a85e7a72be06e752dbfe78c45d6e4b6a.ppt

- Количество слайдов: 33

Tutorial 6 Derek Wright Wednesday, March 2 nd, 2005

Tutorial 6 Derek Wright Wednesday, March 2 nd, 2005

Sensors and Image Systems • • Liquid Crystal Displays Organic Light Emitting Diode Field Emission and Plasma Displays Electronic Paper

Sensors and Image Systems • • Liquid Crystal Displays Organic Light Emitting Diode Field Emission and Plasma Displays Electronic Paper

Display Types • Light Generating – Each pixel generates photons based on image data • Light Controlling – Each pixel controls whether or not light passes through based on image data

Display Types • Light Generating – Each pixel generates photons based on image data • Light Controlling – Each pixel controls whether or not light passes through based on image data

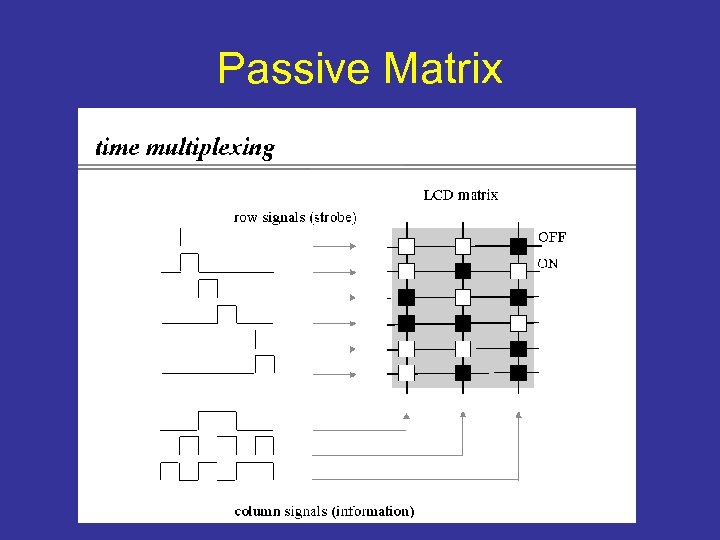

Passive Matrix • Rows (or columns) can only be driven one at a time • Rows are driven sequentially • Columns determine which pixels are on and which are off (based on image data) • Each row is only being driven for (1/rows) • Each pixel mush be driven extra bright to fool the human eye into thinking it’s always on

Passive Matrix • Rows (or columns) can only be driven one at a time • Rows are driven sequentially • Columns determine which pixels are on and which are off (based on image data) • Each row is only being driven for (1/rows) • Each pixel mush be driven extra bright to fool the human eye into thinking it’s always on

Passive Matrix

Passive Matrix

Active Matrix • Each pixel has it’s own circuit that loads and stores that pixel’s data • This allows the pixel to remain on while data is loading in other rows • Enables bigger higher-resolution displays • Pixels do not have to be driven too hard as in passive matrix

Active Matrix • Each pixel has it’s own circuit that loads and stores that pixel’s data • This allows the pixel to remain on while data is loading in other rows • Enables bigger higher-resolution displays • Pixels do not have to be driven too hard as in passive matrix

