608780eafdc7a2ccd1019170d0611ffa.ppt

- Количество слайдов: 59

UNIT - IV TQM TOOLS

UNIT - IV TQM TOOLS

G N B H C N E A M I K R

G N B H C N E A M I K R

s. Un t. ZU, a Chinese general in 500 B. C. If you know your enemy and know yourself, you need not fear the results of a hundred battles. Japanese DANTOTSU word has the meaning of striving to be the ‘BEST OF BEST’. This is the essence of BENCHMARKING

s. Un t. ZU, a Chinese general in 500 B. C. If you know your enemy and know yourself, you need not fear the results of a hundred battles. Japanese DANTOTSU word has the meaning of striving to be the ‘BEST OF BEST’. This is the essence of BENCHMARKING

Bench Marking v. Benchmarking is a systematic method by which organization can measure themselves against the best industry practices. v. Essence of BM is the process of borrowing ideas and adapting them to gain competitive advantage.

Bench Marking v. Benchmarking is a systematic method by which organization can measure themselves against the best industry practices. v. Essence of BM is the process of borrowing ideas and adapting them to gain competitive advantage.

BM Defined Bench Mark is the systematic search for best practice, innovative ideas and highly effective operating procedure W. Edward Deming It is Hazard to copy. It is necessary to understand theory of what one wishes to do.

BM Defined Bench Mark is the systematic search for best practice, innovative ideas and highly effective operating procedure W. Edward Deming It is Hazard to copy. It is necessary to understand theory of what one wishes to do.

Definition By ROBERT CAMP “It is the search for the industry best practices that lead to superior performance.

Definition By ROBERT CAMP “It is the search for the industry best practices that lead to superior performance.

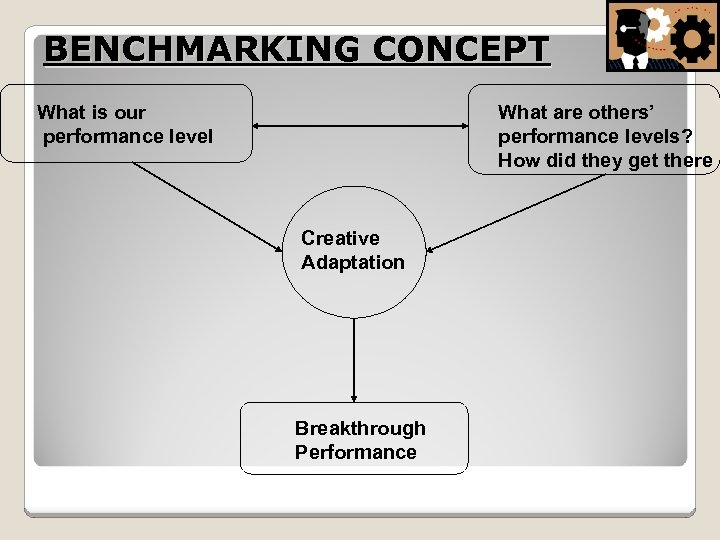

BENCHMARKING CONCEPT What is our performance level What are others’ performance levels? How did they get there Creative Adaptation Breakthrough Performance

BENCHMARKING CONCEPT What is our performance level What are others’ performance levels? How did they get there Creative Adaptation Breakthrough Performance

Reasons for Bench Marking To achieve Business & Competitive Objectives. Goals & Objectives Based on External Environment. Cost Efficient. Continuous Improvement & New Development.

Reasons for Bench Marking To achieve Business & Competitive Objectives. Goals & Objectives Based on External Environment. Cost Efficient. Continuous Improvement & New Development.

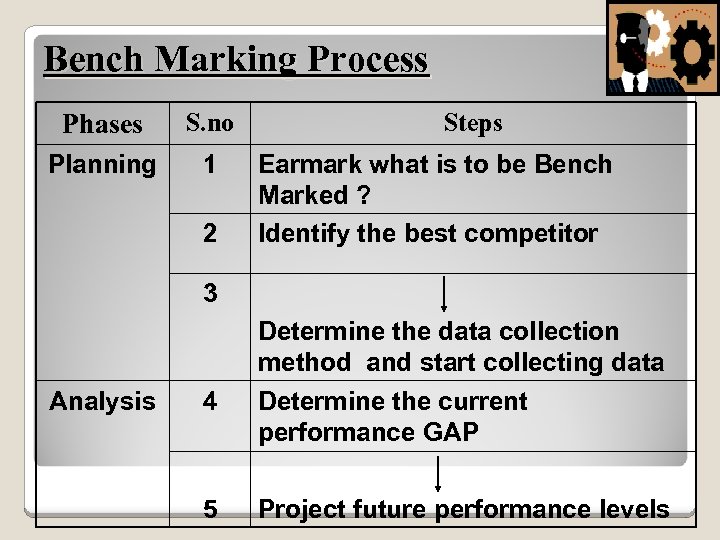

Bench Marking Process Phases S. no Planning 1 2 Steps Earmark what is to be Bench Marked ? Identify the best competitor 3 Analysis 4 5 Determine the data collection method and start collecting data Determine the current performance GAP Project future performance levels

Bench Marking Process Phases S. no Planning 1 2 Steps Earmark what is to be Bench Marked ? Identify the best competitor 3 Analysis 4 5 Determine the data collection method and start collecting data Determine the current performance GAP Project future performance levels

