65224fcd2b9c8c121e681ccc07d1c1ae.ppt

- Количество слайдов: 16

Understand real potential of YBCO CC 1. A Xu, J. Jaroszynski, D. Abraimov, Y. Viouchkov, F. Kametani V. Braccini A. Polyanskii 2. D. Larbalestier Motivation: a) to characterize B = 16 T = 17. 5 deg Ic 200 A B = 32 T 0 Ic 1 k. A Ic ( , B, T) for HTS magnet design - Super. Power Inc Do to the strong anisotropy: the most critical point of the magnet is the end of the outer coil This is in contrast to LTS magnets where the center of the magnet is the most critical To follow rapid changes in commercial conductor from SP b) b) to understand “macroscopic” defects of the tape, influence of soldering c) c) to understand pinning mechanisms d) d) to explore how engineering of YBCO CC could enhance Jc ( , B, T)

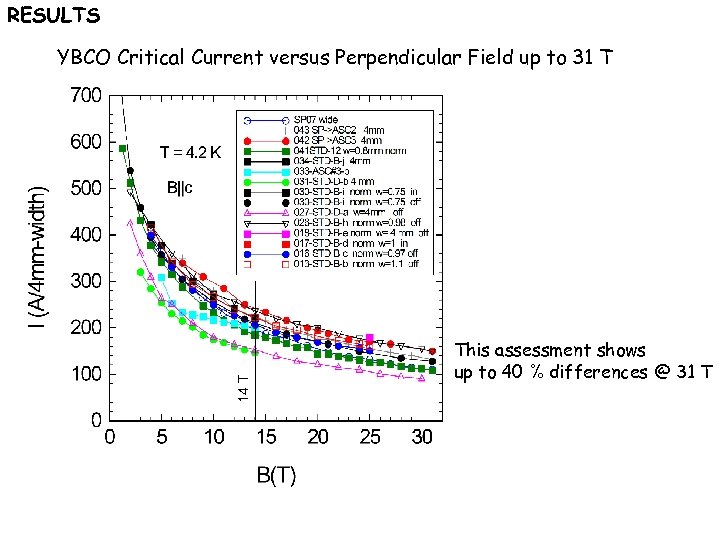

RESULTS 14 T YBCO Critical Current versus Perpendicular Field up to 31 T This assessment shows up to 40 % differences @ 31 T

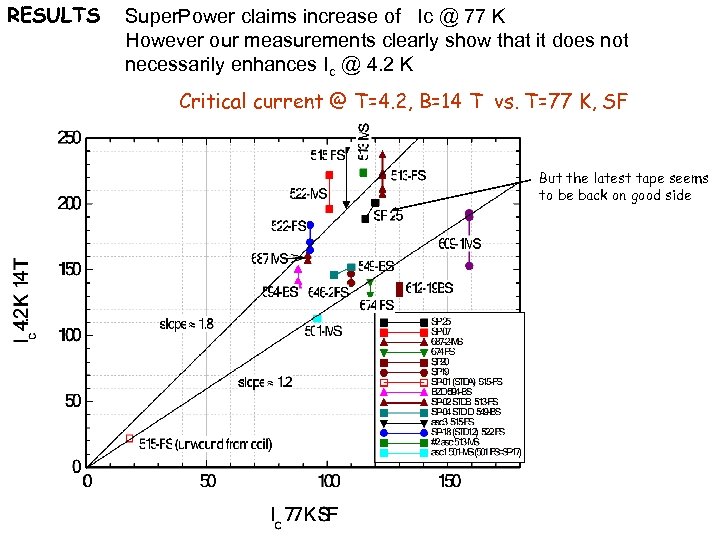

RESULTS Super. Power claims increase of Ic @ 77 K However our measurements clearly show that it does not necessarily enhances Ic @ 4. 2 K Critical current @ T=4. 2, B=14 T vs. T=77 K, SF But the latest tape seems to be back on good side