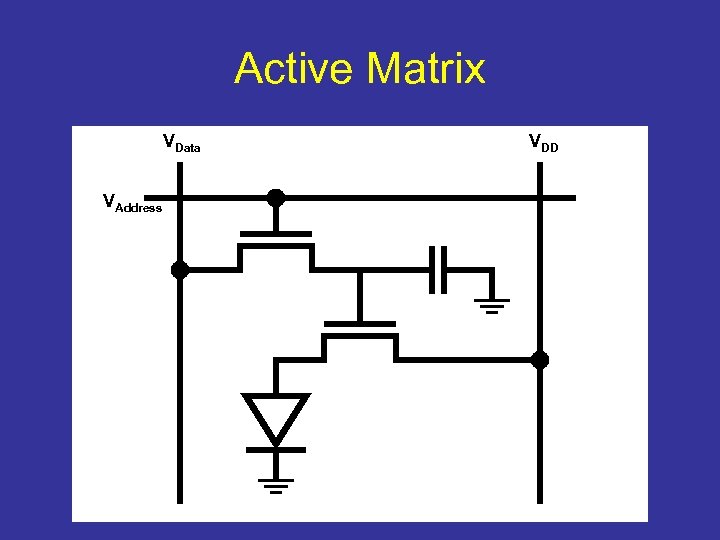

Active Matrix VData VAddress VDD

Active Matrix VData VAddress VDD

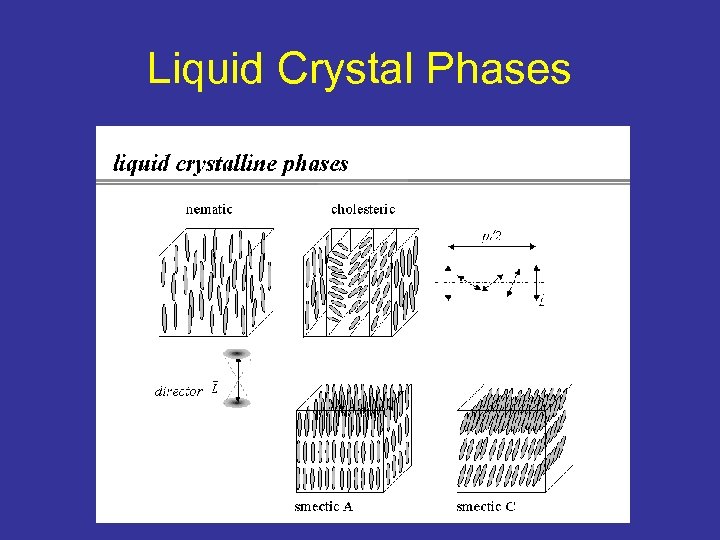

Liquid Crystal Phases

Liquid Crystal Phases

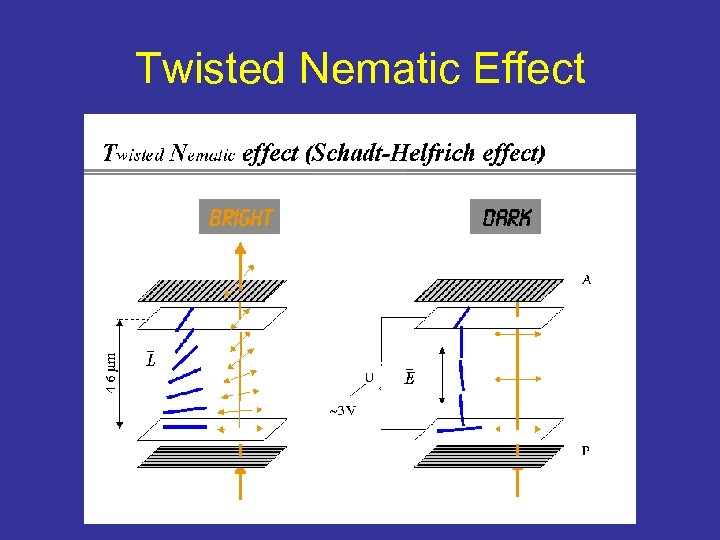

Liquid Crystal Displays • Liquid Crystal Displays (LCDs) exploit liquid crystal’s ability to bend light • Polarized light enters the back of a liquid crystal pixel • The light passes through nematic phase liquid crystal, which bends the light’s polarization plane • The light passes through another polarizer (NW) • When an E-field is applied, the liquid crystal doesn’t bend the light and it can’t pass through the polarizer (NW)

Liquid Crystal Displays • Liquid Crystal Displays (LCDs) exploit liquid crystal’s ability to bend light • Polarized light enters the back of a liquid crystal pixel • The light passes through nematic phase liquid crystal, which bends the light’s polarization plane • The light passes through another polarizer (NW) • When an E-field is applied, the liquid crystal doesn’t bend the light and it can’t pass through the polarizer (NW)

