a11f609e85e74d3948c9630a5623db8a.ppt

- Количество слайдов: 21

UNCLASS Surface Ship Maintenance Program brief for Virginia Ship Repair Association CAPT Mike Stanton USFF N 431 22 APR 2009 United States Fleet Forces Ready Fleet … Global Reach 1

Overview • USFF Fleet Maintenance Directorate • Program objectives: – ‘Planned Service Life’ view of Maintenance – Areas of responsibility • Strategic Maintenance Process: – Requirements & programming – Maintenance execution planning Improve process stability; Reduce process variation – Maintenance execution United States Fleet Forces Ready Fleet … Global Reach 2

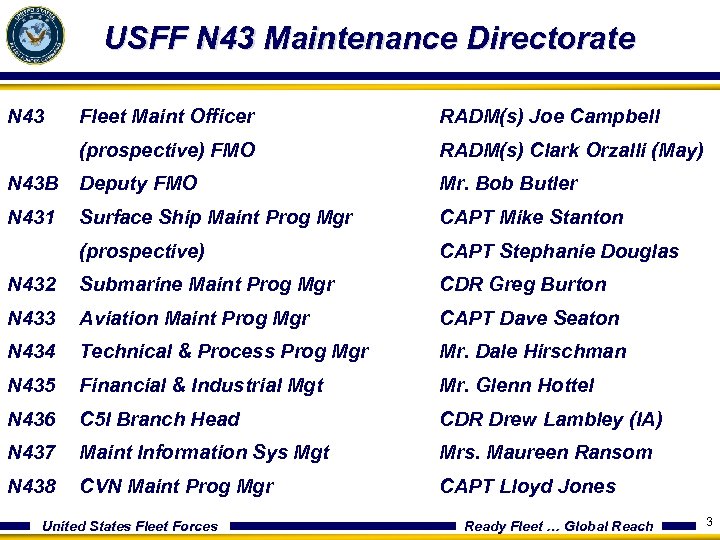

USFF N 43 Maintenance Directorate N 43 Fleet Maint Officer RADM(s) Joe Campbell (prospective) FMO RADM(s) Clark Orzalli (May) N 43 B Deputy FMO Mr. Bob Butler N 431 Surface Ship Maint Prog Mgr CAPT Mike Stanton (prospective) CAPT Stephanie Douglas N 432 Submarine Maint Prog Mgr CDR Greg Burton N 433 Aviation Maint Prog Mgr CAPT Dave Seaton N 434 Technical & Process Prog Mgr Mr. Dale Hirschman N 435 Financial & Industrial Mgt Mr. Glenn Hottel N 436 C 5 I Branch Head CDR Drew Lambley (IA) N 437 Maint Information Sys Mgt Mrs. Maureen Ransom N 438 CVN Maint Prog Mgr CAPT Lloyd Jones United States Fleet Forces Ready Fleet … Global Reach 3