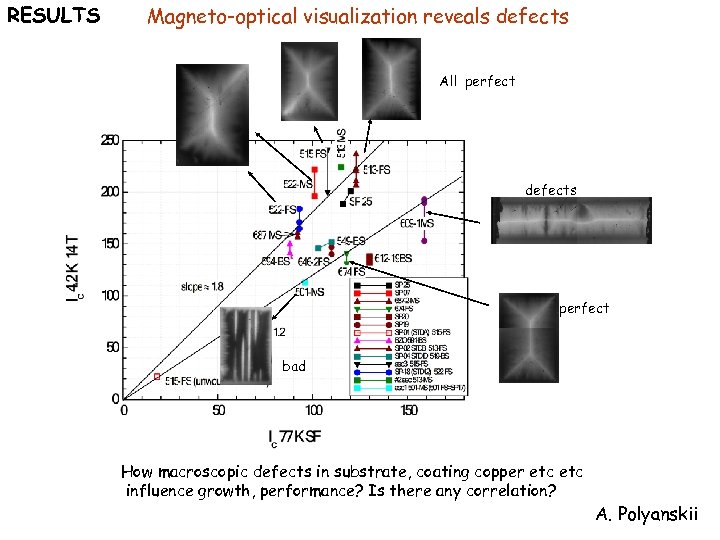

RESULTS Magneto-optical visualization reveals defects All perfect defects perfect bad How macroscopic defects in substrate, coating copper etc influence growth, performance? Is there any correlation? A. Polyanskii

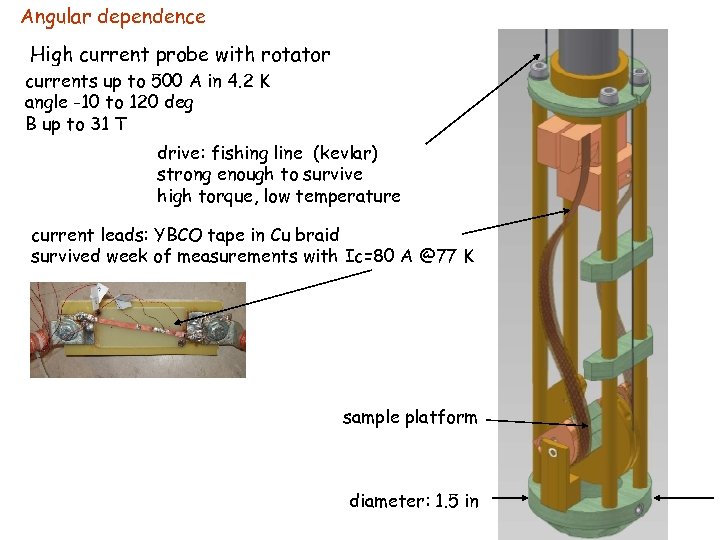

Angular dependence High current probe with rotator currents up to 500 A in 4. 2 K angle -10 to 120 deg B up to 31 T drive: fishing line (kevlar) strong enough to survive high torque, low temperature current leads: YBCO tape in Cu braid survived week of measurements with Ic=80 A @77 K sample platform diameter: 1. 5 in

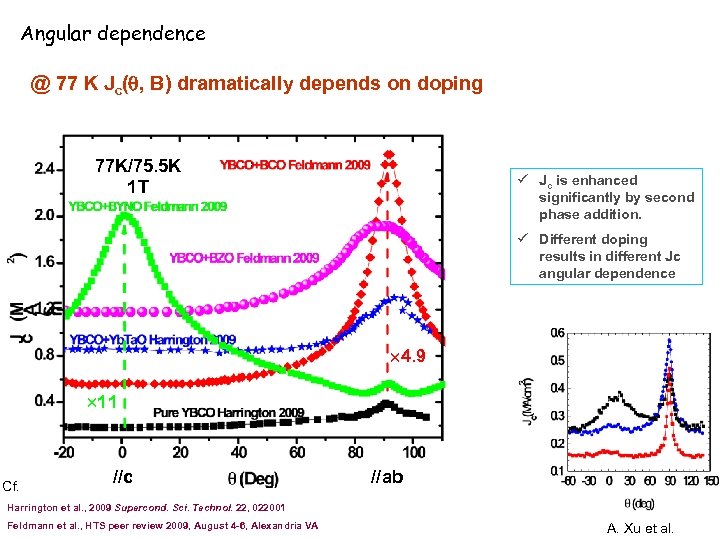

Angular dependence @ 77 K Jc( , B) dramatically depends on doping 77 K/75. 5 K 1 T ü Jc is enhanced significantly by second phase addition. ü Different doping results in different Jc angular dependence 4. 9 11 Cf. //c //ab Harrington et al. , 2009 Supercond. Sci. Technol. 22, 022001 Feldmann et al. , HTS peer review 2009, August 4 -6, Alexandria VA A. Xu et al.

