f7b72491f806c497922cbfc34bf48913.ppt

- Количество слайдов: 43

ULTECH Co. , Ltd. www. ultech. co. kr www. memstech. co. kr

ULTECH Co. , Ltd. www. ultech. co. kr www. memstech. co. kr

Introduction Company name: l Business category: ULTECH Co. , Ltd. Manufacturing of Semiconductor Equipment, MEMS, Display & Solar Cell Equipment l Foundation date: March 15, 1998 l The president: Suk, Chang-Gil l Headquarter Office: 8 -2, Horim-dong, Dalseo-gu, Daegu-si, Korea TEL. 82 -53 -583 -7565 http: //www. ultech. co. kr l ULTECH Co. , Ltd.

Introduction Company name: l Business category: ULTECH Co. , Ltd. Manufacturing of Semiconductor Equipment, MEMS, Display & Solar Cell Equipment l Foundation date: March 15, 1998 l The president: Suk, Chang-Gil l Headquarter Office: 8 -2, Horim-dong, Dalseo-gu, Daegu-si, Korea TEL. 82 -53 -583 -7565 http: //www. ultech. co. kr l ULTECH Co. , Ltd.

Profile l l 1998 1999 l 2000 l 2001 l l l 2002 2003 2004 l l 2005 2006 2007 2008 l 2009 l 2010 l 2011 l 2012 l 2013 Founded ULTECH Co. Incorporate ULTECH Co. , Ltd. Nominated for Venture Company from SMBA (SMBA : Small & Medium Business Administration) Launched the in-situ double-side metal coating system for mass production Appointed Leading Small & Medium Company by Daegu city Moved to the new building in Daegu High-tech zone (Clean room of class 1, 000) Appointed INNO-BIZ Company by SMBA Launched ICP nano etching system Awarded New Generation Leading Technology Company from Daegu Techno Park Exporting Sputter system for mass production to Indonesia Exporting E-beam evaporator system for mass production to China Develop PR Spray & Spin coater for manufacture of 3 D Integrated micro system Participate in SEMICON CHINA 2006 exhibition Exporting the LPCVD/Furnace system to India Launched new model of E-beam evaporator system (SEE-7) Launched new model of Asher system (EURA-200) Exporting LPCVD system to Malaysia Launched E-beam evaporator system for LED production Launched Diffusion furnace for Solar cell production Exporting SPUTTER & THERMAL system to Russia Exporting Wet bench to India Extended FAB-2 Launched PECVD system for Solar cell production Launched Wet bench system for Solar cell production Launched Turnkey Line for Silicon Solar cell production Launched RIE system for Solar cell production Launched Roll to Roll Sputter system for flexible thin film coating Participate in 2013 Shenzhen International Touchscreen Exhibition ULTECH Co. , Ltd.

Profile l l 1998 1999 l 2000 l 2001 l l l 2002 2003 2004 l l 2005 2006 2007 2008 l 2009 l 2010 l 2011 l 2012 l 2013 Founded ULTECH Co. Incorporate ULTECH Co. , Ltd. Nominated for Venture Company from SMBA (SMBA : Small & Medium Business Administration) Launched the in-situ double-side metal coating system for mass production Appointed Leading Small & Medium Company by Daegu city Moved to the new building in Daegu High-tech zone (Clean room of class 1, 000) Appointed INNO-BIZ Company by SMBA Launched ICP nano etching system Awarded New Generation Leading Technology Company from Daegu Techno Park Exporting Sputter system for mass production to Indonesia Exporting E-beam evaporator system for mass production to China Develop PR Spray & Spin coater for manufacture of 3 D Integrated micro system Participate in SEMICON CHINA 2006 exhibition Exporting the LPCVD/Furnace system to India Launched new model of E-beam evaporator system (SEE-7) Launched new model of Asher system (EURA-200) Exporting LPCVD system to Malaysia Launched E-beam evaporator system for LED production Launched Diffusion furnace for Solar cell production Exporting SPUTTER & THERMAL system to Russia Exporting Wet bench to India Extended FAB-2 Launched PECVD system for Solar cell production Launched Wet bench system for Solar cell production Launched Turnkey Line for Silicon Solar cell production Launched RIE system for Solar cell production Launched Roll to Roll Sputter system for flexible thin film coating Participate in 2013 Shenzhen International Touchscreen Exhibition ULTECH Co. , Ltd.

Primary Customers l Samsung Electronics (SEC) l Samsung Electro-Mechanics (SEM) l Samsung Electro-Mechanics China (SEM-China) l Samsung Mobile Display (SMD) l LG Electronics (LGE) l LG Chemical (LG Chem) l LG Display l LG Innotech l AP System l WIreless SOLution (WISOL) l Korea Advanced Nano-fab Center (KANC) l Electronics and Telecommunications Research Institute (ETRI) l Seoul National University l POhang university of Science and TECHnology (POSTECH) l Korea Advanced Institute of Science and Technology (KAIST) l Research Centre Imarat (RCI, india) l University of Malaysia, Perlis (Uni. MAP, Malaysia) l Indian Institute of Technology (IIT Bombay, India) l Oriental Chemical Industry (OCI, Indonesia) l Russia (Avangard, NIIIS, SIGNAL) l Istanbul Technical university MEMS research center (ITU-MEMS , Turkey) ULTECH Co. , Ltd.

Primary Customers l Samsung Electronics (SEC) l Samsung Electro-Mechanics (SEM) l Samsung Electro-Mechanics China (SEM-China) l Samsung Mobile Display (SMD) l LG Electronics (LGE) l LG Chemical (LG Chem) l LG Display l LG Innotech l AP System l WIreless SOLution (WISOL) l Korea Advanced Nano-fab Center (KANC) l Electronics and Telecommunications Research Institute (ETRI) l Seoul National University l POhang university of Science and TECHnology (POSTECH) l Korea Advanced Institute of Science and Technology (KAIST) l Research Centre Imarat (RCI, india) l University of Malaysia, Perlis (Uni. MAP, Malaysia) l Indian Institute of Technology (IIT Bombay, India) l Oriental Chemical Industry (OCI, Indonesia) l Russia (Avangard, NIIIS, SIGNAL) l Istanbul Technical university MEMS research center (ITU-MEMS , Turkey) ULTECH Co. , Ltd.

Facilities l PE-ALD/CVD system (for demonstration) l Sputter system (for demonstration) l Evaporator system (for demonstration) l RTP system (for demonstration) l Clean room (class 10, 000) l Auto welder & tube facing tool l Leak detector l RGA (Residual Gas Analyzer) ULTECH Co. , Ltd.

Facilities l PE-ALD/CVD system (for demonstration) l Sputter system (for demonstration) l Evaporator system (for demonstration) l RTP system (for demonstration) l Clean room (class 10, 000) l Auto welder & tube facing tool l Leak detector l RGA (Residual Gas Analyzer) ULTECH Co. , Ltd.