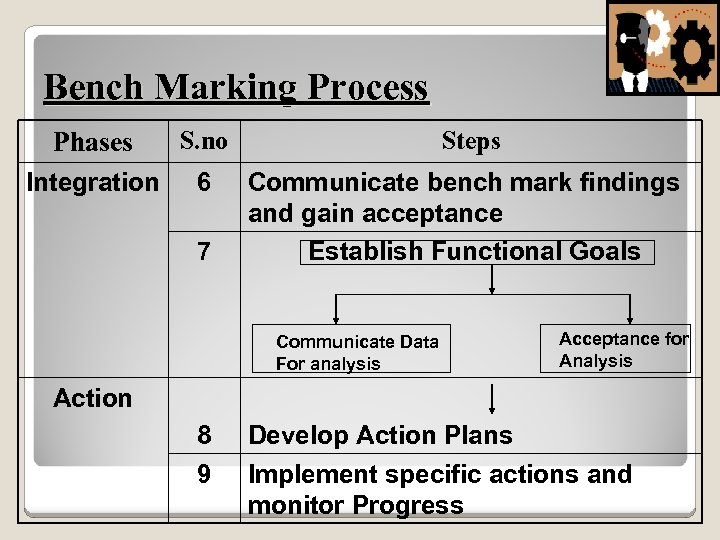

Bench Marking Process Phases S. no Steps Integration 6 Communicate bench mark findings and gain acceptance Establish Functional Goals 7 Communicate Data For analysis Acceptance for Analysis Action 8 9 Develop Action Plans Implement specific actions and monitor Progress

Bench Marking Process Phases S. no Steps Integration 6 Communicate bench mark findings and gain acceptance Establish Functional Goals 7 Communicate Data For analysis Acceptance for Analysis Action 8 9 Develop Action Plans Implement specific actions and monitor Progress

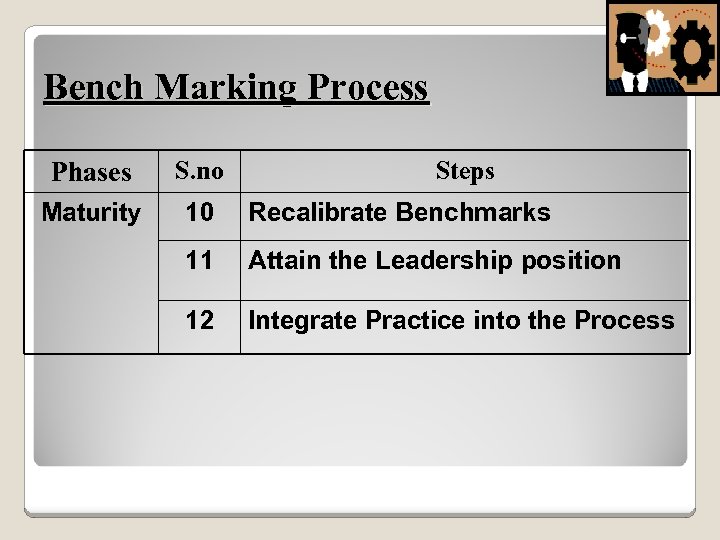

Bench Marking Process Phases S. no Steps Maturity 10 Recalibrate Benchmarks 11 Attain the Leadership position 12 Integrate Practice into the Process

Bench Marking Process Phases S. no Steps Maturity 10 Recalibrate Benchmarks 11 Attain the Leadership position 12 Integrate Practice into the Process

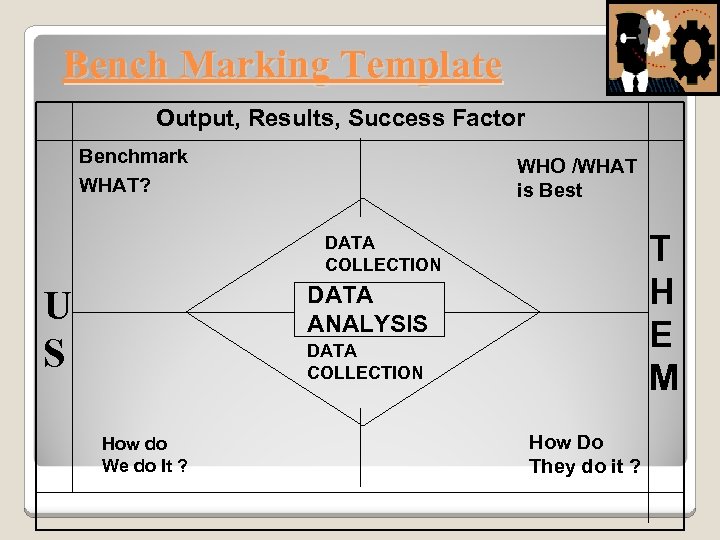

Bench Marking Template Output, Results, Success Factor Benchmark WHAT? WHO /WHAT is Best T H E M DATA COLLECTION DATA ANALYSIS U S DATA COLLECTION How do We do It ? How Do They do it ?

Bench Marking Template Output, Results, Success Factor Benchmark WHAT? WHO /WHAT is Best T H E M DATA COLLECTION DATA ANALYSIS U S DATA COLLECTION How do We do It ? How Do They do it ?

