5eceb0c965a6cc3f7468d8407ab09a86.ppt

- Количество слайдов: 55

Update on Large Grain/Single Crystal Niobium Cavities Peter Kneisel Jefferson Lab September 25 -28, 2006 TTC Meeting at KEK 1

v. Overview What has been done What will be done in the future v Test Series Anodization Tests/T-Mapping: Understanding Q -drop üComparison of Material from different Vendors üSingle Crystal Cavity Performance September 25 -28, 2006 TTC Meeting at KEK 2

What has been done (1) • Four labs are investigating large grain/single crystal niobium cavities: Jlab, DESY, Cornell, KEK • Cavities have been fabricated and tested from 4 different manufacturers: CBMM ( 4 different ingots, Jlab, KEK, ) Ningxia ( 3 different ingots, Jlab, Cornell, DESY, KEK) W. C. Heraeus ( 3 different ingots, DESY, Jlab) Wah Chang ( 1 ingot, Jlab) • The material has been cut by wire EDM, saw cutting + machining, and wire saw cutting • Single cell cavities ranging in frequency from 1300 MHz to 2300 MHz of different shapes and beta values (TESLA, LL_ILC, OC, HG, LL, PD) have been fabricated and tested • Multi-cell cavities ( TESLA (9 -cell), HG (7 -cell), LL_ILC(7 cell) have been fabricated and tested September 25 -28, 2006 TTC Meeting at KEK 3

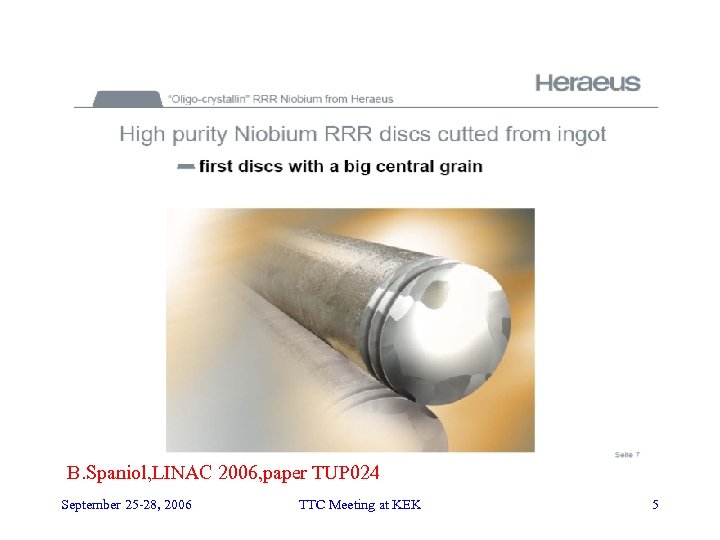

Past Concerns • Vacuum Integrity of grain boundaries No problems encountered until now Does not seem to be a problem • Cost effective cutting method for discs from Ingot Wire EDM not feasible for mass production, time consuming therefore expensive Cutting with wire saw like for marble, Si has been developed by W. C. Heraeus and seems to be efficient • Formability/tolerances of large grain material More difficult, wider tolerances, but no obstacle Better mechanical behaviour expected with single crystal material These issues are under investigation at DESY and Jlab/NIST Some EBW problems encountered at JLab September 25 -28, 2006 TTC Meeting at KEK 4

B. Spaniol, LINAC 2006, paper TUP 024 September 25 -28, 2006 TTC Meeting at KEK 5

![Activities at DESY[Linac 2006, TUP 036] The DESY program has the following components: • Activities at DESY[Linac 2006, TUP 036] The DESY program has the following components: •](https://present5.com/presentation/5eceb0c965a6cc3f7468d8407ab09a86/image-6.jpg)

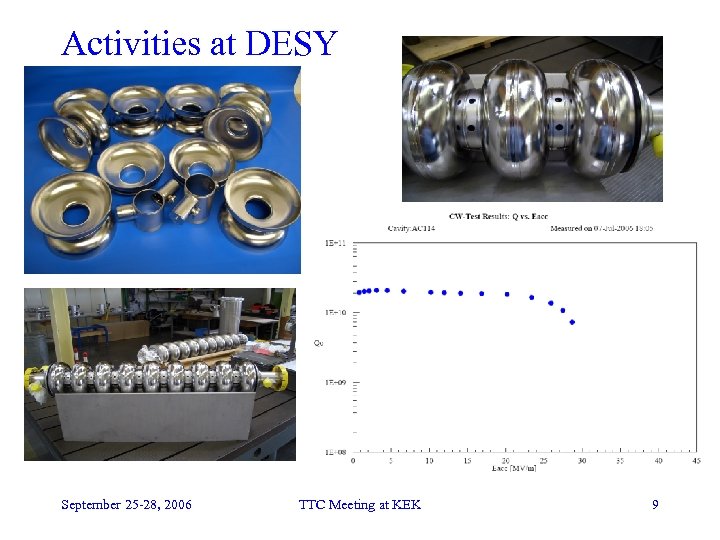

Activities at DESY[Linac 2006, TUP 036] The DESY program has the following components: • Metallurgical/material studies of large grain/single crystal niobium [X. Singer et al. ; SRF 2005] • Fabrication and testing of single cell and 9 -cell cavities as a feasibility study for possible XFEL application • 10 single cell cavities from W. C. Heraeus Niobium( 4 ACCEL, 7 “in house”) • Three 9 -cell cavities from W. C. Heraeus Niobium (ACCEL) • Three single cell cavities from Ningxia Niobium( “in- house”) • Two single crystal cavities ( CBMM, W. C. Heraeus) September 25 -28, 2006 TTC Meeting at KEK 6

![Activities at DESY[Linac 2006, TUP 036] September 25 -28, 2006 TTC Meeting at KEK Activities at DESY[Linac 2006, TUP 036] September 25 -28, 2006 TTC Meeting at KEK](https://present5.com/presentation/5eceb0c965a6cc3f7468d8407ab09a86/image-7.jpg)

Activities at DESY[Linac 2006, TUP 036] September 25 -28, 2006 TTC Meeting at KEK 7

B. Spaniol, LINAC 2006, paper TUP 024 September 25 -28, 2006 TTC Meeting at KEK 8

Activities at DESY September 25 -28, 2006 TTC Meeting at KEK 9

![Activities at Cornell[G. Eremeev, P. Padamsee, EPAC 2006] • 1. 5 GHz Cavity fabricated Activities at Cornell[G. Eremeev, P. Padamsee, EPAC 2006] • 1. 5 GHz Cavity fabricated](https://present5.com/presentation/5eceb0c965a6cc3f7468d8407ab09a86/image-10.jpg)

