21cd139518238fb18bf1192d25b0c511.ppt

- Количество слайдов: 30

Unit 8. Eco-selection: environmentally informed material choice New approaches to Materials Education a course authored by Mike Ashby and David. Cebon, Cambridge, UK, 2007 © MFA and DC 2007

Unit 8. Eco-selection: environmentally informed material choice New approaches to Materials Education a course authored by Mike Ashby and David. Cebon, Cambridge, UK, 2007 © MFA and DC 2007

Outline l Material consumption and the material life-cycle l LCA, problems and solutions l Analysis of products l Strategy for materials selection l Exercises More info: § “Materials: engineering, science, processing and design”, Chapter 20 § “Materials Selection in Mechanical Design”, Chapter 16 © MFA and DC 2007

Outline l Material consumption and the material life-cycle l LCA, problems and solutions l Analysis of products l Strategy for materials selection l Exercises More info: § “Materials: engineering, science, processing and design”, Chapter 20 § “Materials Selection in Mechanical Design”, Chapter 16 © MFA and DC 2007

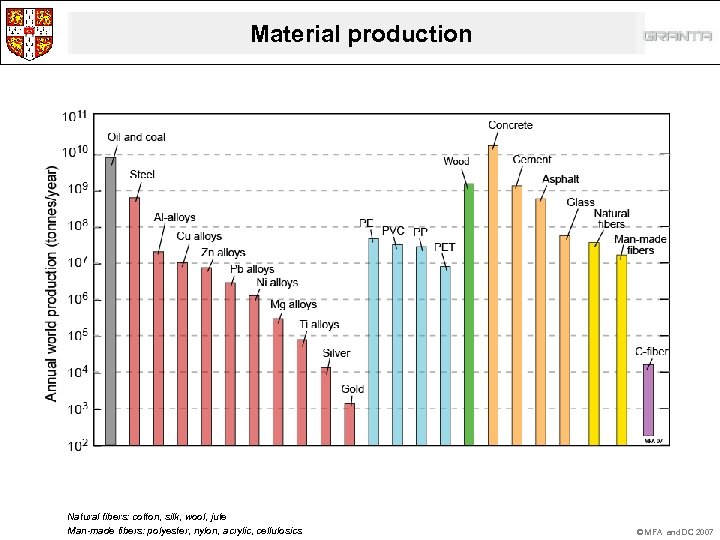

Material production Natural fibers: cotton, silk, wool, jute Man-made fibers: polyester, nylon, acrylic, cellulosics © MFA and DC 2007

Material production Natural fibers: cotton, silk, wool, jute Man-made fibers: polyester, nylon, acrylic, cellulosics © MFA and DC 2007

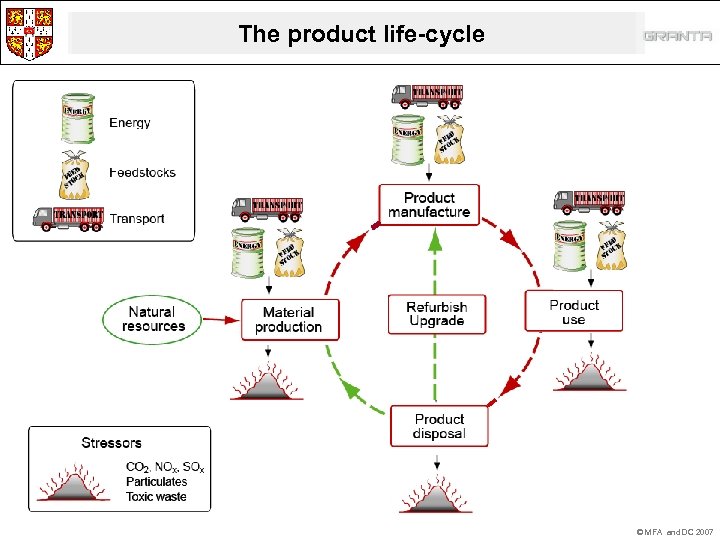

The product life-cycle © MFA and DC 2007

The product life-cycle © MFA and DC 2007

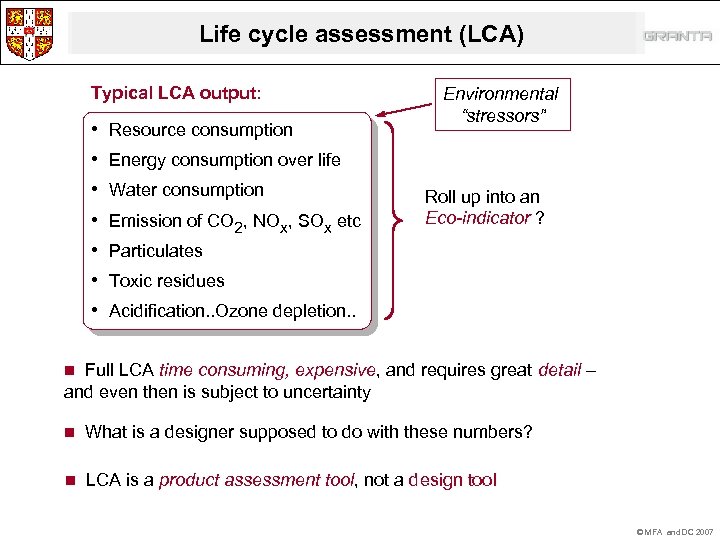

Life cycle assessment (LCA) Typical LCA output: • • Resource consumption Environmental “stressors” Energy consumption over life Water consumption Emission of CO 2, NOx, SOx etc Roll up into an Eco-indicator ? Particulates Toxic residues Acidification. . Ozone depletion. . Full LCA time consuming, expensive, and requires great detail – and even then is subject to uncertainty n n What is a designer supposed to do with these numbers? n LCA is a product assessment tool, not a design tool © MFA and DC 2007

Life cycle assessment (LCA) Typical LCA output: • • Resource consumption Environmental “stressors” Energy consumption over life Water consumption Emission of CO 2, NOx, SOx etc Roll up into an Eco-indicator ? Particulates Toxic residues Acidification. . Ozone depletion. . Full LCA time consuming, expensive, and requires great detail – and even then is subject to uncertainty n n What is a designer supposed to do with these numbers? n LCA is a product assessment tool, not a design tool © MFA and DC 2007

