93205808c21bd6b1612aa5897e6594af.ppt

- Количество слайдов: 33

UNITECH PLASTO COMPONENTS PVT. LTD. Manufacturer of Automotive Plastic Components, Connectors , Painting , Laser Etching & Wiring Harness Company Profile Presentation

UNITECH PLASTO COMPONENTS PVT. LTD. Manufacturer of Automotive Plastic Components, Connectors , Painting , Laser Etching & Wiring Harness Company Profile Presentation

CONTENTS: Milestones Business Profile History & Its Operation Mission & Vision Certifications, Awards & Recognition Our Customers Products & Process Categories Product Application Business Strategies Machines & Technical Equipments Future Plans Page 2

CONTENTS: Milestones Business Profile History & Its Operation Mission & Vision Certifications, Awards & Recognition Our Customers Products & Process Categories Product Application Business Strategies Machines & Technical Equipments Future Plans Page 2

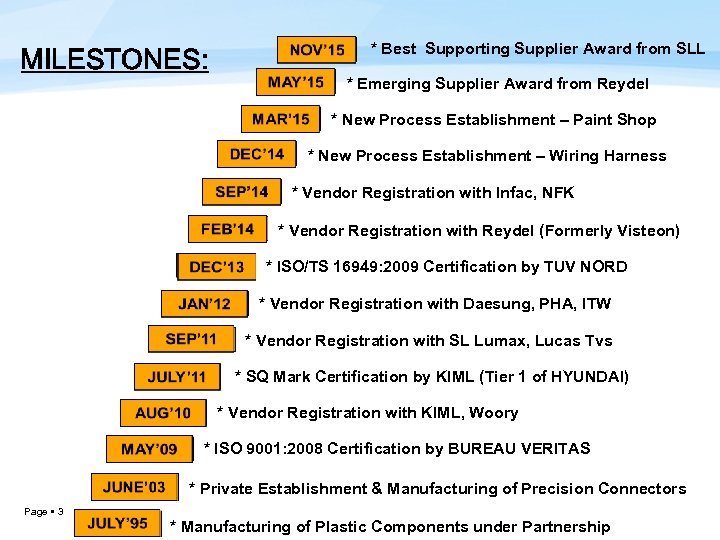

MILESTONES: * Best Supporting Supplier Award from SLL * Emerging Supplier Award from Reydel * New Process Establishment – Paint Shop * New Process Establishment – Wiring Harness * Vendor Registration with Infac, NFK * Vendor Registration with Reydel (Formerly Visteon) * ISO/TS 16949: 2009 Certification by TUV NORD * Vendor Registration with Daesung, PHA, ITW * Vendor Registration with SL Lumax, Lucas Tvs * SQ Mark Certification by KIML (Tier 1 of HYUNDAI) * Vendor Registration with KIML, Woory * ISO 9001: 2008 Certification by BUREAU VERITAS * Private Establishment & Manufacturing of Precision Connectors Page 3 * Manufacturing of Plastic Components under Partnership

MILESTONES: * Best Supporting Supplier Award from SLL * Emerging Supplier Award from Reydel * New Process Establishment – Paint Shop * New Process Establishment – Wiring Harness * Vendor Registration with Infac, NFK * Vendor Registration with Reydel (Formerly Visteon) * ISO/TS 16949: 2009 Certification by TUV NORD * Vendor Registration with Daesung, PHA, ITW * Vendor Registration with SL Lumax, Lucas Tvs * SQ Mark Certification by KIML (Tier 1 of HYUNDAI) * Vendor Registration with KIML, Woory * ISO 9001: 2008 Certification by BUREAU VERITAS * Private Establishment & Manufacturing of Precision Connectors Page 3 * Manufacturing of Plastic Components under Partnership

