Transient Flow Visualization in a Lexmark Printer Project Sponsor: Lexmark International Inc. Matt Casavant Nor Izzati Nordin Wan Afeek Wan Ali Guy Davis

Transient Flow Visualization in a Lexmark Printer Project Sponsor: Lexmark International Inc. Matt Casavant Nor Izzati Nordin Wan Afeek Wan Ali Guy Davis

Lexmark Corporate Background Information • Lexmark was launched in 1991 and the company is known for developing manufacturing, and supplying printing solutions. • Divided into 2 divisions 1) Consumer Printer Division (CPD) 2) Printing Solutions & Services Division (PS&SD) • Environmentally Conscious - Actively searches and uses environmental friendly products.

Lexmark Corporate Background Information • Lexmark was launched in 1991 and the company is known for developing manufacturing, and supplying printing solutions. • Divided into 2 divisions 1) Consumer Printer Division (CPD) 2) Printing Solutions & Services Division (PS&SD) • Environmentally Conscious - Actively searches and uses environmental friendly products.

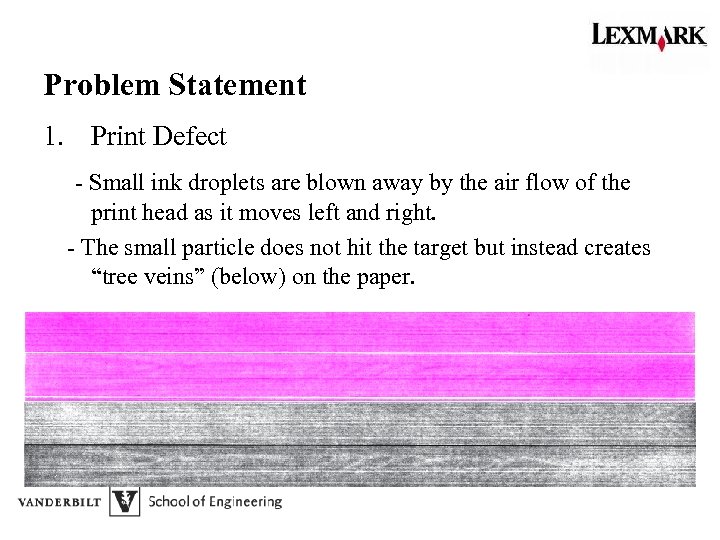

Problem Statement 1. Print Defect - Small ink droplets are blown away by the air flow of the print head as it moves left and right. - The small particle does not hit the target but instead creates “tree veins” (below) on the paper.

Problem Statement 1. Print Defect - Small ink droplets are blown away by the air flow of the print head as it moves left and right. - The small particle does not hit the target but instead creates “tree veins” (below) on the paper.

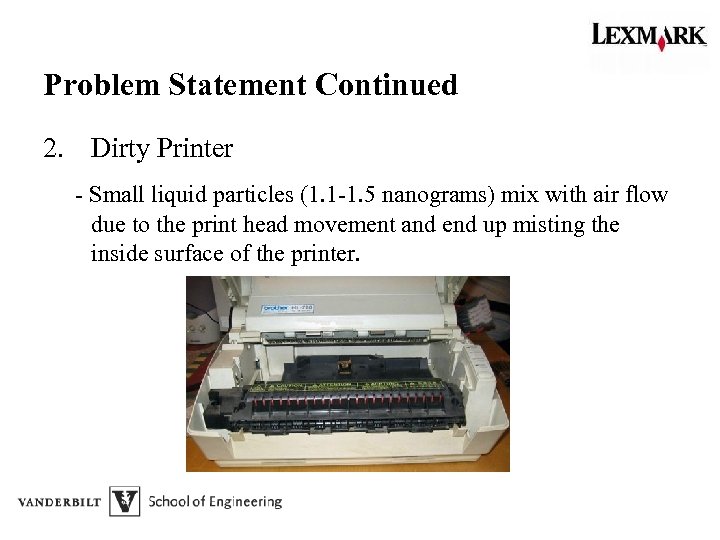

Problem Statement Continued 2. Dirty Printer - Small liquid particles (1. 1 -1. 5 nanograms) mix with air flow due to the print head movement and end up misting the inside surface of the printer.

Problem Statement Continued 2. Dirty Printer - Small liquid particles (1. 1 -1. 5 nanograms) mix with air flow due to the print head movement and end up misting the inside surface of the printer.

Empirical Problem Statement • Use the Vanderbilt water tunnel (thus choosing water as the fluid medium due to the ability to dye flow patterns) to study flow over a container to better understand the flow disturbances it creates. • This will then allow for inconsistent print patterns such as veins to be corrected.

Empirical Problem Statement • Use the Vanderbilt water tunnel (thus choosing water as the fluid medium due to the ability to dye flow patterns) to study flow over a container to better understand the flow disturbances it creates. • This will then allow for inconsistent print patterns such as veins to be corrected.

Wants Needs • Ink particles to hit target (accuracy) • Veins to go away • Clean printer (no small flying ink particles) • • Inexpensive Simplicity in solution Less mess Environmentally friendly

Wants Needs • Ink particles to hit target (accuracy) • Veins to go away • Clean printer (no small flying ink particles) • • Inexpensive Simplicity in solution Less mess Environmentally friendly

Questions/Comments?

Questions/Comments?