b4a6edb5cb2cef462931981d53a97752.ppt

- Количество слайдов: 33

Transform Your Products

Transform Your Products

In. Vision Concept Modeler Program Review Engineering & Quality 12 -February-2007 Transform Your Products

In. Vision Concept Modeler Program Review Engineering & Quality 12 -February-2007 Transform Your Products

Experience the difference… In. Vision Upgrades History Ø v 3. 38 Ø v 3. 40 Ø Pause build on long cartridge change out Ø Stop high vacuum condition Ø Add baffle to Print head adaptor Ø Addition of 2 L vacuum bottle Ø Change vacuum set point 5. 00 Ø Replace nylon fittings with brass on Print head adaptor Ø Grommet strips to clamp feed guides Ø Modified needle housing collar (removed material) Ø Removed potting from vacuum switch 5. 75 inches of H 2 O Transform Your Products

Experience the difference… In. Vision Upgrades History Ø v 3. 38 Ø v 3. 40 Ø Pause build on long cartridge change out Ø Stop high vacuum condition Ø Add baffle to Print head adaptor Ø Addition of 2 L vacuum bottle Ø Change vacuum set point 5. 00 Ø Replace nylon fittings with brass on Print head adaptor Ø Grommet strips to clamp feed guides Ø Modified needle housing collar (removed material) Ø Removed potting from vacuum switch 5. 75 inches of H 2 O Transform Your Products

Experience the difference… In. Vision Upgrades History Ø v 3. 41 (Current) Ø Add mechanical flags to stop support material (S 100) cartridge plunger ~ 20 mm short to stop excessive air from entering the fluid delivery system Ø Z guides added Ø Grounding blocks to eliminate lead screws from turning Ø New needle house stripper Ø New needle housing coating & heater Ø Replace HMS bushings with bearing sleeves Transform Your Products

Experience the difference… In. Vision Upgrades History Ø v 3. 41 (Current) Ø Add mechanical flags to stop support material (S 100) cartridge plunger ~ 20 mm short to stop excessive air from entering the fluid delivery system Ø Z guides added Ø Grounding blocks to eliminate lead screws from turning Ø New needle house stripper Ø New needle housing coating & heater Ø Replace HMS bushings with bearing sleeves Transform Your Products

Experience the difference… In. Vision Upgrades History Ø v 3. 42 (Testing) Ø Better positioning of cartridge to needle housing Ø Tighter holding of cartridge Ø Plunge to hold sequence modified to simulate drum feed plunge movement while checking LOMS level Ø Reduce “Pushed wax” condition Ø Reduce “Mega pixel errors” Ø Reduce “Ratio errors” Ø HMS damaged after Print head moves after “X-following error” Ø Build material expiration change to 2 years Transform Your Products

Experience the difference… In. Vision Upgrades History Ø v 3. 42 (Testing) Ø Better positioning of cartridge to needle housing Ø Tighter holding of cartridge Ø Plunge to hold sequence modified to simulate drum feed plunge movement while checking LOMS level Ø Reduce “Pushed wax” condition Ø Reduce “Mega pixel errors” Ø Reduce “Ratio errors” Ø HMS damaged after Print head moves after “X-following error” Ø Build material expiration change to 2 years Transform Your Products

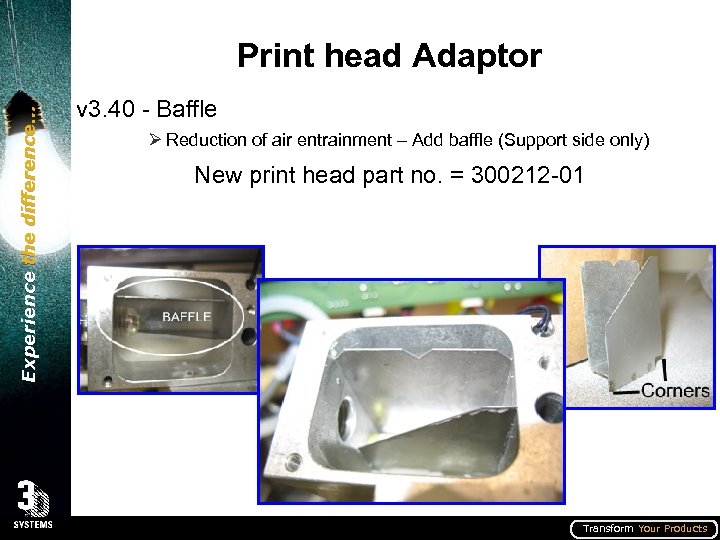

Experience the difference… Print head Adaptor v 3. 40 - Baffle Ø Reduction of air entrainment – Add baffle (Support side only) New print head part no. = 300212 -01 Transform Your Products

Experience the difference… Print head Adaptor v 3. 40 - Baffle Ø Reduction of air entrainment – Add baffle (Support side only) New print head part no. = 300212 -01 Transform Your Products

Experience the difference… Vacuum System v 3. 40 – Stabilize vacuum system Add 2 L bottle to stabilize operation of pressure regulator / 0. 5 L remains Transform Your Products

Experience the difference… Vacuum System v 3. 40 – Stabilize vacuum system Add 2 L bottle to stabilize operation of pressure regulator / 0. 5 L remains Transform Your Products

