3ea718edaeba39e273af8f1341e4959a.ppt

- Количество слайдов: 31

UCIT Lean Six Sigma Initiative Presented by Dave Deleske

Agenda • • Discuss Objectives LSS Overview ITIL and LSS DMAIC Tool Set Review Project Selection Criteria Review Define Phase and Tools Problem Statements and Business Case Review Benefits and Concerns'

Objectives • Start on time and stay on schedule • Encourage support of LSS through understanding and open communication • Provide a foundation and tool set for measureable Improvements of Service for the University

Lean Six Sigma … yet another “flavor of the day” ? ? Who has work that needs to get done? Who has a process that needs improvement? Who Doesn’t !!! How are we doing? How do we know? Are we making a difference? In a Positive or a Negative Way?

Lean Six Sigma How does it Relate to Service Delivery? Incident Management Project Management Change Management Application Development Config Management Server Deployment Any Process

Lean Six Sigma Improvement to Processes (ITIL Included) Incident Management Problem Management Change Management Release Management Config Management Processes – Work Flow Variation and Time

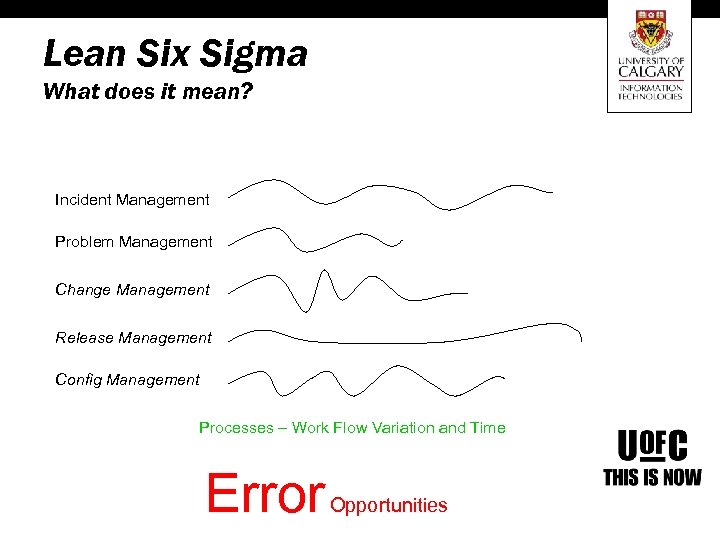

Lean Six Sigma What does it mean? Incident Management Problem Management Change Management Release Management Config Management Processes – Work Flow Variation and Time Error Opportunities

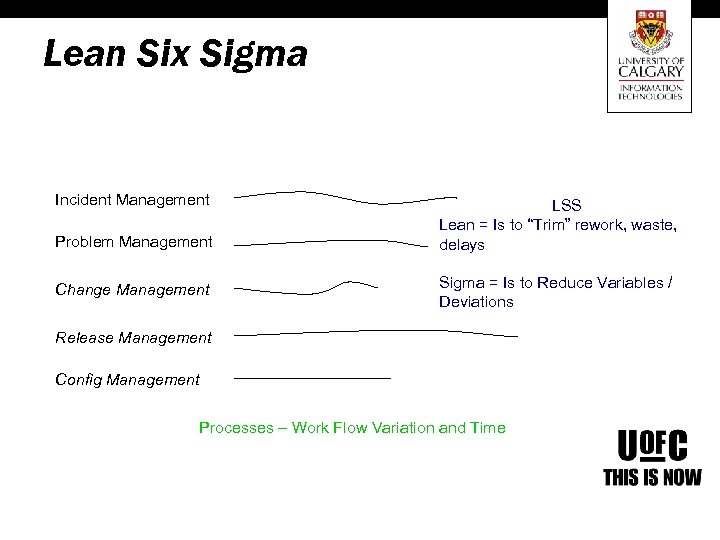

Lean Six Sigma Incident Management Problem Management Change Management LSS Lean = Is to “Trim” rework, waste, delays Sigma = Is to Reduce Variables / Deviations Release Management Config Management Processes – Work Flow Variation and Time

Lean Six Sigma ITSM is a framework for helping IT organizations become more adaptive, flexible, cost-effective, and service oriented How it manages its processes, technology assets, vendors and deploys personnel, to how IT staff view their organizational roles. One of the primary goals of ITSM is to successfully align the delivery of IT services with needs of the business. Six Sigma = seeks to identify and remove the causes of defects and errors in manufacturing and business processes. Metrics Project management is the discipline of planning, organizing and managing resources to bring about the successful completion of specific project goals and objectives. Business analysis is the set of tasks, knowledge, and techniques required to identify business needs and determine solutions to business problems.

