a64c4f354f3c931fe6d2755ac38e88c9.ppt

- Количество слайдов: 13

United Nations Industrial Development Organization INTRODUCTION TO THE TREATMENT OF TANNERY EFFLUENTS What every tanner should know about effluent treatment Part I Compiled by J. Buljan, I. Kral

United Nations Industrial Development Organization INTRODUCTION TO THE TREATMENT OF TANNERY EFFLUENTS What every tanner should know about effluent treatment Part I Compiled by J. Buljan, I. Kral

1. Load, norms, in-house treatment • Pollution load • Discharge norms • General overview of treatment of tannery effluents • Segregation of streams • Treatment of spent liming floats • Treatment of chrome-bearing floats • Linking of individual tanneries to a CETP or MWWW

1. Load, norms, in-house treatment • Pollution load • Discharge norms • General overview of treatment of tannery effluents • Segregation of streams • Treatment of spent liming floats • Treatment of chrome-bearing floats • Linking of individual tanneries to a CETP or MWWW

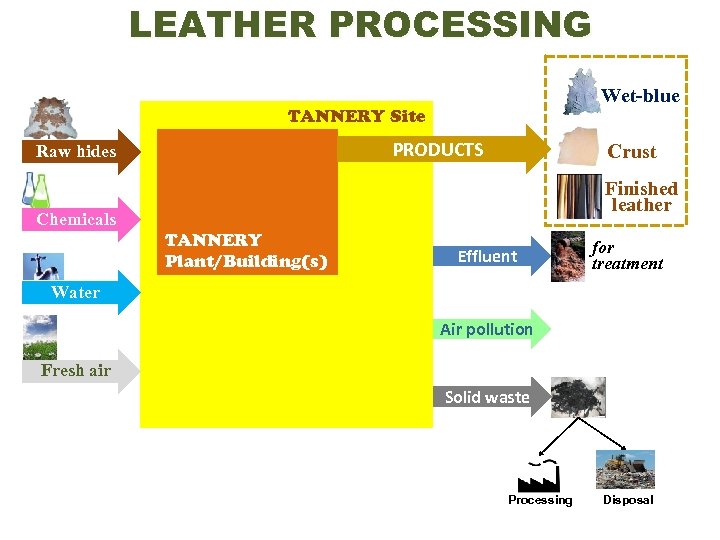

LEATHER PROCESSING Wet-blue TANNERY Site PRODUCTS Raw hides Crust Finished leather Chemicals TANNERY Plant/Building(s) Effluent for treatment Water Air pollution Fresh air Solid waste Processing Disposal

LEATHER PROCESSING Wet-blue TANNERY Site PRODUCTS Raw hides Crust Finished leather Chemicals TANNERY Plant/Building(s) Effluent for treatment Water Air pollution Fresh air Solid waste Processing Disposal

