71cc678aa45bdfe91d9e3f02701f1263.ppt

- Количество слайдов: 19

Transformation of Software Support Facilities Evolving toward the “Lean AISF” Quality Production On Time Harold Lowery WR-ALC/MASF 22 October 2003

Transformation of Software Support Facilities Evolving toward the “Lean AISF” Quality Production On Time Harold Lowery WR-ALC/MASF 22 October 2003

Outline • What is “Lean” ? • What is an “AISF” ? • What is a “Lean AISF” ? 2

Outline • What is “Lean” ? • What is an “AISF” ? • What is a “Lean AISF” ? 2

What is “Lean” ? 1993 Air Force challenges II, manufacturing in Lean Now! 2003 Lean Now! seeks. War industry to principles Japan faced to aerospace. In aftermath of World to apply Lean principles Enterprise-wide. enormous challenges. Without access to capital and lacking The result was the Lean Aerospace Initiative, a consortium of aerospace natural resources, they couldn’t adopt Western style stakeholders, including government, industry, academia, and labor manufacturing, but instead adapted it to their circumstances. organizations. Academic researchers dubbed their approach “lean production”. Lean Aerospace Initiative Toyota Production System Taiichi Ohno Shigeo Shingo 3

What is “Lean” ? 1993 Air Force challenges II, manufacturing in Lean Now! 2003 Lean Now! seeks. War industry to principles Japan faced to aerospace. In aftermath of World to apply Lean principles Enterprise-wide. enormous challenges. Without access to capital and lacking The result was the Lean Aerospace Initiative, a consortium of aerospace natural resources, they couldn’t adopt Western style stakeholders, including government, industry, academia, and labor manufacturing, but instead adapted it to their circumstances. organizations. Academic researchers dubbed their approach “lean production”. Lean Aerospace Initiative Toyota Production System Taiichi Ohno Shigeo Shingo 3

What is “Lean” ? • Specify value: – Defined by the customer • Identify the value stream: – Map process of transforming inputs to outputs – Identify and eliminate waste • Emphasize “Flow” • Customers pull value • Kaizen: – Continuous improvement • Adapted from James Womack and Daniel T. Jones, Lean Thinking (Simon & Schuster, New York, 1996) 4

What is “Lean” ? • Specify value: – Defined by the customer • Identify the value stream: – Map process of transforming inputs to outputs – Identify and eliminate waste • Emphasize “Flow” • Customers pull value • Kaizen: – Continuous improvement • Adapted from James Womack and Daniel T. Jones, Lean Thinking (Simon & Schuster, New York, 1996) 4

What is an AISF ? • Terminology – OFP = Operational Flight Program – AISF = Avionics Integration Support Facility • An AISF is a real-time, closed-loop, hardware-in-the-loop system consisting of avionics hardware, signal processing hardware and software, and simulation software. • Provides all of the required stimulation so that the avionics/OFPs respond as though they were in the aircraft. • The AISF “customer” is the OFP engineer. 5

What is an AISF ? • Terminology – OFP = Operational Flight Program – AISF = Avionics Integration Support Facility • An AISF is a real-time, closed-loop, hardware-in-the-loop system consisting of avionics hardware, signal processing hardware and software, and simulation software. • Provides all of the required stimulation so that the avionics/OFPs respond as though they were in the aircraft. • The AISF “customer” is the OFP engineer. 5