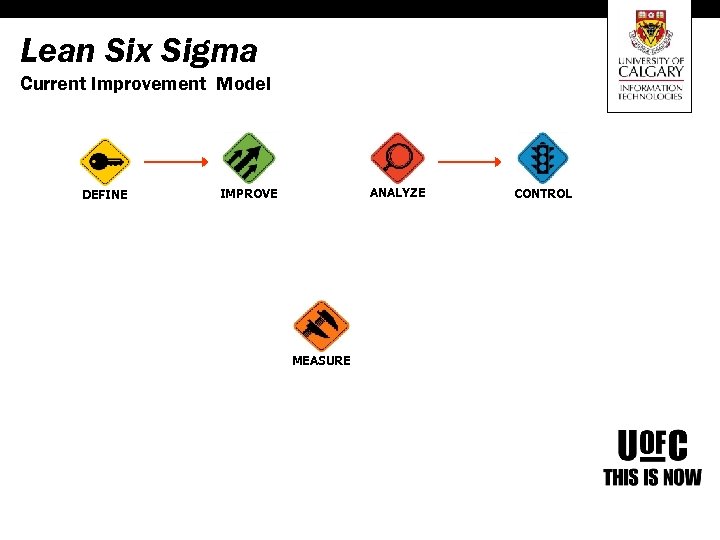

Lean Six Sigma Current Improvement Model DEFINE ANALYZE IMPROVE MEASURE CONTROL

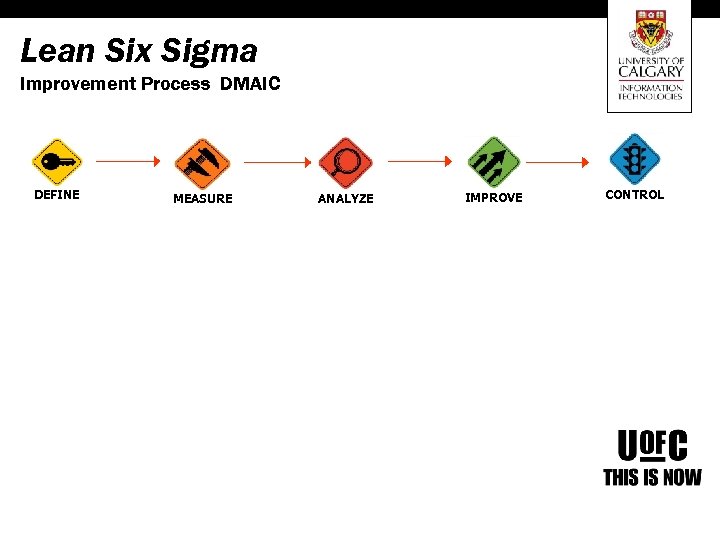

Lean Six Sigma Improvement Process DMAIC DEFINE MEASURE ANALYZE IMPROVE CONTROL

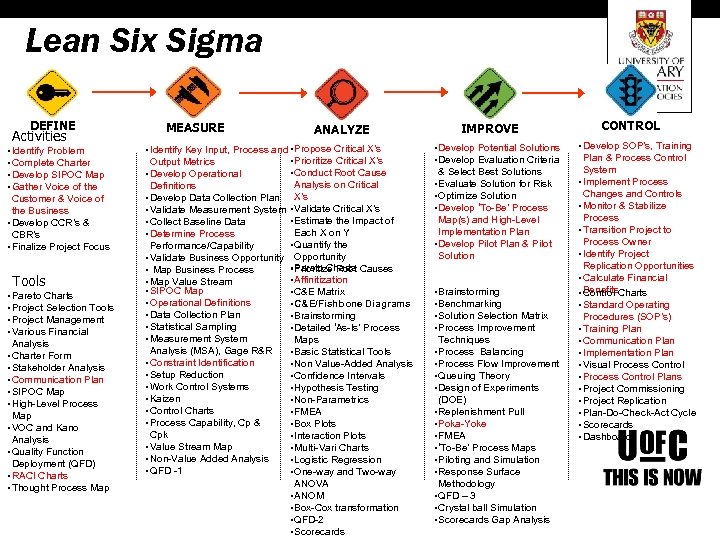

Lean Six Sigma DEFINE Activities • Identify Problem • Complete Charter • Develop SIPOC Map • Gather Voice of the Customer & Voice of the Business • Develop CCR’s & CBR’s • Finalize Project Focus Tools • Pareto Charts • Project Selection Tools • Project Management • Various Financial Analysis • Charter Form • Stakeholder Analysis • Communication Plan • SIPOC Map • High-Level Process Map • VOC and Kano Analysis • Quality Function Deployment (QFD) • RACI Charts • Thought Process Map MEASURE ANALYZE • Identify Key Input, Process and • Propose Critical X’s • Prioritize Critical X’s Output Metrics • Conduct Root Cause • Develop Operational Analysis on Critical X’s • Validate Critical X’s • Estimate the Impact of Each X on Y • Quantify the Performance/Capability • Validate Business Opportunity • Pareto Charts Prioritize Root Causes • Map Business Process • Affinitization • Map Value Stream • SIPOC Map • C&E Matrix • Operational Definitions • C&E/Fishbone Diagrams • Data Collection Plan • Brainstorming • Statistical Sampling • Detailed ‘As-Is’ Process • Measurement System Maps Analysis (MSA), Gage R&R • Basic Statistical Tools • Constraint Identification • Non Value-Added Analysis • Setup Reduction • Confidence Intervals • Work Control Systems • Hypothesis Testing • Kaizen • Non-Parametrics • Control Charts • FMEA • Process Capability, Cp & • Box Plots Cpk • Interaction Plots • Value Stream Map • Multi-Vari Charts • Non-Value Added Analysis • Logistic Regression • QFD -1 • One-way and Two-way ANOVA • ANOM • Box-Cox transformation • QFD-2 • Scorecards Definitions • Develop Data Collection Plan • Validate Measurement System • Collect Baseline Data • Determine Process IMPROVE • Develop Potential Solutions • Develop Evaluation Criteria & Select Best Solutions • Evaluate Solution for Risk • Optimize Solution • Develop ‘To-Be’ Process Map(s) and High-Level Implementation Plan • Develop