5490d55d8cba1cc4fa74aad74b167bf3.ppt

- Количество слайдов: 29

University of Adelaide HSIS 2 NOISE & VIBRATION Q & A

AGENDA • • Project scope outline Project program outline Presentation of the acoustic report Discussion regarding anticipated construction timeframes and likely management methodologies; - Timing / program - Communications - Construction methodologies - User work arounds • Feedback from Users (concerns, work around ideas, methodologies) University of Adelaide - HSIS 2 Noise & Vibration Q & A

PROJECT SCOPE • Multi-modal Teaching Museum • Shared Facilities - Loading Dock - Core Laboratory / Autoclave facilities • Research Laboratory consolidation to MSS & refurbishment • Office consolidation to MSN & refurbishment - Ground level Student Services - Level 1 – consolidation of off campus schools - Level 2 – School of Medicine - Level 3 – Faculty of Health & Medical Sciences • Levels 4, 5 & 6 of MSN to be vacated & mothballed University of Adelaide - HSIS 2 Noise & Vibration Q & A

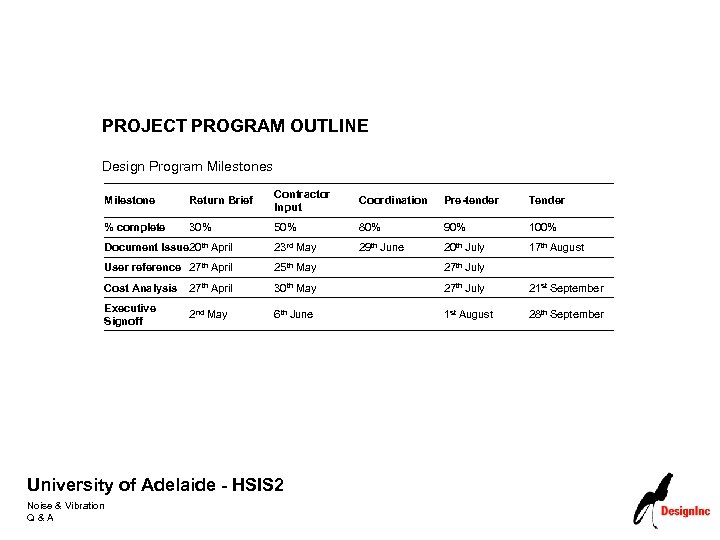

PROJECT PROGRAM OUTLINE Design Program Milestones Milestone Return Brief Contractor Input Coordination Pre-tender Tender % complete 30% 50% 80% 90% 100% Document Issue 20 th April 23 rd May 29 th June 20 th July 17 th August User reference 27 th April 25 th May 27 th July Cost Analysis 27 th April 30 th May 27 th July 21 st September Executive Signoff 2 nd May 6 th June 1 st August 28 th September University of Adelaide - HSIS 2 Noise & Vibration Q & A

PROJECT CONSTRUCTION OUTLINE • Early Works - Multi-modal Teaching Museum - Demolition begins: 1 st May 2017 - Construction begins: 8 th May 2017 - Construction completed: 30 th June 2017 (8 weeks) • Early Works – MSS Level 3 Dentistry - Construction begins: 1 st May 2017 - Construction completed: 9 th June 2017 (6 weeks) • Main Project - Construction begins: mid September 2017 - Construction completed: Late June 2018 (10 months) University of Adelaide - HSIS 2 Noise & Vibration Q & A

Noise & Vibration Survey and Construction Impacts University of Adelaide Medical School

Introduction • Assessment of noise and vibration impacts carried out in 3 stages: 1. Baseline noise and vibration assessment within Animal House 2. Assessment of noise and vibration due to different construction techniques within both the Medical School South and Medical School North Buildings (current) 3. Provision of guidelines for design and construction to minimise construction noise and vibration impacts (future).