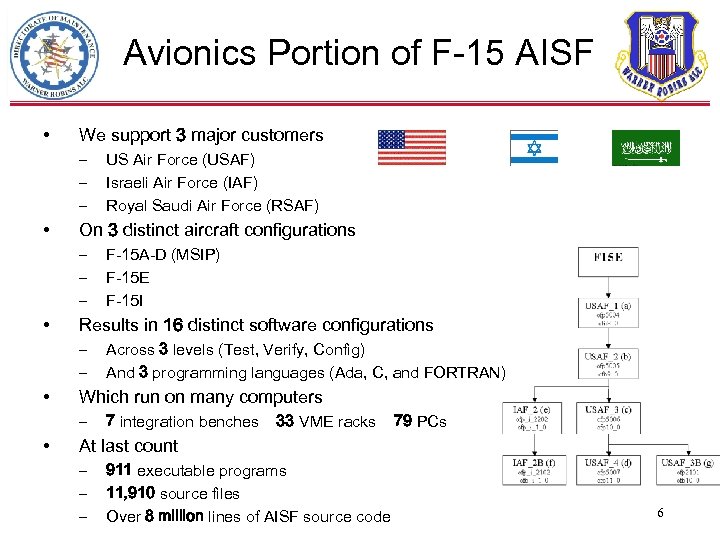

Avionics Portion of F-15 AISF • We support 3 major customers – – – • On 3 distinct aircraft configurations – – – • Across 3 levels (Test, Verify, Config) And 3 programming languages (Ada, C, and FORTRAN) Which run on many computers – • F-15 A-D (MSIP) F-15 E F-15 I Results in 16 distinct software configurations – – • US Air Force (USAF) Israeli Air Force (IAF) Royal Saudi Air Force (RSAF) 7 integration benches 33 VME racks 79 PCs At last count – – – 911 executable programs 11, 910 source files Over 8 million lines of AISF source code 6

Avionics Portion of F-15 AISF • We support 3 major customers – – – • On 3 distinct aircraft configurations – – – • Across 3 levels (Test, Verify, Config) And 3 programming languages (Ada, C, and FORTRAN) Which run on many computers – • F-15 A-D (MSIP) F-15 E F-15 I Results in 16 distinct software configurations – – • US Air Force (USAF) Israeli Air Force (IAF) Royal Saudi Air Force (RSAF) 7 integration benches 33 VME racks 79 PCs At last count – – – 911 executable programs 11, 910 source files Over 8 million lines of AISF source code 6

