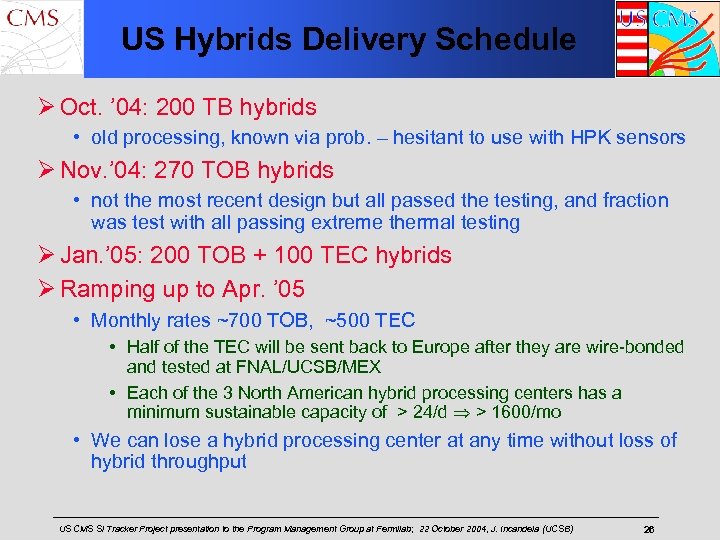

US Hybrids Delivery Schedule Ø Oct. ’ 04: 200 TB hybrids • old processing, known via prob. – hesitant to use with HPK sensors Ø Nov. ’ 04: 270 TOB hybrids • not the most recent design but all passed the testing, and fraction was test with all passing extreme thermal testing Ø Jan. ’ 05: 200 TOB + 100 TEC hybrids Ø Ramping up to Apr. ’ 05 • Monthly rates ~700 TOB, ~500 TEC • Half of the TEC will be sent back to Europe after they are wire-bonded and tested at FNAL/UCSB/MEX • Each of the 3 North American hybrid processing centers has a minimum sustainable capacity of > 24/d > 1600/mo • We can lose a hybrid processing center at any time without loss of hybrid throughput US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 26

US Hybrids Delivery Schedule Ø Oct. ’ 04: 200 TB hybrids • old processing, known via prob. – hesitant to use with HPK sensors Ø Nov. ’ 04: 270 TOB hybrids • not the most recent design but all passed the testing, and fraction was test with all passing extreme thermal testing Ø Jan. ’ 05: 200 TOB + 100 TEC hybrids Ø Ramping up to Apr. ’ 05 • Monthly rates ~700 TOB, ~500 TEC • Half of the TEC will be sent back to Europe after they are wire-bonded and tested at FNAL/UCSB/MEX • Each of the 3 North American hybrid processing centers has a minimum sustainable capacity of > 24/d > 1600/mo • We can lose a hybrid processing center at any time without loss of hybrid throughput US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 26

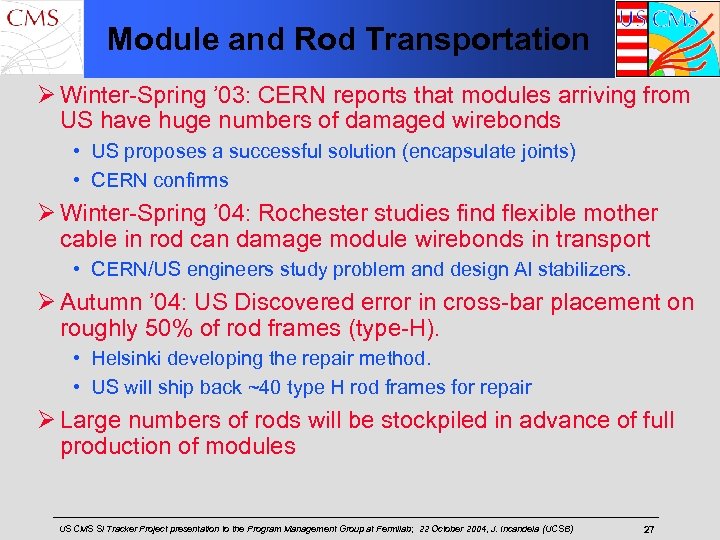

Module and Rod Transportation Ø Winter-Spring ’ 03: CERN reports that modules arriving from US have huge numbers of damaged wirebonds • US proposes a successful solution (encapsulate joints) • CERN confirms Ø Winter-Spring ’ 04: Rochester studies find flexible mother cable in rod can damage module wirebonds in transport • CERN/US engineers study problem and design Al stabilizers. Ø Autumn ’ 04: US Discovered error in cross-bar placement on roughly 50% of rod frames (type-H). • Helsinki developing the repair method. • US will ship back ~40 type H rod frames for repair Ø Large numbers of rods will be stockpiled in advance of full production of modules US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 27

Module and Rod Transportation Ø Winter-Spring ’ 03: CERN reports that modules arriving from US have huge numbers of damaged wirebonds • US proposes a successful solution (encapsulate joints) • CERN confirms Ø Winter-Spring ’ 04: Rochester studies find flexible mother cable in rod can damage module wirebonds in transport • CERN/US engineers study problem and design Al stabilizers. Ø Autumn ’ 04: US Discovered error in cross-bar placement on roughly 50% of rod frames (type-H). • Helsinki developing the repair method. • US will ship back ~40 type H rod frames for repair Ø Large numbers of rods will be stockpiled in advance of full production of modules US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 27

