7c0c6968f5eaf6de616235946e3c94d3.ppt

- Количество слайдов: 27

Treatment of Slaughterhouse Wastewater Mike Lawrence NDSU Fall 2006

Treatment of Slaughterhouse Wastewater Mike Lawrence NDSU Fall 2006

Overview u Challenges u Wastewater Parameters u Treatment Options u Process Modifications u Typical On-site Treatment Options u Design Problem

Overview u Challenges u Wastewater Parameters u Treatment Options u Process Modifications u Typical On-site Treatment Options u Design Problem

Challenges of Slaughterhouse Wastewater u Wastewater contains large amounts of blood, fat, and hair u Wastewater is above municipal standards which leaves two options; on site treatment or pay to be treated elsewhere u On site treatment with low capital and maintenance costs is desirable

Challenges of Slaughterhouse Wastewater u Wastewater contains large amounts of blood, fat, and hair u Wastewater is above municipal standards which leaves two options; on site treatment or pay to be treated elsewhere u On site treatment with low capital and maintenance costs is desirable

Wastewater Parameters u BOD approx. 1, 000 to 4, 000 mg/L u COD approx. 2, 000 to 10, 000 mg/L u SS approx. 200 to 1, 500 mg/L u High Oil and Grease content u Possible high chloride content from salting skins

Wastewater Parameters u BOD approx. 1, 000 to 4, 000 mg/L u COD approx. 2, 000 to 10, 000 mg/L u SS approx. 200 to 1, 500 mg/L u High Oil and Grease content u Possible high chloride content from salting skins

Treatment Options Discharge to sewer to be treated by municipal treatment plant u Land application of wastewater for irrigation u Reduce amount of wastewater and/or concentrations with the wastewater by changing the processes u On site Treatment u – Flow Equalization, Screening, Dissolved Air Flotation, Primary Sedimentation – Aerobic Treatment – Anaerobic Treatment

Treatment Options Discharge to sewer to be treated by municipal treatment plant u Land application of wastewater for irrigation u Reduce amount of wastewater and/or concentrations with the wastewater by changing the processes u On site Treatment u – Flow Equalization, Screening, Dissolved Air Flotation, Primary Sedimentation – Aerobic Treatment – Anaerobic Treatment

In-Plant Modifications to Reduce Pollution Main goal should be to prevent product from entering the waste stream and using the least amount of water possible u Reduce the amount of water used, saves money in two ways u Use high pressure and just enough u Proper detergents u Lower volume of water helps equipment u Reuse as much water as possible u

In-Plant Modifications to Reduce Pollution Main goal should be to prevent product from entering the waste stream and using the least amount of water possible u Reduce the amount of water used, saves money in two ways u Use high pressure and just enough u Proper detergents u Lower volume of water helps equipment u Reuse as much water as possible u

Line Separation u Separating the various waste streams as much as possible u Sanitary lines should be discharged directly to the city sewer u Grease waste streams and non grease waste streams can help reduce treatment costs u Separate Blood line

Line Separation u Separating the various waste streams as much as possible u Sanitary lines should be discharged directly to the city sewer u Grease waste streams and non grease waste streams can help reduce treatment costs u Separate Blood line

Blood Recovery Blood has ultimate BOD of 405, 000 mg/L u One head of cattle contains 49 lbs. of blood which equals 10 lbs. BOD, compared to 0. 2 lbs. discharged person per day u All blood should be recovered in a separate line draining to a tank u Blood is then dried, commonly a continuous drier is used u Profitable end product u

Blood Recovery Blood has ultimate BOD of 405, 000 mg/L u One head of cattle contains 49 lbs. of blood which equals 10 lbs. BOD, compared to 0. 2 lbs. discharged person per day u All blood should be recovered in a separate line draining to a tank u Blood is then dried, commonly a continuous drier is used u Profitable end product u

Stockpen Area u Stockpen waste and other manure should be hauled away as a solid u Cleaned periodically with as little water as possible u Ideally this water would go to a separate tank u From the tank it would be emptied into a truck and land applied