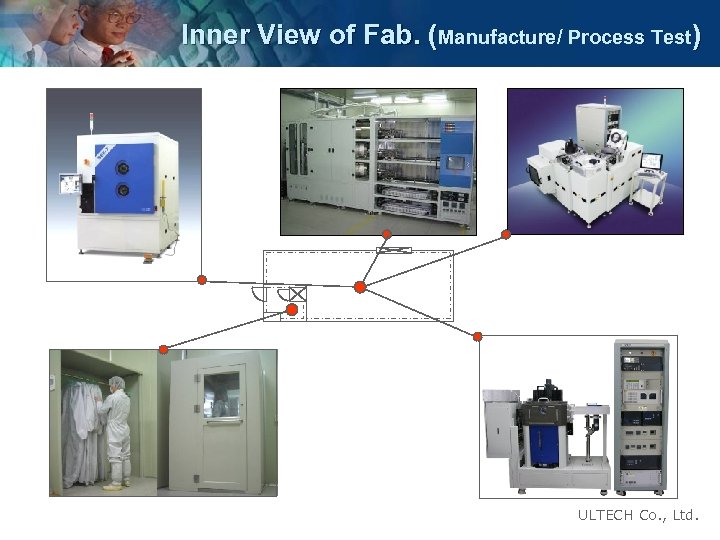

Inner View of Fab. (Manufacture/ Process Test) ULTECH Co. , Ltd.

Inner View of Fab. (Manufacture/ Process Test) ULTECH Co. , Ltd.

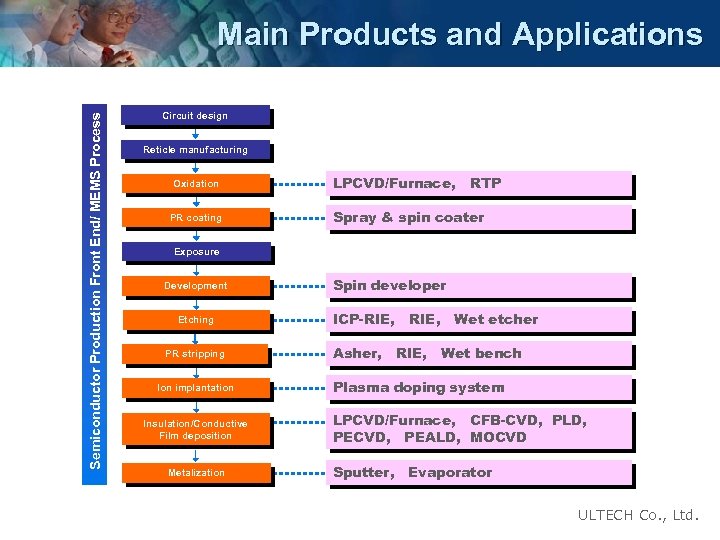

Semiconductor Production Front End/ MEMS Process Main Products and Applications Circuit design Reticle manufacturing Oxidation PR coating LPCVD/Furnace, RTP Spray & spin coater Exposure Development Etching PR stripping Ion implantation Insulation/Conductive Film deposition Metalization Spin developer ICP-RIE, Wet etcher Asher, RIE, Wet bench Plasma doping system LPCVD/Furnace, CFB-CVD, PLD, PECVD, PEALD, MOCVD Sputter, Evaporator ULTECH Co. , Ltd.

Semiconductor Production Front End/ MEMS Process Main Products and Applications Circuit design Reticle manufacturing Oxidation PR coating LPCVD/Furnace, RTP Spray & spin coater Exposure Development Etching PR stripping Ion implantation Insulation/Conductive Film deposition Metalization Spin developer ICP-RIE, Wet etcher Asher, RIE, Wet bench Plasma doping system LPCVD/Furnace, CFB-CVD, PLD, PECVD, PEALD, MOCVD Sputter, Evaporator ULTECH Co. , Ltd.

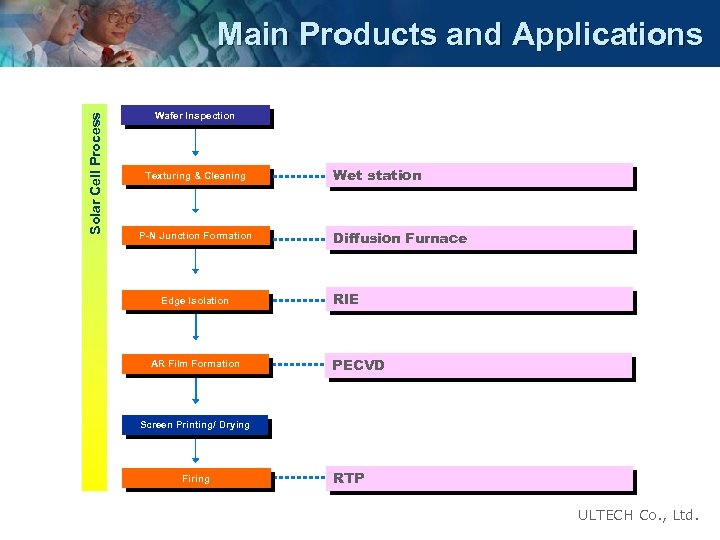

Solar Cell Process Main Products and Applications Wafer Inspection Texturing & Cleaning P-N Junction Formation Edge Isolation AR Film Formation Wet station Diffusion Furnace RIE PECVD Screen Printing/ Drying Firing RTP ULTECH Co. , Ltd.

Solar Cell Process Main Products and Applications Wafer Inspection Texturing & Cleaning P-N Junction Formation Edge Isolation AR Film Formation Wet station Diffusion Furnace RIE PECVD Screen Printing/ Drying Firing RTP ULTECH Co. , Ltd.

Main Products Sputter System l l l Magnetic thin films layer coating Opto-electronic films coating Reflective and anti-reflective optical coating Industrial machinery & tools hard coating Conventional materials coating Metal electrode deposition of information & communication device (Resonator, filter, oscillator, capacitor, PTC, NTC, etc. ) Roll to Roll system Ag Cu Zn. O Rotation Module ULTECH Co. , Ltd.

Main Products Sputter System l l l Magnetic thin films layer coating Opto-electronic films coating Reflective and anti-reflective optical coating Industrial machinery & tools hard coating Conventional materials coating Metal electrode deposition of information & communication device (Resonator, filter, oscillator, capacitor, PTC, NTC, etc. ) Roll to Roll system Ag Cu Zn. O Rotation Module ULTECH Co. , Ltd.