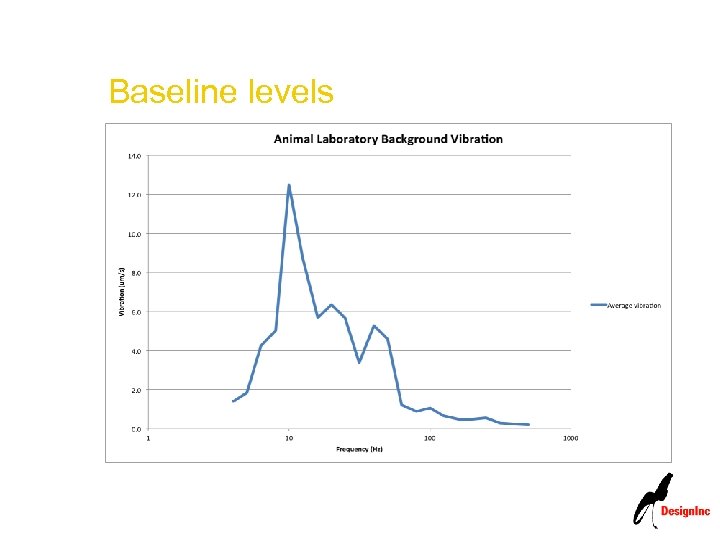

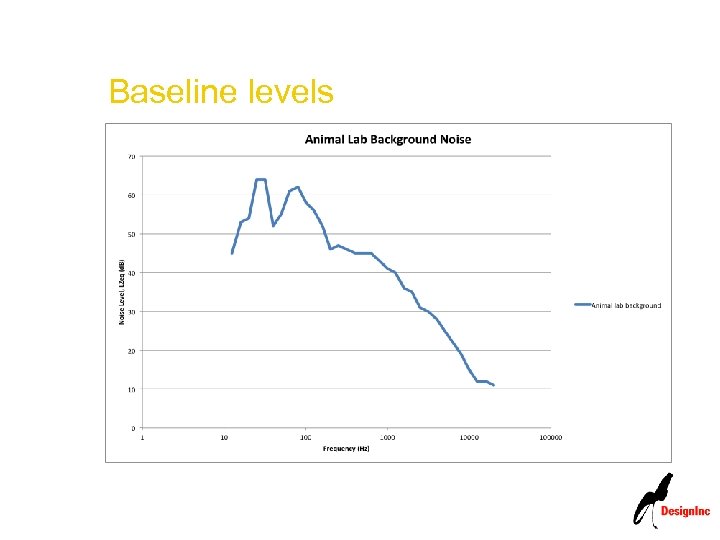

Test procedure Vibration • Vibration field spectra were measured in the Z-axis (vertical, up/down). • Measurement adjacent to the animal cages so as to measure vibration representative of the animal housing. Noise • A spatial average noise level was measured in the animal laboratory. • Measurement times were taken such that the average noise levels were representative for the space.