Twisted Nematic Effect

Twisted Nematic Effect

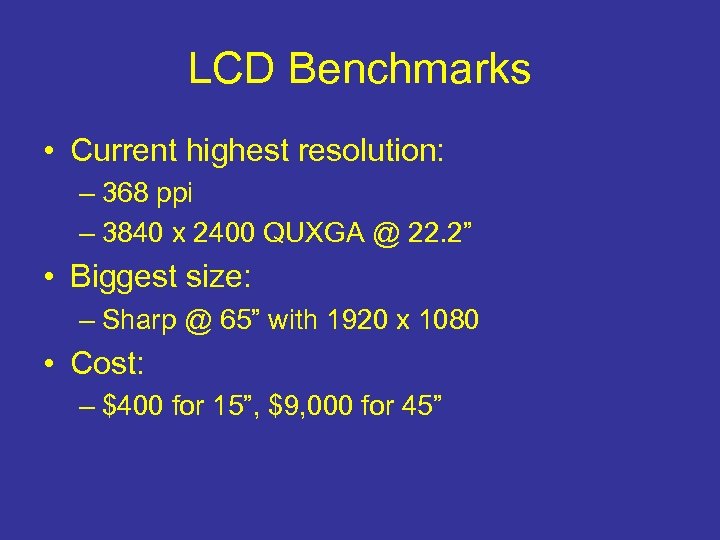

LCD Benchmarks • Current highest resolution: – 368 ppi – 3840 x 2400 QUXGA @ 22. 2” • Biggest size: – Sharp @ 65” with 1920 x 1080 • Cost: – $400 for 15”, $9, 000 for 45”

LCD Benchmarks • Current highest resolution: – 368 ppi – 3840 x 2400 QUXGA @ 22. 2” • Biggest size: – Sharp @ 65” with 1920 x 1080 • Cost: – $400 for 15”, $9, 000 for 45”

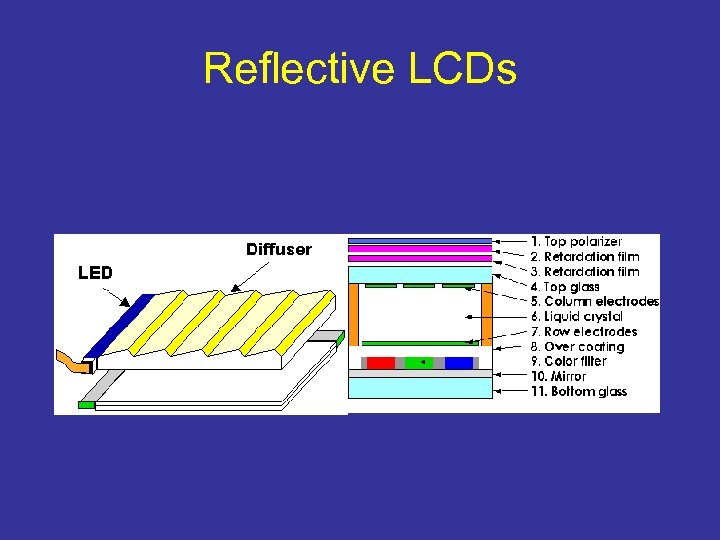

Reflective LCDs • • No backlight Designed to reflect ambient light Bad in the dark Good under bright conditions, like outdoors • Low power with no backlight

Reflective LCDs • • No backlight Designed to reflect ambient light Bad in the dark Good under bright conditions, like outdoors • Low power with no backlight

Reflective LCDs

Reflective LCDs

Transreflective LCDs • Combine features of both transmissive and reflective LCDs • Reflective for high ambient lighting • Transmissive for low ambient lighting • Less power than a fully transmissive LCD • Each pixel is divided into a reflective part and a transmissive part

Transreflective LCDs • Combine features of both transmissive and reflective LCDs • Reflective for high ambient lighting • Transmissive for low ambient lighting • Less power than a fully transmissive LCD • Each pixel is divided into a reflective part and a transmissive part

Projection Displays • An image is produced using either transmissive or reflective means • Optical mirrors and lenses magnify the image to occupy a large area • Liquid Crystal on Semiconductor (LCo. S) current leader in projection televisions • CMOS process means cheap and on-chip integration

Projection Displays • An image is produced using either transmissive or reflective means • Optical mirrors and lenses magnify the image to occupy a large area • Liquid Crystal on Semiconductor (LCo. S) current leader in projection televisions • CMOS process means cheap and on-chip integration