Pilot Plan & Pilot Solution • Brainstorming • Benchmarking • Solution Selection Matrix • Process Improvement Techniques • Process Balancing • Process Flow Improvement • Queuing Theory • Design of Experiments (DOE) • Replenishment Pull • Poka-Yoke • FMEA • ‘To-Be’ Process Maps • Piloting and Simulation • Response Surface Methodology • QFD – 3 • Crystal ball Simulation • Scorecards Gap Analysis CONTROL • Develop SOP’s, Training Plan & Process Control System • Implement Process Changes and Controls • Monitor & Stabilize Process • Transition Project to Process Owner • Identify Project Replication Opportunities • Calculate Financial • Benefits Control Charts • Standard Operating Procedures (SOP’s) • Training Plan • Communication Plan • Implementation Plan • Visual Process Control • Process Control Plans • Project Commissioning • Project Replication • Plan-Do-Check-Act Cycle • Scorecards • Dashboard

Project Selection Some things to watch for when assessing a project’s suitability for DMAIC: • Is data available or easy to obtain? • Does leadership support exist for improving this process? • Is DMAIC really needed or is this a “just do it”: a problem with a known solution that should just be implemented? • Is the team trying to boil the ocean or is the scope reasonable for chartering as a DMAIC project? • Is the process directly related to a key outcome such as profitability, customer satisfaction, or employee satisfaction?

Yellow Belt Project Criteria • • Uses DMAIC Addresses each phase Includes some of the tools Involves 1 -3 people In an area you control or influence Can be done within a month Provides a measurable benefit

Define Objectives Six Sigma calls for unmistakable, measurable results, the goal of the Define phase is to clearly identify and articulate the problem in a clear and measurable way. The basic steps to the Define phase of DMAIC are… • • • Identify or refine the problems in your process that must be solved in order to meet or exceed the customer's specifications or expectations. Identify and quantify customer requirements. Identify and quantify the process output and defects that fall short of these requirements and create a problem statement.