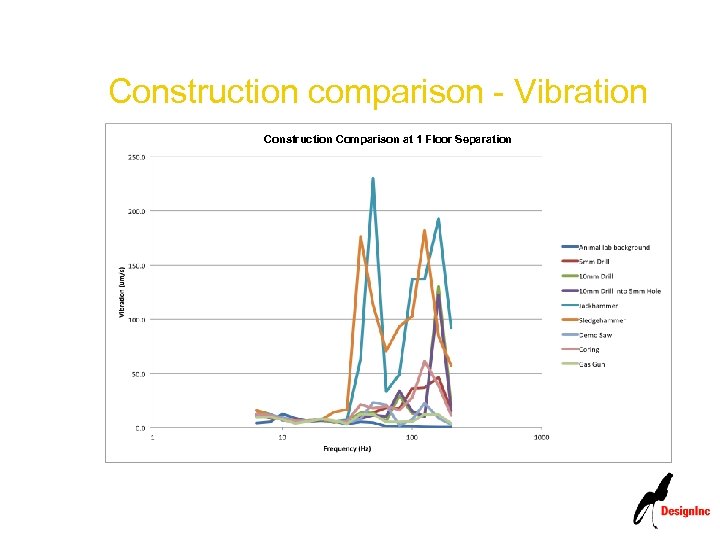

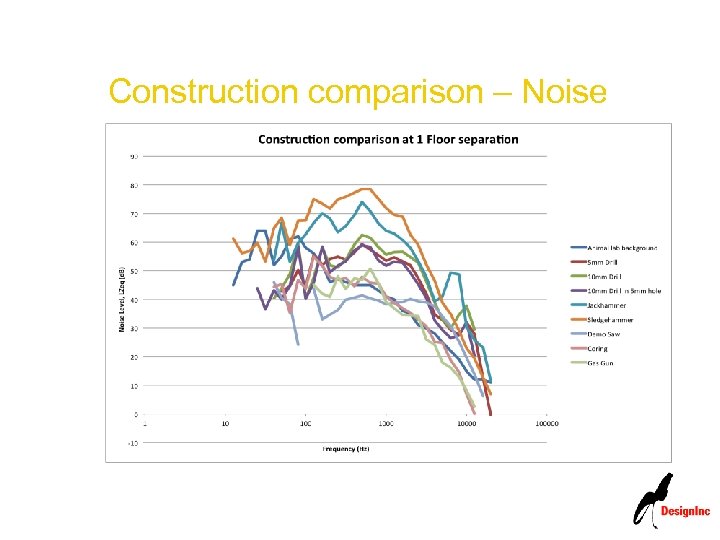

Test procedure – construction survey A selection of construction activities were measured: • 5 mm hammer drill • 10 mm into 5 mm hammer drill hole • Jackhammer • Sledgehammer • Demo saw • Coring • Impact gas gun Measurements of noise and vibration were undertaken directly above or below the construction on each floor of the building.

Baseline levels

Baseline levels

Construction comparison - Vibration Construction Comparison at 1 Floor Separation

Construction comparison – Noise

Summary - Vibration Activity with greatest level of vibration were: • Jackhammering • Sledgehammering • Drilling • Coring Activity with least levels of vibration were: • Demo sawing • Cording • Use of the gas gun

Summary - Noise Activity with highest noise levels were: • Jackhammering • Sledgehammering • Drilling Activity with lowest levels of vibration were: • Demo sawing • Coring • Use of the gas gun

Summary - General • Use of jackhammer & sledgehammer should be avoided if possible • Noise and vibration due to construction activity both have the potential to exceed relevant criteria and existing background levels. • Use demolition saw and remove masonry wall sections in smaller sections. • Place masonry walls in waste bins rather than drop from height. • walls should be placed in waste bins rather than dropped from a height. • Avoid use of hammer drills near the bio resources area. • Acoustic mitigation is not considered to be practical as structure borne noise will transmit via walls and the floor. It is hence not practical to treat these surfaces with an additional acoustic barrier. Next Step • Develop a detailed construction noise and vibration management strategy