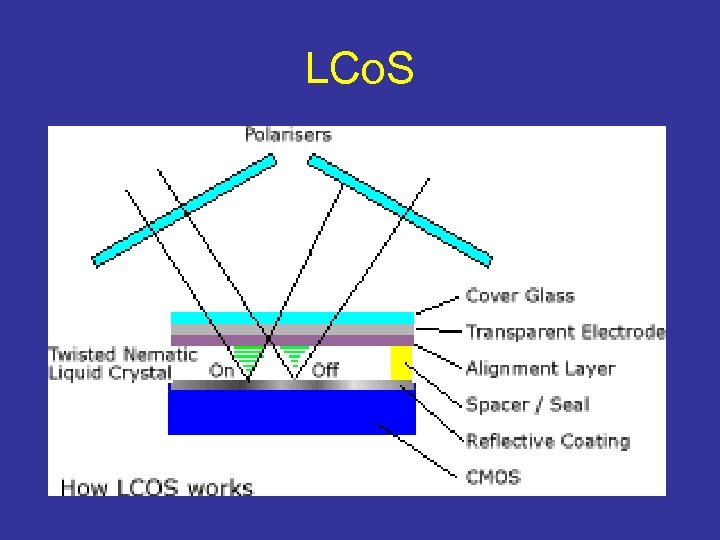

LCo. S

LCo. S

OLEDs • Organic Light Emitting Diodes • Organic molecules can be tailored to act as an LED • They can emit photons • Brighter than current TVs • Fast switching • Should eventually be cheap

OLEDs • Organic Light Emitting Diodes • Organic molecules can be tailored to act as an LED • They can emit photons • Brighter than current TVs • Fast switching • Should eventually be cheap

OLED Deposition • OLEDs can be deposited using many different means – Depends on the physical properties of the organic molecule • Vapour-phase deposition • Liquid-phase deposition – Enables really cheap manufacturing methods, like using an ink-jet printer to pattern the layers

OLED Deposition • OLEDs can be deposited using many different means – Depends on the physical properties of the organic molecule • Vapour-phase deposition • Liquid-phase deposition – Enables really cheap manufacturing methods, like using an ink-jet printer to pattern the layers

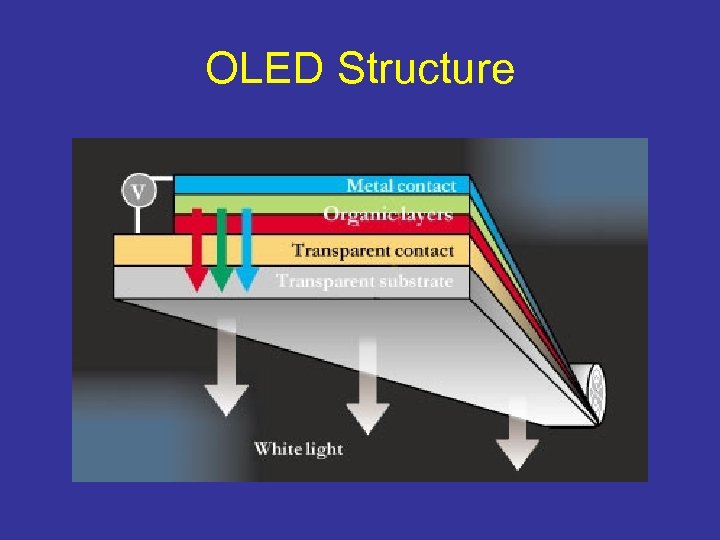

OLED Structure

OLED Structure

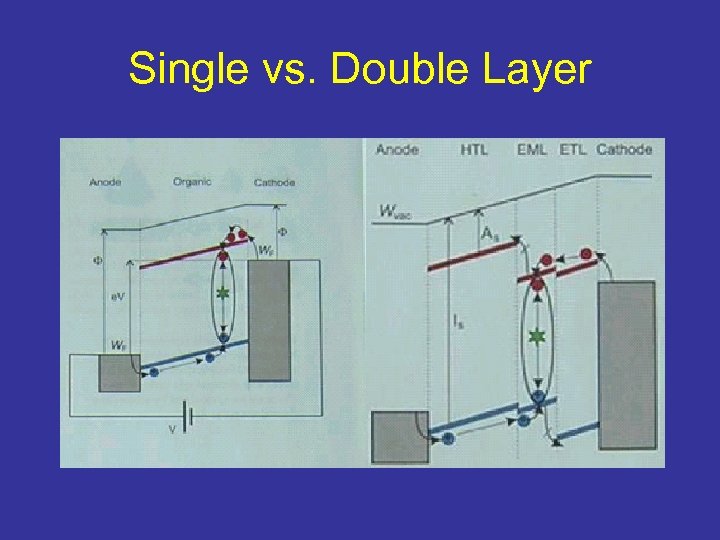

Single vs. Double Layer

Single vs. Double Layer

Field Emission • Occurs under high voltage • Electrons are stripped off of an electron emitter • Accelerated using externally applied Efield • Sharp tips release more electrons • Different than tunneling current