Stockpen Area u Stockpen waste and other manure should be hauled away as a solid u Cleaned periodically with as little water as possible u Ideally this water would go to a separate tank u From the tank it would be emptied into a truck and land applied

On-Site Treatment u Costs of treating on site or letting the municipality treat the waste should calculated u Maintenance and operation should be also put into cost analysis u Flow equalization is usually a very good first step in on-site treatment

On-Site Treatment u Costs of treating on site or letting the municipality treat the waste should calculated u Maintenance and operation should be also put into cost analysis u Flow equalization is usually a very good first step in on-site treatment

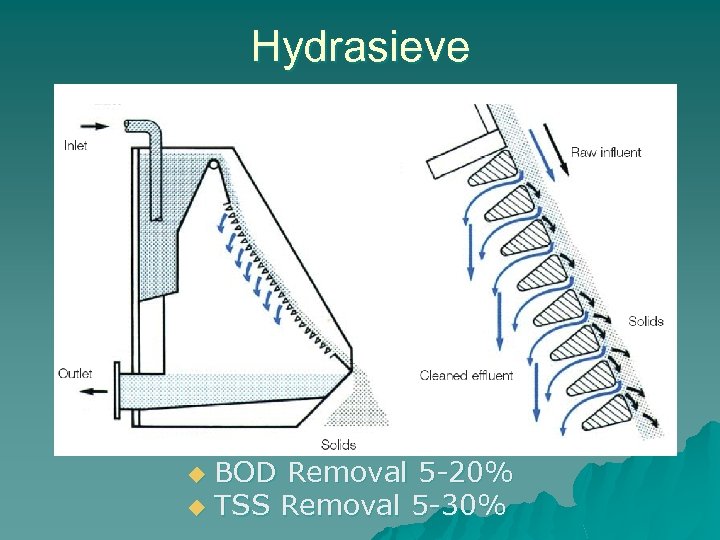

Hydrasieve BOD Removal 5 -20% u TSS Removal 5 -30% u

Hydrasieve BOD Removal 5 -20% u TSS Removal 5 -30% u

Hydrasieve Width Height Capacity Estimated (ft) (gpm) Price 2 5 75 $5, 200 3. 5 5 150 $6, 400 4. 5 7 300 $8, 000 5. 5 7 400 $10, 000 6. 5 7 500 $12, 000 7 7. 3 1000 $20, 000 14 7. 3 2000 $40, 000 21 7. 3 3000 $60, 000 28 7. 3 4000 $80, 000 35 7. 3 5000 $100, 000

Hydrasieve Width Height Capacity Estimated (ft) (gpm) Price 2 5 75 $5, 200 3. 5 5 150 $6, 400 4. 5 7 300 $8, 000 5. 5 7 400 $10, 000 6. 5 7 500 $12, 000 7 7. 3 1000 $20, 000 14 7. 3 2000 $40, 000 21 7. 3 3000 $60, 000 28 7. 3 4000 $80, 000 35 7. 3 5000 $100, 000

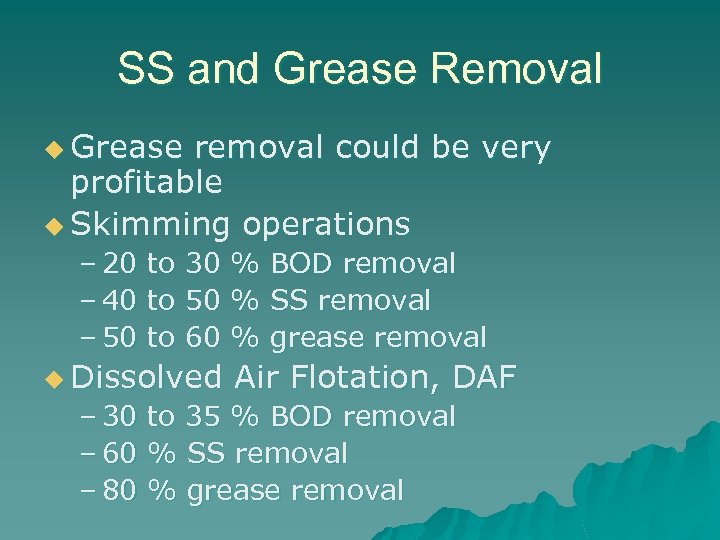

SS and Grease Removal u Grease removal could be very profitable u Skimming operations – 20 to 30 % BOD removal – 40 to 50 % SS removal – 50 to 60 % grease removal u Dissolved – 30 – 60 – 80 Air Flotation, DAF to 35 % BOD removal % SS removal % grease removal

