fff83d9e319acf6262bb93d5ca97cc79.ppt

- Количество слайдов: 19

Trendejä maailmalta Teollinen tuotanto 3 D tulostus, robotiikka, uudet tuotantotavat ja materiaalit Pirkanmaan ennakointipalvelu/Trendexplorer

Trendejä maailmalta § Kalvosarjassa mikrotrendejä eri puolilta maapalloa liittyen ko. aihepiiriin § Sisältää lyhyen kuvauksen trendistä sekä linkin aihetta käsittelevälle nettisivulle § Aineisto on kerätty Trendexplorer-palvelusta, jossa yli 17 000 mikrotrendiä usealta eri alalta § Tässä kalvosarjassa käytetyt trendit ovat Pirkanmaan ennakointipalvelu –hankkeen valitsemia § Käytä aineistoa inspiraation lähteenä esim. uusien tuotteiden ja palveluiden suunnittelussa § Materiaalin kaupallinen käyttö on kielletty Pirkanmaan ennakointipalvelu/Trendexplorer

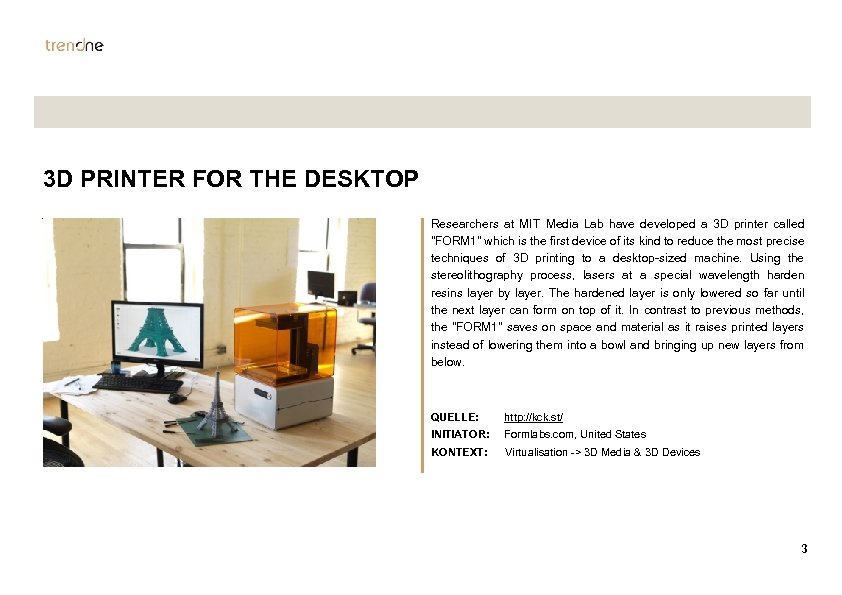

3 D PRINTER FOR THE DESKTOP Researchers at MIT Media Lab have developed a 3 D printer called "FORM 1" which is the first device of its kind to reduce the most precise techniques of 3 D printing to a desktop-sized machine. Using the stereolithography process, lasers at a special wavelength harden resins layer by layer. The hardened layer is only lowered so far until the next layer can form on top of it. In contrast to previous methods, the "FORM 1" saves on space and material as it raises printed layers instead of lowering them into a bowl and bringing up new layers from below. QUELLE: http: //kck. st/ INITIATOR: Formlabs. com, United States KONTEXT: Virtualisation -> 3 D Media & 3 D Devices 3

MANAGING 3 D PRINTING VIA THE INTERNET Git. Hub, the popular platform for open source projects and 3 D prints, has launched its own solution for easy 3 D printing via the internet. With this system, it is no longer necessary for laptops or memory cards to be connected to the Makerbot 3 D printer during the whole printing process. Instead, the files are sent via a website to a server which manages the prints and requests webcam shots to monitor the process. QUELLE: http: //www. 3 ders. org/ INITIATOR: Git. Hub, United States KONTEXT: Timeless Time -> Convenience Services Virtualisation -> 3 D Media & 3 D Devices 4