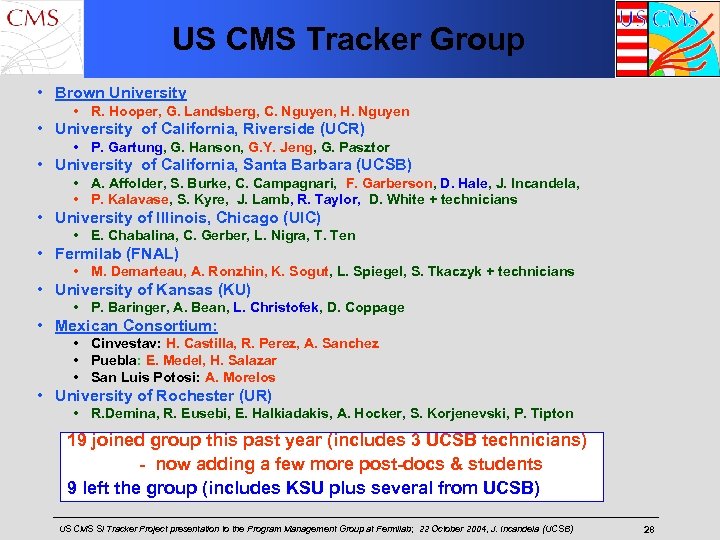

US CMS Tracker Group • Brown University • R. Hooper, G. Landsberg, C. Nguyen, H. Nguyen • University of California, Riverside (UCR) • P. Gartung, G. Hanson, G. Y. Jeng, G. Pasztor • University of California, Santa Barbara (UCSB) • A. Affolder, S. Burke, C. Campagnari, F. Garberson, D. Hale, J. Incandela, • P. Kalavase, S. Kyre, J. Lamb, R. Taylor, D. White + technicians • University of Illinois, Chicago (UIC) • E. Chabalina, C. Gerber, L. Nigra, T. Ten • Fermilab (FNAL) • M. Demarteau, A. Ronzhin, K. Sogut, L. Spiegel, S. Tkaczyk + technicians • University of Kansas (KU) • P. Baringer, A. Bean, L. Christofek, D. Coppage • Mexican Consortium: • Cinvestav: H. Castilla, R. Perez, A. Sanchez • Puebla: E. Medel, H. Salazar • San Luis Potosi: A. Morelos • University of Rochester (UR) • R. Demina, R. Eusebi, E. Halkiadakis, A. Hocker, S. Korjenevski, P. Tipton 19 joined group this past year (includes 3 UCSB technicians) - now adding a few more post-docs & students 9 left the group (includes KSU plus several from UCSB) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 28

US CMS Tracker Group • Brown University • R. Hooper, G. Landsberg, C. Nguyen, H. Nguyen • University of California, Riverside (UCR) • P. Gartung, G. Hanson, G. Y. Jeng, G. Pasztor • University of California, Santa Barbara (UCSB) • A. Affolder, S. Burke, C. Campagnari, F. Garberson, D. Hale, J. Incandela, • P. Kalavase, S. Kyre, J. Lamb, R. Taylor, D. White + technicians • University of Illinois, Chicago (UIC) • E. Chabalina, C. Gerber, L. Nigra, T. Ten • Fermilab (FNAL) • M. Demarteau, A. Ronzhin, K. Sogut, L. Spiegel, S. Tkaczyk + technicians • University of Kansas (KU) • P. Baringer, A. Bean, L. Christofek, D. Coppage • Mexican Consortium: • Cinvestav: H. Castilla, R. Perez, A. Sanchez • Puebla: E. Medel, H. Salazar • San Luis Potosi: A. Morelos • University of Rochester (UR) • R. Demina, R. Eusebi, E. Halkiadakis, A. Hocker, S. Korjenevski, P. Tipton 19 joined group this past year (includes 3 UCSB technicians) - now adding a few more post-docs & students 9 left the group (includes KSU plus several from UCSB) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 28

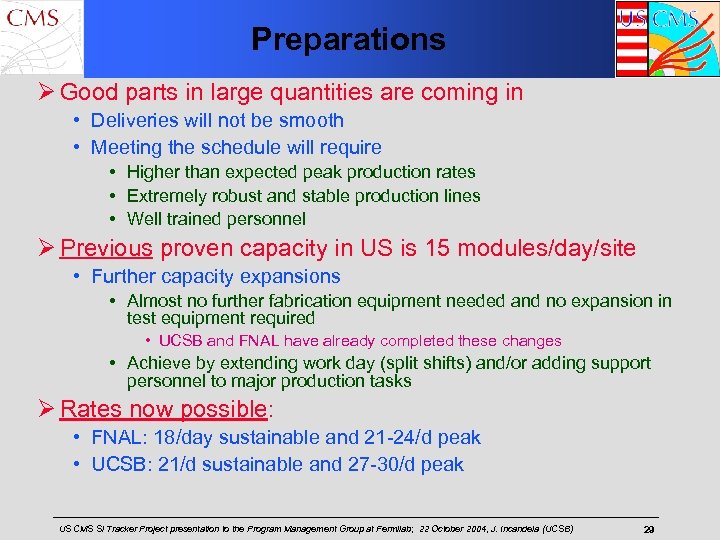

Preparations Ø Good parts in large quantities are coming in • Deliveries will not be smooth • Meeting the schedule will require • Higher than expected peak production rates • Extremely robust and stable production lines • Well trained personnel Ø Previous proven capacity in US is 15 modules/day/site • Further capacity expansions • Almost no further fabrication equipment needed and no expansion in test equipment required • UCSB and FNAL have already completed these changes • Achieve by extending work day (split shifts) and/or adding support personnel to major production tasks Ø Rates now possible: • FNAL: 18/day sustainable and 21 -24/d peak • UCSB: 21/d sustainable and 27 -30/d peak US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 29

Preparations Ø Good parts in large quantities are coming in • Deliveries will not be smooth • Meeting the schedule will require • Higher than expected peak production rates • Extremely robust and stable production lines • Well trained personnel Ø Previous proven capacity in US is 15 modules/day/site • Further capacity expansions • Almost no further fabrication equipment needed and no expansion in test equipment required • UCSB and FNAL have already completed these changes • Achieve by extending work day (split shifts) and/or adding support personnel to major production tasks Ø Rates now possible: • FNAL: 18/day sustainable and 21 -24/d peak • UCSB: 21/d sustainable and 27 -30/d peak US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 29

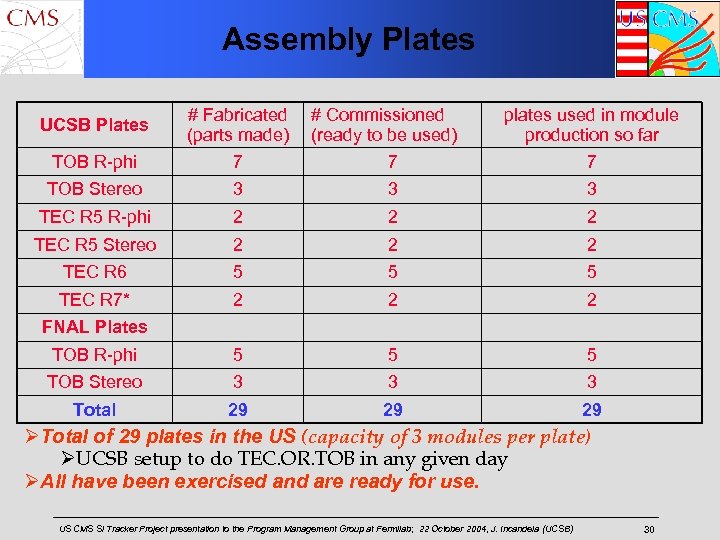

Assembly Plates UCSB Plates TOB R-phi # Fabricated # Commissioned (parts made) (ready to be used) 7 7 plates used in module production so far 7 TOB Stereo 3 3 3 TEC R 5 R-phi 2 2 2 TEC R 5 Stereo 2 2 2 TEC R 6 5 5 5 TEC R 7* 2 2 2 TOB R-phi 5 5 5 TOB Stereo 3 3 3 Total 29 29 29 FNAL Plates ØTotal of 29 plates in the US (capacity of 3 modules per plate) ØUCSB setup to do TEC. OR. TOB in any given day ØAll have been exercised and are ready for use. US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 30