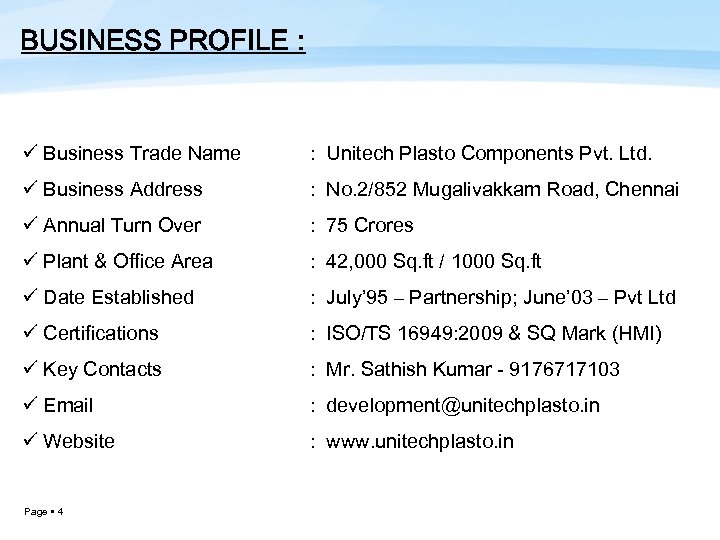

BUSINESS PROFILE : ü Business Trade Name : Unitech Plasto Components Pvt. Ltd. ü Business Address : No. 2/852 Mugalivakkam Road, Chennai ü Annual Turn Over : 75 Crores ü Plant & Office Area : 42, 000 Sq. ft / 1000 Sq. ft ü Date Established : July’ 95 – Partnership; June’ 03 – Pvt Ltd ü Certifications : ISO/TS 16949: 2009 & SQ Mark (HMI) ü Key Contacts : Mr. Sathish Kumar - 9176717103 ü Email : development@unitechplasto. in ü Website : www. unitechplasto. in Page 4

BUSINESS PROFILE : ü Business Trade Name : Unitech Plasto Components Pvt. Ltd. ü Business Address : No. 2/852 Mugalivakkam Road, Chennai ü Annual Turn Over : 75 Crores ü Plant & Office Area : 42, 000 Sq. ft / 1000 Sq. ft ü Date Established : July’ 95 – Partnership; June’ 03 – Pvt Ltd ü Certifications : ISO/TS 16949: 2009 & SQ Mark (HMI) ü Key Contacts : Mr. Sathish Kumar - 9176717103 ü Email : development@unitechplasto. in ü Website : www. unitechplasto. in Page 4

COMPANY HISTORY & ITS OPERATION: ü We are pleased to introduce ourselves as an ISO/TS 16949: 2009 and SQ MARK (HYUNDAI ) Certified company engaged in Designing & Manufacturing of High Precision Plastic Components/Connectors catering to Automobile, Medical, Electrical and Engineering Industry. üOur Component production unit is fully equipped with Microprocessor controlled Injection Moulding machines with in-house testing facility spread over 42, 000 Sq. ft built up area. üThe company assures its clients of their satisfaction by addressing their needs and requirements in a timely manner. üWe believe that we’ll be able to compete globally in the near future since it is the company’s vision to become a highly respected producer of various Injection Moulded Plastic Components. Page 5

COMPANY HISTORY & ITS OPERATION: ü We are pleased to introduce ourselves as an ISO/TS 16949: 2009 and SQ MARK (HYUNDAI ) Certified company engaged in Designing & Manufacturing of High Precision Plastic Components/Connectors catering to Automobile, Medical, Electrical and Engineering Industry. üOur Component production unit is fully equipped with Microprocessor controlled Injection Moulding machines with in-house testing facility spread over 42, 000 Sq. ft built up area. üThe company assures its clients of their satisfaction by addressing their needs and requirements in a timely manner. üWe believe that we’ll be able to compete globally in the near future since it is the company’s vision to become a highly respected producer of various Injection Moulded Plastic Components. Page 5

MISSION & VISION: Ø To become a TIER -1 Supplier to OEM Ø To Provide One Stop solution ØTo be a BENCHMARK supplier ØEstablish Value Addition Process ØAchieve 100 Crores Turnover / Annum Page 6

MISSION & VISION: Ø To become a TIER -1 Supplier to OEM Ø To Provide One Stop solution ØTo be a BENCHMARK supplier ØEstablish Value Addition Process ØAchieve 100 Crores Turnover / Annum Page 6

CERTIFICATION, AWARDS AND RECOGNITION: Certified by ISO/TS 16949: 2009 & SQ MARK Page 7

CERTIFICATION, AWARDS AND RECOGNITION: Certified by ISO/TS 16949: 2009 & SQ MARK Page 7

CERTIFICATION, AWARDS AND RECOGNITION: Best Entrepreneur Award for the year 2006 -07 (District level) Page 8 Best Entrepreneur Award for the year 2007 -08 (State level) Best Women Entrepreneur Award for the year 2006 -07 (State level)

CERTIFICATION, AWARDS AND RECOGNITION: Best Entrepreneur Award for the year 2006 -07 (District level) Page 8 Best Entrepreneur Award for the year 2007 -08 (State level) Best Women Entrepreneur Award for the year 2006 -07 (State level)

