c68ba322f416798a1ddb4f6d3d7c70c5.ppt

- Количество слайдов: 28

UNCLASSIFIED DEFENCE AVIATION SAFETY REGULATION DASR 145 – REQUIREMENTS FOR MAINTENANCE ORGANISATIONS February 2018 UNCLASSIFIED

UNCLASSIFIED DEFENCE AVIATION SAFETY REGULATION DASR 145 – REQUIREMENTS FOR MAINTENANCE ORGANISATIONS February 2018 UNCLASSIFIED

UNCLASSIFIED Scope DASR 145 – Requirements for Maintenance Organisations – Overview of DASR 145 – Key definitions – DASR 145 Breakdown UNCLASSIFIED 2

UNCLASSIFIED Scope DASR 145 – Requirements for Maintenance Organisations – Overview of DASR 145 – Key definitions – DASR 145 Breakdown UNCLASSIFIED 2

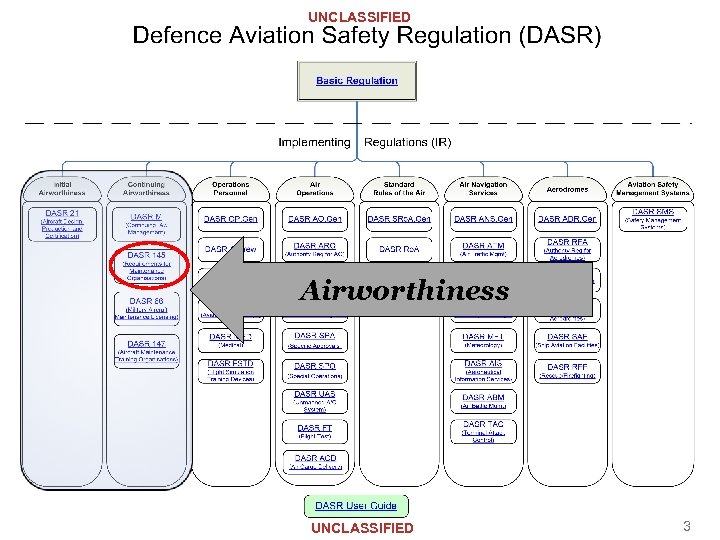

UNCLASSIFIED Airworthiness UNCLASSIFIED 3

UNCLASSIFIED Airworthiness UNCLASSIFIED 3

UNCLASSIFIED DASR 145 - Maintenance Organisation Overview – Applicable to all ADF and Commercial organisations who maintain ADF aircraft and components – Establishes the requirements to be met to perform maintenance – Some functions are the responsibility of the Continuing Airworthiness Management Organisation – There is a subordinate relationship of DASR 145 AMO with its parent DASR M CAMO UNCLASSIFIED 4

UNCLASSIFIED DASR 145 - Maintenance Organisation Overview – Applicable to all ADF and Commercial organisations who maintain ADF aircraft and components – Establishes the requirements to be met to perform maintenance – Some functions are the responsibility of the Continuing Airworthiness Management Organisation – There is a subordinate relationship of DASR 145 AMO with its parent DASR M CAMO UNCLASSIFIED 4