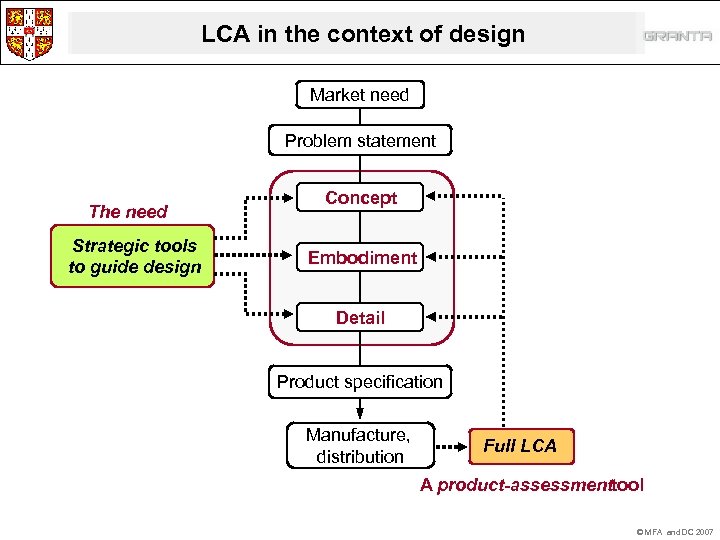

LCA in the context of design Market need Problem statement The need Strategic tools to guide design Concept Embodiment Detail Product specification Manufacture, distribution Full LCA A product-assessmenttool © MFA and DC 2007

LCA in the context of design Market need Problem statement The need Strategic tools to guide design Concept Embodiment Detail Product specification Manufacture, distribution Full LCA A product-assessmenttool © MFA and DC 2007

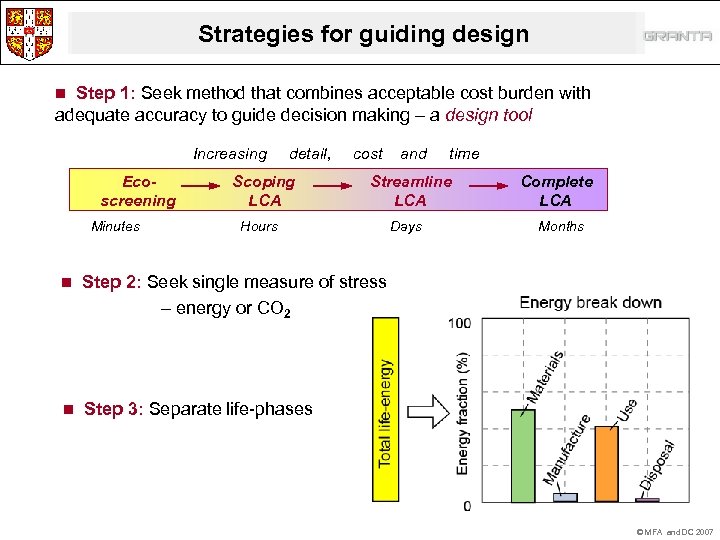

Strategies for guiding design Step 1: Seek method that combines acceptable cost burden with adequate accuracy to guide decision making – a design tool n Increasing Ecoscreening Minutes detail, Scoping LCA cost and time Streamline LCA Hours n Months Step 2: Seek single measure of stress – energy or CO 2 n Days Complete LCA Step 3: Separate life-phases © MFA and DC 2007

Strategies for guiding design Step 1: Seek method that combines acceptable cost burden with adequate accuracy to guide decision making – a design tool n Increasing Ecoscreening Minutes detail, Scoping LCA cost and time Streamline LCA Hours n Months Step 2: Seek single measure of stress – energy or CO 2 n Days Complete LCA Step 3: Separate life-phases © MFA and DC 2007

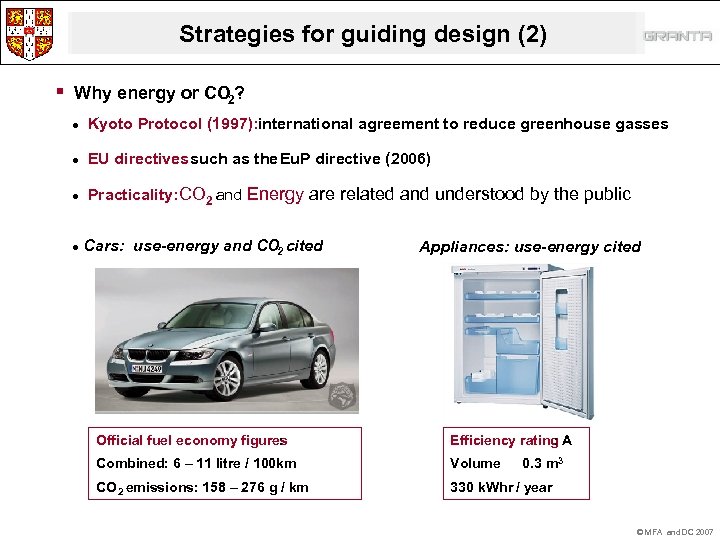

Strategies for guiding design (2) § Why energy or CO 2? l Kyoto Protocol (1997): international agreement to reduce greenhouse gasses l EU directives such as the Eu. P directive (2006) l Practicality: CO 2 and Energy are related and understood by the public l Cars: use-energy and CO 2 cited Appliances: use-energy cited Official fuel economy figures : Efficiency rating A : Combined: 6 – 11 litre / 100 km Volume CO 2 emissions: 158 – 276 g / km 330 k. Whr / year 0. 3 m 3 © MFA and DC 2007

Strategies for guiding design (2) § Why energy or CO 2? l Kyoto Protocol (1997): international agreement to reduce greenhouse gasses l EU directives such as the Eu. P directive (2006) l Practicality: CO 2 and Energy are related and understood by the public l Cars: use-energy and CO 2 cited Appliances: use-energy cited Official fuel economy figures : Efficiency rating A : Combined: 6 – 11 litre / 100 km Volume CO 2 emissions: 158 – 276 g / km 330 k. Whr / year 0. 3 m 3 © MFA and DC 2007