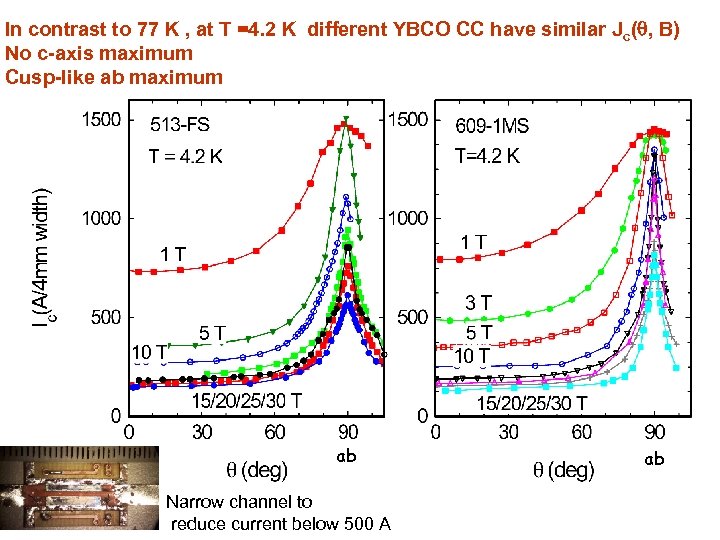

In contrast to 77 K , at T =4. 2 K different YBCO CC have similar Jc( , B) No c-axis maximum Cusp-like ab maximum ab Narrow channel to reduce current below 500 A ab

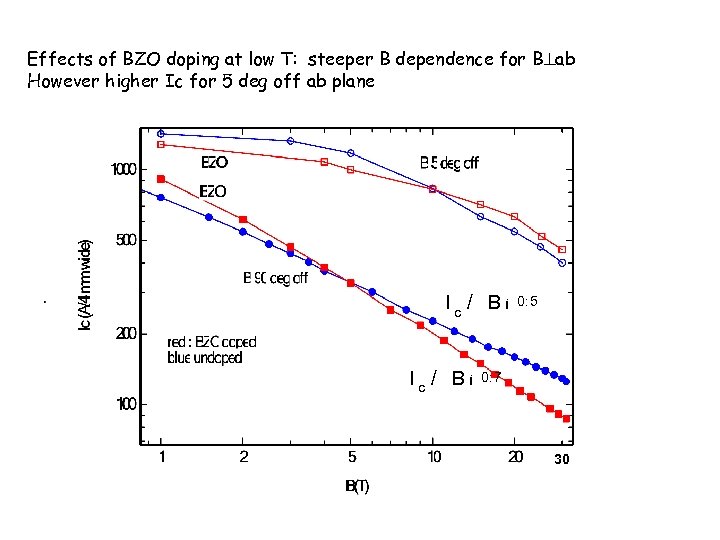

Effects of BZO doping at low T: steeper B dependence for B ab However higher Ic for 5 deg off ab plane Ic / B¡ 0: 5 0: 7 30

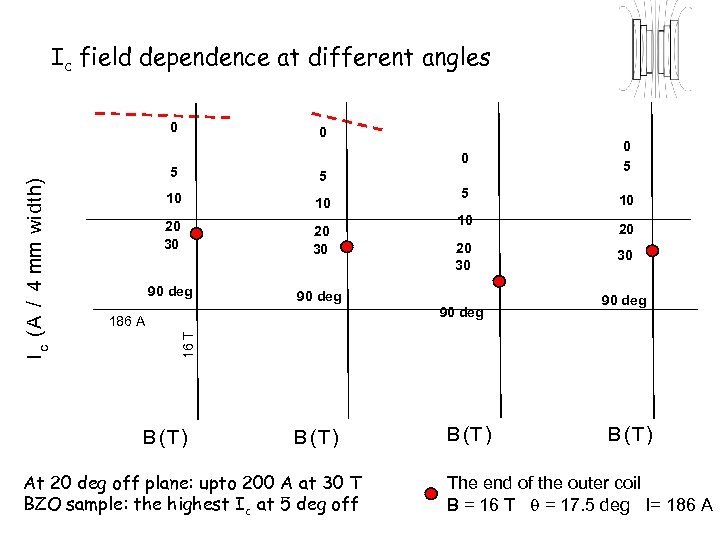

Ic field dependence at different angles 0 0 5 5 10 10 20 30 90 deg 5 10 20 30 90 deg 186 A 0 5 10 20 30 90 deg 16 T I c (A / 4 mm widt h) 0 B (T ) At 20 deg off plane: upto 200 A at 30 T BZO sample: the highest Ic at 5 deg off B (T ) The end of the outer coil B = 16 T = 17. 5 deg I= 186 A