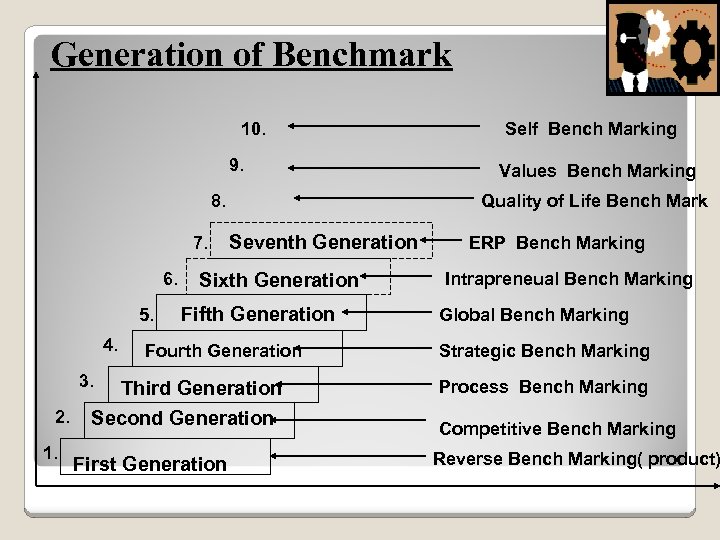

Generation of Benchmark 10. 9. 8. 7. 6. 5. 4. 2. 1. Seventh Generation Fifth Generation Fourth Generation Third Generation Second Generation First Generation Values Bench Marking Quality of Life Bench Mark Sixth Generation 3. Self Bench Marking ERP Bench Marking Intrapreneual Bench Marking Global Bench Marking Strategic Bench Marking Process Bench Marking Competitive Bench Marking Reverse Bench Marking( product)

Generation of Benchmark 10. 9. 8. 7. 6. 5. 4. 2. 1. Seventh Generation Fifth Generation Fourth Generation Third Generation Second Generation First Generation Values Bench Marking Quality of Life Bench Mark Sixth Generation 3. Self Bench Marking ERP Bench Marking Intrapreneual Bench Marking Global Bench Marking Strategic Bench Marking Process Bench Marking Competitive Bench Marking Reverse Bench Marking( product)

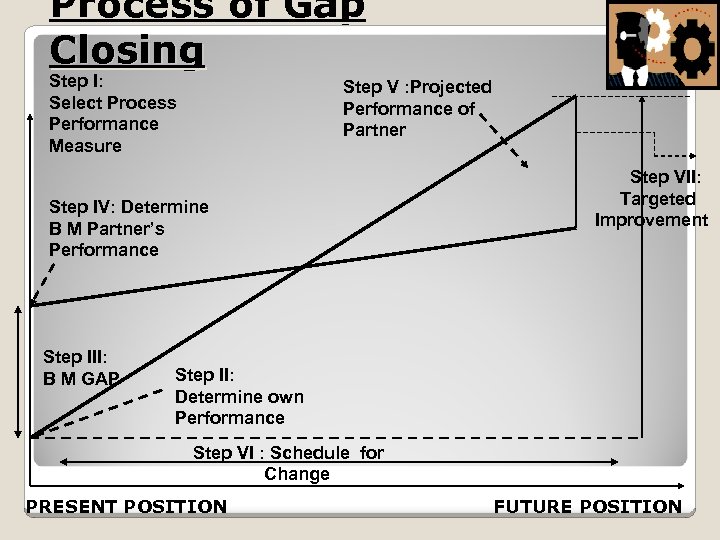

Process of Gap Closing Step I: Select Process Performance Measure Step V : Projected Performance of Partner Step IV: Determine B M Partner’s Performance Step III: B M GAP Step VII: Targeted Improvement Step II: Determine own Performance Step VI : Schedule for Change PRESENT POSITION FUTURE POSITION

Process of Gap Closing Step I: Select Process Performance Measure Step V : Projected Performance of Partner Step IV: Determine B M Partner’s Performance Step III: B M GAP Step VII: Targeted Improvement Step II: Determine own Performance Step VI : Schedule for Change PRESENT POSITION FUTURE POSITION

Reasons For Bench Mark v. Defining Customer Requirements v. Establish Goals and Objectives v. Measures of Productivity v. Becoming Competitive v. Industry best practices to be achieved

Reasons For Bench Mark v. Defining Customer Requirements v. Establish Goals and Objectives v. Measures of Productivity v. Becoming Competitive v. Industry best practices to be achieved

Types of Bench Mark v. Internal BM E. g. Eicher Tractor Comparison Between Units v. Competitive B M Direct Product Competitors v. Functional B M E. g. Best Logistics from same industries (or) Any industries v. Generic B M Same process or functions like Customer service, order entry, regardless of industries.

Types of Bench Mark v. Internal BM E. g. Eicher Tractor Comparison Between Units v. Competitive B M Direct Product Competitors v. Functional B M E. g. Best Logistics from same industries (or) Any industries v. Generic B M Same process or functions like Customer service, order entry, regardless of industries.

BENEFITS OF B M Best Practices incorporated into the process Motivation for creativity & innovation Technological Breakthrough in one’s industry Better professional growth Meet effectively customer requirements Assist in attaining competitive

BENEFITS OF B M Best Practices incorporated into the process Motivation for creativity & innovation Technological Breakthrough in one’s industry Better professional growth Meet effectively customer requirements Assist in attaining competitive

QUALITY F ON DEPLOYMENT

QUALITY F ON DEPLOYMENT

Dr. Yoji Akao, one of the founders of QFD "Time was when a man could order a pair of shoes directly from the cobbler. By measuring the foot himself and personally handling all aspects of manufacturing, the cobbler could assure the customer would be satisfied, ".

Dr. Yoji Akao, one of the founders of QFD "Time was when a man could order a pair of shoes directly from the cobbler. By measuring the foot himself and personally handling all aspects of manufacturing, the cobbler could assure the customer would be satisfied, ".

History of QFD was developed in Japan in the late 1960 s by Professors Shigeru Mizuno and Yoji Akao. At the time, statistical quality control, which was introduced after World War II, had taken roots in the Japanese manufacturing industry.

