901c2ce34aadaf1721cb24d71183e1a4.ppt

- Количество слайдов: 43

Turning LEAN into CLEAN Driving Environmental, Health and Safety Improvement through Lean Manufacturing Jenni Cawein Manager, EHS Engineering

Turning LEAN into CLEAN Driving Environmental, Health and Safety Improvement through Lean Manufacturing Jenni Cawein Manager, EHS Engineering

• Leading healthcare products manufacturer • IV delivery systems, kidney dialysis, blood, oncology, anesthesia products • $9 billion global market leader • 2/3 of operations outside the USA • Represented in more than 110 countries, more than 300 facilities, 50, 000 employees • Key manufacturing processes include plastics extrusion and assembly, chemical compounding, sterilization

• Leading healthcare products manufacturer • IV delivery systems, kidney dialysis, blood, oncology, anesthesia products • $9 billion global market leader • 2/3 of operations outside the USA • Represented in more than 110 countries, more than 300 facilities, 50, 000 employees • Key manufacturing processes include plastics extrusion and assembly, chemical compounding, sterilization

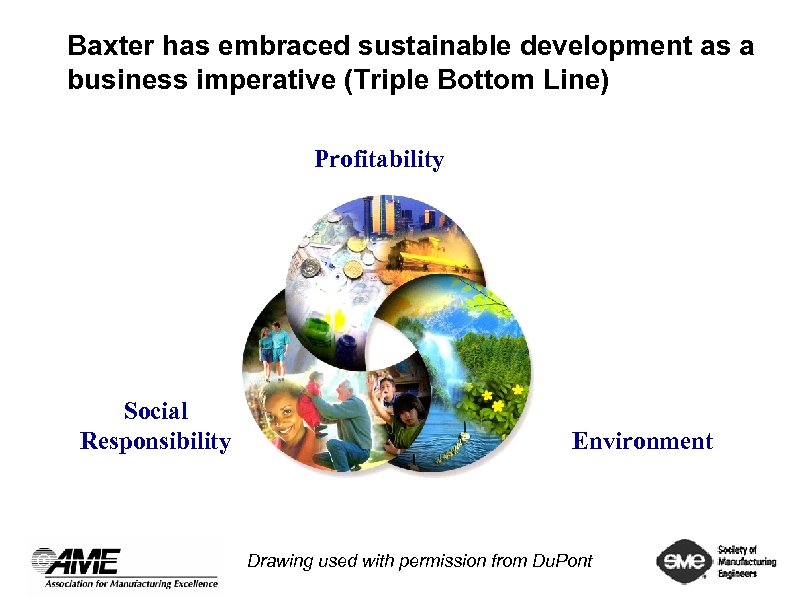

Baxter has embraced sustainable development as a business imperative (Triple Bottom Line) Profitability Social Responsibility Environment Drawing used with permission from Du. Pont

Baxter has embraced sustainable development as a business imperative (Triple Bottom Line) Profitability Social Responsibility Environment Drawing used with permission from Du. Pont

BAXTER’S ENVIRONMENTAL PROGRAM • 100+ EHS professionals • Began in the 1970’s • Measure and report progress on reducing: – – – – Energy Packaging Non-Hazardous Waste Accidents Air Toxics Water Hazardous Waste

BAXTER’S ENVIRONMENTAL PROGRAM • 100+ EHS professionals • Began in the 1970’s • Measure and report progress on reducing: – – – – Energy Packaging Non-Hazardous Waste Accidents Air Toxics Water Hazardous Waste

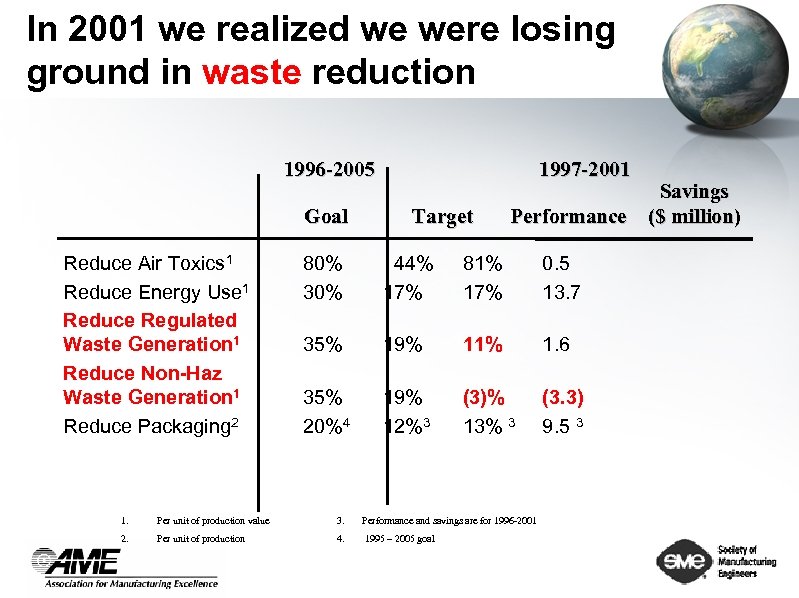

In 2001 we realized we were losing ground in waste reduction 1996 -2005 Goal Reduce Air Toxics 1 Reduce Energy Use 1 Reduce Regulated Waste Generation 1 Reduce Non-Haz Waste Generation 1 Reduce Packaging 2 1997 -2001 Target Savings Performance ($ million) 80% 30% 44% 17% 81% 17% 0. 5 13. 7 35% 19% 11% 1. 6 35% 20%4 19% 12%3 (3)% 13% 3 (3. 3) 9. 5 3 1. Per unit of production value 3. Performance and savings are for 1996 -2001 2. Per unit of production 4. 1995 – 2005 goal

In 2001 we realized we were losing ground in waste reduction 1996 -2005 Goal Reduce Air Toxics 1 Reduce Energy Use 1 Reduce Regulated Waste Generation 1 Reduce Non-Haz Waste Generation 1 Reduce Packaging 2 1997 -2001 Target Savings Performance ($ million) 80% 30% 44% 17% 81% 17% 0. 5 13. 7 35% 19% 11% 1. 6 35% 20%4 19% 12%3 (3)% 13% 3 (3. 3) 9. 5 3 1. Per unit of production value 3. Performance and savings are for 1996 -2001 2. Per unit of production 4. 1995 – 2005 goal

Pollution Prevention: A typical approach • Plant Level: – Pollution Prevention team, usually led by EHS. – Problem: focus often on recycling and end-of-pipe (not generation), on less important aspects (e. g. paper recycling). Lack of integration and poor use of limited resources. Waste reduction as an “extra activity”. • Corporate Level: – Corporate EHS Engineering identifies “Top Opportunity” plants, visits plant, walks plant, looks for opportunities, writes a report, walks away – Problem: no continual improvement focus, no strengthening of EHS management systems (ISO 14001), poor use of limited resources, not aligned with other manufacturing or quality approaches, little value to high performing plants, few results. – Called in Baldrige an “ad hoc” approach (low scorer) We had used these approaches for years and they WEREN’T WORKING!!

Pollution Prevention: A typical approach • Plant Level: – Pollution Prevention team, usually led by EHS. – Problem: focus often on recycling and end-of-pipe (not generation), on less important aspects (e. g. paper recycling). Lack of integration and poor use of limited resources. Waste reduction as an “extra activity”. • Corporate Level: – Corporate EHS Engineering identifies “Top Opportunity” plants, visits plant, walks plant, looks for opportunities, writes a report, walks away – Problem: no continual improvement focus, no strengthening of EHS management systems (ISO 14001), poor use of limited resources, not aligned with other manufacturing or quality approaches, little value to high performing plants, few results. – Called in Baldrige an “ad hoc” approach (low scorer) We had used these approaches for years and they WEREN’T WORKING!!

