501757eb07c6faa9690047efc47ca6d0.ppt

- Количество слайдов: 20

UNIQUE REQUIREMENTS DESERVE UNIQUE SOLUTIONS. MTU ONSITE ENERGY Gas Power Systems © MTU Onsite Energy Gmb. H Alle Rechte vorbehalten / Vertraulich

UNIQUE REQUIREMENTS DESERVE UNIQUE SOLUTIONS. MTU ONSITE ENERGY Gas Power Systems © MTU Onsite Energy Gmb. H Alle Rechte vorbehalten / Vertraulich

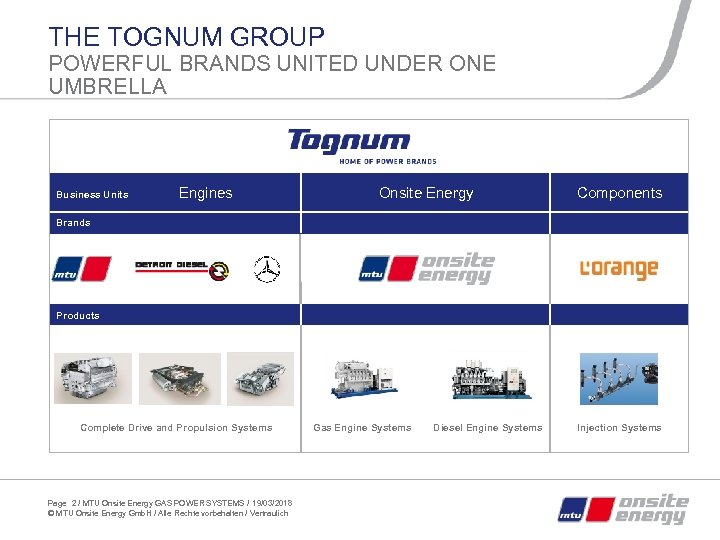

THE TOGNUM GROUP POWERFUL BRANDS UNITED UNDER ONE UMBRELLA Business Units Engines Onsite Energy Components Brands Products Complete Drive and Propulsion Systems Page 2 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich Gas Engine Systems Diesel Engine Systems Injection Systems

THE TOGNUM GROUP POWERFUL BRANDS UNITED UNDER ONE UMBRELLA Business Units Engines Onsite Energy Components Brands Products Complete Drive and Propulsion Systems Page 2 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich Gas Engine Systems Diesel Engine Systems Injection Systems

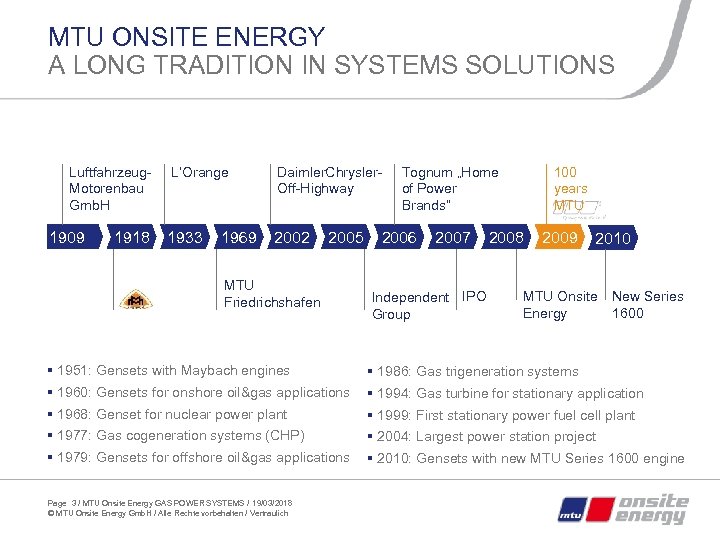

MTU ONSITE ENERGY A LONG TRADITION IN SYSTEMS SOLUTIONS Luftfahrzeug. Motorenbau Gmb. H 1909 1918 L‘Orange Daimler. Chrysler. Off-Highway 1933 2002 1969 2005 MTU Friedrichshafen Tognum „Home of Power Brands” 2006 2007 Independent IPO Group 100 years MTU 2008 2009 2010 MTU Onsite Energy New Series 1600 § 1951: Gensets with Maybach engines § 1986: Gas trigeneration systems § 1960: Gensets for onshore oil&gas applications § 1994: Gas turbine for stationary application § 1968: Genset for nuclear power plant § 1999: First stationary power fuel cell plant § 1977: Gas cogeneration systems (CHP) § 2004: Largest power station project § 1979: Gensets for offshore oil&gas applications § 2010: Gensets with new MTU Series 1600 engine Page 3 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