History of QFD was developed in Japan in the late 1960 s by Professors Shigeru Mizuno and Yoji Akao. At the time, statistical quality control, which was introduced after World War II, had taken roots in the Japanese manufacturing industry.

Once a team has identified the customers' Why use QFD? wants, QFD is used for two fundamental reasons: To improve the communication of customer wants throughout the organization. To improve the completeness of specifications and to make them traceable directly to customer wants and needs.

Once a team has identified the customers' Why use QFD? wants, QFD is used for two fundamental reasons: To improve the communication of customer wants throughout the organization. To improve the completeness of specifications and to make them traceable directly to customer wants and needs.

QFD links the needs of the customer (end user) with design, development, engineering, manufacturing, and service functions. QFD empowers organizations to exceed normal expectations and provide a level of unanticipated excitement that generates value. QFD means

QFD links the needs of the customer (end user) with design, development, engineering, manufacturing, and service functions. QFD empowers organizations to exceed normal expectations and provide a level of unanticipated excitement that generates value. QFD means

What is QFD? v. Quality Function Deployment (QFD) is a systematic process for motivating a business to focus on its customers. v. It is used by cross-functional teams to identify and resolve issues involve in providing products, processes, services and strategies which will more than satisfy their customers.

What is QFD? v. Quality Function Deployment (QFD) is a systematic process for motivating a business to focus on its customers. v. It is used by cross-functional teams to identify and resolve issues involve in providing products, processes, services and strategies which will more than satisfy their customers.

Understanding Customer Requirements What is QFD? Quality Systems Thinking + Psychology + Knowledge Maximizing Positive Quality That Adds Value Comprehensive Quality System for Customer Satisfaction Strategy to Stay Ahead of The Game

Understanding Customer Requirements What is QFD? Quality Systems Thinking + Psychology + Knowledge Maximizing Positive Quality That Adds Value Comprehensive Quality System for Customer Satisfaction Strategy to Stay Ahead of The Game

A team identified the following customer groups: Users who are mainly concerned with functionality. Management who is mainly concerned with financial and strategic issues. Distribution and Purchasing Agents who are concerned with purchase transaction and availability issues. Internal workers who are concerned with how the product will affect the quality of their work life.

A team identified the following customer groups: Users who are mainly concerned with functionality. Management who is mainly concerned with financial and strategic issues. Distribution and Purchasing Agents who are concerned with purchase transaction and availability issues. Internal workers who are concerned with how the product will affect the quality of their work life.

How do we capture our Customers' Requirements? One on one customer interviews Focus groups In-context customer visits

How do we capture our Customers' Requirements? One on one customer interviews Focus groups In-context customer visits

VOICE OF CUSTOMER What should we use to prioritize Requirements? Prioritizing Requirements Importance to the Customer Our Current Product Competitor One Competitor Two Our Future Product Improvement Factor Overall Importance Percent Importance

VOICE OF CUSTOMER What should we use to prioritize Requirements? Prioritizing Requirements Importance to the Customer Our Current Product Competitor One Competitor Two Our Future Product Improvement Factor Overall Importance Percent Importance

QFD is quite different in that it seeks out both "spoken" and "unspoken" customer requirements and maximizes "positive" quality (such as ease of use, fun, luxury) that creates value. How does QFD differ from other quality initiatives?

QFD is quite different in that it seeks out both "spoken" and "unspoken" customer requirements and maximizes "positive" quality (such as ease of use, fun, luxury) that creates value. How does QFD differ from other quality initiatives?

What are the characteristics of QFD as a quality system? QFD is a quality system that implements elements of Systems Thinking and Psychology of customer needs, what, and how end users become interested. QFD is a quality method of good Knowledge. QFD is a quality system for strategic competitiveness. Quality Function Deployment (QFD) is the only comprehensive quality system that satisfy the customer throughout the development and business process -- end to end.

What are the characteristics of QFD as a quality system? QFD is a quality system that implements elements of Systems Thinking and Psychology of customer needs, what, and how end users become interested. QFD is a quality method of good Knowledge. QFD is a quality system for strategic competitiveness. Quality Function Deployment (QFD) is the only comprehensive quality system that satisfy the customer throughout the development and business process -- end to end.

What are the tools of QFD? 7 Management and Planning Tools Which industry and business are using QFD? QFD has been applied in virtually every industry and business, from aerospace, manufacturing, software, communication, IT, chemical and pharmaceutical, transportation, defense, government, R&D, food to service industry. Why is a conventional design process not sufficient? Conventional design processes focus more on engineering capabilities and less on customer needs

What are the tools of QFD? 7 Management and Planning Tools Which industry and business are using QFD? QFD has been applied in virtually every industry and business, from aerospace, manufacturing, software, communication, IT, chemical and pharmaceutical, transportation, defense, government, R&D, food to service industry. Why is a conventional design process not sufficient? Conventional design processes focus more on engineering capabilities and less on customer needs

"Expected" quality or requirements are essentially basic functions or features that customers normally expect of a product or service. "Exciting" quality or requirements are sort of "out of ordinary" functions or features of a product or service that cause "wow" reactions in customers. What are "expected quality" and "exciting quality? "

"Expected" quality or requirements are essentially basic functions or features that customers normally expect of a product or service. "Exciting" quality or requirements are sort of "out of ordinary" functions or features of a product or service that cause "wow" reactions in customers. What are "expected quality" and "exciting quality? "

What is the House of Quality? The House of Quality is an assembly of Why it isn't a QFD? several deployment hierarchies and tables, including the Demanded Quality Hierarchy, Quality Characteristics Hierarchy, the relationships matrix, the Quality Planning Table, and Design Planning Table. It is a table that connects dots between the Voice of the Customer and the Voice of the Engine