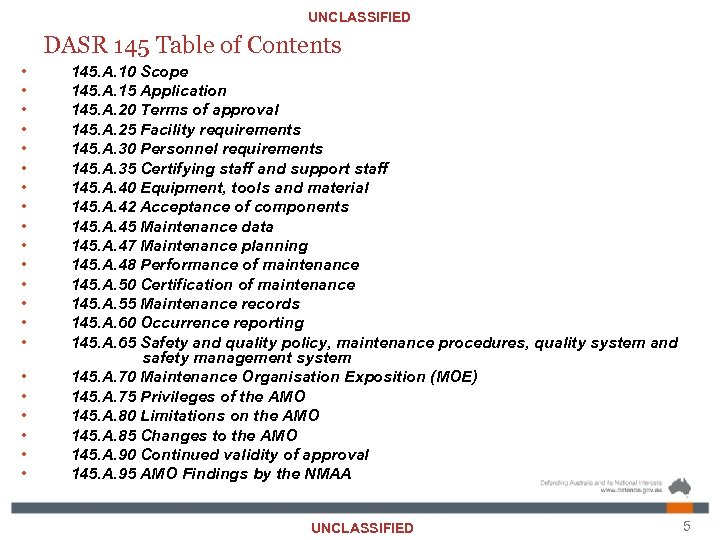

UNCLASSIFIED DASR 145 Table of Contents • • • • • • 145. A. 10 Scope 145. A. 15 Application 145. A. 20 Terms of approval 145. A. 25 Facility requirements 145. A. 30 Personnel requirements 145. A. 35 Certifying staff and support staff 145. A. 40 Equipment, tools and material 145. A. 42 Acceptance of components 145. A. 45 Maintenance data 145. A. 47 Maintenance planning 145. A. 48 Performance of maintenance 145. A. 50 Certification of maintenance 145. A. 55 Maintenance records 145. A. 60 Occurrence reporting 145. A. 65 Safety and quality policy, maintenance procedures, quality system and safety management system 145. A. 70 Maintenance Organisation Exposition (MOE) 145. A. 75 Privileges of the AMO 145. A. 80 Limitations on the AMO 145. A. 85 Changes to the AMO 145. A. 90 Continued validity of approval 145. A. 95 AMO Findings by the NMAA UNCLASSIFIED 5

UNCLASSIFIED DASR 145 Table of Contents • • • • • • 145. A. 10 Scope 145. A. 15 Application 145. A. 20 Terms of approval 145. A. 25 Facility requirements 145. A. 30 Personnel requirements 145. A. 35 Certifying staff and support staff 145. A. 40 Equipment, tools and material 145. A. 42 Acceptance of components 145. A. 45 Maintenance data 145. A. 47 Maintenance planning 145. A. 48 Performance of maintenance 145. A. 50 Certification of maintenance 145. A. 55 Maintenance records 145. A. 60 Occurrence reporting 145. A. 65 Safety and quality policy, maintenance procedures, quality system and safety management system 145. A. 70 Maintenance Organisation Exposition (MOE) 145. A. 75 Privileges of the AMO 145. A. 80 Limitations on the AMO 145. A. 85 Changes to the AMO 145. A. 90 Continued validity of approval 145. A. 95 AMO Findings by the NMAA UNCLASSIFIED 5

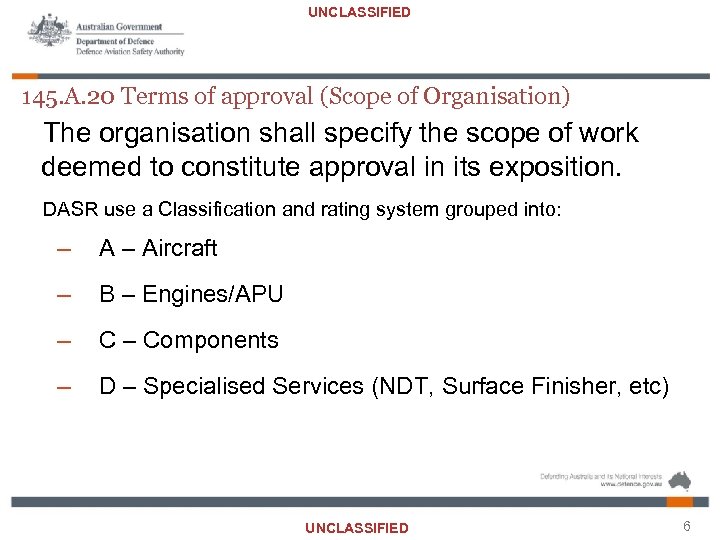

UNCLASSIFIED 145. A. 20 Terms of approval (Scope of Organisation) The organisation shall specify the scope of work deemed to constitute approval in its exposition. DASR use a Classification and rating system grouped into: – Aircraft – B – Engines/APU – Components – D – Specialised Services (NDT, Surface Finisher, etc) UNCLASSIFIED 6

UNCLASSIFIED 145. A. 20 Terms of approval (Scope of Organisation) The organisation shall specify the scope of work deemed to constitute approval in its exposition. DASR use a Classification and rating system grouped into: – Aircraft – B – Engines/APU – Components – D – Specialised Services (NDT, Surface Finisher, etc) UNCLASSIFIED 6