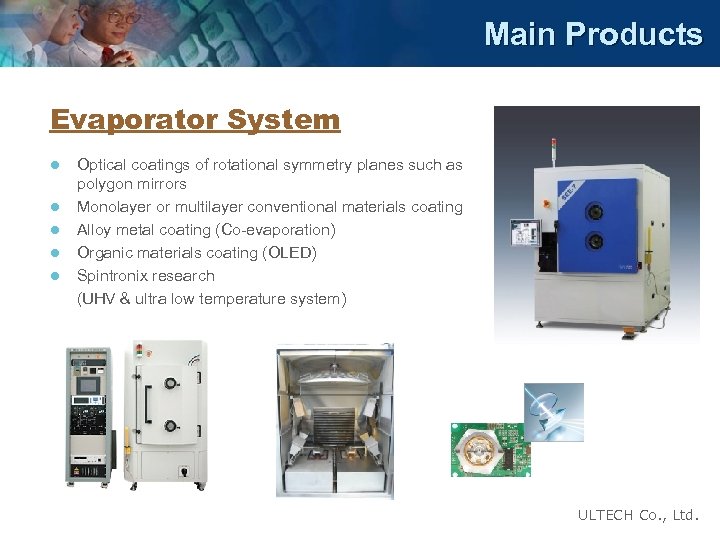

Main Products Evaporator System l l l Optical coatings of rotational symmetry planes such as polygon mirrors Monolayer or multilayer conventional materials coating Alloy metal coating (Co-evaporation) Organic materials coating (OLED) Spintronix research (UHV & ultra low temperature system) ULTECH Co. , Ltd.

Main Products Evaporator System l l l Optical coatings of rotational symmetry planes such as polygon mirrors Monolayer or multilayer conventional materials coating Alloy metal coating (Co-evaporation) Organic materials coating (OLED) Spintronix research (UHV & ultra low temperature system) ULTECH Co. , Ltd.

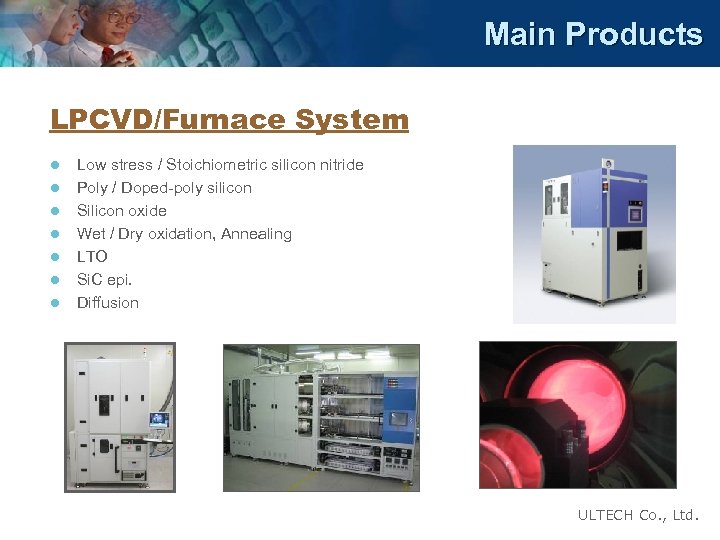

Main Products LPCVD/Furnace System l l l l Low stress / Stoichiometric silicon nitride Poly / Doped-poly silicon Silicon oxide Wet / Dry oxidation, Annealing LTO Si. C epi. Diffusion ULTECH Co. , Ltd.

Main Products LPCVD/Furnace System l l l l Low stress / Stoichiometric silicon nitride Poly / Doped-poly silicon Silicon oxide Wet / Dry oxidation, Annealing LTO Si. C epi. Diffusion ULTECH Co. , Ltd.

Main Products PECVD System l l l Amorphous silicon deposition Poly silicon deposition Silicon oxide deposition Silicon nitride deposition Metal oxide deposition High-k dielectrics deposition ULTECH Co. , Ltd.

Main Products PECVD System l l l Amorphous silicon deposition Poly silicon deposition Silicon oxide deposition Silicon nitride deposition Metal oxide deposition High-k dielectrics deposition ULTECH Co. , Ltd.

Main Products ALD System l l Metal deposition : Ru, Ti. N, WN, Al. N, Poly silicon deposition Silicon nitride deposition Metal oxide deposition: Al 2 O 3, Hf. O 2, Zn. O, Ti. O 2, Ta 2 O 5, CIGS ULTECH Co. , Ltd.

Main Products ALD System l l Metal deposition : Ru, Ti. N, WN, Al. N, Poly silicon deposition Silicon nitride deposition Metal oxide deposition: Al 2 O 3, Hf. O 2, Zn. O, Ti. O 2, Ta 2 O 5, CIGS ULTECH Co. , Ltd.

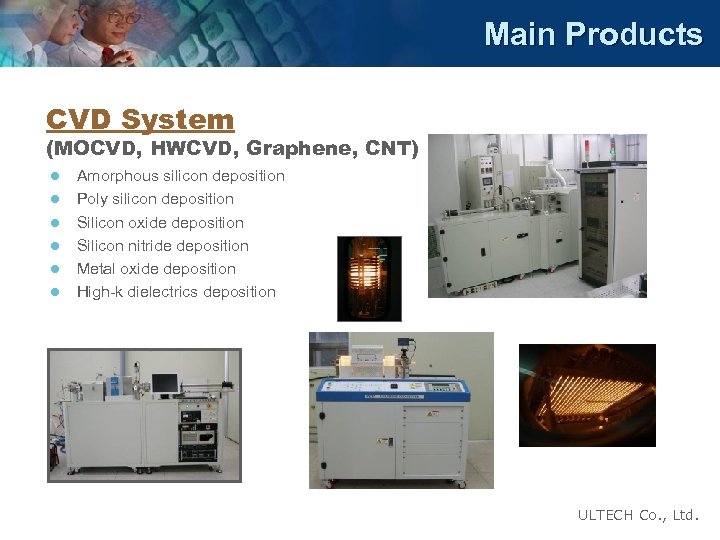

Main Products CVD System (MOCVD, HWCVD, Graphene, CNT) l l l Amorphous silicon deposition Poly silicon deposition Silicon oxide deposition Silicon nitride deposition Metal oxide deposition High-k dielectrics deposition ULTECH Co. , Ltd.

Main Products CVD System (MOCVD, HWCVD, Graphene, CNT) l l l Amorphous silicon deposition Poly silicon deposition Silicon oxide deposition Silicon nitride deposition Metal oxide deposition High-k dielectrics deposition ULTECH Co. , Ltd.

Main Products Dry Etching System (ICP-RIE, RIE) l l Bulk / Poly silicon etching (MEMS & NANO) Dielectrics etching (Si. O 2, Si 3 N 4, etc. ) Compound semiconductors etching (Ga. As, Ga. N, etc. ) Polymide etching ULTECH Co. , Ltd.

Main Products Dry Etching System (ICP-RIE, RIE) l l Bulk / Poly silicon etching (MEMS & NANO) Dielectrics etching (Si. O 2, Si 3 N 4, etc. ) Compound semiconductors etching (Ga. As, Ga. N, etc. ) Polymide etching ULTECH Co. , Ltd.