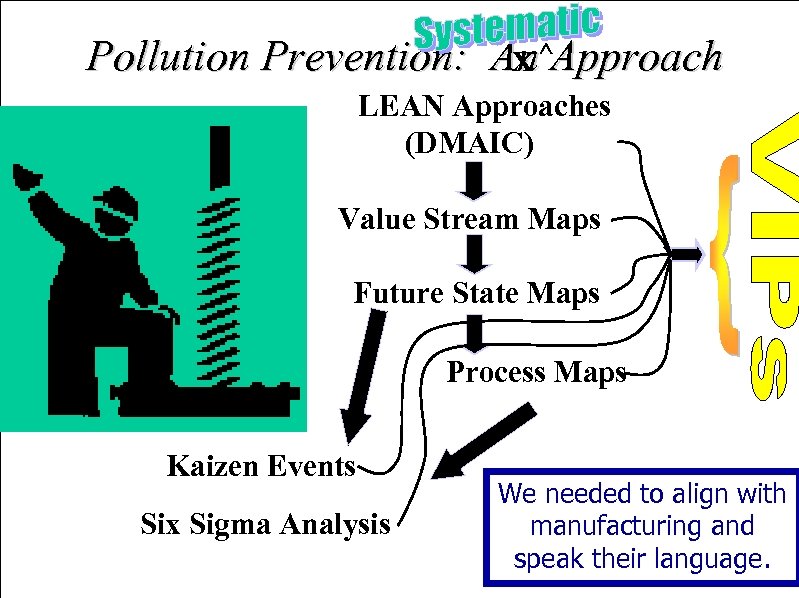

Pollution Prevention: An^Approach X LEAN Approaches (DMAIC) Value Stream Maps Future State Maps Process Maps Kaizen Events Six Sigma Analysis We needed to align with manufacturing and speak their language.

Pollution Prevention: An^Approach X LEAN Approaches (DMAIC) Value Stream Maps Future State Maps Process Maps Kaizen Events Six Sigma Analysis We needed to align with manufacturing and speak their language.

What is Lean ? • A process of continuously identifying, reducing and eliminating waste (non-value added activity) • Waste is defined as anything other than the minimum amount of equipment, materials, parts, space, and worker’s time which are absolutely essential to add value to the product. Shoichiro Toyoda President, Toyota

What is Lean ? • A process of continuously identifying, reducing and eliminating waste (non-value added activity) • Waste is defined as anything other than the minimum amount of equipment, materials, parts, space, and worker’s time which are absolutely essential to add value to the product. Shoichiro Toyoda President, Toyota

Some Lean Tools • Kaizen Rapid Improvement Process, including Value Stream mapping and Kaizen events – Reduce waste by continual improvement • 5 S: Sort, Straighten, Shine, Standardize, Sustain – Reduce waste by orderly workplace, reorganization of space • Pull vs. Push systems, and just-in-time production (kanban signals) – Reduce waste associated with excess inventory, packaging, over -production

Some Lean Tools • Kaizen Rapid Improvement Process, including Value Stream mapping and Kaizen events – Reduce waste by continual improvement • 5 S: Sort, Straighten, Shine, Standardize, Sustain – Reduce waste by orderly workplace, reorganization of space • Pull vs. Push systems, and just-in-time production (kanban signals) – Reduce waste associated with excess inventory, packaging, over -production

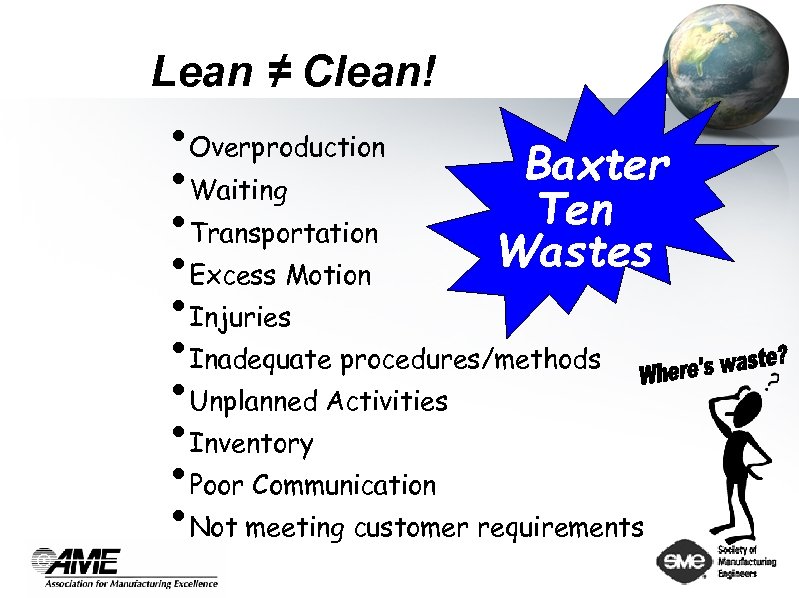

Lean ≠ Clean! • Overproduction Baxter • Waiting Ten • Transportation Wastes • Excess Motion • Injuries • Inadequate procedures/methods • Unplanned Activities • Inventory • Poor Communication • Not meeting customer requirements

Lean ≠ Clean! • Overproduction Baxter • Waiting Ten • Transportation Wastes • Excess Motion • Injuries • Inadequate procedures/methods • Unplanned Activities • Inventory • Poor Communication • Not meeting customer requirements

LEAN “Blind Spots” • Kaizen team at one plant decided segregating plastics was a waste of time – Result: where recycling revenues had been obtained from clean, segregated plastics, we now had a pile of trash to dispose. • Another plant neglected to consult EHS during a lean-initiated redesign of product line, resulting in machine-guarding problems – Result: delays in production, as well as costly retrofits. • Other companies have reported similar challenges – e. g. replacing aqueous cleaner with hazardous solvents may cut takt time, but is it smarter? Hazardous waste is costly to dispose, and generation may kick a plant into higher level of regulation.

LEAN “Blind Spots” • Kaizen team at one plant decided segregating plastics was a waste of time – Result: where recycling revenues had been obtained from clean, segregated plastics, we now had a pile of trash to dispose. • Another plant neglected to consult EHS during a lean-initiated redesign of product line, resulting in machine-guarding problems – Result: delays in production, as well as costly retrofits. • Other companies have reported similar challenges – e. g. replacing aqueous cleaner with hazardous solvents may cut takt time, but is it smarter? Hazardous waste is costly to dispose, and generation may kick a plant into higher level of regulation.

Our Challenge • Lean engineers did not have expertise in EHS, and were not going to focus on “environmental” waste • EHS personnel did not have expertise in Lean, and were not being included or consulted. • There were clearly gaps in lean that could hurt us in environmental performance and jeopardize worker safety • Lean was a huge train driving through Baxter, and we needed to understand how to leverage it to help achieve EHS goals!

Our Challenge • Lean engineers did not have expertise in EHS, and were not going to focus on “environmental” waste • EHS personnel did not have expertise in Lean, and were not being included or consulted. • There were clearly gaps in lean that could hurt us in environmental performance and jeopardize worker safety • Lean was a huge train driving through Baxter, and we needed to understand how to leverage it to help achieve EHS goals!

Option 1: Support it and/or add environmental aspects LEAN can have EHS benefits (in and of itself)

Option 1: Support it and/or add environmental aspects LEAN can have EHS benefits (in and of itself)

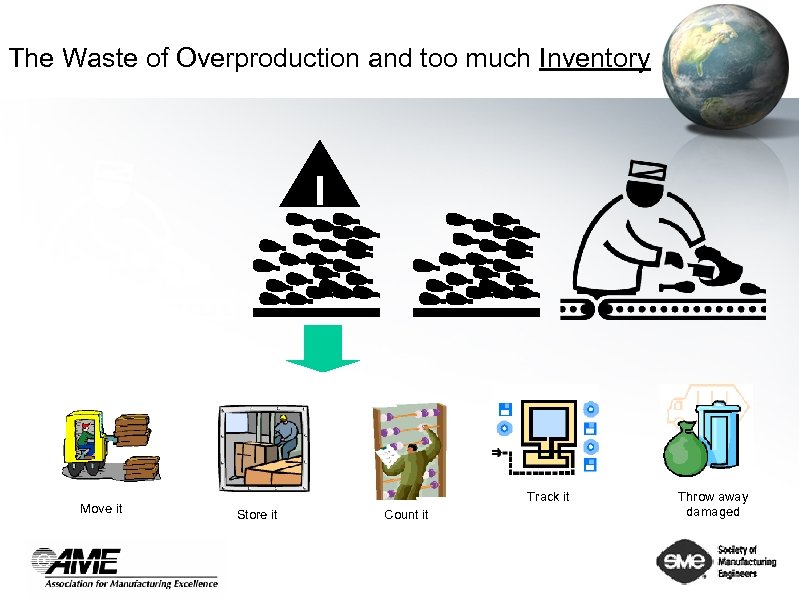

The Waste of Overproduction and too much Inventory I Move it Track it Store it Count it Throw away damaged

The Waste of Overproduction and too much Inventory I Move it Track it Store it Count it Throw away damaged

EHS Benefits • Space utilization (energy, other resources) • Reduced rework, scrap and discards (waste) • Reduced handling and storage requirements (corrugated, pallets, batteries and lubricants forklifts, etc. ) • Reduced risk of accidents from moving things