Field Emission • Occurs under high voltage • Electrons are stripped off of an electron emitter • Accelerated using externally applied Efield • Sharp tips release more electrons • Different than tunneling current

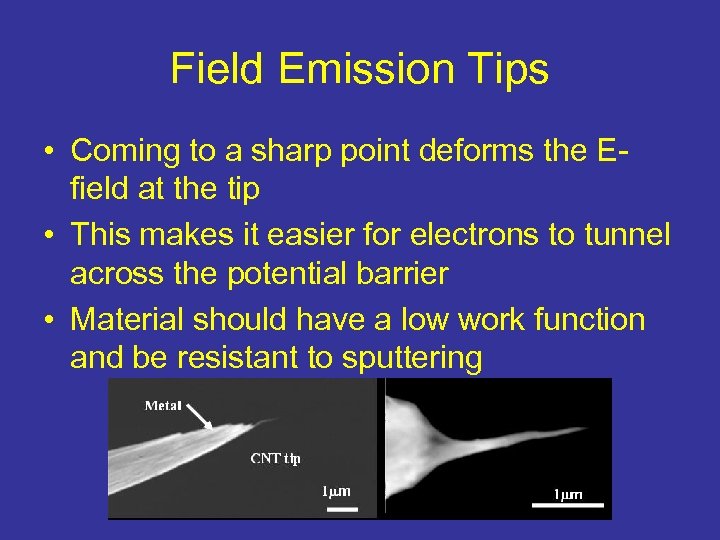

Field Emission Tips • Coming to a sharp point deforms the Efield at the tip • This makes it easier for electrons to tunnel across the potential barrier • Material should have a low work function and be resistant to sputtering

Field Emission Tips • Coming to a sharp point deforms the Efield at the tip • This makes it easier for electrons to tunnel across the potential barrier • Material should have a low work function and be resistant to sputtering

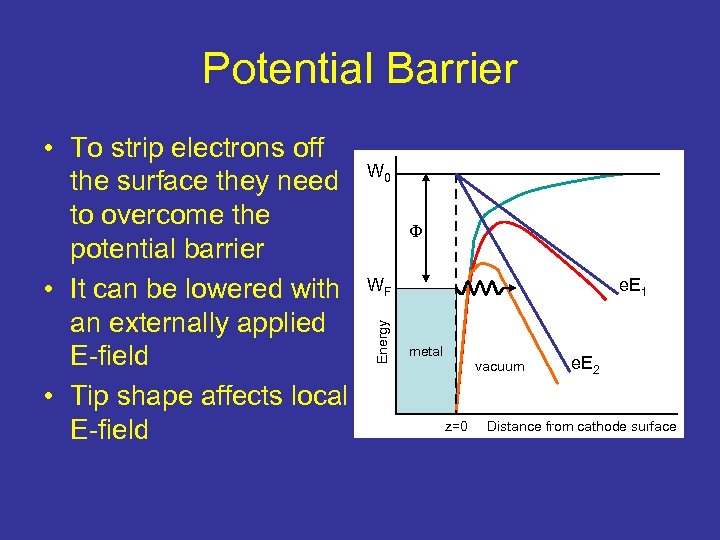

Potential Barrier W 0 WF Energy • To strip electrons off the surface they need to overcome the potential barrier • It can be lowered with an externally applied E-field • Tip shape affects local E-field e. E 1 metal vacuum z=0 e. E 2 Distance from cathode surface

Potential Barrier W 0 WF Energy • To strip electrons off the surface they need to overcome the potential barrier • It can be lowered with an externally applied E-field • Tip shape affects local E-field e. E 1 metal vacuum z=0 e. E 2 Distance from cathode surface