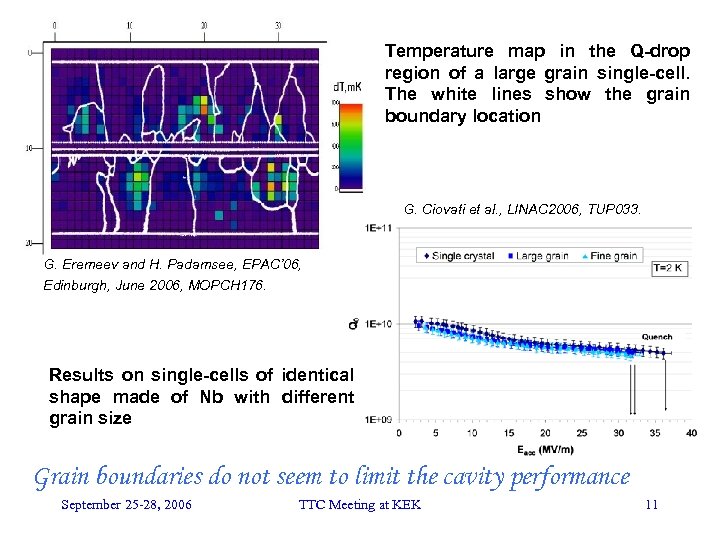

Activities at Cornell[G. Eremeev, P. Padamsee, EPAC 2006] • 1. 5 GHz Cavity fabricated from large grain Chinese niobium • After horizontal EP reached Eacc= 30 MV/m with low field Q of 4 x 1010 • T-mapping showed that largest heating is not on grain boundary September 25 -28, 2006 TTC Meeting at KEK 10

Temperature map in the Q-drop region of a large grain single-cell. The white lines show the grain boundary location G. Ciovati et al. , LINAC 2006, TUP 033. G. Eremeev and H. Padamsee, EPAC’ 06, Edinburgh, June 2006, MOPCH 176. Results on single-cells of identical shape made of Nb with different grain size Grain boundaries do not seem to limit the cavity performance September 25 -28, 2006 TTC Meeting at KEK 11

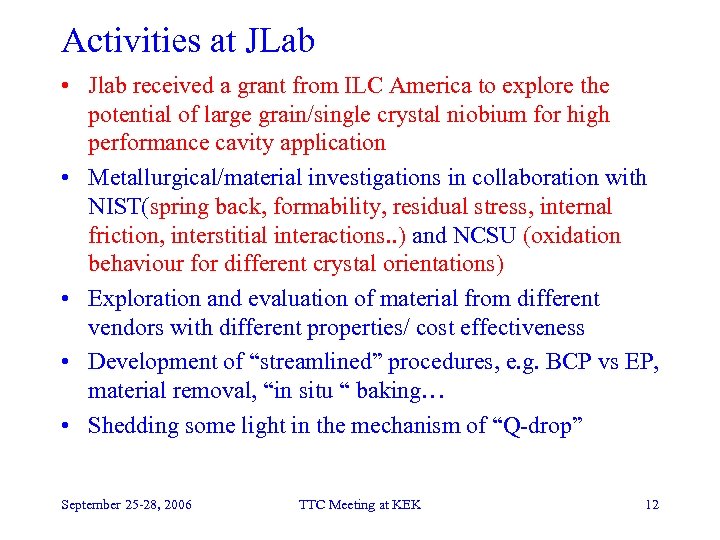

Activities at JLab • Jlab received a grant from ILC America to explore the potential of large grain/single crystal niobium for high performance cavity application • Metallurgical/material investigations in collaboration with NIST(spring back, formability, residual stress, internal friction, interstitial interactions. . ) and NCSU (oxidation behaviour for different crystal orientations) • Exploration and evaluation of material from different vendors with different properties/ cost effectiveness • Development of “streamlined” procedures, e. g. BCP vs EP, material removal, “in situ “ baking… • Shedding some light in the mechanism of “Q-drop” September 25 -28, 2006 TTC Meeting at KEK 12

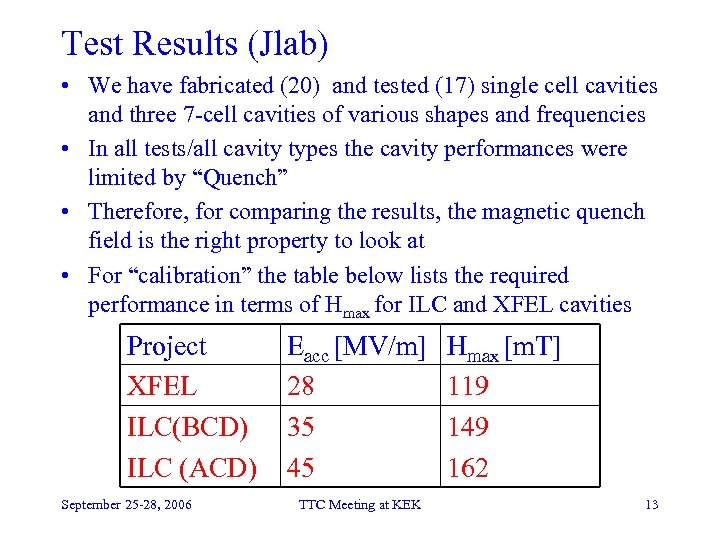

Test Results (Jlab) • We have fabricated (20) and tested (17) single cell cavities and three 7 -cell cavities of various shapes and frequencies • In all tests/all cavity types the cavity performances were limited by “Quench” • Therefore, for comparing the results, the magnetic quench field is the right property to look at • For “calibration” the table below lists the required performance in terms of Hmax for ILC and XFEL cavities Project XFEL ILC(BCD) ILC (ACD) September 25 -28, 2006 Eacc [MV/m] 28 35 45 TTC Meeting at KEK Hmax [m. T] 119 149 162 13

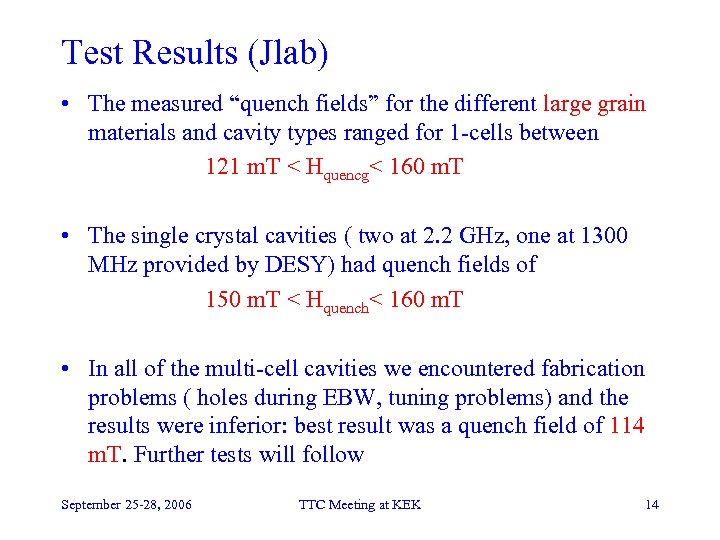

Test Results (Jlab) • The measured “quench fields” for the different large grain materials and cavity types ranged for 1 -cells between 121 m. T < Hquencg< 160 m. T • The single crystal cavities ( two at 2. 2 GHz, one at 1300 MHz provided by DESY) had quench fields of 150 m. T < Hquench< 160 m. T • In all of the multi-cell cavities we encountered fabrication problems ( holes during EBW, tuning problems) and the results were inferior: best result was a quench field of 114 m. T. Further tests will follow September 25 -28, 2006 TTC Meeting at KEK 14