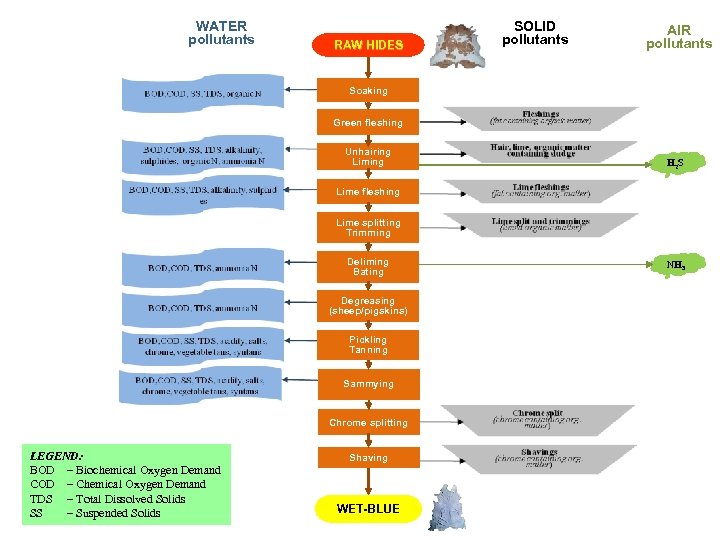

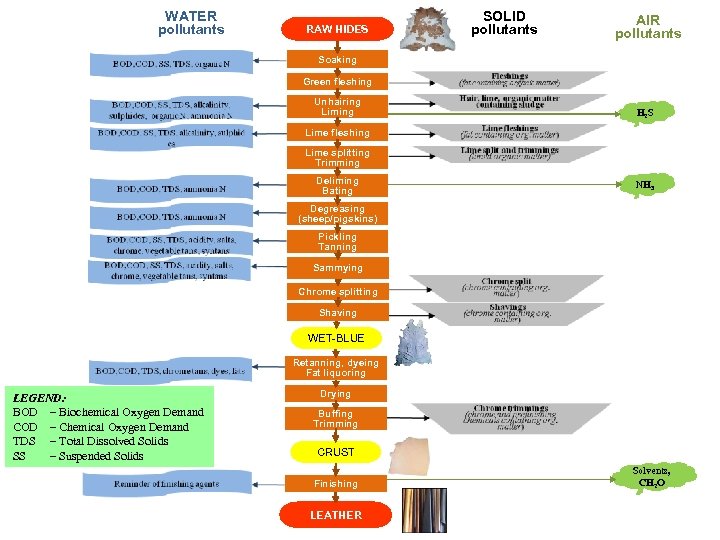

WATER pollutants RAW HIDES SOLID pollutants AIR pollutants Soaking Green fleshing Unhairing Liming H 2 S Lime fleshing Lime splitting Trimming Deliming Bating Degreasing (sheep/pigskins) Pickling Tanning Sammying Chrome splitting LEGEND: BOD – Biochemical Oxygen Demand COD – Chemical Oxygen Demand TDS – Total Dissolved Solids SS – Suspended Solids Shaving WET-BLUE NH 3

WATER pollutants RAW HIDES SOLID pollutants AIR pollutants Soaking Green fleshing Unhairing Liming H 2 S Lime fleshing Lime splitting Trimming Deliming Bating Degreasing (sheep/pigskins) Pickling Tanning Sammying Chrome splitting LEGEND: BOD – Biochemical Oxygen Demand COD – Chemical Oxygen Demand TDS – Total Dissolved Solids SS – Suspended Solids Shaving WET-BLUE NH 3

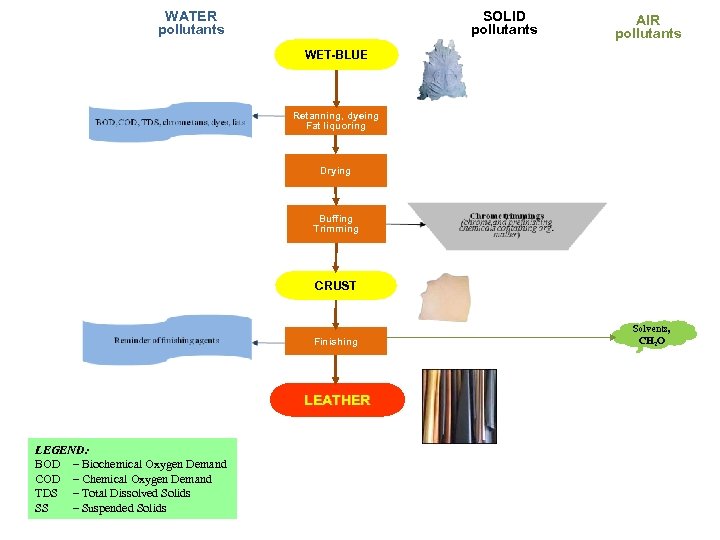

WATER pollutants SOLID pollutants AIR pollutants WET-BLUE Retanning, dyeing Fat liquoring Drying Buffing Trimming CRUST Finishing LEATHER LEGEND: BOD – Biochemical Oxygen Demand COD – Chemical Oxygen Demand TDS – Total Dissolved Solids SS – Suspended Solids Solvents, CH 2 O

WATER pollutants SOLID pollutants AIR pollutants WET-BLUE Retanning, dyeing Fat liquoring Drying Buffing Trimming CRUST Finishing LEATHER LEGEND: BOD – Biochemical Oxygen Demand COD – Chemical Oxygen Demand TDS – Total Dissolved Solids SS – Suspended Solids Solvents, CH 2 O

WATER pollutants RAW HIDES SOLID pollutants AIR pollutants Soaking Green fleshing Unhairing Liming H 2 S Lime fleshing Lime splitting Trimming Deliming Bating NH 3 Degreasing (sheep/pigskins) Pickling Tanning Sammying Chrome splitting Shaving WET-BLUE Retanning, dyeing Fat liquoring LEGEND: BOD – Biochemical Oxygen Demand COD – Chemical Oxygen Demand TDS – Total Dissolved Solids SS – Suspended Solids Drying Buffing Trimming CRUST Finishing LEATHER Solvents, CH 2 O