MTU ONSITE ENERGY A LONG TRADITION IN SYSTEMS SOLUTIONS Luftfahrzeug. Motorenbau Gmb. H 1909 1918 L‘Orange Daimler. Chrysler. Off-Highway 1933 2002 1969 2005 MTU Friedrichshafen Tognum „Home of Power Brands” 2006 2007 Independent IPO Group 100 years MTU 2008 2009 2010 MTU Onsite Energy New Series 1600 § 1951: Gensets with Maybach engines § 1986: Gas trigeneration systems § 1960: Gensets for onshore oil&gas applications § 1994: Gas turbine for stationary application § 1968: Genset for nuclear power plant § 1999: First stationary power fuel cell plant § 1977: Gas cogeneration systems (CHP) § 2004: Largest power station project § 1979: Gensets for offshore oil&gas applications § 2010: Gensets with new MTU Series 1600 engine Page 3 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

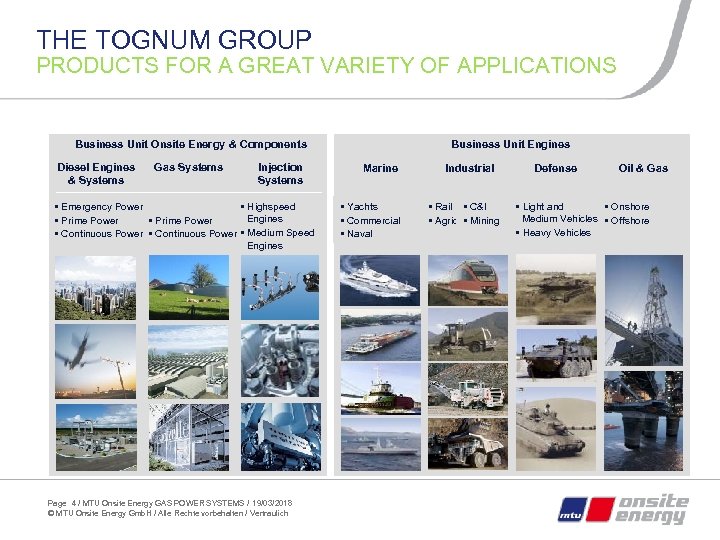

THE TOGNUM GROUP PRODUCTS FOR A GREAT VARIETY OF APPLICATIONS Business Unit Onsite Energy & Components Diesel Engines & Systems Gas Systems Injection Systems • Emergency Power • Highspeed Engines • Prime Power • Continuous Power • Medium Speed Engines Page 4 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich Business Unit Engines Marine • Yachts • Commercial • Naval Industrial • Rail • C&I • Agric. • Mining Defense Oil & Gas • Light and • Onshore Medium Vehicles • Offshore • Heavy Vehicles

THE TOGNUM GROUP PRODUCTS FOR A GREAT VARIETY OF APPLICATIONS Business Unit Onsite Energy & Components Diesel Engines & Systems Gas Systems Injection Systems • Emergency Power • Highspeed Engines • Prime Power • Continuous Power • Medium Speed Engines Page 4 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich Business Unit Engines Marine • Yachts • Commercial • Naval Industrial • Rail • C&I • Agric. • Mining Defense Oil & Gas • Light and • Onshore Medium Vehicles • Offshore • Heavy Vehicles