EHS Benefits • Space utilization (energy, other resources) • Reduced rework, scrap and discards (waste) • Reduced handling and storage requirements (corrugated, pallets, batteries and lubricants forklifts, etc. ) • Reduced risk of accidents from moving things

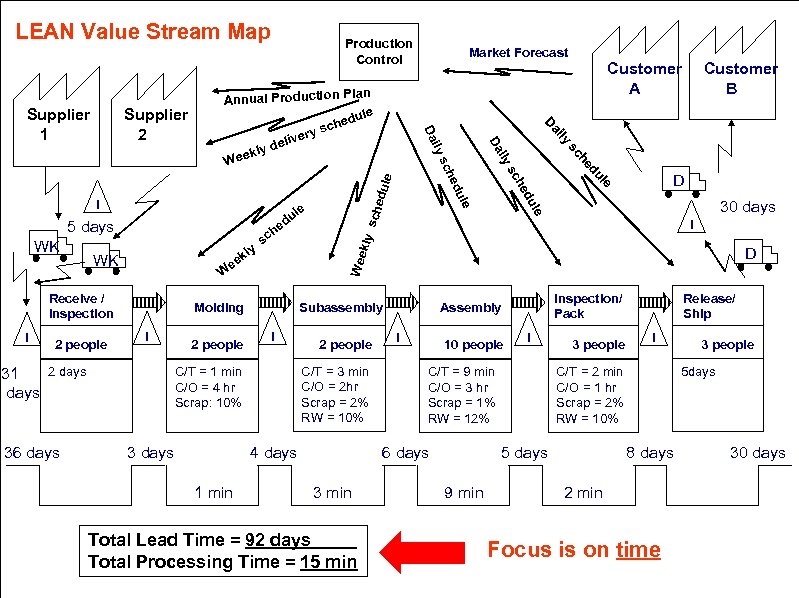

LEAN Value Stream Map Customer A le 2 days 31 days 36 days 2 people edu sch 30 days kly D Wee I 2 people C/T = 3 min C/O = 2 hr Scrap = 2% RW = 10% 4 days 1 min D I I 10 people Total Lead Time = 92 days Total Processing Time = 15 min I C/T = 9 min C/O = 3 hr Scrap = 1% RW = 12% 6 days 3 min Inspection/ Pack Assembly Subassembly C/T = 1 min C/O = 4 hr Scrap: 10% 3 days le du Molding I he sc 2 people ily Da I Customer B le du Receive / Inspection ly h sc he k ee W WK le WK u ed 5 days sc sch e l du e ily I Da Supplier 2 an Annual Production Pl dule che s ery eliv ly d eek W Market Forecast Da Supplier 1 Production Control 3 people I 3 people 5 days C/T = 2 min C/O = 1 hr Scrap = 2% RW = 10% 5 days 9 min Release/ Ship 8 days 2 min Focus is on time 30 days

LEAN Value Stream Map Customer A le 2 days 31 days 36 days 2 people edu sch 30 days kly D Wee I 2 people C/T = 3 min C/O = 2 hr Scrap = 2% RW = 10% 4 days 1 min D I I 10 people Total Lead Time = 92 days Total Processing Time = 15 min I C/T = 9 min C/O = 3 hr Scrap = 1% RW = 12% 6 days 3 min Inspection/ Pack Assembly Subassembly C/T = 1 min C/O = 4 hr Scrap: 10% 3 days le du Molding I he sc 2 people ily Da I Customer B le du Receive / Inspection ly h sc he k ee W WK le WK u ed 5 days sc sch e l du e ily I Da Supplier 2 an Annual Production Pl dule che s ery eliv ly d eek W Market Forecast Da Supplier 1 Production Control 3 people I 3 people 5 days C/T = 2 min C/O = 1 hr Scrap = 2% RW = 10% 5 days 9 min Release/ Ship 8 days 2 min Focus is on time 30 days

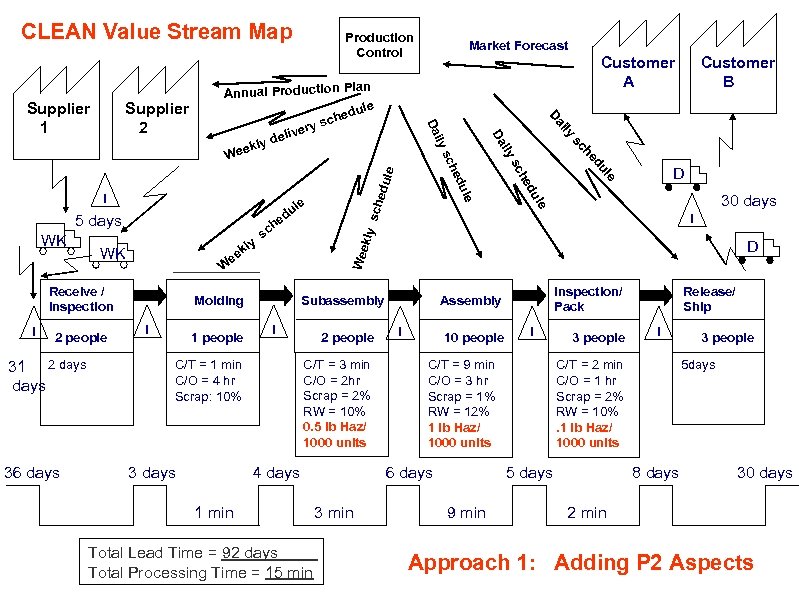

CLEAN Value Stream Map Customer A le edu sch 30 days kly D Wee 2 people C/T = 3 min C/O = 2 hr Scrap = 2% RW = 10% 0. 5 lb Haz/ 1000 units 4 days 1 min le I C/T = 1 min C/O = 4 hr Scrap: 10% 3 days u ed 36 days h sc 31 2 days 1 people D I I 10 people Total Lead Time = 92 days Total Processing Time = 15 min I C/T = 9 min C/O = 3 hr Scrap = 1% RW = 12% 1 lb Haz/ 1000 units 6 days 3 min Inspection/ Pack Assembly Subassembly Molding I ily 2 people Da I Customer B le Receive / Inspection ly h sc u ed k ee W WK le WK u ed 5 days h sc sch e l du e ily I Da Supplier 2 an Annual Production Pl ule hed c ry s live e ly d eek W Market Forecast Da Supplier 1 Production Control 3 people I 3 people 5 days C/T = 2 min C/O = 1 hr Scrap = 2% RW = 10%. 1 lb Haz/ 1000 units 5 days 9 min Release/ Ship 8 days 30 days 2 min Approach 1: Adding P 2 Aspects

CLEAN Value Stream Map Customer A le edu sch 30 days kly D Wee 2 people C/T = 3 min C/O = 2 hr Scrap = 2% RW = 10% 0. 5 lb Haz/ 1000 units 4 days 1 min le I C/T = 1 min C/O = 4 hr Scrap: 10% 3 days u ed 36 days h sc 31 2 days 1 people D I I 10 people Total Lead Time = 92 days Total Processing Time = 15 min I C/T = 9 min C/O = 3 hr Scrap = 1% RW = 12% 1 lb Haz/ 1000 units 6 days 3 min Inspection/ Pack Assembly Subassembly Molding I ily 2 people Da I Customer B le Receive / Inspection ly h sc u ed k ee W WK le WK u ed 5 days h sc sch e l du e ily I Da Supplier 2 an Annual Production Pl ule hed c ry s live e ly d eek W Market Forecast Da Supplier 1 Production Control 3 people I 3 people 5 days C/T = 2 min C/O = 1 hr Scrap = 2% RW = 10%. 1 lb Haz/ 1000 units 5 days 9 min Release/ Ship 8 days 30 days 2 min Approach 1: Adding P 2 Aspects