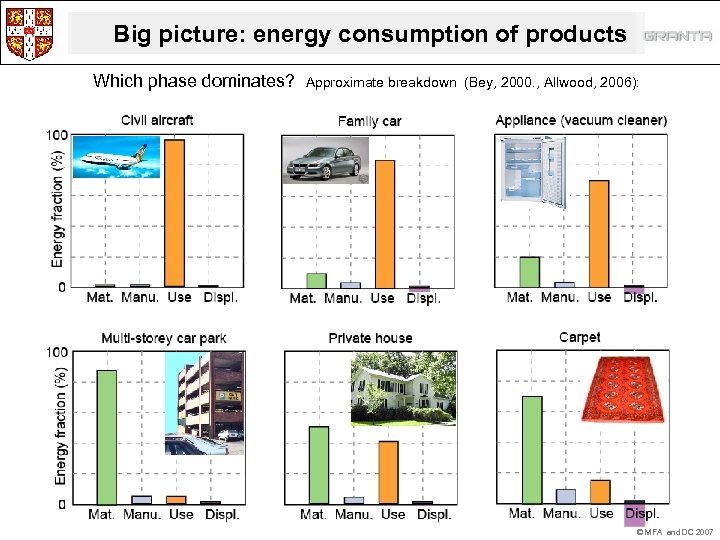

Big picture: energy consumption of products Which phase dominates? Approximate breakdown (Bey, 2000. , Allwood, 2006): © MFA and DC 2007

Big picture: energy consumption of products Which phase dominates? Approximate breakdown (Bey, 2000. , Allwood, 2006): © MFA and DC 2007

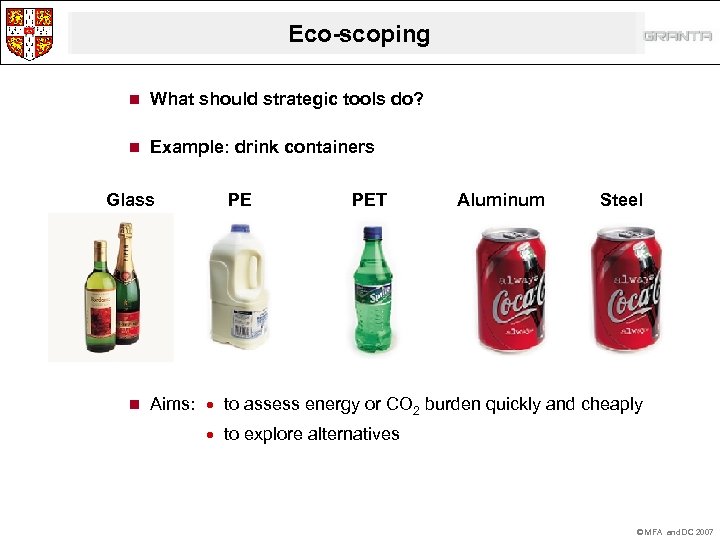

Eco-scoping n What should strategic tools do? n Example: drink containers Glass n PE PET Aluminum Steel Aims: to assess energy or CO 2 burden quickly and cheaply to explore alternatives © MFA and DC 2007

Eco-scoping n What should strategic tools do? n Example: drink containers Glass n PE PET Aluminum Steel Aims: to assess energy or CO 2 burden quickly and cheaply to explore alternatives © MFA and DC 2007

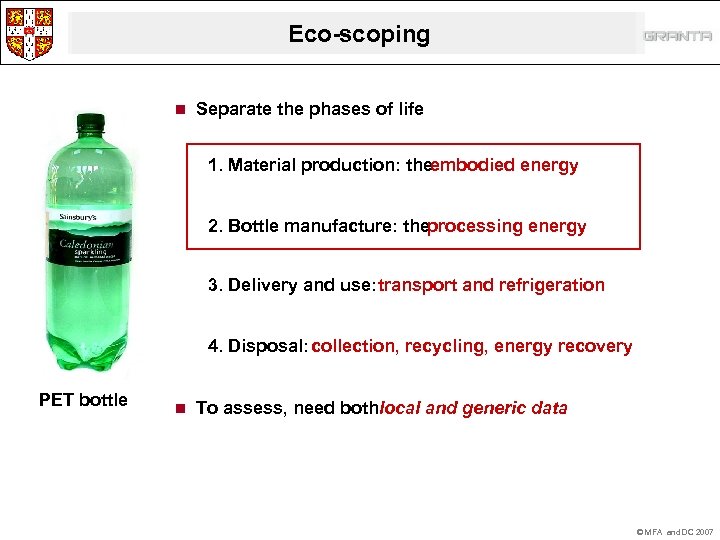

Eco-scoping n Separate the phases of life 1. Material production: theembodied energy 2. Bottle manufacture: theprocessing energy 3. Delivery and use: transport and refrigeration 4. Disposal: collection, recycling, energy recovery PET bottle n To assess, need bothlocal and generic data. © MFA and DC 2007

Eco-scoping n Separate the phases of life 1. Material production: theembodied energy 2. Bottle manufacture: theprocessing energy 3. Delivery and use: transport and refrigeration 4. Disposal: collection, recycling, energy recovery PET bottle n To assess, need bothlocal and generic data. © MFA and DC 2007

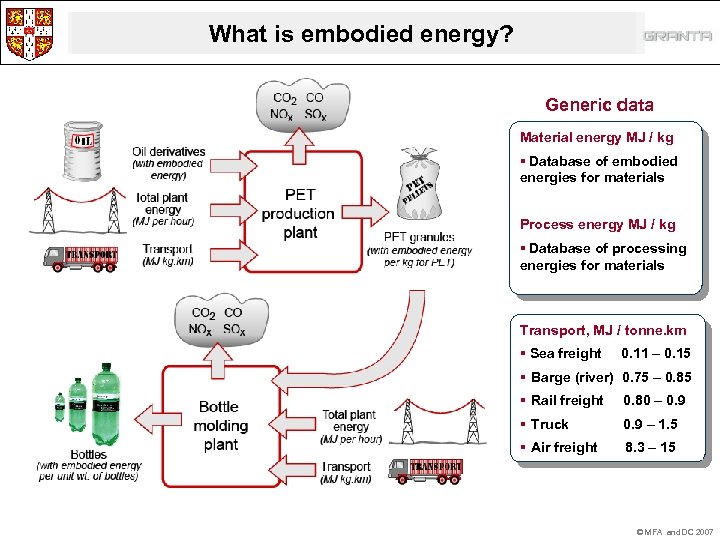

What is embodied energy? Generic data Material energy MJ / kg § Database of embodied energies for materials Process energy MJ / kg § Database of processing energies for materials Transport, MJ / tonne. km § Sea freight 0. 11 – 0. 15 § Barge (river) 0. 75 – 0. 85 § Rail freight 0. 80 – 0. 9 § Truck 0. 9 – 1. 5 § Air freight 8. 3 – 15 © MFA and DC 2007

