90962b56fd563fa7a1c7ee0bf882560d.ppt

- Количество слайдов: 18

Trends in supplier selection In the past: supplier selection should be purchasing’s domain Now: necessary to bring together organizational resources outside and inside of the supply area to achieve sound supplier choices – fewer suppliers – long-term contracts – EDI – continuing improvement in quality, price, and services

Trends in supplier selection In the past: supplier selection should be purchasing’s domain Now: necessary to bring together organizational resources outside and inside of the supply area to achieve sound supplier choices – fewer suppliers – long-term contracts – EDI – continuing improvement in quality, price, and services

Fewer suppliers and closer relationships • Extensive communication and cooperation over a long period of time • New suppliers are expensive, and take a period of learning • Going for the lowest cost suppliers? Supply link Internal link Customer link

Fewer suppliers and closer relationships • Extensive communication and cooperation over a long period of time • New suppliers are expensive, and take a period of learning • Going for the lowest cost suppliers? Supply link Internal link Customer link

Make or buy? • Issues: – Increasing global competition – Pressure to reduce costs – Downsizing – Focus on the firm’s core competencies Moving toward outsourcing!

Make or buy? • Issues: – Increasing global competition – Pressure to reduce costs – Downsizing – Focus on the firm’s core competencies Moving toward outsourcing!

Why make? • Capture all the added-value • Full control • Purchase is limited to raw material • Backward integration and full ownership

Why make? • Capture all the added-value • Full control • Purchase is limited to raw material • Backward integration and full ownership

Why buy? • Flexibility • Focus on corporate strength • Closeness to customers • Emphasis on productivity and competitiveness • Can you excel in all aspects in manufacturing and services?

Why buy? • Flexibility • Focus on corporate strength • Closeness to customers • Emphasis on productivity and competitiveness • Can you excel in all aspects in manufacturing and services?

Decision on outsourcing • Manufacturing: • Services:

Decision on outsourcing • Manufacturing: • Services:

Reasons for make instead of buy • The quantity is too small and no supplier is interested in providing the goods • Quality requirements may be so unusual as to require special processing methods that suppliers cannot provide • To preserve technological secrets • To obtain a lower cost • To take advantage of idle equipment or labor

Reasons for make instead of buy • The quantity is too small and no supplier is interested in providing the goods • Quality requirements may be so unusual as to require special processing methods that suppliers cannot provide • To preserve technological secrets • To obtain a lower cost • To take advantage of idle equipment or labor

Reasons for make instead of buy • To ensure steady running of the corporation’s own facilities; leaving the suppliers to bear the burden of fluctuation in demand • To avoid single-source dependency • Political issues • Emotional reasons

Reasons for make instead of buy • To ensure steady running of the corporation’s own facilities; leaving the suppliers to bear the burden of fluctuation in demand • To avoid single-source dependency • Political issues • Emotional reasons

Reasons for buying outside • The organization may lack administrative or technical experience in the production of the items or services • Limited capacity • Supplier has a reputation for their components which are demanded by the customers • The challenge of maintaining a long-term technological and economical viability for a non-core activity • A decision to make is difficult to reverse

Reasons for buying outside • The organization may lack administrative or technical experience in the production of the items or services • Limited capacity • Supplier has a reputation for their components which are demanded by the customers • The challenge of maintaining a long-term technological and economical viability for a non-core activity • A decision to make is difficult to reverse

Reasons for buying outside • Difficult to justify the true long-term costs of the make decision • More flexibility in selecting sources and substitute items • Firms have to determine where the value added activities are and how to distinguish themselves • Superior supply management expertise • Less overhead

Reasons for buying outside • Difficult to justify the true long-term costs of the make decision • More flexibility in selecting sources and substitute items • Firms have to determine where the value added activities are and how to distinguish themselves • Superior supply management expertise • Less overhead

The gray zone of make or buy • To what extent do I buy or make?

The gray zone of make or buy • To what extent do I buy or make?