Define Objectives cont. • • • State the project goal, which also must be a clear and measurable goal, and include a time limit for the project's completion. Determine the few vital factors that are Critical to Quality, which need to be measured, analyzed, improved and controlled. And finally, create a project charter, which will contain the problem definition, goal, business case, project scope, team members, and high level project plan for the M, A, I and C phases.

Define – Tools The tools most commonly used in the Define phase are: - Voice of the Customer - Critical-To-Quality (CTQ) tree - Affinity Diagram - Process map - Project Charter - Suppliers, Inputs, Process, Output, and Customers (SIPOC) - Kano Model - Stakeholder analysis

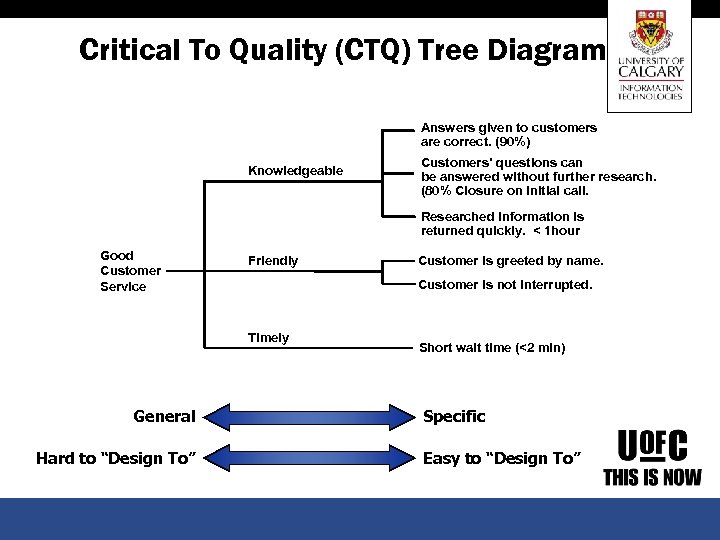

CTQ • CTQs (critical to quality characteristics) that have the most impact on quality - separating the “vital few” from the “trivial many”- and creates a map of the process to be improved. .

Critical To Quality (CTQ) Tree Diagram Answers given to customers are correct. (90%) Knowledgeable Customers’ questions can be answered without further research. (80% Closure on Initial call. Researched information is returned quickly. < 1 hour Good Customer Service Friendly Customer is not interrupted. Timely General Hard to “Design To” Customer is greeted by name. Short wait time (<2 min) Specific Easy to “Design To”

Process Mapping • Business Process Mapping Completed, verified, and validated high -level 'as is' (not 'should be' or 'could be') business process map. Completed SIPOC representation, describing the Suppliers, Inputs, Process, Outputs, and Customers.

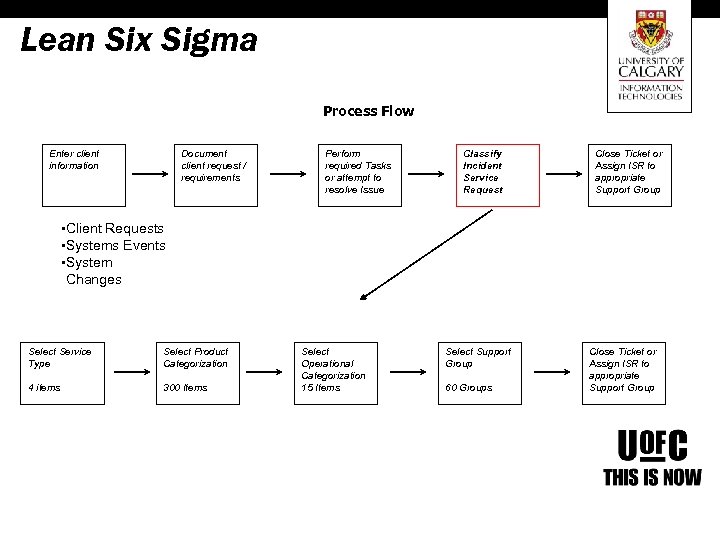

Lean Six Sigma Process Flow Enter client information Document client request / requirements Perform required Tasks or attempt to resolve Issue Classify Incident Service Request Close Ticket or Assign ISR to appropriate Support Group • Client Requests • Systems Events • System Changes Select Service Type Select Product Categorization 4 items 300 Items Select Operational Categorization 15 Items Select Support Group 60 Groups Close Ticket or Assign ISR to appropriate Support Group

