ed5c30584c027b7c103002a2e30910d2.ppt

- Количество слайдов: 137

Unit 5 Quality Systems

Unit 5 Quality Systems

• A German company wins a huge contract to sell components to a factory in North Carolina. • A Swiss firm becomes the leading supplier of power line filters in the U. S.

• A German company wins a huge contract to sell components to a factory in North Carolina. • A Swiss firm becomes the leading supplier of power line filters in the U. S.

• A Japanese electronics conglomerate outbids several European manufacturers for a project in South America. • These are not isolated events, but rather an indication that we have entered a new age in commerce.

• A Japanese electronics conglomerate outbids several European manufacturers for a project in South America. • These are not isolated events, but rather an indication that we have entered a new age in commerce.

INTRODUCTION • Today, more and more business and industry leaders realize that in order to thrive, or even survive, in the new global economy, their companies must become truly world-class. • And that means quality. • Quality in your products and services. Quality in your practices and procedures. Quality you maintain and you can prove - because it is documented.

INTRODUCTION • Today, more and more business and industry leaders realize that in order to thrive, or even survive, in the new global economy, their companies must become truly world-class. • And that means quality. • Quality in your products and services. Quality in your practices and procedures. Quality you maintain and you can prove - because it is documented.

• Quality as a competitive weapon. • And that is the reason for the growing move to ISO 9000 certification. • The best companies are starting to insist on it. Your competitors may already be pursuing it. And if you plan to do business in Europe or Japan, it is absolutely essential.

• Quality as a competitive weapon. • And that is the reason for the growing move to ISO 9000 certification. • The best companies are starting to insist on it. Your competitors may already be pursuing it. And if you plan to do business in Europe or Japan, it is absolutely essential.

DO YOU KNOW? ? ? • The race for ISO certification has already started. In the first half of 2003, it is estimated that over 60, 000 European companies are registered in compliance with the ISO 9000 standards. In the U. S. , over 1000 companies have been certified. (In 2005, the number of certified companies more than doubled. )

DO YOU KNOW? ? ? • The race for ISO certification has already started. In the first half of 2003, it is estimated that over 60, 000 European companies are registered in compliance with the ISO 9000 standards. In the U. S. , over 1000 companies have been certified. (In 2005, the number of certified companies more than doubled. )

What does the term "ISO" stand for? • The term ISO stands for the International Organization for Standardization. You would reasonably assume that it ought to be IOS, but it isn't. Apparently, the term ISO was chosen (instead of IOS), because iso in Greek means equal, and ISO wanted to convey the idea of equality - the idea that they develop standards to place organizations on an equal footing.

What does the term "ISO" stand for? • The term ISO stands for the International Organization for Standardization. You would reasonably assume that it ought to be IOS, but it isn't. Apparently, the term ISO was chosen (instead of IOS), because iso in Greek means equal, and ISO wanted to convey the idea of equality - the idea that they develop standards to place organizations on an equal footing.

HISTORY OF ISO • The International Standards Organization (ISO), in Geneva, Switzerland, was founded in 1946 to develop a common set of standards in manufacturing, trade and communications. • It is composed of the national standards institutes and organizations of 97 countries worldwide, including the American National Standards Institute (ANSI).

HISTORY OF ISO • The International Standards Organization (ISO), in Geneva, Switzerland, was founded in 1946 to develop a common set of standards in manufacturing, trade and communications. • It is composed of the national standards institutes and organizations of 97 countries worldwide, including the American National Standards Institute (ANSI).

HISTORY OF ISO • The ISO publishes thousands of standards, but the ISO 9000 series is having a major impact on international trade. • First published in 1987, the standards have been rapidly adopted by organizations in Europe, Asia and North America. In addition, there is a movement by several industries in the EEC where ISO certification is now a prerequisite to product certification. And that trend is growing.

HISTORY OF ISO • The ISO publishes thousands of standards, but the ISO 9000 series is having a major impact on international trade. • First published in 1987, the standards have been rapidly adopted by organizations in Europe, Asia and North America. In addition, there is a movement by several industries in the EEC where ISO certification is now a prerequisite to product certification. And that trend is growing.

HISTORY OF ISO • The standards have been endorsed by the American Society of Quality Control, the European Standards Institutes, and by the Japanese Industrial Standards Committee. • In the U. S. , the American Society for Quality Control runs the Registrar Accreditation Board (RAB), which is accountable to ISO when it comes to certification. The RAB has recognized over 40 certification bodies that have trained certified auditors.

HISTORY OF ISO • The standards have been endorsed by the American Society of Quality Control, the European Standards Institutes, and by the Japanese Industrial Standards Committee. • In the U. S. , the American Society for Quality Control runs the Registrar Accreditation Board (RAB), which is accountable to ISO when it comes to certification. The RAB has recognized over 40 certification bodies that have trained certified auditors.

ISO… ISO is the world’s leading developer of International Standards ISO standards are designed to be implemented worldwide.

ISO… ISO is the world’s leading developer of International Standards ISO standards are designed to be implemented worldwide.

ISO. ISO standards specify the requirements • for state-of-the-art products, services, • processes, materials and systems, • and for good conformity assessment, • managerial and organizational practice

ISO. ISO standards specify the requirements • for state-of-the-art products, services, • processes, materials and systems, • and for good conformity assessment, • managerial and organizational practice

What exactly is ISO 9000? • The ISO 9000 series classifies products into generic product categories: hardware, software, processed materials and services. • ISO 9000 - Explains fundamental quality concepts and provides guidelines for the selection and application of each standard. • ISO 9001 - Model for quality assurance in design, development, production, installation and servicing. • ISO 9004 - Guidelines for the applications of standards in quality management and quality systems.

What exactly is ISO 9000? • The ISO 9000 series classifies products into generic product categories: hardware, software, processed materials and services. • ISO 9000 - Explains fundamental quality concepts and provides guidelines for the selection and application of each standard. • ISO 9001 - Model for quality assurance in design, development, production, installation and servicing. • ISO 9004 - Guidelines for the applications of standards in quality management and quality systems.

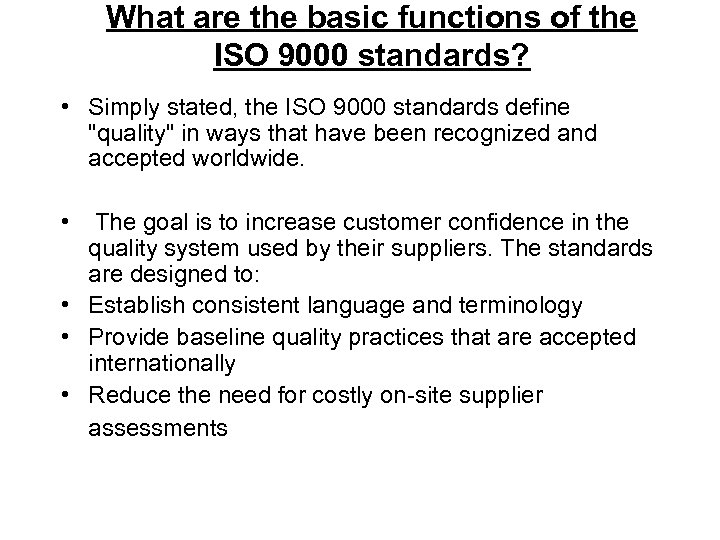

What are the basic functions of the ISO 9000 standards? • Simply stated, the ISO 9000 standards define "quality" in ways that have been recognized and accepted worldwide. • The goal is to increase customer confidence in the quality system used by their suppliers. The standards are designed to: • Establish consistent language and terminology • Provide baseline quality practices that are accepted internationally • Reduce the need for costly on-site supplier assessments

What are the basic functions of the ISO 9000 standards? • Simply stated, the ISO 9000 standards define "quality" in ways that have been recognized and accepted worldwide. • The goal is to increase customer confidence in the quality system used by their suppliers. The standards are designed to: • Establish consistent language and terminology • Provide baseline quality practices that are accepted internationally • Reduce the need for costly on-site supplier assessments

• It doesn't matter what size they are or what they do. • It can help both product and service oriented organizations achieve standards of quality that are recognized and respected throughout the world.

• It doesn't matter what size they are or what they do. • It can help both product and service oriented organizations achieve standards of quality that are recognized and respected throughout the world.

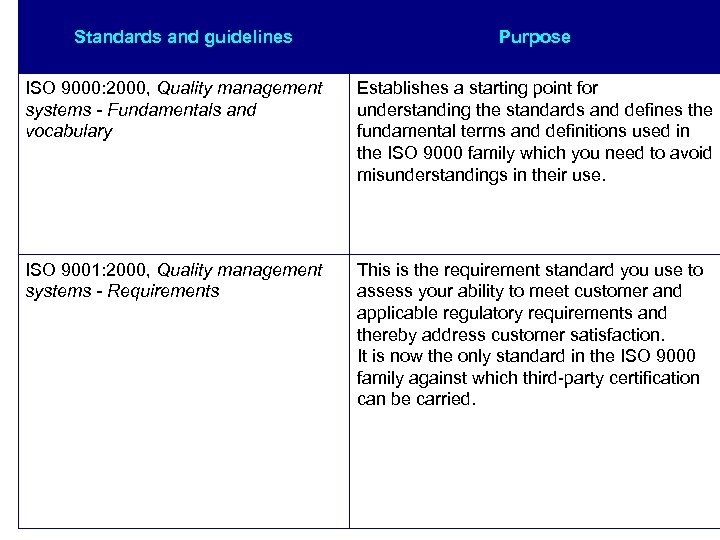

Standards and guidelines Purpose ISO 9000: 2000, Quality management systems - Fundamentals and vocabulary Establishes a starting point for understanding the standards and defines the fundamental terms and definitions used in the ISO 9000 family which you need to avoid misunderstandings in their use. ISO 9001: 2000, Quality management systems - Requirements This is the requirement standard you use to assess your ability to meet customer and applicable regulatory requirements and thereby address customer satisfaction. It is now the only standard in the ISO 9000 family against which third-party certification can be carried.

Standards and guidelines Purpose ISO 9000: 2000, Quality management systems - Fundamentals and vocabulary Establishes a starting point for understanding the standards and defines the fundamental terms and definitions used in the ISO 9000 family which you need to avoid misunderstandings in their use. ISO 9001: 2000, Quality management systems - Requirements This is the requirement standard you use to assess your ability to meet customer and applicable regulatory requirements and thereby address customer satisfaction. It is now the only standard in the ISO 9000 family against which third-party certification can be carried.