What is the House of Quality? The House of Quality is an assembly of Why it isn't a QFD? several deployment hierarchies and tables, including the Demanded Quality Hierarchy, Quality Characteristics Hierarchy, the relationships matrix, the Quality Planning Table, and Design Planning Table. It is a table that connects dots between the Voice of the Customer and the Voice of the Engine

BENEFITS OF QFD Improves Customer Satisfaction Reduces Development Time Improves Team Work Reduces Cost Quick New Product Release Documentation Critical Quality Features Right Technology

BENEFITS OF QFD Improves Customer Satisfaction Reduces Development Time Improves Team Work Reduces Cost Quick New Product Release Documentation Critical Quality Features Right Technology

Genichi Taguchi TAGUCHI’S QUALITY LOSS FUNCTION

Genichi Taguchi TAGUCHI’S QUALITY LOSS FUNCTION

INTRODUCTION Taguchi Methods is a statistical methods developed largely by GENICHI TAGUCHI to improve quality of manufactured goods. The philosophy of off-line quality control. Innovations in the design of experiments.

INTRODUCTION Taguchi Methods is a statistical methods developed largely by GENICHI TAGUCHI to improve quality of manufactured goods. The philosophy of off-line quality control. Innovations in the design of experiments.

Taguchi defines Quality as “the loss imparted by the Taguchi Loss Function Definition product to society from the time the product is shipped. ” LOSS = Cost to operate, Failure to function, maintenance and repair cost, customer satisfaction, poor design. Product to be produced “being within specification”

Taguchi defines Quality as “the loss imparted by the Taguchi Loss Function Definition product to society from the time the product is shipped. ” LOSS = Cost to operate, Failure to function, maintenance and repair cost, customer satisfaction, poor design. Product to be produced “being within specification”

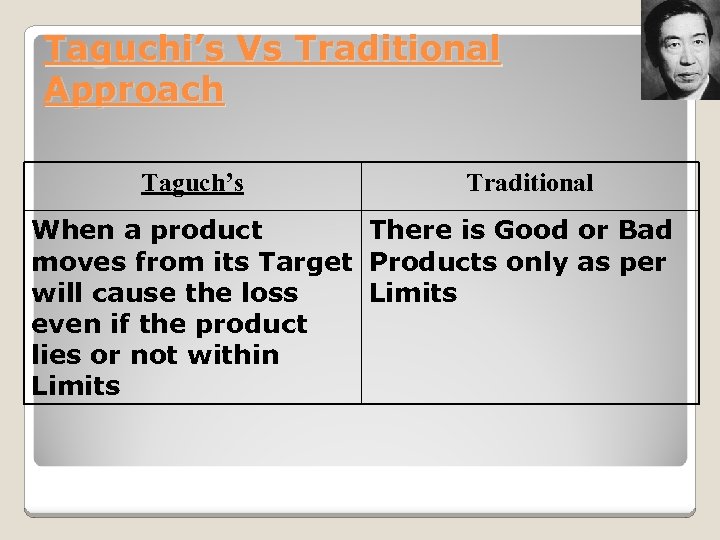

Taguchi’s Vs Traditional Approach Taguch’s Traditional When a product There is Good or Bad moves from its Target Products only as per will cause the loss Limits even if the product lies or not within Limits

Taguchi’s Vs Traditional Approach Taguch’s Traditional When a product There is Good or Bad moves from its Target Products only as per will cause the loss Limits even if the product lies or not within Limits

Taguchi’s Quadratic Quality Loss Function Quality Loss Occurs when a product’s deviates from target or nominal value. Deviation Grows, then Loss increases. Taguchi’s U-shaped loss Function Curve.

Taguchi’s Quadratic Quality Loss Function Quality Loss Occurs when a product’s deviates from target or nominal value. Deviation Grows, then Loss increases. Taguchi’s U-shaped loss Function Curve.

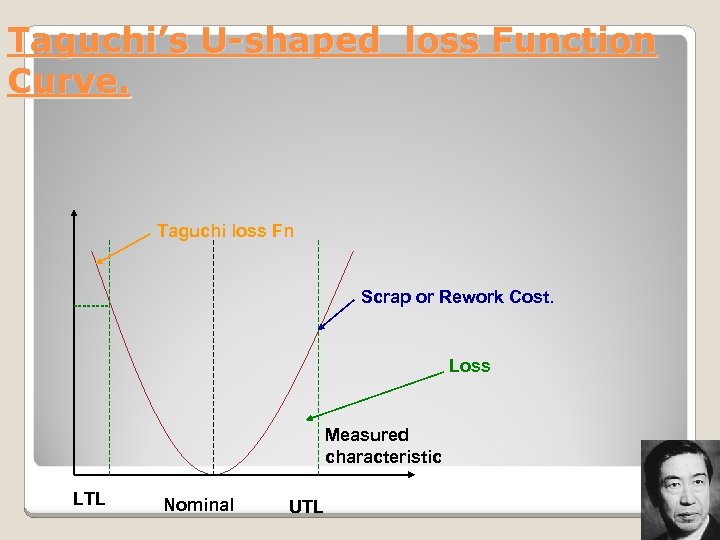

Taguchi’s U-shaped loss Function Curve. Taguchi loss Fn Scrap or Rework Cost. Loss Measured characteristic LTL Nominal UTL

Taguchi’s U-shaped loss Function Curve. Taguchi loss Fn Scrap or Rework Cost. Loss Measured characteristic LTL Nominal UTL