What is embodied energy? Generic data Material energy MJ / kg § Database of embodied energies for materials Process energy MJ / kg § Database of processing energies for materials Transport, MJ / tonne. km § Sea freight 0. 11 – 0. 15 § Barge (river) 0. 75 – 0. 85 § Rail freight 0. 80 – 0. 9 § Truck 0. 9 – 1. 5 § Air freight 8. 3 – 15 © MFA and DC 2007

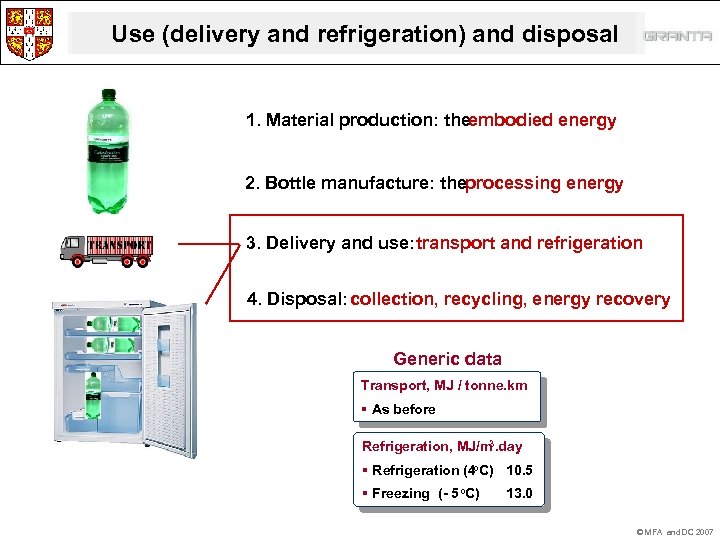

Use (delivery and refrigeration) and disposal 1. Material production: theembodied energy 2. Bottle manufacture: theprocessing energy 3. Delivery and use: transport and refrigeration 4. Disposal: collection, recycling, energy recovery Generic data Transport, MJ / tonne. km § As before 3 Refrigeration, MJ/m. day § Refrigeration (4 o. C) 10. 5 § Freezing (- 5 o. C) 13. 0 © MFA and DC 2007

Use (delivery and refrigeration) and disposal 1. Material production: theembodied energy 2. Bottle manufacture: theprocessing energy 3. Delivery and use: transport and refrigeration 4. Disposal: collection, recycling, energy recovery Generic data Transport, MJ / tonne. km § As before 3 Refrigeration, MJ/m. day § Refrigeration (4 o. C) 10. 5 § Freezing (- 5 o. C) 13. 0 © MFA and DC 2007

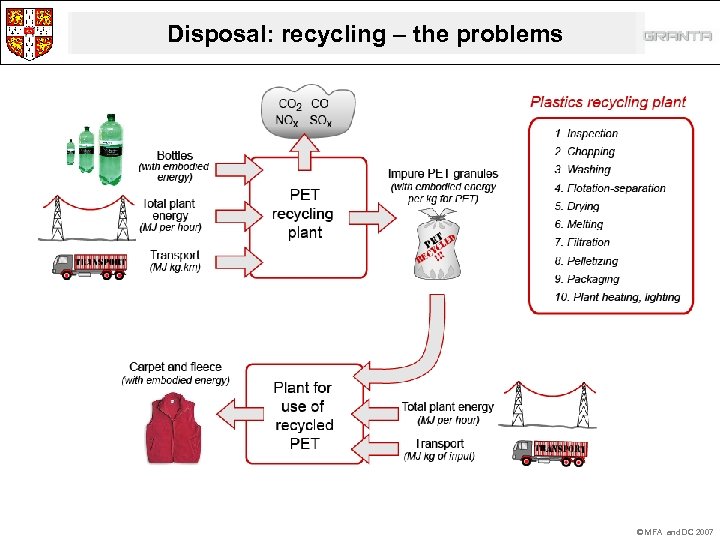

Disposal: recycling – the problems © MFA and DC 2007

Disposal: recycling – the problems © MFA and DC 2007

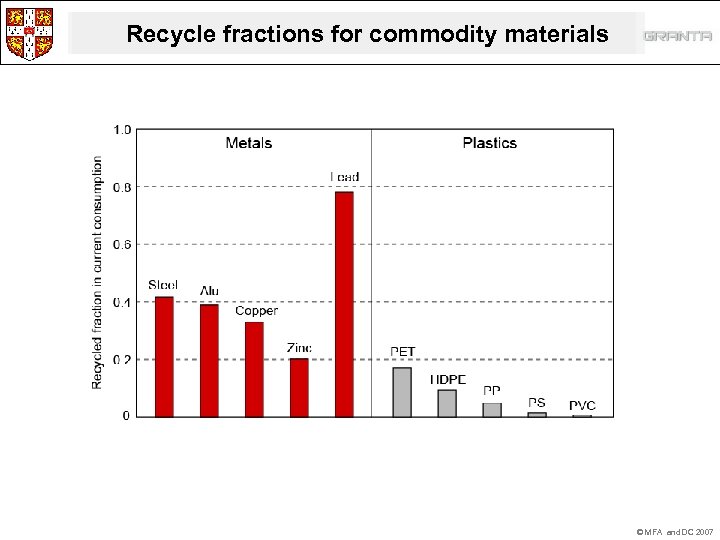

Recycle fractions for commodity materials © MFA and DC 2007

Recycle fractions for commodity materials © MFA and DC 2007

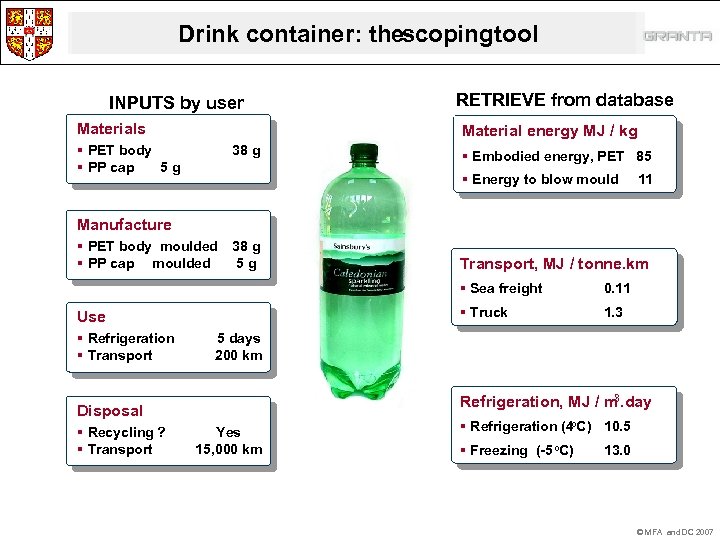

Drink container: thescoping tool INPUTS by user Materials § PET body § PP cap 5 g RETRIEVE from database Material energy MJ / kg 38 g § Embodied energy, PET 85 § Energy to blow mould 11 Manufacture § PET body moulded 38 g § PP cap moulded 5 g Transport, MJ / tonne. km § Sea freight § Truck Use § Refrigeration § Transport 1. 3 5 days 200 km 3 Refrigeration, MJ / m. day Disposal § Recycling ? § Transport 0. 11 Yes 15, 000 km § Refrigeration (4 o. C) 10. 5 § Freezing (-5 o. C) 13. 0 © MFA and DC 2007