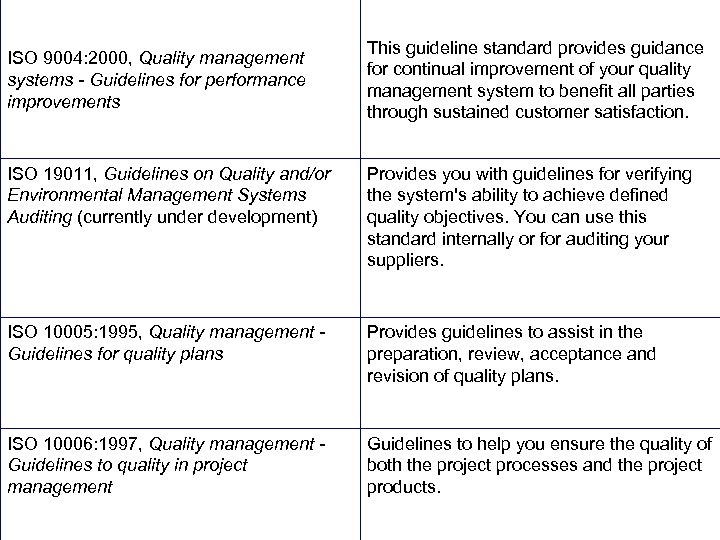

ISO 9004: 2000, Quality management systems - Guidelines for performance improvements This guideline standard provides guidance for continual improvement of your quality management system to benefit all parties through sustained customer satisfaction. ISO 19011, Guidelines on Quality and/or Environmental Management Systems Auditing (currently under development) Provides you with guidelines for verifying the system's ability to achieve defined quality objectives. You can use this standard internally or for auditing your suppliers. ISO 10005: 1995, Quality management Guidelines for quality plans Provides guidelines to assist in the preparation, review, acceptance and revision of quality plans. ISO 10006: 1997, Quality management Guidelines to quality in project management Guidelines to help you ensure the quality of both the project processes and the project products.

ISO 9004: 2000, Quality management systems - Guidelines for performance improvements This guideline standard provides guidance for continual improvement of your quality management system to benefit all parties through sustained customer satisfaction. ISO 19011, Guidelines on Quality and/or Environmental Management Systems Auditing (currently under development) Provides you with guidelines for verifying the system's ability to achieve defined quality objectives. You can use this standard internally or for auditing your suppliers. ISO 10005: 1995, Quality management Guidelines for quality plans Provides guidelines to assist in the preparation, review, acceptance and revision of quality plans. ISO 10006: 1997, Quality management Guidelines to quality in project management Guidelines to help you ensure the quality of both the project processes and the project products.

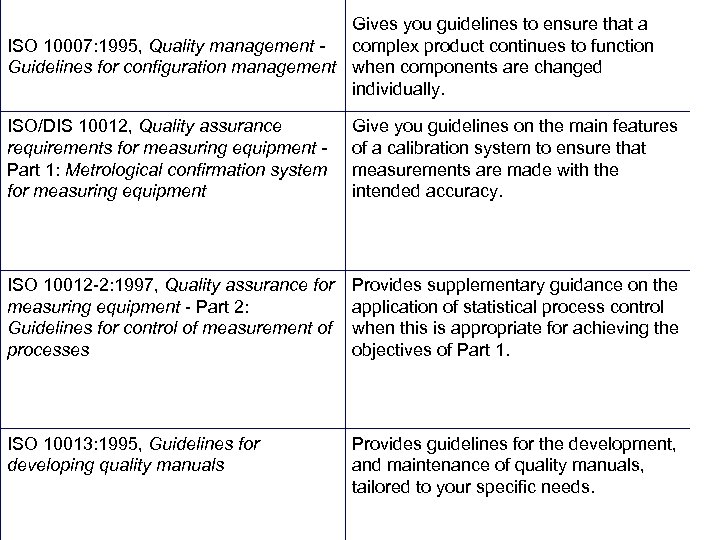

Gives you guidelines to ensure that a ISO 10007: 1995, Quality management - complex product continues to function Guidelines for configuration management when components are changed individually. ISO/DIS 10012, Quality assurance requirements for measuring equipment Part 1: Metrological confirmation system for measuring equipment Give you guidelines on the main features of a calibration system to ensure that measurements are made with the intended accuracy. ISO 10012 -2: 1997, Quality assurance for measuring equipment - Part 2: Guidelines for control of measurement of processes Provides supplementary guidance on the application of statistical process control when this is appropriate for achieving the objectives of Part 1. ISO 10013: 1995, Guidelines for developing quality manuals Provides guidelines for the development, and maintenance of quality manuals, tailored to your specific needs.

Gives you guidelines to ensure that a ISO 10007: 1995, Quality management - complex product continues to function Guidelines for configuration management when components are changed individually. ISO/DIS 10012, Quality assurance requirements for measuring equipment Part 1: Metrological confirmation system for measuring equipment Give you guidelines on the main features of a calibration system to ensure that measurements are made with the intended accuracy. ISO 10012 -2: 1997, Quality assurance for measuring equipment - Part 2: Guidelines for control of measurement of processes Provides supplementary guidance on the application of statistical process control when this is appropriate for achieving the objectives of Part 1. ISO 10013: 1995, Guidelines for developing quality manuals Provides guidelines for the development, and maintenance of quality manuals, tailored to your specific needs.

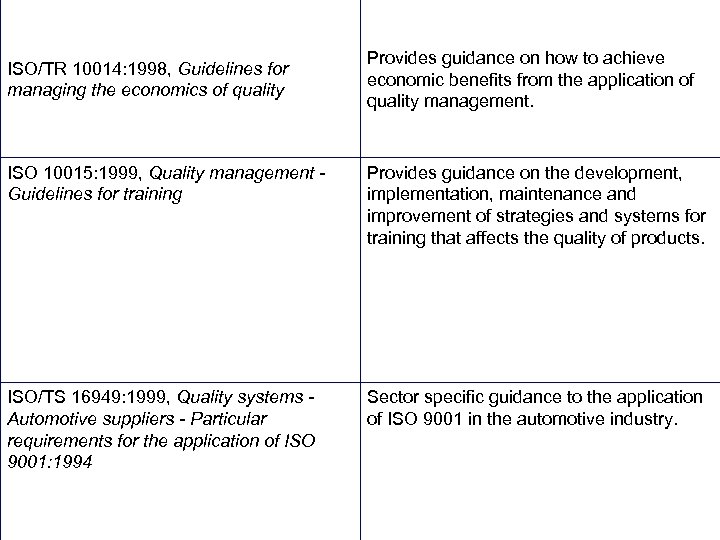

ISO/TR 10014: 1998, Guidelines for managing the economics of quality Provides guidance on how to achieve economic benefits from the application of quality management. ISO 10015: 1999, Quality management Guidelines for training Provides guidance on the development, implementation, maintenance and improvement of strategies and systems for training that affects the quality of products. ISO/TS 16949: 1999, Quality systems Automotive suppliers - Particular requirements for the application of ISO 9001: 1994 Sector specific guidance to the application of ISO 9001 in the automotive industry.

ISO/TR 10014: 1998, Guidelines for managing the economics of quality Provides guidance on how to achieve economic benefits from the application of quality management. ISO 10015: 1999, Quality management Guidelines for training Provides guidance on the development, implementation, maintenance and improvement of strategies and systems for training that affects the quality of products. ISO/TS 16949: 1999, Quality systems Automotive suppliers - Particular requirements for the application of ISO 9001: 1994 Sector specific guidance to the application of ISO 9001 in the automotive industry.

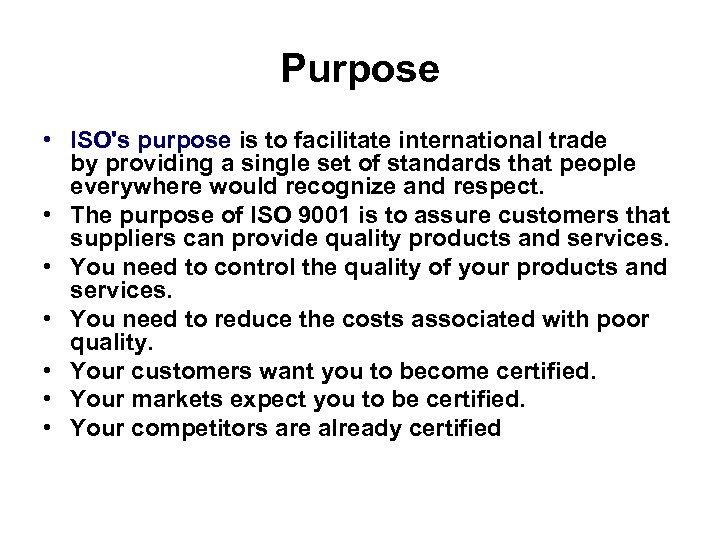

Purpose • ISO's purpose is to facilitate international trade by providing a single set of standards that people everywhere would recognize and respect. • The purpose of ISO 9001 is to assure customers that suppliers can provide quality products and services. • You need to control the quality of your products and services. • You need to reduce the costs associated with poor quality. • Your customers want you to become certified. • Your markets expect you to be certified. • Your competitors are already certified

Purpose • ISO's purpose is to facilitate international trade by providing a single set of standards that people everywhere would recognize and respect. • The purpose of ISO 9001 is to assure customers that suppliers can provide quality products and services. • You need to control the quality of your products and services. • You need to reduce the costs associated with poor quality. • Your customers want you to become certified. • Your markets expect you to be certified. • Your competitors are already certified

Why is ISO 9000 Important? • ISO 9000 is important because of its orientation. • ISO 9000 is important because of its international orientation. . • ISO is also important because of its systemic orientation. if you want to have a quality attitude you must have a quality system. This is what ISO recognizes, and this is why ISO 9000 is important.

Why is ISO 9000 Important? • ISO 9000 is important because of its orientation. • ISO 9000 is important because of its international orientation. . • ISO is also important because of its systemic orientation. if you want to have a quality attitude you must have a quality system. This is what ISO recognizes, and this is why ISO 9000 is important.

Why has ISO 9000 become so important? • For the first time, there is one internationally accepted standard of quality. • There is a way to determine and measure that quality. • There is even a way to prove it. .

Why has ISO 9000 become so important? • For the first time, there is one internationally accepted standard of quality. • There is a way to determine and measure that quality. • There is even a way to prove it. .

How can a company determine whether it will benefit from ISO 9000 certification? • International • Does your company, or the companies you supply, have a global focus? • Do you, or others in your industry, derive a significant amount of revenue from international business? • Do you see that as a future growth opportunity for your organization?

How can a company determine whether it will benefit from ISO 9000 certification? • International • Does your company, or the companies you supply, have a global focus? • Do you, or others in your industry, derive a significant amount of revenue from international business? • Do you see that as a future growth opportunity for your organization?

How can a company determine whether it will benefit from ISO 9000 certification? • New business o Are you getting ISO 9000 inquiries from the companies you sell to? o Are there other companies you could do business with, if you gained ISO 9000 certification? o Do you do business with any government agencies? Would that represent a new source of business for you in the future?