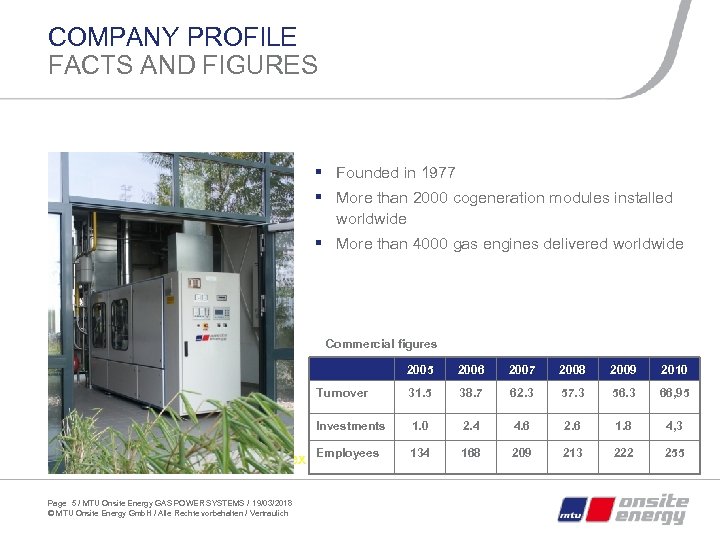

COMPANY PROFILE FACTS AND FIGURES § Founded in 1977 § More than 2000 cogeneration modules installed worldwide § More than 4000 gas engines delivered worldwide Commercial figures 2005 Page 5 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich 2007 2008 2009 2010 Turnover 120 k. W Cogeneration Plant at MTU’s OG Augsburg office complex 2006 31. 5 38. 7 62. 3 57. 3 56. 3 66, 95 Investments 1. 0 2. 4 4. 6 2. 6 1. 8 4, 3 Employees 134 168 209 213 222 255

COMPANY PROFILE FACTS AND FIGURES § Founded in 1977 § More than 2000 cogeneration modules installed worldwide § More than 4000 gas engines delivered worldwide Commercial figures 2005 Page 5 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich 2007 2008 2009 2010 Turnover 120 k. W Cogeneration Plant at MTU’s OG Augsburg office complex 2006 31. 5 38. 7 62. 3 57. 3 56. 3 66, 95 Investments 1. 0 2. 4 4. 6 2. 6 1. 8 4, 3 Employees 134 168 209 213 222 255

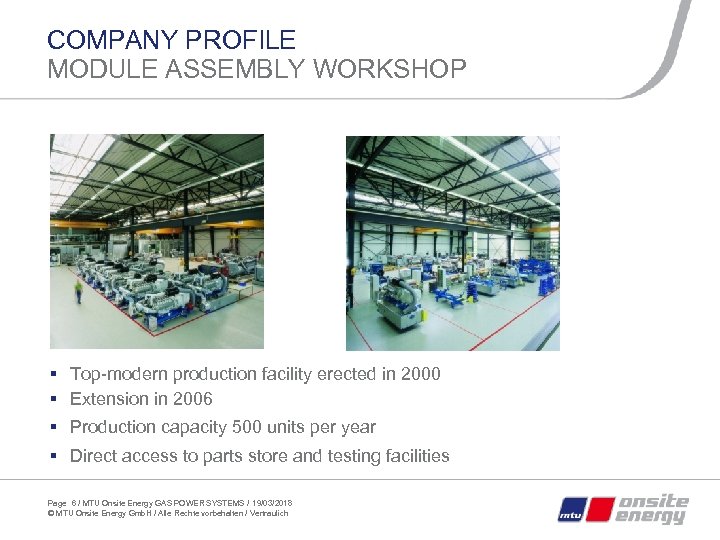

COMPANY PROFILE MODULE ASSEMBLY WORKSHOP § Top-modern production facility erected in 2000 § Extension in 2006 § Production capacity 500 units per year § Direct access to parts store and testing facilities Page 6 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

COMPANY PROFILE MODULE ASSEMBLY WORKSHOP § Top-modern production facility erected in 2000 § Extension in 2006 § Production capacity 500 units per year § Direct access to parts store and testing facilities Page 6 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