Drink container: thescoping tool INPUTS by user Materials § PET body § PP cap 5 g RETRIEVE from database Material energy MJ / kg 38 g § Embodied energy, PET 85 § Energy to blow mould 11 Manufacture § PET body moulded 38 g § PP cap moulded 5 g Transport, MJ / tonne. km § Sea freight § Truck Use § Refrigeration § Transport 1. 3 5 days 200 km 3 Refrigeration, MJ / m. day Disposal § Recycling ? § Transport 0. 11 Yes 15, 000 km § Refrigeration (4 o. C) 10. 5 § Freezing (-5 o. C) 13. 0 © MFA and DC 2007

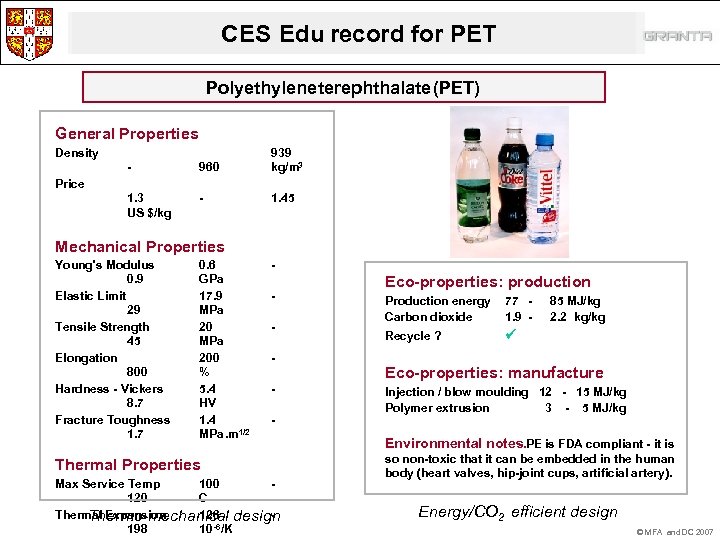

CES Edu record for PET Polyethylene terephthalate (PET) General Properties Density - 960 939 kg/m 3 1. 3 US $/kg - 1. 45 Price Mechanical Properties Young's Modulus 0. 9 Elastic Limit 29 Tensile Strength 45 Elongation 800 Hardness - Vickers 8. 7 Fracture Toughness 1. 7 0. 6 GPa 17. 9 MPa 200 % 5. 4 HV 1. 4 MPa. m 1/2 - Thermal Properties Max Service Temp 100 120 C Thermal Expansion 126 Thermo-mechanical design -6 /K 198 10 Eco-properties: production Production energy Carbon dioxide 77 1. 9 - Recycle ? 85 MJ/kg 2. 2 kg/kg Eco-properties: manufacture Injection / blow moulding 12 - 15 MJ/kg Polymer extrusion 3 - 5 MJ/kg Environmental notes. PE is FDA compliant - it is so non-toxic that it can be embedded in the human body (heart valves, hip-joint cups, artificial artery). Energy/CO 2 efficient design © MFA and DC 2007

CES Edu record for PET Polyethylene terephthalate (PET) General Properties Density - 960 939 kg/m 3 1. 3 US $/kg - 1. 45 Price Mechanical Properties Young's Modulus 0. 9 Elastic Limit 29 Tensile Strength 45 Elongation 800 Hardness - Vickers 8. 7 Fracture Toughness 1. 7 0. 6 GPa 17. 9 MPa 200 % 5. 4 HV 1. 4 MPa. m 1/2 - Thermal Properties Max Service Temp 100 120 C Thermal Expansion 126 Thermo-mechanical design -6 /K 198 10 Eco-properties: production Production energy Carbon dioxide 77 1. 9 - Recycle ? 85 MJ/kg 2. 2 kg/kg Eco-properties: manufacture Injection / blow moulding 12 - 15 MJ/kg Polymer extrusion 3 - 5 MJ/kg Environmental notes. PE is FDA compliant - it is so non-toxic that it can be embedded in the human body (heart valves, hip-joint cups, artificial artery). Energy/CO 2 efficient design © MFA and DC 2007