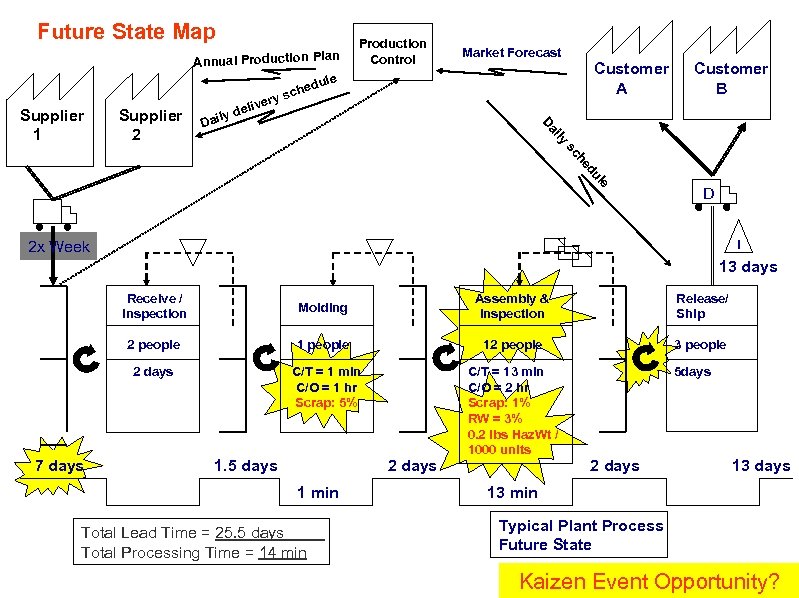

Future State Map Supplier 2 Production Control Market Forecast Customer A Customer B ily Da Supplier 1 an Annual Production Pl ule hed c ry s live e ly d Dai le du he sc D I 2 x Week 13 days Receive / Inspection Assembly & Inspection Release/ Ship 2 people 12 people 3 people 2 days 7 days Molding C/T = 1 min C/O = 1 hr Scrap: 5% C/T = 13 min C/O = 2 hr Scrap: 1% RW = 3% 0. 2 lbs Haz. Wt / 1000 units 1. 5 days 2 days 1 min Total Lead Time = 25. 5 days Total Processing Time = 14 min 5 days 2 days 13 min Typical Plant Process Future State Kaizen Event Opportunity?

Future State Map Supplier 2 Production Control Market Forecast Customer A Customer B ily Da Supplier 1 an Annual Production Pl ule hed c ry s live e ly d Dai le du he sc D I 2 x Week 13 days Receive / Inspection Assembly & Inspection Release/ Ship 2 people 12 people 3 people 2 days 7 days Molding C/T = 1 min C/O = 1 hr Scrap: 5% C/T = 13 min C/O = 2 hr Scrap: 1% RW = 3% 0. 2 lbs Haz. Wt / 1000 units 1. 5 days 2 days 1 min Total Lead Time = 25. 5 days Total Processing Time = 14 min 5 days 2 days 13 min Typical Plant Process Future State Kaizen Event Opportunity?

Option 2: Learn to use lean tools to systematically understand (and improve) the most important EHS aspects.

Option 2: Learn to use lean tools to systematically understand (and improve) the most important EHS aspects.

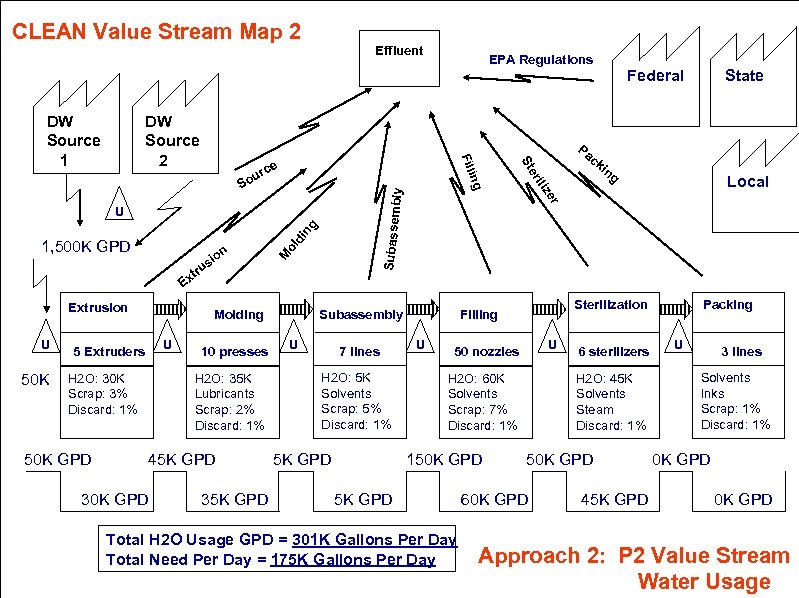

CLEAN Value Stream Map 2 Effluent EPA Regulations Federal bly Subassem ng di ol M on i us r t Ex Extrusion U 50 K Molding U 5 Extruders H 2 O: 30 K Scrap: 3% Discard: 1% 50 K GPD 10 presses H 2 O: 35 K Lubricants Scrap: 2% Discard: 1% 45 K GPD 30 K GPD 35 K GPD Local r 1, 500 K GPD ng ize U ki il er S ing e urc o Pa c St DW Source 2 Fill DW Source 1 State Subassembly U 7 lines H 2 O: 5 K Solvents Scrap: 5% Discard: 1% 5 K GPD Sterilization Filling U U 50 nozzles H 2 O: 60 K Solvents Scrap: 7% Discard: 1% 150 K GPD 5 K GPD Total H 2 O Usage GPD = 301 K Gallons Per Day Total Need Per Day = 175 K Gallons Per Day 6 sterilizers H 2 O: 45 K Solvents Steam Discard: 1% 50 K GPD 60 K GPD 45 K GPD Packing U 3 lines Solvents Inks Scrap: 1% Discard: 1% 0 K GPD Approach 2: P 2 Value Stream Water Usage

CLEAN Value Stream Map 2 Effluent EPA Regulations Federal bly Subassem ng di ol M on i us r t Ex Extrusion U 50 K Molding U 5 Extruders H 2 O: 30 K Scrap: 3% Discard: 1% 50 K GPD 10 presses H 2 O: 35 K Lubricants Scrap: 2% Discard: 1% 45 K GPD 30 K GPD 35 K GPD Local r 1, 500 K GPD ng ize U ki il er S ing e urc o Pa c St DW Source 2 Fill DW Source 1 State Subassembly U 7 lines H 2 O: 5 K Solvents Scrap: 5% Discard: 1% 5 K GPD Sterilization Filling U U 50 nozzles H 2 O: 60 K Solvents Scrap: 7% Discard: 1% 150 K GPD 5 K GPD Total H 2 O Usage GPD = 301 K Gallons Per Day Total Need Per Day = 175 K Gallons Per Day 6 sterilizers H 2 O: 45 K Solvents Steam Discard: 1% 50 K GPD 60 K GPD 45 K GPD Packing U 3 lines Solvents Inks Scrap: 1% Discard: 1% 0 K GPD Approach 2: P 2 Value Stream Water Usage

Option 3: Use LEAN projects to help drill down and find EHS opportunities. Add new tools to enhance lean and close gaps.

Option 3: Use LEAN projects to help drill down and find EHS opportunities. Add new tools to enhance lean and close gaps.

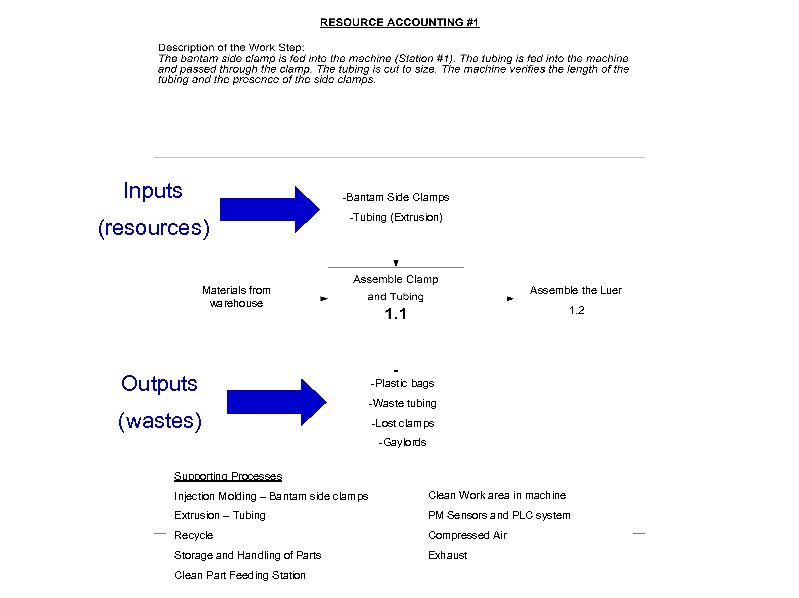

Process Mapping with Resource Accounting • Developed by Dr. Robert Pojasek (Harvard University) • Systems approach, defined from identifying opportunities through completion • Can be used alone, or can build upon lean value stream map.

Process Mapping with Resource Accounting • Developed by Dr. Robert Pojasek (Harvard University) • Systems approach, defined from identifying opportunities through completion • Can be used alone, or can build upon lean value stream map.