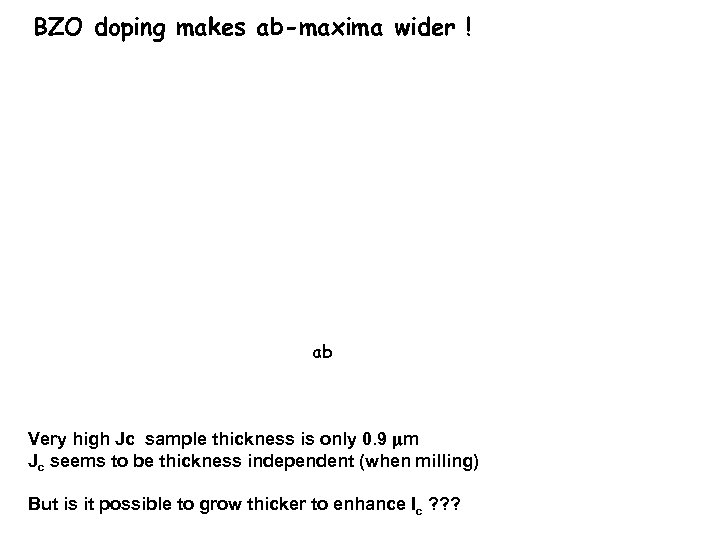

BZO doping makes ab-maxima wider ! ab Very high Jc sample thickness is only 0. 9 m Jc seems to be thickness independent (when milling) But is it possible to grow thicker to enhance Ic ? ? ?

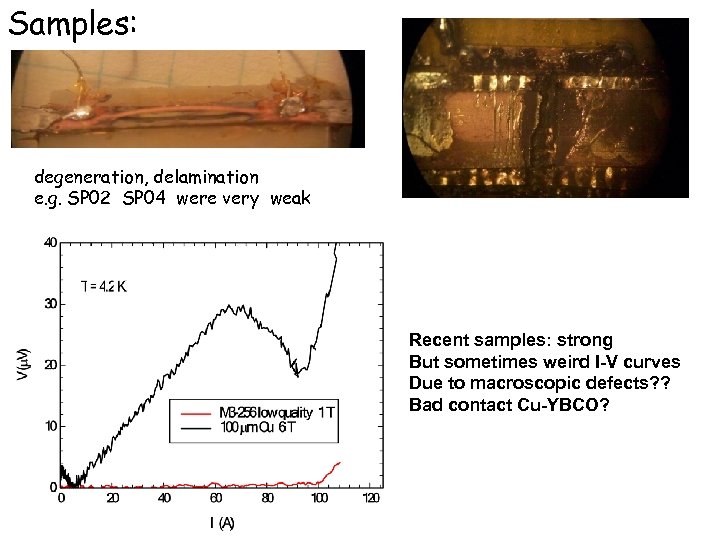

Samples: degeneration, delamination e. g. SP 02 SP 04 were very weak Recent samples: strong But sometimes weird I-V curves Due to macroscopic defects? ? Bad contact Cu-YBCO?

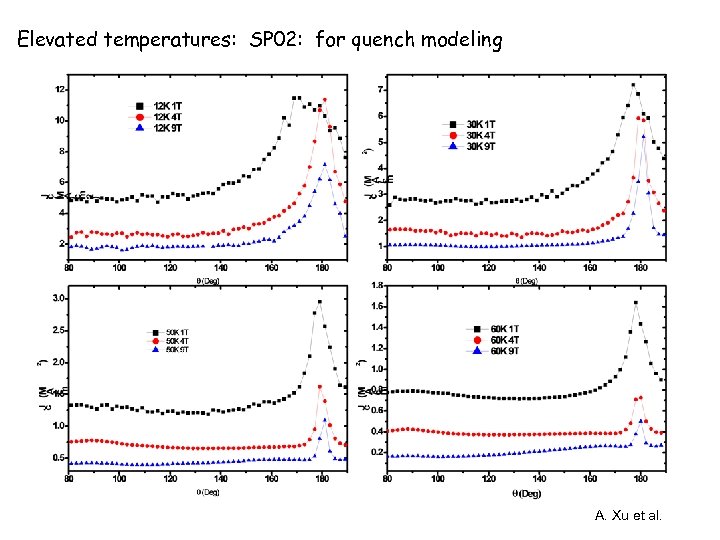

Elevated temperatures: SP 02: for quench modeling A. Xu et al.

