b9e553adaf5c5067d7fa731548e2adc1.ppt

- Количество слайдов: 20

Tyler Crawford Shannon Daily Fabrication of an electrospun nanofibrous scaffold for use in the field of tissue engineering

Purpose: To create a polycaprolactone mesh which enables cell activity and seeks to eventually provide an application in the field of tissue engineering toward biomimetic skin graft.

The Extracellular Matrix (ECM) ECM - main structural tissue of skin › Helps skin renew and generate › Provides signals to intercellular pathways Engineered ECMs are known as scaffolds

Electrospinning Ability to create scaffolds › Mimic the ECM (size and porosity) › High surface to volume ratio Easy to vary mechanical and biological properties through changing materials Flexible- allows cells to manipulate their environment

Polycaprolactone (PCL) Biocompatible polymer Biodegradable at a rate that allows increased cell growth and stability Easy to manipulate Relatively low melting point - easy to use

Polycaprolactone Clinically safe (FDA approval) Proven to have potential for scaffolds in relation to tissue regeneration › Has created scaffolds w/ ideal conditions High porosities Large amounts of surface areas

Additional Biochemical Material Adding another biochemical can: › Increase stress resistance › Provide better adhesion of cells to the final scaffold › Increase the potential for cell proliferation Biochemical should › Be a component of skin naturally › Must be able to be combined in a solution to be electrospun

Chitosan (CHT) Natural polymer that exhibits biocompatible and biodegradable qualities Cellular binding capabilities Anti-bacterial properties High viscosity which limits electrospinning

Experimental Design Procedure: Create control meshes of pure PCL › Solution= PCL and acetic acid (solvent) › Electrospin Starting parameters: 15 wt. % concentration, 20 cm from tip of syringe to collector plate, & 20 k. V

Procedure continued: Vary voltage to create 9 meshes › 3 Voltages- 3 trials for each 20 k. V 15 k. V 25 k. V Examine mesh using Scanning Electron Microscope (SEM) Culture fibroblast cells onto mesh

Procedure continued: Observing cells › Inverted light microscope Analyze cell growth › Cell counts in cells per unit area (mm 2) › Means and standard deviations › ANOVA (Analysis of Variance) tests

Procedure continued: Create solutions of PCL and chitosan Electrospin Vary concentration of chitosan to PCL ›. 5% CHT › 1% CHT › 2% CHT Total of 9 meshes (3 trials of each concentration)

Procedure continued: Analyze with SEM Culture fibroblast cells and seed into meshes created Determine cell density Analyze with means, standard deviations, and ANOVA tests

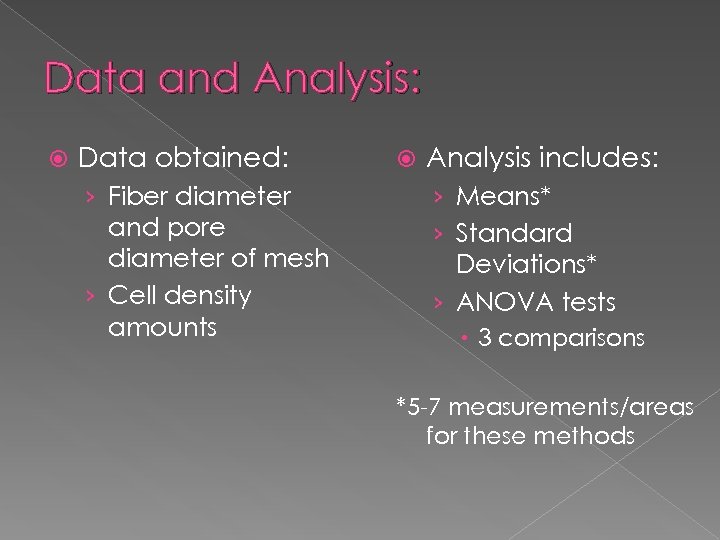

Data and Analysis: Data obtained: › Fiber diameter and pore diameter of mesh › Cell density amounts Analysis includes: › Means* › Standard Deviations* › ANOVA tests 3 comparisons *5 -7 measurements/areas for these methods

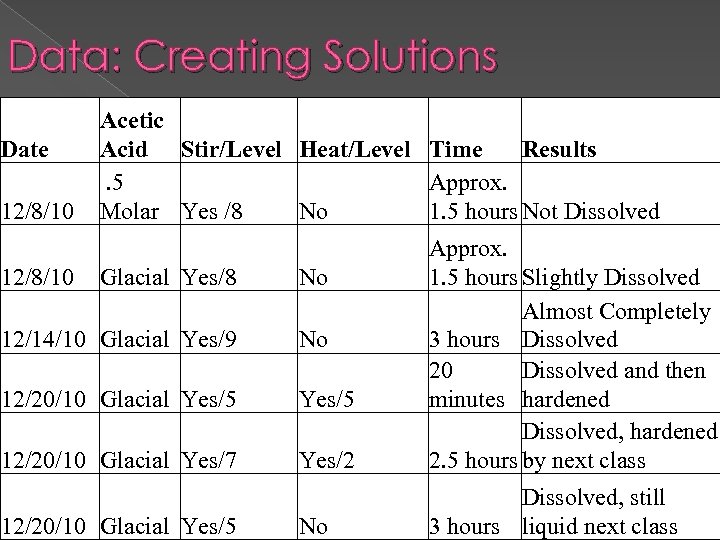

Data: Creating Solutions Date 12/8/10 Acetic Acid Stir/Level Heat/Level Time Results. 5 Approx. Molar Yes /8 No 1. 5 hours Not Dissolved Glacial Yes/8 No 12/14/10 Glacial Yes/9 No 12/20/10 Glacial Yes/5 12/20/10 Glacial Yes/7 Yes/2 Approx. 1. 5 hours Slightly Dissolved Almost Completely 3 hours Dissolved 20 Dissolved and then minutes hardened Dissolved, hardened 2. 5 hours by next class No Dissolved, still 3 hours liquid next class 12/8/10 12/20/10 Glacial Yes/5