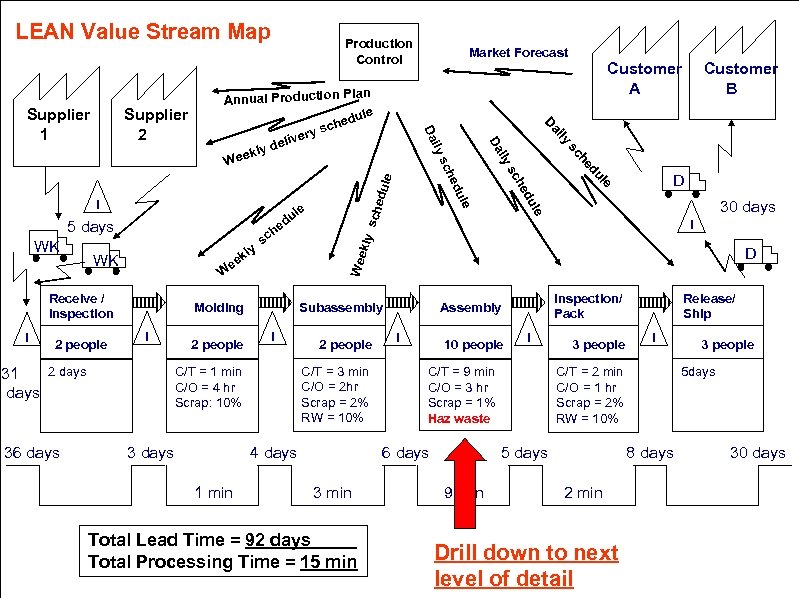

LEAN Value Stream Map Customer A le 2 days 31 days 36 days 2 people edu sch 30 days kly D Wee I 2 people C/T = 3 min C/O = 2 hr Scrap = 2% RW = 10% 4 days 1 min D I I 10 people Total Lead Time = 92 days Total Processing Time = 15 min I C/T = 9 min C/O = 3 hr Scrap = 1% Haz waste 6 days 3 min Inspection/ Pack Assembly Subassembly C/T = 1 min C/O = 4 hr Scrap: 10% 3 days le du Molding I he sc 2 people ily Da I Customer B le du Receive / Inspection ly h sc he k ee W WK le WK u ed 5 days sc sch e l du e ily I Da Supplier 2 an Annual Production Pl dule che s ery eliv ly d eek W Market Forecast Da Supplier 1 Production Control 3 people I 8 days 2 min Drill down to next level of detail 3 people 5 days C/T = 2 min C/O = 1 hr Scrap = 2% RW = 10% 5 days 9 min Release/ Ship 30 days

LEAN Value Stream Map Customer A le 2 days 31 days 36 days 2 people edu sch 30 days kly D Wee I 2 people C/T = 3 min C/O = 2 hr Scrap = 2% RW = 10% 4 days 1 min D I I 10 people Total Lead Time = 92 days Total Processing Time = 15 min I C/T = 9 min C/O = 3 hr Scrap = 1% Haz waste 6 days 3 min Inspection/ Pack Assembly Subassembly C/T = 1 min C/O = 4 hr Scrap: 10% 3 days le du Molding I he sc 2 people ily Da I Customer B le du Receive / Inspection ly h sc he k ee W WK le WK u ed 5 days sc sch e l du e ily I Da Supplier 2 an Annual Production Pl dule che s ery eliv ly d eek W Market Forecast Da Supplier 1 Production Control 3 people I 8 days 2 min Drill down to next level of detail 3 people 5 days C/T = 2 min C/O = 1 hr Scrap = 2% RW = 10% 5 days 9 min Release/ Ship 30 days

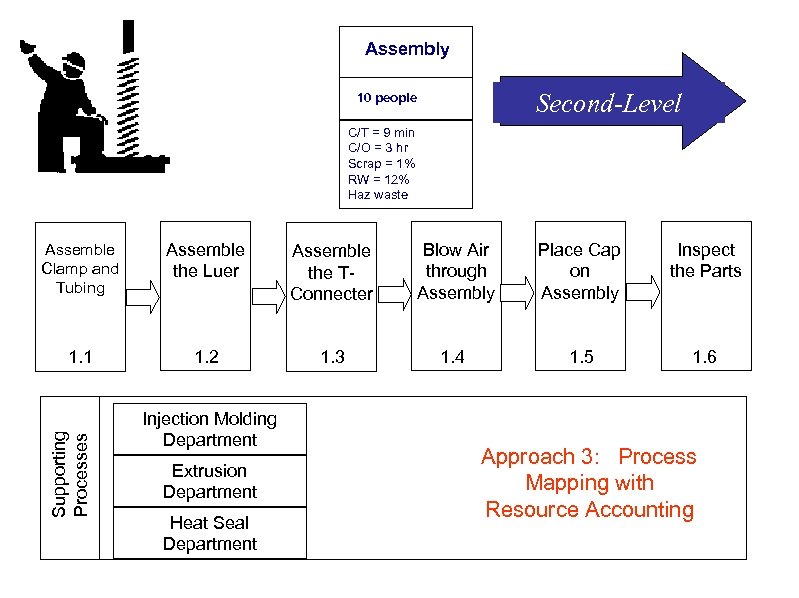

Assembly Second-Level 10 people C/T = 9 min C/O = 3 hr Scrap = 1% RW = 12% Haz waste Assemble the Luer Assemble the TConnecter Blow Air through Assembly Place Cap on Assembly Inspect the Parts 1. 1 1. 2 1. 3 1. 4 1. 5 1. 6 Supporting Processes Assemble Clamp and Tubing Injection Molding Department Extrusion Department Heat Seal Department Approach 3: Process Mapping with Resource Accounting

Assembly Second-Level 10 people C/T = 9 min C/O = 3 hr Scrap = 1% RW = 12% Haz waste Assemble the Luer Assemble the TConnecter Blow Air through Assembly Place Cap on Assembly Inspect the Parts 1. 1 1. 2 1. 3 1. 4 1. 5 1. 6 Supporting Processes Assemble Clamp and Tubing Injection Molding Department Extrusion Department Heat Seal Department Approach 3: Process Mapping with Resource Accounting

Inputs -Bantam Side Clamps (resources) -Tubing (Extrusion) Materials from warehouse Outputs (wastes) Assemble the Luer 1. 2 -Plastic bags -Waste tubing -Lost clamps -Gaylords Supporting Processes Injection Molding – Bantam side clamps Clean Work area in machine Extrusion – Tubing PM Sensors and PLC system Recycle Compressed Air Storage and Handling of Parts Exhaust Clean Part Feeding Station

Inputs -Bantam Side Clamps (resources) -Tubing (Extrusion) Materials from warehouse Outputs (wastes) Assemble the Luer 1. 2 -Plastic bags -Waste tubing -Lost clamps -Gaylords Supporting Processes Injection Molding – Bantam side clamps Clean Work area in machine Extrusion – Tubing PM Sensors and PLC system Recycle Compressed Air Storage and Handling of Parts Exhaust Clean Part Feeding Station

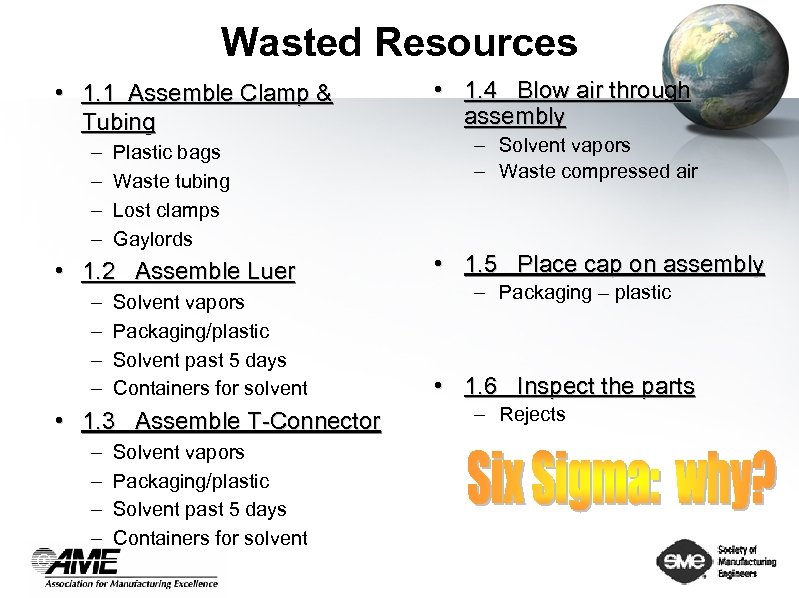

Wasted Resources • 1. 1 Assemble Clamp & Tubing – – Plastic bags Waste tubing Lost clamps Gaylords • 1. 2 Assemble Luer – – Solvent vapors Packaging/plastic Solvent past 5 days Containers for solvent • 1. 3 Assemble T-Connector – – Solvent vapors Packaging/plastic Solvent past 5 days Containers for solvent • 1. 4 Blow air through assembly – Solvent vapors – Waste compressed air • 1. 5 Place cap on assembly – Packaging – plastic • 1. 6 Inspect the parts – Rejects