Standard B (SP 02) vs temperature

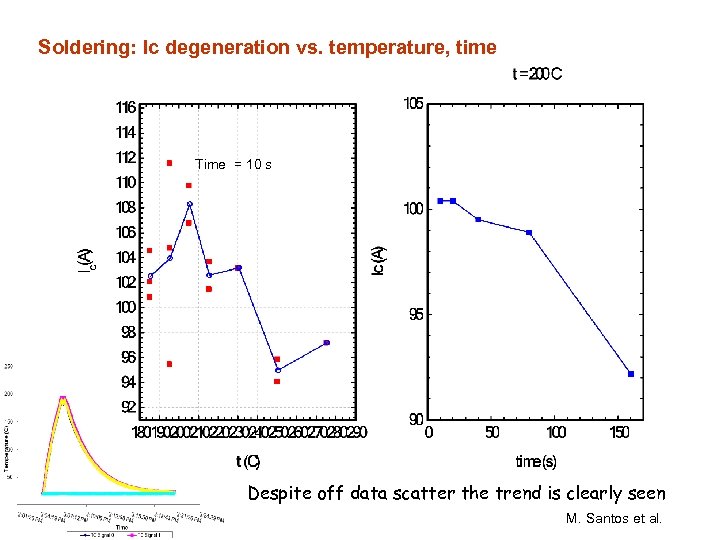

Soldering: Ic degeneration vs. temperature, time Time = 10 s Despite off data scatter the trend is clearly seen M. Santos et al.

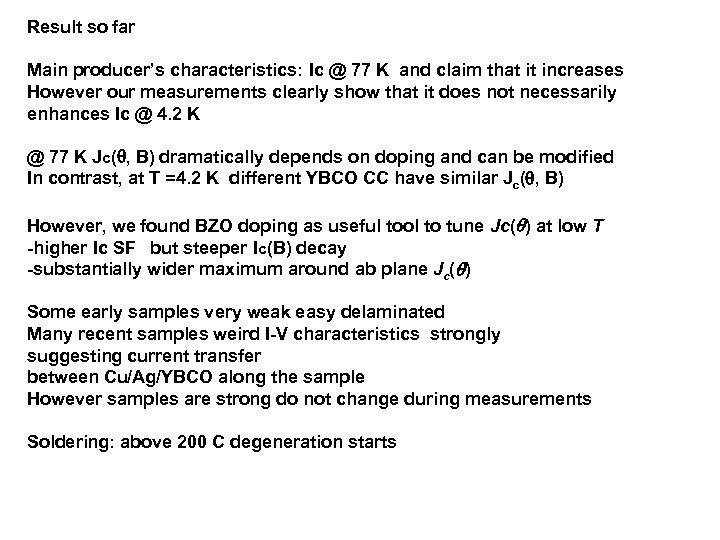

Result so far Main producer’s characteristics: Ic @ 77 K and claim that it increases However our measurements clearly show that it does not necessarily enhances Ic @ 4. 2 K @ 77 K Jc( , B) dramatically depends on doping and can be modified In contrast, at T =4. 2 K different YBCO CC have similar Jc( , B) However, we found BZO doping as useful tool to tune Jc( ) at low T -higher Ic SF but steeper Ic(B) decay -substantially wider maximum around ab plane Jc( ) Some early samples very weak easy delaminated Many recent samples weird I-V characteristics strongly suggesting current transfer between Cu/Ag/YBCO along the sample However samples are strong do not change during measurements Soldering: above 200 C degeneration starts

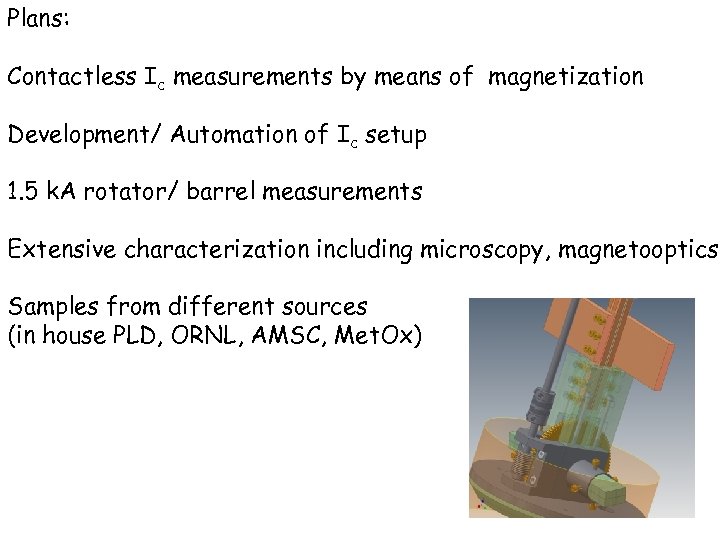

Plans: Contactless Ic measurements by means of magnetization Development/ Automation of Ic setup 1. 5 k. A rotator/ barrel measurements Extensive characterization including microscopy, magnetooptics Samples from different sources (in house PLD, ORNL, AMSC, Met. Ox)

65224fcd2b9c8c121e681ccc07d1c1ae.ppt