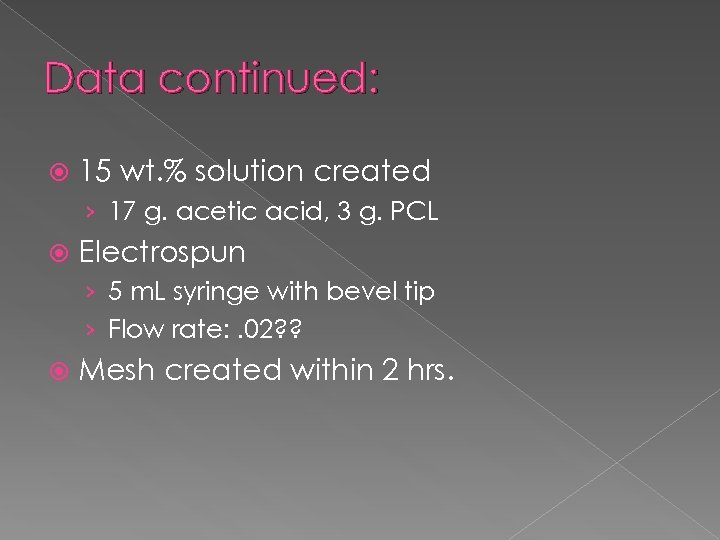

Data continued: 15 wt. % solution created › 17 g. acetic acid, 3 g. PCL Electrospun › 5 m. L syringe with bevel tip › Flow rate: . 02? ? Mesh created within 2 hrs.

Data continued:

Progress Background Research Experimental Design ISEF (International Science and Engineering Fair) Forms Started solutions Just began spinning

References Akhyari, P. , Kamiya, H. , Haverich, A. , Karck, M. , & Lichtenberg, A. (2008). Myocardial tissue engineering: The extracellular matrix. European Journal of Cardio-Thoracic Surgery, 34, 229 -241. doi: 10. 1016/j. ejcts. 2008. 03. 062 Bhardwaj, N. & Kundu, S. C. (2010). Electrospinning: A fascinating fiber fabrication technique. Biotechnology Advances, 28, 325 -347. doi: 10. 1016/j. biotechadv. 2010. 01. 004 Chong, E. J. , Phan, T. T. , Lim, I. J. , Zhang, Y. Z. , Bay, B. H. , Ramakrishna, S. , & Lim, C. T. (2007). Evaluation of electrospun PCL/gelatin nanofibrous scaffold for wound healing and layered dermal reconstitution. Acta Biomaterialia, 3, 321 -330. doi: 10. 1016/j. actbio. 2007. 01. 002 Geng, X. , Kwon, O-H. , & Jang, J. (2005). Electrospinning of chitosan dissolved in concentrated acetic acid solution. Biomaterials, 26, 5427 -5432. Han, J. , Branford-White, C. J. , & Zhu, L. M. (2010). Preparation of poly(є-caprolactone)/poly(trimethylene carbonate) blend nanofibers by electrospinning. Carbohydrate Polymers, 79, 214 -218. doi: 10. 1016/j. carbpol. 2009. 07. 052 Homayoni, H. , Ravandi, S. A. H. , & Valizadeh, M. (2009). Electrospinning of chitosan nanofibers: Processing optimization. Carbohydrate Polymers, 77, 656 -661. Lowery, J. L. , Datta, N. , & Rutledge, G. C. (2010). Effect of fiber diameter, pore size and seeding method on growth of human dermal fibroblasts in electrospun poly(є-caprolactone) fibrous mats. Biomaterials, 31, 491 -504. doi: 10. 1016/j. biomaterials. 2009. 072 Nisbet, D. R. , Forsythe, J. S. , Shen, W. , Finkelstein, D. I. , & Horne, M. K. (2009). A review of the cellular response on electrospun nanofibers for tissue engineering. Journal of Biomaterials Application, 24, 7 -29. Pham, Q. P. , Sharama, V. , & Mikos, A. G. (2006). Electrospinning of polymeric nanofibers for tissue engineering applications: A review. Tissue Engineering, 12, 1197 -1211. Shevchenko, R. V. , James, S. L. , & James, S. E. (2010). A review of tissue-engineered skin bioconstructs available for skin reconstruction. Journal of the Royal Society Interface, 7, 229 -258. doi: 10. 1098/rsif. 2009. 0403 Sill, T. J. , & von Recum, H. A. (2008). Electrospinning: Applications in drug delivery and tissue engineering. Biomaterials, 29, 1989 -2006. doi: 10. 1016/j. biomaterials. 2008. 011 Woodruff, M. A. , & Hutmacher, D. W. (in press). The return of a forgotten polymer- Polycaprolactone in the 21 st century. Progress in Polymer Science. doi: 10. 1016/j. progpolymsci. 2010. 04. 002

THE END ANY QUESTIONS?

b9e553adaf5c5067d7fa731548e2adc1.ppt