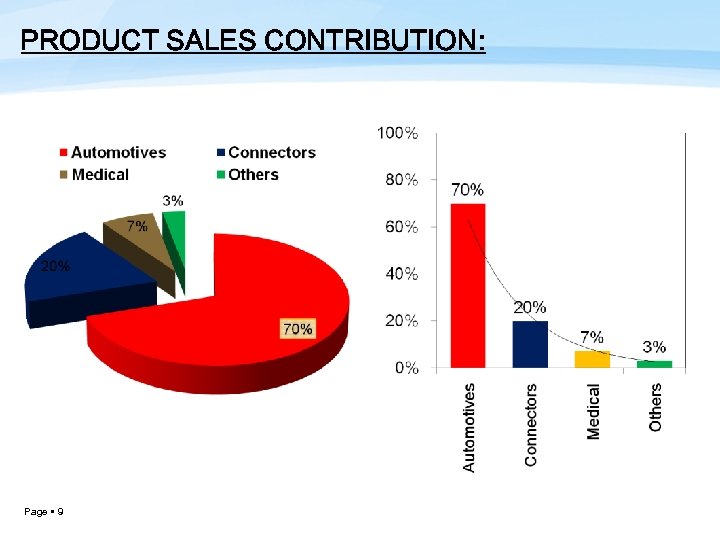

PRODUCT SALES CONTRIBUTION: Page 9

PRODUCT SALES CONTRIBUTION: Page 9

MAJOR CUSTOMERS: OEM’S Thru TIER 1 - AUTOMOTIVES Page 10

MAJOR CUSTOMERS: OEM’S Thru TIER 1 - AUTOMOTIVES Page 10

MAJOR CUSTOMERS: TIER 1 CUSTOMERS - AUTOMOTIVES Page 11

MAJOR CUSTOMERS: TIER 1 CUSTOMERS - AUTOMOTIVES Page 11

MAJOR CUSTOMERS: MEDICAL & ELECTRICAL SECTORS Page 12

MAJOR CUSTOMERS: MEDICAL & ELECTRICAL SECTORS Page 12

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - AUTOMOTIVES Page 13

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - AUTOMOTIVES Page 13

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - AUTOMOTIVES Page 14

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - AUTOMOTIVES Page 14

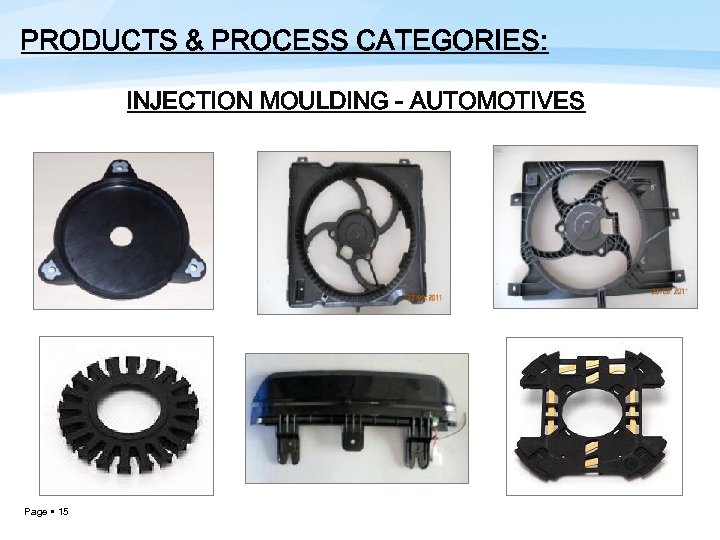

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - AUTOMOTIVES Page 15

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - AUTOMOTIVES Page 15

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - AUTOMOTIVES Page 16

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - AUTOMOTIVES Page 16

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - AUTOMOTIVES Page 17

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - AUTOMOTIVES Page 17