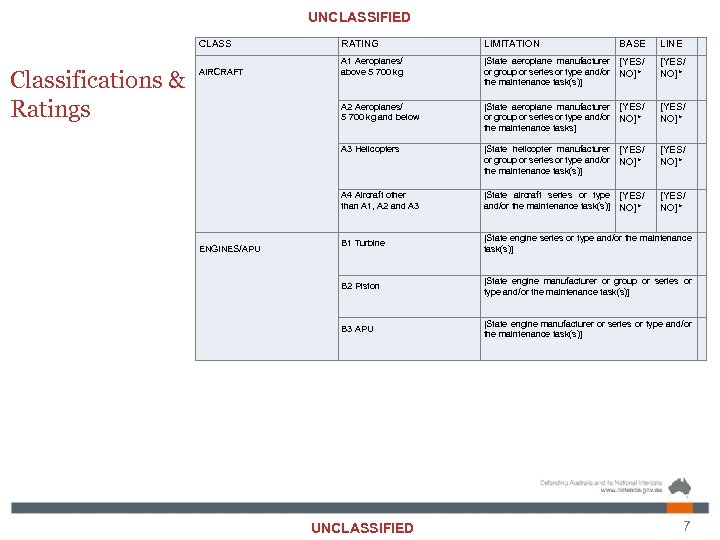

UNCLASSIFIED CLASS Classifications & Ratings RATING LIMITATION AIRCRAFT A 1 Aeroplanes/ above 5 700 kg LINE [State aeroplane manufacturer [YES/ or group or series or type and/or NO]* the maintenance task(s)] [YES/ NO]* A 2 Aeroplanes/ 5 700 kg and below [State aeroplane manufacturer [YES/ or group or series or type and/or NO]* the maintenance tasks] [YES/ NO]* A 3 Helicopters [State helicopter manufacturer [YES/ or group or series or type and/or NO]* the maintenance task(s)] [YES/ NO]* [State aircraft series or type [YES/ and/or the maintenance task(s)] NO]* [YES/ NO]* A 4 Aircraft other than A 1, A 2 and A 3 ENGINES/APU B 1 Turbine B 2 Piston B 3 APU UNCLASSIFIED BASE [State engine series or type and/or the maintenance task(s)] [State engine manufacturer or group or series or type and/or the maintenance task(s)] [State engine manufacturer or series or type and/or the maintenance task(s)] 7

UNCLASSIFIED CLASS Classifications & Ratings RATING LIMITATION AIRCRAFT A 1 Aeroplanes/ above 5 700 kg LINE [State aeroplane manufacturer [YES/ or group or series or type and/or NO]* the maintenance task(s)] [YES/ NO]* A 2 Aeroplanes/ 5 700 kg and below [State aeroplane manufacturer [YES/ or group or series or type and/or NO]* the maintenance tasks] [YES/ NO]* A 3 Helicopters [State helicopter manufacturer [YES/ or group or series or type and/or NO]* the maintenance task(s)] [YES/ NO]* [State aircraft series or type [YES/ and/or the maintenance task(s)] NO]* [YES/ NO]* A 4 Aircraft other than A 1, A 2 and A 3 ENGINES/APU B 1 Turbine B 2 Piston B 3 APU UNCLASSIFIED BASE [State engine series or type and/or the maintenance task(s)] [State engine manufacturer or group or series or type and/or the maintenance task(s)] [State engine manufacturer or series or type and/or the maintenance task(s)] 7