How can a company determine whether it will benefit from ISO 9000 certification? • New business o Are you getting ISO 9000 inquiries from the companies you sell to? o Are there other companies you could do business with, if you gained ISO 9000 certification? o Do you do business with any government agencies? Would that represent a new source of business for you in the future?

How can a company determine whether it will benefit from ISO 9000 certification? • Quality • Is quality an integral part of your entire organization, across all functions? • Is your company's reputation based on quality? Is that one of the important selling points in the industry in which you compete? • Do you want to give your existing quality assurance program a platform to improve quality? • Most importantly, do you see quality as a competitive edge that could help you accomplish your organization's goals in the 90 s?

How can a company determine whether it will benefit from ISO 9000 certification? • Quality • Is quality an integral part of your entire organization, across all functions? • Is your company's reputation based on quality? Is that one of the important selling points in the industry in which you compete? • Do you want to give your existing quality assurance program a platform to improve quality? • Most importantly, do you see quality as a competitive edge that could help you accomplish your organization's goals in the 90 s?

• If you answered "yes" to several of these questions, your organization may benefit from ISO 9000 certification.

• If you answered "yes" to several of these questions, your organization may benefit from ISO 9000 certification.

Can it give a competitive edge? • You can use ISO 9000 certification to gain or maintain approved vendor status, even when companies reduce the number of their suppliers. • You can enter new and lucrative markets that were previously closed to you.

Can it give a competitive edge? • You can use ISO 9000 certification to gain or maintain approved vendor status, even when companies reduce the number of their suppliers. • You can enter new and lucrative markets that were previously closed to you.

Can it give a competitive edge? • You can successfully compete with virtually any other company in your industry. • In fact, small and medium-sized companies are using ISO 9000 to win business away from much larger organizations.

Can it give a competitive edge? • You can successfully compete with virtually any other company in your industry. • In fact, small and medium-sized companies are using ISO 9000 to win business away from much larger organizations.

NEED • Many manufacturers even have to undergo customer-driven "quality audits, " which can be expensive and time-consuming. • ISO 9000 practically eliminates the need for many customer-driven quality programs. • ISO 9000 certification is a uniform standard, accepted and recognized internationally. So you save money.

NEED • Many manufacturers even have to undergo customer-driven "quality audits, " which can be expensive and time-consuming. • ISO 9000 practically eliminates the need for many customer-driven quality programs. • ISO 9000 certification is a uniform standard, accepted and recognized internationally. So you save money.

NEED • you begin to accrue benefits even before you achieve ISO 9000 certification. • The preparation for ISO 9000 registration involves a close analysis of your existing quality systems. • ISO 9000 can improve overall business efficiency

NEED • you begin to accrue benefits even before you achieve ISO 9000 certification. • The preparation for ISO 9000 registration involves a close analysis of your existing quality systems. • ISO 9000 can improve overall business efficiency

NEED • ISO 9000 can ensure timely, accurate, accessible information • ISO 9000 can help you develop "best practices" and eliminate costly surprises • ISO 9000 improves the quality of your information

NEED • ISO 9000 can ensure timely, accurate, accessible information • ISO 9000 can help you develop "best practices" and eliminate costly surprises • ISO 9000 improves the quality of your information

NEED FOR ISO • Companies who have achieved ISO 9000 certification enjoy a significant advantage in satisfying their customers and gaining new ones. It also helps maintain approved vendor status, as the trend is to reduce the number of suppliers. • In fact, a recent study of certified companies revealed that ISO 9000 certification had also brought unexpected benefits, such as greater operational efficiency, increased profitability, savings in administrative costs, and improvements in marketing and sales activity.

NEED FOR ISO • Companies who have achieved ISO 9000 certification enjoy a significant advantage in satisfying their customers and gaining new ones. It also helps maintain approved vendor status, as the trend is to reduce the number of suppliers. • In fact, a recent study of certified companies revealed that ISO 9000 certification had also brought unexpected benefits, such as greater operational efficiency, increased profitability, savings in administrative costs, and improvements in marketing and sales activity.

NEED • ISO standards contribute to making the development, manufacturing and supply of products and services more efficient, safer and cleaner. • They make trade between countries easier and fairer. • They provide governments with a technical base for health, safety and environmental legislation. • They aid in transferring technology to developing countries. • ISO standards also serve to safeguard consumers, and users in general, of products and services - as well as to make their lives simpler.

NEED • ISO standards contribute to making the development, manufacturing and supply of products and services more efficient, safer and cleaner. • They make trade between countries easier and fairer. • They provide governments with a technical base for health, safety and environmental legislation. • They aid in transferring technology to developing countries. • ISO standards also serve to safeguard consumers, and users in general, of products and services - as well as to make their lives simpler.

NEED FOR ISO • ISO 9000 is sweeping the world. It is rapidly becoming the most important quality standard. • Thousands of companies in over 100 countries have already adopted it, and many more are in the process of doing so. Why? • Because it controls quality. • It saves money. • Customers expect it. • And competitors use it.

NEED FOR ISO • ISO 9000 is sweeping the world. It is rapidly becoming the most important quality standard. • Thousands of companies in over 100 countries have already adopted it, and many more are in the process of doing so. Why? • Because it controls quality. • It saves money. • Customers expect it. • And competitors use it.

ISO 9001 : 2000 WHAT IS IT ? – WHAT DOES IT DO ? • A Model for Quality Management Systems • Defines Minimum Requirements for QM Systems • Provides a base line for Assessment and Certification COMMON SENSE MANAGEMENT

ISO 9001 : 2000 WHAT IS IT ? – WHAT DOES IT DO ? • A Model for Quality Management Systems • Defines Minimum Requirements for QM Systems • Provides a base line for Assessment and Certification COMMON SENSE MANAGEMENT

ISO 9001 : 2000 - SCOPE General • Needs to demonstrate consistency • Aims to enhance Customer Satisfaction Application • Generic and intended to be applicable to all Organizations, Type, Size and Product • Requirements that are not applicable can be considered for exclusion

ISO 9001 : 2000 - SCOPE General • Needs to demonstrate consistency • Aims to enhance Customer Satisfaction Application • Generic and intended to be applicable to all Organizations, Type, Size and Product • Requirements that are not applicable can be considered for exclusion

QUALITY SYSTEM Organizational Structure Procedures, Processes and Resources needed to implement Quality Management

QUALITY SYSTEM Organizational Structure Procedures, Processes and Resources needed to implement Quality Management

THE FOUR ABSOLUTES OF QUALITY 1. 2. 3. 4. QUALITY IS CONFORMANCE TO REQUIREMENTS Do What you said you would do THE SYSTEM FOR PRODUCING QUALITY IS PREVENTION NOT APPRAISAL Solve Problems permanently THE PERFORMANCE STANDARD IS ZERO DEFECTS Right First Time and Every Time QUALITY IS MEASURED BY THE COST OF NONCONFORMANCE Repair / Rework is paid for out of Profits

THE FOUR ABSOLUTES OF QUALITY 1. 2. 3. 4. QUALITY IS CONFORMANCE TO REQUIREMENTS Do What you said you would do THE SYSTEM FOR PRODUCING QUALITY IS PREVENTION NOT APPRAISAL Solve Problems permanently THE PERFORMANCE STANDARD IS ZERO DEFECTS Right First Time and Every Time QUALITY IS MEASURED BY THE COST OF NONCONFORMANCE Repair / Rework is paid for out of Profits

QUALITY CONTROL – QUALITY ASSURANCE • Quality Control is REACTIVE whereas Quality Assurance is PROACTIVE • Quality Control deals with DETECTION Quality Assurance deals with PREVENTION i. e. All the planned and systematic actions necessary to prevent problems and ensure confidence that the product will satisfy the requirements for quality

QUALITY CONTROL – QUALITY ASSURANCE • Quality Control is REACTIVE whereas Quality Assurance is PROACTIVE • Quality Control deals with DETECTION Quality Assurance deals with PREVENTION i. e. All the planned and systematic actions necessary to prevent problems and ensure confidence that the product will satisfy the requirements for quality

QUALITY ASSESSMENT Comparison of a Quality Management System with the requirement system with the requirements of a standard or standards to determine the degree of compliance with the specified requirements

QUALITY ASSESSMENT Comparison of a Quality Management System with the requirement system with the requirements of a standard or standards to determine the degree of compliance with the specified requirements

QUALITY ASSURANCE Part of Quality Management, focused on providing confidence that Quality requirements will be fulfilled ISO 9000 : 2000

QUALITY ASSURANCE Part of Quality Management, focused on providing confidence that Quality requirements will be fulfilled ISO 9000 : 2000

QUALITY MANAGEMENT SYSTEMS Management System to direct and control an Organization with regard to Quality ISO 9000 : 2000

QUALITY MANAGEMENT SYSTEMS Management System to direct and control an Organization with regard to Quality ISO 9000 : 2000

• Documentation is at the core • "Documentation sounds simple, but it's one of the principal things that must happen with ISO 9000. " - Mark Morrow, Sr. Editor, Quality Systems Update

• Documentation is at the core • "Documentation sounds simple, but it's one of the principal things that must happen with ISO 9000. " - Mark Morrow, Sr. Editor, Quality Systems Update

DOCUMENT CONTROL Procedures for controlling all documents required by the standard are required to be established and maintained. These procedures must ensure the following: § The documents can be located , § The documents are periodically reviewed, and approved by authorized personnel, § The current versions are available at locations where operations essential to the functioning of EMS are done. § Obsolete documents are promptly removed § Further, documentation must be legible,

DOCUMENT CONTROL Procedures for controlling all documents required by the standard are required to be established and maintained. These procedures must ensure the following: § The documents can be located , § The documents are periodically reviewed, and approved by authorized personnel, § The current versions are available at locations where operations essential to the functioning of EMS are done. § Obsolete documents are promptly removed § Further, documentation must be legible,

RECORDS Ø Procedures for identification, maintenance, and disposition of environmental records are required to be established and maintained. Ø The records must be legible, identifiable and traceable to the activity involved. Ø The records must be stored/maintained so that they are readily retrievable and protected against damage, deterioration, or loss. Ø Retention times must be established and recorded. Ø Records must be maintained, as appropriate, to demonstrate conformance to the standard.

RECORDS Ø Procedures for identification, maintenance, and disposition of environmental records are required to be established and maintained. Ø The records must be legible, identifiable and traceable to the activity involved. Ø The records must be stored/maintained so that they are readily retrievable and protected against damage, deterioration, or loss. Ø Retention times must be established and recorded. Ø Records must be maintained, as appropriate, to demonstrate conformance to the standard.