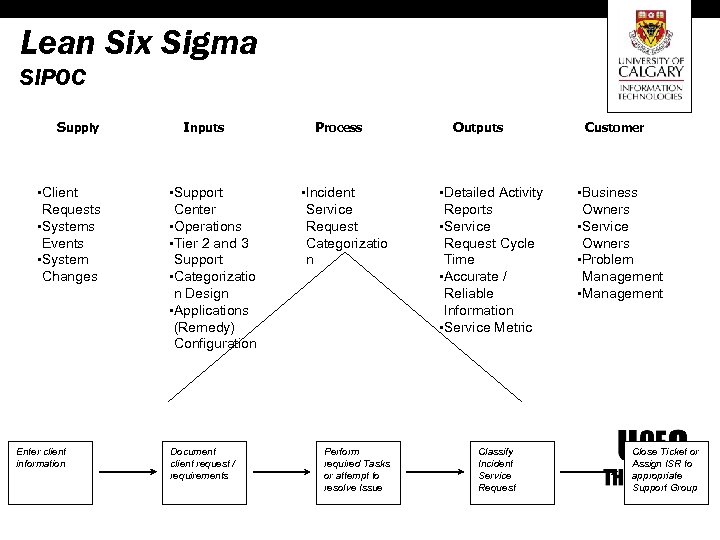

Lean Six Sigma SIPOC Supply Inputs • Client • Support Requests • Systems Events • System Changes Center • Operations • Tier 2 and 3 Support • Categorizatio n Design • Applications (Remedy) Configuration Enter client information Document client request / requirements Process • Incident Service Request Categorizatio n Perform required Tasks or attempt to resolve Issue Outputs Customer • Detailed Activity • Business Reports • Service Request Cycle Time • Accurate / Reliable Information • Service Metric Owners • Service Owners • Problem Management • Management Classify Incident Service Request Close Ticket or Assign ISR to appropriate Support Group

Relating the Problem What is your Problem ? ? Is it really …. Why is that important How is it related to Business Objectives? What factors contribute to those Objectives? Y=f(x) From Y determine CTQ’s x = ? Problem (Which one ? ? ) Can it Measureable?