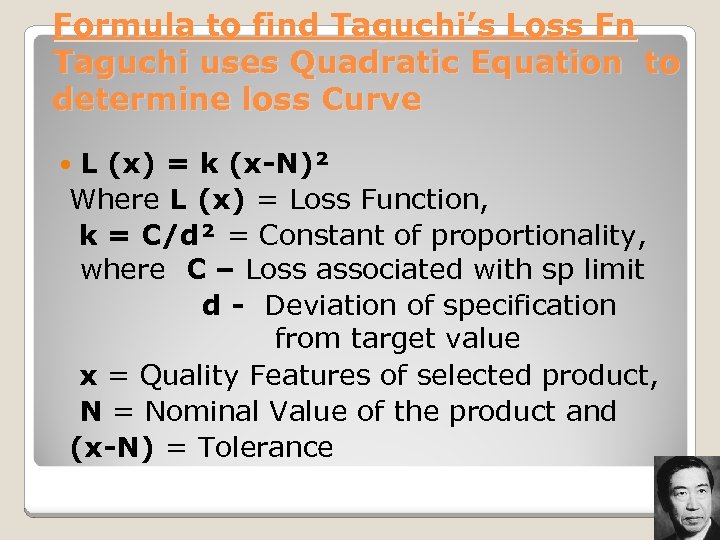

Formula to find Taguchi’s Loss Fn Taguchi uses Quadratic Equation to determine loss Curve L (x) = k (x-N)² Where L (x) = Loss Function, k = C/d² = Constant of proportionality, where C – Loss associated with sp limit d - Deviation of specification from target value x = Quality Features of selected product, N = Nominal Value of the product and (x-N) = Tolerance

Formula to find Taguchi’s Loss Fn Taguchi uses Quadratic Equation to determine loss Curve L (x) = k (x-N)² Where L (x) = Loss Function, k = C/d² = Constant of proportionality, where C – Loss associated with sp limit d - Deviation of specification from target value x = Quality Features of selected product, N = Nominal Value of the product and (x-N) = Tolerance

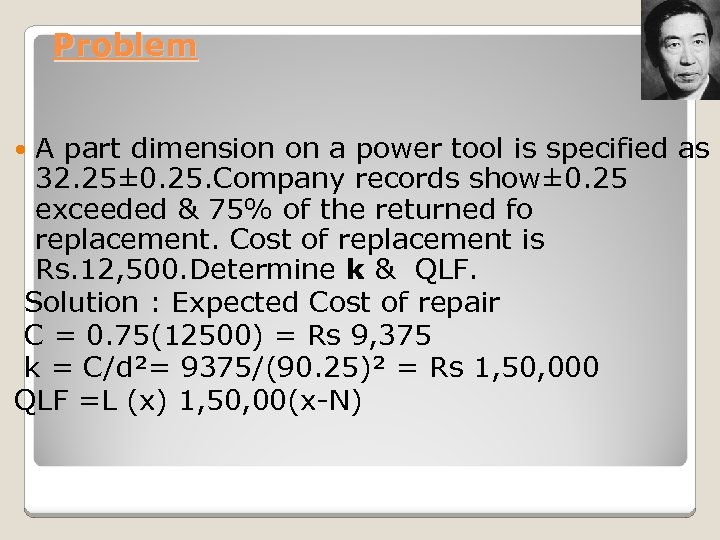

Problem A part dimension on a power tool is specified as 32. 25± 0. 25. Company records show± 0. 25 exceeded & 75% of the returned fo replacement. Cost of replacement is Rs. 12, 500. Determine k & QLF. Solution : Expected Cost of repair C = 0. 75(12500) = Rs 9, 375 k = C/d²= 9375/(90. 25)² = Rs 1, 50, 000 QLF =L (x) 1, 50, 00(x-N)

Problem A part dimension on a power tool is specified as 32. 25± 0. 25. Company records show± 0. 25 exceeded & 75% of the returned fo replacement. Cost of replacement is Rs. 12, 500. Determine k & QLF. Solution : Expected Cost of repair C = 0. 75(12500) = Rs 9, 375 k = C/d²= 9375/(90. 25)² = Rs 1, 50, 000 QLF =L (x) 1, 50, 00(x-N)

l a i. Ve t t o C t e U an. C d n o e r t P n i a M

l a i. Ve t t o C t e U an. C d n o e r t P n i a M

definition q. Maintenance is defined as the management, control, execution and quality assurance of activities which ensure the achievement of optimum availability and performance of a plant in order to meet business objectives.

definition q. Maintenance is defined as the management, control, execution and quality assurance of activities which ensure the achievement of optimum availability and performance of a plant in order to meet business objectives.

t. PM - Meaning TPM is a partnership between the maintenance and production organization to improve product quality, reduce waste, reduce cost, increase equipment availability and improve maintenance state.

t. PM - Meaning TPM is a partnership between the maintenance and production organization to improve product quality, reduce waste, reduce cost, increase equipment availability and improve maintenance state.

