41f2bbc1d22e5620ce03c5677b5ad3dd.ppt

- Количество слайдов: 26

Transporte Internacional & Supply Chain Integration US- Mexico Chamber of Commerce Dallas - Irving - Fort Worth, TEXAS September 2008

Transporte Internacional & Supply Chain Integration US- Mexico Chamber of Commerce Dallas - Irving - Fort Worth, TEXAS September 2008

Business Environment Logistics in Mexico Challenges 2

Business Environment Logistics in Mexico Challenges 2

Business Environment • Corporate Structure: trends Multinational Corporations & Globally Integrated Corporations 3

Business Environment • Corporate Structure: trends Multinational Corporations & Globally Integrated Corporations 3

Business Environment • Multinational Corporations • Foreign markets expansion – Product Development: focus on covering the need of the selected local market – Establish individual full operation in foreign markets – Utilize local labor and raw materials as much as possible according to availability – Bring manufacturing processes, supervisors and adjusted original designs to satisfy local needs – Generate changes in local markets 4

Business Environment • Multinational Corporations • Foreign markets expansion – Product Development: focus on covering the need of the selected local market – Establish individual full operation in foreign markets – Utilize local labor and raw materials as much as possible according to availability – Bring manufacturing processes, supervisors and adjusted original designs to satisfy local needs – Generate changes in local markets 4

Business Environment • Globally Integrated Corporations • Foreign markets expansion – Product Development: focus on global market demands – Sources, manufacturing plants and raw materials are located in different countries/ regions – Specialization of the Supply Chain participants – Outsourcing – Generate changes on the participants of the Chain Supply 5

Business Environment • Globally Integrated Corporations • Foreign markets expansion – Product Development: focus on global market demands – Sources, manufacturing plants and raw materials are located in different countries/ regions – Specialization of the Supply Chain participants – Outsourcing – Generate changes on the participants of the Chain Supply 5

Multinational Corporation

Multinational Corporation

Globally Integrated Corporation

Globally Integrated Corporation

Logistics & Distribution Mexico

Logistics & Distribution Mexico

Logistics • 206, 314 miles of Highways • 75% of freight is mobilized over the road Source: SCT

Logistics • 206, 314 miles of Highways • 75% of freight is mobilized over the road Source: SCT

Logistics Ferromex UP KCSM Ferrosur Trans- ístmico Chiapas - Mayab Coahuila - Durango • 16, 560 Railroad miles • 17% of freight is mobilized on rail Source: SCT

Logistics Ferromex UP KCSM Ferrosur Trans- ístmico Chiapas - Mayab Coahuila - Durango • 16, 560 Railroad miles • 17% of freight is mobilized on rail Source: SCT

Logistics ENSENADA • 17 Sea entry ports GUAYMAS • 7. 5% of freight is mobilized by sea cargo ALTAMIRA MAZATLAN TAMPICO PROGRESO TUXPAN VERACRUZ COATZACOALCOS MANZANILLO LAZARO CARDENAS Source: SCT SALINA CRUZ

Logistics ENSENADA • 17 Sea entry ports GUAYMAS • 7. 5% of freight is mobilized by sea cargo ALTAMIRA MAZATLAN TAMPICO PROGRESO TUXPAN VERACRUZ COATZACOALCOS MANZANILLO LAZARO CARDENAS Source: SCT SALINA CRUZ

CHALLENGES working with GLOBALLY INTEGRATED CORPORATIONS 12

CHALLENGES working with GLOBALLY INTEGRATED CORPORATIONS 12

Logistics Challenges: JIT capabilities Information technology Transportation Compliance Security Distribution Cultural Diversity (WMS, TMS, RFID)

Logistics Challenges: JIT capabilities Information technology Transportation Compliance Security Distribution Cultural Diversity (WMS, TMS, RFID)

Logistics • What to look for in a 3 th Part Logistic Organization (3 PL) 1) Industry expertise 2) Information Technology 3) Infrastructure 4) Alliances with other service providers 5) Specific programs and Logistics Solutions 14

Logistics • What to look for in a 3 th Part Logistic Organization (3 PL) 1) Industry expertise 2) Information Technology 3) Infrastructure 4) Alliances with other service providers 5) Specific programs and Logistics Solutions 14