Phosphor Screens • Made of inorganic powders with particle grain size 3 to 8 m • Electron impact causes photon emission, just like in CRT • Layer can’t be too thick or emitted photons will get re-adsorbed • Layer can’t be too thin or too many electrons will pass through without impact • Optimal thickness = ~2 x grain size

Phosphor Screens • Made of inorganic powders with particle grain size 3 to 8 m • Electron impact causes photon emission, just like in CRT • Layer can’t be too thick or emitted photons will get re-adsorbed • Layer can’t be too thin or too many electrons will pass through without impact • Optimal thickness = ~2 x grain size

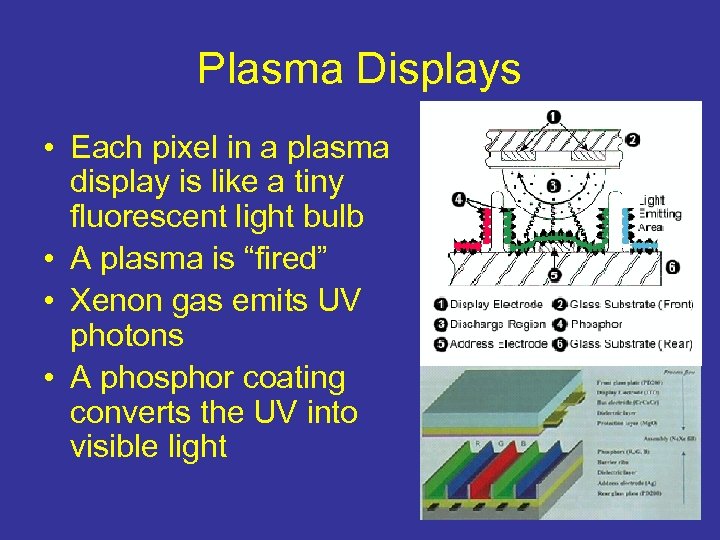

Plasma Displays • Each pixel in a plasma display is like a tiny fluorescent light bulb • A plasma is “fired” • Xenon gas emits UV photons • A phosphor coating converts the UV into visible light

Plasma Displays • Each pixel in a plasma display is like a tiny fluorescent light bulb • A plasma is “fired” • Xenon gas emits UV photons • A phosphor coating converts the UV into visible light

Electronic Paper • Ultimate goal of display technologies: – Emulate printed paper • • Ultra-low power Perfectly bistable (keeps image with no power) Flexible, foldable High contrast ratio Appear paper white Lightweight User-friendly

Electronic Paper • Ultimate goal of display technologies: – Emulate printed paper • • Ultra-low power Perfectly bistable (keeps image with no power) Flexible, foldable High contrast ratio Appear paper white Lightweight User-friendly

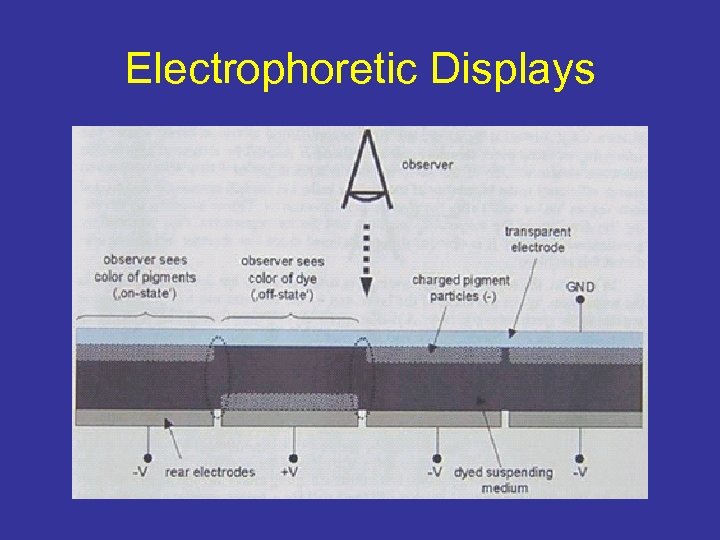

Electrophoretic Displays • A solution of black dye and suspended white particles • The white particles move in an applied Efield • There’s a transparent electrode (ITO) and a back electrode • Voltage is used to move the white particles to the surface for a white pixel, or to the bottom for a dark pixel