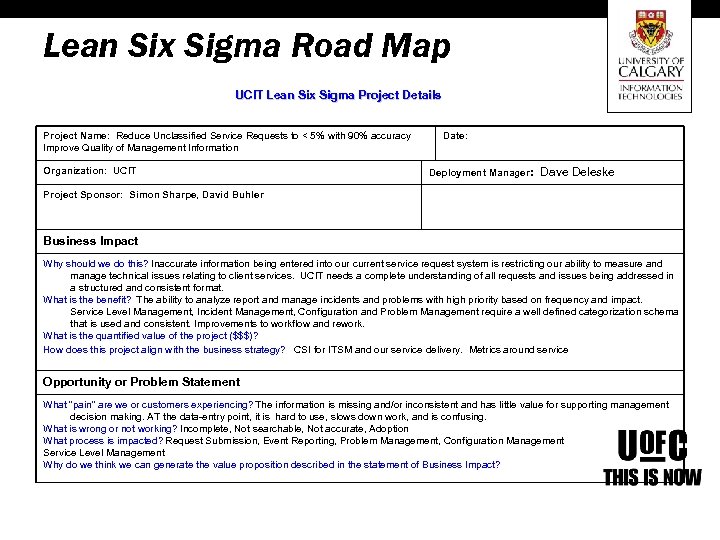

Lean Six Sigma Road Map UCIT Lean Six Sigma Project Details Project Name: Reduce Unclassified Service Requests to < 5% with 90% accuracy Improve Quality of Management Information Organization: UCIT Date: Deployment Manager: Dave Deleske Project Sponsor: Simon Sharpe, David Buhler Business Impact Why should we do this? Inaccurate information being entered into our current service request system is restricting our ability to measure and manage technical issues relating to client services. UCIT needs a complete understanding of all requests and issues being addressed in a structured and consistent format. What is the benefit? The ability to analyze report and manage incidents and problems with high priority based on frequency and impact. Service Level Management, Incident Management, Configuration and Problem Management require a well defined categorization schema that is used and consistent. Improvements to workflow and rework. What is the quantified value of the project ($$$)? How does this project align with the business strategy? CSI for ITSM and our service delivery. Metrics around service Opportunity or Problem Statement What "pain" are we or customers experiencing? The information is missing and/or inconsistent and has little value for supporting management decision making. AT the data-entry point, it is hard to use, slows down work, and is confusing. What is wrong or not working? Incomplete, Not searchable, Not accurate, Adoption What process is impacted? Request Submission, Event Reporting, Problem Management, Configuration Management Service Level Management Why do we think we can generate the value proposition described in the statement of Business Impact?

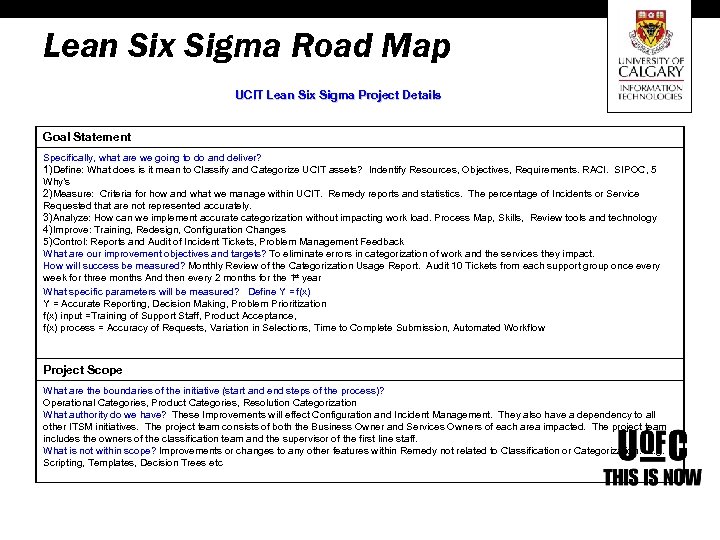

Lean Six Sigma Road Map UCIT Lean Six Sigma Project Details Goal Statement Specifically, what are we going to do and deliver? 1)Define: What does is it mean to Classify and Categorize UCIT assets? Indentify Resources, Objectives, Requirements. RACI. SIPOC, 5 Why’s 2)Measure: Criteria for how and what we manage within UCIT. Remedy reports and statistics. The percentage of Incidents or Service Requested that are not represented accurately. 3)Analyze: How can we implement accurate categorization without impacting work load. Process Map, Skills, Review tools and technology 4)Improve: Training, Redesign, Configuration Changes 5)Control: Reports and Audit of Incident Tickets, Problem Management Feedback What are our improvement objectives and targets? To eliminate errors in categorization of work and the services they impact. How will success be measured? Monthly Review of the Categorization Usage Report. Audit 10 Tickets from each support group once every week for three months And then every 2 months for the 1 st year What specific parameters will be measured? Define Y = f(x) Y = Accurate Reporting, Decision Making, Problem Prioritization f(x) input =Training of Support Staff, Product Acceptance, f(x) process = Accuracy of Requests, Variation in Selections, Time to Complete Submission, Automated Workflow Project Scope What are the boundaries of the initiative (start and end steps of the process)? Operational Categories, Product Categories, Resolution Categorization What authority do we have? These Improvements will effect Configuration and Incident Management. They also have a dependency to all other ITSM initiatives. The project team consists of both the Business Owner and Services Owners of each area impacted. The project team includes the owners of the classification team and the supervisor of the first line staff. What is not within scope? Improvements or changes to any other features within Remedy not related to Classification or Categorization. E. g. Scripting, Templates, Decision Trees etc