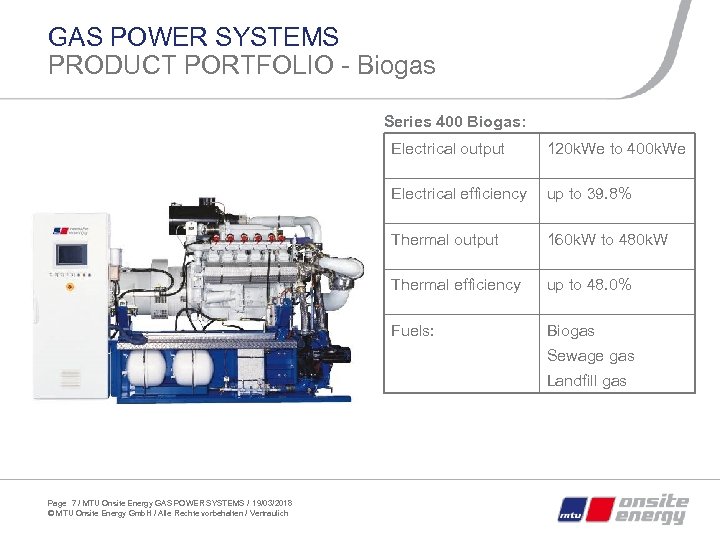

GAS POWER SYSTEMS PRODUCT PORTFOLIO - Biogas Series 400 Biogas: Electrical output 120 k. We to 400 k. We Electrical efficiency up to 39. 8% Thermal output 160 k. W to 480 k. W Thermal efficiency up to 48. 0% Fuels: Biogas Sewage gas Landfill gas Page 7 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

GAS POWER SYSTEMS PRODUCT PORTFOLIO - Biogas Series 400 Biogas: Electrical output 120 k. We to 400 k. We Electrical efficiency up to 39. 8% Thermal output 160 k. W to 480 k. W Thermal efficiency up to 48. 0% Fuels: Biogas Sewage gas Landfill gas Page 7 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

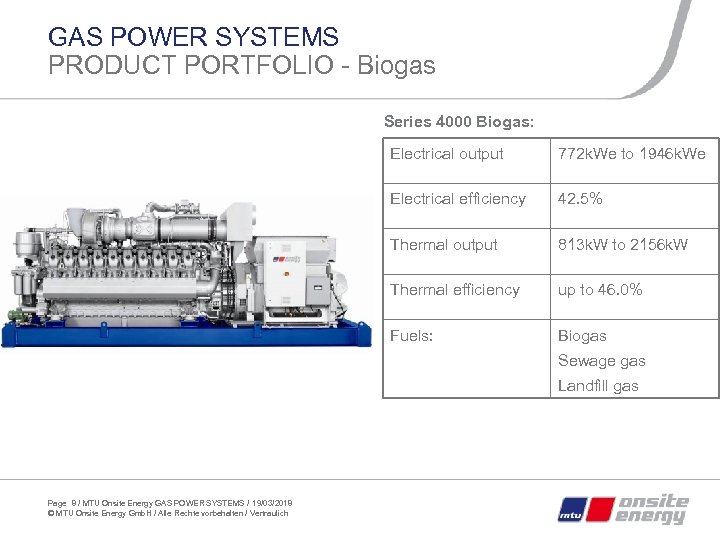

GAS POWER SYSTEMS PRODUCT PORTFOLIO - Biogas Series 4000 Biogas: Electrical output 772 k. We to 1946 k. We Electrical efficiency 42. 5% Thermal output 813 k. W to 2156 k. W Thermal efficiency up to 46. 0% Fuels: Biogas Sewage gas Landfill gas Page 8 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

GAS POWER SYSTEMS PRODUCT PORTFOLIO - Biogas Series 4000 Biogas: Electrical output 772 k. We to 1946 k. We Electrical efficiency 42. 5% Thermal output 813 k. W to 2156 k. W Thermal efficiency up to 46. 0% Fuels: Biogas Sewage gas Landfill gas Page 8 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

GAS POWER SYSTEMS KEY BENEFITS § Engine manufacturer: State-of-the-art technology for our gas engines Series 400 and 4000 and in-house development and production of major components § Economical: Low life cycle costs with proven records from the field § Eco-friendly: Renewables as biogas and natural gas with total efficiency up to 92% preserve the environment and deliver sustainability § Reliable: Premium quality products stand for high availability: industry-leading engine from MTU, generator supplied by Leroy-Somer or Stamford § Flexible solutions: Gensets, power modules and containerized solutions - plus complete system engineering § Intelligent and dependable: Customizable MTU Onsite Energy control electronics with remote support Page 9 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

GAS POWER SYSTEMS KEY BENEFITS § Engine manufacturer: State-of-the-art technology for our gas engines Series 400 and 4000 and in-house development and production of major components § Economical: Low life cycle costs with proven records from the field § Eco-friendly: Renewables as biogas and natural gas with total efficiency up to 92% preserve the environment and deliver sustainability § Reliable: Premium quality products stand for high availability: industry-leading engine from MTU, generator supplied by Leroy-Somer or Stamford § Flexible solutions: Gensets, power modules and containerized solutions - plus complete system engineering § Intelligent and dependable: Customizable MTU Onsite Energy control electronics with remote support Page 9 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