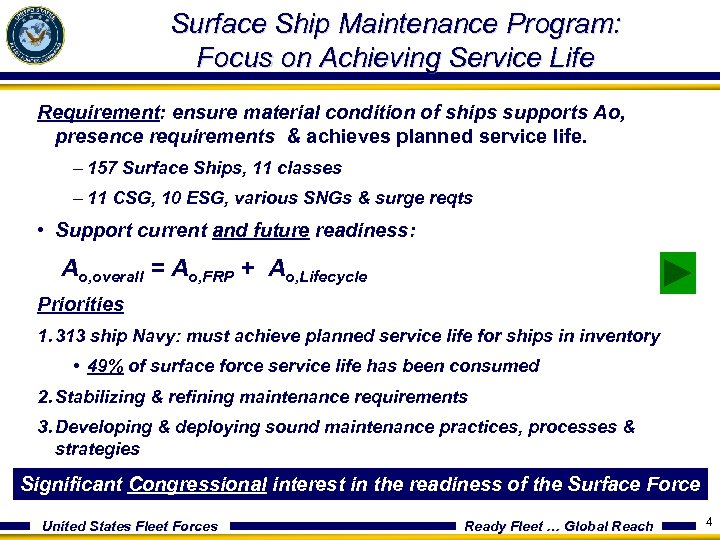

Surface Ship Maintenance Program: Focus on Achieving Service Life Requirement: ensure material condition of ships supports Ao, presence requirements & achieves planned service life. – 157 Surface Ships, 11 classes – 11 CSG, 10 ESG, various SNGs & surge reqts • Support current and future readiness: Ao, overall = Ao, FRP + Ao, Lifecycle Priorities 1. 313 ship Navy: must achieve planned service life for ships in inventory • 49% of surface force service life has been consumed 2. Stabilizing & refining maintenance requirements 3. Developing & deploying sound maintenance practices, processes & strategies Significant Congressional interest in the readiness of the Surface Force United States Fleet Forces Ready Fleet … Global Reach 4

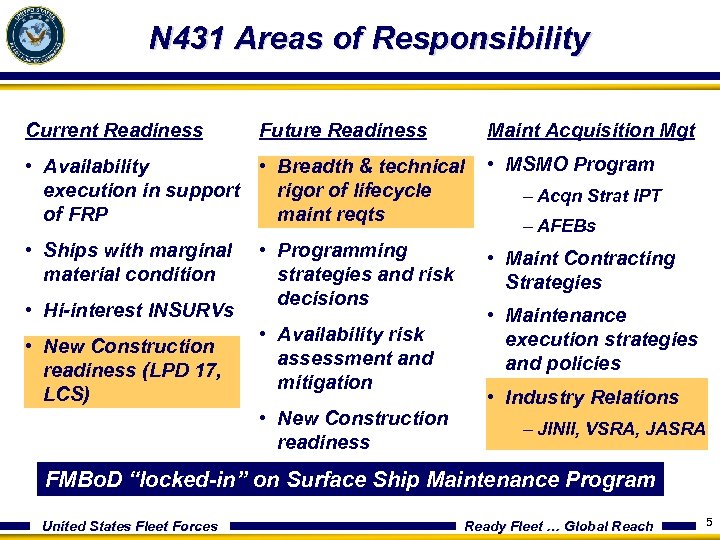

N 431 Areas of Responsibility Current Readiness Future Readiness Maint Acquisition Mgt • Availability • Breadth & technical execution in support rigor of lifecycle of FRP maint reqts • MSMO Program • Ships with marginal material condition • Maint Contracting Strategies • Hi-interest INSURVs • New Construction readiness (LPD 17, LCS) • Programming strategies and risk decisions • Availability risk assessment and mitigation • New Construction readiness – Acqn Strat IPT – AFEBs • Maintenance execution strategies and policies • Industry Relations – JINII, VSRA, JASRA FMBo. D “locked-in” on Surface Ship Maintenance Program United States Fleet Forces Ready Fleet … Global Reach 5