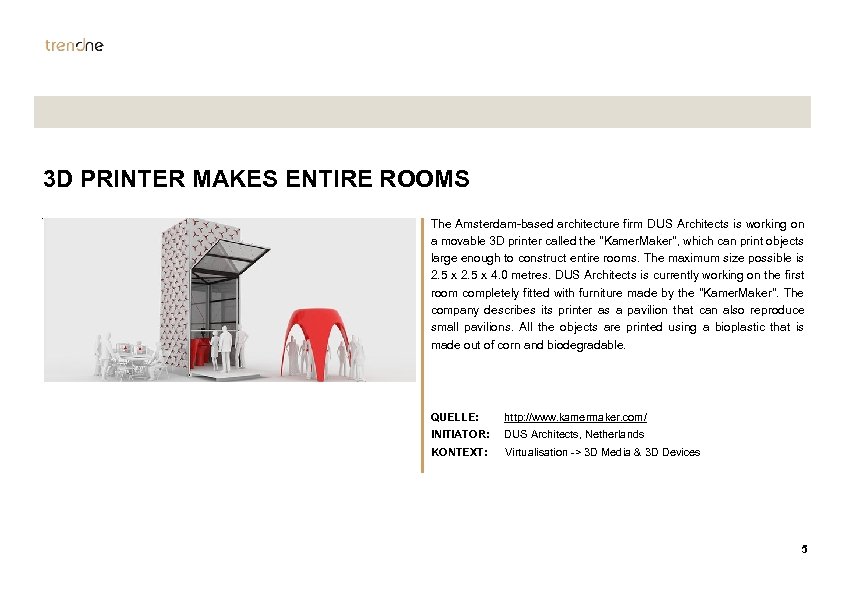

3 D PRINTER MAKES ENTIRE ROOMS The Amsterdam-based architecture firm DUS Architects is working on a movable 3 D printer called the "Kamer. Maker", which can print objects large enough to construct entire rooms. The maximum size possible is 2. 5 x 4. 0 metres. DUS Architects is currently working on the first room completely fitted with furniture made by the "Kamer. Maker". The company describes its printer as a pavilion that can also reproduce small pavilions. All the objects are printed using a bioplastic that is made out of corn and biodegradable. QUELLE: http: //www. kamermaker. com/ INITIATOR: DUS Architects, Netherlands KONTEXT: Virtualisation -> 3 D Media & 3 D Devices 5

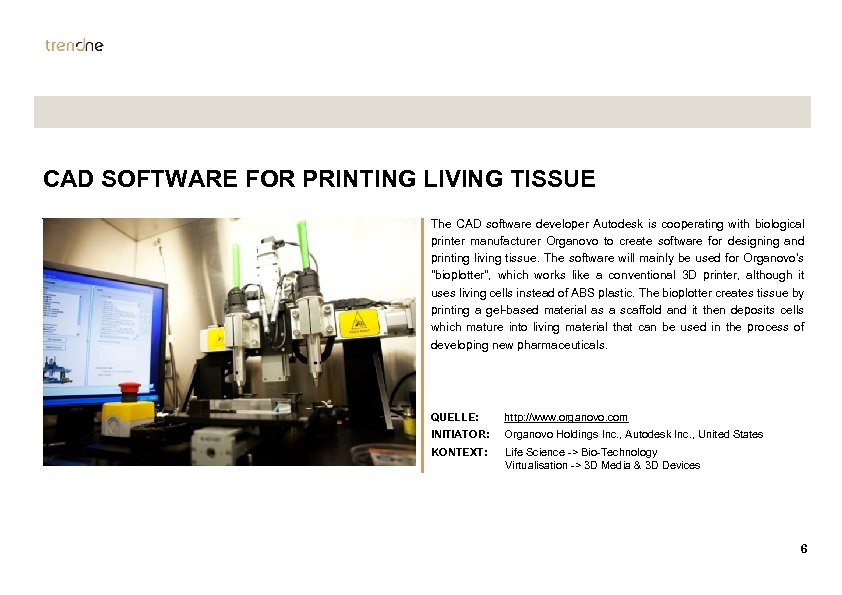

CAD SOFTWARE FOR PRINTING LIVING TISSUE The CAD software developer Autodesk is cooperating with biological printer manufacturer Organovo to create software for designing and printing living tissue. The software will mainly be used for Organovo's "bioplotter", which works like a conventional 3 D printer, although it uses living cells instead of ABS plastic. The bioplotter creates tissue by printing a gel-based material as a scaffold and it then deposits cells which mature into living material that can be used in the process of developing new pharmaceuticals. QUELLE: http: //www. organovo. com INITIATOR: Organovo Holdings Inc. , Autodesk Inc. , United States KONTEXT: Life Science -> Bio-Technology Virtualisation -> 3 D Media & 3 D Devices 6