Assembly Plates UCSB Plates TOB R-phi # Fabricated # Commissioned (parts made) (ready to be used) 7 7 plates used in module production so far 7 TOB Stereo 3 3 3 TEC R 5 R-phi 2 2 2 TEC R 5 Stereo 2 2 2 TEC R 6 5 5 5 TEC R 7* 2 2 2 TOB R-phi 5 5 5 TOB Stereo 3 3 3 Total 29 29 29 FNAL Plates ØTotal of 29 plates in the US (capacity of 3 modules per plate) ØUCSB setup to do TEC. OR. TOB in any given day ØAll have been exercised and are ready for use. US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 30

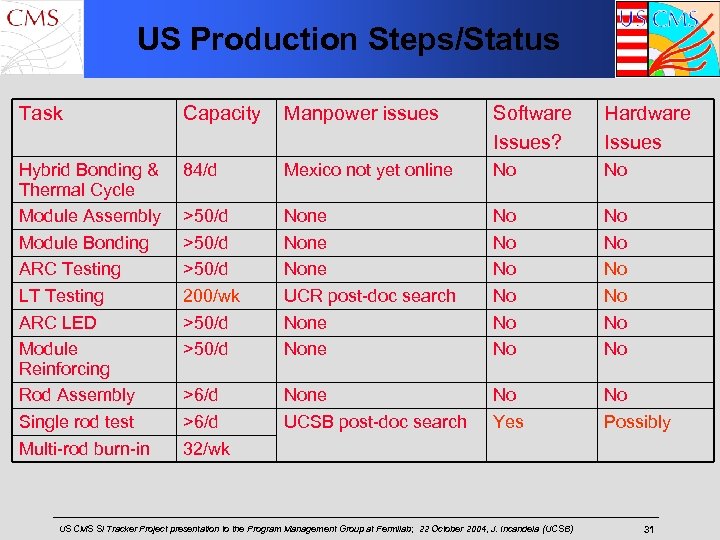

US Production Steps/Status Task Capacity Manpower issues Software Issues? Hardware Issues Hybrid Bonding & Thermal Cycle Module Assembly Module Bonding ARC Testing LT Testing ARC LED Module Reinforcing Rod Assembly Single rod test Multi-rod burn-in 84/d Mexico not yet online No No >50/d 200/wk >50/d None UCR post-doc search None No No No >6/d 32/wk None UCSB post-doc search No Yes No Possibly US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 31

US Production Steps/Status Task Capacity Manpower issues Software Issues? Hardware Issues Hybrid Bonding & Thermal Cycle Module Assembly Module Bonding ARC Testing LT Testing ARC LED Module Reinforcing Rod Assembly Single rod test Multi-rod burn-in 84/d Mexico not yet online No No >50/d 200/wk >50/d None UCR post-doc search None No No No >6/d 32/wk None UCSB post-doc search No Yes No Possibly US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 31

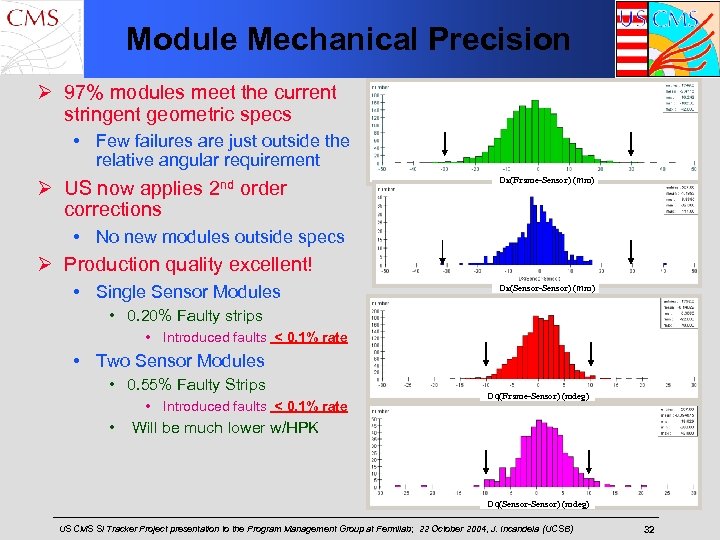

Module Mechanical Precision Ø 97% modules meet the current stringent geometric specs • Few failures are just outside the relative angular requirement Ø US now applies 2 nd order corrections Dx(Frame-Sensor) (mm) • No new modules outside specs Ø Production quality excellent! • Single Sensor Modules Dx(Sensor-Sensor) (mm) • 0. 20% Faulty strips • Introduced faults < 0. 1% rate • Two Sensor Modules • 0. 55% Faulty Strips • Introduced faults < 0. 1% rate Dq(Frame-Sensor) (mdeg) • Will be much lower w/HPK Dq(Sensor-Sensor) (mdeg) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 32

Module Mechanical Precision Ø 97% modules meet the current stringent geometric specs • Few failures are just outside the relative angular requirement Ø US now applies 2 nd order corrections Dx(Frame-Sensor) (mm) • No new modules outside specs Ø Production quality excellent! • Single Sensor Modules Dx(Sensor-Sensor) (mm) • 0. 20% Faulty strips • Introduced faults < 0. 1% rate • Two Sensor Modules • 0. 55% Faulty Strips • Introduced faults < 0. 1% rate Dq(Frame-Sensor) (mdeg) • Will be much lower w/HPK Dq(Sensor-Sensor) (mdeg) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 32

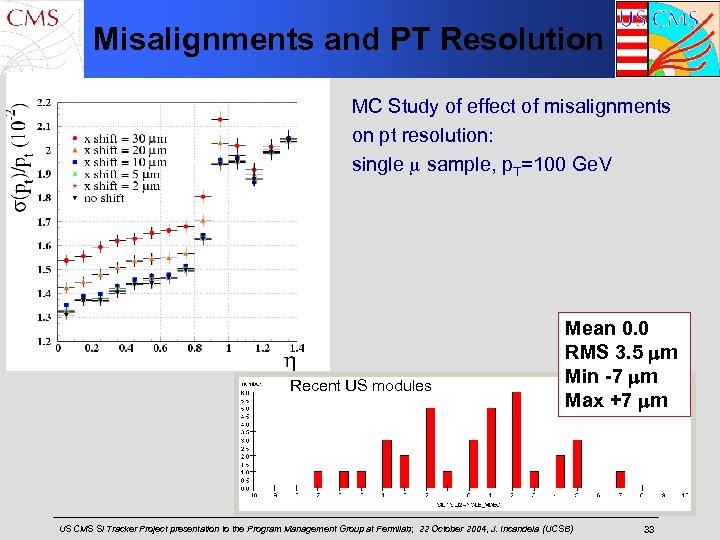

Misalignments and PT Resolution MC Study of effect of misalignments on pt resolution: single m sample, p. T=100 Ge. V Recent US modules Mean 0. 0 RMS 3. 5 mm Min -7 mm Max +7 mm US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 33