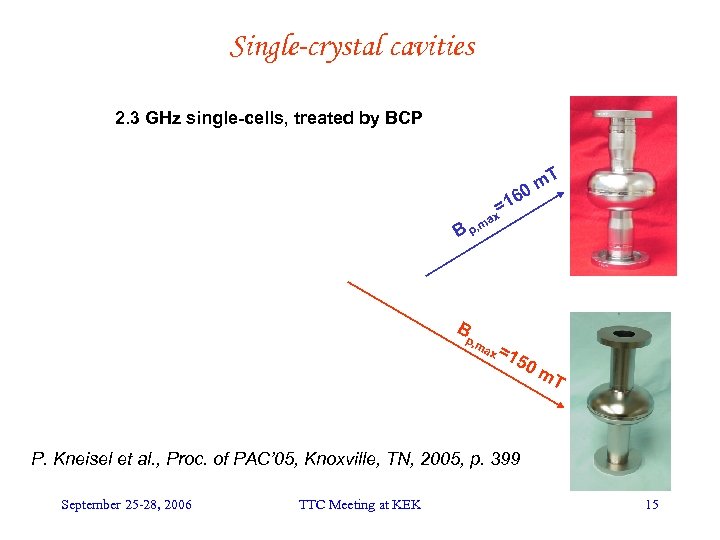

Single-crystal cavities 2. 3 GHz single-cells, treated by BCP m. T 0 16 = x a B p, m ax = 15 0 m T P. Kneisel et al. , Proc. of PAC’ 05, Knoxville, TN, 2005, p. 399 September 25 -28, 2006 TTC Meeting at KEK 15

What will be done in the future: • DESY • Testing of 9 -cell large grain cavities (BCP, EP) • Testing of single cystal 1 -cell cavity (EP after BCP at Jlab) • Purchase of large grain ingot • KEK • Fabrication and testing of large grain cavity from CBMM and Ningxia material after CBP and EP • Tokyo-Denkai: new furnace installation • Cornell • 6 more single cell cavities from Chinese niobium tests, vertical EP? • Jlab • Completion of 7 -cell tests, single crystal tests • Completion and testing of two 9 -cell TESLA cavities • Five single cell cavities each from Ningxia (TESLA shape) and W. C. Heraeus (ILC_LL shape) material • 1 -cell and 5 -cell cavity for 1 AMP FEL ( with end groups) from CBMM material • Single Crystal Niobium Technology Workshop September 25 -28, 2006 TTC Meeting at KEK 16

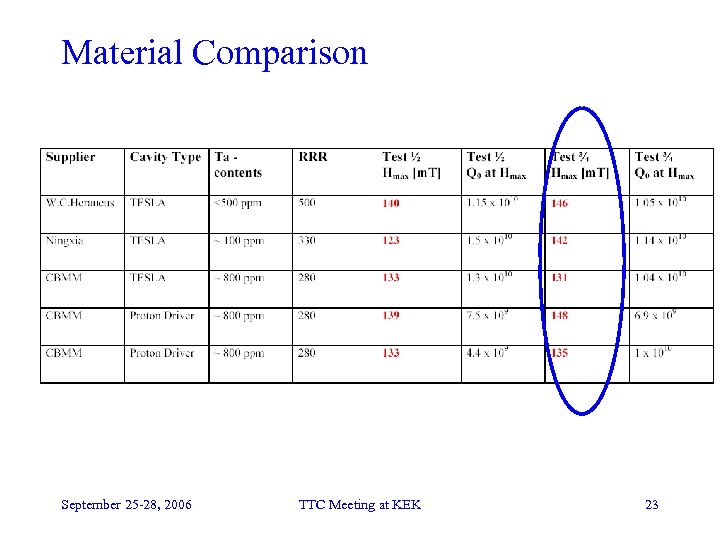

Test Series Material Comparison with TESLA Single Cells W. C. Heraeus Ningxia CBMM September 25 -28, 2006 TTC Meeting at KEK 17

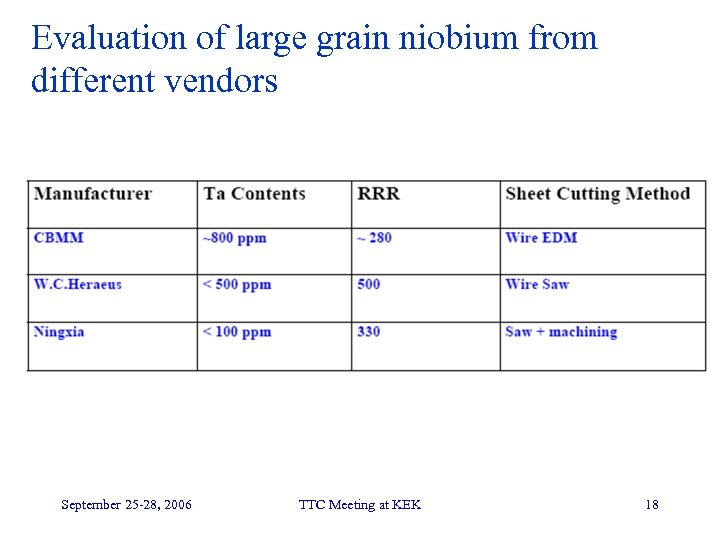

Evaluation of large grain niobium from different vendors September 25 -28, 2006 TTC Meeting at KEK 18

