168bf8d836b6c222277214bcae40adc0.ppt

- Количество слайдов: 12

Update on Mass Production Layering A. Bozek, N. Alexander, G. Flint, D. Goodin, R. Petzoldt Presented by Amy Bozek at the HAPL Workshop at LLNL June 20 -21, 2005

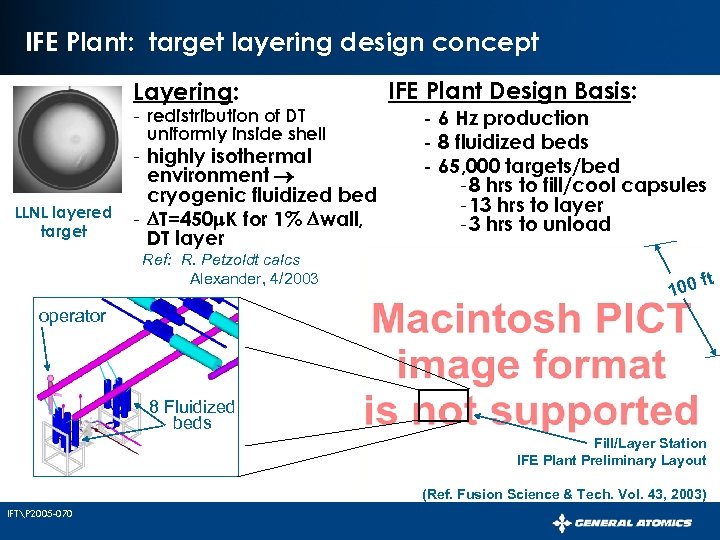

IFE Plant: target layering design concept Layering: - redistribution of DT uniformly inside shell LLNL layered target - highly isothermal environment cryogenic fluidized bed - T=450 K for 1% wall, DT layer Ref: R. Petzoldt calcs Alexander, 4/2003 IFE Plant Design Basis: - 6 Hz production - 8 fluidized beds - 65, 000 targets/bed - 8 hrs to fill/cool capsules - 13 hrs to layer - 3 hrs to unload 100 ft operator 8 Fluidized beds Fill/Layer Station IFE Plant Preliminary Layout (Ref. Fusion Science & Tech. Vol. 43, 2003) IFTP 2005 -070

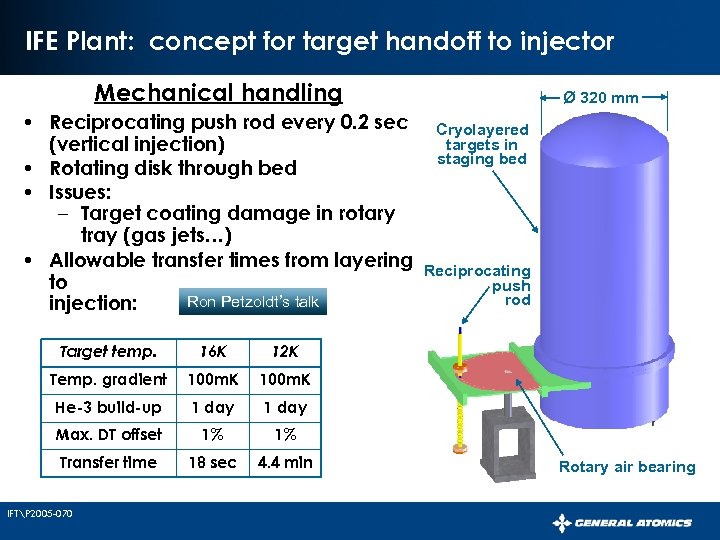

IFE Plant: concept for target handoff to injector Mechanical handling • Reciprocating push rod every 0. 2 sec (vertical injection) • Rotating disk through bed • Issues: – Target coating damage in rotary tray (gas jets…) • Allowable transfer times from layering to Ron Petzoldt’s talk injection: Target temp. 16 K 100 m. K 1 day Max. DT offset 1% 1% Transfer time 18 sec 4. 4 min Reciprocating push rod 100 m. K He-3 build-up Cryolayered targets in staging bed 12 K Temp. gradient Ø 320 mm IFTP 2005 -070 Rotary air bearing