SS and Grease Removal u Grease removal could be very profitable u Skimming operations – 20 to 30 % BOD removal – 40 to 50 % SS removal – 50 to 60 % grease removal u Dissolved – 30 – 60 – 80 Air Flotation, DAF to 35 % BOD removal % SS removal % grease removal

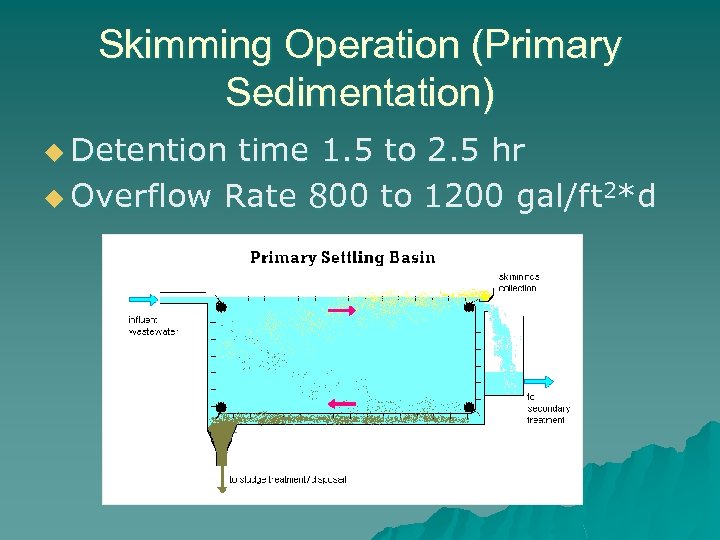

Skimming Operation (Primary Sedimentation) u Detention time 1. 5 to 2. 5 hr u Overflow Rate 800 to 1200 gal/ft 2*d

Skimming Operation (Primary Sedimentation) u Detention time 1. 5 to 2. 5 hr u Overflow Rate 800 to 1200 gal/ft 2*d

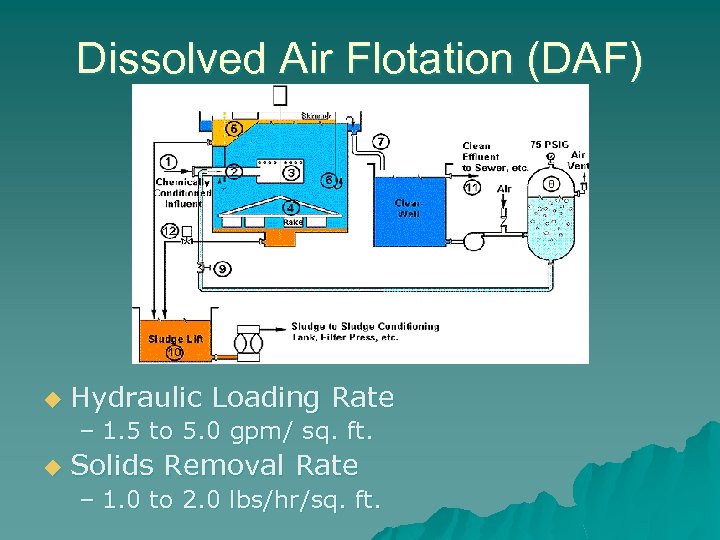

Dissolved Air Flotation (DAF) u Hydraulic Loading Rate – 1. 5 to 5. 0 gpm/ sq. ft. u Solids Removal Rate – 1. 0 to 2. 0 lbs/hr/sq. ft.

Dissolved Air Flotation (DAF) u Hydraulic Loading Rate – 1. 5 to 5. 0 gpm/ sq. ft. u Solids Removal Rate – 1. 0 to 2. 0 lbs/hr/sq. ft.