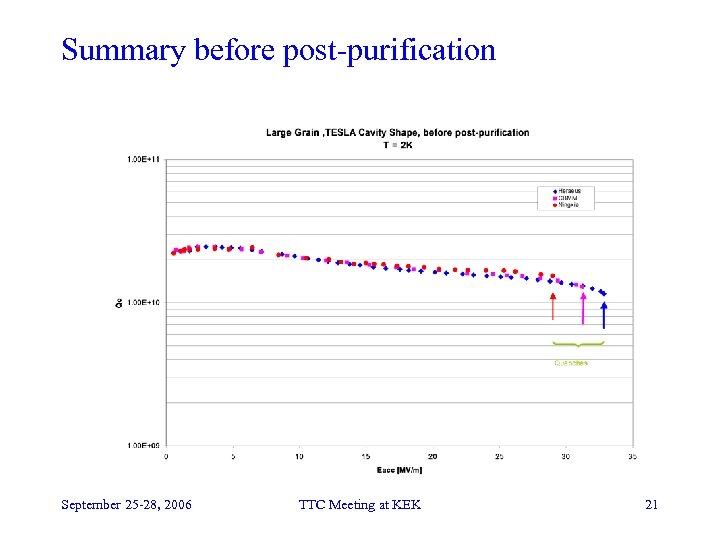

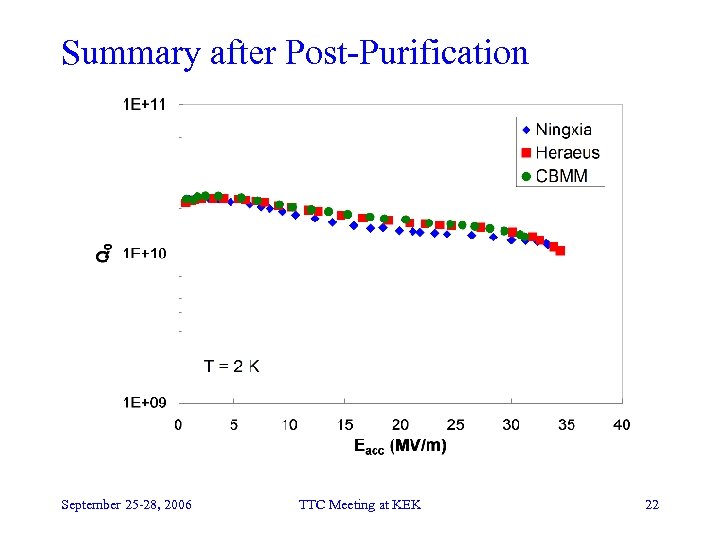

Fabrication and Treatment Fabrication – Standard deep drawing after cutting of sheets ( wire EDM/CBMM, saw cut/Ningxia, diamond saw/Heraeus) – Machining – Welding of beam pipes to half cell – Mechanical grinding – Equator weld Surface Treatment – – – – ~ 50 micron bcp Hydrogen degassing at 600 C for 10 hrs ~ 50 micron bcp, Test #1 12 hrs “in situ” baking at 120 C, Test #2 1200 C, 3 hrs post-purification with Ti ~ 50 micron bcp, Test #3 12 hrs “in situ” baking at 120 C, Test #4 September 25 -28, 2006 TTC Meeting at KEK 19

CBMM Large Grain Ingot”D”: before post purification September 25 -28, 2006 TTC Meeting at KEK 20

Summary before post-purification September 25 -28, 2006 TTC Meeting at KEK 21

Summary after Post-Purification September 25 -28, 2006 TTC Meeting at KEK 22

Material Comparison September 25 -28, 2006 TTC Meeting at KEK 23

Summary • Materials with different properties (RRR, Ta. . ) and prepared by different cutting methods behaved very similar after BCP only • It is not clear yet, what the important features for best performance are • There is a significant price difference in the different materials • We are going to fabricate 5 single cell cavities each from Ningxia and W. C. Heraeus material to get some statistics • The 9 -cell cavities for FNAL are being fabricated from CBMM large grain niobium September 25 -28, 2006 TTC Meeting at KEK 24

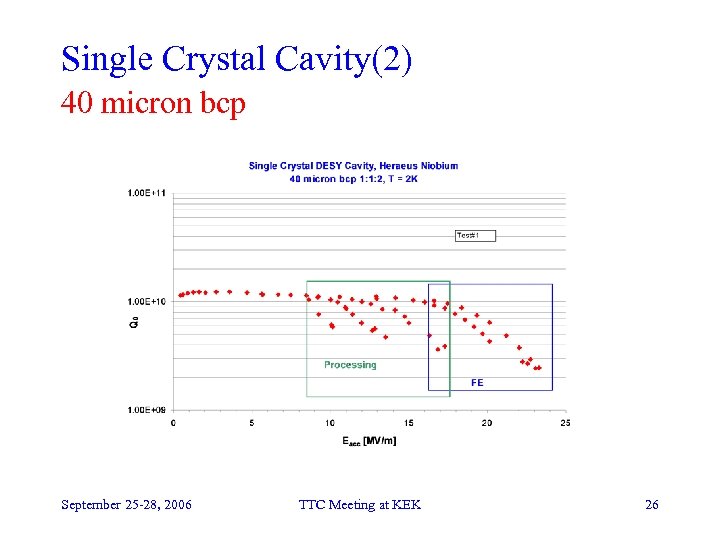

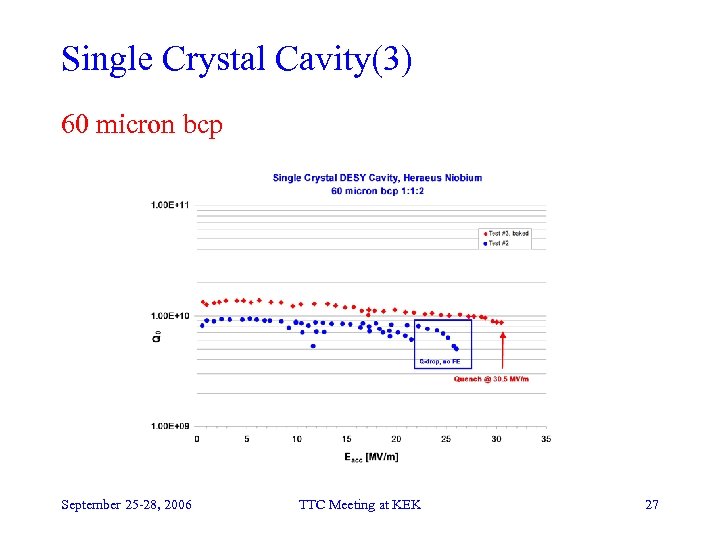

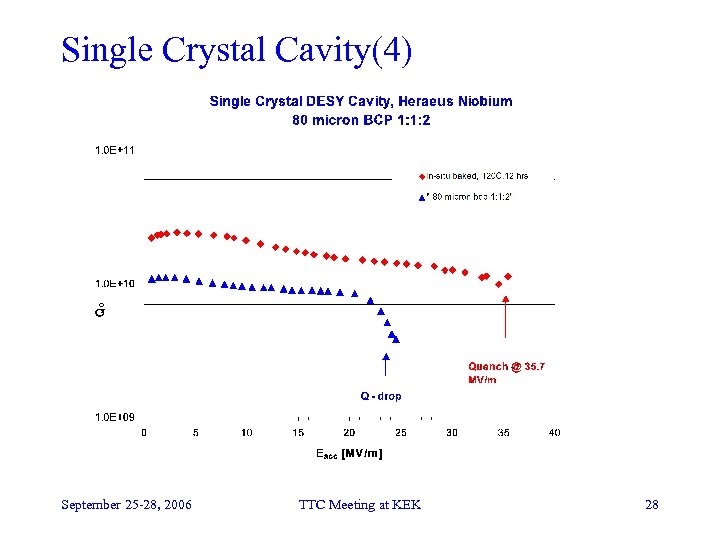

Single Crystal TESLA Cavity(DESY/Jlab) • This cavity has been fabricated by ACCEL from single crystal W. C. Heraeus RRR niobium under the guidance of Xenia and Waldemar Singer • The center single crystal was enlarged by rolling with intermediate annealing steps and deep drawing was used forming of half cells. • It has been shipped to Jlab for surface treatment and testing • A test series is in progress, during which successively material is being removed by BCP only, starting at 40 micron after fabrication and the cavity performance is being tested. • The tests consist of R(T) and Q vs E measurement at 2 K after the BCP treatment and subsequent measurements after “in situ” baking at 120 C for 12 hrs. September 25 -28, 2006 TTC Meeting at KEK 25