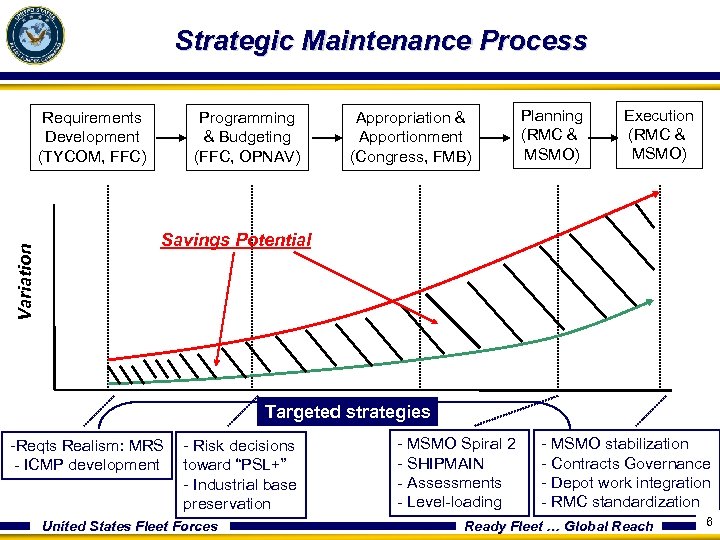

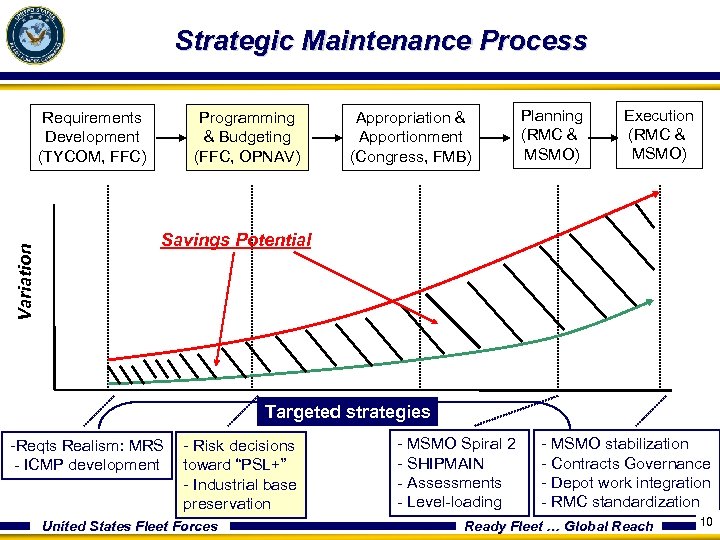

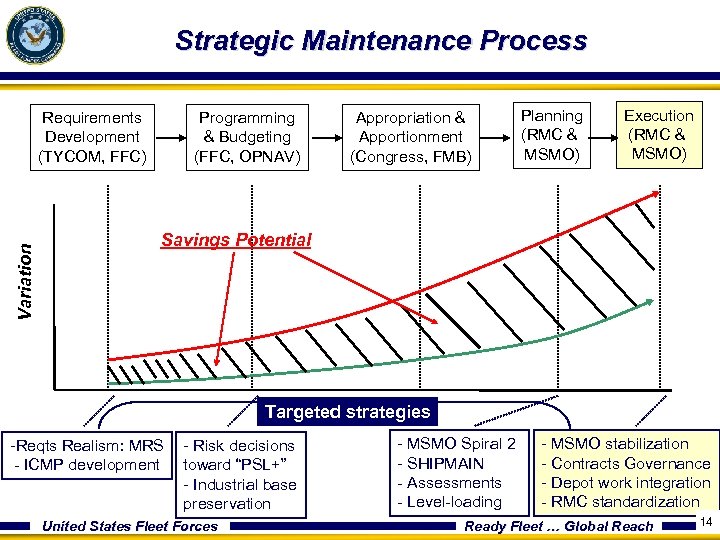

Strategic Maintenance Process Variation Requirements Development (TYCOM, FFC) Programming & Budgeting (FFC, OPNAV) Appropriation & Apportionment (Congress, FMB) Planning (RMC & MSMO) Execution (RMC & MSMO) Savings Potential Process stage Targeted strategies -Reqts Realism: MRS - ICMP development - Risk decisions toward “PSL+” - Industrial base preservation United States Fleet Forces - MSMO Spiral 2 - SHIPMAIN - Assessments - Level-loading - MSMO stabilization - Contracts Governance - Depot work integration - RMC standardization Ready Fleet … Global Reach 6