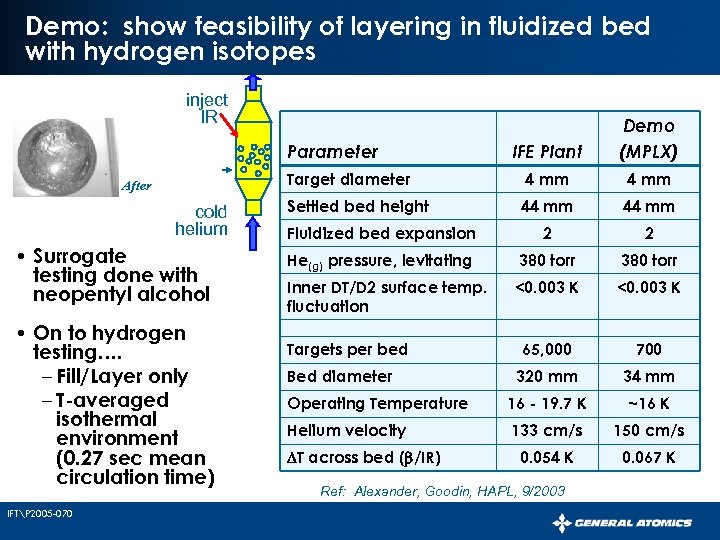

Demo: show feasibility of layering in fluidized bed with hydrogen isotopes inject IR IFE Plant Demo (MPLX) Target diameter 4 mm Settled bed height 44 mm Fluidized bed expansion 2 2 He(g) pressure, levitating 380 torr Inner DT/D 2 surface temp. fluctuation <0. 003 K 65, 000 700 320 mm 34 mm Operating Temperature 16 - 19. 7 K ~16 K Helium velocity 133 cm/s 150 cm/s 0. 054 K 0. 067 K Parameter After cold helium • Surrogate testing done with neopentyl alcohol • On to hydrogen testing…. – Fill/Layer only – T-averaged isothermal environment (0. 27 sec mean circulation time) IFTP 2005 -070 Targets per bed Bed diameter T across bed ( /IR) Ref: Alexander, Goodin, HAPL, 9/2003

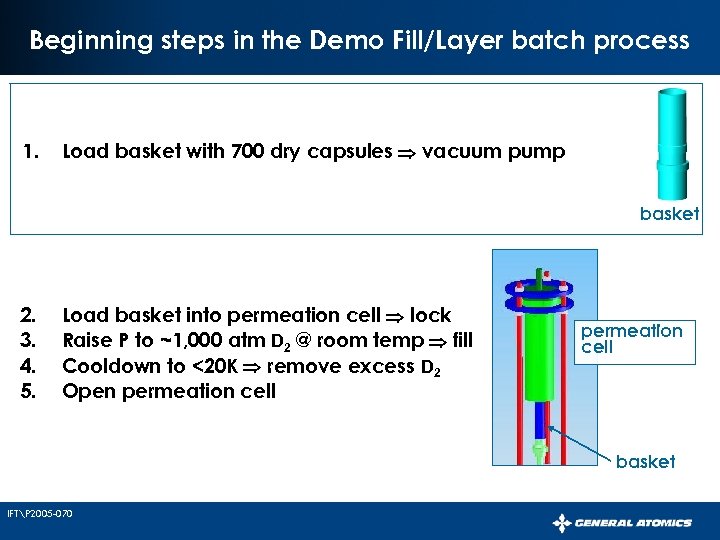

Beginning steps in the Demo Fill/Layer batch process 1. Load basket with 700 dry capsules vacuum pump basket 2. 3. 4. 5. Load basket into permeation cell lock Raise P to ~1, 000 atm D 2 @ room temp fill Cooldown to <20 K remove excess D 2 Open permeation cell basket IFTP 2005 -070

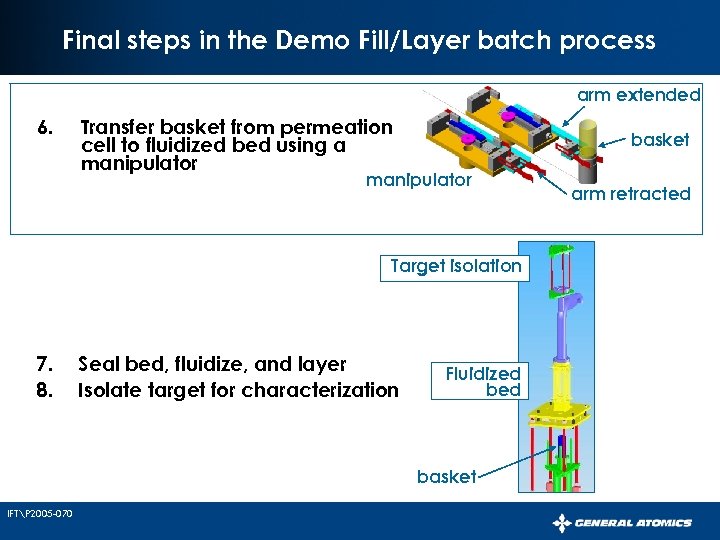

Final steps in the Demo Fill/Layer batch process arm extended 6. Transfer basket from permeation cell to fluidized bed using a manipulator basket manipulator Target isolation 7. 8. Seal bed, fluidize, and layer Isolate target for characterization Fluidized basket IFTP 2005 -070 arm retracted

