4f138b69bf9a0a6f3dbb183e37518d99.ppt

- Количество слайдов: 32

Understanding 22000 Food Safety Management Systems Copyright © 2011 Vinca, LLC dba 22000 -Tools. com

Understanding 22000 Food Safety Management Systems Copyright © 2011 Vinca, LLC dba 22000 -Tools. com

What is ISO 22000? A set of requirements for a Food Safety Management System (FSMS) It was developed to fill the need for a worldwide Food Safety Standard

What is ISO 22000? A set of requirements for a Food Safety Management System (FSMS) It was developed to fill the need for a worldwide Food Safety Standard

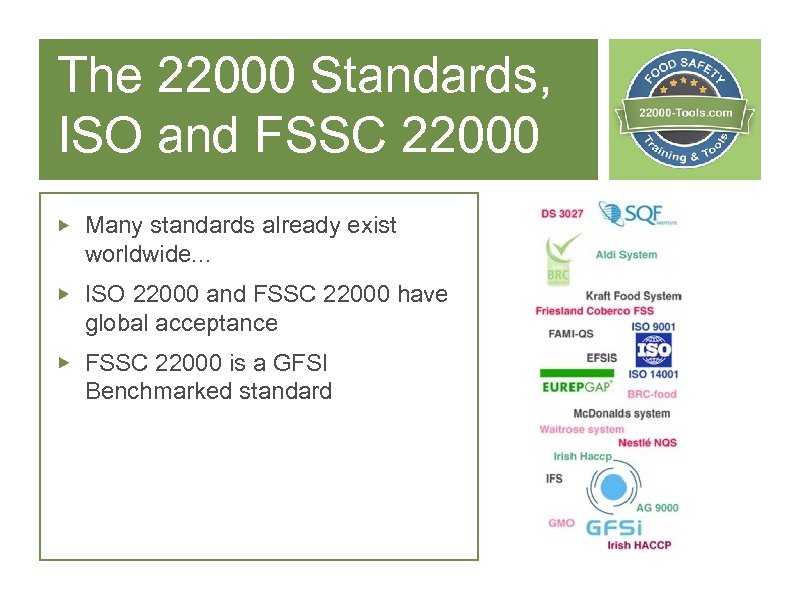

The 22000 Standards, ISO and FSSC 22000 Many standards already exist worldwide. . . ISO 22000 and FSSC 22000 have global acceptance FSSC 22000 is a GFSI Benchmarked standard

The 22000 Standards, ISO and FSSC 22000 Many standards already exist worldwide. . . ISO 22000 and FSSC 22000 have global acceptance FSSC 22000 is a GFSI Benchmarked standard

What is ISO 22000? ISO 22000 Applies to all stages of the supply chain Is aligned with ISO 9001 to enhance compatibility with existing management system FSSC 22000 Applies to Food Manufacturers Contains the requirements of ISO 22000 and the ISO/TS 22002 -1, or ISO/TS 22002 -4. ISO/TS 22002 -1 contains specific requirements for prerequisite programs (PRPs). The ISO/TS 22002 -4 contains PRP requirements for Food Packaging Manufacturers

What is ISO 22000? ISO 22000 Applies to all stages of the supply chain Is aligned with ISO 9001 to enhance compatibility with existing management system FSSC 22000 Applies to Food Manufacturers Contains the requirements of ISO 22000 and the ISO/TS 22002 -1, or ISO/TS 22002 -4. ISO/TS 22002 -1 contains specific requirements for prerequisite programs (PRPs). The ISO/TS 22002 -4 contains PRP requirements for Food Packaging Manufacturers

What is ISO 22000? Sections 4 - 8 Contain the requirements ISO 22000 Standard Section 1: Scope Section 2: Normative Reference Section 3: Terms & Definitions Section 4: General Requirements Section 5: Management Responsibility Section 6: Resource Management Section 7: Planning & Realization of Safe Products Section 8: Validation, Verification & Improvement

What is ISO 22000? Sections 4 - 8 Contain the requirements ISO 22000 Standard Section 1: Scope Section 2: Normative Reference Section 3: Terms & Definitions Section 4: General Requirements Section 5: Management Responsibility Section 6: Resource Management Section 7: Planning & Realization of Safe Products Section 8: Validation, Verification & Improvement

4. 1 General Establish an effective Food Safety Management System (FSMS) Keep it current

4. 1 General Establish an effective Food Safety Management System (FSMS) Keep it current