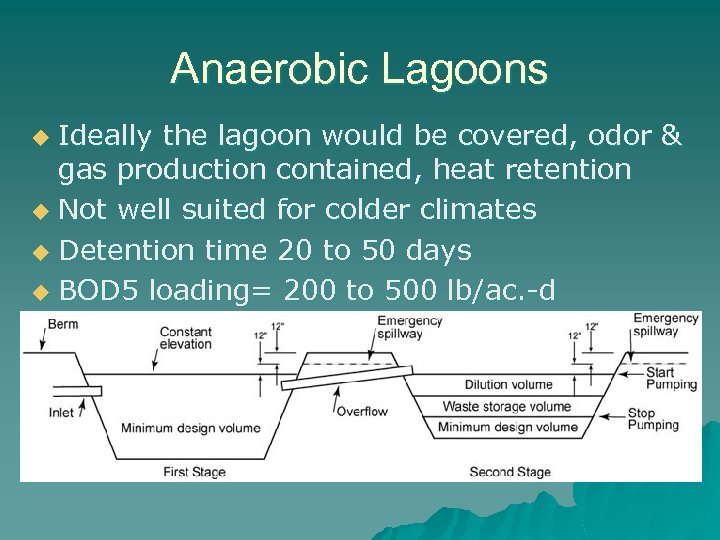

Anaerobic Lagoons Ideally the lagoon would be covered, odor & gas production contained, heat retention u Not well suited for colder climates u Detention time 20 to 50 days u BOD 5 loading= 200 to 500 lb/ac. -d u

Anaerobic Lagoons Ideally the lagoon would be covered, odor & gas production contained, heat retention u Not well suited for colder climates u Detention time 20 to 50 days u BOD 5 loading= 200 to 500 lb/ac. -d u

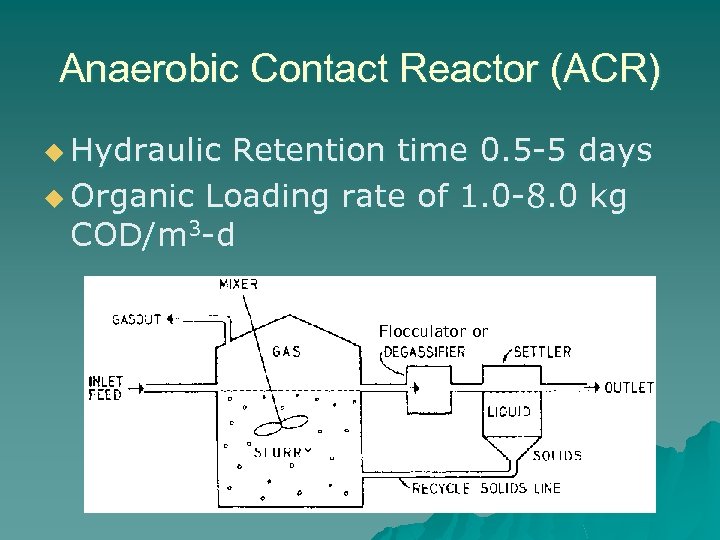

Anaerobic Contact Reactor (ACR) u Hydraulic Retention time 0. 5 -5 days u Organic Loading rate of 1. 0 -8. 0 kg COD/m 3 -d Flocculator or

Anaerobic Contact Reactor (ACR) u Hydraulic Retention time 0. 5 -5 days u Organic Loading rate of 1. 0 -8. 0 kg COD/m 3 -d Flocculator or