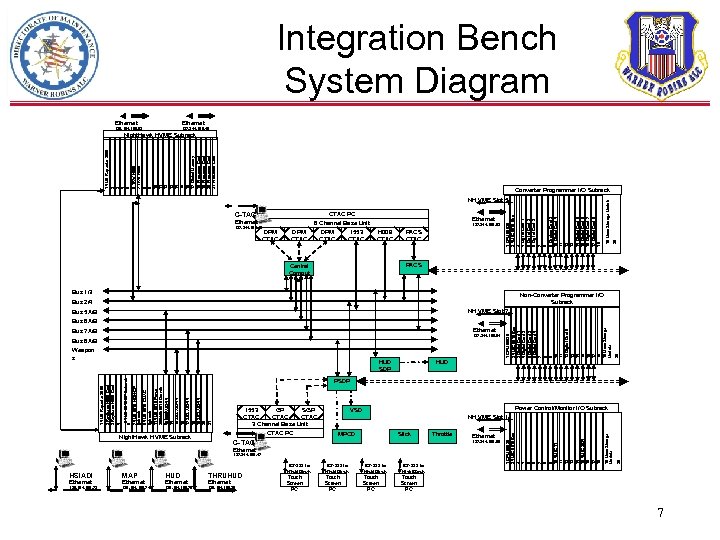

Ethernet 137. 244. 198. 46 DPM CTAC Night. Hawk HVME Subrack HSIADI MAP HUD THRUHUD 129. 194. 185. 73 129. 194. 185. 74 129. 194. 185. 75 129. 194. 185. 76 Ethernet DPM CTAC RS-232 to Night. Hawk Touch Screen PC CTAC PC 6 Channel Base Unit DPM 1553 CTAC Weapon s GP 1553 SGP CTAC 3 Channel Base Unit CTAC PC RS-232 to Night. Hawk Touch Screen PC H 009 CTAC Central Comput er MPCD RS-232 to Night. Hawk Touch Screen PC PACS CTAC Ethernet 137. 244. 198. 93 Bus 5 A/B Bus 7 A/B Bus 8 A/B Ethernet 137. 244. 198. 94 HUD SDP VSD Ethernet C-TAC Stick 137. 244. 198. 47 RS-232 to Night. Hawk Touch Screen PC Throttle 137. 244. 198. 95 Ethernet Bus 1/3 Bus 2/4 20 19 Mass Storage Module 1 CPU 68030 2 VMIC 5510 Bus 3 4 Digital Card 1 5 Digital Card 2 6 Digital Card 3 7 8 9 Custom Card 3 10 Digital Card 4 11 12 13 14 Digital Card 5 15 Digital Card 6 16 Digital Card 7 17 Digital Card 8 18 NH VME Slot 5 20 Ethernet 19 Mass Storage Module C-TAC 1 CPU 68030 2 VMIC 5510 Bus 3 Digital Card 1 4 Digital Card 2 5 Digital Card 3 6 Digital Card 4 7 8 9 10 11 12 Digital Card 5 13 14 15 16 17 18 19 Mass Storage Module 129. 194. 185. 62 1 CPU 68030 2 VMIC 5510 Bus 3 4 5 6 7 8 9 10 VMIC ? ? 11 12 13 14 15 VMIC 2534 16 17 18 1 VME Repeater 2000 2 3 4 5 6 TRW H 009 7 TRW H 009 8 9 10 11 12 13 14 15 16 17 Global Memory 18 Processor Card 19 Processor Card 20 Processor Card 21 Processor Card Ethernet 20 5 VME 5510 CP Subrack 6 7 VME 5510 NON-CP Subrack 8 9 VME 5510 CMAC Subrack 10 11 VME 5510 Power Subrack 5510 Growth 12 VME Subrack 13 SBS ABI-V 4 14 15 SBS ABI-V 4 16 17 SBS ABI-V 4 18 19 SBS ABI-V 4 20 21 1 VME Repeater 2000 2 Raytheon H 009 Card 3 Raytheon H 009 Card 4 Integration Bench System Diagram Night. Hawk HVME Subrack Ethernet 137. 244. 198. 45 Converter Programmer I/O Subrack PACS Non-Converter Programmer I/O Subrack Bus 6 A/B NH VME Slot 7 HUD PSDP NH VME Slot 11 Power Control/Monitor I/O Subrack 7

Ethernet 137. 244. 198. 46 DPM CTAC Night. Hawk HVME Subrack HSIADI MAP HUD THRUHUD 129. 194. 185. 73 129. 194. 185. 74 129. 194. 185. 75 129. 194. 185. 76 Ethernet DPM CTAC RS-232 to Night. Hawk Touch Screen PC CTAC PC 6 Channel Base Unit DPM 1553 CTAC Weapon s GP 1553 SGP CTAC 3 Channel Base Unit CTAC PC RS-232 to Night. Hawk Touch Screen PC H 009 CTAC Central Comput er MPCD RS-232 to Night. Hawk Touch Screen PC PACS CTAC Ethernet 137. 244. 198. 93 Bus 5 A/B Bus 7 A/B Bus 8 A/B Ethernet 137. 244. 198. 94 HUD SDP VSD Ethernet C-TAC Stick 137. 244. 198. 47 RS-232 to Night. Hawk Touch Screen PC Throttle 137. 244. 198. 95 Ethernet Bus 1/3 Bus 2/4 20 19 Mass Storage Module 1 CPU 68030 2 VMIC 5510 Bus 3 4 Digital Card 1 5 Digital Card 2 6 Digital Card 3 7 8 9 Custom Card 3 10 Digital Card 4 11 12 13 14 Digital Card 5 15 Digital Card 6 16 Digital Card 7 17 Digital Card 8 18 NH VME Slot 5 20 Ethernet 19 Mass Storage Module C-TAC 1 CPU 68030 2 VMIC 5510 Bus 3 Digital Card 1 4 Digital Card 2 5 Digital Card 3 6 Digital Card 4 7 8 9 10 11 12 Digital Card 5 13 14 15 16 17 18 19 Mass Storage Module 129. 194. 185. 62 1 CPU 68030 2 VMIC 5510 Bus 3 4 5 6 7 8 9 10 VMIC ? ? 11 12 13 14 15 VMIC 2534 16 17 18 1 VME Repeater 2000 2 3 4 5 6 TRW H 009 7 TRW H 009 8 9 10 11 12 13 14 15 16 17 Global Memory 18 Processor Card 19 Processor Card 20 Processor Card 21 Processor Card Ethernet 20 5 VME 5510 CP Subrack 6 7 VME 5510 NON-CP Subrack 8 9 VME 5510 CMAC Subrack 10 11 VME 5510 Power Subrack 5510 Growth 12 VME Subrack 13 SBS ABI-V 4 14 15 SBS ABI-V 4 16 17 SBS ABI-V 4 18 19 SBS ABI-V 4 20 21 1 VME Repeater 2000 2 Raytheon H 009 Card 3 Raytheon H 009 Card 4 Integration Bench System Diagram Night. Hawk HVME Subrack Ethernet 137. 244. 198. 45 Converter Programmer I/O Subrack PACS Non-Converter Programmer I/O Subrack Bus 6 A/B NH VME Slot 7 HUD PSDP NH VME Slot 11 Power Control/Monitor I/O Subrack 7