Key Questions in Records Management • Identify what records to be maintained. • Authorize who keeps them and where and how they are kept. • Determine how long they are kept (retention time) • Determine how they are accessed and disposed , including good storage and retrieval system

Key Questions in Records Management • Identify what records to be maintained. • Authorize who keeps them and where and how they are kept. • Determine how long they are kept (retention time) • Determine how they are accessed and disposed , including good storage and retrieval system

QUALITY AUDIT systematic, independent and documented process for obtaining audit evidence and evaluating it objectively to determine the extent to which the audit criteria are fulfilled ISO 19011 : 2002

QUALITY AUDIT systematic, independent and documented process for obtaining audit evidence and evaluating it objectively to determine the extent to which the audit criteria are fulfilled ISO 19011 : 2002

AUDIT CRITERIA Set of policies, procedures or requirements AUDIT EVIDENCE Records, statements of fact or other information, which are relevant to the audit criteria and verifiable

AUDIT CRITERIA Set of policies, procedures or requirements AUDIT EVIDENCE Records, statements of fact or other information, which are relevant to the audit criteria and verifiable

AUDITS Objectives • Determination of Compliance with specified Requirements • Identification of Weakness • Management Tool for Improvement Planned and Independent Defined Standards and / or Procedures

AUDITS Objectives • Determination of Compliance with specified Requirements • Identification of Weakness • Management Tool for Improvement Planned and Independent Defined Standards and / or Procedures

AUDIT OBJECTIVES • To determine Compliance or Non. Conformity of the Quality System elements with specified requirements • To determine the effectiveness of the implemented Quality System in meeting Quality objectives • To afford an opportunity to improve the Quality System Cont…

AUDIT OBJECTIVES • To determine Compliance or Non. Conformity of the Quality System elements with specified requirements • To determine the effectiveness of the implemented Quality System in meeting Quality objectives • To afford an opportunity to improve the Quality System Cont…

AUDIT OBJECTIVES • To meet regulatory Requirements • To Permit the listing of the Audited Organization in the Register of Audited Companies

AUDIT OBJECTIVES • To meet regulatory Requirements • To Permit the listing of the Audited Organization in the Register of Audited Companies

AUDITS 1 st PARTY 2 nd PARTY 3 rd PARTY PRODUCT SERVICE QUALITY INTERNAL EXTRINSIC PROCESS SYSTEM FINANCIAL ENVIRONMENTAL

AUDITS 1 st PARTY 2 nd PARTY 3 rd PARTY PRODUCT SERVICE QUALITY INTERNAL EXTRINSIC PROCESS SYSTEM FINANCIAL ENVIRONMENTAL

AUDITS 1 st PARTY • • INTERNAL Required by ISO and Other Standards Any Trained personnel can be used Documentation Awareness Timing / Timescales easily adjusted to suit individuals • Advice / Assistance with corrective actions • Must not replace responsibility for Quality

AUDITS 1 st PARTY • • INTERNAL Required by ISO and Other Standards Any Trained personnel can be used Documentation Awareness Timing / Timescales easily adjusted to suit individuals • Advice / Assistance with corrective actions • Must not replace responsibility for Quality

AUDITS 2 nd PARTY • • • EXTERNAL Supplier or Sub-Contractor approval Quality Personnel-Role Choice of Standards Timing / Timescales more important Team Leader’s Authority The power of the contract

AUDITS 2 nd PARTY • • • EXTERNAL Supplier or Sub-Contractor approval Quality Personnel-Role Choice of Standards Timing / Timescales more important Team Leader’s Authority The power of the contract

AUDITS 3 rd PARTY • • • EXTRINSIC Totally Independent International / National Standards Qualified or Registered Assessors Timing / Timescales very important Team Leader only Recommends

AUDITS 3 rd PARTY • • • EXTRINSIC Totally Independent International / National Standards Qualified or Registered Assessors Timing / Timescales very important Team Leader only Recommends

CONDUCT OF THE AUDIT • • • Enter the area Introductions by guide Explain what you want to see Investigate to the depth necessary No problems found, move on Don’t keep on auditing until problems are found

CONDUCT OF THE AUDIT • • • Enter the area Introductions by guide Explain what you want to see Investigate to the depth necessary No problems found, move on Don’t keep on auditing until problems are found

AUDIT PROGRAMME RESPONSIBILITIES Those assigned the responsibility for managing the audit programme should • Establish the objective and extent of the audit programme • Establish the responsibilities and procedures, and ensure resources are provided • Ensure the implementation of the audit programme • Ensure that appropriate audit programme records are maintained, and • Monitor, review and improve the audit programme

AUDIT PROGRAMME RESPONSIBILITIES Those assigned the responsibility for managing the audit programme should • Establish the objective and extent of the audit programme • Establish the responsibilities and procedures, and ensure resources are provided • Ensure the implementation of the audit programme • Ensure that appropriate audit programme records are maintained, and • Monitor, review and improve the audit programme

AUDIT PROGRAMME RESOURCES When identifying resources for the audit programme, consideration should be given to • Financial resources necessary to develop, implement, manage and improve audit activities • Audit techniques Cont…

AUDIT PROGRAMME RESOURCES When identifying resources for the audit programme, consideration should be given to • Financial resources necessary to develop, implement, manage and improve audit activities • Audit techniques Cont…

AUDIT PROGRAMME RESOURCES • Process to achieve and maintain the competence of auditors, and to improve auditor performance • The availability of auditors and technical experts having competence appropriate to the particular audit programme objectives • The extent of the audit programme and • Travelling time, accommodation and other auditing needs

AUDIT PROGRAMME RESOURCES • Process to achieve and maintain the competence of auditors, and to improve auditor performance • The availability of auditors and technical experts having competence appropriate to the particular audit programme objectives • The extent of the audit programme and • Travelling time, accommodation and other auditing needs

AUDIT PROGRAMME PROCEDURES Audit programme procedures should address the following • Planning and scheduling audits • Assuring the competence of auditors and audit team leaders • Selecting appropriate audit teams and assigning their roles and responsibilities Cont…

AUDIT PROGRAMME PROCEDURES Audit programme procedures should address the following • Planning and scheduling audits • Assuring the competence of auditors and audit team leaders • Selecting appropriate audit teams and assigning their roles and responsibilities Cont…

AUDIT PROGRAMME PROCEDURES • • Conducting audits Conducting audit follow-up, if applicable Maintaining audit programme records Monitoring the performance and effectiveness of the audit programme • Reporting to top management on the overall achievements of the audit programme

AUDIT PROGRAMME PROCEDURES • • Conducting audits Conducting audit follow-up, if applicable Maintaining audit programme records Monitoring the performance and effectiveness of the audit programme • Reporting to top management on the overall achievements of the audit programme

AUDIT PROGRAMME IMPLEMENTATION The implementation of an audit programme should address the following: • Communicating the audit programme to relevant parties • Coordinating and scheduling audits and other activities relevant to the audit programme • Establishing and maintaining a process for the evaluation of the auditors and their continual professional development Cont…

AUDIT PROGRAMME IMPLEMENTATION The implementation of an audit programme should address the following: • Communicating the audit programme to relevant parties • Coordinating and scheduling audits and other activities relevant to the audit programme • Establishing and maintaining a process for the evaluation of the auditors and their continual professional development Cont…

AUDIT PROGRAMME IMPLEMENTATION • Ensuring the selection of audit teams • Providing necessary resources to the audit teams • Ensuring the conduct of audits according to the audit programme • Ensuring the control of records of the audit activities • Ensuring review and approval of the audit reports, and ensuring their distribution to the audit client and other specified parties • Ensuring audit follow-up, if applicable

AUDIT PROGRAMME IMPLEMENTATION • Ensuring the selection of audit teams • Providing necessary resources to the audit teams • Ensuring the conduct of audits according to the audit programme • Ensuring the control of records of the audit activities • Ensuring review and approval of the audit reports, and ensuring their distribution to the audit client and other specified parties • Ensuring audit follow-up, if applicable

AUDIT PROGRAMME RECORDS Records should be maintained to demonstrate the implementation of the audit programme and should include the following: • Records related to individual audits, such as – – – Audit plans Audit reports Nonconformity reports Corrective and preventive action reports, and Audit follow-up reports, if applicable Cont…

AUDIT PROGRAMME RECORDS Records should be maintained to demonstrate the implementation of the audit programme and should include the following: • Records related to individual audits, such as – – – Audit plans Audit reports Nonconformity reports Corrective and preventive action reports, and Audit follow-up reports, if applicable Cont…

AUDIT PROGRAMME RECORDS • Results of audit programme review • Records related to audit personnel covering subjects such as – Auditor competence and performance evaluation – Audit team selection, and – Maintenance and improvement of competence

AUDIT PROGRAMME RECORDS • Results of audit programme review • Records related to audit personnel covering subjects such as – Auditor competence and performance evaluation – Audit team selection, and – Maintenance and improvement of competence

AUDIT PROGRAMME MONITORING AND REVIEWING • • • The audit programme review should consider, for example Results and trends from monitoring Conformity with procedures Evolving needs and expectations of interested parties Audit programme records Alternative or new auditing practices, and Consistency in performance between audit teams in similar situations

AUDIT PROGRAMME MONITORING AND REVIEWING • • • The audit programme review should consider, for example Results and trends from monitoring Conformity with procedures Evolving needs and expectations of interested parties Audit programme records Alternative or new auditing practices, and Consistency in performance between audit teams in similar situations

AUDITORS RESPONSIBILITIES • • • Developing the audit schedule Ensure team is always punctual The agreed programme is adhered to Valid restrictions are observed Team members complete designated tasks • Confidentiality is preserved Cont…

AUDITORS RESPONSIBILITIES • • • Developing the audit schedule Ensure team is always punctual The agreed programme is adhered to Valid restrictions are observed Team members complete designated tasks • Confidentiality is preserved Cont…

AUDITORS RESPONSIBILITIES • Arguments are avoided • No criticism is levelled at individuals • Chairs all meetings: - opening, review, team and closing • Summarise findings • Makes recommendation • Files audit report

AUDITORS RESPONSIBILITIES • Arguments are avoided • No criticism is levelled at individuals • Chairs all meetings: - opening, review, team and closing • Summarise findings • Makes recommendation • Files audit report

AUDITOR DUTIES • • • Support the team leader Prepare checklist Arrive on time Participate at opening meeting Carry out assigned tasks

AUDITOR DUTIES • • • Support the team leader Prepare checklist Arrive on time Participate at opening meeting Carry out assigned tasks

AUDITOR DUTIES • • • Keep to the timetable Document all findings Keep auditee informed Assist team leader with reports Safeguard all documents Maintain confidentiality

AUDITOR DUTIES • • • Keep to the timetable Document all findings Keep auditee informed Assist team leader with reports Safeguard all documents Maintain confidentiality

AUDITOR TRAINING Auditor Training should consider the following: • Knowledge & Understanding of the standards used to Audit Quality Systems • Audit Techniques such as Examining, Questioning, Evaluating and Reporting • Additional skills needed to manage an audit E. g. : Planning, Organizing, Communicating and Directing