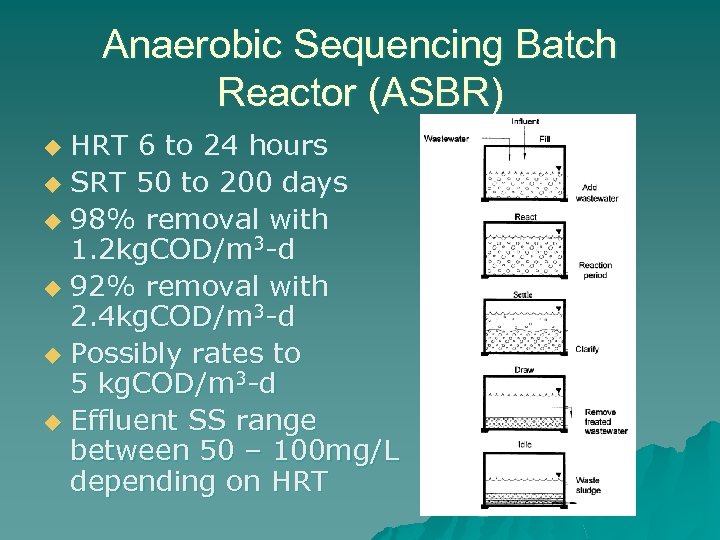

Anaerobic Sequencing Batch Reactor (ASBR) HRT 6 to 24 hours u SRT 50 to 200 days u 98% removal with 1. 2 kg. COD/m 3 -d u 92% removal with 2. 4 kg. COD/m 3 -d u Possibly rates to 5 kg. COD/m 3 -d u Effluent SS range between 50 – 100 mg/L depending on HRT u

Anaerobic Sequencing Batch Reactor (ASBR) HRT 6 to 24 hours u SRT 50 to 200 days u 98% removal with 1. 2 kg. COD/m 3 -d u 92% removal with 2. 4 kg. COD/m 3 -d u Possibly rates to 5 kg. COD/m 3 -d u Effluent SS range between 50 – 100 mg/L depending on HRT u

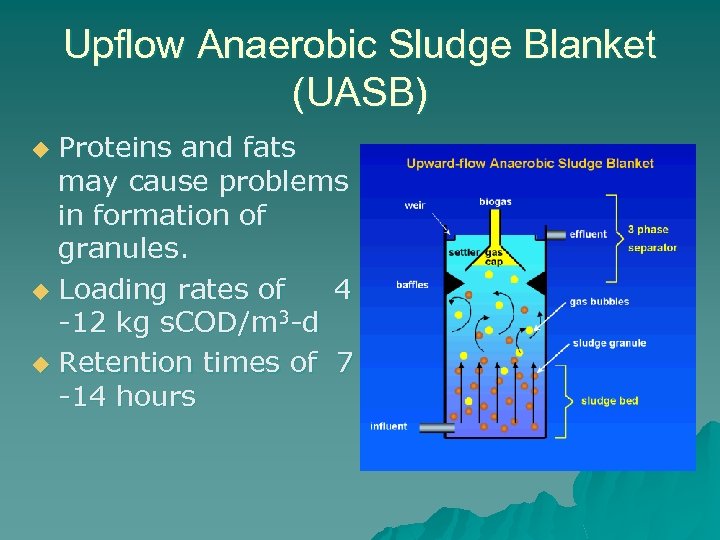

Upflow Anaerobic Sludge Blanket (UASB) Proteins and fats may cause problems in formation of granules. u Loading rates of 4 -12 kg s. COD/m 3 -d u Retention times of 7 -14 hours u

Upflow Anaerobic Sludge Blanket (UASB) Proteins and fats may cause problems in formation of granules. u Loading rates of 4 -12 kg s. COD/m 3 -d u Retention times of 7 -14 hours u

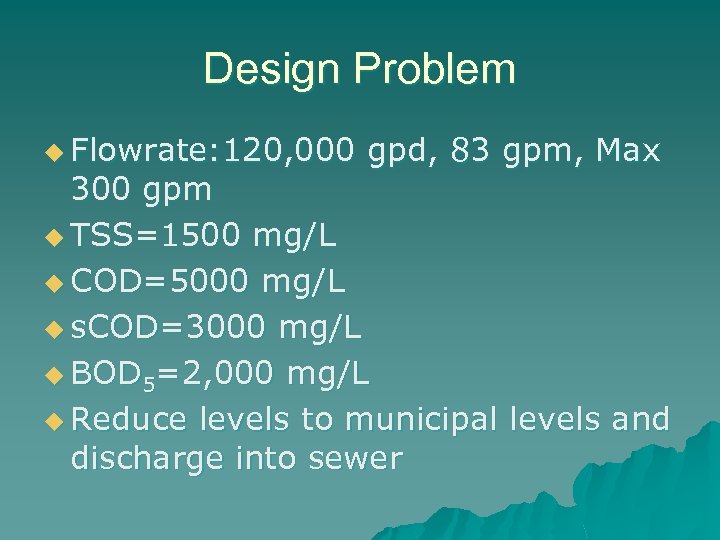

Design Problem u Flowrate: 120, 000 gpd, 83 gpm, Max 300 gpm u TSS=1500 mg/L u COD=5000 mg/L u s. COD=3000 mg/L u BOD 5=2, 000 mg/L u Reduce levels to municipal levels and discharge into sewer