APPLICATION EXAMPLE BIOGAS INSTALLATION “ÜHLFELD” § Type: 2 x GR 370 B 5 § Electrical Output: 2 x 370 k. Wel § Biogas derived from fermented renewable materials (maize silage, grain) Customer requirements: § Operation 8200 h/a, 24 h/day § Availability > 95% Selling Electricity Page 10 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

APPLICATION EXAMPLE BIOGAS INSTALLATION “ÜHLFELD” § Type: 2 x GR 370 B 5 § Electrical Output: 2 x 370 k. Wel § Biogas derived from fermented renewable materials (maize silage, grain) Customer requirements: § Operation 8200 h/a, 24 h/day § Availability > 95% Selling Electricity Page 10 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

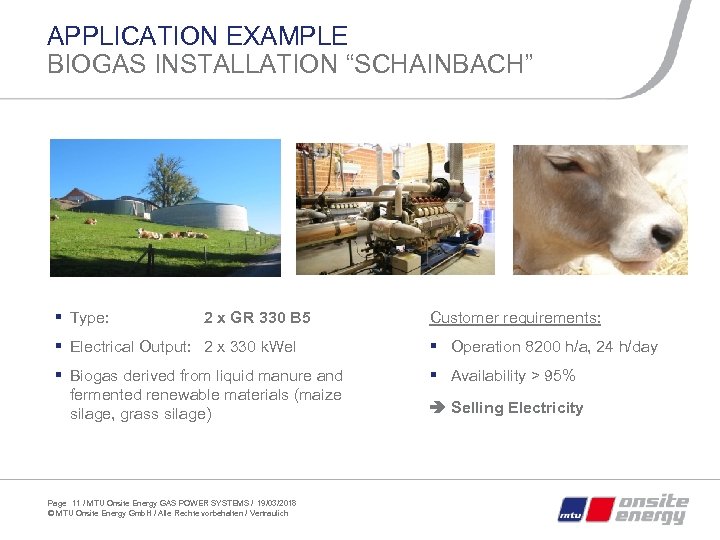

APPLICATION EXAMPLE BIOGAS INSTALLATION “SCHAINBACH” § Type: 2 x GR 330 B 5 Customer requirements: § Electrical Output: 2 x 330 k. Wel § Operation 8200 h/a, 24 h/day § Biogas derived from liquid manure and fermented renewable materials (maize silage, grass silage) § Availability > 95% Page 11 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich Selling Electricity

APPLICATION EXAMPLE BIOGAS INSTALLATION “SCHAINBACH” § Type: 2 x GR 330 B 5 Customer requirements: § Electrical Output: 2 x 330 k. Wel § Operation 8200 h/a, 24 h/day § Biogas derived from liquid manure and fermented renewable materials (maize silage, grass silage) § Availability > 95% Page 11 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich Selling Electricity

Group Overview 2011 Page 12 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

Group Overview 2011 Page 12 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

Mission Statement To deliver renewable and conventional high efficiency on-site electrical, cooling and heat generation solutions. To supply energy efficient products and services providing substantial financial and CO 2 savings to our customers Page 13 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

Mission Statement To deliver renewable and conventional high efficiency on-site electrical, cooling and heat generation solutions. To supply energy efficient products and services providing substantial financial and CO 2 savings to our customers Page 13 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

Company Information HISTORY: Established in 1998, with operations in Europe, Middle East and Australia PEOPLE: Experienced management team, engineers, administration staff, and maintenance technicians IN-HOUSE DESIGN: Engineering design team; Auto. CAD capabilities; PI cover INSTALL & COMMISSION: Fully trained team with M&E expertise to deliver solution from design to handover AFTER-SALES: 24/7 in-house maintenance team with personal PDAs and monitoring systems QUALITY & ENVIRONMENTAL: Currently implementing systems for ISO Accreditation. Established relationships and OEM status with industry leading suppliers PROVEN: Over 10 years experience in delivery of complex projects in HVAC, CHP/Tri-Generation, and District Heating applications Social Responsibility: ‘Power to Change’ – Current focus is on Haiti & East Timor Page 14 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