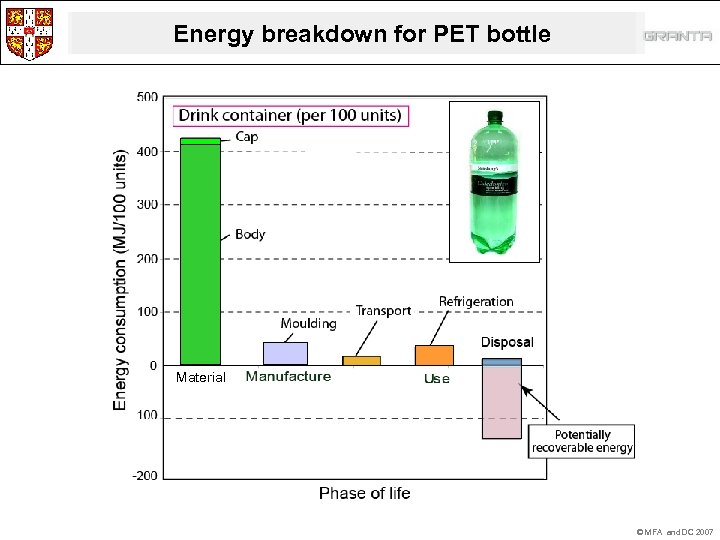

Energy breakdown for PET bottle Material © MFA and DC 2007

Energy breakdown for PET bottle Material © MFA and DC 2007

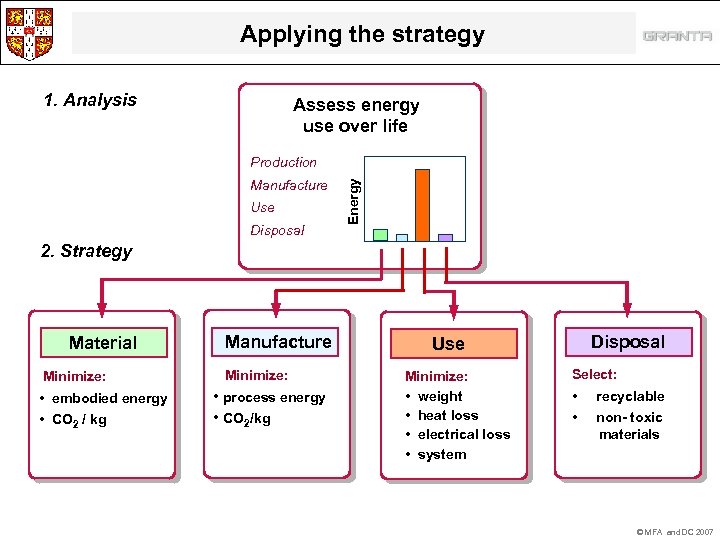

Applying the strategy 1. Analysis Assess energy use over life Manufacture Use Disposal Energy Production 2. Strategy Material Minimize: • embodied energy • CO 2 / kg Manufacture Minimize: • process energy • CO 2/kg Disposal Use Minimize: • weight • heat loss • electrical loss • system Select: • • recyclable non- toxic materials © MFA and DC 2007

Applying the strategy 1. Analysis Assess energy use over life Manufacture Use Disposal Energy Production 2. Strategy Material Minimize: • embodied energy • CO 2 / kg Manufacture Minimize: • process energy • CO 2/kg Disposal Use Minimize: • weight • heat loss • electrical loss • system Select: • • recyclable non- toxic materials © MFA and DC 2007

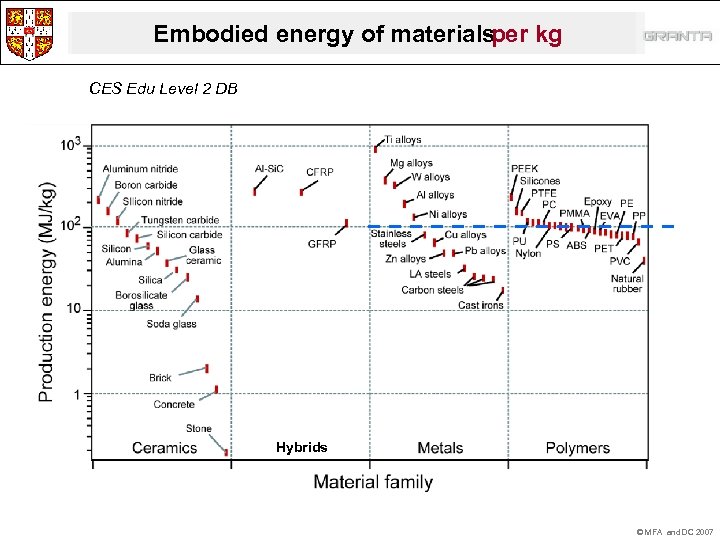

Embodied energy of materials per kg CES Edu Level 2 DB Hybrids © MFA and DC 2007

Embodied energy of materials per kg CES Edu Level 2 DB Hybrids © MFA and DC 2007

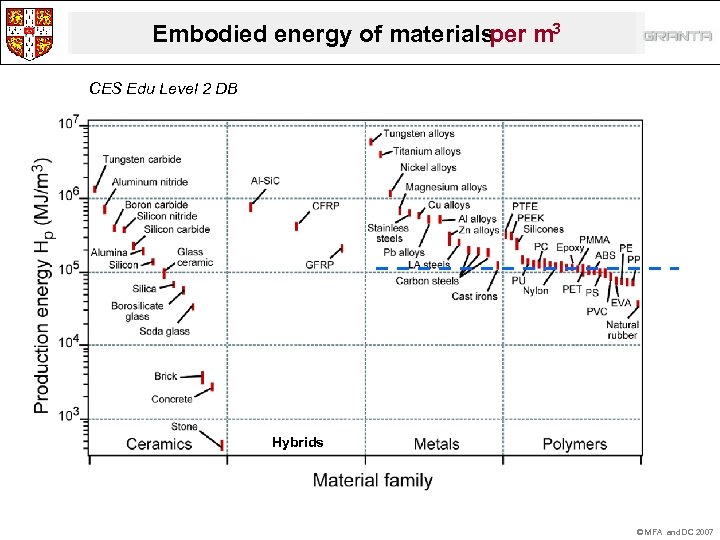

Embodied energy of materials per m 3 CES Edu Level 2 DB Hybrids © MFA and DC 2007

Embodied energy of materials per m 3 CES Edu Level 2 DB Hybrids © MFA and DC 2007

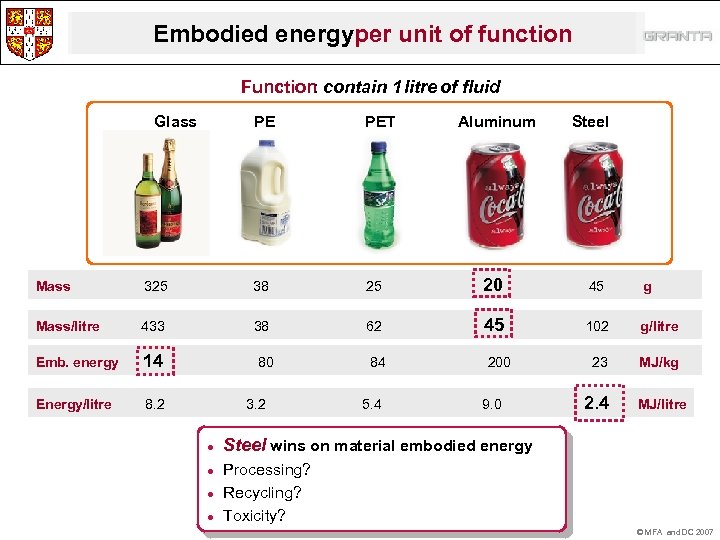

Embodied energyper unit of function Function contain 1 litre of fluid : Glass PE PET Aluminum Steel Mass 325 38 25 20 45 g Mass/litre 433 38 62 45 102 g/litre Emb. energy 14 80 84 200 23 MJ/kg Energy/litre 8. 2 2. 4 MJ/litre 3. 2 l l 5. 4 9. 0 Steel wins on material embodied energy Processing? Recycling? Toxicity? © MFA and DC 2007