WATER pollutants RAW HIDES SOLID pollutants AIR pollutants Soaking Green fleshing Unhairing Liming H 2 S Lime fleshing Lime splitting Trimming Deliming Bating NH 3 Degreasing (sheep/pigskins) Pickling Tanning Sammying Chrome splitting Shaving WET-BLUE Retanning, dyeing Fat liquoring LEGEND: BOD – Biochemical Oxygen Demand COD – Chemical Oxygen Demand TDS – Total Dissolved Solids SS – Suspended Solids Drying Buffing Trimming CRUST Finishing LEATHER Solvents, CH 2 O

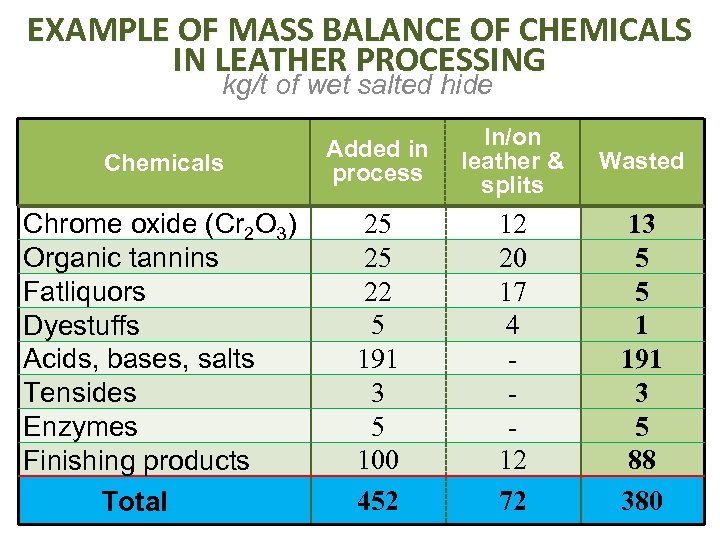

EXAMPLE OF MASS BALANCE OF CHEMICALS IN LEATHER PROCESSING kg/t of wet salted hide Chemicals Added in process In/on leather & splits Wasted Chrome oxide (Cr 2 O 3) Organic tannins Fatliquors Dyestuffs Acids, bases, salts Tensides Enzymes Finishing products Total 25 25 22 5 191 3 5 100 452 12 20 17 4 12 72 13 5 5 1 191 3 5 88 380

EXAMPLE OF MASS BALANCE OF CHEMICALS IN LEATHER PROCESSING kg/t of wet salted hide Chemicals Added in process In/on leather & splits Wasted Chrome oxide (Cr 2 O 3) Organic tannins Fatliquors Dyestuffs Acids, bases, salts Tensides Enzymes Finishing products Total 25 25 22 5 191 3 5 100 452 12 20 17 4 12 72 13 5 5 1 191 3 5 88 380

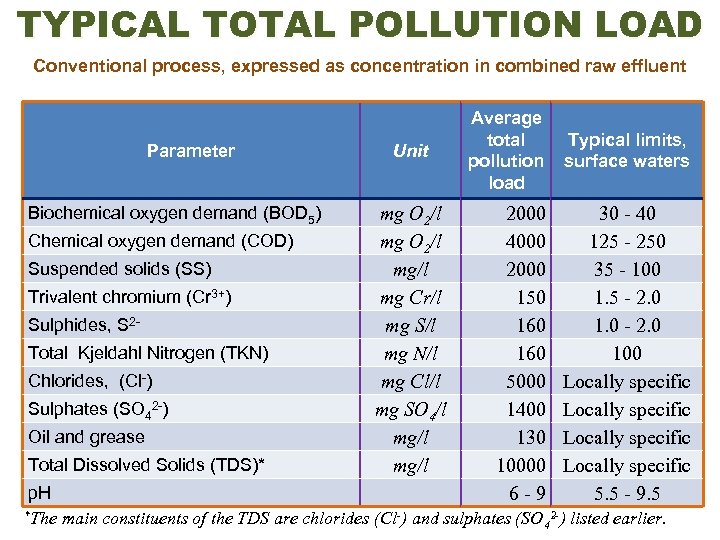

TYPICAL TOTAL POLLUTION LOAD Conventional process, expressed as concentration in combined raw effluent Parameter Biochemical oxygen demand (BOD 5) Chemical oxygen demand (COD) Suspended solids (SS) Trivalent chromium (Cr 3+) Sulphides, S 2 Total Kjeldahl Nitrogen (TKN) Chlorides, (Cl-) Sulphates (SO 42 -) Oil and grease Total Dissolved Solids (TDS)* Unit mg O 2/l mg/l mg Cr/l mg S/l mg N/l mg Cl/l mg SO 4/l mg/l Average total pollution load Typical limits, surface waters 2000 4000 2000 150 160 5000 1400 130 10000 6 -9 30 - 40 125 - 250 35 - 100 1. 5 - 2. 0 1. 0 - 2. 0 100 Locally specific 5. 5 - 9. 5 p. H *The main constituents of the TDS are chlorides (Cl-) and sulphates (SO 2 -) listed earlier. 4