Wasted Resources • 1. 1 Assemble Clamp & Tubing – – Plastic bags Waste tubing Lost clamps Gaylords • 1. 2 Assemble Luer – – Solvent vapors Packaging/plastic Solvent past 5 days Containers for solvent • 1. 3 Assemble T-Connector – – Solvent vapors Packaging/plastic Solvent past 5 days Containers for solvent • 1. 4 Blow air through assembly – Solvent vapors – Waste compressed air • 1. 5 Place cap on assembly – Packaging – plastic • 1. 6 Inspect the parts – Rejects

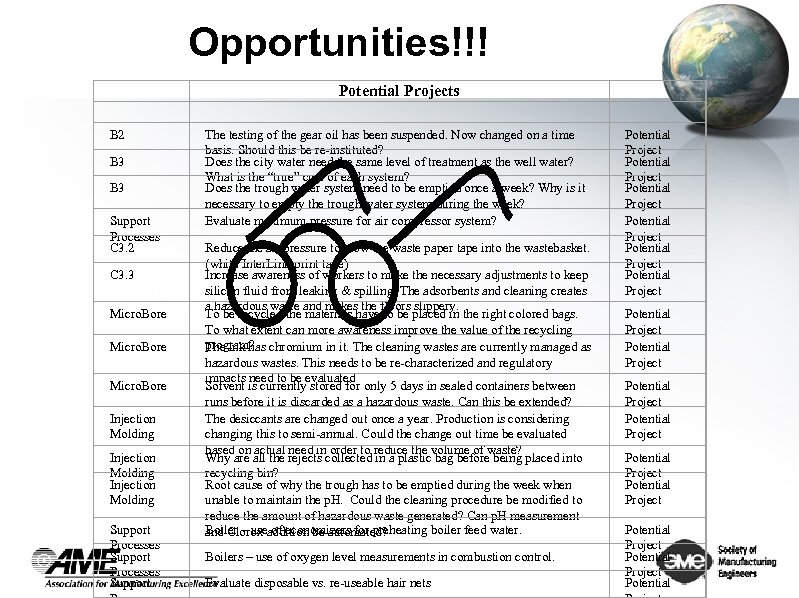

Opportunities!!! Potential Projects B 2 The testing of the gear oil has been suspended. Now changed on a time basis. Should this be re-instituted? Does the city water need the same level of treatment as the well water? What is the “true” cost of each system? Does the trough water system need to be emptied once a week? Why is it necessary to empty the trough water system during the week? Evaluate maximum pressure for air compressor system? Potential Project Potential Project B 3 Support Processes C 3. 2 C 3. 3 Micro. Bore Injection Molding Support Processes Support Reduce the air pressure to blow the waste paper tape into the wastebasket. (white Inter. Link print tape) Increase awareness of workers to make the necessary adjustments to keep silicon fluid from leaking & spilling. The adsorbents and cleaning creates a hazardous waste and makes the floors slippery. To be recycled the materials have to be placed in the right colored bags. To what extent can more awareness improve the value of the recycling program? The ink has chromium in it. The cleaning wastes are currently managed as hazardous wastes. This needs to be re-characterized and regulatory impacts need to be evaluated Solvent is currently stored for only 5 days in sealed containers between runs before it is discarded as a hazardous waste. Can this be extended? The desiccants are changed out once a year. Production is considering changing this to semi-annual. Could the change out time be evaluated based on actual need in order to reduce the volume of waste? Why are all the rejects collected in a plastic bag before being placed into recycling bin? Root cause of why the trough has to be emptied during the week when unable to maintain the p. H. Could the cleaning procedure be modified to reduce the amount of hazardous waste generated? Can p. H measurement Boiler – use of economizers for preheating boiler feed water. and Clorox addition be automated? Boilers – use of oxygen level measurements in combustion control. Evaluate disposable vs. re-useable hair nets Potential Project Potential Project Potential

Opportunities!!! Potential Projects B 2 The testing of the gear oil has been suspended. Now changed on a time basis. Should this be re-instituted? Does the city water need the same level of treatment as the well water? What is the “true” cost of each system? Does the trough water system need to be emptied once a week? Why is it necessary to empty the trough water system during the week? Evaluate maximum pressure for air compressor system? Potential Project Potential Project B 3 Support Processes C 3. 2 C 3. 3 Micro. Bore Injection Molding Support Processes Support Reduce the air pressure to blow the waste paper tape into the wastebasket. (white Inter. Link print tape) Increase awareness of workers to make the necessary adjustments to keep silicon fluid from leaking & spilling. The adsorbents and cleaning creates a hazardous waste and makes the floors slippery. To be recycled the materials have to be placed in the right colored bags. To what extent can more awareness improve the value of the recycling program? The ink has chromium in it. The cleaning wastes are currently managed as hazardous wastes. This needs to be re-characterized and regulatory impacts need to be evaluated Solvent is currently stored for only 5 days in sealed containers between runs before it is discarded as a hazardous waste. Can this be extended? The desiccants are changed out once a year. Production is considering changing this to semi-annual. Could the change out time be evaluated based on actual need in order to reduce the volume of waste? Why are all the rejects collected in a plastic bag before being placed into recycling bin? Root cause of why the trough has to be emptied during the week when unable to maintain the p. H. Could the cleaning procedure be modified to reduce the amount of hazardous waste generated? Can p. H measurement Boiler – use of economizers for preheating boiler feed water. and Clorox addition be automated? Boilers – use of oxygen level measurements in combustion control. Evaluate disposable vs. re-useable hair nets Potential Project Potential Project Potential

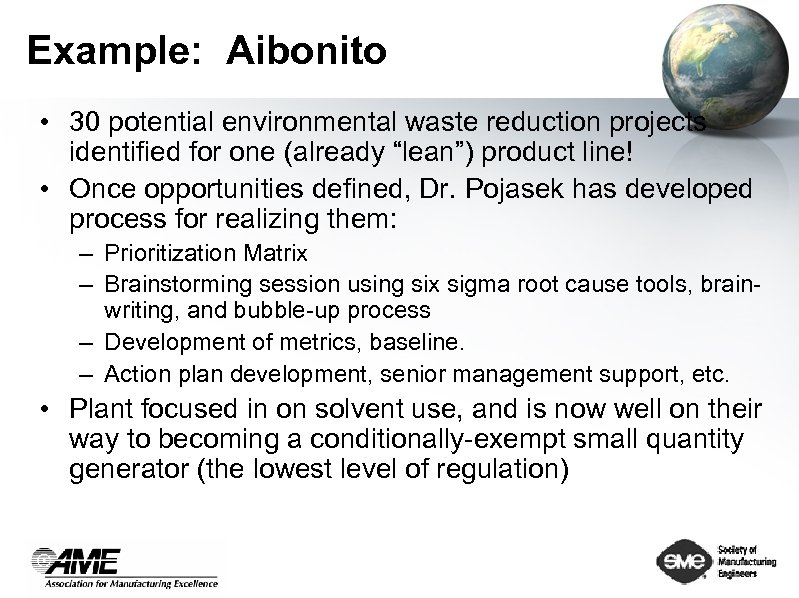

Example: Aibonito • 30 potential environmental waste reduction projects identified for one (already “lean”) product line! • Once opportunities defined, Dr. Pojasek has developed process for realizing them: – Prioritization Matrix – Brainstorming session using six sigma root cause tools, brainwriting, and bubble-up process – Development of metrics, baseline. – Action plan development, senior management support, etc. • Plant focused in on solvent use, and is now well on their way to becoming a conditionally-exempt small quantity generator (the lowest level of regulation)

Example: Aibonito • 30 potential environmental waste reduction projects identified for one (already “lean”) product line! • Once opportunities defined, Dr. Pojasek has developed process for realizing them: – Prioritization Matrix – Brainstorming session using six sigma root cause tools, brainwriting, and bubble-up process – Development of metrics, baseline. – Action plan development, senior management support, etc. • Plant focused in on solvent use, and is now well on their way to becoming a conditionally-exempt small quantity generator (the lowest level of regulation)

Those plants that have embraced the concepts are now refining and improving them Examples

Those plants that have embraced the concepts are now refining and improving them Examples