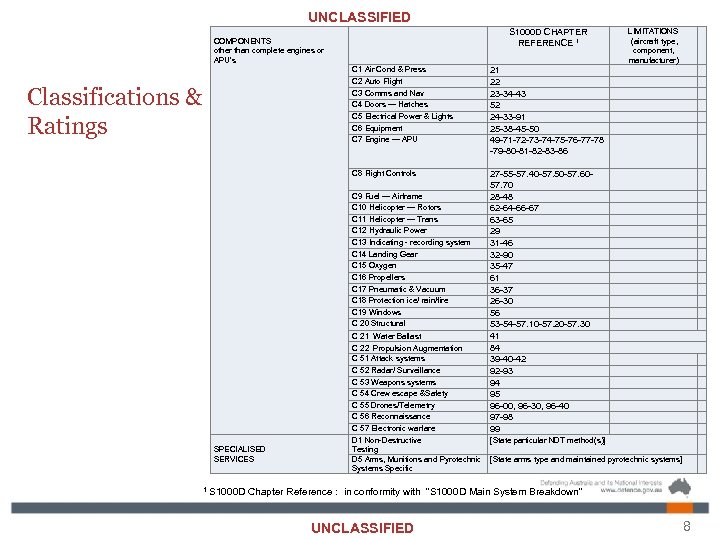

UNCLASSIFIED COMPONENTS other than complete engines or APU's C 1 Air Cond & Press C 2 Auto Flight C 3 Comms and Nav C 4 Doors — Hatches C 5 Electrical Power & Lights C 6 Equipment C 7 Engine — APU Classifications & Ratings C 8 Flight Controls C 9 Fuel — Airframe C 10 Helicopter — Rotors C 11 Helicopter — Trans C 12 Hydraulic Power C 13 Indicating - recording system C 14 Landing Gear C 15 Oxygen C 16 Propellers C 17 Pneumatic & Vacuum C 18 Protection ice/ rain/fire C 19 Windows C 20 Structural SPECIALISED SERVICES LIMITATIONS (aircraft type, component, manufacturer) S 1000 D CHAPTER REFERENCE 1 21 22 23 -34 -43 52 24 -33 -91 25 -38 -45 -50 49 -71 -72 -73 -74 -75 -76 -77 -78 -79 -80 -81 -82 -83 -86 27 -55 -57. 40 -57. 50 -57. 6057. 70 28 -48 62 -64 -66 -67 63 -65 29 31 -46 32 -90 35 -47 61 36 -37 26 -30 56 53 -54 -57. 10 -57. 20 -57. 30 41 84 39 -40 -42 92 -93 94 95 96 -00, 96 -30, 96 -40 97 -98 99 C 21 Water Ballast C 22 Propulsion Augmentation C 51 Attack systems C 52 Radar/ Surveillance C 53 Weapons systems C 54 Crew escape &Safety C 55 Drones/Telemetry C 56 Reconnaissance C 57 Electronic warfare D 1 Non-Destructive [State particular NDT method(s)] Testing D 5 Arms, Munitions and Pyrotechnic [State arms type and maintained pyrotechnic systems] Systems Specific 1 S 1000 D Chapter Reference : in conformity with “S 1000 D Main System Breakdown” UNCLASSIFIED 8

UNCLASSIFIED COMPONENTS other than complete engines or APU's C 1 Air Cond & Press C 2 Auto Flight C 3 Comms and Nav C 4 Doors — Hatches C 5 Electrical Power & Lights C 6 Equipment C 7 Engine — APU Classifications & Ratings C 8 Flight Controls C 9 Fuel — Airframe C 10 Helicopter — Rotors C 11 Helicopter — Trans C 12 Hydraulic Power C 13 Indicating - recording system C 14 Landing Gear C 15 Oxygen C 16 Propellers C 17 Pneumatic & Vacuum C 18 Protection ice/ rain/fire C 19 Windows C 20 Structural SPECIALISED SERVICES LIMITATIONS (aircraft type, component, manufacturer) S 1000 D CHAPTER REFERENCE 1 21 22 23 -34 -43 52 24 -33 -91 25 -38 -45 -50 49 -71 -72 -73 -74 -75 -76 -77 -78 -79 -80 -81 -82 -83 -86 27 -55 -57. 40 -57. 50 -57. 6057. 70 28 -48 62 -64 -66 -67 63 -65 29 31 -46 32 -90 35 -47 61 36 -37 26 -30 56 53 -54 -57. 10 -57. 20 -57. 30 41 84 39 -40 -42 92 -93 94 95 96 -00, 96 -30, 96 -40 97 -98 99 C 21 Water Ballast C 22 Propulsion Augmentation C 51 Attack systems C 52 Radar/ Surveillance C 53 Weapons systems C 54 Crew escape &Safety C 55 Drones/Telemetry C 56 Reconnaissance C 57 Electronic warfare D 1 Non-Destructive [State particular NDT method(s)] Testing D 5 Arms, Munitions and Pyrotechnic [State arms type and maintained pyrotechnic systems] Systems Specific 1 S 1000 D Chapter Reference : in conformity with “S 1000 D Main System Breakdown” UNCLASSIFIED 8

UNCLASSIFIED 145. A. 25 Facilities – Appropriate for the planned maintenance activities including office accommodation • 145. A. 25 (c)(6) -. . …tasks must be suspended until satisfactory conditions are re-established. – Military operational needs should be taken into account when establishing a suitable working environment. However, as far as is practicable, the requirements should be adhered to. – Supports personnel effectiveness (working environment, human factors) – Storage, segregation and access requirements for components, equipment, tools and materials UNCLASSIFIED 9

UNCLASSIFIED 145. A. 25 Facilities – Appropriate for the planned maintenance activities including office accommodation • 145. A. 25 (c)(6) -. . …tasks must be suspended until satisfactory conditions are re-established. – Military operational needs should be taken into account when establishing a suitable working environment. However, as far as is practicable, the requirements should be adhered to. – Supports personnel effectiveness (working environment, human factors) – Storage, segregation and access requirements for components, equipment, tools and materials UNCLASSIFIED 9