Electrophoretic Displays • A solution of black dye and suspended white particles • The white particles move in an applied Efield • There’s a transparent electrode (ITO) and a back electrode • Voltage is used to move the white particles to the surface for a white pixel, or to the bottom for a dark pixel

Electrophoretic Displays

Electrophoretic Displays

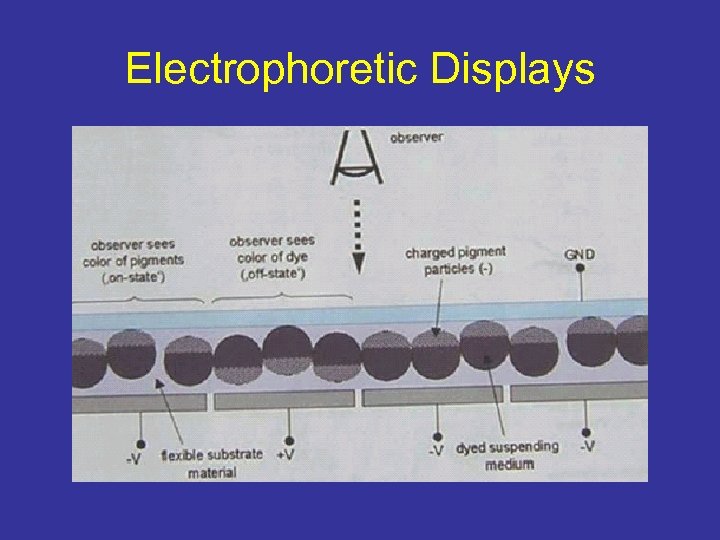

Electrophoretic Displays • Improvements can be made “microencapsulating” dye and pigment • Prevents lateral motion between pixels • Pigments tend to want to stick together under high field – Microcapsules prevent agglomeration of sizes bigger than the capsule – Improves display lifetime

Electrophoretic Displays • Improvements can be made “microencapsulating” dye and pigment • Prevents lateral motion between pixels • Pigments tend to want to stick together under high field – Microcapsules prevent agglomeration of sizes bigger than the capsule – Improves display lifetime

Electrophoretic Displays

Electrophoretic Displays

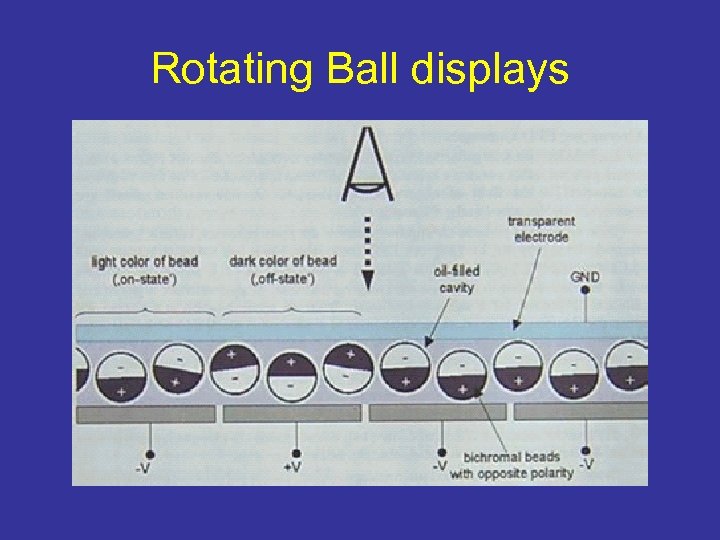

Rotating Ball Displays • Tiny balls (~100 m) are made with one half white and one half black • There is a macroscopic charge on the balls, so that black is positive and white is negative (or vice versa) • The balls are suspended in oil and sandwiched between transparent and flexible substrates • An external E-field “printer” is used to write the pattern to the display

Rotating Ball Displays • Tiny balls (~100 m) are made with one half white and one half black • There is a macroscopic charge on the balls, so that black is positive and white is negative (or vice versa) • The balls are suspended in oil and sandwiched between transparent and flexible substrates • An external E-field “printer” is used to write the pattern to the display

Rotating Ball displays

Rotating Ball displays

Thank You! • This presentation will be available on the web.

Thank You! • This presentation will be available on the web.