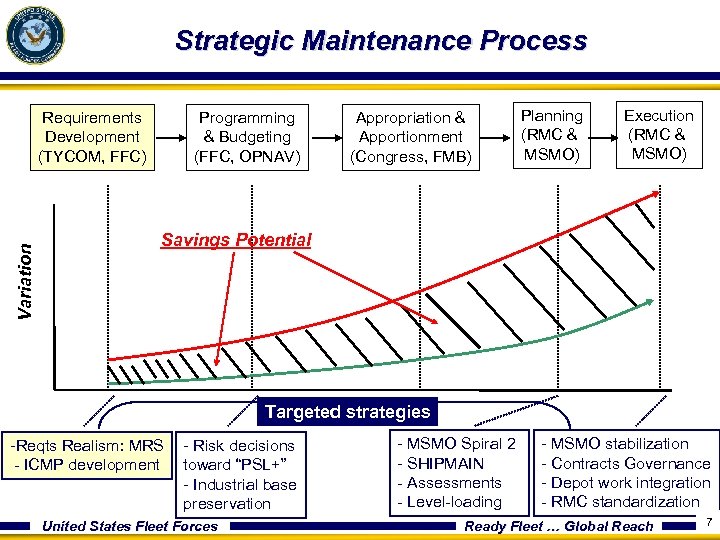

Strategic Maintenance Process Variation Requirements Development (TYCOM, FFC) Programming & Budgeting (FFC, OPNAV) Appropriation & Apportionment (Congress, FMB) Planning (RMC & MSMO) Execution (RMC & MSMO) Savings Potential Process stage Targeted strategies -Reqts Realism: MRS - ICMP development - Risk decisions toward “PSL+” - Industrial base preservation United States Fleet Forces - MSMO Spiral 2 - SHIPMAIN - Assessments - Level-loading - MSMO stabilization - Contracts Governance - Depot work integration - RMC standardization Ready Fleet … Global Reach 7

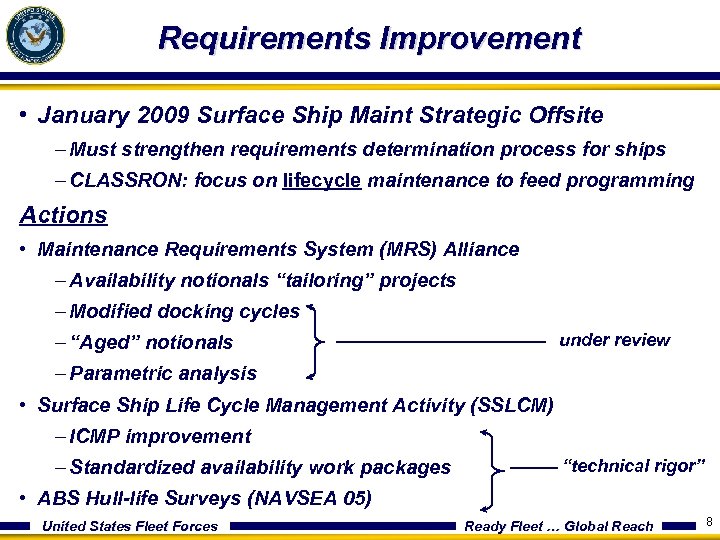

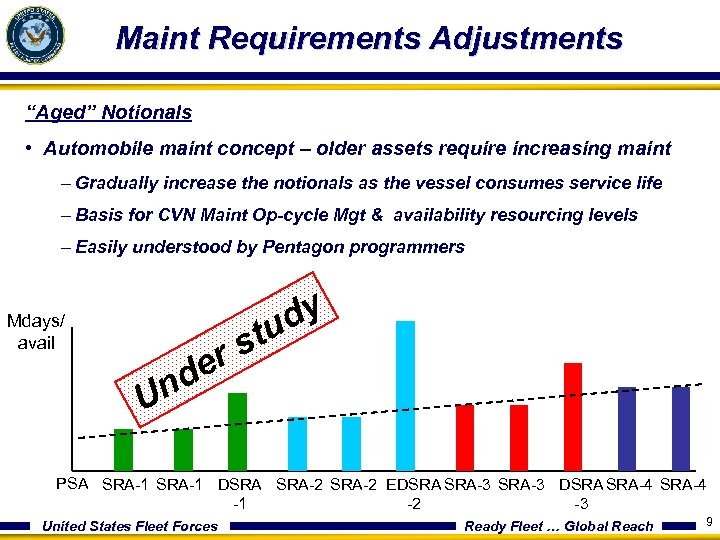

Requirements Improvement • January 2009 Surface Ship Maint Strategic Offsite – Must strengthen requirements determination process for ships – CLASSRON: focus on lifecycle maintenance to feed programming Actions • Maintenance Requirements System (MRS) Alliance – Availability notionals “tailoring” projects – Modified docking cycles under review – “Aged” notionals – Parametric analysis • Surface Ship Life Cycle Management Activity (SSLCM) – ICMP improvement – Standardized availability work packages “technical rigor” • ABS Hull-life Surveys (NAVSEA 05) United States Fleet Forces Ready Fleet … Global Reach 8