4. 2 Documentation Requirements Document your system Control your documents

4. 2 Documentation Requirements Document your system Control your documents

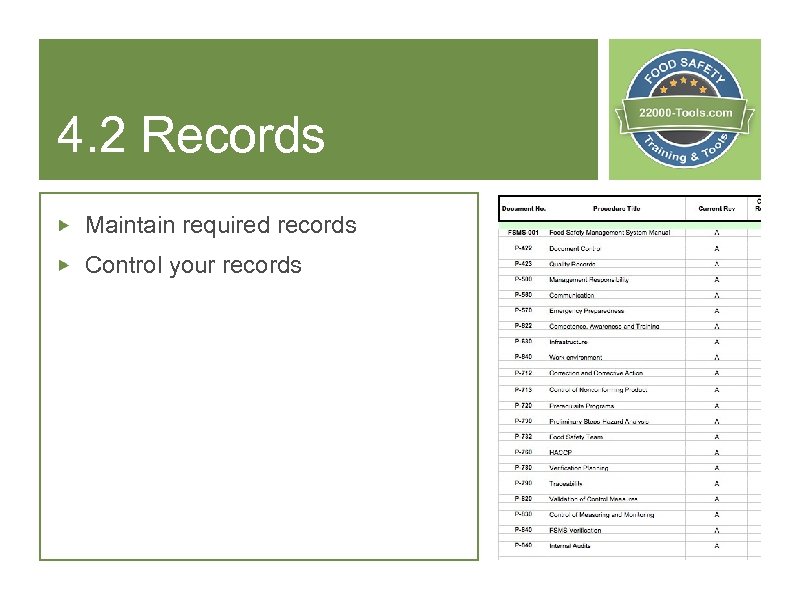

4. 2 Records Maintain required records Control your records

4. 2 Records Maintain required records Control your records

5. 1 Management Commitment Management must be involved in and committed to the FSMS. Objectives support safety Everyone knows the importance of meeting the requirements

5. 1 Management Commitment Management must be involved in and committed to the FSMS. Objectives support safety Everyone knows the importance of meeting the requirements

5. 2 Food Safety Policy Management creates for Food Safety Policy Management is responsible for communicating the policy Management is responsible for ensuring that the policy is implemented

5. 2 Food Safety Policy Management creates for Food Safety Policy Management is responsible for communicating the policy Management is responsible for ensuring that the policy is implemented

5. 3 FSMS Planning As top management, take an active role in planning the system Be involved in the design and implementation Make sure the integrity is maintained as changes are made

5. 3 FSMS Planning As top management, take an active role in planning the system Be involved in the design and implementation Make sure the integrity is maintained as changes are made

5. 4 Responsibility and Authority Define responsibilities and authority Communicate them Everyone is responsible for reporting problems with the FSMS - make sure they know that

5. 4 Responsibility and Authority Define responsibilities and authority Communicate them Everyone is responsible for reporting problems with the FSMS - make sure they know that

5. 5 Food Safety Team Leader Appointed by top management Reports to top management on the status of the FSMS

5. 5 Food Safety Team Leader Appointed by top management Reports to top management on the status of the FSMS

5. 6 Communication Establish a system for external communication Establish a system for internal communication

5. 6 Communication Establish a system for external communication Establish a system for internal communication

5. 7 Emergency Preparedness • Be prepared to respond to emergency situations Prepare an emergency plan to address potential situations: Fire Flood Accidents Contamination Others. . .

5. 7 Emergency Preparedness • Be prepared to respond to emergency situations Prepare an emergency plan to address potential situations: Fire Flood Accidents Contamination Others. . .

5. 8 Management Review Key step in a Management Systems approach Management meets to evaluate the performance of the FSMS

5. 8 Management Review Key step in a Management Systems approach Management meets to evaluate the performance of the FSMS

6 Resource Management Top management is responsible for providing the resources required Human resources Infrastructure Work Environment

6 Resource Management Top management is responsible for providing the resources required Human resources Infrastructure Work Environment

7 Planning & Realization of Safe Product Your organization will need to plan all of the processes that go into making your product in order to ensure a safe end product

7 Planning & Realization of Safe Product Your organization will need to plan all of the processes that go into making your product in order to ensure a safe end product

7. 2 Prerequisite Program • Prerequisite Programs: • Basic Conditions and activities that are necessary to maintain a hygienic environment throughout the food chain The Food safety Team establishes PRPs For FSSC 22000 you will also include prerequisite programs to meet the requirements of ISO/TS 22002 -1 or ISO/TS 22002 -4

7. 2 Prerequisite Program • Prerequisite Programs: • Basic Conditions and activities that are necessary to maintain a hygienic environment throughout the food chain The Food safety Team establishes PRPs For FSSC 22000 you will also include prerequisite programs to meet the requirements of ISO/TS 22002 -1 or ISO/TS 22002 -4