UNCLASSIFIED 145. A. 30 Personnel requirements – Accountable Manager (Corporate authority) • No specific qualification and experience requirements • Accountable Manager is FEGCDR/DGAVN/COMFAA for ADF DASR 145 Organisations – Nominated management team • Functions may be “subdivided” • LineBaseWorkshop Managers – Maintenance Man-hour plans and personnel competence requirements and standards – limited aircrew maintenance and one-off approvals at remote locations UNCLASSIFIED 10

UNCLASSIFIED 145. A. 30 Personnel requirements – Accountable Manager (Corporate authority) • No specific qualification and experience requirements • Accountable Manager is FEGCDR/DGAVN/COMFAA for ADF DASR 145 Organisations – Nominated management team • Functions may be “subdivided” • LineBaseWorkshop Managers – Maintenance Man-hour plans and personnel competence requirements and standards – limited aircrew maintenance and one-off approvals at remote locations UNCLASSIFIED 10

UNCLASSIFIED 145. A. 35 Certifying staff and support staff – Allows for “National Equivalent” • A Defence Technical Equivalent Qualification (DTEQ) is the combination of an RTO-issued Aeroskills qualification (or, if applicable, a Statement of Attainment) and a task authorisation issued under the TAREG system. Less formally, DTEQ is the extant ADO aviation trade authorisation and training methodology – Licenced by Authority, Authorised to certify by the organisation following competence assessment – Ongoing competence / continuation training requirements – Minimum age for certifying staff UNCLASSIFIED 11

UNCLASSIFIED 145. A. 35 Certifying staff and support staff – Allows for “National Equivalent” • A Defence Technical Equivalent Qualification (DTEQ) is the combination of an RTO-issued Aeroskills qualification (or, if applicable, a Statement of Attainment) and a task authorisation issued under the TAREG system. Less formally, DTEQ is the extant ADO aviation trade authorisation and training methodology – Licenced by Authority, Authorised to certify by the organisation following competence assessment – Ongoing competence / continuation training requirements – Minimum age for certifying staff UNCLASSIFIED 11

UNCLASSIFIED 145. A. 40 Equipment, tools and material – Requirement to have available and use the necessary equipment, tools and material to perform the approved scope of work – Use of alternate tools • IAW Maintenance Organisation Exposition procedures – Equipment and tools must be permanently available. – Calibration and control processes required. • NOT tool control but the control of calibrated tools. UNCLASSIFIED 12

UNCLASSIFIED 145. A. 40 Equipment, tools and material – Requirement to have available and use the necessary equipment, tools and material to perform the approved scope of work – Use of alternate tools • IAW Maintenance Organisation Exposition procedures – Equipment and tools must be permanently available. – Calibration and control processes required. • NOT tool control but the control of calibrated tools. UNCLASSIFIED 12

UNCLASSIFIED 145. A. 42 Acceptance of components – Segregation of serviceable and unserviceable components – Control of unsalvageable/scrap/life expired items – Component Marking/Labelling requirements – Pre-installation requirements – Fabrication of parts – Standard Part, Raw Material and Component usage and classification requirements. UNCLASSIFIED 13

UNCLASSIFIED 145. A. 42 Acceptance of components – Segregation of serviceable and unserviceable components – Control of unsalvageable/scrap/life expired items – Component Marking/Labelling requirements – Pre-installation requirements – Fabrication of parts – Standard Part, Raw Material and Component usage and classification requirements. UNCLASSIFIED 13

UNCLASSIFIED 145. A. 45 Maintenance data – Must have applicable and current maintenance data – Requirement to inform author of errors with data – Requirements/Allowances for the limited modification of maintenance data – Availability of maintenance data – Maintaining the accuracy of maintenance data UNCLASSIFIED 14

UNCLASSIFIED 145. A. 45 Maintenance data – Must have applicable and current maintenance data – Requirement to inform author of errors with data – Requirements/Allowances for the limited modification of maintenance data – Availability of maintenance data – Maintaining the accuracy of maintenance data UNCLASSIFIED 14