AUDITOR TRAINING Auditor Training should consider the following: • Knowledge & Understanding of the standards used to Audit Quality Systems • Audit Techniques such as Examining, Questioning, Evaluating and Reporting • Additional skills needed to manage an audit E. g. : Planning, Organizing, Communicating and Directing

THE AUDIT CYCLE PREPARATIONS v Documentation Review v Preliminary visit v Audit Planning PERFORMANCE v Opening Meeting v Gathering Information Cont…

THE AUDIT CYCLE PREPARATIONS v Documentation Review v Preliminary visit v Audit Planning PERFORMANCE v Opening Meeting v Gathering Information Cont…

THE AUDIT CYCLE v Team Meetings v Non-Conformity Reporting v Closing Meeting FOLLOW-UP ACTIONS v Audit Report v Corrective Action Verification v Surveillance

THE AUDIT CYCLE v Team Meetings v Non-Conformity Reporting v Closing Meeting FOLLOW-UP ACTIONS v Audit Report v Corrective Action Verification v Surveillance

TEAM MEETINGS • Discuss the Findings of Team • Team Leader Agrefs: – Non-Conformities – Wording – Categorization • Resolve any Issues • Identify any modifications to the programme as a result of the findings to Date OBJECTIVE Ensure that the Team presents a unified response at the wash-up meeting

TEAM MEETINGS • Discuss the Findings of Team • Team Leader Agrefs: – Non-Conformities – Wording – Categorization • Resolve any Issues • Identify any modifications to the programme as a result of the findings to Date OBJECTIVE Ensure that the Team presents a unified response at the wash-up meeting

WASH-UP MEETINGS • • Presentation of findings to Date Resolution of any issues Agree Non-Conformity Categorization Obtain signatures and possible corrective action completion dates • Monitor Audit Progress • Monitor Auditor / Company interrelationships • Keep everyone informed. No surprises at the closing meeting

WASH-UP MEETINGS • • Presentation of findings to Date Resolution of any issues Agree Non-Conformity Categorization Obtain signatures and possible corrective action completion dates • Monitor Audit Progress • Monitor Auditor / Company interrelationships • Keep everyone informed. No surprises at the closing meeting

CLOSING MEETING AGENDA • Thank Company and Guides • Confirm Standard and Scope • Disclaimer • Confirm Confidentiality • Define Categories of Non-Conformities • Questions Deferred Cont…

CLOSING MEETING AGENDA • Thank Company and Guides • Confirm Standard and Scope • Disclaimer • Confirm Confidentiality • Define Categories of Non-Conformities • Questions Deferred Cont…

CLOSING MEETING AGENDA • Findings Presented • Team Leaders Summary • Recommendations • Questions Answered • Corrective Action Dates Agreed • Close Meeting

CLOSING MEETING AGENDA • Findings Presented • Team Leaders Summary • Recommendations • Questions Answered • Corrective Action Dates Agreed • Close Meeting

RECOMMENDATIONS The Company’s Quality System: • Meets the Requirements of ISO 9001: 2000 Registration to the agreed scope will be recommended • Will meet the requirements of ISO 9001: 2000 Registration will be deferred until the completion and verification of the necessary corrective actions • Does not meet the requirements of ISO 9001: 2000 Registration cannot be recommended

RECOMMENDATIONS The Company’s Quality System: • Meets the Requirements of ISO 9001: 2000 Registration to the agreed scope will be recommended • Will meet the requirements of ISO 9001: 2000 Registration will be deferred until the completion and verification of the necessary corrective actions • Does not meet the requirements of ISO 9001: 2000 Registration cannot be recommended

FOLLOW-UP ACTIONS • Deferred Registration Close out or Down rate all outstanding Major / Hold point Non-Conformities. Clear as many Minor / On-Going improvements as possible • Routine Surveillance visits • Re-Registration

FOLLOW-UP ACTIONS • Deferred Registration Close out or Down rate all outstanding Major / Hold point Non-Conformities. Clear as many Minor / On-Going improvements as possible • Routine Surveillance visits • Re-Registration

AUDIT REPORT • Report Identification • Purpose, Objective and Scope of the Audit • Details of Auditors, Dates etc • Reference documents (e. g. Quality Manual, Procedures) • Summary of Audit Results as declared at the Closing Meeting Cont…

AUDIT REPORT • Report Identification • Purpose, Objective and Scope of the Audit • Details of Auditors, Dates etc • Reference documents (e. g. Quality Manual, Procedures) • Summary of Audit Results as declared at the Closing Meeting Cont…

AUDIT REPORT • Details of all Non-Conformities and Observations • Reference to any additional supporting Evidence • Recommendations • Conclusions • Distribution

AUDIT REPORT • Details of all Non-Conformities and Observations • Reference to any additional supporting Evidence • Recommendations • Conclusions • Distribution

NOTE TAKING Recording the objective evidence: • Admissible statements • Document numbers and issue/revision levels • Identifiers • Departments • Name of auditee Cont…

NOTE TAKING Recording the objective evidence: • Admissible statements • Document numbers and issue/revision levels • Identifiers • Departments • Name of auditee Cont…

NOTE TAKING • Notes could be used as reference for: – – Immediate investigation Investigation later Use by a colleague Subsequent audits • Notes must therefore be: – Legible – Retrievable Cont…

NOTE TAKING • Notes could be used as reference for: – – Immediate investigation Investigation later Use by a colleague Subsequent audits • Notes must therefore be: – Legible – Retrievable Cont…

NOTE TAKING • Notes taken during an audit are a record of: – The audit sample taken – What was reported – What was observed • Notes may be referenced by subsequent auditors

NOTE TAKING • Notes taken during an audit are a record of: – The audit sample taken – What was reported – What was observed • Notes may be referenced by subsequent auditors

NONCONFORMITY A situation where there is a likelihood that nonconforming product or service will occur, or where the benefits of the management standard are not being realized, because of the absence of, or lack of adherence to a procedure Cont…

NONCONFORMITY A situation where there is a likelihood that nonconforming product or service will occur, or where the benefits of the management standard are not being realized, because of the absence of, or lack of adherence to a procedure Cont…

NONCONFORMITY • Non fulfillment of a requirement • Specified requirements – conditions of contract – quality standard – quality manual – procedures – legal regulatory requirements Cont…

NONCONFORMITY • Non fulfillment of a requirement • Specified requirements – conditions of contract – quality standard – quality manual – procedures – legal regulatory requirements Cont…

NONCONFORMITY • Manual is not conforming with the quality standard (intent) • Practice is not in line with the intent (implementation) • Practice is not effective (effectiveness)

NONCONFORMITY • Manual is not conforming with the quality standard (intent) • Practice is not in line with the intent (implementation) • Practice is not effective (effectiveness)

THE PURPOSE OF NCR’S To convey your findings to the company in a clear, concise and accurate way so that they know exactly what needs to be done v To provide a record that gives an accurate picture which can subsequently be reviewed remotely from the company v To ensure that another auditor can follow up the corrective action on your findings just as easily as you would yourself v

THE PURPOSE OF NCR’S To convey your findings to the company in a clear, concise and accurate way so that they know exactly what needs to be done v To provide a record that gives an accurate picture which can subsequently be reviewed remotely from the company v To ensure that another auditor can follow up the corrective action on your findings just as easily as you would yourself v

NCR WORDING Report exactly what you observed v Give a factual report, not a commentary or opinion v Write legibly – If you can’t – then print v Choose your words with care for easy reading v Avoid the use of adjectives and adverbs v Try to use words and phrases taken from the chosen paragraph of the standard v Cont…

NCR WORDING Report exactly what you observed v Give a factual report, not a commentary or opinion v Write legibly – If you can’t – then print v Choose your words with care for easy reading v Avoid the use of adjectives and adverbs v Try to use words and phrases taken from the chosen paragraph of the standard v Cont…

NCR WORDING Choose the requirement paragraph with care as a guide to corrective action v Establish “TRACEABILITY” in your report. Be specific – Quote Details v Report accurately – But no personal criticism v Be sure that your report is based on “UNSHAKEABLE” facts v

NCR WORDING Choose the requirement paragraph with care as a guide to corrective action v Establish “TRACEABILITY” in your report. Be specific – Quote Details v Report accurately – But no personal criticism v Be sure that your report is based on “UNSHAKEABLE” facts v

CERTIFICATION Audit against the Requirements of ISO 9000 : 2000 by an accredited certification body which approves then registers or certifies the supplier resulting in: v. Issue of a Certificate v. Entry in the DTI Register v. Use of LOGO on Literature NOTE CERTIFICATION BODIES DO NOT ACCREDITATE SUPPLIERS

CERTIFICATION Audit against the Requirements of ISO 9000 : 2000 by an accredited certification body which approves then registers or certifies the supplier resulting in: v. Issue of a Certificate v. Entry in the DTI Register v. Use of LOGO on Literature NOTE CERTIFICATION BODIES DO NOT ACCREDITATE SUPPLIERS

ACCREDITATION The term Accreditation in the context of Quality Systems is used to denote certification bodies who’s ability to audit against the requirements of ISO 9000 has been independently audited by a National Authority using agreed criteria NOTE Most people assume Accreditation and Certification to be the same thing – they are not

ACCREDITATION The term Accreditation in the context of Quality Systems is used to denote certification bodies who’s ability to audit against the requirements of ISO 9000 has been independently audited by a National Authority using agreed criteria NOTE Most people assume Accreditation and Certification to be the same thing – they are not

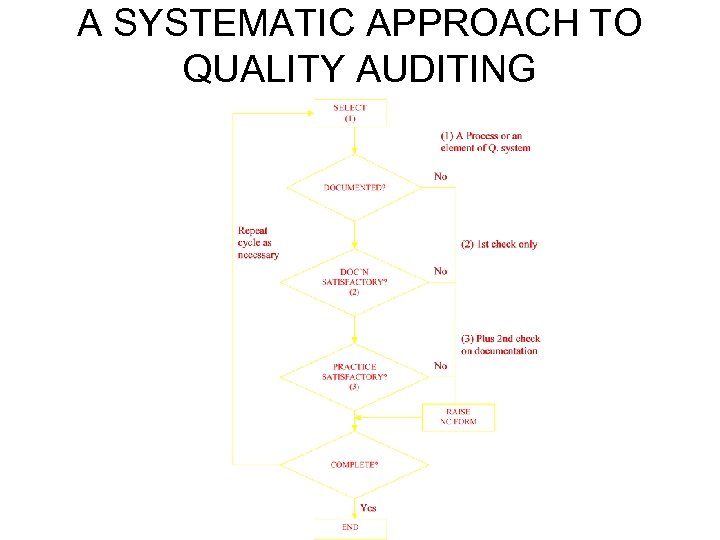

A SYSTEMATIC APPROACH TO QUALITY AUDITING

A SYSTEMATIC APPROACH TO QUALITY AUDITING

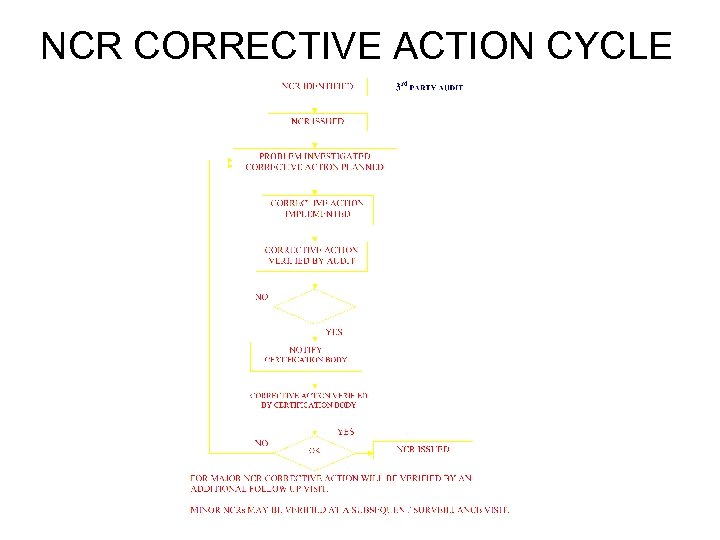

NCR CORRECTIVE ACTION CYCLE

NCR CORRECTIVE ACTION CYCLE

ISO 14000 INTRODUCTION • In the present day, environmental matter is not limited only in one country or specific area. The environmental impact effects everywhere and leads to problem all over the world. • Environmental conservation has become so complicated that it causes pressure to all business organizations. • The International Organization for Standardization had led to the development of the International Standard for environmental management system series (ISO 14000).