TYPICAL TOTAL POLLUTION LOAD Conventional process, expressed as concentration in combined raw effluent Parameter Biochemical oxygen demand (BOD 5) Chemical oxygen demand (COD) Suspended solids (SS) Trivalent chromium (Cr 3+) Sulphides, S 2 Total Kjeldahl Nitrogen (TKN) Chlorides, (Cl-) Sulphates (SO 42 -) Oil and grease Total Dissolved Solids (TDS)* Unit mg O 2/l mg/l mg Cr/l mg S/l mg N/l mg Cl/l mg SO 4/l mg/l Average total pollution load Typical limits, surface waters 2000 4000 2000 150 160 5000 1400 130 10000 6 -9 30 - 40 125 - 250 35 - 100 1. 5 - 2. 0 1. 0 - 2. 0 100 Locally specific 5. 5 - 9. 5 p. H *The main constituents of the TDS are chlorides (Cl-) and sulphates (SO 2 -) listed earlier. 4

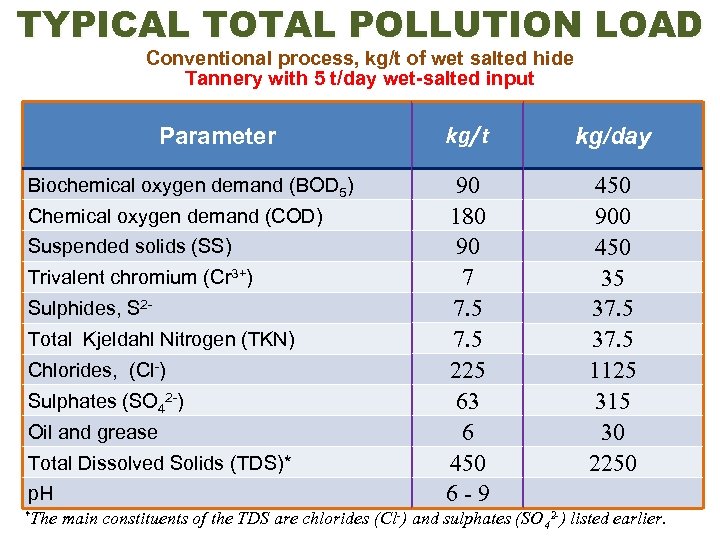

TYPICAL TOTAL POLLUTION LOAD Conventional process, kg/t of wet salted hide Tannery with 5 t/day wet-salted input Parameter Biochemical oxygen demand (BOD 5) Chemical oxygen demand (COD) Suspended solids (SS) Trivalent chromium (Cr 3+) Sulphides, S 2 Total Kjeldahl Nitrogen (TKN) Chlorides, (Cl-) Sulphates (SO 42 -) Oil and grease Total Dissolved Solids (TDS)* p. H *The kg/t kg/day 90 180 90 7 7. 5 225 63 6 450 6 -9 450 900 450 35 37. 5 1125 315 30 2250 main constituents of the TDS are chlorides (Cl-) and sulphates (SO 42 -) listed earlier.

TYPICAL TOTAL POLLUTION LOAD Conventional process, kg/t of wet salted hide Tannery with 5 t/day wet-salted input Parameter Biochemical oxygen demand (BOD 5) Chemical oxygen demand (COD) Suspended solids (SS) Trivalent chromium (Cr 3+) Sulphides, S 2 Total Kjeldahl Nitrogen (TKN) Chlorides, (Cl-) Sulphates (SO 42 -) Oil and grease Total Dissolved Solids (TDS)* p. H *The kg/t kg/day 90 180 90 7 7. 5 225 63 6 450 6 -9 450 900 450 35 37. 5 1125 315 30 2250 main constituents of the TDS are chlorides (Cl-) and sulphates (SO 42 -) listed earlier.