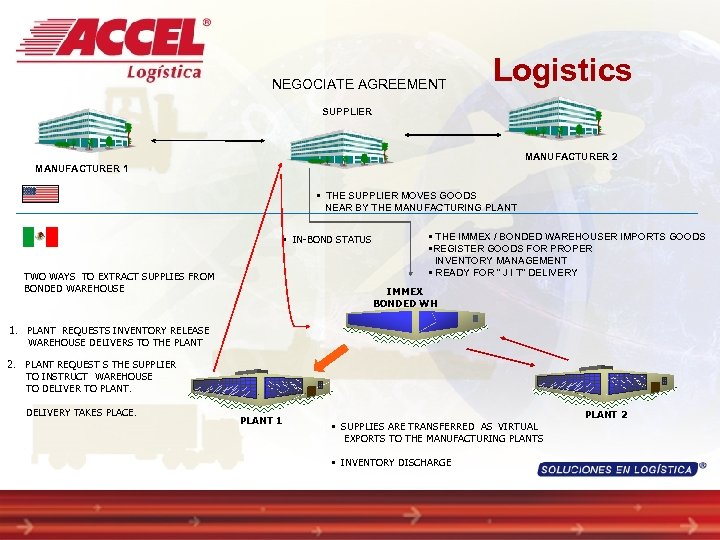

Logistics Foreign Suppliers Program What are the benefits: • Safe inventory storage for in-bond shipments • Allows Just In Time deliveries • Limited Income Tax Exposure (Foreign suppliers without presence in Mexico) • Deferment of all Import Duties and Taxes (Until goods are extracted from the in-bond areas/warehouse) • Domestic & International Distribution Center

Logistics Foreign Suppliers Program What are the benefits: • Safe inventory storage for in-bond shipments • Allows Just In Time deliveries • Limited Income Tax Exposure (Foreign suppliers without presence in Mexico) • Deferment of all Import Duties and Taxes (Until goods are extracted from the in-bond areas/warehouse) • Domestic & International Distribution Center

Logistics Foreign Suppliers Programs Who benefits: • Manufacturing Plants • Manufacturers under IMMEX Program • Foreign suppliers and distributors without presence in Mexico • Mexican importers

Logistics Foreign Suppliers Programs Who benefits: • Manufacturing Plants • Manufacturers under IMMEX Program • Foreign suppliers and distributors without presence in Mexico • Mexican importers

Logistics Foreign Suppliers Programs Who can provide the service: √ IMMEX certified entity √ A bonded warehouser Level 1 (Almacenadoras) • Registered as an Auxiliary Credit Organization before the Secretaria de Hacienda y Crédito Publico (SHCP) • Authorized by the SHCP to operate under the Mexican In-Bond Regime (Regimen de Deposito Fiscal Mexicano) • Certified by the Mexican Customs Administration Source: SHCP

Logistics Foreign Suppliers Programs Who can provide the service: √ IMMEX certified entity √ A bonded warehouser Level 1 (Almacenadoras) • Registered as an Auxiliary Credit Organization before the Secretaria de Hacienda y Crédito Publico (SHCP) • Authorized by the SHCP to operate under the Mexican In-Bond Regime (Regimen de Deposito Fiscal Mexicano) • Certified by the Mexican Customs Administration Source: SHCP

NEGOCIATE AGREEMENT Logistics SUPPLIER MANUFACTURER 2 MANUFACTURER 1 • THE SUPPLIER MOVES GOODS NEAR BY THE MANUFACTURING PLANT • IN-BOND STATUS TWO WAYS TO EXTRACT SUPPLIES FROM BONDED WAREHOUSE • THE IMMEX / BONDED WAREHOUSER IMPORTS GOODS • REGISTER GOODS FOR PROPER INVENTORY MANAGEMENT • READY FOR “ J I T” DELIVERY IMMEX BONDED WH 1. PLANT REQUESTS INVENTORY RELEASE WAREHOUSE DELIVERS TO THE PLANT 2. PLANT REQUEST S THE SUPPLIER TO INSTRUCT WAREHOUSE TO DELIVER TO PLANT. DELIVERY TAKES PLACE. PLANT 1 • SUPPLIES ARE TRANSFERRED AS VIRTUAL EXPORTS TO THE MANUFACTURING PLANTS • INVENTORY DISCHARGE PLANT 2

NEGOCIATE AGREEMENT Logistics SUPPLIER MANUFACTURER 2 MANUFACTURER 1 • THE SUPPLIER MOVES GOODS NEAR BY THE MANUFACTURING PLANT • IN-BOND STATUS TWO WAYS TO EXTRACT SUPPLIES FROM BONDED WAREHOUSE • THE IMMEX / BONDED WAREHOUSER IMPORTS GOODS • REGISTER GOODS FOR PROPER INVENTORY MANAGEMENT • READY FOR “ J I T” DELIVERY IMMEX BONDED WH 1. PLANT REQUESTS INVENTORY RELEASE WAREHOUSE DELIVERS TO THE PLANT 2. PLANT REQUEST S THE SUPPLIER TO INSTRUCT WAREHOUSE TO DELIVER TO PLANT. DELIVERY TAKES PLACE. PLANT 1 • SUPPLIES ARE TRANSFERRED AS VIRTUAL EXPORTS TO THE MANUFACTURING PLANTS • INVENTORY DISCHARGE PLANT 2

Dallas Office Leopoldo Prendes Business Development Manager - NA 972 -281 -6274 E-mail: lprendes@accelonline. com

Dallas Office Leopoldo Prendes Business Development Manager - NA 972 -281 -6274 E-mail: lprendes@accelonline. com