Main Products Wet Etcher & Wet Bench System l l l Si Anisotropic Wet Etch PSL, Electroplating V-Groove, U-Groove, Cavity formation Membrane, micro-channel formation Available mixing of Cleaning / Chemical etching / Solvent / Developer bench ULTECH Co. , Ltd.

Main Products Wet Etcher & Wet Bench System l l l Si Anisotropic Wet Etch PSL, Electroplating V-Groove, U-Groove, Cavity formation Membrane, micro-channel formation Available mixing of Cleaning / Chemical etching / Solvent / Developer bench ULTECH Co. , Ltd.

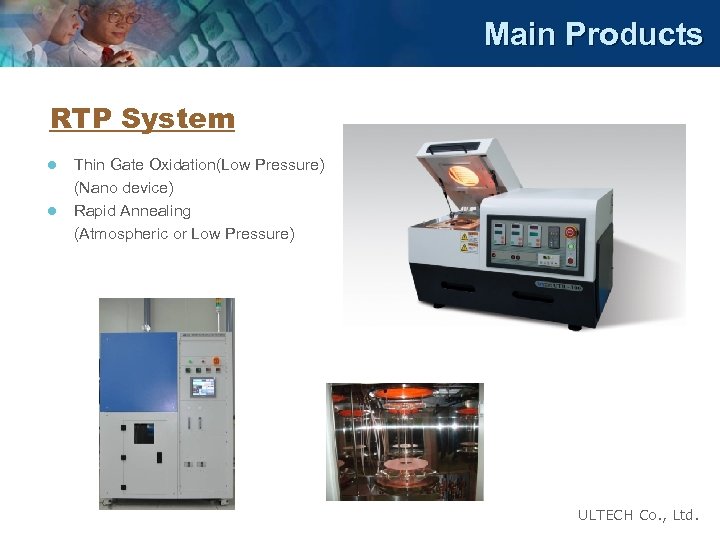

Main Products RTP System l l Thin Gate Oxidation(Low Pressure) (Nano device) Rapid Annealing (Atmospheric or Low Pressure) ULTECH Co. , Ltd.

Main Products RTP System l l Thin Gate Oxidation(Low Pressure) (Nano device) Rapid Annealing (Atmospheric or Low Pressure) ULTECH Co. , Ltd.

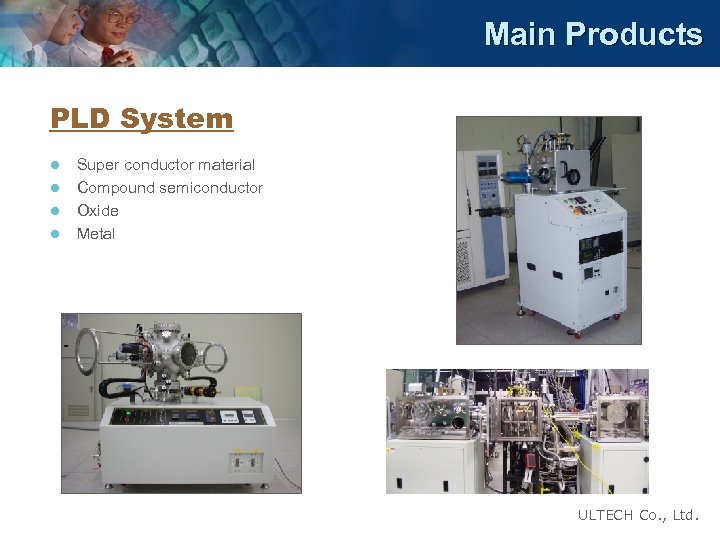

Main Products PLD System l l Super conductor material Compound semiconductor Oxide Metal ULTECH Co. , Ltd.

Main Products PLD System l l Super conductor material Compound semiconductor Oxide Metal ULTECH Co. , Ltd.

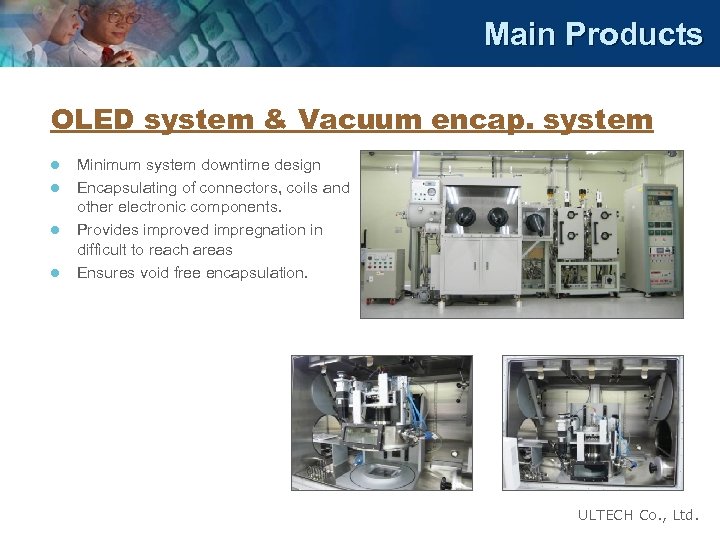

Main Products OLED system & Vacuum encap. system l l Minimum system downtime design Encapsulating of connectors, coils and other electronic components. Provides improved impregnation in difficult to reach areas Ensures void free encapsulation. ULTECH Co. , Ltd.

Main Products OLED system & Vacuum encap. system l l Minimum system downtime design Encapsulating of connectors, coils and other electronic components. Provides improved impregnation in difficult to reach areas Ensures void free encapsulation. ULTECH Co. , Ltd.

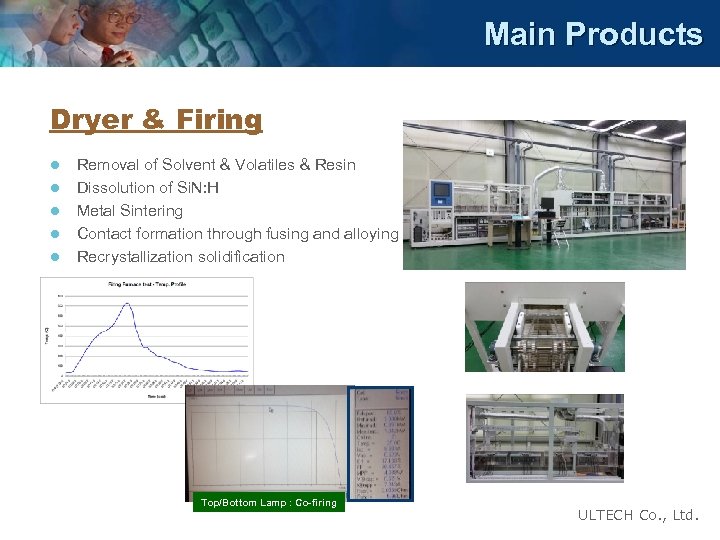

Main Products Dryer & Firing l l l Removal of Solvent & Volatiles & Resin Dissolution of Si. N: H Metal Sintering Contact formation through fusing and alloying Recrystallization solidification Top/Bottom Lamp : Co-firing ULTECH Co. , Ltd.