Maint Requirements Adjustments “Aged” Notionals • Automobile maint concept – older assets require increasing maint – Gradually increase the notionals as the vessel consumes service life – Basis for CVN Maint Op-cycle Mgt & availability resourcing levels – Easily understood by Pentagon programmers Mdays/ avail dy tu rs de Un PSA SRA-1 DSRA SRA-2 EDSRA SRA-3 DSRA SRA-4 -1 -2 -3 United States Fleet Forces Ready Fleet … Global Reach 9

Strategic Maintenance Process Variation Requirements Development (TYCOM, FFC) Programming & Budgeting (FFC, OPNAV) Appropriation & Apportionment (Congress, FMB) Planning (RMC & MSMO) Execution (RMC & MSMO) Savings Potential Process stage Targeted strategies -Reqts Realism: MRS - ICMP development - Risk decisions toward “PSL+” - Industrial base preservation United States Fleet Forces - MSMO Spiral 2 - SHIPMAIN - Assessments - Level-loading - MSMO stabilization - Contracts Governance - Depot work integration - RMC standardization Ready Fleet … Global Reach 10

Programming Considerations • Meeting maintenance requirements since 2003 with baseline funding plus supplemental appropriations – How to transition out of supplementals yet still secure needed funding(? ) – Fiscal policies of new administration…. • How is risk managed against shortfalls – Preserve industrial base vs. service life risk? • Phasing with major modernization programs • Full funding vs. timing of funding • Measurements tricky: – Near term effects and long-term effects United States Fleet Forces Ready Fleet … Global Reach 11

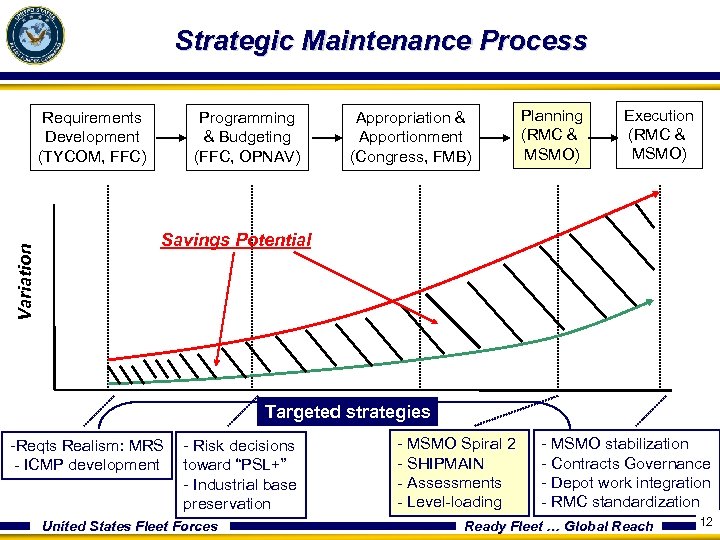

Strategic Maintenance Process Variation Requirements Development (TYCOM, FFC) Programming & Budgeting (FFC, OPNAV) Appropriation & Apportionment (Congress, FMB) Planning (RMC & MSMO) Execution (RMC & MSMO) Savings Potential Process stage Targeted strategies -Reqts Realism: MRS - ICMP development - Risk decisions toward “PSL+” - Industrial base preservation United States Fleet Forces - MSMO Spiral 2 - SHIPMAIN - Assessments - Level-loading - MSMO stabilization - Contracts Governance - Depot work integration - RMC standardization Ready Fleet … Global Reach 12

Execution Planning • Incremental improvements in MSMO Spiral 2 • MCIT replaces SHIPMAIN – Focused on avail planning & execution performance • What of “assessments”? – Re-institute shipboard assessments to facilitate avail planning • SSLCM: ICMP deploying BAWPs & AWPs • Expanding role of MFOM – Valuating lifecycle maintenance actions • Port-loading considerations (source of variation) • Technical requirements clarification & stabilization United States Fleet Forces Ready Fleet … Global Reach 13