Misalignments and PT Resolution MC Study of effect of misalignments on pt resolution: single m sample, p. T=100 Ge. V Recent US modules Mean 0. 0 RMS 3. 5 mm Min -7 mm Max +7 mm US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 33

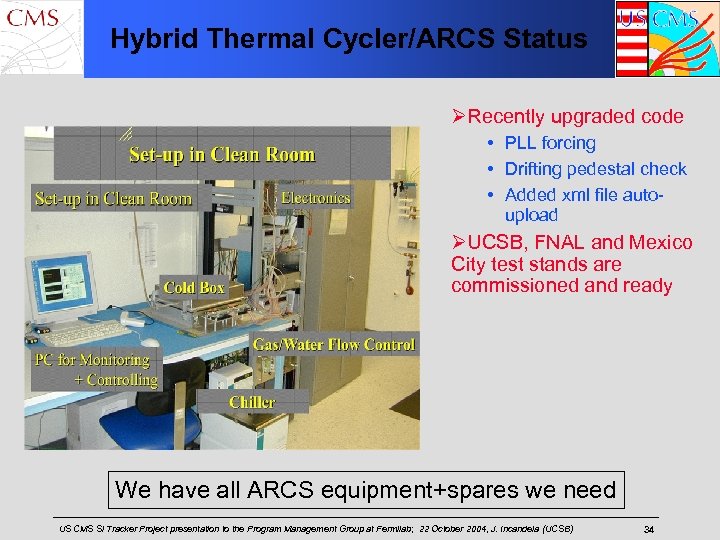

Hybrid Thermal Cycler/ARCS Status ØRecently upgraded code • PLL forcing • Drifting pedestal check • Added xml file autoupload ØUCSB, FNAL and Mexico City test stands are commissioned and ready We have all ARCS equipment+spares we need US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 34

Hybrid Thermal Cycler/ARCS Status ØRecently upgraded code • PLL forcing • Drifting pedestal check • Added xml file autoupload ØUCSB, FNAL and Mexico City test stands are commissioned and ready We have all ARCS equipment+spares we need US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 34

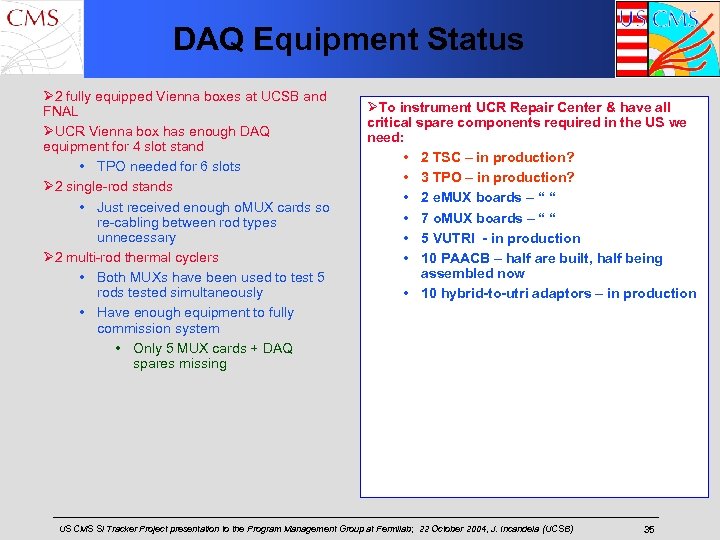

DAQ Equipment Status Ø 2 fully equipped Vienna boxes at UCSB and FNAL ØUCR Vienna box has enough DAQ equipment for 4 slot stand • TPO needed for 6 slots Ø 2 single-rod stands • Just received enough o. MUX cards so re-cabling between rod types unnecessary Ø 2 multi-rod thermal cyclers • Both MUXs have been used to test 5 rods tested simultaneously • Have enough equipment to fully commission system • Only 5 MUX cards + DAQ spares missing ØTo instrument UCR Repair Center & have all critical spare components required in the US we need: • 2 TSC – in production? • 3 TPO – in production? • 2 e. MUX boards – “ “ • 7 o. MUX boards – “ “ • 5 VUTRI - in production • 10 PAACB – half are built, half being assembled now • 10 hybrid-to-utri adaptors – in production US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 35

DAQ Equipment Status Ø 2 fully equipped Vienna boxes at UCSB and FNAL ØUCR Vienna box has enough DAQ equipment for 4 slot stand • TPO needed for 6 slots Ø 2 single-rod stands • Just received enough o. MUX cards so re-cabling between rod types unnecessary Ø 2 multi-rod thermal cyclers • Both MUXs have been used to test 5 rods tested simultaneously • Have enough equipment to fully commission system • Only 5 MUX cards + DAQ spares missing ØTo instrument UCR Repair Center & have all critical spare components required in the US we need: • 2 TSC – in production? • 3 TPO – in production? • 2 e. MUX boards – “ “ • 7 o. MUX boards – “ “ • 5 VUTRI - in production • 10 PAACB – half are built, half being assembled now • 10 hybrid-to-utri adaptors – in production US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 35

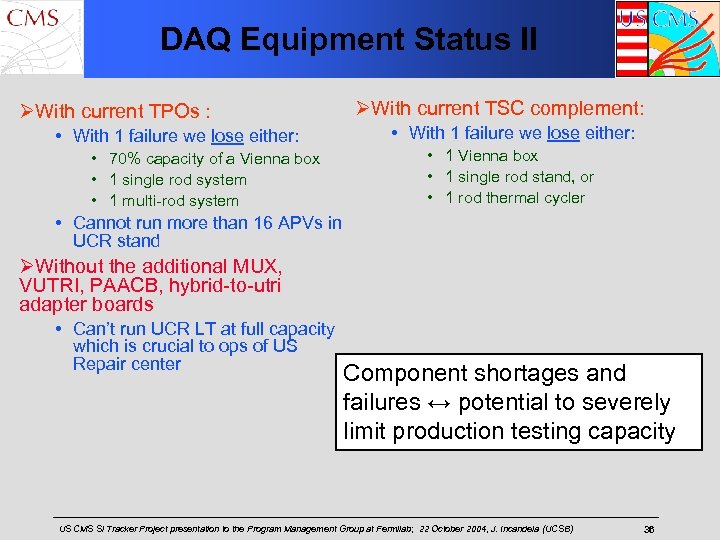

DAQ Equipment Status II ØWith current TSC complement: ØWith current TPOs : • With 1 failure we lose either: • 1 Vienna box • 1 single rod stand, or • 1 rod thermal cycler • 70% capacity of a Vienna box • 1 single rod system • 1 multi-rod system • Cannot run more than 16 APVs in UCR stand ØWithout the additional MUX, VUTRI, PAACB, hybrid-to-utri adapter boards • Can’t run UCR LT at full capacity which is crucial to ops of US Repair center Component shortages and failures ↔ potential to severely limit production testing capacity US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 36