7. 3 Preliminary Steps • The Food Safety Team Identifies product characteristics Describe intended use Prepare flow diagrams Describe process steps and control measures

7. 3 Preliminary Steps • The Food Safety Team Identifies product characteristics Describe intended use Prepare flow diagrams Describe process steps and control measures

7. 4 Hazard Analysis • The Food Safety Team Verifies the accuracy of the flow diagrams Conducts hazard analysis to identify potential food safety hazards Selects control measures to prevent or eliminate those hazards

7. 4 Hazard Analysis • The Food Safety Team Verifies the accuracy of the flow diagrams Conducts hazard analysis to identify potential food safety hazards Selects control measures to prevent or eliminate those hazards

7. 5 Establish Operational PRPs • Operational PRPs: Similar to a Critical Control Point, an Operational Prerequisite Program is a control point where biological, physical, or chemical hazards identified in hazard analysis can be controlled. Your food safety team will determine if the control point is a CCP or o. PRP using the decision criteria in Section 7 of the standard. The Food Safety Team establishes Operational PRPs

7. 5 Establish Operational PRPs • Operational PRPs: Similar to a Critical Control Point, an Operational Prerequisite Program is a control point where biological, physical, or chemical hazards identified in hazard analysis can be controlled. Your food safety team will determine if the control point is a CCP or o. PRP using the decision criteria in Section 7 of the standard. The Food Safety Team establishes Operational PRPs

7. 6 Establish the HACCP Plan • The Food Safety Team Documents the HACCP plan

7. 6 Establish the HACCP Plan • The Food Safety Team Documents the HACCP plan

7. 7 Updating • The Food Safety Team Updates any preliminary information that may have changed during or as a result of the hazard analysis

7. 7 Updating • The Food Safety Team Updates any preliminary information that may have changed during or as a result of the hazard analysis

7. 8 Verification Planning • Identify what verification activities are required including verification of PRPs, the HACCP Plan and other procedures. • Verification will include internal audits, any food safety or GMP audits, verification of cleaning records and HACCP records and other activities that you identify for your system.

7. 8 Verification Planning • Identify what verification activities are required including verification of PRPs, the HACCP Plan and other procedures. • Verification will include internal audits, any food safety or GMP audits, verification of cleaning records and HACCP records and other activities that you identify for your system.

7. 9 Traceability • A traceability system ensures that the identification of product is maintained from raw material to delivery. Establish the traceability of product From supplier to distribution

7. 9 Traceability • A traceability system ensures that the identification of product is maintained from raw material to delivery. Establish the traceability of product From supplier to distribution

7. 10 Control of Nonconformity • When a control limit is exceeded or a PRP is found to be out of control affected product must be controlled. Corrections Corrective actions Handling of potentially unsafe product

7. 10 Control of Nonconformity • When a control limit is exceeded or a PRP is found to be out of control affected product must be controlled. Corrections Corrective actions Handling of potentially unsafe product

8. 2 Validation, & 8. 3 Control of Measuring & Monitoring • All measuring equipment must be capable of the required measurements and show calibration to national or international standards. • Calibrate and control measuring equipment to ensure that measurements are valid

8. 2 Validation, & 8. 3 Control of Measuring & Monitoring • All measuring equipment must be capable of the required measurements and show calibration to national or international standards. • Calibrate and control measuring equipment to ensure that measurements are valid

8. 4 Verification Establish and document an internal audit process The Food Safety Team evaluates and analyzes verification results The Food Safety Team takes any necessary action

8. 4 Verification Establish and document an internal audit process The Food Safety Team evaluates and analyzes verification results The Food Safety Team takes any necessary action

8. 5 Improvement Continually improve the FSMS through the use of: Management review Internal audits Corrective actions Verification results Validation results

8. 5 Improvement Continually improve the FSMS through the use of: Management review Internal audits Corrective actions Verification results Validation results

8. 5 Updating the FSMS Top management is responsible for seeing that the FSMS is continually updated The Food Safety Management Team evaluates the FSMS at planned intervals

8. 5 Updating the FSMS Top management is responsible for seeing that the FSMS is continually updated The Food Safety Management Team evaluates the FSMS at planned intervals

Further Resources Online ISO 22000 Training for your Food Safety Team Leader and your Food Safety Team is available at 22000 -tools. com.

Further Resources Online ISO 22000 Training for your Food Safety Team Leader and your Food Safety Team is available at 22000 -tools. com.