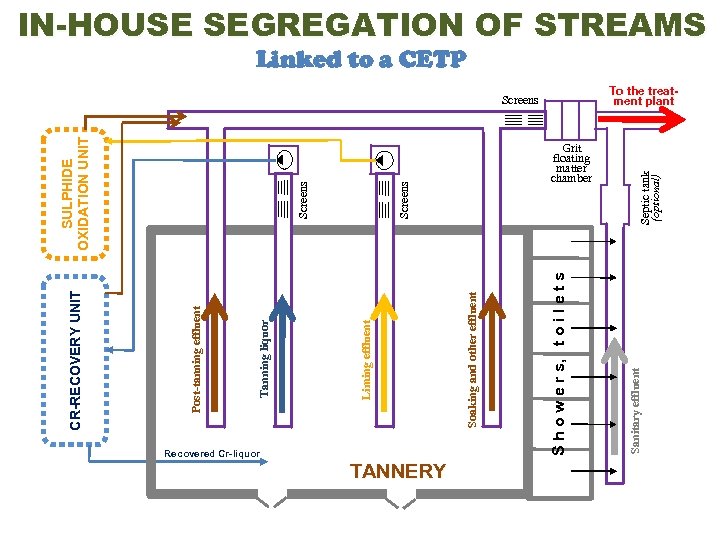

TANNERY Screens SULPHIDE OXIDATION UNIT Grit floating matter chamber Septic tank (optional) Screens Sanitary effluent S h o w e r s, t o i l e t s Recovered Cr-liquor Soaking and other effluent Liming effluent Tanning liquor Post-tanning effluent CR-RECOVERY UNIT IN-HOUSE SEGREGATION OF STREAMS Linked to a CETP To the treatment plant

TANNERY Screens SULPHIDE OXIDATION UNIT Grit floating matter chamber Septic tank (optional) Screens Sanitary effluent S h o w e r s, t o i l e t s Recovered Cr-liquor Soaking and other effluent Liming effluent Tanning liquor Post-tanning effluent CR-RECOVERY UNIT IN-HOUSE SEGREGATION OF STREAMS Linked to a CETP To the treatment plant

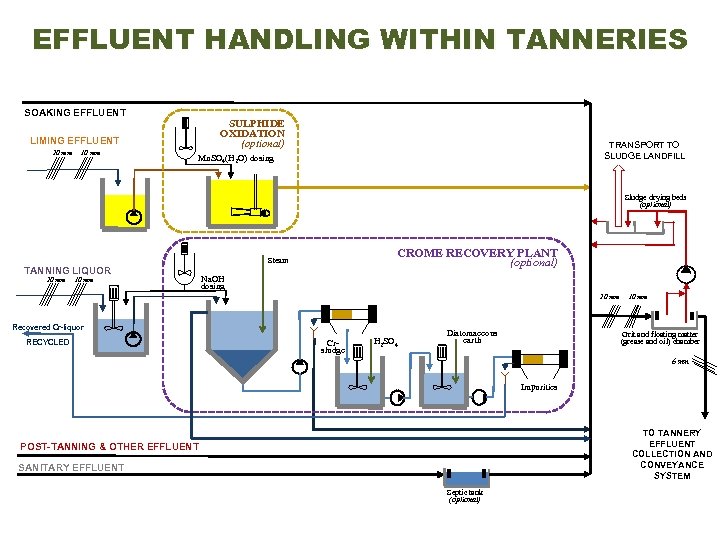

EFFLUENT HANDLING WITHIN TANNERIES SOAKING EFFLUENT SULPHIDE OXIDATION (optional) LIMING EFFLUENT 20 mm 10 mm TRANSPORT TO SLUDGE LANDFILL Mn. SO 4(H 2 O) dosing Sludge drying beds (optional) TANNING LIQUOR 20 mm 10 mm CROME RECOVERY PLANT (optional) Steam Na. OH dosing 20 mm Recovered Cr-liquor RECYCLED Crsludge H 2 SO 4 Diatomaceous earth 10 mm Grit and floating matter (grease and oil) chamber 6 mm Impurities TO TANNERY EFFLUENT COLLECTION AND CONVEYANCE SYSTEM POST-TANNING & OTHER EFFLUENT SANITARY EFFLUENT Septic tank (optional)