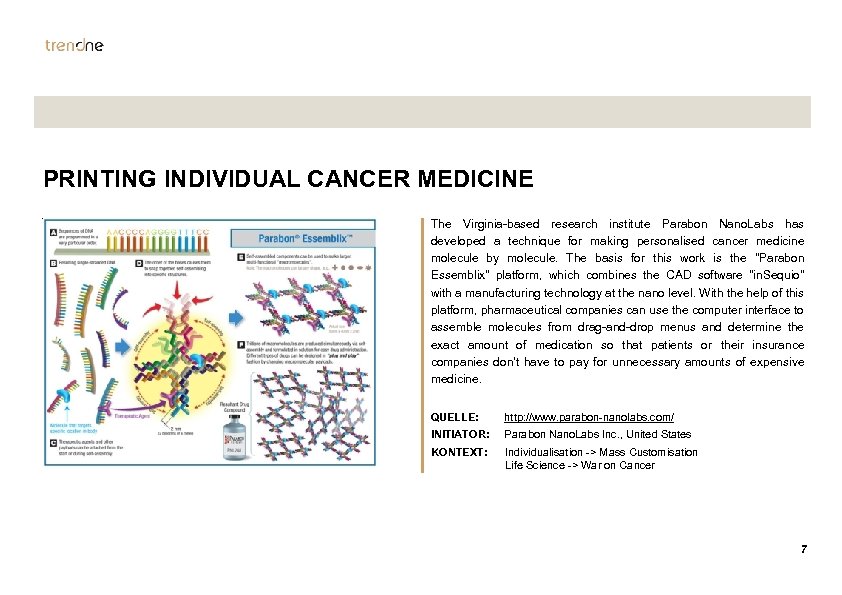

PRINTING INDIVIDUAL CANCER MEDICINE The Virginia-based research institute Parabon Nano. Labs has developed a technique for making personalised cancer medicine molecule by molecule. The basis for this work is the "Parabon Essemblix" platform, which combines the CAD software "in. Sequio" with a manufacturing technology at the nano level. With the help of this platform, pharmaceutical companies can use the computer interface to assemble molecules from drag-and-drop menus and determine the exact amount of medication so that patients or their insurance companies don't have to pay for unnecessary amounts of expensive medicine. QUELLE: http: //www. parabon-nanolabs. com/ INITIATOR: Parabon Nano. Labs Inc. , United States KONTEXT: Individualisation -> Mass Customisation Life Science -> War on Cancer 7

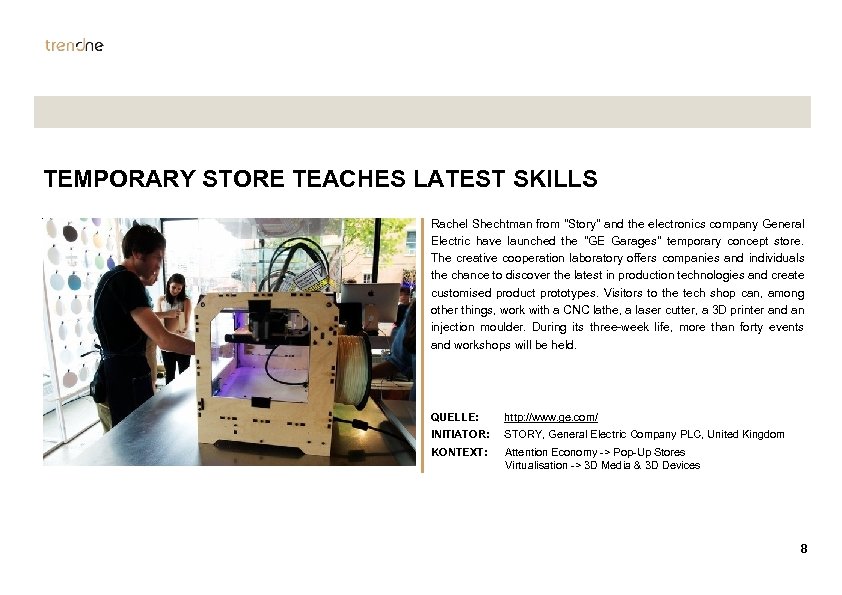

TEMPORARY STORE TEACHES LATEST SKILLS Rachel Shechtman from "Story" and the electronics company General Electric have launched the "GE Garages" temporary concept store. The creative cooperation laboratory offers companies and individuals the chance to discover the latest in production technologies and create customised product prototypes. Visitors to the tech shop can, among other things, work with a CNC lathe, a laser cutter, a 3 D printer and an injection moulder. During its three-week life, more than forty events and workshops will be held. QUELLE: http: //www. ge. com/ INITIATOR: STORY, General Electric Company PLC, United Kingdom KONTEXT: Attention Economy -> Pop-Up Stores Virtualisation -> 3 D Media & 3 D Devices 8