Embodied energyper unit of function Function contain 1 litre of fluid : Glass PE PET Aluminum Steel Mass 325 38 25 20 45 g Mass/litre 433 38 62 45 102 g/litre Emb. energy 14 80 84 200 23 MJ/kg Energy/litre 8. 2 2. 4 MJ/litre 3. 2 l l 5. 4 9. 0 Steel wins on material embodied energy Processing? Recycling? Toxicity? © MFA and DC 2007

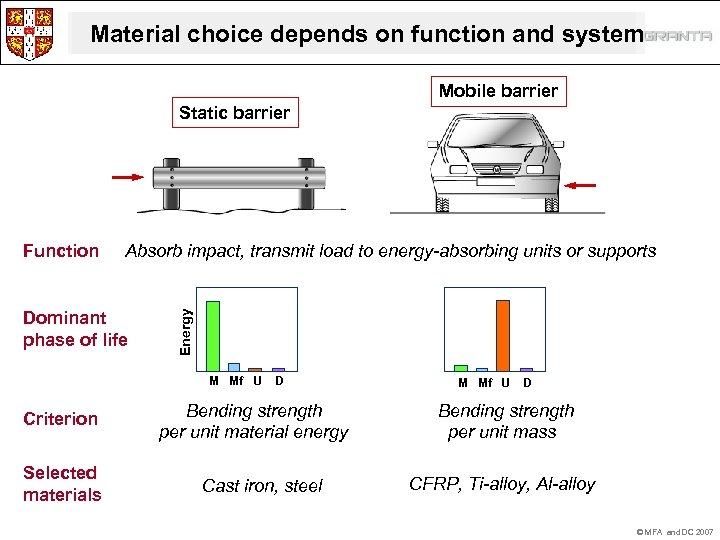

Material choice depends on function and system Mobile barrier Static barrier Absorb impact, transmit load to energy-absorbing units or supports Dominant phase of life Energy Function M Mf U Criterion Selected materials D Bending strength per unit material energy Cast iron, steel M Mf U D Bending strength per unit mass CFRP, Ti-alloy, Al-alloy © MFA and DC 2007

Material choice depends on function and system Mobile barrier Static barrier Absorb impact, transmit load to energy-absorbing units or supports Dominant phase of life Energy Function M Mf U Criterion Selected materials D Bending strength per unit material energy Cast iron, steel M Mf U D Bending strength per unit mass CFRP, Ti-alloy, Al-alloy © MFA and DC 2007

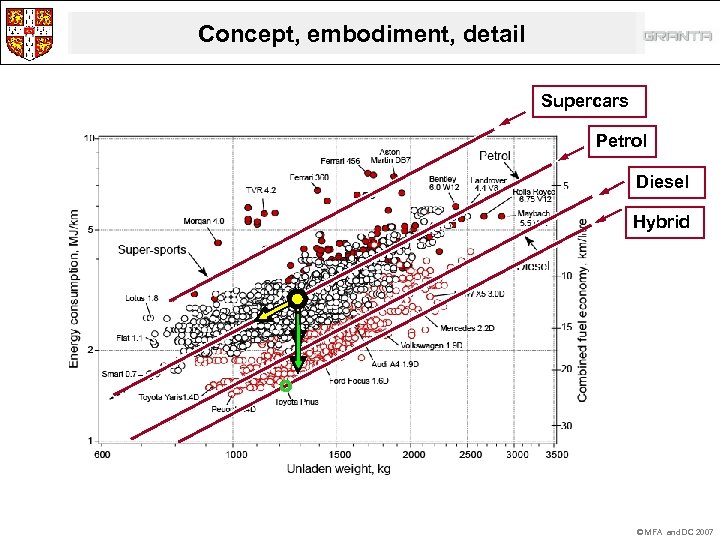

Concept, embodiment, detail Supercars Petrol Diesel Hybrid © MFA and DC 2007

Concept, embodiment, detail Supercars Petrol Diesel Hybrid © MFA and DC 2007

The main points Scoping LCA gives quick, approximate “portrait” of energy / CO 2 burden of products. A practical tool for assessing eco-burden and guiding (re)-design. Separate the life-phases § Material § Manufacture § Use § Disposal Base material choice on relative contributions to stress Consider system dependence § Optimise within one concept § Explore alternative concepts The CES Edu. Pack provides data to help with this © MFA and DC 2007

The main points Scoping LCA gives quick, approximate “portrait” of energy / CO 2 burden of products. A practical tool for assessing eco-burden and guiding (re)-design. Separate the life-phases § Material § Manufacture § Use § Disposal Base material choice on relative contributions to stress Consider system dependence § Optimise within one concept § Explore alternative concepts The CES Edu. Pack provides data to help with this © MFA and DC 2007

Demo © MFA and DC 2007

Demo © MFA and DC 2007

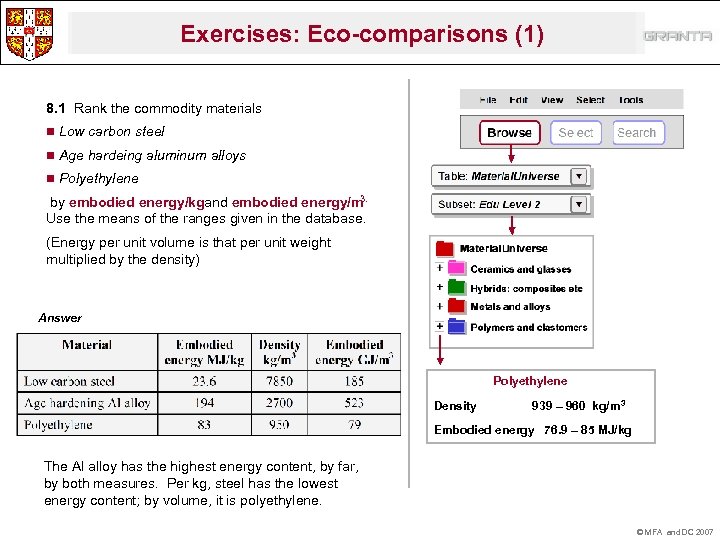

Exercises: Eco-comparisons (1) 8. 1 Rank the commodity materials n Low carbon steel n Age hardeing aluminum alloys n Polyethylene 3. by embodied energy/kgand embodied energy/m Use the means of the ranges given in the database. (Energy per unit volume is that per unit weight multiplied by the density) Answer Polyethylene Density 939 – 960 kg/m 3 Embodied energy 76. 9 – 85 MJ/kg The Al alloy has the highest energy content, by far, by both measures. Per kg, steel has the lowest energy content; by volume, it is polyethylene. © MFA and DC 2007