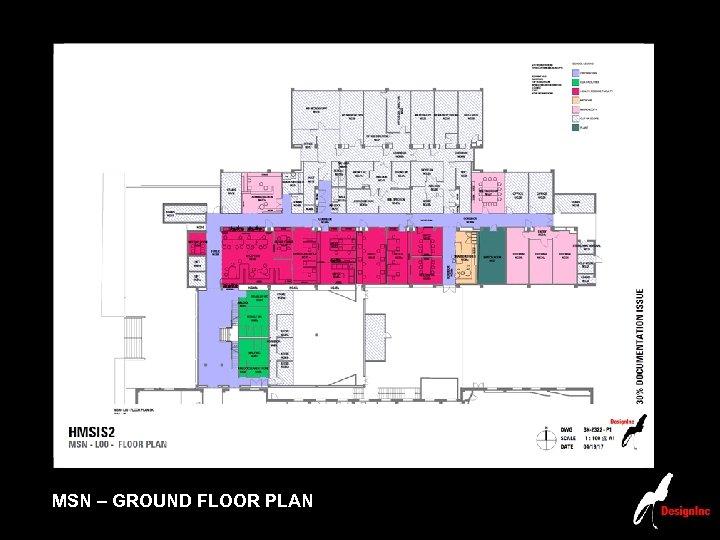

MSN – GROUND FLOOR PLAN

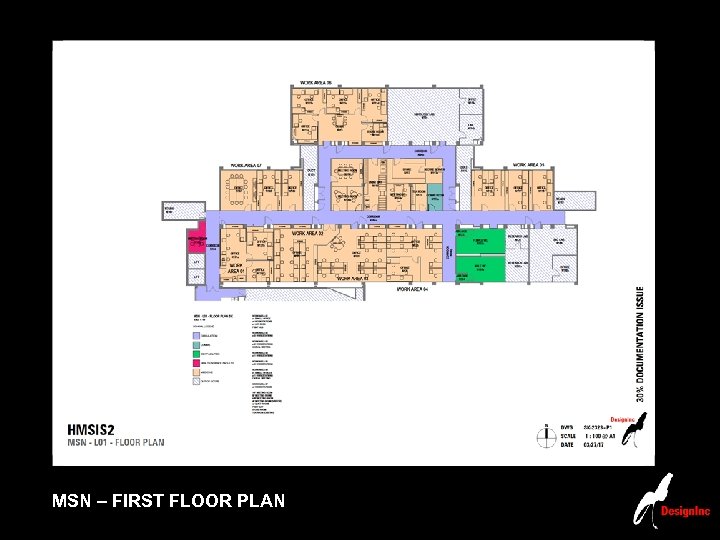

MSN – FIRST FLOOR PLAN

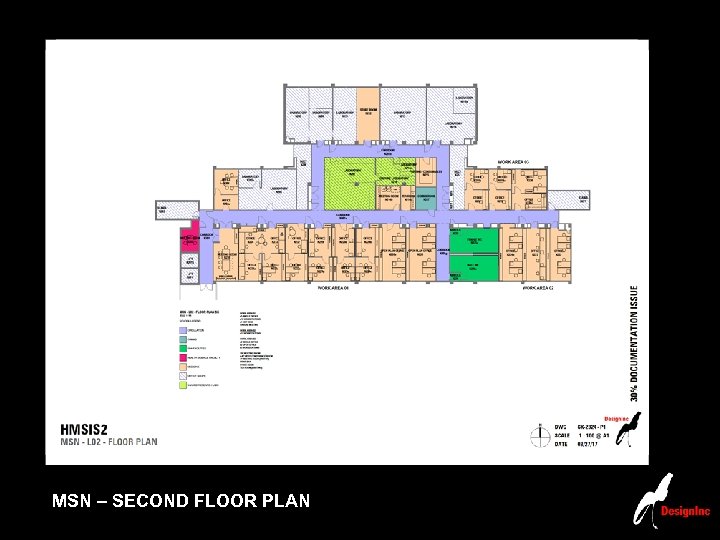

MSN – SECOND FLOOR PLAN

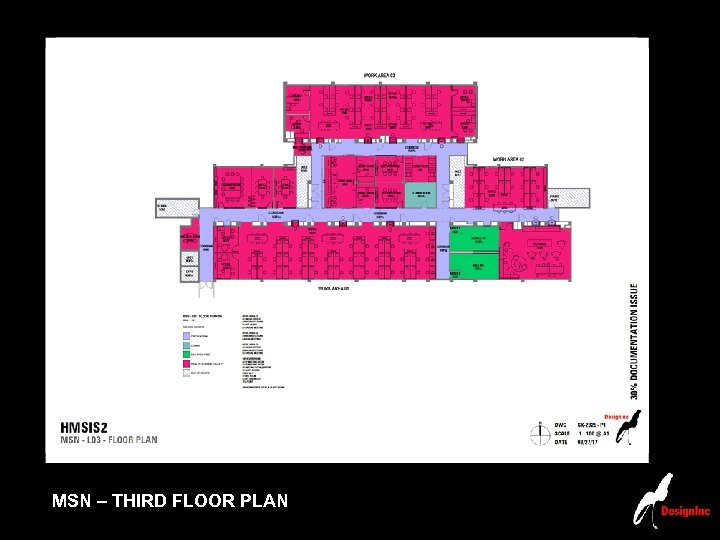

MSN – THIRD FLOOR PLAN

MSN – SIXTH FLOOR PLAN

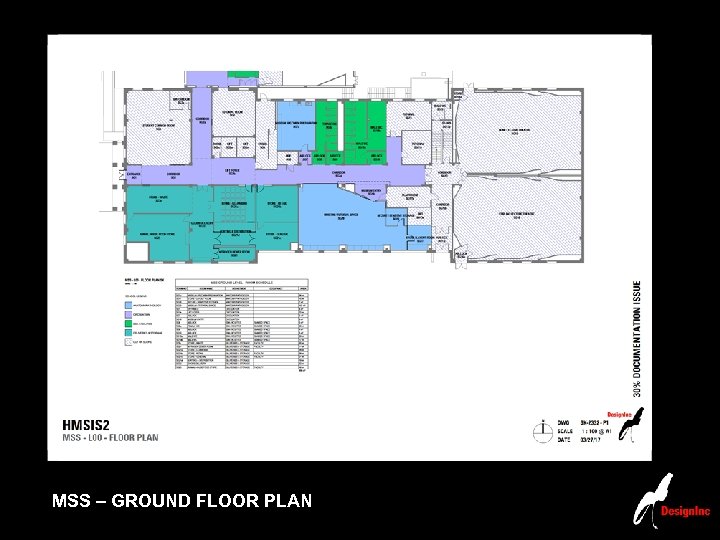

MSS – GROUND FLOOR PLAN

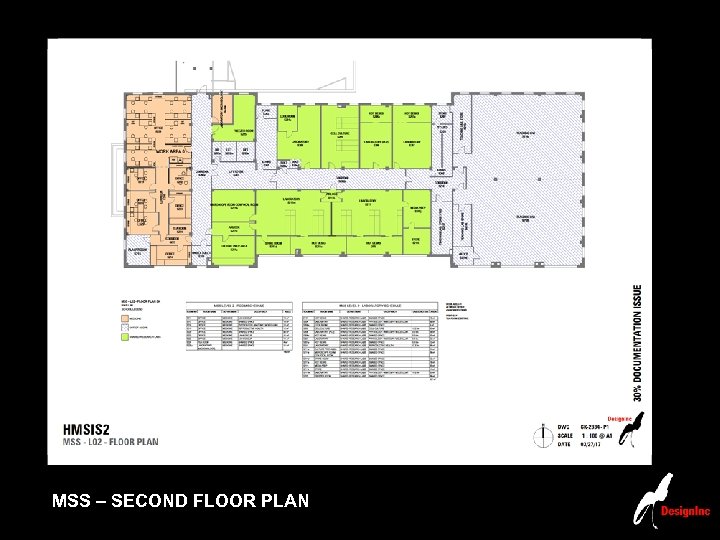

MSS – SECOND FLOOR PLAN

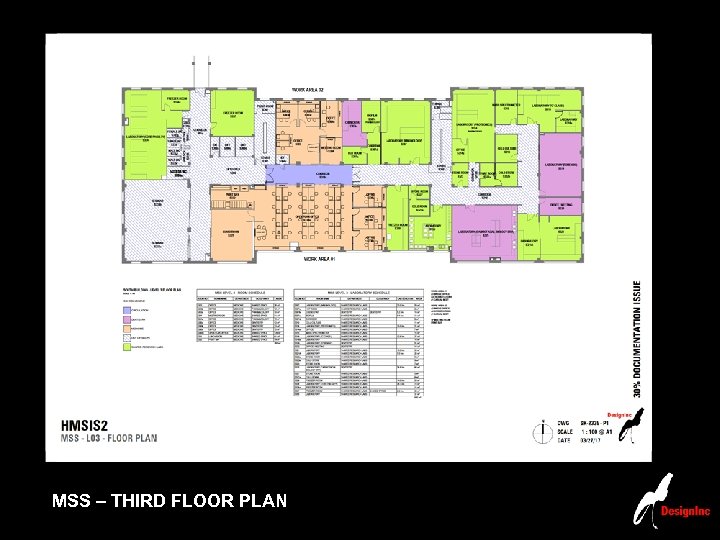

MSS – THIRD FLOOR PLAN