Single Crystal Cavity(2) 40 micron bcp September 25 -28, 2006 TTC Meeting at KEK 26

Single Crystal Cavity(3) 60 micron bcp September 25 -28, 2006 TTC Meeting at KEK 27

Single Crystal Cavity(4) September 25 -28, 2006 TTC Meeting at KEK 28

Single Crystal Cavity(5) ERL September 25 -28, 2006 TTC Meeting at KEK 29

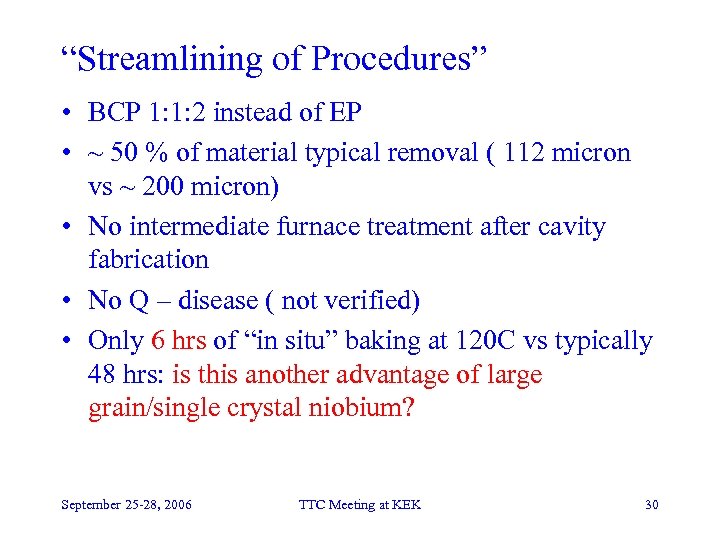

“Streamlining of Procedures” • BCP 1: 1: 2 instead of EP • ~ 50 % of material typical removal ( 112 micron vs ~ 200 micron) • No intermediate furnace treatment after cavity fabrication • No Q – disease ( not verified) • Only 6 hrs of “in situ” baking at 120 C vs typically 48 hrs: is this another advantage of large grain/single crystal niobium? September 25 -28, 2006 TTC Meeting at KEK 30

Thanks to Xenia Singer, Waldemar Singer, Gigi Ciovati, Lutz Lilje, Hasan Padamsee, Rongli Geng, Kenji Saito for providing me with informations for this talk September 25 -28, 2006 TTC Meeting at KEK 31

Back – up Slides September 25 -28, 2006 TTC Meeting at KEK 32

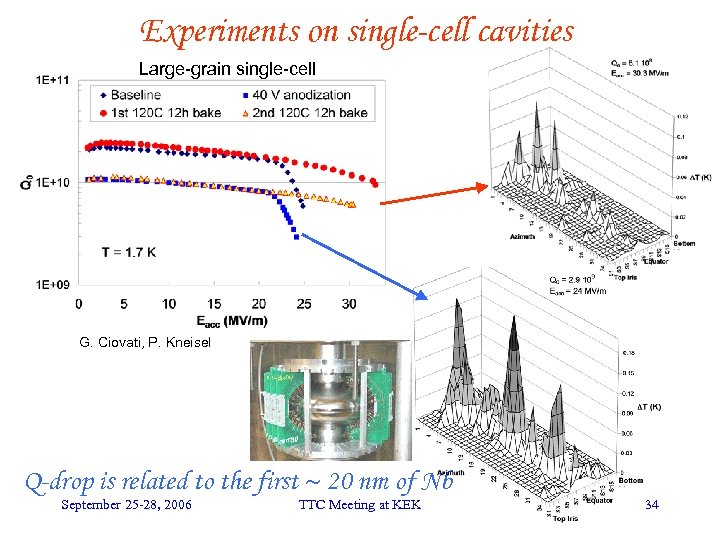

Understanding the “Q-drop”(1) • Investigations mainly carried out with large grain single cell cavities with and without T-mapping • Results: • Q-drop always eliminated after “in-situ” baking for 12 hrs at 120 C on bcp’d large grain cavities • Q-drop most likely caused by “hot spots”, which can be generated by anodization and eliminated by baking at will; T-maps show the strong reduction of ‘hot spots” after baking and re-appearance at different places after anodization • Oxygen distribution in penetration depth has major influence on Q- drop September 25 -28, 2006 TTC Meeting at KEK 33

Experiments on single-cell cavities Large-grain single-cell G. Ciovati, P. Kneisel Q-drop is related to the first 20 nm of Nb September 25 -28, 2006 TTC Meeting at KEK 34

Understanding the “Q-drop”(2) Question under investigation • How important is the surface topology for eliminating the Q-drop after baking”? Q-drop is always eliminated after baking in ep’d surfaces and bcp’d large grain surfaces. However, it re-appears after a small amount of surface treatment, which does not change the topology. • What are the best/most cost effective conditions for baking? (duration, atmosphere) Baking in air e. g. degrades the surface somewhat, but Q-drop is still absent • What feature of a surface/material determines the location of a “hot spot”? Hot spots move around after elimination and re-generation by e. g. anodization • Is the magnetic behaviour ( flux penetration) of a niobium surface a property, which can be related to the Q-drop/hot spots? Will be investigated with coaxial TE 011 cavity and subsequent magnetization measurements on the sample September 25 -28, 2006 TTC Meeting at KEK 35

Large-grain sc baked in air G. Ciovati, P. Kneisel • Performance degradation appears when T > 120 °C in air: • dissociation of the oxide layer allows diffusion of O, H, N into the Nb September 25 -28, 2006 TTC Meeting at KEK 36

Ningxia Large Grain Nb September 25 -28, 2006 TTC Meeting at KEK 37

W. C. Heraeus Large Grain Nb Before Post-Purification September 25 -28, 2006 TTC Meeting at KEK 38

W. C. Heraeus Large Grain Nb September 25 -28, 2006 TTC Meeting at KEK 39

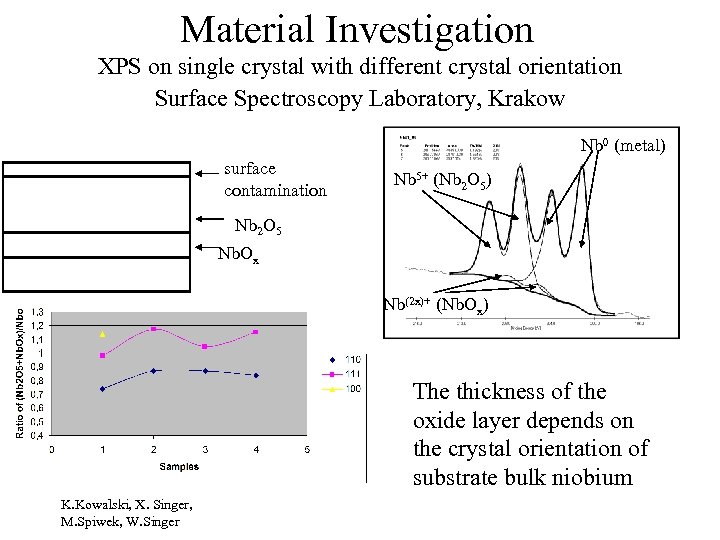

Material Investigation XPS on single crystal with different crystal orientation Surface Spectroscopy Laboratory, Krakow Nb 0 (metal) surface contamination Nb 5+ (Nb 2 O 5) Nb 2 O 5 Nb. Ox Nb(2 x)+ (Nb. Ox) The thickness of the oxide layer depends on the crystal orientation of substrate bulk niobium K. Kowalski, X. Singer, M. Spiwek, W. Singer