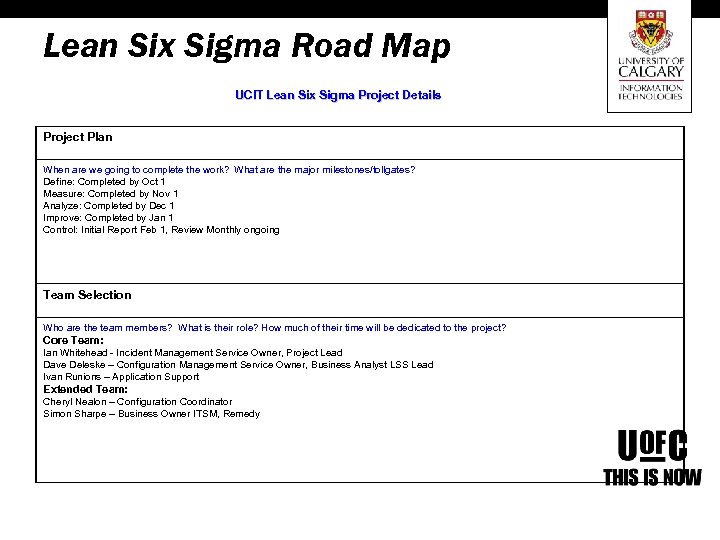

Lean Six Sigma Road Map UCIT Lean Six Sigma Project Details Project Plan When are we going to complete the work? What are the major milestones/tollgates? Define: Completed by Oct 1 Measure: Completed by Nov 1 Analyze: Completed by Dec 1 Improve: Completed by Jan 1 Control: Initial Report Feb 1, Review Monthly ongoing Team Selection Who are the team members? What is their role? How much of their time will be dedicated to the project? Core Team: Ian Whitehead - Incident Management Service Owner, Project Lead Dave Deleske – Configuration Management Service Owner, Business Analyst LSS Lead Ivan Runions – Application Support Extended Team: Cheryl Nealon – Configuration Coordinator Simon Sharpe – Business Owner ITSM, Remedy

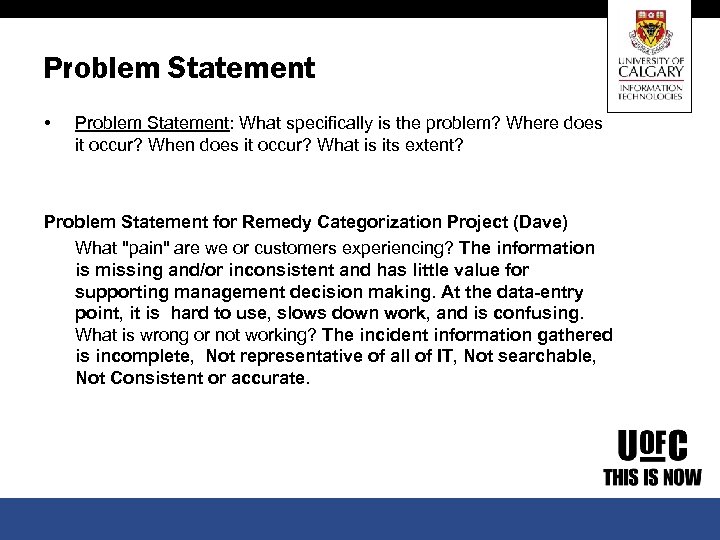

Problem Statement • Problem Statement: What specifically is the problem? Where does it occur? When does it occur? What is its extent? Problem Statement for Remedy Categorization Project (Dave) What "pain" are we or customers experiencing? The information is missing and/or inconsistent and has little value for supporting management decision making. At the data-entry point, it is hard to use, slows down work, and is confusing. What is wrong or not working? The incident information gathered is incomplete, Not representative of all of IT, Not searchable, Not Consistent or accurate.

Business Case What are the compelling business reasons for embarking on this project? Is the project linked to key business goals and objectives? What key business process output measure(s) will the project leverage and how? What are the rough order estimates on cost savings/opportunities on this project?

Goal Statement What is the goal or target for the improvement team's project? Do the problem and goal statements meet the SMART criteria (specific, measurable, attainable, relevant, and time-bound)? Has anyone else (internal or external to the organization) attempted to solve this problem or a similar one before? If so, what knowledge can be leveraged from these previous efforts? How will the project team and the organization measure complete success for this project?

Lean Six Sigma How are we doing ? ? Taking us from I think, to I can show you !!

Review Benefits and Concerns Benefits Concerns

3ea718edaeba39e273af8f1341e4959a.ppt