EXPRESSIVE ROBOT AS FACTORY WORKER Vanguard Plastics is now using an industrial robot developed by Rethink Robotics called "Baxter" in its factory in Connecticut and thus hopes to make production in the USA more competitive. "Baxter" is approx. two metres tall, weighs 300 pounds and can be programmed by any employee without needing specialist skills. The integrated screen represents the robot's face, enabling it to make simple expressions to let colleagues know if it is performing its work correctly or if there is a technical problem. QUELLE: http: //www. heartlandrobotics. com/ INITIATOR: Rethink Robotics, Vanguard Plastics, United States KONTEXT: Life Science -> Robotics 9

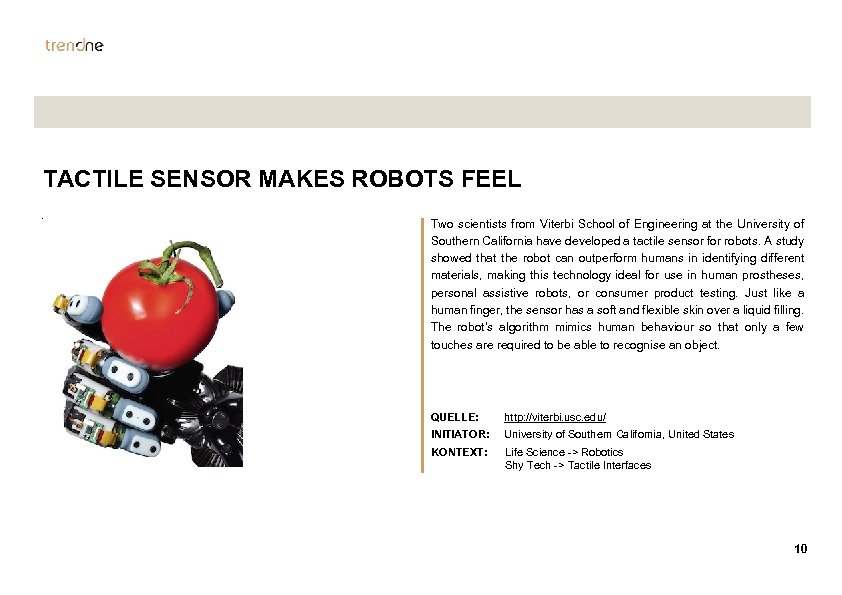

TACTILE SENSOR MAKES ROBOTS FEEL Two scientists from Viterbi School of Engineering at the University of Southern California have developed a tactile sensor for robots. A study showed that the robot can outperform humans in identifying different materials, making this technology ideal for use in human prostheses, personal assistive robots, or consumer product testing. Just like a human finger, the sensor has a soft and flexible skin over a liquid filling. The robot's algorithm mimics human behaviour so that only a few touches are required to be able to recognise an object. QUELLE: http: //viterbi. usc. edu/ INITIATOR: University of Southern California, United States KONTEXT: Life Science -> Robotics Shy Tech -> Tactile Interfaces 10

SLEEVES MEASURE WORKPLACE EFFICIENCY Researchers at Germany's Fraunhofer Institute for Factory Operation and Automation have developed sleeves that can automatically time the actions of workers in factories where products are mass-produced. The sleeves are fitted with three small sensors and are worn by the workers. The sensors are located on the upper and lower arm, and the hand. They measure the acceleration and angular velocities of the arms and hands. The resulting data is then analysed by software that works out how much time is required for the individual work activities. QUELLE: http: //www. fraunhofer. de/ INITIATOR: Fraunhofer-Institut für Fabrikbetrieb und -automatisierung IFF, Germany Security & Surveillance Systems Homing -> KONTEXT: Shy Tech -> Smart Sensors 11

PLATFORM PROMOTES FACTORIES FOR FASHION BUSINESS The New York company Maker's Row wants to simplify the manufacturing process in the fashion industry and connects both small and medium-sized fashion firms to industry-specific factories and suppliers across the United States. From its own platform, Maker's Row offers a database with the profiles of individual manufacturers that designers can get to know via a video tour and a summary of the production process in six easy steps. The fashion labels can then save the profiles of potential manufacturers so that they can contact them and rate them whenever they want. QUELLE: http: //makersrow. com/ INITIATOR: Maker’s Row Inc. , United States KONTEXT: Knowledge Society -> Information Quality Sustainability -> Information Transparency 12