MSS – FOUTH FLOOR PLAN

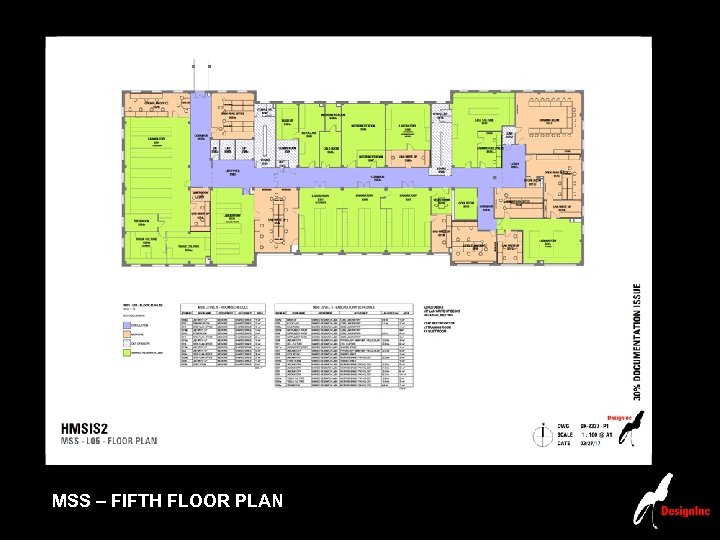

MSS – FIFTH FLOOR PLAN

DISCUSSION • • • Timing / program Communications Construction methodologies User work arounds Feedback from Users (concerns, work around ideas, methodologies) University of Adelaide - HSIS 2 Noise & Vibration Q & A

FEED BACK • Concerns • Work around ideas • Methodologies University of Adelaide - HSIS 2 Noise & Vibration Q & A

www. designinc. com. au

5490d55d8cba1cc4fa74aad74b167bf3.ppt