UNCLASSIFIED 145. A. 47 Maintenance planning – All necessary personnel, tooling, equipment, materials, maintenance data and facilities available – Requirement to take into account Human Factors when planning maintenance tasks and shifts – Shift and task handovers to be controlled – Other factor to be considered logistics, inventory control, accommodation, manhours estimation, man-hours availability, preparation of work, hangar availability, environmental conditions (access, lighting standards and cleanliness), co-ordination with internal and external suppliers, etc. scheduling of safety-critical tasks during periods when staff are likely to be most alert, military operational commitments, location (e. g. Main Operating Base, Deployed Operating Base). UNCLASSIFIED 15

UNCLASSIFIED 145. A. 47 Maintenance planning – All necessary personnel, tooling, equipment, materials, maintenance data and facilities available – Requirement to take into account Human Factors when planning maintenance tasks and shifts – Shift and task handovers to be controlled – Other factor to be considered logistics, inventory control, accommodation, manhours estimation, man-hours availability, preparation of work, hangar availability, environmental conditions (access, lighting standards and cleanliness), co-ordination with internal and external suppliers, etc. scheduling of safety-critical tasks during periods when staff are likely to be most alert, military operational commitments, location (e. g. Main Operating Base, Deployed Operating Base). UNCLASSIFIED 15

UNCLASSIFIED 145. A. 48 Performance of maintenance – Personnel performing maintenance shall be qualified for the tasks performed – Maintenance performed using methods, tools, equipment, etc as specified in maintenance data – Risk of multiple errors during maintenance being repeated in identical maintenance tasks minimised – Error capturing method to be implemented after the performance of any critical maintenance task – after completion of maintenance a general verification is carried out to ensure the aircraft or component is clear of all tools, equipment and any extraneous parts or material Tool Control – Proper facilities are used UNCLASSIFIED 16

UNCLASSIFIED 145. A. 48 Performance of maintenance – Personnel performing maintenance shall be qualified for the tasks performed – Maintenance performed using methods, tools, equipment, etc as specified in maintenance data – Risk of multiple errors during maintenance being repeated in identical maintenance tasks minimised – Error capturing method to be implemented after the performance of any critical maintenance task – after completion of maintenance a general verification is carried out to ensure the aircraft or component is clear of all tools, equipment and any extraneous parts or material Tool Control – Proper facilities are used UNCLASSIFIED 16

UNCLASSIFIED 145. A. 50 Certification of maintenance – Certification of Aircraft & Component Release to Service (CRS) – Reporting requirements to the CAMO for new defects or inability to complete maintenance ordered – Requirements for Deferred Defects that the CAMO agrees may be deferred • Five Methods available - explained in next slides and AMC/GM 145. A. 50 (e) – Requirements for the use of components without appropriate certification UNCLASSIFIED 17

UNCLASSIFIED 145. A. 50 Certification of maintenance – Certification of Aircraft & Component Release to Service (CRS) – Reporting requirements to the CAMO for new defects or inability to complete maintenance ordered – Requirements for Deferred Defects that the CAMO agrees may be deferred • Five Methods available - explained in next slides and AMC/GM 145. A. 50 (e) – Requirements for the use of components without appropriate certification UNCLASSIFIED 17

UNCLASSIFIED Authorisation of Flight with Non-standard CRE (AFns. CRE) There are five methods: 1. Method 1. The Minimum Equipment List (MEL) or Configuration Deviation List (CDL) method, if available. 2. Method 2. The deferred defect process where no MEL/CDL exists or the defect is not covered by the MEL/CDL. • This is a technical assessment by the 145 • Involves CAMO (or Delegate) for logistical/operational decision 3. Method 3. The CAMO management process for AFns. CRE. • Task a 145 maintenance organisation to rectify the defect • Provide a life extension (i. e. repackage life within Airworthiness Limitation) • Seek an approved repair (may be unrepaired damage) from a Military Design Organisation Approval (MDOA) • Seek a Military Permit to Fly (MPTF) UNCLASSIFIED 18

UNCLASSIFIED Authorisation of Flight with Non-standard CRE (AFns. CRE) There are five methods: 1. Method 1. The Minimum Equipment List (MEL) or Configuration Deviation List (CDL) method, if available. 2. Method 2. The deferred defect process where no MEL/CDL exists or the defect is not covered by the MEL/CDL. • This is a technical assessment by the 145 • Involves CAMO (or Delegate) for logistical/operational decision 3. Method 3. The CAMO management process for AFns. CRE. • Task a 145 maintenance organisation to rectify the defect • Provide a life extension (i. e. repackage life within Airworthiness Limitation) • Seek an approved repair (may be unrepaired damage) from a Military Design Organisation Approval (MDOA) • Seek a Military Permit to Fly (MPTF) UNCLASSIFIED 18