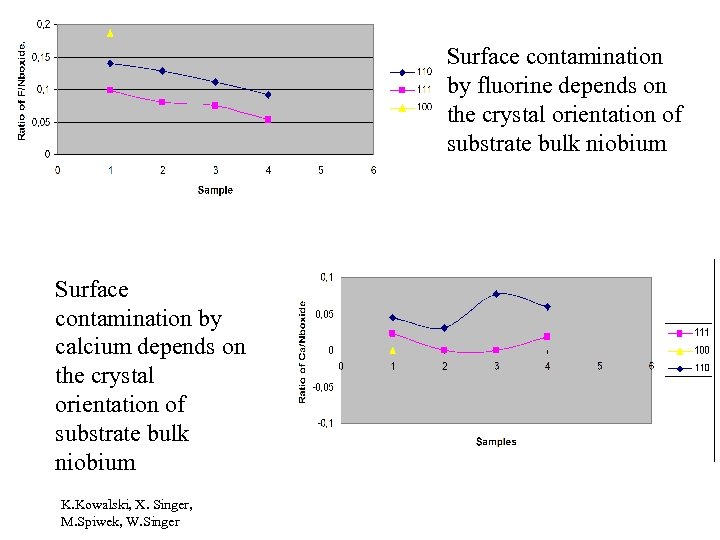

Surface contamination by fluorine depends on the crystal orientation of substrate bulk niobium Surface contamination by calcium depends on the crystal orientation of substrate bulk niobium K. Kowalski, X. Singer, M. Spiwek, W. Singer

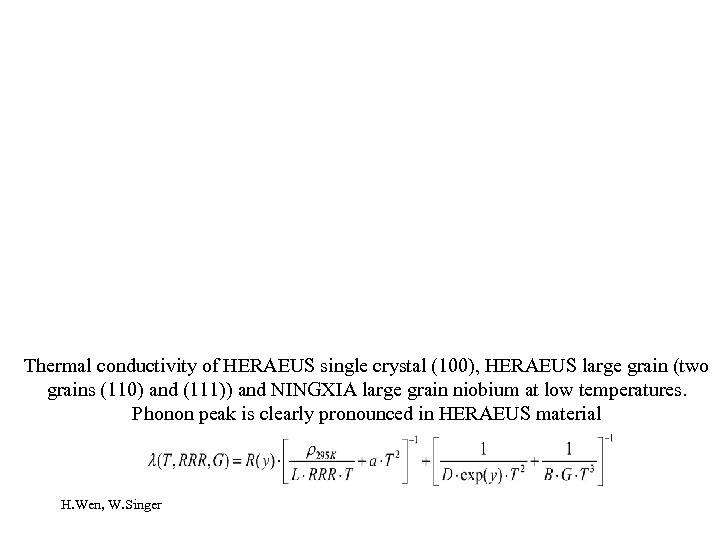

Thermal conductivity of HERAEUS single crystal (100), HERAEUS large grain (two grains (110) and (111)) and NINGXIA large grain niobium at low temperatures. Phonon peak is clearly pronounced in HERAEUS material H. Wen, W. Singer

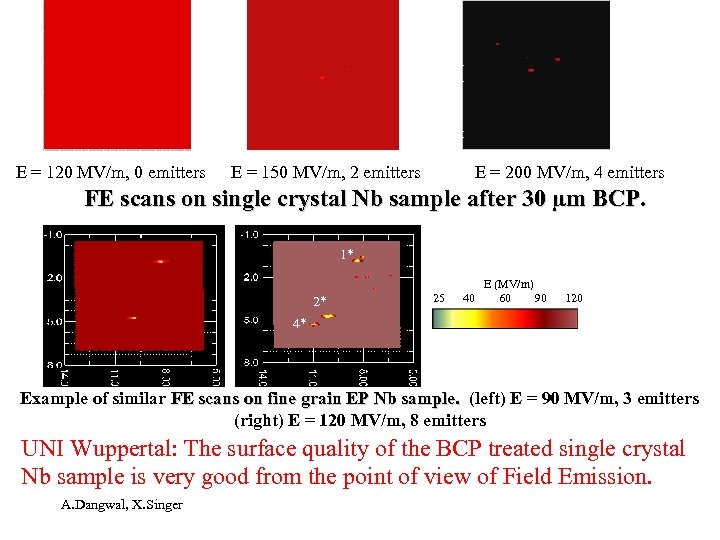

E = 120 MV/m, 0 emitters E = 200 MV/m, 4 emitters E = 150 MV/m, 2 emitters FE scans on single crystal Nb sample after 30 µm BCP. 1* 2* 25 E (MV/m) 40 60 90 120 4* Example of similar FE scans on fine grain EP Nb sample. (left) E = 90 MV/m, 3 emitters (right) E = 120 MV/m, 8 emitters UNI Wuppertal: The surface quality of the BCP treated single crystal Nb sample is very good from the point of view of Field Emission. A. Dangwal, X. Singer

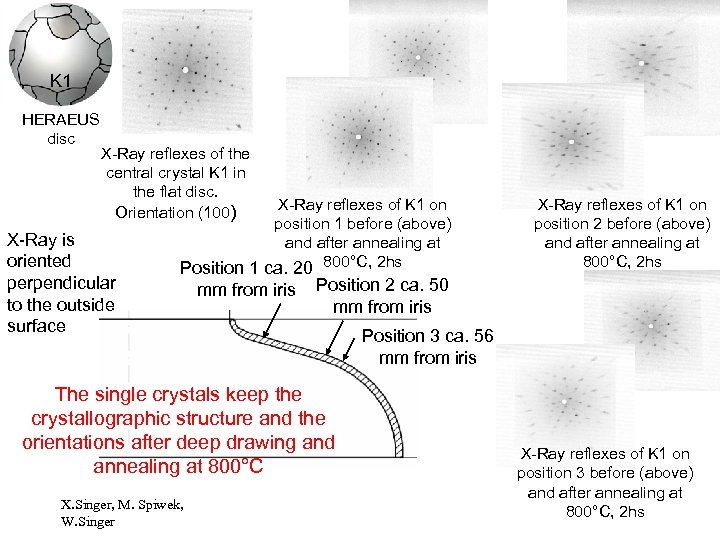

K 1 HERAEUS disc X-Ray reflexes of the central crystal K 1 in the flat disc. Orientation (100) X-Ray is oriented perpendicular to the outside surface X-Ray reflexes of K 1 on position 1 before (above) and after annealing at Position 1 ca. 20 800°C, 2 hs mm from iris Position 2 ca. 50 mm from iris The single crystals keep the crystallographic structure and the orientations after deep drawing and annealing at 800°C X. Singer, M. Spiwek, W. Singer X-Ray reflexes of K 1 on position 2 before (above) and after annealing at 800°C, 2 hs Position 3 ca. 56 mm from iris X-Ray reflexes of K 1 on position 3 before (above) and after annealing at 800°C, 2 hs