Strategic Maintenance Process Variation Requirements Development (TYCOM, FFC) Programming & Budgeting (FFC, OPNAV) Appropriation & Apportionment (Congress, FMB) Planning (RMC & MSMO) Execution (RMC & MSMO) Savings Potential Process stage Targeted strategies -Reqts Realism: MRS - ICMP development - Risk decisions toward “PSL+” - Industrial base preservation United States Fleet Forces - MSMO Spiral 2 - SHIPMAIN - Assessments - Level-loading - MSMO stabilization - Contracts Governance - Depot work integration - RMC standardization Ready Fleet … Global Reach 14

Maintenance Execution • MSMO –Over-arching objective: stabilize MSMO • Permits contractor focus, commitment, repetition, improvement –Incremental improvements for MSMO Spiral 2 • Beneficial to Navy and industry • Comprehensive Contracting Strategy –Contracts Governance Process –Depot Work Integration United States Fleet Forces Ready Fleet … Global Reach 15

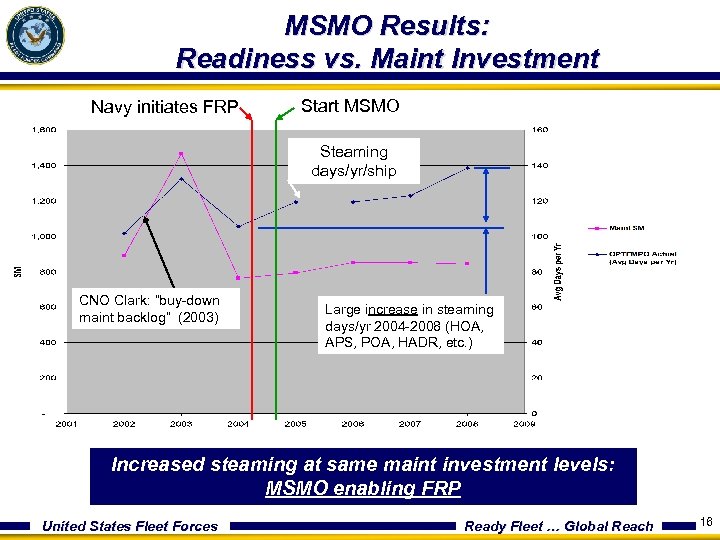

MSMO Results: Readiness vs. Maint Investment Navy initiates FRP Start MSMO Steaming days/yr/ship CNO Clark: “buy-down maint backlog” (2003) Large increase in steaming days/yr 2004 -2008 (HOA, APS, POA, HADR, etc. ) Increased steaming at same maint investment levels: MSMO enabling FRP United States Fleet Forces Ready Fleet … Global Reach 16

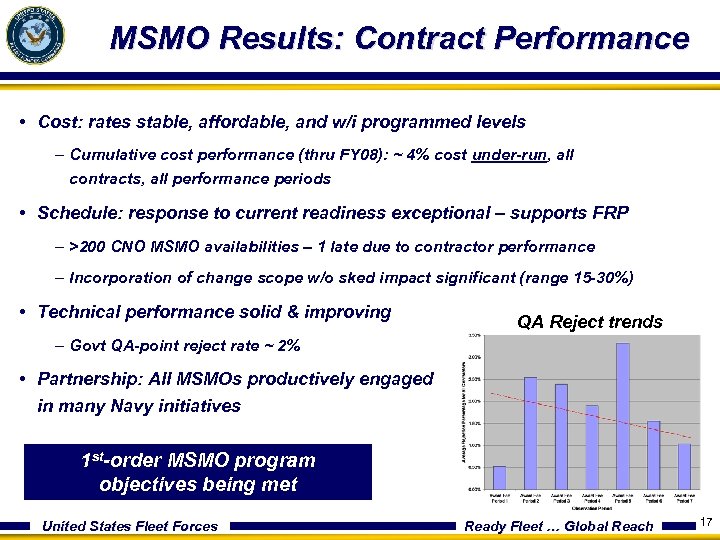

MSMO Results: Contract Performance • Cost: rates stable, affordable, and w/i programmed levels – Cumulative cost performance (thru FY 08): ~ 4% cost under-run, all contracts, all performance periods • Schedule: response to current readiness exceptional – supports FRP – >200 CNO MSMO availabilities – 1 late due to contractor performance – Incorporation of change scope w/o sked impact significant (range 15 -30%) • Technical performance solid & improving QA Reject trends – Govt QA-point reject rate ~ 2% • Partnership: All MSMOs productively engaged in many Navy initiatives 1 st-order MSMO program objectives being met United States Fleet Forces Ready Fleet … Global Reach 17