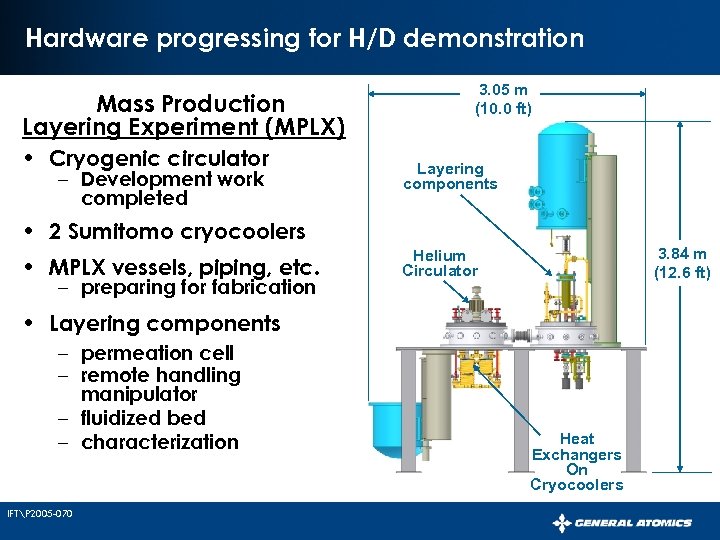

Hardware progressing for H/D demonstration Mass Production Layering Experiment (MPLX) • Cryogenic circulator – Development work completed 3. 05 m (10. 0 ft) Layering components • 2 Sumitomo cryocoolers • MPLX vessels, piping, etc. – preparing for fabrication 3. 84 m (12. 6 ft) Helium Circulator • Layering components – permeation cell – remote handling manipulator – fluidized bed – characterization IFTP 2005 -070 Heat Exchangers On Cryocoolers

MPLX major components Helium Circulator In-house Permeation cell Cryocooler and its compressor (1 of 2) In-house IFTP 2005 -070 LANL

Demo proven hardware - plus new designs • Permeation cell – design complete and provenused on D 2 TS, OMEGA • Manipulator • Fluidized bed – designed for fluidized or stationary bed operation – provisions for IR heat and alpha sources in helium loop – demonstrate time-averaged isothermal layering environment (target circulation time = 0. 27 sec) • Characterization – shadowography as baseline – others possible… IFTP 2005 -070

Demo: current status and near-term plans… • Major MPLX cryogenic components in-house • MPLX basic vacuum and process flow hardware starting fabrication - delivery February 2006 • Ongoing hardware development: – Fluidized bed seal (optimize seal mat’l/size/shape & drive) – Remote handled manipulator testing (actuation & gripper arm) – Additional characterization methods to be examined • Demo Objective: fill with hydrogen, layer, and characterize HAPL-sized capsules in a time-avg’d isothermal temperature environment IFTP 2005 -070

Backup viewgraph • Backup slide - advanced handoff concept IFTP 2005 -070

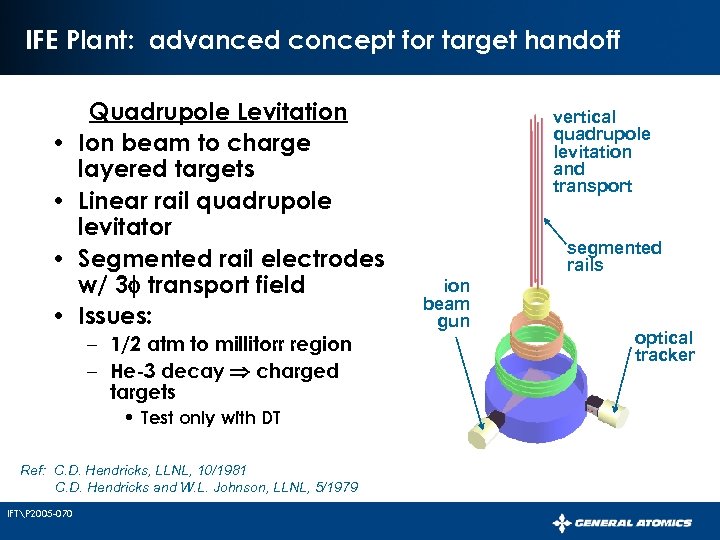

IFE Plant: advanced concept for target handoff • • Quadrupole Levitation Ion beam to charge layered targets Linear rail quadrupole levitator Segmented rail electrodes w/ 3 transport field Issues: – 1/2 atm to millitorr region – He-3 decay charged targets • Test only with DT Ref: C. D. Hendricks, LLNL, 10/1981 C. D. Hendricks and W. L. Johnson, LLNL, 5/1979 IFTP 2005 -070 vertical quadrupole levitation and transport segmented rails ion beam gun optical tracker

168bf8d836b6c222277214bcae40adc0.ppt