UNCLASSIFIED Authorisation of Flight with Non-standard CRE cont. 4. Method 4. Issue a Command Clearance in accordance with the SPA. 10 a Command Clearance - Deliberate. • The CAMO engages the Military Air Operator to seek Command Clearance as required by SPA. 10 Command Clearance 5. Method 5. Issue a Command Clearance in accordance with the SPA. 10 b Command Clearance – Immediate • The CAMO engages the Military Air Operator to seek Command Clearance as required by SPA. 10 Command Clearance Note: Methods 1 through 3 are covered under Initial/Continued/Continuing Airworthiness approvals (DASR M/145) and instruments (Designs/MPTF) subject to NMAA approval and issue whereas methods 4 and 5 are Operational Airworthiness instruments authorised via the command chain. The MEL/CDL can be used by the pilot or authorised certifying staff to defer a defect. The deferred defect is documented in the aircraft technical log and the aircraft continuing airworthiness record system. UNCLASSIFIED 19

UNCLASSIFIED Authorisation of Flight with Non-standard CRE cont. 4. Method 4. Issue a Command Clearance in accordance with the SPA. 10 a Command Clearance - Deliberate. • The CAMO engages the Military Air Operator to seek Command Clearance as required by SPA. 10 Command Clearance 5. Method 5. Issue a Command Clearance in accordance with the SPA. 10 b Command Clearance – Immediate • The CAMO engages the Military Air Operator to seek Command Clearance as required by SPA. 10 Command Clearance Note: Methods 1 through 3 are covered under Initial/Continued/Continuing Airworthiness approvals (DASR M/145) and instruments (Designs/MPTF) subject to NMAA approval and issue whereas methods 4 and 5 are Operational Airworthiness instruments authorised via the command chain. The MEL/CDL can be used by the pilot or authorised certifying staff to defer a defect. The deferred defect is documented in the aircraft technical log and the aircraft continuing airworthiness record system. UNCLASSIFIED 19

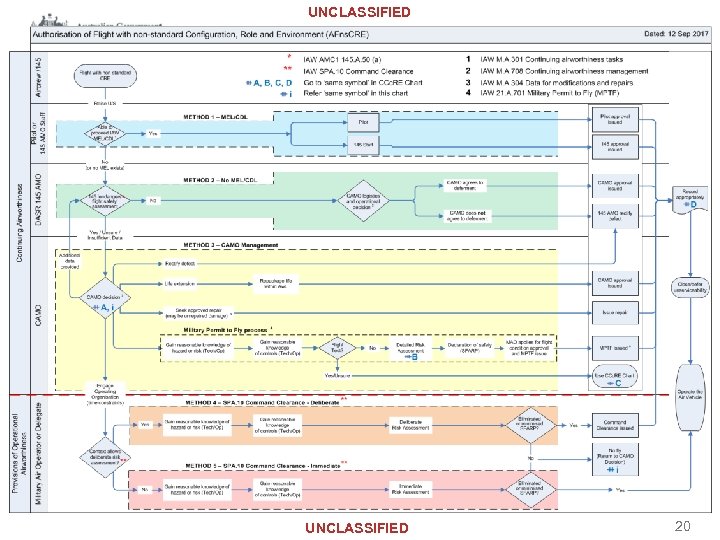

UNCLASSIFIED 20

UNCLASSIFIED 20

UNCLASSIFIED 145. A. 55 Maintenance records Requirements for: – Recording of Maintenance – Maintenance records reporting requirements to the CAMO – Retention of maintenance records – Storage and protection requirements for records UNCLASSIFIED 21

UNCLASSIFIED 145. A. 55 Maintenance records Requirements for: – Recording of Maintenance – Maintenance records reporting requirements to the CAMO – Retention of maintenance records – Storage and protection requirements for records UNCLASSIFIED 21

UNCLASSIFIED 145. A. 60 Occurrence reporting Requirements for – External (authority) reporting requirements for safety issues – Internal reporting of error/hazards/unsafe conditions – Trends analysis and continuous improvement requirements – Reporting UNCLASSIFIED 22

UNCLASSIFIED 145. A. 60 Occurrence reporting Requirements for – External (authority) reporting requirements for safety issues – Internal reporting of error/hazards/unsafe conditions – Trends analysis and continuous improvement requirements – Reporting UNCLASSIFIED 22