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - CONNECTORS Page 18

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - CONNECTORS Page 18

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - CONNECTORS Page 19

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - CONNECTORS Page 19

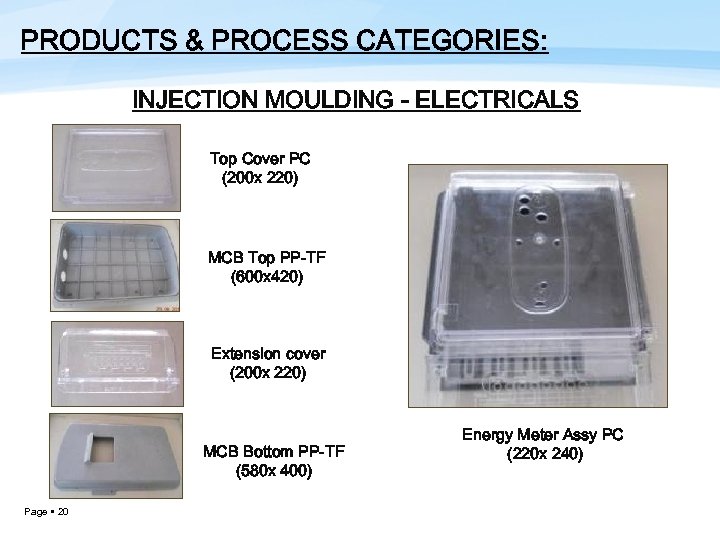

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - ELECTRICALS Top Cover PC (200 x 220) MCB Top PP-TF (600 x 420) Extension cover (200 x 220) MCB Bottom PP-TF (580 x 400) Page 20 Energy Meter Assy PC (220 x 240)

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - ELECTRICALS Top Cover PC (200 x 220) MCB Top PP-TF (600 x 420) Extension cover (200 x 220) MCB Bottom PP-TF (580 x 400) Page 20 Energy Meter Assy PC (220 x 240)

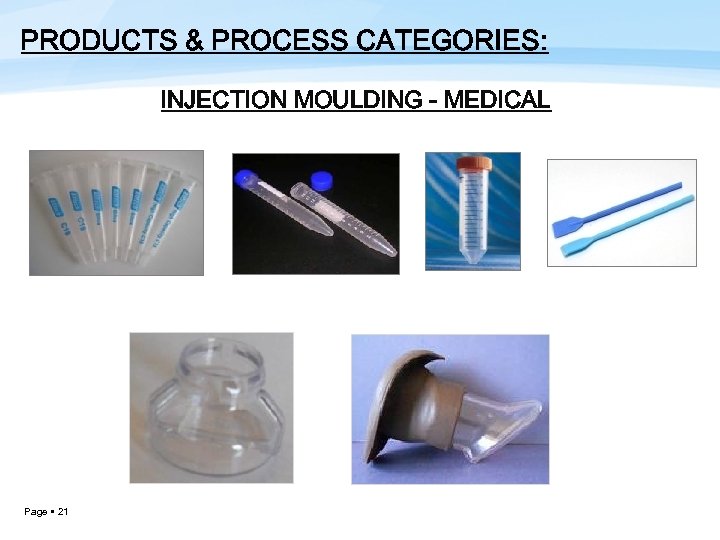

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - MEDICAL Page 21

PRODUCTS & PROCESS CATEGORIES: INJECTION MOULDING - MEDICAL Page 21

PAD PRINTING – AUTOMOTIVES / MEDICAL Parameter Cycles per hour Specification 1500 Strokes Print image size max Ø 55 mm – Ø 90 mm Cliché size Control Page 22 70 x 140 mm PLC

PAD PRINTING – AUTOMOTIVES / MEDICAL Parameter Cycles per hour Specification 1500 Strokes Print image size max Ø 55 mm – Ø 90 mm Cliché size Control Page 22 70 x 140 mm PLC