AISF “As Is” State • Most existing AISFs – were built in the late 1980 s and early 1990 s, – based on older minicomputer hardware that is expensive to maintain, – use proprietary operating systems and/or software development toolsets that are no longer supported by industry. • Expensive to maintain – Vendor support contracts – Obsolete hardware and software • Broken components can’t be repaired • Replacement components can’t be purchased • Knowledge base vanishing • Unable to use latest technology – 2 GB limit on simulation host computer hard drives 8

AISF “As Is” State • Most existing AISFs – were built in the late 1980 s and early 1990 s, – based on older minicomputer hardware that is expensive to maintain, – use proprietary operating systems and/or software development toolsets that are no longer supported by industry. • Expensive to maintain – Vendor support contracts – Obsolete hardware and software • Broken components can’t be repaired • Replacement components can’t be purchased • Knowledge base vanishing • Unable to use latest technology – 2 GB limit on simulation host computer hard drives 8

AISF “To Be” State • Updated AISF is – based on relatively inexpensive computer hardware – conforms to open industry standards – uses Open Source software where appropriate • Less expensive to maintain – fewer support contracts and software licenses • Able to use latest technology – faster cycle time to meet new requirements – leaner modification/support process – less expensive to modify over time 9

AISF “To Be” State • Updated AISF is – based on relatively inexpensive computer hardware – conforms to open industry standards – uses Open Source software where appropriate • Less expensive to maintain – fewer support contracts and software licenses • Able to use latest technology – faster cycle time to meet new requirements – leaner modification/support process – less expensive to modify over time 9

Lean AISF Example APG-70 Radar Bench • Graphical User Interface (GUI) • Before – Hardware: Silicon Graphics Onyx • Support Contract: $61 K annual – Software: UIMX • Vendor no longer exists • After – Hardware: Linux PC • Support Contract: $0 – Software: Tcl/Tk • Open standard • Cost Savings: $61 K annual 10

Lean AISF Example APG-70 Radar Bench • Graphical User Interface (GUI) • Before – Hardware: Silicon Graphics Onyx • Support Contract: $61 K annual – Software: UIMX • Vendor no longer exists • After – Hardware: Linux PC • Support Contract: $0 – Software: Tcl/Tk • Open standard • Cost Savings: $61 K annual 10

Lean AISF Example APG-70 OFP Toolset • OFP source code and toolset • Before – Hardware: IBM 9221 Model 170 • Support Contract: $103 K annual • After – Hardware: Intel server – Software: FLEX-S emulation of IBM • Support Contract: $33 K annual • Cost Savings: $70 K annual 11

Lean AISF Example APG-70 OFP Toolset • OFP source code and toolset • Before – Hardware: IBM 9221 Model 170 • Support Contract: $103 K annual • After – Hardware: Intel server – Software: FLEX-S emulation of IBM • Support Contract: $33 K annual • Cost Savings: $70 K annual 11

Lean AISF Example APG-70 Simulation • Real-time simulation • Before – Hardware: VAXstation 4000 • Support Contract: $44 K annual – VMS • After – Hardware: Motorola MV 2400 Power. PC – Software: Vx. Works • License: $4 K • Cost Savings: $40 K annual 12

Lean AISF Example APG-70 Simulation • Real-time simulation • Before – Hardware: VAXstation 4000 • Support Contract: $44 K annual – VMS • After – Hardware: Motorola MV 2400 Power. PC – Software: Vx. Works • License: $4 K • Cost Savings: $40 K annual 12

Lean AISF Example APG-70 Simulation • SCRAMnet reflective memory interface • Before – Hardware: SCRAMnet reflective memory interface – Support: Obsolete QBus • No longer supported by vendor • One spare in existence • After – Hardware: Industry standard Ethernet backbone – Software: RTI NDDS Network Data Delivery System 13