Exercises: Eco-comparisons (1) 8. 1 Rank the commodity materials n Low carbon steel n Age hardeing aluminum alloys n Polyethylene 3. by embodied energy/kgand embodied energy/m Use the means of the ranges given in the database. (Energy per unit volume is that per unit weight multiplied by the density) Answer Polyethylene Density 939 – 960 kg/m 3 Embodied energy 76. 9 – 85 MJ/kg The Al alloy has the highest energy content, by far, by both measures. Per kg, steel has the lowest energy content; by volume, it is polyethylene. © MFA and DC 2007

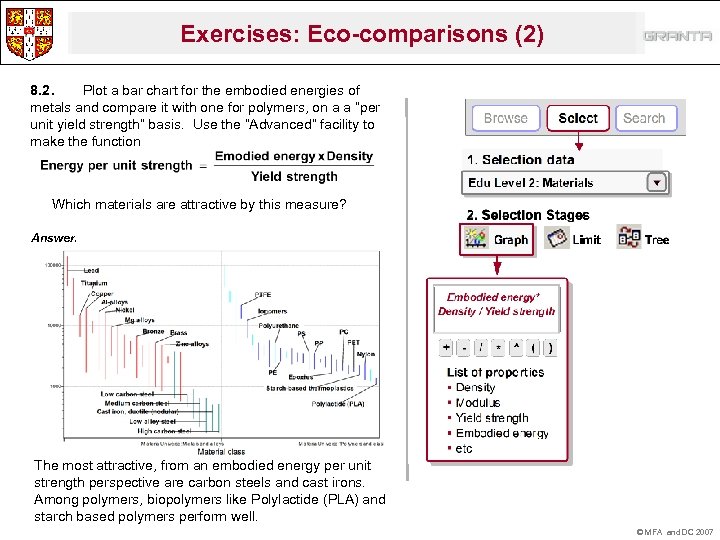

Exercises: Eco-comparisons (2) 8. 2. Plot a bar chart for the embodied energies of metals and compare it with one for polymers, on a a “per unit yield strength” basis. Use the “Advanced” facility to make the function Which materials are attractive by this measure? Answer. The most attractive, from an embodied energy per unit strength perspective are carbon steels and cast irons. Among polymers, biopolymers like Polylactide (PLA) and starch based polymers perform well. © MFA and DC 2007

Exercises: Eco-comparisons (2) 8. 2. Plot a bar chart for the embodied energies of metals and compare it with one for polymers, on a a “per unit yield strength” basis. Use the “Advanced” facility to make the function Which materials are attractive by this measure? Answer. The most attractive, from an embodied energy per unit strength perspective are carbon steels and cast irons. Among polymers, biopolymers like Polylactide (PLA) and starch based polymers perform well. © MFA and DC 2007

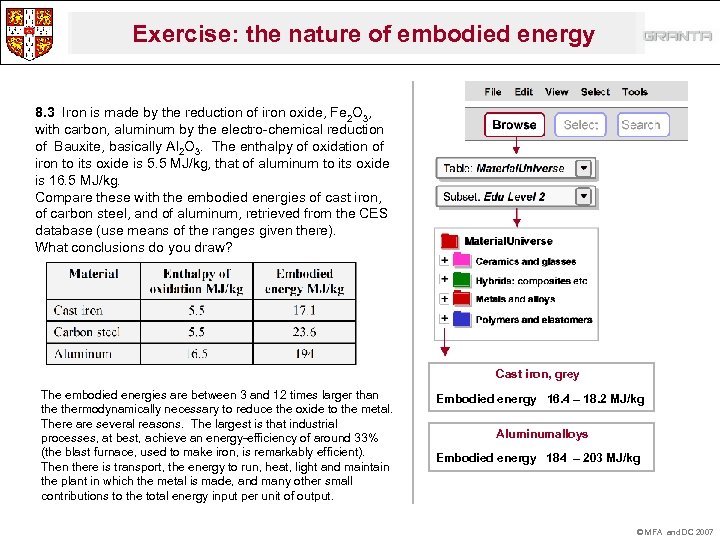

Exercise: the nature of embodied energy 8. 3 Iron is made by the reduction of iron oxide, Fe 2 O 3, with carbon, aluminum by the electro-chemical reduction of Bauxite, basically Al 2 O 3. The enthalpy of oxidation of iron to its oxide is 5. 5 MJ/kg, that of aluminum to its oxide is 16. 5 MJ/kg. Compare these with the embodied energies of cast iron, of carbon steel, and of aluminum, retrieved from the CES database (use means of the ranges given there). What conclusions do you draw? Cast iron, grey The embodied energies are between 3 and 12 times larger than thermodynamically necessary to reduce the oxide to the metal. There are several reasons. The largest is that industrial processes, at best, achieve an energy-efficiency of around 33% (the blast furnace, used to make iron, is remarkably efficient). Then there is transport, the energy to run, heat, light and maintain the plant in which the metal is made, and many other small contributions to the total energy input per unit of output. Embodied energy 16. 4 – 18. 2 MJ/kg Aluminumalloys Embodied energy 184 – 203 MJ/kg © MFA and DC 2007

Exercise: the nature of embodied energy 8. 3 Iron is made by the reduction of iron oxide, Fe 2 O 3, with carbon, aluminum by the electro-chemical reduction of Bauxite, basically Al 2 O 3. The enthalpy of oxidation of iron to its oxide is 5. 5 MJ/kg, that of aluminum to its oxide is 16. 5 MJ/kg. Compare these with the embodied energies of cast iron, of carbon steel, and of aluminum, retrieved from the CES database (use means of the ranges given there). What conclusions do you draw? Cast iron, grey The embodied energies are between 3 and 12 times larger than thermodynamically necessary to reduce the oxide to the metal. There are several reasons. The largest is that industrial processes, at best, achieve an energy-efficiency of around 33% (the blast furnace, used to make iron, is remarkably efficient). Then there is transport, the energy to run, heat, light and maintain the plant in which the metal is made, and many other small contributions to the total energy input per unit of output. Embodied energy 16. 4 – 18. 2 MJ/kg Aluminumalloys Embodied energy 184 – 203 MJ/kg © MFA and DC 2007

End of Unit 8 © MFA and DC 2007

End of Unit 8 © MFA and DC 2007