PRODUCTS & PROCESS CATEGORIES: PAD PRINTING – AUTOMOTIVES / MEDICAL PAD PRINTING MACHINE Page 23

PRODUCTS & PROCESS CATEGORIES: PAD PRINTING – AUTOMOTIVES / MEDICAL PAD PRINTING MACHINE Page 23

PRODUCTS & PROCESS CATEGORIES: SCREEN PRINTING – AUTOMOTIVES Page 24

PRODUCTS & PROCESS CATEGORIES: SCREEN PRINTING – AUTOMOTIVES Page 24

PAINT SHOP Page 25 25

PAINT SHOP Page 25 25

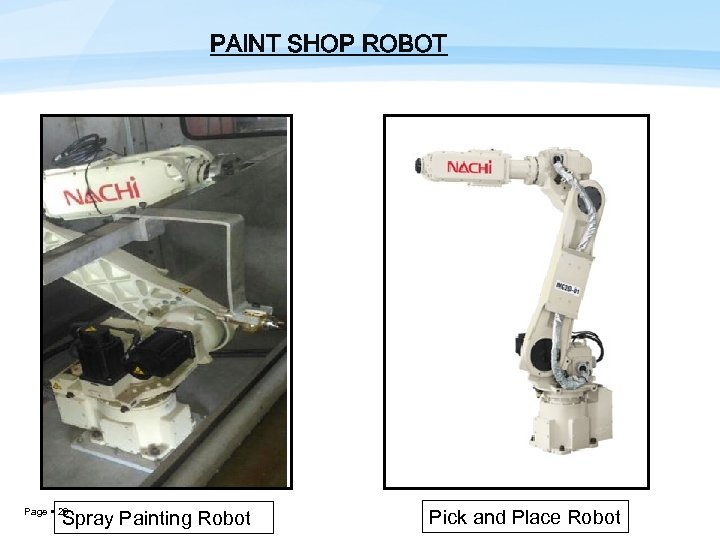

PAINT SHOP ROBOT Page 26 Spray Painting Robot Pick and Place Robot

PAINT SHOP ROBOT Page 26 Spray Painting Robot Pick and Place Robot

PAINT SHOP FLOOR VIEW Page 27

PAINT SHOP FLOOR VIEW Page 27

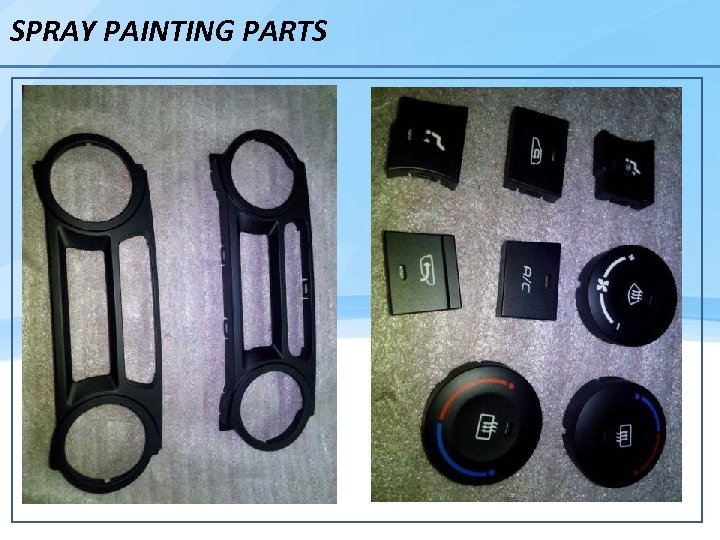

SPRAY PAINTING PARTS

SPRAY PAINTING PARTS

SPRAY PAINTING PARTS

SPRAY PAINTING PARTS

SPRAY PAINTING PARTS

SPRAY PAINTING PARTS

PAINT SHOP – QUALITY EQUIPMENTS FORD CUP LUX METER SPECTROMETER HYGROMETER DFT METER ANEMOMETER Page 31

PAINT SHOP – QUALITY EQUIPMENTS FORD CUP LUX METER SPECTROMETER HYGROMETER DFT METER ANEMOMETER Page 31

LASERETCHING – AUTOMOTIVES Parameter Marking Speed

LASERETCHING – AUTOMOTIVES Parameter Marking Speed

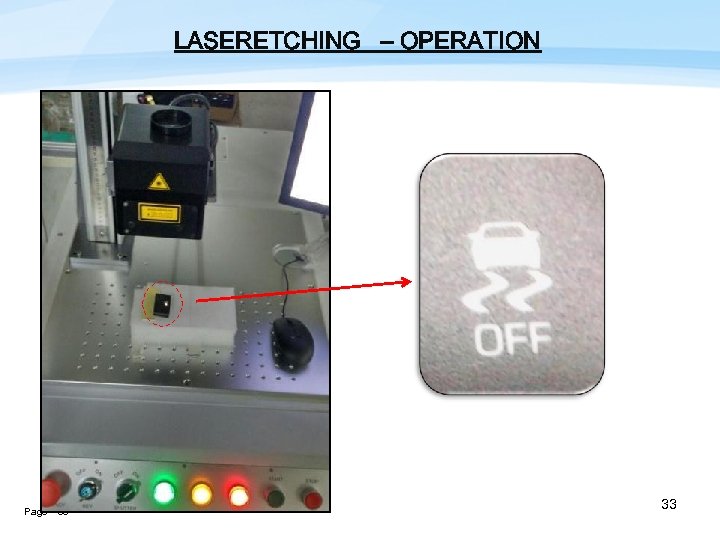

LASERETCHING – OPERATION Page 33 33

LASERETCHING – OPERATION Page 33 33