Lean AISF Example APG-70 Simulation • SCRAMnet reflective memory interface • Before – Hardware: SCRAMnet reflective memory interface – Support: Obsolete QBus • No longer supported by vendor • One spare in existence • After – Hardware: Industry standard Ethernet backbone – Software: RTI NDDS Network Data Delivery System 13

Lean AISF Example Avionics Benches • OFP source code and toolset • Before – Hardware: Concurrent Night. Hawk 5808 • Support Contract: $333 K annual • After – Hardware: Intel servers – Software: Linux – Support Contract: $0 K annual • Cost Savings: $333 K annual 14

Lean AISF Example Avionics Benches • OFP source code and toolset • Before – Hardware: Concurrent Night. Hawk 5808 • Support Contract: $333 K annual • After – Hardware: Intel servers – Software: Linux – Support Contract: $0 K annual • Cost Savings: $333 K annual 14

Processes Due for Improvement • • • Documentation Generation Software Build Process Software Configuration Management Automated Test via Scripts Problem Reporting 15

Processes Due for Improvement • • • Documentation Generation Software Build Process Software Configuration Management Automated Test via Scripts Problem Reporting 15

Trade Studies • • Configuration Management Tools Real-Time Operating Systems for VME racks User Interfaces Synthetic Mission Displays 16

Trade Studies • • Configuration Management Tools Real-Time Operating Systems for VME racks User Interfaces Synthetic Mission Displays 16

Backup Slides 17

Backup Slides 17

Backup Slides • "We're passing on our lessons learned. And we're still a work in progress. Because one of the most important things we've learned is Lean Electronics, when done properly, is never done. “ – Tom Regan, plant manager at the Rockwell Collins Decorah, Iowa plant. – This Lean Electronics (sm) model facilty reduced their entire plant work-inprocess by 46%. 18

Backup Slides • "We're passing on our lessons learned. And we're still a work in progress. Because one of the most important things we've learned is Lean Electronics, when done properly, is never done. “ – Tom Regan, plant manager at the Rockwell Collins Decorah, Iowa plant. – This Lean Electronics (sm) model facilty reduced their entire plant work-inprocess by 46%. 18

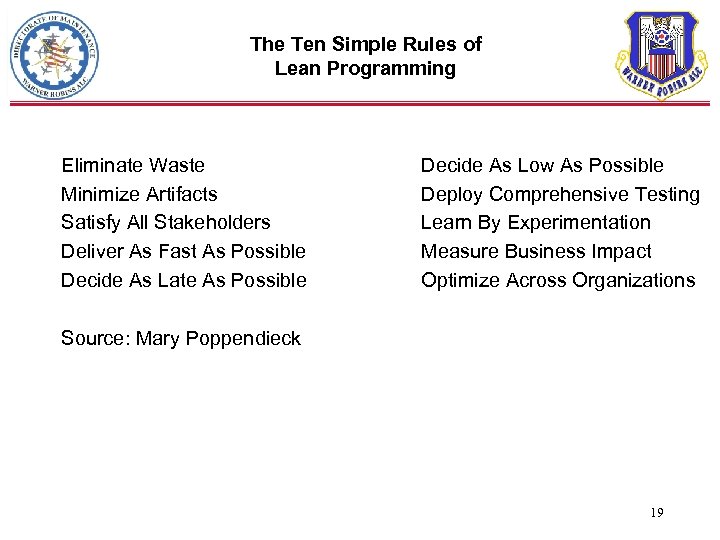

The Ten Simple Rules of Lean Programming Eliminate Waste Minimize Artifacts Satisfy All Stakeholders Deliver As Fast As Possible Decide As Late As Possible Decide As Low As Possible Deploy Comprehensive Testing Learn By Experimentation Measure Business Impact Optimize Across Organizations Source: Mary Poppendieck 19

The Ten Simple Rules of Lean Programming Eliminate Waste Minimize Artifacts Satisfy All Stakeholders Deliver As Fast As Possible Decide As Late As Possible Decide As Low As Possible Deploy Comprehensive Testing Learn By Experimentation Measure Business Impact Optimize Across Organizations Source: Mary Poppendieck 19