Company Information HISTORY: Established in 1998, with operations in Europe, Middle East and Australia PEOPLE: Experienced management team, engineers, administration staff, and maintenance technicians IN-HOUSE DESIGN: Engineering design team; Auto. CAD capabilities; PI cover INSTALL & COMMISSION: Fully trained team with M&E expertise to deliver solution from design to handover AFTER-SALES: 24/7 in-house maintenance team with personal PDAs and monitoring systems QUALITY & ENVIRONMENTAL: Currently implementing systems for ISO Accreditation. Established relationships and OEM status with industry leading suppliers PROVEN: Over 10 years experience in delivery of complex projects in HVAC, CHP/Tri-Generation, and District Heating applications Social Responsibility: ‘Power to Change’ – Current focus is on Haiti & East Timor Page 14 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

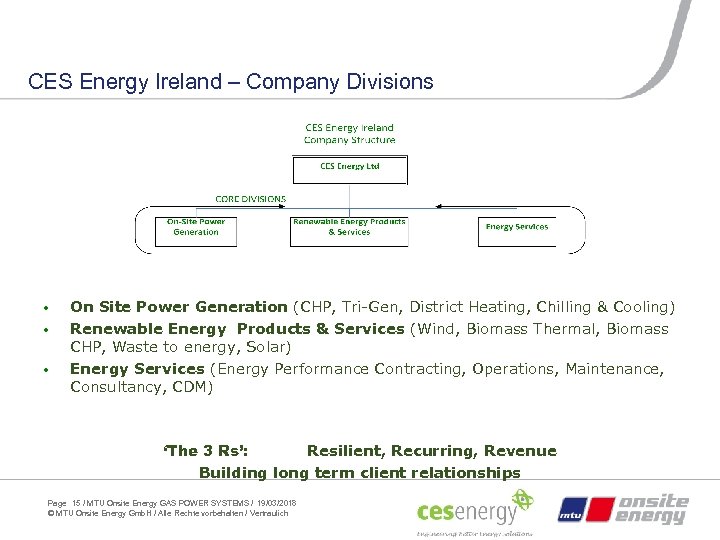

CES Energy Ireland – Company Divisions • • • On Site Power Generation (CHP, Tri-Gen, District Heating, Chilling & Cooling) Renewable Energy Products & Services (Wind, Biomass Thermal, Biomass CHP, Waste to energy, Solar) Energy Services (Energy Performance Contracting, Operations, Maintenance, Consultancy, CDM) ‘The 3 Rs’: Resilient, Recurring, Revenue Building long term client relationships Page 15 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

CES Energy Ireland – Company Divisions • • • On Site Power Generation (CHP, Tri-Gen, District Heating, Chilling & Cooling) Renewable Energy Products & Services (Wind, Biomass Thermal, Biomass CHP, Waste to energy, Solar) Energy Services (Energy Performance Contracting, Operations, Maintenance, Consultancy, CDM) ‘The 3 Rs’: Resilient, Recurring, Revenue Building long term client relationships Page 15 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