ISO 14000 INTRODUCTION • In the present day, environmental matter is not limited only in one country or specific area. The environmental impact effects everywhere and leads to problem all over the world. • Environmental conservation has become so complicated that it causes pressure to all business organizations. • The International Organization for Standardization had led to the development of the International Standard for environmental management system series (ISO 14000).

ISO 14000 INTRODUCTION • After the success of the ISO 9000 series of quality standards in 1987, the International Standards Organization is nearing completion and publication of a comprehensive set of standards for environmental management. • This series of standards is designed to cover the whole area of environmental issues for organizations in the global marketplace.

ISO 14000 INTRODUCTION • After the success of the ISO 9000 series of quality standards in 1987, the International Standards Organization is nearing completion and publication of a comprehensive set of standards for environmental management. • This series of standards is designed to cover the whole area of environmental issues for organizations in the global marketplace.

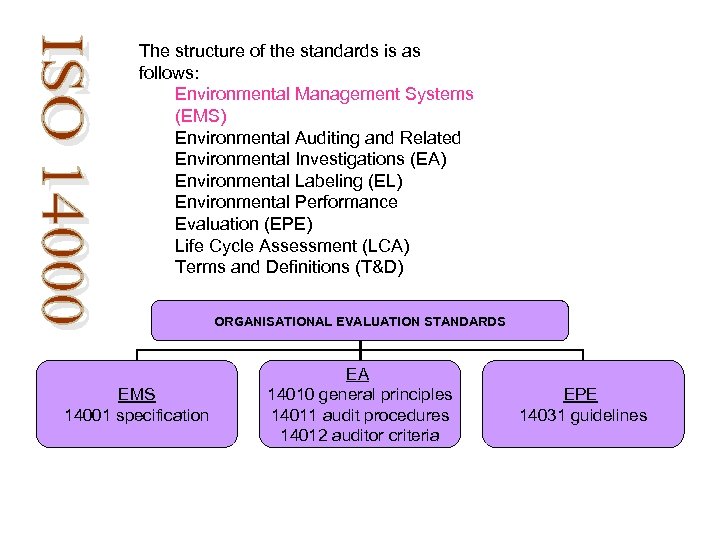

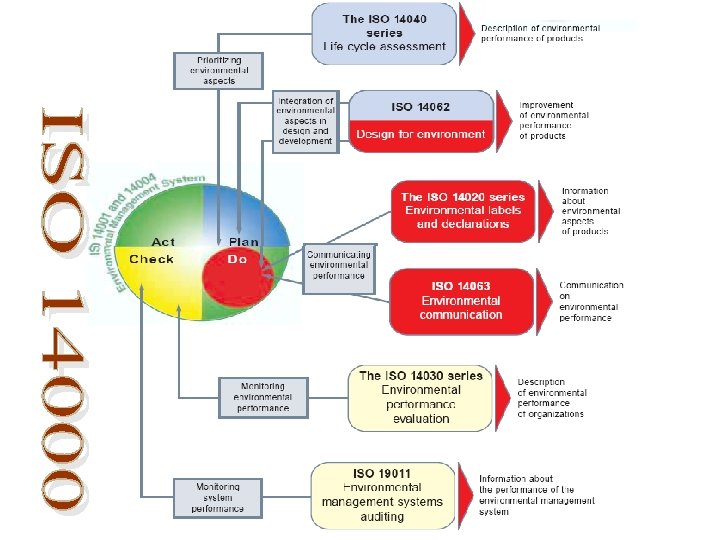

Continues. . • The structure of the standards is as follows: – Environmental Management Systems (EMS) – Environmental Auditing and Related Environmental Investigations (EA) – Environmental Labeling (EL) – Environmental Performance Evaluation (EPE) – Life Cycle Assessment (LCA) – Terms and Definitions (T&D) • ISO 14000 Series is the set of standards relating to environmental management system. • Generally, the standard used for certification is – ISO 14001 Environmental Management Systems Specifications with Guidance for Use.

Continues. . • The structure of the standards is as follows: – Environmental Management Systems (EMS) – Environmental Auditing and Related Environmental Investigations (EA) – Environmental Labeling (EL) – Environmental Performance Evaluation (EPE) – Life Cycle Assessment (LCA) – Terms and Definitions (T&D) • ISO 14000 Series is the set of standards relating to environmental management system. • Generally, the standard used for certification is – ISO 14001 Environmental Management Systems Specifications with Guidance for Use.

ISO 14000 SERIES • The ISO 14000 series is a set of standards concerning EMS including the activities of designing, producing, delivering and servicing. • The concept of the standard is to enable the organization to continually develop and improve its EMS. • Although the series comprises of many standards, the standard ISO 14001 is used as the direction for EMS certification.

ISO 14000 SERIES • The ISO 14000 series is a set of standards concerning EMS including the activities of designing, producing, delivering and servicing. • The concept of the standard is to enable the organization to continually develop and improve its EMS. • Although the series comprises of many standards, the standard ISO 14001 is used as the direction for EMS certification.

WHAT IS ISO 14000 • ISO 14000 is a series of voluntary international standards pertaining to environmental issues. • They are designed to reduce the environmental effects from all aspects of business activities. It is believed that higher efficiency would be realized and "the cost of doing business" would also be reduced , by minimizing business exposure to environmental issues.

WHAT IS ISO 14000 • ISO 14000 is a series of voluntary international standards pertaining to environmental issues. • They are designed to reduce the environmental effects from all aspects of business activities. It is believed that higher efficiency would be realized and "the cost of doing business" would also be reduced , by minimizing business exposure to environmental issues.

What is not ISO 14000 • Is not a PRODUCT and PERFORMANCE standard. • Does not establish levels of pollutants or performance. • Does not establish test standards. • Does not involve initial performance testing. • Does not requires or establish final performance goal. • Does not require the meeting of zero emissions. • Does not mandate best practice technology. • Does not require disclosure of performance levels. • Does not require disclosure of audit results.

What is not ISO 14000 • Is not a PRODUCT and PERFORMANCE standard. • Does not establish levels of pollutants or performance. • Does not establish test standards. • Does not involve initial performance testing. • Does not requires or establish final performance goal. • Does not require the meeting of zero emissions. • Does not mandate best practice technology. • Does not require disclosure of performance levels. • Does not require disclosure of audit results.

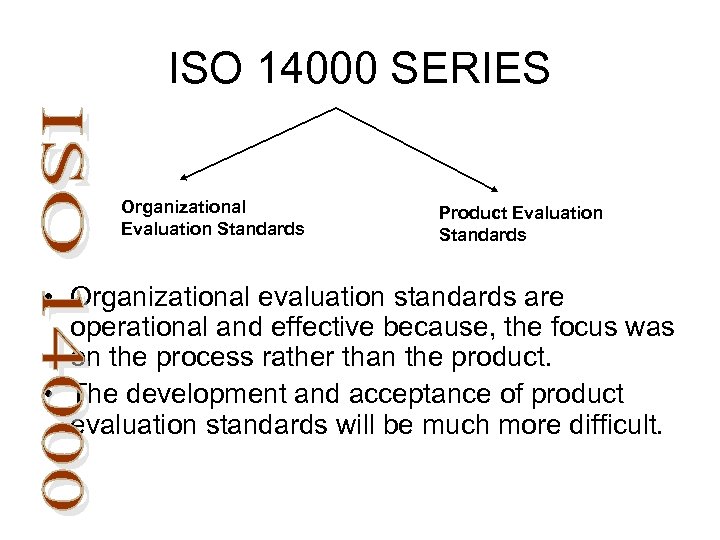

ISO 14000 SERIES Organizational Evaluation Standards Product Evaluation Standards • Organizational evaluation standards are operational and effective because, the focus was on the process rather than the product. • The development and acceptance of product evaluation standards will be much more difficult.

ISO 14000 SERIES Organizational Evaluation Standards Product Evaluation Standards • Organizational evaluation standards are operational and effective because, the focus was on the process rather than the product. • The development and acceptance of product evaluation standards will be much more difficult.