Main Products Dryer & Firing l l l Removal of Solvent & Volatiles & Resin Dissolution of Si. N: H Metal Sintering Contact formation through fusing and alloying Recrystallization solidification Top/Bottom Lamp : Co-firing ULTECH Co. , Ltd.

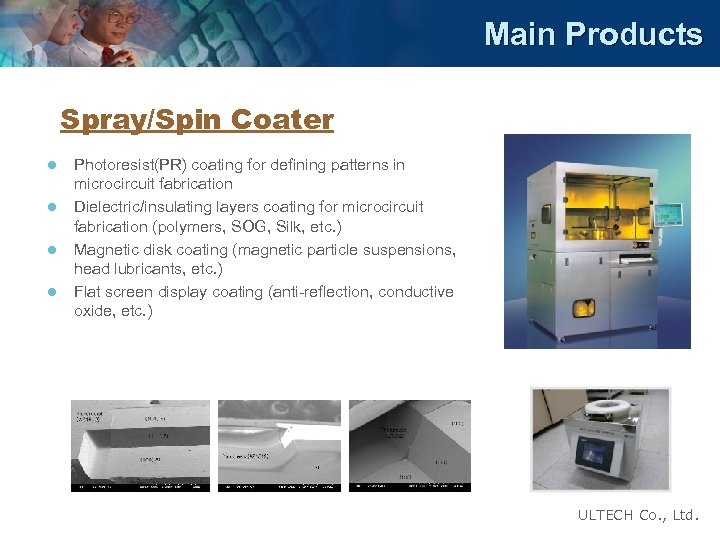

Main Products Spray/Spin Coater l l Photoresist(PR) coating for defining patterns in microcircuit fabrication Dielectric/insulating layers coating for microcircuit fabrication (polymers, SOG, Silk, etc. ) Magnetic disk coating (magnetic particle suspensions, head lubricants, etc. ) Flat screen display coating (anti-reflection, conductive oxide, etc. ) ULTECH Co. , Ltd.

Main Products Spray/Spin Coater l l Photoresist(PR) coating for defining patterns in microcircuit fabrication Dielectric/insulating layers coating for microcircuit fabrication (polymers, SOG, Silk, etc. ) Magnetic disk coating (magnetic particle suspensions, head lubricants, etc. ) Flat screen display coating (anti-reflection, conductive oxide, etc. ) ULTECH Co. , Ltd.

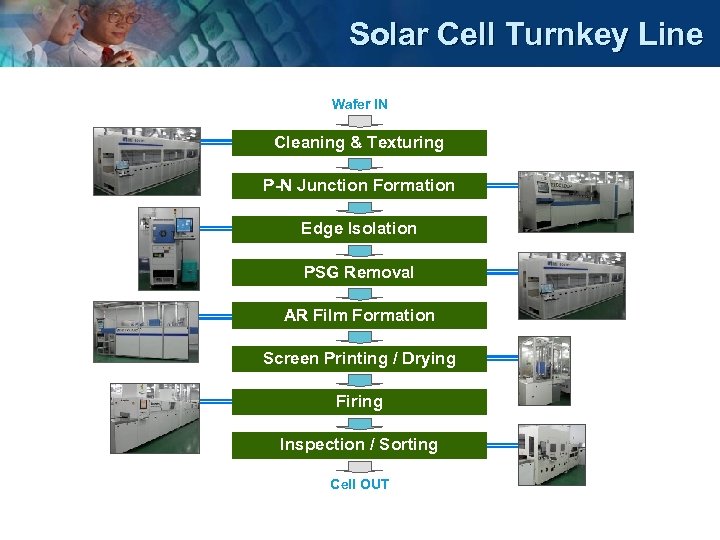

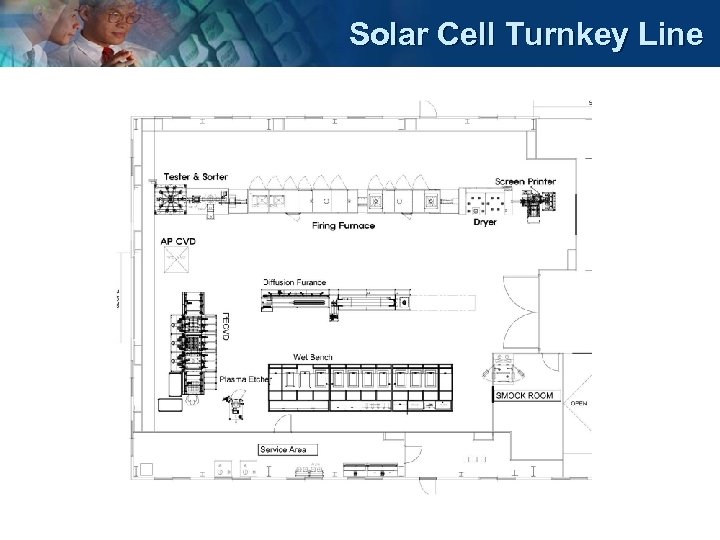

Solar Cell Turnkey Line Wafer IN Cleaning & Texturing P-N Junction Formation Edge Isolation PSG Removal AR Film Formation Screen Printing / Drying Firing Inspection / Sorting Cell OUT

Solar Cell Turnkey Line Wafer IN Cleaning & Texturing P-N Junction Formation Edge Isolation PSG Removal AR Film Formation Screen Printing / Drying Firing Inspection / Sorting Cell OUT

Solar Cell Turnkey Line

Solar Cell Turnkey Line

“S” University Research Lab. l l l 2003년 _ PLD #1 2006년 _ PLD #2 2009년 _ PLD #3 2011년 _ PLD #4 2012년 _ Thermal Evaporator 2013년 _ Sputter

“S” University Research Lab. l l l 2003년 _ PLD #1 2006년 _ PLD #2 2009년 _ PLD #3 2011년 _ PLD #4 2012년 _ Thermal Evaporator 2013년 _ Sputter

“K” University Research Lab. l l l l l 2006년 _ RIE 2007년 _ Furnace 2008년 _ SPUTTER #1 2009년 _ SPUTTER #2 Vertical LPCVD 2010년 _ SPUTTER #3 Furnace & RTA 2011년 _ SPUTTER #4 RTA #1 2012년 _ RTA #2 2013년 _ UV Curing 2014년 _ Box Furnace