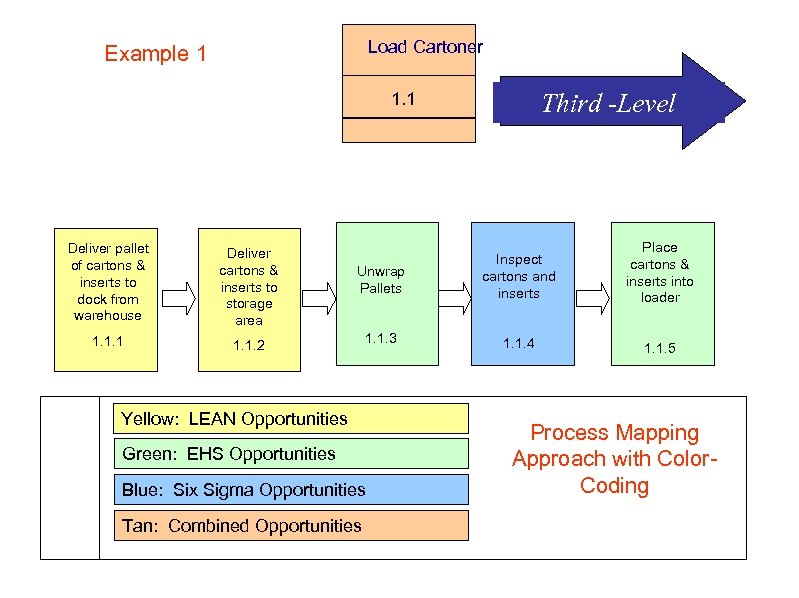

Load Cartoner Example 1 Third -Level 1. 1 Deliver pallet of cartons & inserts to dock from warehouse Deliver cartons & inserts to storage area 1. 1. 1 Unwrap Pallets Inspect cartons and inserts Place cartons & inserts into loader 1. 1. 3 1. 1. 4 1. 1. 5 1. 1. 2 Yellow: LEAN Opportunities Green: EHS Opportunities Blue: Six Sigma Opportunities Tan: Combined Opportunities Process Mapping Approach with Color. Coding

Load Cartoner Example 1 Third -Level 1. 1 Deliver pallet of cartons & inserts to dock from warehouse Deliver cartons & inserts to storage area 1. 1. 1 Unwrap Pallets Inspect cartons and inserts Place cartons & inserts into loader 1. 1. 3 1. 1. 4 1. 1. 5 1. 1. 2 Yellow: LEAN Opportunities Green: EHS Opportunities Blue: Six Sigma Opportunities Tan: Combined Opportunities Process Mapping Approach with Color. Coding

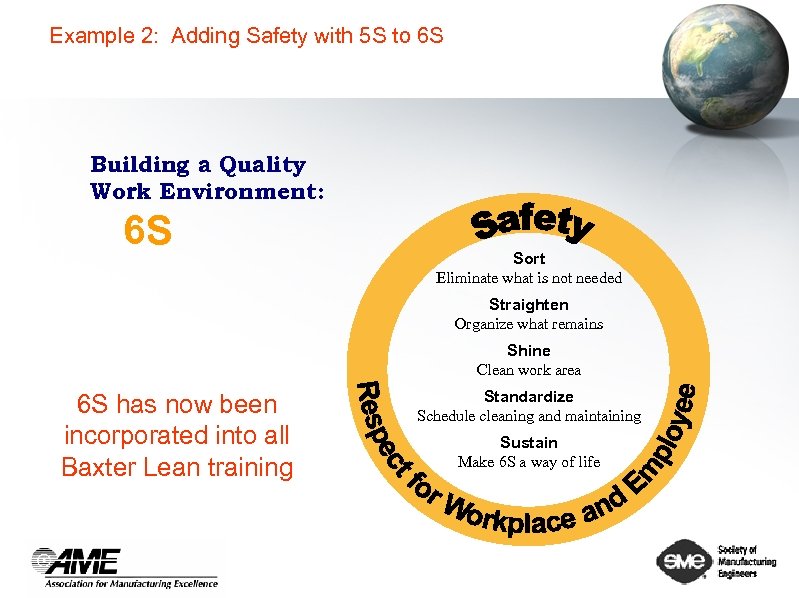

Example 2: Adding Safety with 5 S to 6 S Building a Quality Work Environment: 6 S Sort Eliminate what is not needed Straighten Organize what remains Shine Clean work area 6 S has now been incorporated into all Baxter Lean training Standardize Schedule cleaning and maintaining Sustain Make 6 S a way of life

Example 2: Adding Safety with 5 S to 6 S Building a Quality Work Environment: 6 S Sort Eliminate what is not needed Straighten Organize what remains Shine Clean work area 6 S has now been incorporated into all Baxter Lean training Standardize Schedule cleaning and maintaining Sustain Make 6 S a way of life

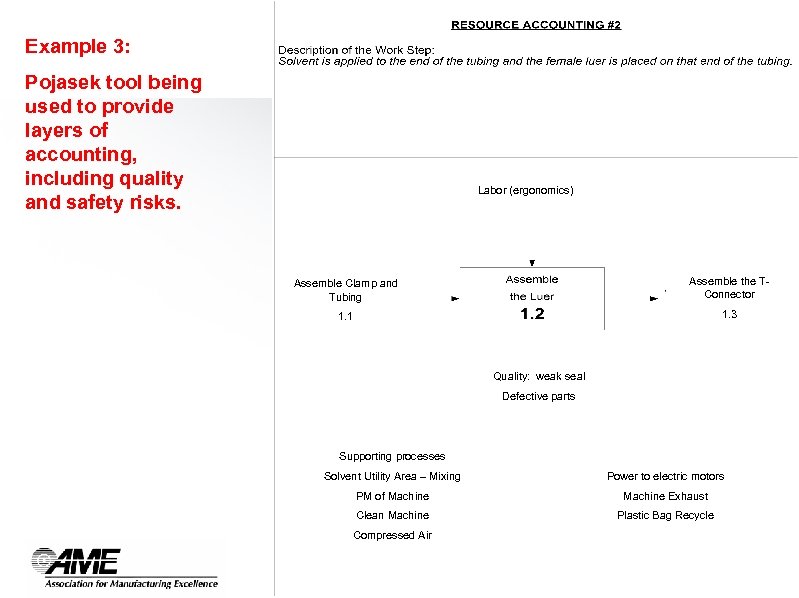

Example 3: Pojasek tool being used to provide layers of accounting, including quality and safety risks. Labor (ergonomics) Assemble Clamp and Tubing Assemble the TConnector 1. 1 1. 3 Quality: weak seal Defective parts Supporting processes Solvent Utility Area – Mixing Power to electric motors PM of Machine Exhaust Clean Machine Plastic Bag Recycle Compressed Air

Example 3: Pojasek tool being used to provide layers of accounting, including quality and safety risks. Labor (ergonomics) Assemble Clamp and Tubing Assemble the TConnector 1. 1 1. 3 Quality: weak seal Defective parts Supporting processes Solvent Utility Area – Mixing Power to electric motors PM of Machine Exhaust Clean Machine Plastic Bag Recycle Compressed Air

Deployment • Began with Baxter’s “LEAN” champion to integrate EHS awareness into his training sessions – True cost of wasted raw materials, water value stream map, importance of including EHS • Training EHS personnel world-wide in LEAN • Selected plants to pilot (1 week) – Target those actively deploying lean – Selected plants for learning (e. g. struggling plants, highperforming plants, different manufacturing types) • Posting completed process maps with metrics – These can be used by other plants for benchmarking

Deployment • Began with Baxter’s “LEAN” champion to integrate EHS awareness into his training sessions – True cost of wasted raw materials, water value stream map, importance of including EHS • Training EHS personnel world-wide in LEAN • Selected plants to pilot (1 week) – Target those actively deploying lean – Selected plants for learning (e. g. struggling plants, highperforming plants, different manufacturing types) • Posting completed process maps with metrics – These can be used by other plants for benchmarking

Learnings so far • Opportunities identified on every line, no matter how simple – Simple act of “learning to see” generates ideas, similar in lean. • Pareto principle holds: 20% of the steps cause 80% of the problems – LEAN, quality, safety, environmental opportunities tend to come together • Process seems to work best at high performing plants. – Culture change may be needed first. Beginning with 6 S and setting environmental metrics (setting baseline, true cost of waste) helps.

Learnings so far • Opportunities identified on every line, no matter how simple – Simple act of “learning to see” generates ideas, similar in lean. • Pareto principle holds: 20% of the steps cause 80% of the problems – LEAN, quality, safety, environmental opportunities tend to come together • Process seems to work best at high performing plants. – Culture change may be needed first. Beginning with 6 S and setting environmental metrics (setting baseline, true cost of waste) helps.