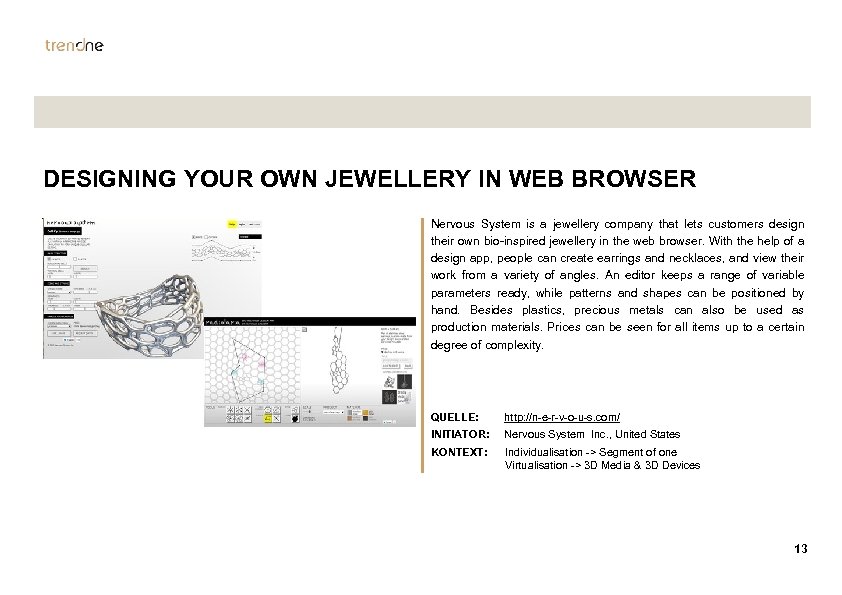

DESIGNING YOUR OWN JEWELLERY IN WEB BROWSER Nervous System is a jewellery company that lets customers design their own bio-inspired jewellery in the web browser. With the help of a design app, people can create earrings and necklaces, and view their work from a variety of angles. An editor keeps a range of variable parameters ready, while patterns and shapes can be positioned by hand. Besides plastics, precious metals can also be used as production materials. Prices can be seen for all items up to a certain degree of complexity. QUELLE: http: //n-e-r-v-o-u-s. com/ INITIATOR: Nervous System Inc. , United States KONTEXT: Individualisation -> Segment of one Virtualisation -> 3 D Media & 3 D Devices 13

GOURMET BURGERS FROM AUTOMATED PRODUCTION Frying burgers can sometimes require plenty of time and staff, but this is not the case with the fully automated burger machine from Momentum Machines. The designers hope that the money saved will be used to invest in top-shelf ingredients for the machine's inputs. After placing an order, the vegetables are chopped up in the machine. The ordered meat is added in the right portion and fried. The machine is capable of producing an average of 360 burgers per hour, which are packed and made available for immediate consumption. QUELLE: http: //momentummachines. com/ INITIATOR: Momentum Machines, United States KONTEXT: Life Science -> Robotics Timeless Time -> Fast Casual Dining 14

PAPER STOPS FOOD FROM ROTTING The start-up Fenugreen has produced paper called "Fresh Paper" that prevents food from going mouldy. The technology was developed by Kavita Shukla and involves adding a mixture of spices, including fenugreek, to the paper. This inhibits bacterial and fungal growth, as well as the enzymes that cause fruit to over-ripen. Small squares of spice-infused paper can extend the shelf life of produce up to four times longer than usual. QUELLE: http: //www. fenugreen. com/ INITIATOR: Fenugreen LLC, United States KONTEXT: Shy Tech -> Advanced & Smart Materials Sustainability -> Smart Basic 15

MAKING BIOPLASTICS FROM WOOD REMAINS The Fraunhofer Society is opening a testing facility in Leuna, Germany, to search for methods for making oil-based products from renewable resources. The researchers there want to manufacture plastics from carbohydrates. The problem with this method was always the fact that carbohydrates are mostly contained in food products. The researchers have therefore developed technology in which wood remains from paper production are used instead of sugar or starch. Cellulose can be extracted from the wood waste and used as the raw material for bioplastics. QUELLE: http: //www. fraunhofer. de/ INITIATOR: Fraunhofer-Zentrum für Chemisch-Biotechnologische Prozesse (CPB), Germany Shy Tech -> Advanced & Smart Materials KONTEXT: Sustainability -> Economising 16