DAQ Equipment Status II ØWith current TSC complement: ØWith current TPOs : • With 1 failure we lose either: • 1 Vienna box • 1 single rod stand, or • 1 rod thermal cycler • 70% capacity of a Vienna box • 1 single rod system • 1 multi-rod system • Cannot run more than 16 APVs in UCR stand ØWithout the additional MUX, VUTRI, PAACB, hybrid-to-utri adapter boards • Can’t run UCR LT at full capacity which is crucial to ops of US Repair center Component shortages and failures ↔ potential to severely limit production testing capacity US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 36

Backup Equipment Ø Spare sensor and hybrid tools were produced at UCSB for UCSB, FNAL and Brussels. Ø Upgraded OGP computer OS and OGP software • Automated routine occasionally missed fiducial marks. The new software fixes this problem. Ø Set up back-up gantry computers with spare U 600 controllers and expansion cards already installed. Ø We purchased backup components for every piece of production equipment or tooling that, if it were to fail, would cause a reduction in production rates. US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 37

Backup Equipment Ø Spare sensor and hybrid tools were produced at UCSB for UCSB, FNAL and Brussels. Ø Upgraded OGP computer OS and OGP software • Automated routine occasionally missed fiducial marks. The new software fixes this problem. Ø Set up back-up gantry computers with spare U 600 controllers and expansion cards already installed. Ø We purchased backup components for every piece of production equipment or tooling that, if it were to fail, would cause a reduction in production rates. US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 37

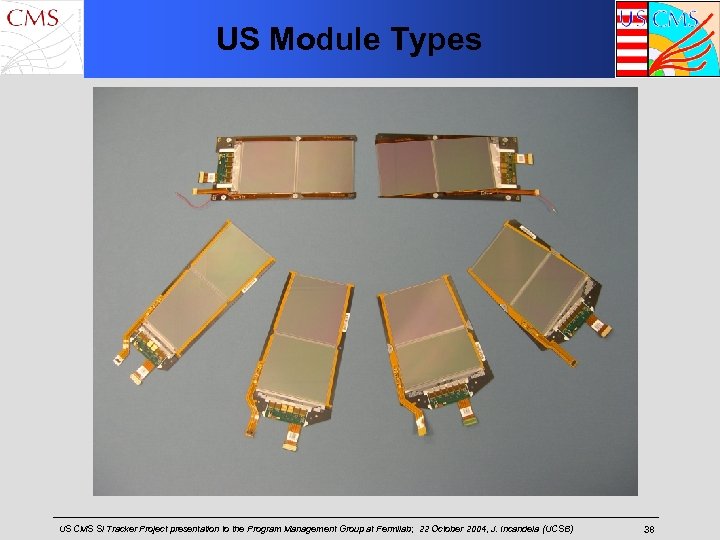

US Module Types US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 38

US Module Types US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 38

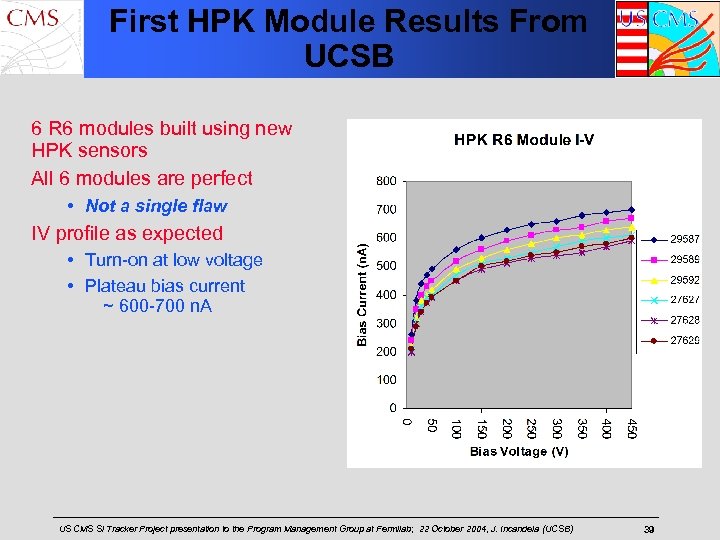

First HPK Module Results From UCSB 6 R 6 modules built using new HPK sensors All 6 modules are perfect • Not a single flaw IV profile as expected • Turn-on at low voltage • Plateau bias current ~ 600 -700 n. A US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 39

First HPK Module Results From UCSB 6 R 6 modules built using new HPK sensors All 6 modules are perfect • Not a single flaw IV profile as expected • Turn-on at low voltage • Plateau bias current ~ 600 -700 n. A US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 39

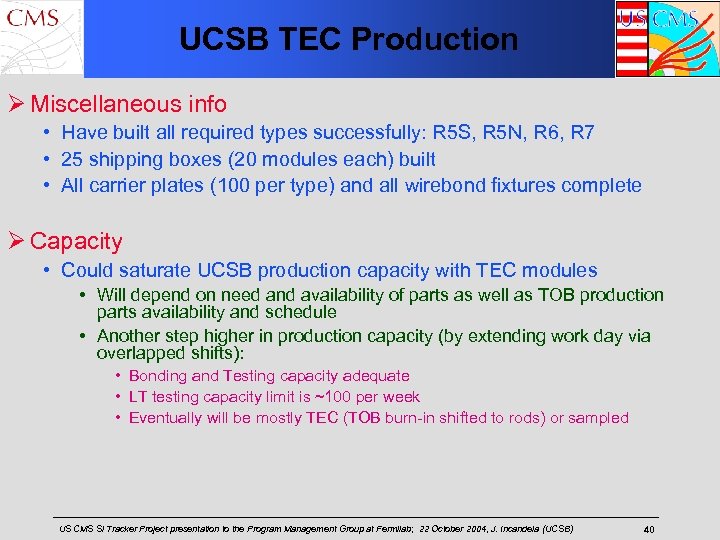

UCSB TEC Production Ø Miscellaneous info • Have built all required types successfully: R 5 S, R 5 N, R 6, R 7 • 25 shipping boxes (20 modules each) built • All carrier plates (100 per type) and all wirebond fixtures complete Ø Capacity • Could saturate UCSB production capacity with TEC modules • Will depend on need and availability of parts as well as TOB production parts availability and schedule • Another step higher in production capacity (by extending work day via overlapped shifts): • Bonding and Testing capacity adequate • LT testing capacity limit is ~100 per week • Eventually will be mostly TEC (TOB burn-in shifted to rods) or sampled US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 40