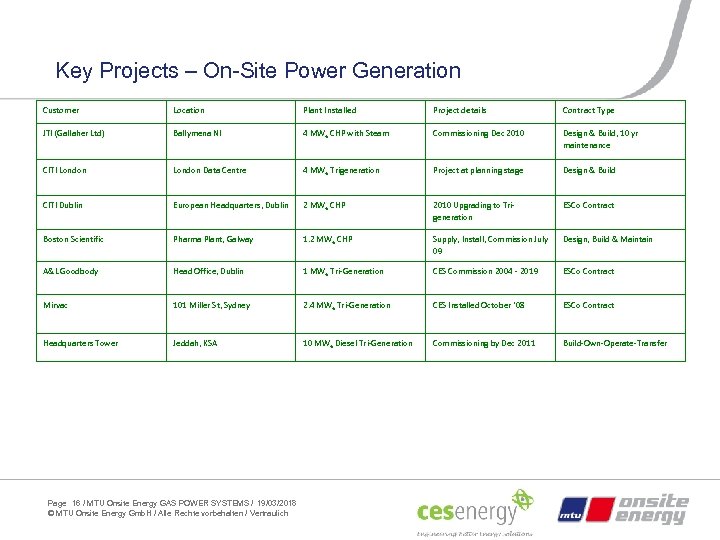

Key Projects – On-Site Power Generation Customer Location Plant Installed Project details Contract Type JTI (Gallaher Ltd) Ballymena NI 4 MWe CHP with Steam Commissioning Dec 2010 Design & Build, 10 yr maintenance CITI London Data Centre 4 MWe Trigeneration Project at planning stage Design & Build CITI Dublin European Headquarters, Dublin 2 MWe CHP 2010 Upgrading to Trigeneration ESCo Contract Boston Scientific Pharma Plant, Galway 1. 2 MWe CHP Supply, Install, Commission July 09 Design, Build & Maintain A&L Goodbody Head Office, Dublin 1 MWe Tri-Generation CES Commission 2004 - 2019 ESCo Contract Mirvac 101 Miller St, Sydney 2. 4 MWe Tri-Generation CES Installed October ‘ 08 ESCo Contract Headquarters Tower Jeddah, KSA 10 MWe Diesel Tri-Generation Commissioning by Dec 2011 Build-Own-Operate-Transfer Page 16 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

Key Projects – On-Site Power Generation Customer Location Plant Installed Project details Contract Type JTI (Gallaher Ltd) Ballymena NI 4 MWe CHP with Steam Commissioning Dec 2010 Design & Build, 10 yr maintenance CITI London Data Centre 4 MWe Trigeneration Project at planning stage Design & Build CITI Dublin European Headquarters, Dublin 2 MWe CHP 2010 Upgrading to Trigeneration ESCo Contract Boston Scientific Pharma Plant, Galway 1. 2 MWe CHP Supply, Install, Commission July 09 Design, Build & Maintain A&L Goodbody Head Office, Dublin 1 MWe Tri-Generation CES Commission 2004 - 2019 ESCo Contract Mirvac 101 Miller St, Sydney 2. 4 MWe Tri-Generation CES Installed October ‘ 08 ESCo Contract Headquarters Tower Jeddah, KSA 10 MWe Diesel Tri-Generation Commissioning by Dec 2011 Build-Own-Operate-Transfer Page 16 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

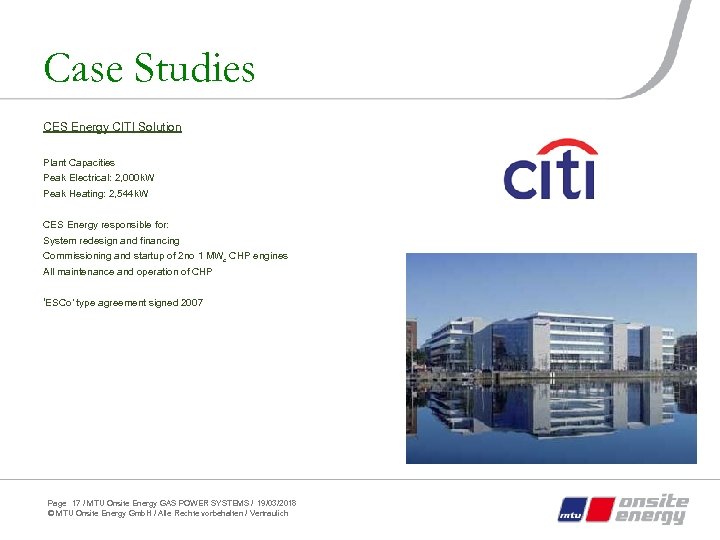

Case Studies CES Energy CITI Solution Plant Capacities Peak Electrical: 2, 000 k. W Peak Heating: 2, 544 k. W CES Energy responsible for: System redesign and financing Commissioning and startup of 2 no 1 MWe CHP engines All maintenance and operation of CHP ‘ESCo’ type agreement signed 2007 Page 17 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

Case Studies CES Energy CITI Solution Plant Capacities Peak Electrical: 2, 000 k. W Peak Heating: 2, 544 k. W CES Energy responsible for: System redesign and financing Commissioning and startup of 2 no 1 MWe CHP engines All maintenance and operation of CHP ‘ESCo’ type agreement signed 2007 Page 17 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