MSMO Controls, Oversight, Governance MSMO success due to: • All contracts issued under proper Navy contract & technical warrants • Contract stability: focus, investment, process improvement • RMC exercising contractual authorities • DCAA periodic cost audits • Award fee evaluation boards – frequent feedback & accountability • Standing MSMO Acqn IPT providing dynamic review & adjustment • Rigorous oversight by ASN(RDA) – Balancing competition, performance incentives, stability – Approved additional contract strengthening in MSMO Spiral 2 (FY 10 -14) • Navy submitting report to Congress in FY 10 Budget Request substantiating rationale for executing DDG Modernization w/ MSMO Many pieces contributing to overall program strength United States Fleet Forces Ready Fleet … Global Reach 18

Update: Comprehensive Contracting & Depot Work Integration Policy for Comprehensive Contracting and Depot Work Integration – Approved by ASN(RDA) 27 March 2009 – Enabling instructions & policies implemented JFMM Ch 7 A (30 Jun 08) • Key elements/enablers – All work coincident to depot availabilities shall be planned, integrated and coordinated through the NSA using the LMA as the planning agent – LMAs shall have first opportunity to execute all depot work for which they have organic capability, capacity and cost reasonableness • Programs shall budget for reasonable depot installation costs – AITs shall execute AIT-unique work, and can execute depot installation work if the LMA does not meet the aforementioned requirements – NSAs shall remain the single authoritative voice to equitably resolve availability disputes and disruptions amongst all customers Policy successfully executed on several major CNO availabilities United States Fleet Forces Ready Fleet … Global Reach 19

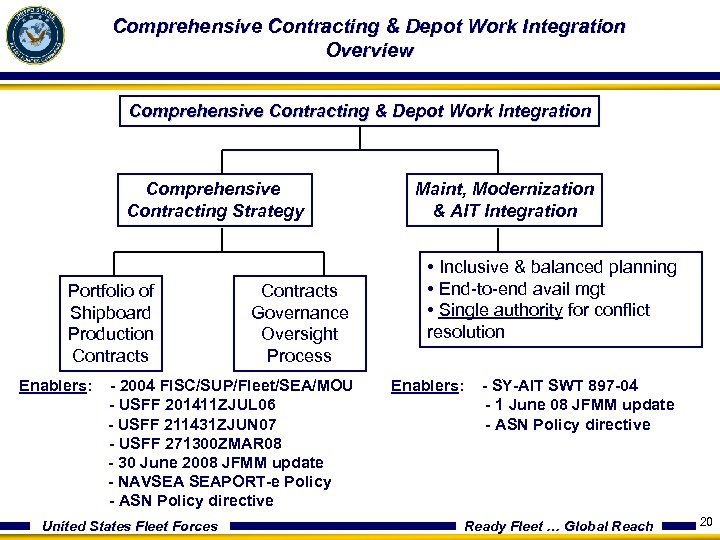

Comprehensive Contracting & Depot Work Integration Overview Comprehensive Contracting & Depot Work Integration Comprehensive Contracting Strategy Portfolio of Shipboard Production Contracts Enablers: Contracts Governance Oversight Process - 2004 FISC/SUP/Fleet/SEA/MOU - USFF 201411 ZJUL 06 - USFF 211431 ZJUN 07 - USFF 271300 ZMAR 08 - 30 June 2008 JFMM update - NAVSEA SEAPORT-e Policy - ASN Policy directive United States Fleet Forces Maint, Modernization & AIT Integration • Inclusive & balanced planning • End-to-end avail mgt • Single authority for conflict resolution Enablers: - SY-AIT SWT 897 -04 - 1 June 08 JFMM update - ASN Policy directive Ready Fleet … Global Reach 20

Questions? United States Fleet Forces Ready Fleet … Global Reach 21

a11f609e85e74d3948c9630a5623db8a.ppt