UCSB TEC Production Ø Miscellaneous info • Have built all required types successfully: R 5 S, R 5 N, R 6, R 7 • 25 shipping boxes (20 modules each) built • All carrier plates (100 per type) and all wirebond fixtures complete Ø Capacity • Could saturate UCSB production capacity with TEC modules • Will depend on need and availability of parts as well as TOB production parts availability and schedule • Another step higher in production capacity (by extending work day via overlapped shifts): • Bonding and Testing capacity adequate • LT testing capacity limit is ~100 per week • Eventually will be mostly TEC (TOB burn-in shifted to rods) or sampled US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 40

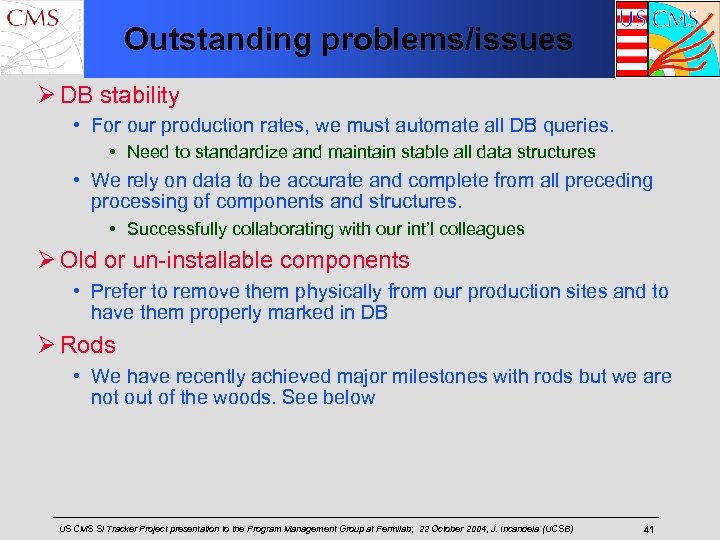

Outstanding problems/issues Ø DB stability • For our production rates, we must automate all DB queries. • Need to standardize and maintain stable all data structures • We rely on data to be accurate and complete from all preceding processing of components and structures. • Successfully collaborating with our int’l colleagues Ø Old or un-installable components • Prefer to remove them physically from our production sites and to have them properly marked in DB Ø Rods • We have recently achieved major milestones with rods but we are not out of the woods. See below US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 41

Outstanding problems/issues Ø DB stability • For our production rates, we must automate all DB queries. • Need to standardize and maintain stable all data structures • We rely on data to be accurate and complete from all preceding processing of components and structures. • Successfully collaborating with our int’l colleagues Ø Old or un-installable components • Prefer to remove them physically from our production sites and to have them properly marked in DB Ø Rods • We have recently achieved major milestones with rods but we are not out of the woods. See below US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 41

Rods Ø Rod assembly understood Ø Rod Testing • Single rod testing is under control • Multi-rod • Had many problems with software and hardware • Recently achieved major milestone at FNAL • Can now run maximum at capacity (8 SS rods or 6 DS rods – i. e. up to 72 modules) for 3 days with thermal cycles! Ø Remaining • Get UCSB multi-rod test stand operational at same level as FNAL • Had problems with some hardware- now fixed • To finalize fault finding tests • Finalize Database info and transfer methods Ø Need experience with many rods to determine if there are issues with components. US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 42

Rods Ø Rod assembly understood Ø Rod Testing • Single rod testing is under control • Multi-rod • Had many problems with software and hardware • Recently achieved major milestone at FNAL • Can now run maximum at capacity (8 SS rods or 6 DS rods – i. e. up to 72 modules) for 3 days with thermal cycles! Ø Remaining • Get UCSB multi-rod test stand operational at same level as FNAL • Had problems with some hardware- now fixed • To finalize fault finding tests • Finalize Database info and transfer methods Ø Need experience with many rods to determine if there are issues with components. US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 42

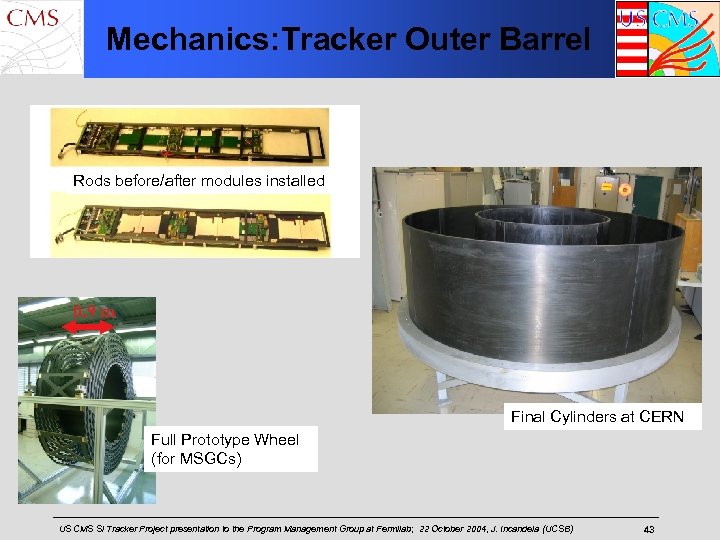

Mechanics: Tracker Outer Barrel Rods before/after modules installed 0. 9 m Final Cylinders at CERN Full Prototype Wheel (for MSGCs) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 43

Mechanics: Tracker Outer Barrel Rods before/after modules installed 0. 9 m Final Cylinders at CERN Full Prototype Wheel (for MSGCs) US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 43