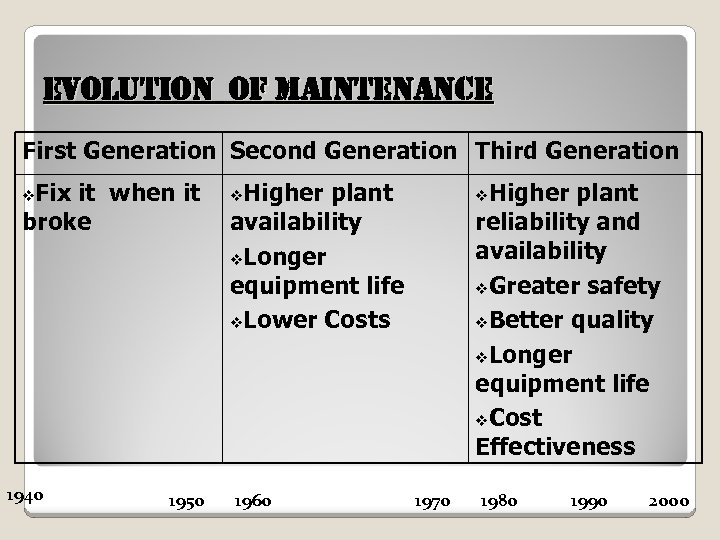

e. Vol. Ution of Maintenan. Ce First Generation Second Generation Third Generation Fix it when it broke v 1940 1950 Higher plant availability v. Longer equipment life v. Lower Costs Higher plant reliability and availability v. Greater safety v. Better quality v. Longer equipment life v. Cost Effectiveness v 1960 v 1970 1980 1990 2000

e. Vol. Ution of Maintenan. Ce First Generation Second Generation Third Generation Fix it when it broke v 1940 1950 Higher plant availability v. Longer equipment life v. Lower Costs Higher plant reliability and availability v. Greater safety v. Better quality v. Longer equipment life v. Cost Effectiveness v 1960 v 1970 1980 1990 2000

t. YPes of Maintenan. Ce q. Corrective (or) breakdown maintenance It implies that repairs are made after failure of machine or equipment q. Scheduled (or) Routine maintenance It is a stitch-in-time procedure aimed to avoiding breakdowns

t. YPes of Maintenan. Ce q. Corrective (or) breakdown maintenance It implies that repairs are made after failure of machine or equipment q. Scheduled (or) Routine maintenance It is a stitch-in-time procedure aimed to avoiding breakdowns

t. YPes of Maintenan. Ce q. Preventive maintenance It is carried out before the failure arises (or) prior to the equipment actually breakdowns. E. g. Overhauling & Periodic upkeep. q. Predictive maintenance Equipment Condition evaluated periodically and maintenance carried out.

t. YPes of Maintenan. Ce q. Preventive maintenance It is carried out before the failure arises (or) prior to the equipment actually breakdowns. E. g. Overhauling & Periodic upkeep. q. Predictive maintenance Equipment Condition evaluated periodically and maintenance carried out.

o. BJe. Cti. Ves of t. PM Improve Equipment Effectiveness Achieve Autonomous Plan Maintenance To Train all staff in maintenance skills To Zero Breakdowns

o. BJe. Cti. Ves of t. PM Improve Equipment Effectiveness Achieve Autonomous Plan Maintenance To Train all staff in maintenance skills To Zero Breakdowns

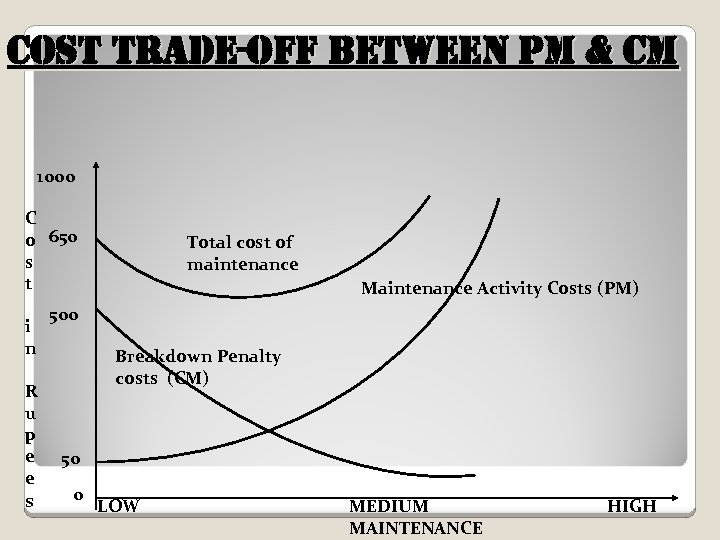

Cost trade-off Between PM & CM 1000 C o 650 s t i n R u p e e s Total cost of maintenance Maintenance Activity Costs (PM) 500 Breakdown Penalty costs (CM) 50 0 LOW MEDIUM MAINTENANCE HIGH

Cost trade-off Between PM & CM 1000 C o 650 s t i n R u p e e s Total cost of maintenance Maintenance Activity Costs (PM) 500 Breakdown Penalty costs (CM) 50 0 LOW MEDIUM MAINTENANCE HIGH

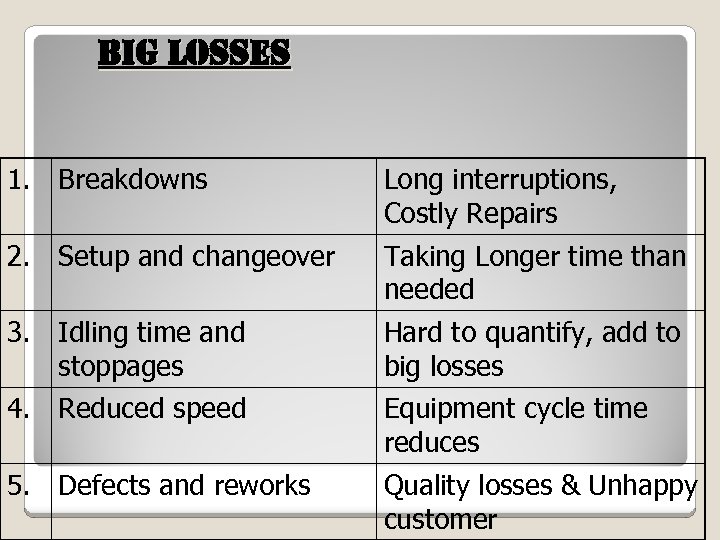

Big losses 1. Breakdowns Long interruptions, Costly Repairs 2. Setup and changeover Taking Longer time than needed 3. Idling time and stoppages Hard to quantify, add to big losses 4. Reduced speed Equipment cycle time reduces 5. Defects and reworks Quality losses & Unhappy customer