Design Problem u Flowrate: 120, 000 gpd, 83 gpm, Max 300 gpm u TSS=1500 mg/L u COD=5000 mg/L u s. COD=3000 mg/L u BOD 5=2, 000 mg/L u Reduce levels to municipal levels and discharge into sewer

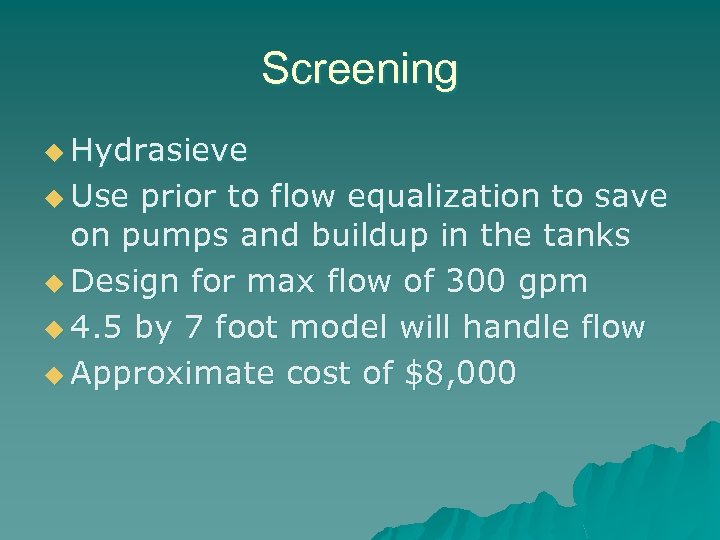

Screening u Hydrasieve u Use prior to flow equalization to save on pumps and buildup in the tanks u Design for max flow of 300 gpm u 4. 5 by 7 foot model will handle flow u Approximate cost of $8, 000

Screening u Hydrasieve u Use prior to flow equalization to save on pumps and buildup in the tanks u Design for max flow of 300 gpm u 4. 5 by 7 foot model will handle flow u Approximate cost of $8, 000

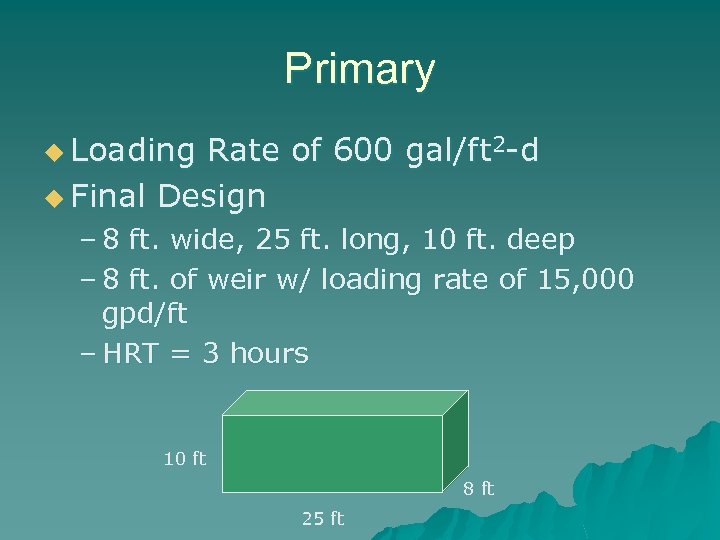

Primary u Loading Rate of 600 gal/ft 2 -d u Final Design – 8 ft. wide, 25 ft. long, 10 ft. deep – 8 ft. of weir w/ loading rate of 15, 000 gpd/ft – HRT = 3 hours 10 ft 8 ft 25 ft