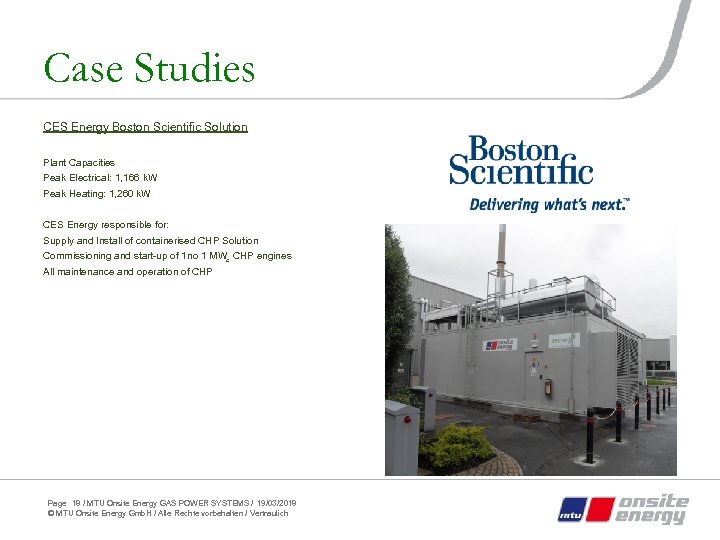

Case Studies CES Energy Boston Scientific Solution Plant Capacities Peak Electrical: 1, 166 k. W Peak Heating: 1, 260 k. W CES Energy responsible for: Supply and Install of containerised CHP Solution Commissioning and start-up of 1 no 1 MWe CHP engines All maintenance and operation of CHP Page 18 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

Case Studies CES Energy Boston Scientific Solution Plant Capacities Peak Electrical: 1, 166 k. W Peak Heating: 1, 260 k. W CES Energy responsible for: Supply and Install of containerised CHP Solution Commissioning and start-up of 1 no 1 MWe CHP engines All maintenance and operation of CHP Page 18 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

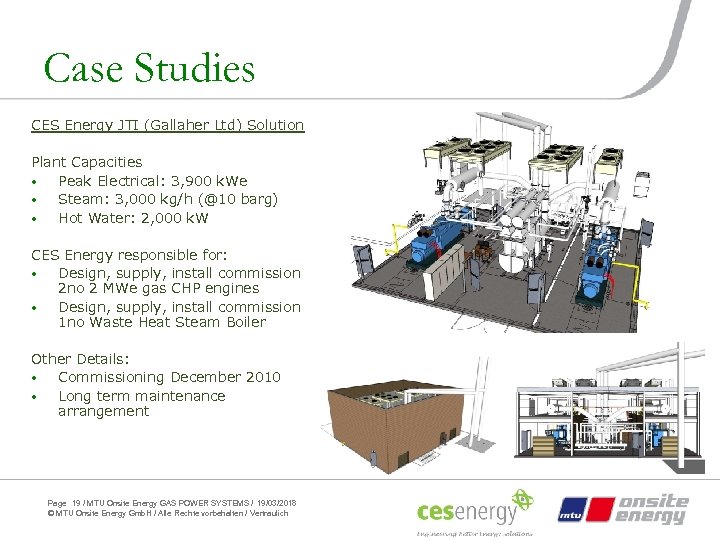

Case Studies CES Energy JTI (Gallaher Ltd) Solution Plant Capacities • Peak Electrical: 3, 900 k. We • Steam: 3, 000 kg/h (@10 barg) • Hot Water: 2, 000 k. W CES Energy responsible for: • Design, supply, install commission 2 no 2 MWe gas CHP engines • Design, supply, install commission 1 no Waste Heat Steam Boiler Other Details: • Commissioning December 2010 • Long term maintenance arrangement Page 19 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

Case Studies CES Energy JTI (Gallaher Ltd) Solution Plant Capacities • Peak Electrical: 3, 900 k. We • Steam: 3, 000 kg/h (@10 barg) • Hot Water: 2, 000 k. W CES Energy responsible for: • Design, supply, install commission 2 no 2 MWe gas CHP engines • Design, supply, install commission 1 no Waste Heat Steam Boiler Other Details: • Commissioning December 2010 • Long term maintenance arrangement Page 19 / MTU Onsite Energy GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich

THANK YOU FOR YOUR ATTENTION Page 20 / MTU Onsite. Gmb. H GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich All rights reserved

THANK YOU FOR YOUR ATTENTION Page 20 / MTU Onsite. Gmb. H GAS POWER SYSTEMS / 19/03/2018 © MTU Onsite Energy Gmb. H / Alle Rechte vorbehalten / Vertraulich All rights reserved