Big losses 1. Breakdowns Long interruptions, Costly Repairs 2. Setup and changeover Taking Longer time than needed 3. Idling time and stoppages Hard to quantify, add to big losses 4. Reduced speed Equipment cycle time reduces 5. Defects and reworks Quality losses & Unhappy customer

Benefits v. Increased productivity v. Equipment reliability v. Reduced down time v. Increased plant capacity v. Low production maintenance costs v. Team work Between Production & Maintenance People v. Improved safety & Profit

Benefits v. Increased productivity v. Equipment reliability v. Reduced down time v. Increased plant capacity v. Low production maintenance costs v. Team work Between Production & Maintenance People v. Improved safety & Profit

FAILURE MODE EFFECTIVE ANALYSIS

FAILURE MODE EFFECTIVE ANALYSIS

Introduction Failure Mode Effect Analysis is an analytical technique that goes in for combining Technology and Experience of people to identify foreseen failures in a product or process and planning to eliminate the Failure. Definition FMEA is a group of activities to understand evaluate potential failure of product or process and its effects, and identify actions that eliminate or reduce the potential failures.

Introduction Failure Mode Effect Analysis is an analytical technique that goes in for combining Technology and Experience of people to identify foreseen failures in a product or process and planning to eliminate the Failure. Definition FMEA is a group of activities to understand evaluate potential failure of product or process and its effects, and identify actions that eliminate or reduce the potential failures.

Types of FMEA Major Classification Design FMEA Process FMEA Sub Classification Equipment FMEA Maintenance FMEA Service FMEA System FMEA

Types of FMEA Major Classification Design FMEA Process FMEA Sub Classification Equipment FMEA Maintenance FMEA Service FMEA System FMEA

DESIGN FMEA Design FMEA use in the design process by identifying known and foreseeable failures modes and ranking failures according to their impact on the product.

DESIGN FMEA Design FMEA use in the design process by identifying known and foreseeable failures modes and ranking failures according to their impact on the product.

PROCESS FMEA It is used to identify potential process failure modes by ranking failures and establishing priorities, and its impact on the Internal or external customers.

PROCESS FMEA It is used to identify potential process failure modes by ranking failures and establishing priorities, and its impact on the Internal or external customers.

RELIABILITY Reliability is defined as the probability that the product will perform as per the expectation for a certain period of time, under the given operating conditions, and the given set of product performance characteristics. The part, assembly, or process under consideration, the reliability of each sub system and factors that contribute to failure to be found.

RELIABILITY Reliability is defined as the probability that the product will perform as per the expectation for a certain period of time, under the given operating conditions, and the given set of product performance characteristics. The part, assembly, or process under consideration, the reliability of each sub system and factors that contribute to failure to be found.

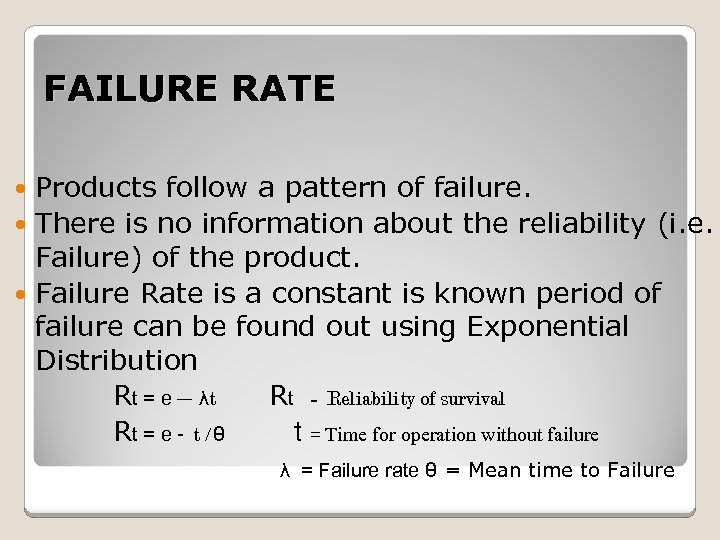

FAILURE RATE Products follow a pattern of failure. There is no information about the reliability (i. e. Failure) of the product. Failure Rate is a constant is known period of failure can be found out using Exponential Distribution Rt = e – λt Rt = Reliability of survival Rt = e - t / θ t = Time for operation without failure λ = Failure rate θ = Mean time to Failure

FAILURE RATE Products follow a pattern of failure. There is no information about the reliability (i. e. Failure) of the product. Failure Rate is a constant is known period of failure can be found out using Exponential Distribution Rt = e – λt Rt = Reliability of survival Rt = e - t / θ t = Time for operation without failure λ = Failure rate θ = Mean time to Failure

Failure Rate λ =. 0002 per hour PROBLEM What is the probability that it will survive or reliable during the first 200 hours of operations? Solution Rt = e – λt = e – (200) (0. 0002) = 96. 08 %

Failure Rate λ =. 0002 per hour PROBLEM What is the probability that it will survive or reliable during the first 200 hours of operations? Solution Rt = e – λt = e – (200) (0. 0002) = 96. 08 %