Primary u Loading Rate of 600 gal/ft 2 -d u Final Design – 8 ft. wide, 25 ft. long, 10 ft. deep – 8 ft. of weir w/ loading rate of 15, 000 gpd/ft – HRT = 3 hours 10 ft 8 ft 25 ft

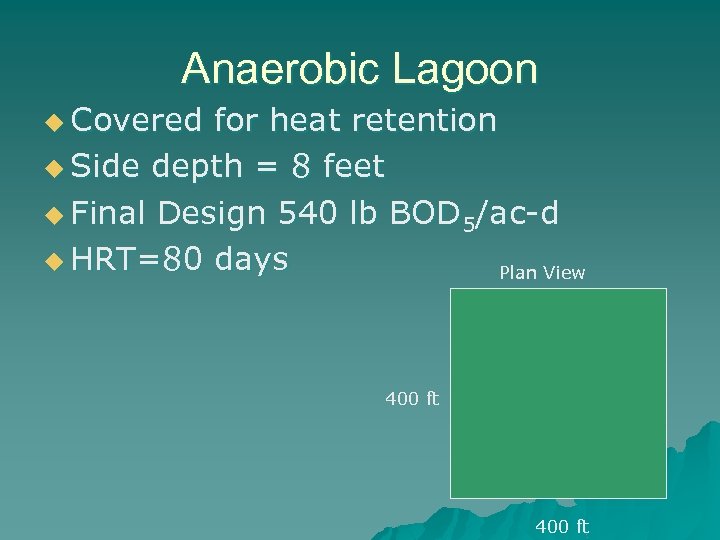

Anaerobic Lagoon u Covered for heat retention u Side depth = 8 feet u Final Design 540 lb BOD 5/ac-d u HRT=80 days Plan View 400 ft

Anaerobic Lagoon u Covered for heat retention u Side depth = 8 feet u Final Design 540 lb BOD 5/ac-d u HRT=80 days Plan View 400 ft

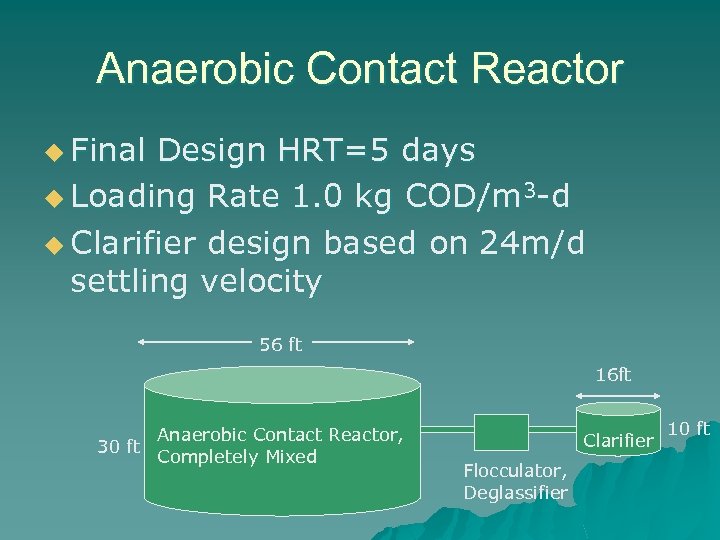

Anaerobic Contact Reactor u Final Design HRT=5 days u Loading Rate 1. 0 kg COD/m 3 -d u Clarifier design based on 24 m/d settling velocity 56 ft 16 ft Anaerobic Contact Reactor, 30 ft Completely Mixed Clarifier Flocculator, Deglassifier 10 ft

Anaerobic Contact Reactor u Final Design HRT=5 days u Loading Rate 1. 0 kg COD/m 3 -d u Clarifier design based on 24 m/d settling velocity 56 ft 16 ft Anaerobic Contact Reactor, 30 ft Completely Mixed Clarifier Flocculator, Deglassifier 10 ft