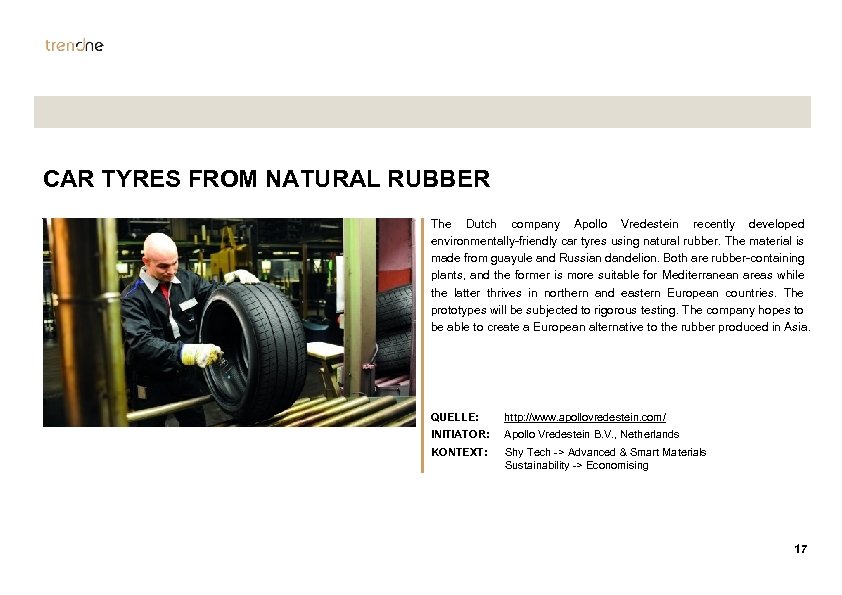

CAR TYRES FROM NATURAL RUBBER The Dutch company Apollo Vredestein recently developed environmentally-friendly car tyres using natural rubber. The material is made from guayule and Russian dandelion. Both are rubber-containing plants, and the former is more suitable for Mediterranean areas while the latter thrives in northern and eastern European countries. The prototypes will be subjected to rigorous testing. The company hopes to be able to create a European alternative to the rubber produced in Asia. QUELLE: http: //www. apollovredestein. com/ INITIATOR: Apollo Vredestein B. V. , Netherlands KONTEXT: Shy Tech -> Advanced & Smart Materials Sustainability -> Economising 17

NANOMATERIAL MAKES MORE EFFICIENT CARS POSSIBLE Rhode Island-based Nano. Steel has unveiled a nano-structure alloy that is significantly lighter than materials currently used in car chassis, which would make them much more fuel efficient. The material also meets safety standards regarding strength and durability, and should come out on the market in 2013. It is available in three different strengths, which possess an elongation performance of 35, 30 and 15 percent respectively. Thanks to its natural pliancy, it can also be coldformed, making it cost effective. QUELLE: http: //www. nanosteelco. com/ INITIATOR: The Nano. Steel Company Inc. , United States KONTEXT: Life Science -> Nanotechnology Sustainability -> Economising 18

CONTACT BLOG. TRENDONE. COM WWW. TRENDEXPLORER. COM WWW. FACEBOOK. COM/TRENDONE WWW. TWITTER. COM/TRENDONE TREND ONE GMBH HAMBURG / GERMANY TREND ONE GMBH BERLIN / GERMANY TREND ONE GMBH VIENNA / AUSTRIA GASSTRASSE 2 22761 HAMBURG BRUNNENSTRASSE 37 10115 BERLIN SPITTELBERGGASSE 3/6 1070 WIEN TEL +49 (0)40 – 238038 – 33 FAX +49 (0)40 – 238038 – 36 TEL +49 (0)30 – 509148 – 56 FAX +49 (0)30 – 509148 – 60 TEL +43 (0)1 – 5230500 FAX +43 (0)1 – 5230500 – 15 INFO@TRENDONE. COM WWW. TRENDONE. COM DISCLAIMER 2013 COPYRIGHT ALL RIGHTS RESERVED. THE DOCUMENTED TRENDS IN THIS PRESENTATION AND TRENDS THESES ARE INTELLECTUAL PROPERTY OF TRENDONE GMBH AND ARE SUBJECT TO THE APPLICABLE COPYRIGHT LAWS. THE PICTURES ARE USED ONLY FOR RESEARCH AND ILLUSTRATION PURPOSES. THEY ARE NOT FREE FOR PUBLICATION.

fff83d9e319acf6262bb93d5ca97cc79.ppt