The structure of the standards is as follows: Environmental Management Systems (EMS) Environmental Auditing and Related Environmental Investigations (EA) Environmental Labeling (EL) Environmental Performance Evaluation (EPE) Life Cycle Assessment (LCA) Terms and Definitions (T&D) ORGANISATIONAL EVALUATION STANDARDS EMS 14001 specification EA 14010 general principles 14011 audit procedures 14012 auditor criteria EPE 14031 guidelines

The structure of the standards is as follows: Environmental Management Systems (EMS) Environmental Auditing and Related Environmental Investigations (EA) Environmental Labeling (EL) Environmental Performance Evaluation (EPE) Life Cycle Assessment (LCA) Terms and Definitions (T&D) ORGANISATIONAL EVALUATION STANDARDS EMS 14001 specification EA 14010 general principles 14011 audit procedures 14012 auditor criteria EPE 14031 guidelines

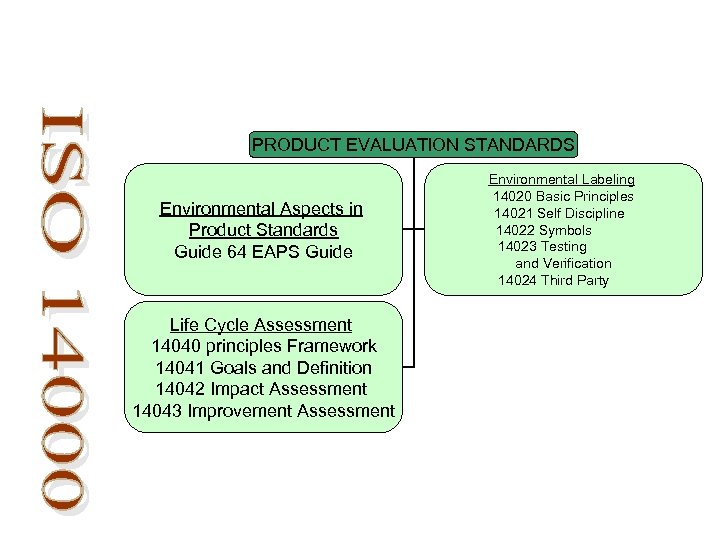

PRODUCT EVALUATION STANDARDS Environmental Aspects in Product Standards Guide 64 EAPS Guide Life Cycle Assessment 14040 principles Framework 14041 Goals and Definition 14042 Impact Assessment 14043 Improvement Assessment Environmental Labeling 14020 Basic Principles 14021 Self Discipline 14022 Symbols 14023 Testing and Verification 14024 Third Party

PRODUCT EVALUATION STANDARDS Environmental Aspects in Product Standards Guide 64 EAPS Guide Life Cycle Assessment 14040 principles Framework 14041 Goals and Definition 14042 Impact Assessment 14043 Improvement Assessment Environmental Labeling 14020 Basic Principles 14021 Self Discipline 14022 Symbols 14023 Testing and Verification 14024 Third Party

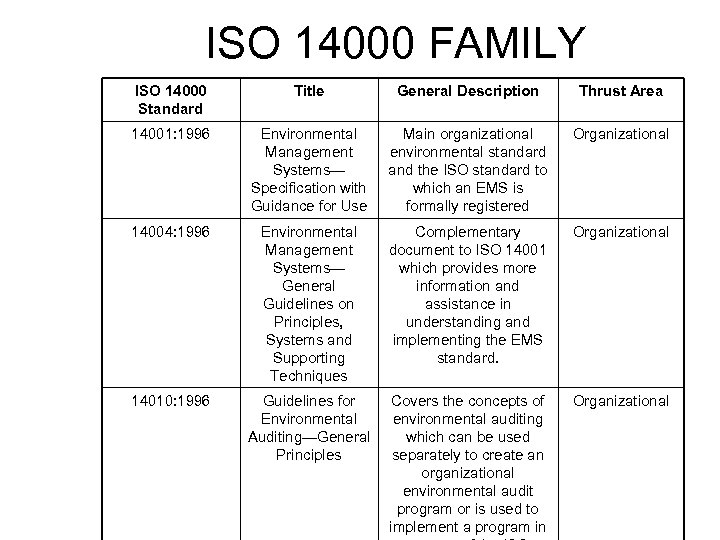

ISO 14000 FAMILY ISO 14000 Standard Title General Description Thrust Area 14001: 1996 Environmental Management Systems— Specification with Guidance for Use Main organizational environmental standard and the ISO standard to which an EMS is formally registered Organizational 14004: 1996 Environmental Management Systems— General Guidelines on Principles, Systems and Supporting Techniques Complementary document to ISO 14001 which provides more information and assistance in understanding and implementing the EMS standard. Organizational 14010: 1996 Guidelines for Environmental Auditing—General Principles Covers the concepts of environmental auditing which can be used separately to create an organizational environmental audit program or is used to implement a program in Organizational

ISO 14000 FAMILY ISO 14000 Standard Title General Description Thrust Area 14001: 1996 Environmental Management Systems— Specification with Guidance for Use Main organizational environmental standard and the ISO standard to which an EMS is formally registered Organizational 14004: 1996 Environmental Management Systems— General Guidelines on Principles, Systems and Supporting Techniques Complementary document to ISO 14001 which provides more information and assistance in understanding and implementing the EMS standard. Organizational 14010: 1996 Guidelines for Environmental Auditing—General Principles Covers the concepts of environmental auditing which can be used separately to create an organizational environmental audit program or is used to implement a program in Organizational

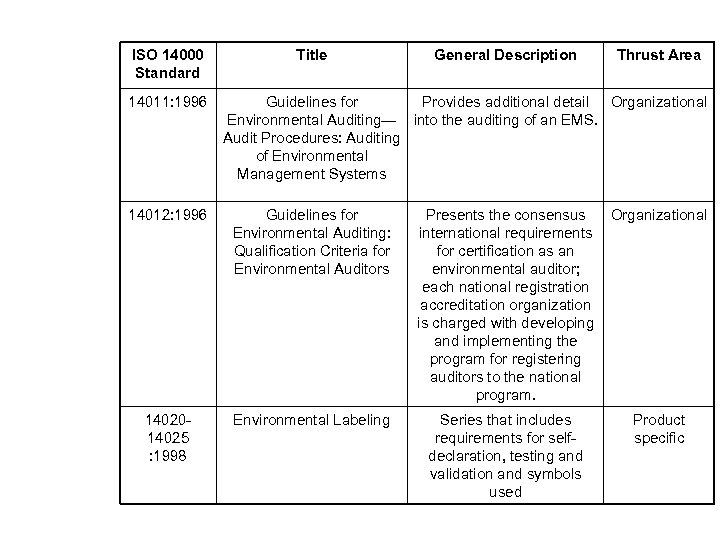

ISO 14000 Standard 14011: 1996 Title General Description Thrust Area Guidelines for Provides additional detail Organizational Environmental Auditing— into the auditing of an EMS. Audit Procedures: Auditing of Environmental Management Systems 14012: 1996 Guidelines for Environmental Auditing: Qualification Criteria for Environmental Auditors 1402014025 : 1998 Environmental Labeling Presents the consensus Organizational international requirements for certification as an environmental auditor; each national registration accreditation organization is charged with developing and implementing the program for registering auditors to the national program. Series that includes requirements for selfdeclaration, testing and validation and symbols used Product specific

ISO 14000 Standard 14011: 1996 Title General Description Thrust Area Guidelines for Provides additional detail Organizational Environmental Auditing— into the auditing of an EMS. Audit Procedures: Auditing of Environmental Management Systems 14012: 1996 Guidelines for Environmental Auditing: Qualification Criteria for Environmental Auditors 1402014025 : 1998 Environmental Labeling Presents the consensus Organizational international requirements for certification as an environmental auditor; each national registration accreditation organization is charged with developing and implementing the program for registering auditors to the national program. Series that includes requirements for selfdeclaration, testing and validation and symbols used Product specific

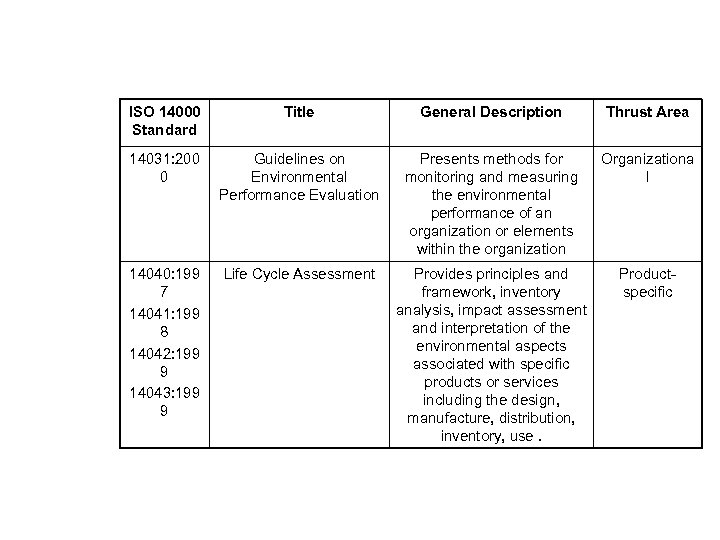

ISO 14000 Standard Title General Description Thrust Area 14031: 200 0 Guidelines on Environmental Performance Evaluation Presents methods for monitoring and measuring the environmental performance of an organization or elements within the organization Organizationa l 14040: 199 7 14041: 199 8 14042: 199 9 14043: 199 9 Life Cycle Assessment Provides principles and framework, inventory analysis, impact assessment and interpretation of the environmental aspects associated with specific products or services including the design, manufacture, distribution, inventory, use. Productspecific

ISO 14000 Standard Title General Description Thrust Area 14031: 200 0 Guidelines on Environmental Performance Evaluation Presents methods for monitoring and measuring the environmental performance of an organization or elements within the organization Organizationa l 14040: 199 7 14041: 199 8 14042: 199 9 14043: 199 9 Life Cycle Assessment Provides principles and framework, inventory analysis, impact assessment and interpretation of the environmental aspects associated with specific products or services including the design, manufacture, distribution, inventory, use. Productspecific

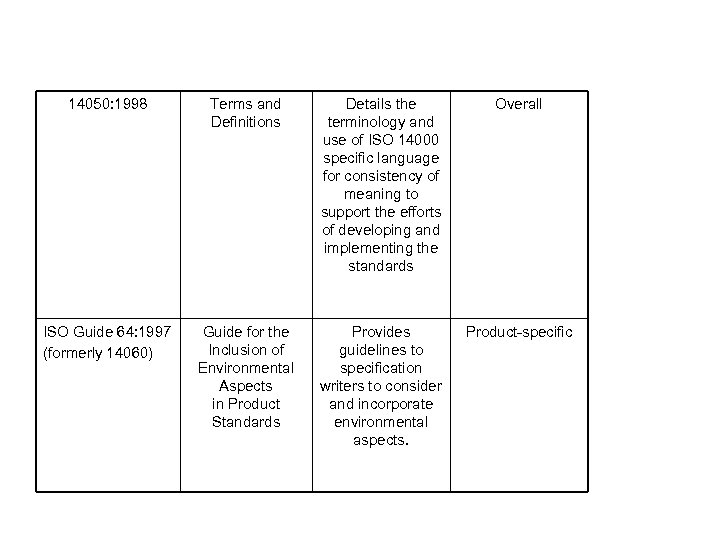

14050: 1998 Terms and Definitions Details the terminology and use of ISO 14000 specific language for consistency of meaning to support the efforts of developing and implementing the standards Overall ISO Guide 64: 1997 (formerly 14060) Guide for the Inclusion of Environmental Aspects in Product Standards Provides guidelines to specification writers to consider and incorporate environmental aspects. Product-specific

14050: 1998 Terms and Definitions Details the terminology and use of ISO 14000 specific language for consistency of meaning to support the efforts of developing and implementing the standards Overall ISO Guide 64: 1997 (formerly 14060) Guide for the Inclusion of Environmental Aspects in Product Standards Provides guidelines to specification writers to consider and incorporate environmental aspects. Product-specific

ISO 14000 POLICY • Prevention of pollution. • Continual Environmental Improvement. • Commitment to comply with Environmental Laws and Regulations • Applicable in size and scope.