UNCLASSIFIED 145. A. 65 Safety and quality policy, maintenance procedures, quality system and SMS – Requirement for a safety and quality system, including – Independent auditing requirements – Internal feedback and response system for addressing findings – Human factors and performance management – The organisation shall establish a safety management system in accordance with DASR SMS UNCLASSIFIED 23

UNCLASSIFIED 145. A. 65 Safety and quality policy, maintenance procedures, quality system and SMS – Requirement for a safety and quality system, including – Independent auditing requirements – Internal feedback and response system for addressing findings – Human factors and performance management – The organisation shall establish a safety management system in accordance with DASR SMS UNCLASSIFIED 23

UNCLASSIFIED 145. A. 70 Maintenance Organisation Exposition (MOE) – Approved by the NMAA – Description of organisation structure, scope of approval, quality system, maintenance procedures (high level procedures), terms of reference and MOE amendment process – Safety & Quality Policy – Can be from an approved EASA Part 145 organisation. Military aspects still need to be covered UNCLASSIFIED 24

UNCLASSIFIED 145. A. 70 Maintenance Organisation Exposition (MOE) – Approved by the NMAA – Description of organisation structure, scope of approval, quality system, maintenance procedures (high level procedures), terms of reference and MOE amendment process – Safety & Quality Policy – Can be from an approved EASA Part 145 organisation. Military aspects still need to be covered UNCLASSIFIED 24

UNCLASSIFIED 145. A. 75 Privileges of the AMO – Maintain any aircraft and/or component for which it is approved at the locations identified in the approval certificate and in the MOE – Requirements for subcontracting of maintenance to – Approved, and – Unapproved organisations – Issue Certificate of Release to Service (CRS) as per 145. A. 50 on completion of maintenance. UNCLASSIFIED 25

UNCLASSIFIED 145. A. 75 Privileges of the AMO – Maintain any aircraft and/or component for which it is approved at the locations identified in the approval certificate and in the MOE – Requirements for subcontracting of maintenance to – Approved, and – Unapproved organisations – Issue Certificate of Release to Service (CRS) as per 145. A. 50 on completion of maintenance. UNCLASSIFIED 25

UNCLASSIFIED Limitations and Changes 145. A. 80 Limitations on the AMO – The organisation shall only maintain an aircraft or component for which it is approved when all the necessary facilities, equipment, tooling, material, maintenance data and certifying staff are available. 145. A. 85 Changes to the AMO – Which changes require notification to be made to the authority – Name change, location changes, management changes – Anything that could affect the approval – Ownership of the approved organisation. UNCLASSIFIED 26

UNCLASSIFIED Limitations and Changes 145. A. 80 Limitations on the AMO – The organisation shall only maintain an aircraft or component for which it is approved when all the necessary facilities, equipment, tooling, material, maintenance data and certifying staff are available. 145. A. 85 Changes to the AMO – Which changes require notification to be made to the authority – Name change, location changes, management changes – Anything that could affect the approval – Ownership of the approved organisation. UNCLASSIFIED 26

UNCLASSIFIED Continued Validity & Findings 145. A. 90 Continued validity of the approval – Unlimited duration based on – Satisfactory handling of findings – The NMAA being granted Access – Certificate of approval has not been surrendered or revoked 145. A. 95 AMO Findings by the AMO – Level 1 and Level 2 – GM added to include intention for NMAA to make observations – Requirement for corrective action plan within defined timeframes UNCLASSIFIED 27

UNCLASSIFIED Continued Validity & Findings 145. A. 90 Continued validity of the approval – Unlimited duration based on – Satisfactory handling of findings – The NMAA being granted Access – Certificate of approval has not been surrendered or revoked 145. A. 95 AMO Findings by the AMO – Level 1 and Level 2 – GM added to include intention for NMAA to make observations – Requirement for corrective action plan within defined timeframes UNCLASSIFIED 27

UNCLASSIFIED Additional Information • Additional information is available from the DASA Website • DASR – http: //www. defence. gov. au/DASP/DASR-Regulations/ • DASR 145 – http: //www. defence. gov. au/DASP/DASR-Regulations/DASR 145/Default. asp UNCLASSIFIED 33

UNCLASSIFIED Additional Information • Additional information is available from the DASA Website • DASR – http: //www. defence. gov. au/DASP/DASR-Regulations/ • DASR 145 – http: //www. defence. gov. au/DASP/DASR-Regulations/DASR 145/Default. asp UNCLASSIFIED 33