Cultural Diversity • Corporate – Build strong relationship – Personalized costumer care – Partnership – Flexibility – Long term goals oriented – Participant in the decision making process – Compatible 20

Cultural Diversity • Corporate – Build strong relationship – Personalized costumer care – Partnership – Flexibility – Long term goals oriented – Participant in the decision making process – Compatible 20

Cultural Diversity • Ethnic / region – Awareness – Human factor – Auto evaluation – Different region different meaning – Tolerance to other groups – Flexibility – Open to learn 21

Cultural Diversity • Ethnic / region – Awareness – Human factor – Auto evaluation – Different region different meaning – Tolerance to other groups – Flexibility – Open to learn 21

Case Study : Industry: Design, engineering, testing and manufacturer of auto parts Company profile: Original Equipment Manufacturer (OEM) Operations: Europe, Asia, the Americas Description of goods: 4, 000 pound steel coils Origin and destination: Ontario, Canada – Nuevo Leon, Mexico Transportation: Rail (preferred) or truck (secondary)

Case Study : Industry: Design, engineering, testing and manufacturer of auto parts Company profile: Original Equipment Manufacturer (OEM) Operations: Europe, Asia, the Americas Description of goods: 4, 000 pound steel coils Origin and destination: Ontario, Canada – Nuevo Leon, Mexico Transportation: Rail (preferred) or truck (secondary)

First approach by the manufacturer : Quantity: 45, 000 pounds of steel Frequency: weekly Type of service: door to door delivery Transportation: rail or truck (previously by truck) Considerations: manufacturing plant can process maximum of 45, 000 pounds a week

First approach by the manufacturer : Quantity: 45, 000 pounds of steel Frequency: weekly Type of service: door to door delivery Transportation: rail or truck (previously by truck) Considerations: manufacturing plant can process maximum of 45, 000 pounds a week

Landed cost : Transportation: Fuel surcharge: Trans/load Origin: Trans/load Destination: Customs Broker fee One per week total cost: One month total cost: RAIL USD$ 9, 953. 00 $ 924. 00 $ 1, 425. 00 $ 1, 500. 00 $ 14, 302. 00 $ 57, 208. 00 TRUCK $ 5, 820. 00 Included n/a $ 500. 00 $ 6, 320. 00 $ 25, 280. 00 Capacity used ¼ of a rail car maximum

Landed cost : Transportation: Fuel surcharge: Trans/load Origin: Trans/load Destination: Customs Broker fee One per week total cost: One month total cost: RAIL USD$ 9, 953. 00 $ 924. 00 $ 1, 425. 00 $ 1, 500. 00 $ 14, 302. 00 $ 57, 208. 00 TRUCK $ 5, 820. 00 Included n/a $ 500. 00 $ 6, 320. 00 $ 25, 280. 00 Capacity used ¼ of a rail car maximum

Review : • Plant manufacturing capacity by month = Maximum 190, 000 pound aprox. • 1 Railcar maximum capacity = 190, 000 pounds / 40 -45 steel coils • JIT delivery required • Warehouse cost • Simplification of the logistics process • Rail cost VS truck cost and capacity • Border crossing cost

Review : • Plant manufacturing capacity by month = Maximum 190, 000 pound aprox. • 1 Railcar maximum capacity = 190, 000 pounds / 40 -45 steel coils • JIT delivery required • Warehouse cost • Simplification of the logistics process • Rail cost VS truck cost and capacity • Border crossing cost

Final proposal : Transportation: Fuel surcharge: Trans/load Origin: Trans/load Destination: Customs Broker fee One per week total cost: Warehouse cost: RAIL $9, 953. 00 $ 924. 00 $ 1, 425. 00 $ n/a $ 500. 00 n/a $ 3, 500. 00 RAIL $ 9, 953. 00 $ 924. 00 $ 1, 425. 00 $ 1, 500. 00 $ 14, 302. 00 n/a TRUCK $ 5, 820. 00 Included n/a $ 500. 00 $ 6, 320. 00 n/a (Includes space, handling, trans/load & 4 deliveries by truck) One month total cost: $ 16, 302. 00 $ 57, 208. 00 $ 25, 280. 00 Capacity used 97 % of a railcar ¼ of a rail car maximum

Final proposal : Transportation: Fuel surcharge: Trans/load Origin: Trans/load Destination: Customs Broker fee One per week total cost: Warehouse cost: RAIL $9, 953. 00 $ 924. 00 $ 1, 425. 00 $ n/a $ 500. 00 n/a $ 3, 500. 00 RAIL $ 9, 953. 00 $ 924. 00 $ 1, 425. 00 $ 1, 500. 00 $ 14, 302. 00 n/a TRUCK $ 5, 820. 00 Included n/a $ 500. 00 $ 6, 320. 00 n/a (Includes space, handling, trans/load & 4 deliveries by truck) One month total cost: $ 16, 302. 00 $ 57, 208. 00 $ 25, 280. 00 Capacity used 97 % of a railcar ¼ of a rail car maximum