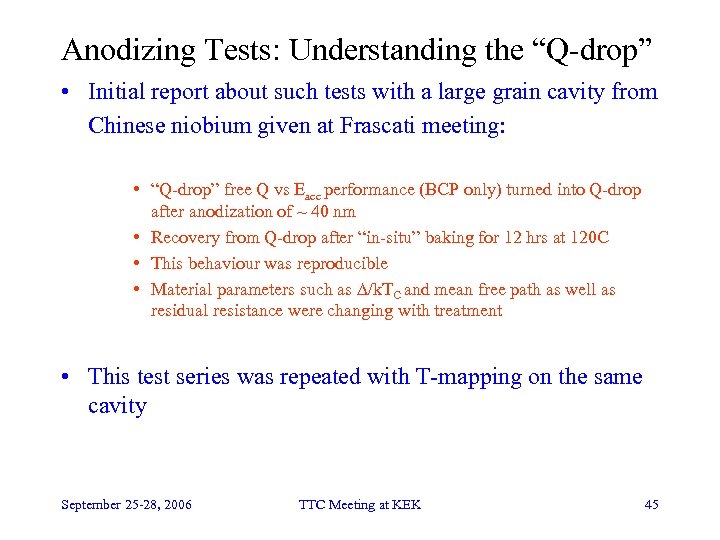

Anodizing Tests: Understanding the “Q-drop” • Initial report about such tests with a large grain cavity from Chinese niobium given at Frascati meeting: • “Q-drop” free Q vs Eacc performance (BCP only) turned into Q-drop after anodization of ~ 40 nm • Recovery from Q-drop after “in-situ” baking for 12 hrs at 120 C • This behaviour was reproducible • Material parameters such as D/k. TC and mean free path as well as residual resistance were changing with treatment • This test series was repeated with T-mapping on the same cavity September 25 -28, 2006 TTC Meeting at KEK 45

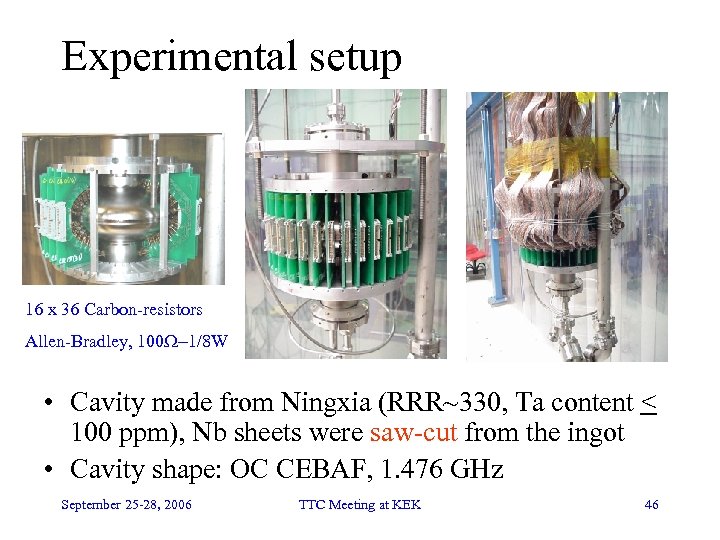

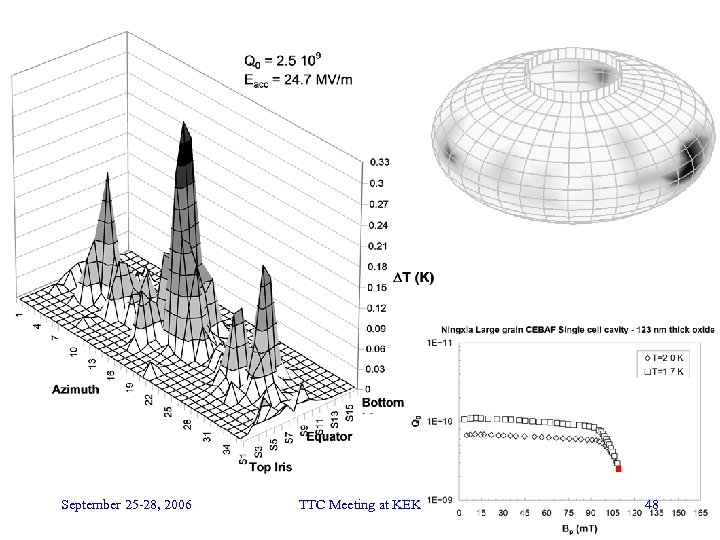

Experimental setup 16 x 36 Carbon-resistors Allen-Bradley, 100 W-1/8 W • Cavity made from Ningxia (RRR~330, Ta content < 100 ppm), Nb sheets were saw-cut from the ingot • Cavity shape: OC CEBAF, 1. 476 GHz September 25 -28, 2006 TTC Meeting at KEK 46

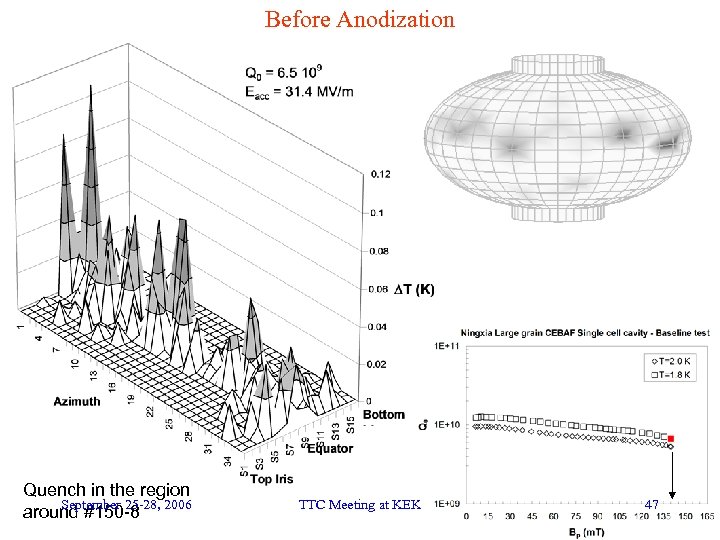

Before Anodization Quench in the region September 25 -28, around #150 -8 2006 TTC Meeting at KEK 47