“K” University Research Lab. l l l l l 2006년 _ RIE 2007년 _ Furnace 2008년 _ SPUTTER #1 2009년 _ SPUTTER #2 Vertical LPCVD 2010년 _ SPUTTER #3 Furnace & RTA 2011년 _ SPUTTER #4 RTA #1 2012년 _ RTA #2 2013년 _ UV Curing 2014년 _ Box Furnace

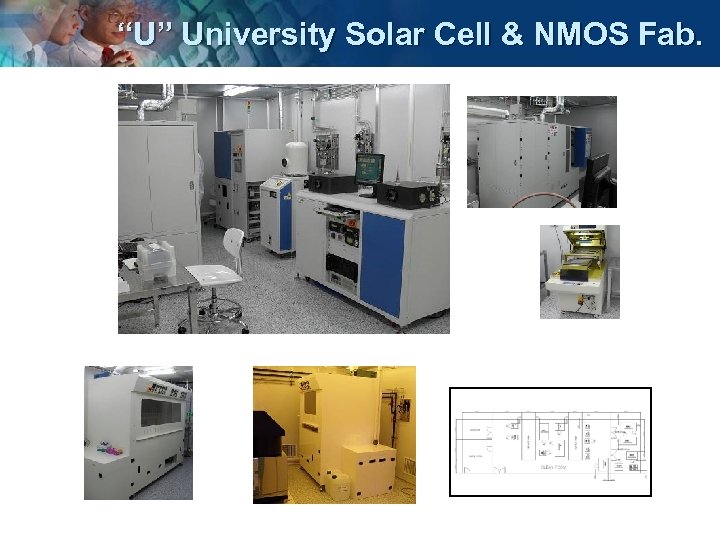

“U” University Solar Cell & NMOS Fab.

“U” University Solar Cell & NMOS Fab.

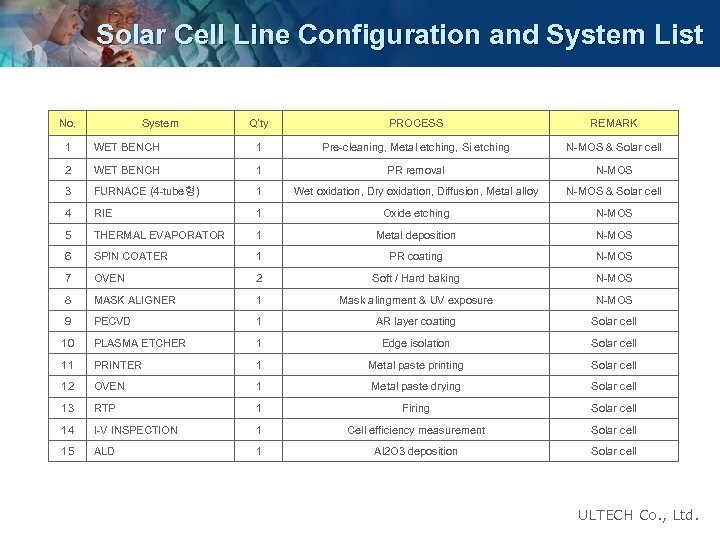

Solar Cell Line Configuration and System List No. System Q’ty PROCESS REMARK 1 WET BENCH 1 Pre-cleaning, Metal etching, Si etching N-MOS & Solar cell 2 WET BENCH 1 PR removal N-MOS 3 FURNACE (4 -tube형) 1 Wet oxidation, Dry oxidation, Diffusion, Metal alloy N-MOS & Solar cell 4 RIE 1 Oxide etching N-MOS 5 THERMAL EVAPORATOR 1 Metal deposition N-MOS 6 SPIN COATER 1 PR coating N-MOS 7 OVEN 2 Soft / Hard baking N-MOS 8 MASK ALIGNER 1 Mask alingment & UV exposure N-MOS 9 PECVD 1 AR layer coating Solar cell 10 PLASMA ETCHER 1 Edge isolation Solar cell 11 PRINTER 1 Metal paste printing Solar cell 12 OVEN 1 Metal paste drying Solar cell 13 RTP 1 Firing Solar cell 14 I-V INSPECTION 1 Cell efficiency measurement Solar cell 15 ALD 1 Al 2 O 3 deposition Solar cell ULTECH Co. , Ltd.

Solar Cell Line Configuration and System List No. System Q’ty PROCESS REMARK 1 WET BENCH 1 Pre-cleaning, Metal etching, Si etching N-MOS & Solar cell 2 WET BENCH 1 PR removal N-MOS 3 FURNACE (4 -tube형) 1 Wet oxidation, Dry oxidation, Diffusion, Metal alloy N-MOS & Solar cell 4 RIE 1 Oxide etching N-MOS 5 THERMAL EVAPORATOR 1 Metal deposition N-MOS 6 SPIN COATER 1 PR coating N-MOS 7 OVEN 2 Soft / Hard baking N-MOS 8 MASK ALIGNER 1 Mask alingment & UV exposure N-MOS 9 PECVD 1 AR layer coating Solar cell 10 PLASMA ETCHER 1 Edge isolation Solar cell 11 PRINTER 1 Metal paste printing Solar cell 12 OVEN 1 Metal paste drying Solar cell 13 RTP 1 Firing Solar cell 14 I-V INSPECTION 1 Cell efficiency measurement Solar cell 15 ALD 1 Al 2 O 3 deposition Solar cell ULTECH Co. , Ltd.

취업과 중소기업 2014. 10. 31. (주) 울텍 대표이사 석창길

취업과 중소기업 2014. 10. 31. (주) 울텍 대표이사 석창길

(주) 울 텍 v v Company name: Business category: v v Foundation date: The president: Employee: Headquarter Office: ULTECH Co. , Ltd. Manufacturing of Semiconductor Equipment, MEMS, Display & Solar Cell Equipment March 15, 1998 Suk, Chang-Gil 25 persons 8 -2, Horim-dong, Dalseo-gu, Daegu, Korea TEL. 82 -53 -583 -7565 http: //www. ultech. co. kr

(주) 울 텍 v v Company name: Business category: v v Foundation date: The president: Employee: Headquarter Office: ULTECH Co. , Ltd. Manufacturing of Semiconductor Equipment, MEMS, Display & Solar Cell Equipment March 15, 1998 Suk, Chang-Gil 25 persons 8 -2, Horim-dong, Dalseo-gu, Daegu, Korea TEL. 82 -53 -583 -7565 http: //www. ultech. co. kr