Control involved • Cost control – Negotiation of a reasonable cost – Proper choice of the contract type – Imposed incentives • Schedule control – Develop a good master schedule that covers all necessary activities – Good report system and recovery programs

Control involved • Cost control – Negotiation of a reasonable cost – Proper choice of the contract type – Imposed incentives • Schedule control – Develop a good master schedule that covers all necessary activities – Good report system and recovery programs

Control involved • Technical control – The end product conforms to the performance requirements • Configuration control – All changes are documented – Essential to after-market services and spares

Control involved • Technical control – The end product conforms to the performance requirements • Configuration control – All changes are documented – Essential to after-market services and spares

Outsourcing • Urge to downsize and focus on value added activities and core competencies • Outsource entire function or elements – What should be kept in-house? • IS function outsource market: $50 billion • Contract logistics industry: $50 billion in annual revenue in 2000

Outsourcing • Urge to downsize and focus on value added activities and core competencies • Outsource entire function or elements – What should be kept in-house? • IS function outsource market: $50 billion • Contract logistics industry: $50 billion in annual revenue in 2000

Outsourcing in logistics • • • Transportation deregulation Focus on core competencies Reduction in inventory Enhanced logistics management computer programs Just-in-time requires highly accurate delivery and information

Outsourcing in logistics • • • Transportation deregulation Focus on core competencies Reduction in inventory Enhanced logistics management computer programs Just-in-time requires highly accurate delivery and information

Drawbacks of outsourcing • Human issues (layoffs) • Union relationships • Control issues (partnership, strategic alliance)

Drawbacks of outsourcing • Human issues (layoffs) • Union relationships • Control issues (partnership, strategic alliance)

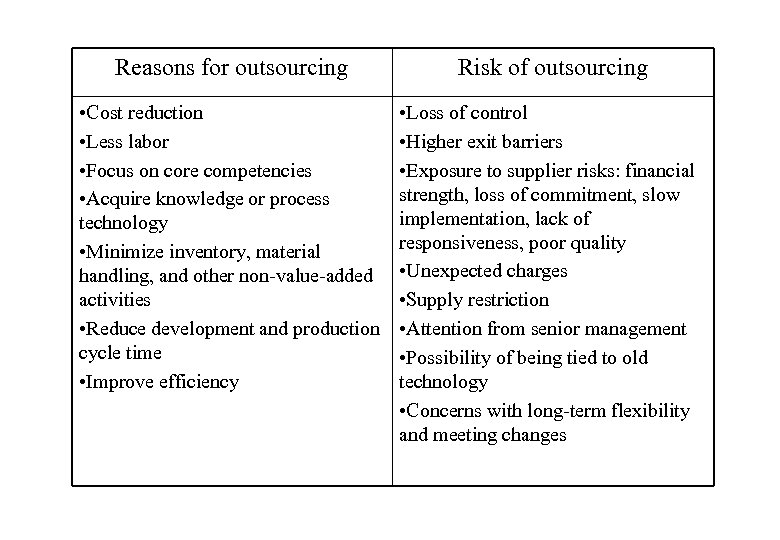

Reasons for outsourcing Risk of outsourcing • Cost reduction • Less labor • Focus on core competencies • Acquire knowledge or process technology • Minimize inventory, material handling, and other non-value-added activities • Reduce development and production cycle time • Improve efficiency • Loss of control • Higher exit barriers • Exposure to supplier risks: financial strength, loss of commitment, slow implementation, lack of responsiveness, poor quality • Unexpected charges • Supply restriction • Attention from senior management • Possibility of being tied to old technology • Concerns with long-term flexibility and meeting changes

Reasons for outsourcing Risk of outsourcing • Cost reduction • Less labor • Focus on core competencies • Acquire knowledge or process technology • Minimize inventory, material handling, and other non-value-added activities • Reduce development and production cycle time • Improve efficiency • Loss of control • Higher exit barriers • Exposure to supplier risks: financial strength, loss of commitment, slow implementation, lack of responsiveness, poor quality • Unexpected charges • Supply restriction • Attention from senior management • Possibility of being tied to old technology • Concerns with long-term flexibility and meeting changes

What’s to be outsourced? • • Human resource Data entry Training Maintenance Manufacturing R&D Software development Web function

What’s to be outsourced? • • Human resource Data entry Training Maintenance Manufacturing R&D Software development Web function