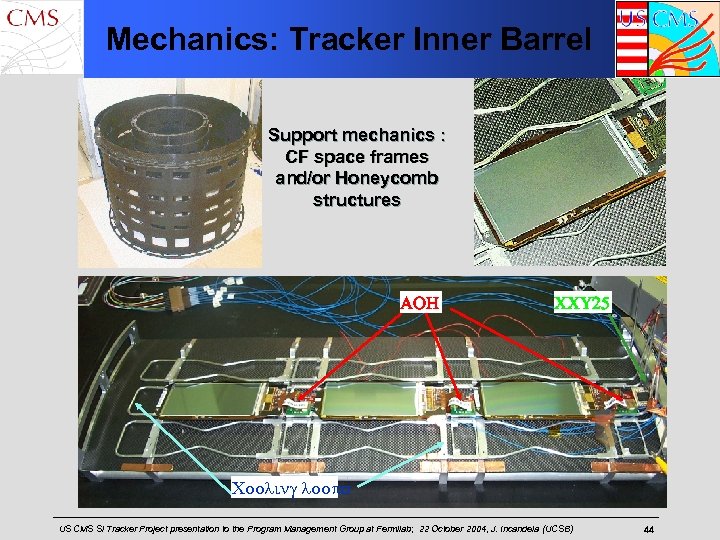

Mechanics: Tracker Inner Barrel Support mechanics : CF space frames and/or Honeycomb structures AOH CCU 25 Cooling loops US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 44

Mechanics: Tracker Inner Barrel Support mechanics : CF space frames and/or Honeycomb structures AOH CCU 25 Cooling loops US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 44

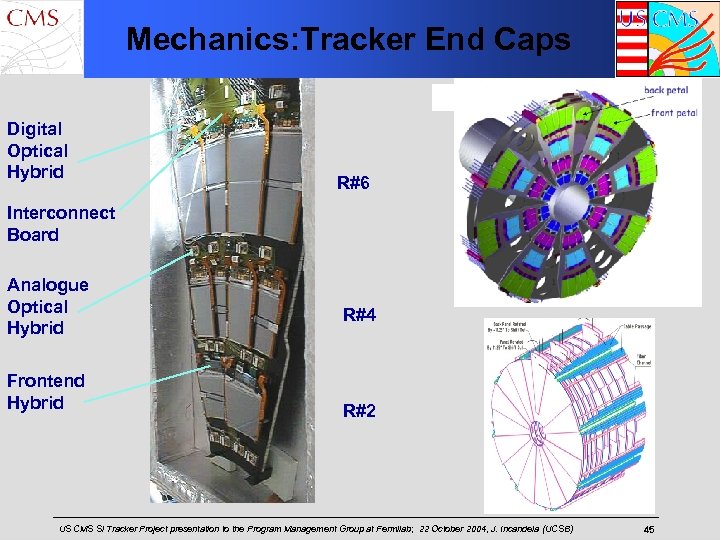

Mechanics: Tracker End Caps Digital Optical Hybrid R#6 Interconnect Board Analogue Optical Hybrid Frontend Hybrid R#4 R#2 US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 45

Mechanics: Tracker End Caps Digital Optical Hybrid R#6 Interconnect Board Analogue Optical Hybrid Frontend Hybrid R#4 R#2 US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 45

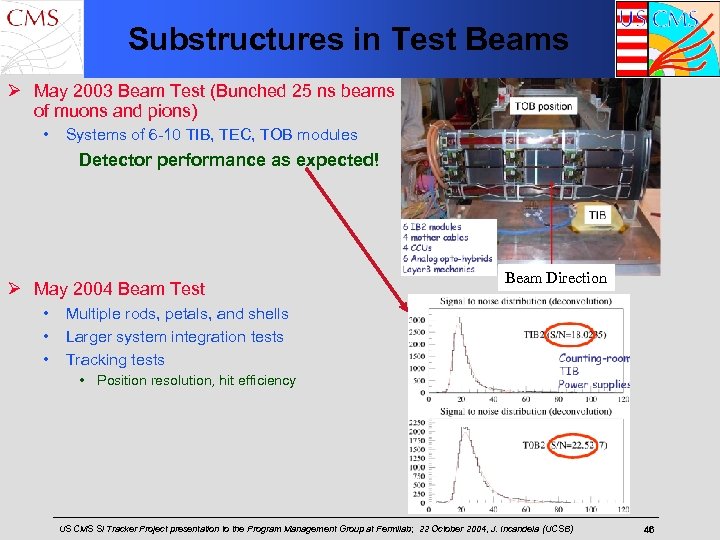

Substructures in Test Beams Ø May 2003 Beam Test (Bunched 25 ns beams of muons and pions) • Systems of 6 -10 TIB, TEC, TOB modules Detector performance as expected! Ø May 2004 Beam Test • • • Beam Direction Multiple rods, petals, and shells Larger system integration tests Tracking tests • Position resolution, hit efficiency US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 46

Substructures in Test Beams Ø May 2003 Beam Test (Bunched 25 ns beams of muons and pions) • Systems of 6 -10 TIB, TEC, TOB modules Detector performance as expected! Ø May 2004 Beam Test • • • Beam Direction Multiple rods, petals, and shells Larger system integration tests Tracking tests • Position resolution, hit efficiency US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 46

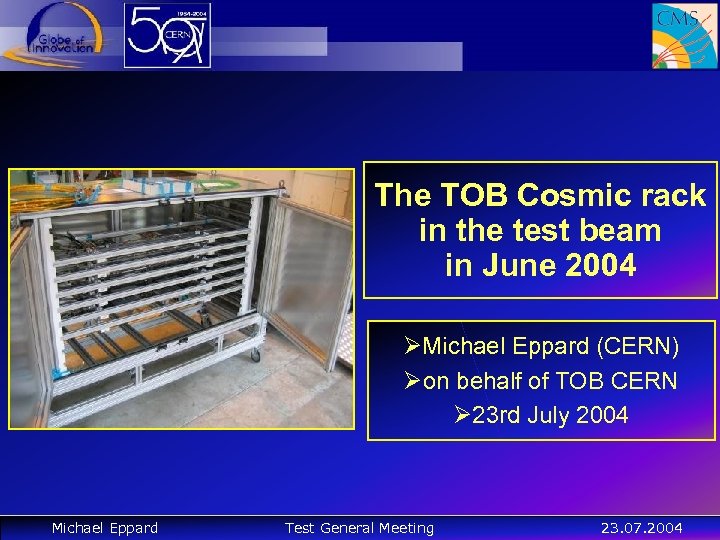

The TOB Cosmic rack in the test beam in June 2004 ØMichael Eppard (CERN) Øon behalf of TOB CERN Ø 23 rd July 2004 Michael Eppard Test General Meeting 23. 07. 2004

The TOB Cosmic rack in the test beam in June 2004 ØMichael Eppard (CERN) Øon behalf of TOB CERN Ø 23 rd July 2004 Michael Eppard Test General Meeting 23. 07. 2004