ISO 14000 POLICY • Prevention of pollution. • Continual Environmental Improvement. • Commitment to comply with Environmental Laws and Regulations • Applicable in size and scope.

ISO 14000 Policy, Continued • Establish framework for setting and reviewing objectives and targets • Documented, implemented, maintained, and communicated to employees. • Available to the public

ISO 14000 Policy, Continued • Establish framework for setting and reviewing objectives and targets • Documented, implemented, maintained, and communicated to employees. • Available to the public

ISO 14000 Concepts The basic concept underlying the ISO 14000 series is that in order to consistently meet environmental performance expectations, an organization must implement and maintain an effective environmental management system. While the system cannot guarantee that environmental incidents will never occur, --it is intended to minimize the likelihood and severity of their occurrence -- it can guarantee that when they occur, there is a mechanism in place to investigate the causes and to take corrective and preventive action.

ISO 14000 Concepts The basic concept underlying the ISO 14000 series is that in order to consistently meet environmental performance expectations, an organization must implement and maintain an effective environmental management system. While the system cannot guarantee that environmental incidents will never occur, --it is intended to minimize the likelihood and severity of their occurrence -- it can guarantee that when they occur, there is a mechanism in place to investigate the causes and to take corrective and preventive action.

REQUIREMENTS Procedures to ensure that the company can identify legal and other environments requirements are required to be established and maintained. It is also required to know how the organization § Access and identify legal and other requirements § Keep track of changes to legal and other requirements §Communicate relevant information about legal and other requirements to employees

REQUIREMENTS Procedures to ensure that the company can identify legal and other environments requirements are required to be established and maintained. It is also required to know how the organization § Access and identify legal and other requirements § Keep track of changes to legal and other requirements §Communicate relevant information about legal and other requirements to employees

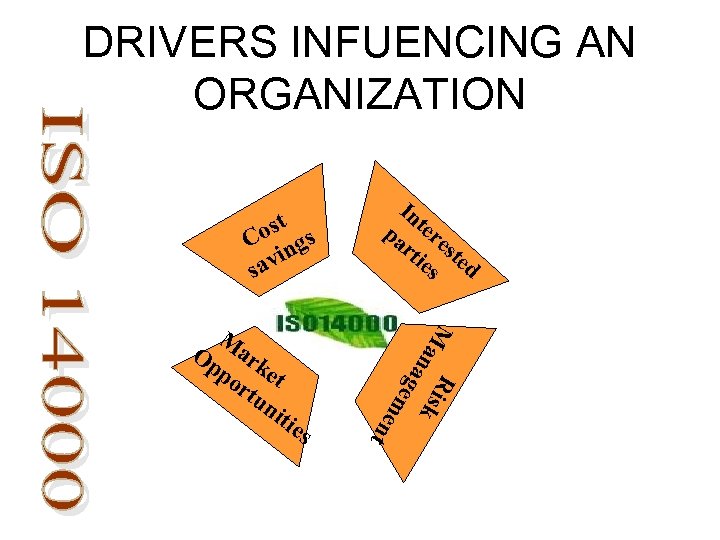

DRIVERS INFUENCING AN ORGANIZATION ost s C ng i av s M R an is ag k e s m en t M Op ark po et rtu ni tie In pa tere rt st ies ed

DRIVERS INFUENCING AN ORGANIZATION ost s C ng i av s M R an is ag k e s m en t M Op ark po et rtu ni tie In pa tere rt st ies ed

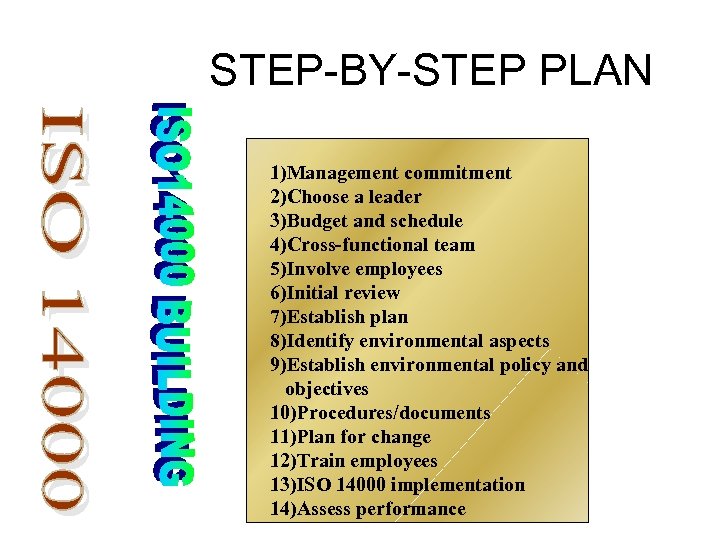

STEP-BY-STEP PLAN 1)Management commitment 2)Choose a leader 3)Budget and schedule 4)Cross-functional team 5)Involve employees 6)Initial review 7)Establish plan 8)Identify environmental aspects 9)Establish environmental policy and objectives 10)Procedures/documents 11)Plan for change 12)Train employees 13)ISO 14000 implementation 14)Assess performance

STEP-BY-STEP PLAN 1)Management commitment 2)Choose a leader 3)Budget and schedule 4)Cross-functional team 5)Involve employees 6)Initial review 7)Establish plan 8)Identify environmental aspects 9)Establish environmental policy and objectives 10)Procedures/documents 11)Plan for change 12)Train employees 13)ISO 14000 implementation 14)Assess performance

1. Gaining Management Commitment: An organization must have commitment and careful planning to figure out 1) What it needs to do, 2) How it will be done, and 3) Which people of the organization should be involved 2. Choosing a leader: The choice of the leader is critical. The person must have some experience with the quality management programme and have the time and temperamental commitment. Necessary authority, an understanding of the organization and project management skills

1. Gaining Management Commitment: An organization must have commitment and careful planning to figure out 1) What it needs to do, 2) How it will be done, and 3) Which people of the organization should be involved 2. Choosing a leader: The choice of the leader is critical. The person must have some experience with the quality management programme and have the time and temperamental commitment. Necessary authority, an understanding of the organization and project management skills

3. Preparing a budget and Schedule: Leader is responsible for preparing a preliminary budget in which costs will likely include staff and employee time, training consultant fees, materials. The schedule should consider the various tasks and roadblocks, depending on the dimension and complexity of the organization. 4. Constituting a project team: A team with representation from key management functions and production or service areas can identify and assess issues, opportunities and existing processes.

3. Preparing a budget and Schedule: Leader is responsible for preparing a preliminary budget in which costs will likely include staff and employee time, training consultant fees, materials. The schedule should consider the various tasks and roadblocks, depending on the dimension and complexity of the organization. 4. Constituting a project team: A team with representation from key management functions and production or service areas can identify and assess issues, opportunities and existing processes.

5. Employee participation: A great source of knowledge on environmental and health and safety issues related to their areas well as on the effectiveness of current processes and procedures. 6. Undertaking an initial review: Preparation of a list of the environmental requirements of the organization (regulations, guidelines and other documents). The preparatory review itself should be comprehensive in consideration of input processes and output.

5. Employee participation: A great source of knowledge on environmental and health and safety issues related to their areas well as on the effectiveness of current processes and procedures. 6. Undertaking an initial review: Preparation of a list of the environmental requirements of the organization (regulations, guidelines and other documents). The preparatory review itself should be comprehensive in consideration of input processes and output.

7. Establishing a plan: Quantified targets will show management the quantum of workload required for implementation what resources are needed and opportunities for cost-effective improvement. 8. Evaluating Environmental aspects: Actual environmental aspects and impacts of the organization should be listed out. To each of these identified aspects, the level of risk involved with conformance and nonconformance should be evaluated.

7. Establishing a plan: Quantified targets will show management the quantum of workload required for implementation what resources are needed and opportunities for cost-effective improvement. 8. Evaluating Environmental aspects: Actual environmental aspects and impacts of the organization should be listed out. To each of these identified aspects, the level of risk involved with conformance and nonconformance should be evaluated.

9. Establishing an environmental policy and objectives: Foundation and direction for the management system. The policy needs to clarify compliance with environmental legislation that may affect the organization and stress a commitment to continuous improvement. The organization will declare its primary environmental objectives. 10. Preparing procedures and Documents: Develop procedures and other system documents which might involve modifying current environmental procedures or adapting other business procedures (such as quality, ergonomics, health and safety management procedures)

9. Establishing an environmental policy and objectives: Foundation and direction for the management system. The policy needs to clarify compliance with environmental legislation that may affect the organization and stress a commitment to continuous improvement. The organization will declare its primary environmental objectives. 10. Preparing procedures and Documents: Develop procedures and other system documents which might involve modifying current environmental procedures or adapting other business procedures (such as quality, ergonomics, health and safety management procedures)

11. Planning for Change: It should be made sure that the system is sufficiently flexible and simple. Avoid making it so rigid to reflect the realities of operations and activities. 12. Training of Employees: Training of employees wit regard to the environmental impacts of their activities, any new/modified procedures and any new responsibilities.

11. Planning for Change: It should be made sure that the system is sufficiently flexible and simple. Avoid making it so rigid to reflect the realities of operations and activities. 12. Training of Employees: Training of employees wit regard to the environmental impacts of their activities, any new/modified procedures and any new responsibilities.

13. Implementation of ISO 14000: To clean up the obvious problems, and identify areas where the organization is not complying with the regulations or customer demands. Those areas where that organization stands to gain greater efficiency should be targeted. (scrap and waste reduction projects, recycling and elimination of liabilities) 14. Assessing the performance: Planned comprehensive periodic audit to ensure that it is effective in operation, meeting specified goals, and the system continues to perform in accordance with relevant regulations and standards. Management review is also required to ensure that it is suitable and effective in operation. Provides the opportunity to improve the system and environmental performance over time.

13. Implementation of ISO 14000: To clean up the obvious problems, and identify areas where the organization is not complying with the regulations or customer demands. Those areas where that organization stands to gain greater efficiency should be targeted. (scrap and waste reduction projects, recycling and elimination of liabilities) 14. Assessing the performance: Planned comprehensive periodic audit to ensure that it is effective in operation, meeting specified goals, and the system continues to perform in accordance with relevant regulations and standards. Management review is also required to ensure that it is suitable and effective in operation. Provides the opportunity to improve the system and environmental performance over time.

TYPES OF RECORDS • Environmental aspects determination documentation • Legal and other regulatory requirements and records of regulatory violations. • Permits consents, licenses and other approvals • Progress reports towards meeting objectives and targets. • Hazardous material spills, other incident reports and follow ups. • MSDS • Sampling and monitoring data • Maintenance records • Calibration and maintenance records for instrumentation • Training records • EMS audit and regulatory compliance audit reports • Management review documentation