September 25 -28, 2006 TTC Meeting at KEK 48

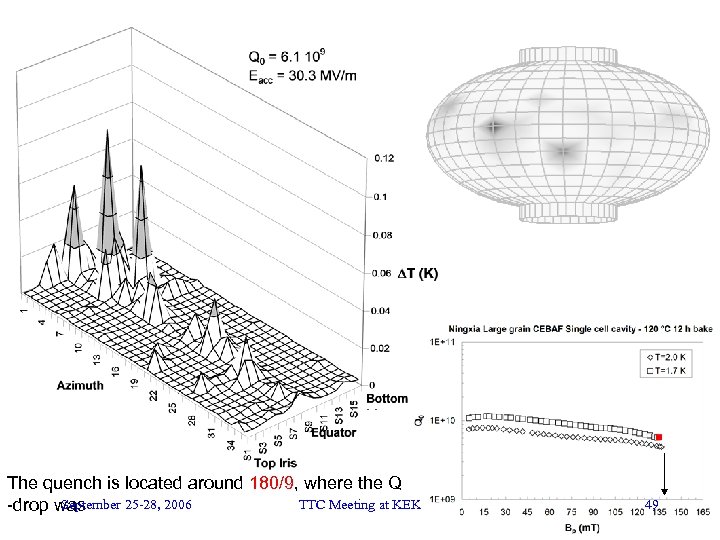

The quench is located around 180/9, where the Q September 25 -28, 2006 TTC Meeting at KEK -drop was 49

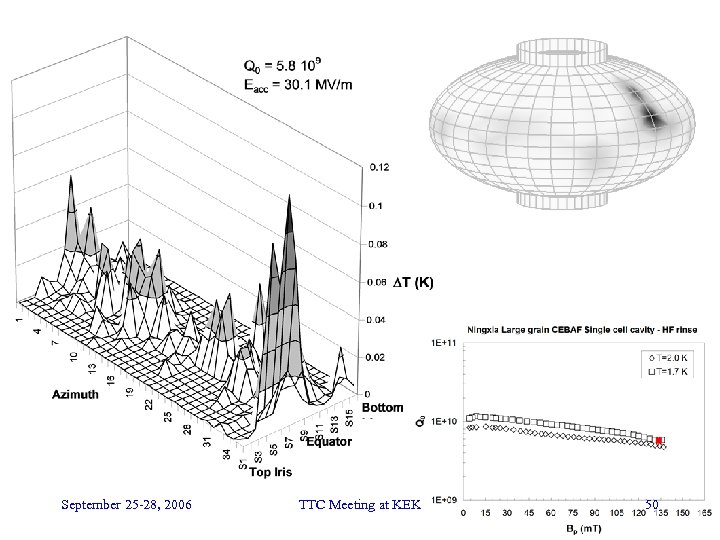

September 25 -28, 2006 TTC Meeting at KEK 50

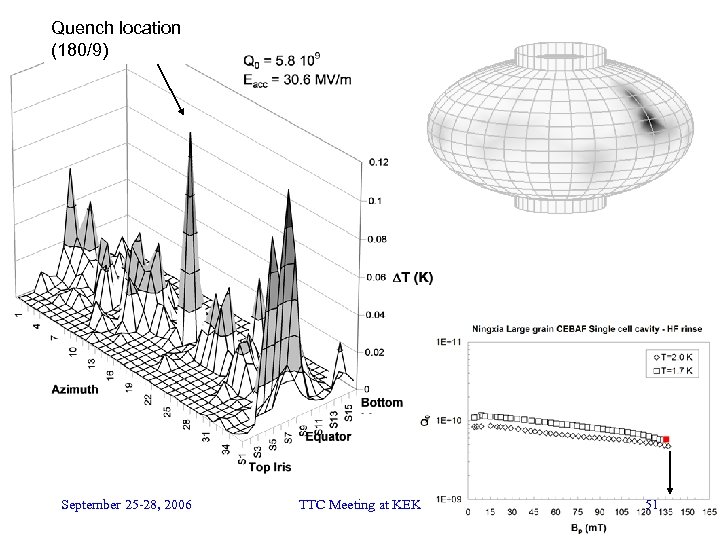

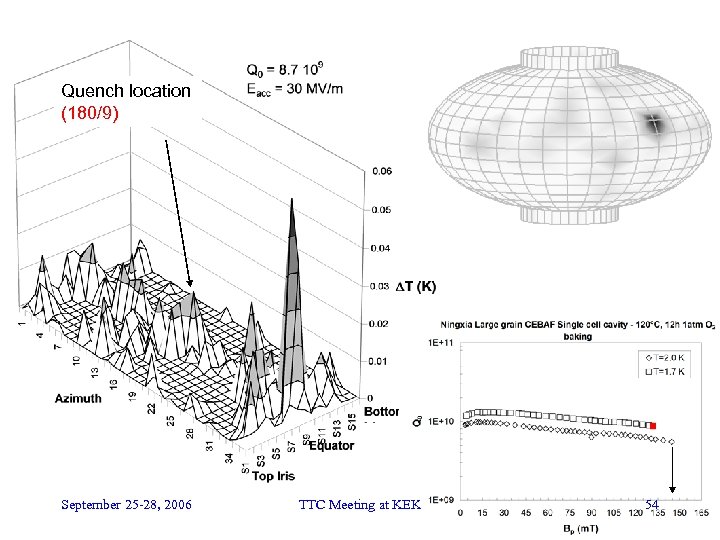

Quench location (180/9) September 25 -28, 2006 TTC Meeting at KEK 51

Conclusion • Q-drop and “hot spots” can be generated and eliminated by anodization and “in situ” baking • There is strong evidence that oxygen diffusion is involved in the Q-drop phenomenon • The question then is: Can one generate a single “hot spot” by generating an area on a cavity surface with increased oxygen concentration? And if so, can this “hot spot” be eliminated/reduced by “in situ” baking? September 25 -28, 2006 TTC Meeting at KEK 52

120 °C 12 h oxygen baking • The cavity was disconnected from test stand, and placed in baking station • The cavity was evacuated to 6. 3 10 -9 mbar (66% H 2 O, 23% H 2, 6. 5% N 2, 2. 9% CO 2) • The cavity was filled with research grade oxygen (99. 9969% purity) to 756 torr and baked at 120°C for 12 h • The cavity was disassembled and degreased in ultrasonic • 1 h HPR in closed cabinet • Dried overnight in class 10 • Top flange assembled, 1 h HPR in closed cabinet • Dried overnight in class 10 • Assembled and evacuated on test stand. Pressure was about 5 10 -8 mbar before cool-down September 25 -28, 2006 TTC Meeting at KEK 53

Quench location (180/9) September 25 -28, 2006 TTC Meeting at KEK 54

Conclusion • ? ? • Baking can be combined with drying process – saves time September 25 -28, 2006 TTC Meeting at KEK 55

5eceb0c965a6cc3f7468d8407ab09a86.ppt