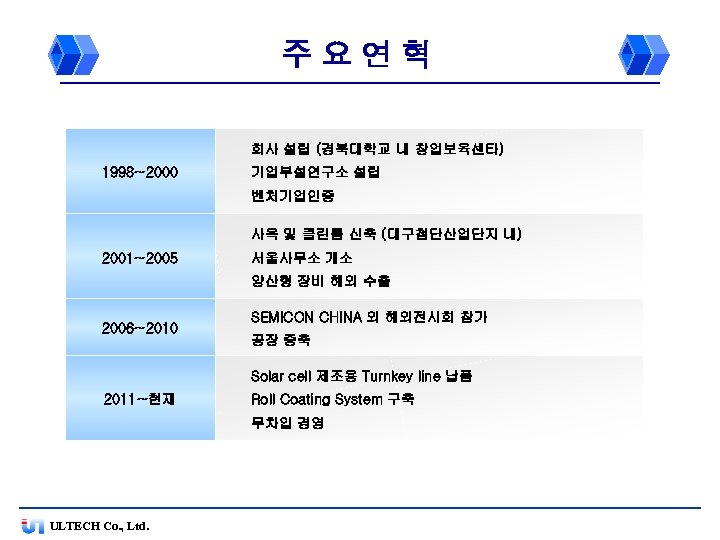

주요연혁 회사 설립 (경북대학교 내 창업보육센타) 1998~2000 기업부설연구소 설립 벤처기업인증 사옥 및 클린룸 신축 (대구첨단산업단지 내) 2001~2005 서울사무소 개소 양산형 장비 해외 수출 2006~2010 SEMICON CHINA 외 해외전시회 참가 공장 증축 Solar cell 제조용 Turnkey line 납품 2011~현재 Roll Coating System 구축 무차입 경영 ULTECH Co. , Ltd.

주요연혁 회사 설립 (경북대학교 내 창업보육센타) 1998~2000 기업부설연구소 설립 벤처기업인증 사옥 및 클린룸 신축 (대구첨단산업단지 내) 2001~2005 서울사무소 개소 양산형 장비 해외 수출 2006~2010 SEMICON CHINA 외 해외전시회 참가 공장 증축 Solar cell 제조용 Turnkey line 납품 2011~현재 Roll Coating System 구축 무차입 경영 ULTECH Co. , Ltd.

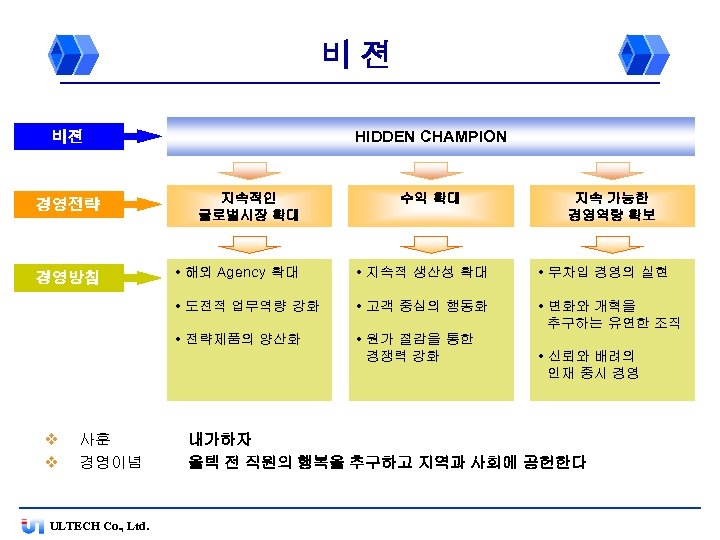

비젼 HIDDEN CHAMPION 비젼 경영전략 지속적인 글로벌시장 확대 경영방침 • 해외 Agency 확대 • 지속적 생산성 확대 • 무차입 경영의 실현 • 도전적 업무역량 강화 • 고객 중심의 행동화 • 변화와 개혁을 추구하는 유연한 조직 • 전략제품의 양산화 • 원가 절감을 통한 경쟁력 강화 v v 사훈 경영이념 ULTECH Co. , Ltd. 수익 확대 지속 가능한 경영역량 확보 • 신뢰와 배려의 인재 중시 경영 내가하자 울텍 전 직원의 행복을 추구하고 지역과 사회에 공헌한다

비젼 HIDDEN CHAMPION 비젼 경영전략 지속적인 글로벌시장 확대 경영방침 • 해외 Agency 확대 • 지속적 생산성 확대 • 무차입 경영의 실현 • 도전적 업무역량 강화 • 고객 중심의 행동화 • 변화와 개혁을 추구하는 유연한 조직 • 전략제품의 양산화 • 원가 절감을 통한 경쟁력 강화 v v 사훈 경영이념 ULTECH Co. , Ltd. 수익 확대 지속 가능한 경영역량 확보 • 신뢰와 배려의 인재 중시 경영 내가하자 울텍 전 직원의 행복을 추구하고 지역과 사회에 공헌한다

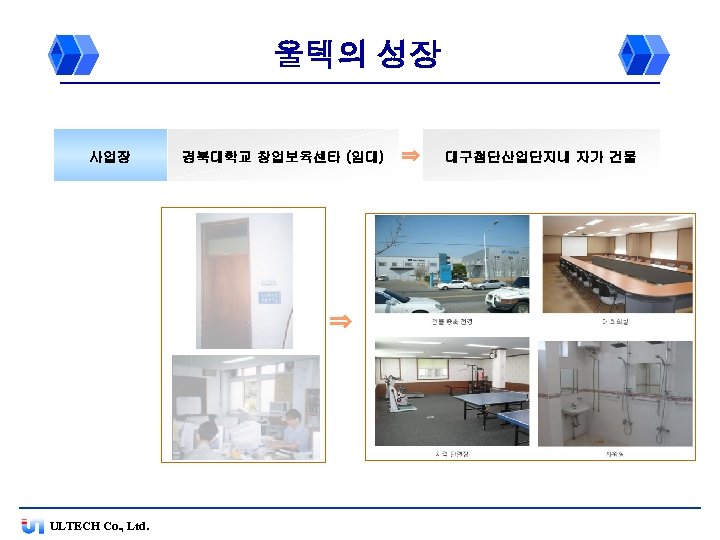

울텍의 성장 사업장 경북대학교 창업보육센타 (임대) ⇒ ULTECH Co. , Ltd. ⇒ 대구첨단산업단지내 자가 건물

울텍의 성장 사업장 경북대학교 창업보육센타 (임대) ⇒ ULTECH Co. , Ltd. ⇒ 대구첨단산업단지내 자가 건물

울텍의 성장 자본 5천만원 ⇒ 58억원 인원 4명 ⇒ 25명 수주단가 8백만원 ⇒ 30억원 Turnkey line 매출액/인당 5천만원 ⇒ 2. 5억원 ULTECH Co. , Ltd.

울텍의 성장 자본 5천만원 ⇒ 58억원 인원 4명 ⇒ 25명 수주단가 8백만원 ⇒ 30억원 Turnkey line 매출액/인당 5천만원 ⇒ 2. 5억원 ULTECH Co. , Ltd.