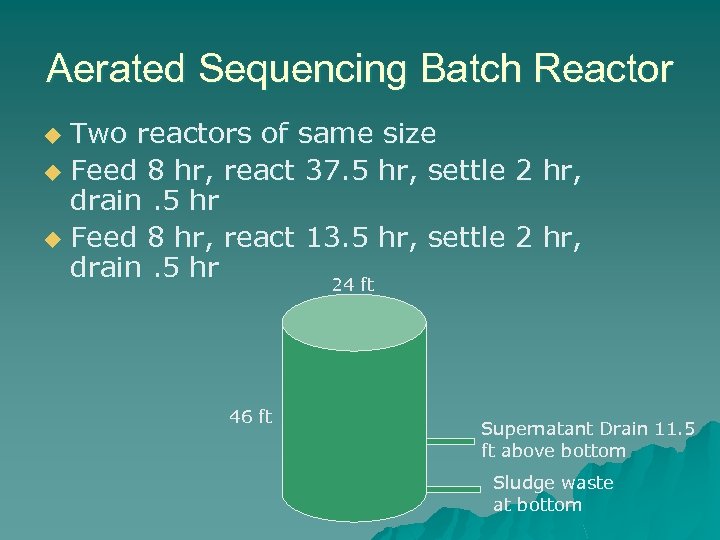

Aerated Sequencing Batch Reactor Two reactors of same size u Feed 8 hr, react 37. 5 hr, settle 2 hr, drain. 5 hr u Feed 8 hr, react 13. 5 hr, settle 2 hr, drain. 5 hr 24 ft u 46 ft Supernatant Drain 11. 5 ft above bottom Sludge waste at bottom

Aerated Sequencing Batch Reactor Two reactors of same size u Feed 8 hr, react 37. 5 hr, settle 2 hr, drain. 5 hr u Feed 8 hr, react 13. 5 hr, settle 2 hr, drain. 5 hr 24 ft u 46 ft Supernatant Drain 11. 5 ft above bottom Sludge waste at bottom

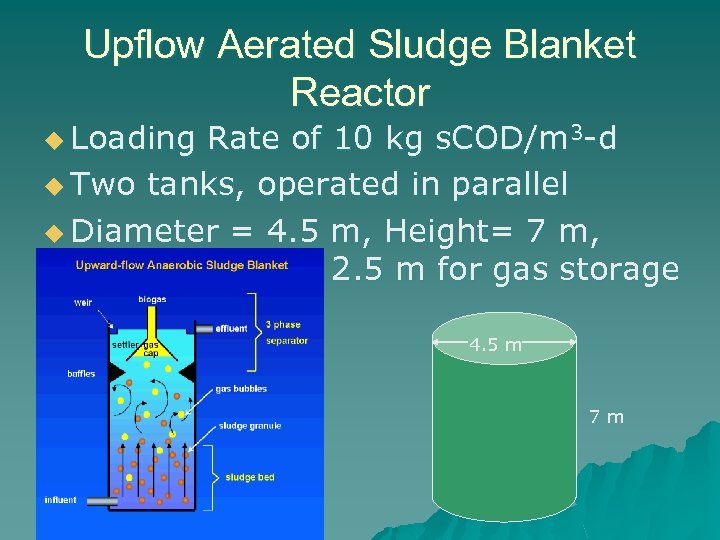

Upflow Aerated Sludge Blanket Reactor u Loading Rate of 10 kg s. COD/m 3 -d u Two tanks, operated in parallel u Diameter = 4. 5 m, Height= 7 m, 2. 5 m for gas storage 4. 5 m 7 m

Upflow Aerated Sludge Blanket Reactor u Loading Rate of 10 kg s. COD/m 3 -d u Two tanks, operated in parallel u Diameter = 4. 5 m, Height= 7 m, 2. 5 m for gas storage 4. 5 m 7 m

Final Design u Include Hydrasieve: effectiveness and low capital, O & M costs u Upflow Anaerobic Sludge Blanket Reactor u Tank is smaller than most of the others due to high organic loading rate u Provides constant source of methane gas

Final Design u Include Hydrasieve: effectiveness and low capital, O & M costs u Upflow Anaerobic Sludge Blanket Reactor u Tank is smaller than most of the others due to high organic loading rate u Provides constant source of methane gas