EFFLUENT HANDLING WITHIN TANNERIES SOAKING EFFLUENT SULPHIDE OXIDATION (optional) LIMING EFFLUENT 20 mm 10 mm TRANSPORT TO SLUDGE LANDFILL Mn. SO 4(H 2 O) dosing Sludge drying beds (optional) TANNING LIQUOR 20 mm 10 mm CROME RECOVERY PLANT (optional) Steam Na. OH dosing 20 mm Recovered Cr-liquor RECYCLED Crsludge H 2 SO 4 Diatomaceous earth 10 mm Grit and floating matter (grease and oil) chamber 6 mm Impurities TO TANNERY EFFLUENT COLLECTION AND CONVEYANCE SYSTEM POST-TANNING & OTHER EFFLUENT SANITARY EFFLUENT Septic tank (optional)

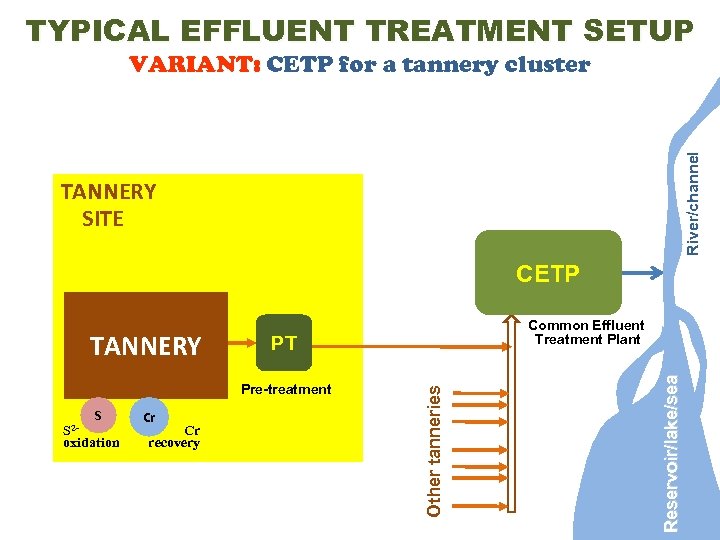

TYPICAL EFFLUENT TREATMENT SETUP River/channel VARIANT: CETP for a tannery cluster TANNERY SITE CETP Pre-treatment S 2 - S oxidation Cr Cr recovery Reservoir/lake/sea PT Other tanneries TANNERY Common Effluent Treatment Plant

TYPICAL EFFLUENT TREATMENT SETUP River/channel VARIANT: CETP for a tannery cluster TANNERY SITE CETP Pre-treatment S 2 - S oxidation Cr Cr recovery Reservoir/lake/sea PT Other tanneries TANNERY Common Effluent Treatment Plant

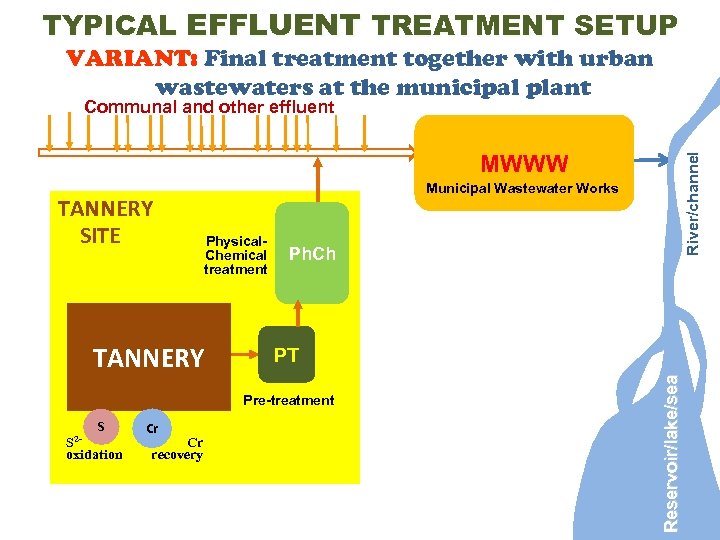

TYPICAL EFFLUENT TREATMENT SETUP VARIANT: Final treatment together with urban wastewaters at the municipal plant Communal and other effluent Municipal Wastewater Works Physical. Chemical treatment TANNERY Ph. Ch PT Pre-treatment S 2 - S oxidation Cr Cr recovery Reservoir/lake/sea TANNERY SITE River/channel MWWW

TYPICAL EFFLUENT TREATMENT SETUP VARIANT: Final treatment together with urban wastewaters at the municipal plant Communal and other effluent Municipal Wastewater Works Physical. Chemical treatment TANNERY Ph. Ch PT Pre-treatment S 2 - S oxidation Cr Cr recovery Reservoir/lake/sea TANNERY SITE River/channel MWWW