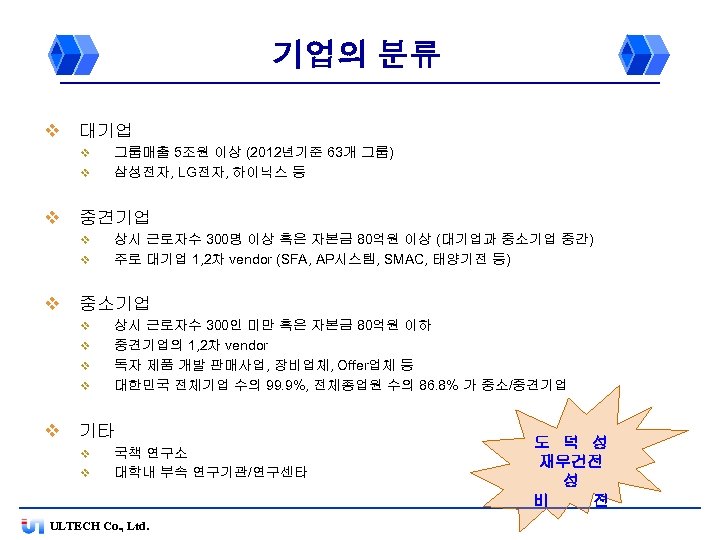

기업의 분류 v 대기업 v v v 중견기업 v v v 상시 근로자수 300명 이상 혹은 자본금 80억원 이상 (대기업과 중소기업 중간) 주로 대기업 1, 2차 vendor (SFA, AP시스템, SMAC, 태양기전 등) 중소기업 v v v 그룹매출 5조원 이상 (2012년기준 63개 그룹) 삼성전자, LG전자, 하이닉스 등 상시 근로자수 300인 미만 혹은 자본금 80억원 이하 중견기업의 1, 2차 vendor 독자 제품 개발 판매사업, 장비업체, Offer업체 등 대한민국 전체기업 수의 99. 9%, 전체종업원 수의 86. 8% 가 중소/중견기업 기타 v v 국책 연구소 대학내 부속 연구기관/연구센타 ULTECH Co. , Ltd. 도 덕 성 재무건전 성 비 젼

기업의 분류 v 대기업 v v v 중견기업 v v v 상시 근로자수 300명 이상 혹은 자본금 80억원 이상 (대기업과 중소기업 중간) 주로 대기업 1, 2차 vendor (SFA, AP시스템, SMAC, 태양기전 등) 중소기업 v v v 그룹매출 5조원 이상 (2012년기준 63개 그룹) 삼성전자, LG전자, 하이닉스 등 상시 근로자수 300인 미만 혹은 자본금 80억원 이하 중견기업의 1, 2차 vendor 독자 제품 개발 판매사업, 장비업체, Offer업체 등 대한민국 전체기업 수의 99. 9%, 전체종업원 수의 86. 8% 가 중소/중견기업 기타 v v 국책 연구소 대학내 부속 연구기관/연구센타 ULTECH Co. , Ltd. 도 덕 성 재무건전 성 비 젼

중소기업의 특성 v v v 유연성 위험성 행동의 자유도 기술 습득 용이 전사적 인화단결 ULTECH Co. , Ltd.

중소기업의 특성 v v v 유연성 위험성 행동의 자유도 기술 습득 용이 전사적 인화단결 ULTECH Co. , Ltd.

JOB INTERVIEW 요령 v v v 신입답게 질문의 핵심파악과 간결한 답변 있는 그대로 용모단정 침착성 조직친화 지식 인재상 실천 ULTECH Co. , Ltd. 책임

JOB INTERVIEW 요령 v v v 신입답게 질문의 핵심파악과 간결한 답변 있는 그대로 용모단정 침착성 조직친화 지식 인재상 실천 ULTECH Co. , Ltd. 책임

직장생활 요령 v 적극성 ULTECH Co. , Ltd.

직장생활 요령 v 적극성 ULTECH Co. , Ltd.

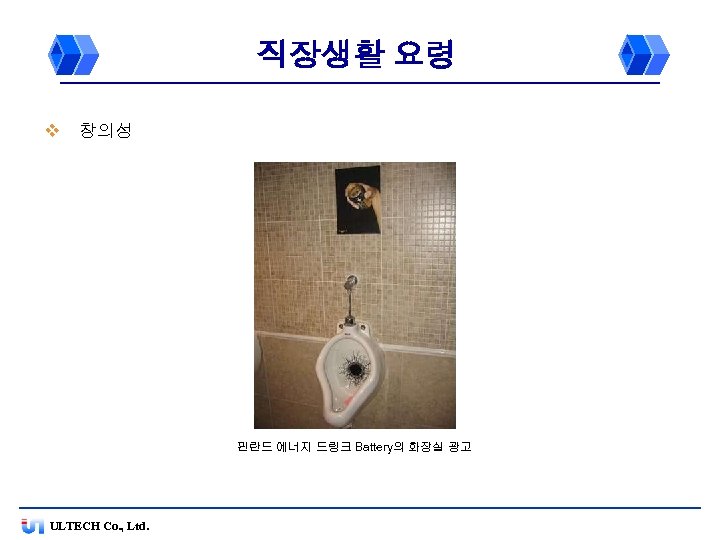

직장생활 요령 v 창의성 핀란드 에너지 드링크 Battery의 화장실 광고 ULTECH Co. , Ltd.

직장생활 요령 v 창의성 핀란드 에너지 드링크 Battery의 화장실 광고 ULTECH Co. , Ltd.

직장생활 요령 v 인내심 ULTECH Co. , Ltd.

직장생활 요령 v 인내심 ULTECH Co. , Ltd.

직장에서의 성공과 행복 v 모방 ULTECH Co. , Ltd.

직장에서의 성공과 행복 v 모방 ULTECH Co. , Ltd.

직장에서의 성공과 행복 v 목표의 동일 자신을 위해 열심히 일을 하는 게 궁극적으로 회사에 기여 ULTECH Co. , Ltd.

직장에서의 성공과 행복 v 목표의 동일 자신을 위해 열심히 일을 하는 게 궁극적으로 회사에 기여 ULTECH Co. , Ltd.

직장에서의 성공과 행복 v 안에서 새는 바가지 밖에서도 샌다 여기서 성공한 사람이 다른 곳에서도 성공한다 성공의 법칙--- 성공하고 싶은 사람은 지금 이 자리에서 우선 성공 을 해야 한다 ULTECH Co. , Ltd.

직장에서의 성공과 행복 v 안에서 새는 바가지 밖에서도 샌다 여기서 성공한 사람이 다른 곳에서도 성공한다 성공의 법칙--- 성공하고 싶은 사람은 지금 이 자리에서 우선 성공 을 해야 한다 ULTECH Co. , Ltd.

직장에서의 성공과 행복 v 갑질 기술이 갑이다 ULTECH Co. , Ltd.

직장에서의 성공과 행복 v 갑질 기술이 갑이다 ULTECH Co. , Ltd.