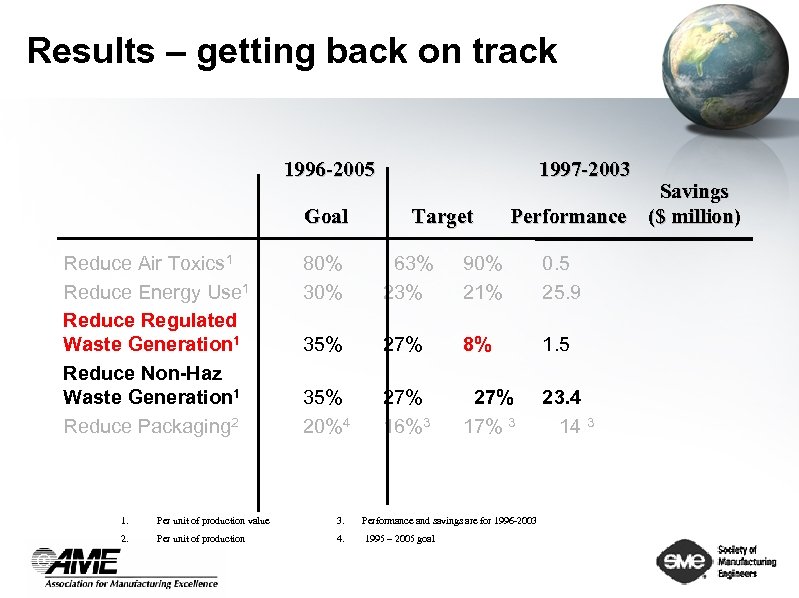

Results – getting back on track 1996 -2005 Goal Reduce Air Toxics 1 Reduce Energy Use 1 Reduce Regulated Waste Generation 1 Reduce Non-Haz Waste Generation 1 Reduce Packaging 2 1997 -2003 Target Savings Performance ($ million) 80% 30% 63% 23% 90% 21% 0. 5 25. 9 35% 27% 8% 1. 5 35% 20%4 27% 16%3 27% 17% 3 23. 4 14 3 1. Per unit of production value 3. Performance and savings are for 1996 -2003 2. Per unit of production 4. 1995 – 2005 goal

Results – getting back on track 1996 -2005 Goal Reduce Air Toxics 1 Reduce Energy Use 1 Reduce Regulated Waste Generation 1 Reduce Non-Haz Waste Generation 1 Reduce Packaging 2 1997 -2003 Target Savings Performance ($ million) 80% 30% 63% 23% 90% 21% 0. 5 25. 9 35% 27% 8% 1. 5 35% 20%4 27% 16%3 27% 17% 3 23. 4 14 3 1. Per unit of production value 3. Performance and savings are for 1996 -2003 2. Per unit of production 4. 1995 – 2005 goal

Still early, but it appears that: • Non-hazardous waste and energy reductions can be achieved with Lean manufacturing ALONE – reductions correspond best with plants active in Lean • But hazardous waste reductions are associated with Lean + Pojasek process mapping and resource accounting – Focus and prioritization on hazardous components likely brought by EHS involvement – Years of work have concentrated on reducing hazardous waste, so that is “high-hanging” fruit • Applying value stream mapping tools to environmental aspects (such as water usage) is promising

Still early, but it appears that: • Non-hazardous waste and energy reductions can be achieved with Lean manufacturing ALONE – reductions correspond best with plants active in Lean • But hazardous waste reductions are associated with Lean + Pojasek process mapping and resource accounting – Focus and prioritization on hazardous components likely brought by EHS involvement – Years of work have concentrated on reducing hazardous waste, so that is “high-hanging” fruit • Applying value stream mapping tools to environmental aspects (such as water usage) is promising

The Future: • EHS and Lean Corporate will continue to train Lean engineers and EHS personnel (target end 2005) • We will continue to modify and improve tools as we learn from plants and other companies • We are now reaching into our supply chain through the Green Supplier Network

The Future: • EHS and Lean Corporate will continue to train Lean engineers and EHS personnel (target end 2005) • We will continue to modify and improve tools as we learn from plants and other companies • We are now reaching into our supply chain through the Green Supplier Network

Green Suppliers Network (GSN) • Partnership between NIST (Department of Commerce), the USEPA, and industry – NIST Manufacturing Extension Partnership (MEP) • Nationwide network of technical assistance centers for industry • Experts in manufacturing efficiency, e. g. LEAN • Focus: increase productivity of US manufacturing base – US Environmental Protection Agency • Regulatory Agency • Focus: protect public health and the environment – Industry • Traditionally regulated by EPA and assisted by NIST • Focus: profitability, cost and risk reduction, productivity and growth

Green Suppliers Network (GSN) • Partnership between NIST (Department of Commerce), the USEPA, and industry – NIST Manufacturing Extension Partnership (MEP) • Nationwide network of technical assistance centers for industry • Experts in manufacturing efficiency, e. g. LEAN • Focus: increase productivity of US manufacturing base – US Environmental Protection Agency • Regulatory Agency • Focus: protect public health and the environment – Industry • Traditionally regulated by EPA and assisted by NIST • Focus: profitability, cost and risk reduction, productivity and growth

How GSN works • USEPA partners with largest manufacturers • Largest manufacturers (e. g. Baxter) choose suppliers and urge them to participate. • Local NIST-MEP sends technical expert(s) to train the supplier in Lean/Clean manufacturing, find opportunities for cost savings, waste and resource reduction and greater efficiency. • Funding comes from NIST, EPA and supplier • All savings stay with the supplier • Overall goal is to reach 80% of the US manufacturing base that typically do not participate in new environmental approaches.

How GSN works • USEPA partners with largest manufacturers • Largest manufacturers (e. g. Baxter) choose suppliers and urge them to participate. • Local NIST-MEP sends technical expert(s) to train the supplier in Lean/Clean manufacturing, find opportunities for cost savings, waste and resource reduction and greater efficiency. • Funding comes from NIST, EPA and supplier • All savings stay with the supplier • Overall goal is to reach 80% of the US manufacturing base that typically do not participate in new environmental approaches.

GSN represents a marriage of pollution prevention (Clean) with core manufacturing (Lean) – which we were trying to do internally! USEPA NIST

GSN represents a marriage of pollution prevention (Clean) with core manufacturing (Lean) – which we were trying to do internally! USEPA NIST

Feedback from Supplier on GSN • • Valuable process Engineer spent one week Examined every aspect of their operations Value stream (lean) map of one process line and developed report helps them focus on greatest impacts and prioritize projects. • 16 opportunities identified: 5 environmental (waste, energy reductions), 15 cost savings (material handling, lean) – One project will eliminate a hazardous solvent entirely.

Feedback from Supplier on GSN • • Valuable process Engineer spent one week Examined every aspect of their operations Value stream (lean) map of one process line and developed report helps them focus on greatest impacts and prioritize projects. • 16 opportunities identified: 5 environmental (waste, energy reductions), 15 cost savings (material handling, lean) – One project will eliminate a hazardous solvent entirely.

Key Messages • Lean has helped us reduce wasted resources (energy, raw material waste and trash) • But lean must be modified or combined with other tools to see benefits in some environmentally significant aspects (hazardous waste, chemicals, water usage) • We have had some success with: – modifying Value Stream Mapping tools to address environmental aspects, such as water – Pojasek Process Mapping / Resource accounting – which aligns well with, and builds upon, Lean • It’s an on-going learning experience!!

Key Messages • Lean has helped us reduce wasted resources (energy, raw material waste and trash) • But lean must be modified or combined with other tools to see benefits in some environmentally significant aspects (hazardous waste, chemicals, water usage) • We have had some success with: – modifying Value Stream Mapping tools to address environmental aspects, such as water – Pojasek Process Mapping / Resource accounting – which aligns well with, and builds upon, Lean • It’s an on-going learning experience!!

For More Information • jenni_cawein@baxter. com • For information on Process Mapping and Resource Accounting: www. pojasek-associates. com or email rpojasek @sprynet. com • For information on the Green Supplier Network: Contact Kristin Pierre, Pierre. Kristin@epamail. epa. gov or Alex Folk, Alex. Folk@nist. gov

For More Information • jenni_cawein@baxter. com • For information on Process Mapping and Resource Accounting: www. pojasek-associates. com or email rpojasek @sprynet. com • For information on the Green Supplier Network: Contact Kristin Pierre, Pierre. Kristin@epamail. epa. gov or Alex Folk, Alex. Folk@nist. gov