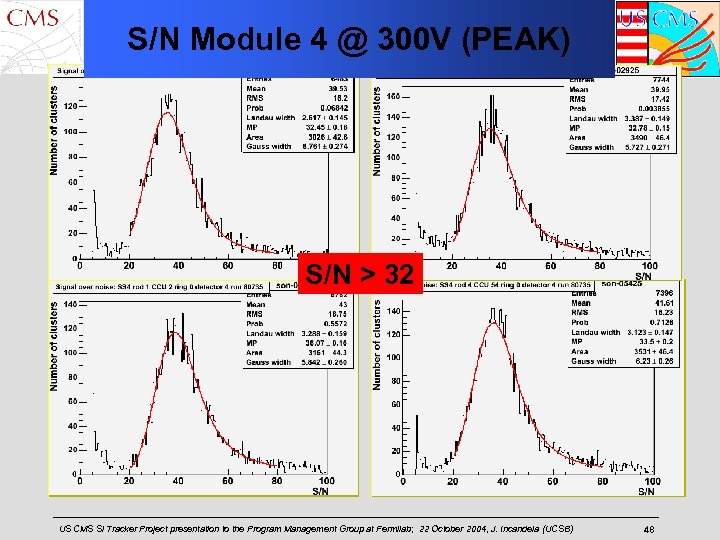

S/N Module 4 @ 300 V (PEAK) S/N > 32 US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 48

S/N Module 4 @ 300 V (PEAK) S/N > 32 US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 48

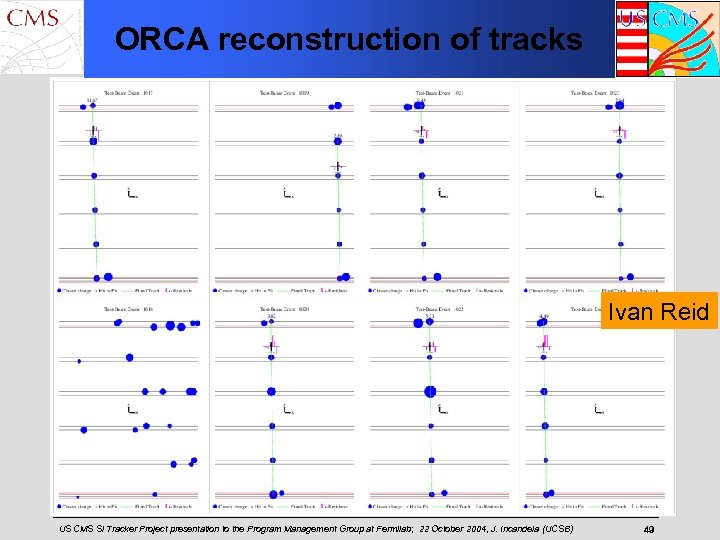

ORCA reconstruction of tracks Ivan Reid US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 49

ORCA reconstruction of tracks Ivan Reid US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 49

Cost Performance Ø Delays have cost us • Recently extended production to Jan. 2006 • Net increase of 600 k$ in project Ø Other US costs • Paid for Masks (NRE) at Hamamatsu to be able to transfer sensor order from ST • 290 k$ • Misc. equipment for higher/more robust production • ~100 K$ Ø Anticipated costs • US Tech. to work at CERN on hybrids for 6 months • 50 k$ (? ) Ø Currently schedule has no contingency… US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 50

Cost Performance Ø Delays have cost us • Recently extended production to Jan. 2006 • Net increase of 600 k$ in project Ø Other US costs • Paid for Masks (NRE) at Hamamatsu to be able to transfer sensor order from ST • 290 k$ • Misc. equipment for higher/more robust production • ~100 K$ Ø Anticipated costs • US Tech. to work at CERN on hybrids for 6 months • 50 k$ (? ) Ø Currently schedule has no contingency… US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 50

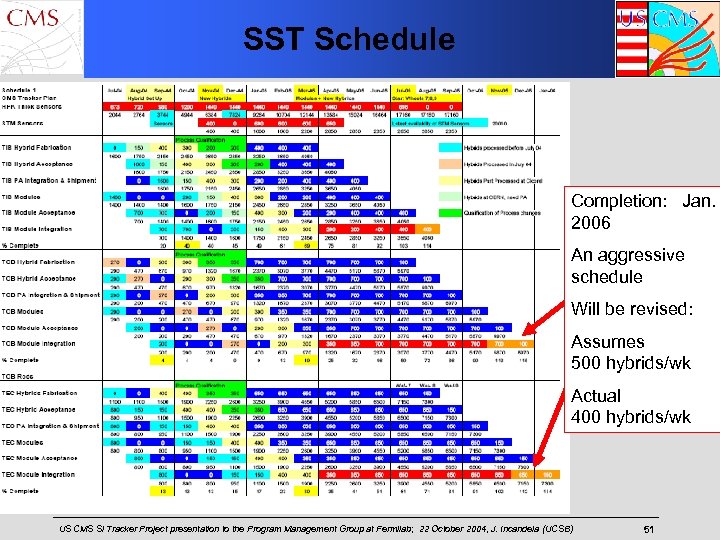

SST Schedule Completion: Jan. 2006 An aggressive schedule Will be revised: Assumes 500 hybrids/wk Actual 400 hybrids/wk US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 51

SST Schedule Completion: Jan. 2006 An aggressive schedule Will be revised: Assumes 500 hybrids/wk Actual 400 hybrids/wk US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 51

Summary Ø No longer have a manpower shortage • In process of adding some personnel at UCSB Ø Have studied all possible threats to production stability • Purchased or manufactured spares Ø Further increased capacity to ~50 modules/d • Requires manpower (~ 4 -5 FTE total) Ø Systems • All stages of production have been exercised and are near to final except rod testing • Multi-rod stands rapidly converging US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 52

Summary Ø No longer have a manpower shortage • In process of adding some personnel at UCSB Ø Have studied all possible threats to production stability • Purchased or manufactured spares Ø Further increased capacity to ~50 modules/d • Requires manpower (~ 4 -5 FTE total) Ø Systems • All stages of production have been exercised and are near to final except rod testing • Multi-rod stands rapidly converging US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 52

Conclusion Ø Strips have been at war with poor components • ST sensors have too many uncertainties • Switched to HPK! • Hybrids problem is solved – large deliveries starting early ‘ 05 Ø US Role has been extremely important Ø We are doing everything we can do US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 53

Conclusion Ø Strips have been at war with poor components • ST sensors have too many uncertainties • Switched to HPK! • Hybrids problem is solved – large deliveries starting early ‘ 05 Ø US Role has been extremely important Ø We are doing everything we can do US CMS Si Tracker Project presentation to the Program Management Group at Fermilab; 22 October 2004, J. Incandela (UCSB) 53