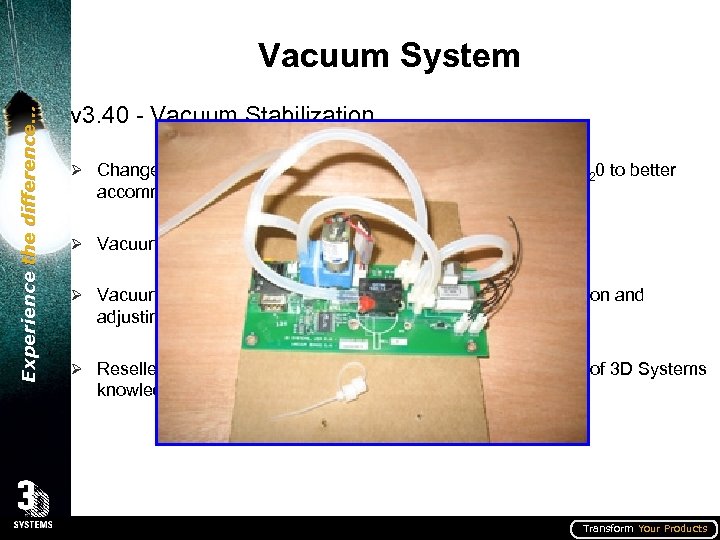

Experience the difference… Vacuum System v 3. 40 - Vacuum Stabilization Ø Changed set point and switch of pressure regulator to 5. 75” H 20 to better accommodate material densities Ø Vacuum level being set at supplier location Ø Vacuum setting confirmed at the contract manufacturing location and adjusting in the field should not be necessary Ø Resellers should not be adjusting vacuum levels independent of 3 D Systems knowledge Transform Your Products

Experience the difference… Vacuum System v 3. 40 - Vacuum Stabilization Ø Changed set point and switch of pressure regulator to 5. 75” H 20 to better accommodate material densities Ø Vacuum level being set at supplier location Ø Vacuum setting confirmed at the contract manufacturing location and adjusting in the field should not be necessary Ø Resellers should not be adjusting vacuum levels independent of 3 D Systems knowledge Transform Your Products

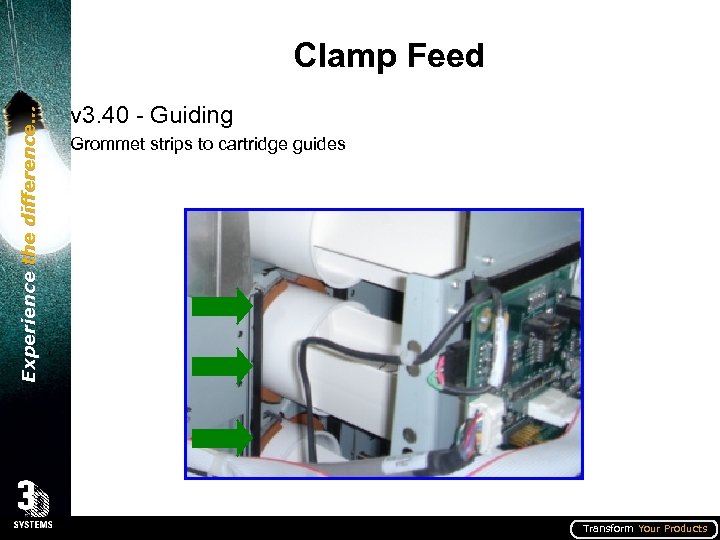

Experience the difference… Clamp Feed v 3. 40 - Guiding Grommet strips to cartridge guides Transform Your Products

Experience the difference… Clamp Feed v 3. 40 - Guiding Grommet strips to cartridge guides Transform Your Products

Experience the difference… Print head v 3. 40 - Print Head Priming Rotate Print head 135° to remove trapped air Ø \us-bur-na 01groupsUS-GJ-MS 03Doc Control CenterPUBLICATIONSIn. Visioninverted printhead procedure_Rev. zip Ø Provided inside upgrade kit Transform Your Products

Experience the difference… Print head v 3. 40 - Print Head Priming Rotate Print head 135° to remove trapped air Ø \us-bur-na 01groupsUS-GJ-MS 03Doc Control CenterPUBLICATIONSIn. Visioninverted printhead procedure_Rev. zip Ø Provided inside upgrade kit Transform Your Products

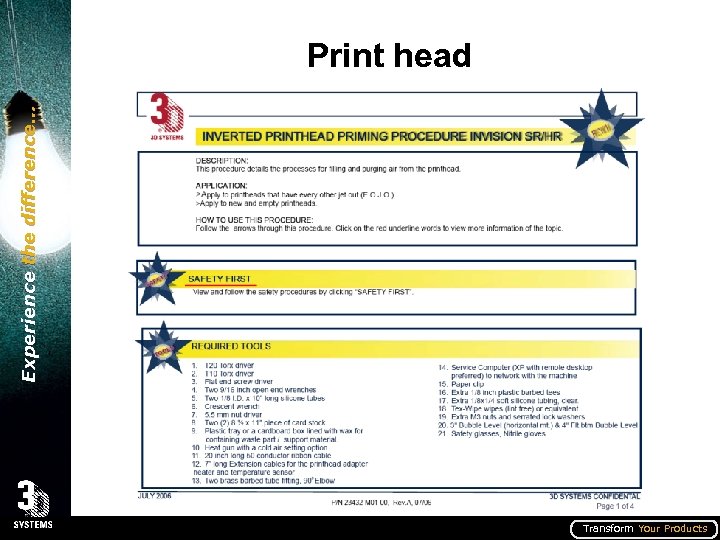

Experience the difference… Print head Transform Your Products

Experience the difference… Print head Transform Your Products

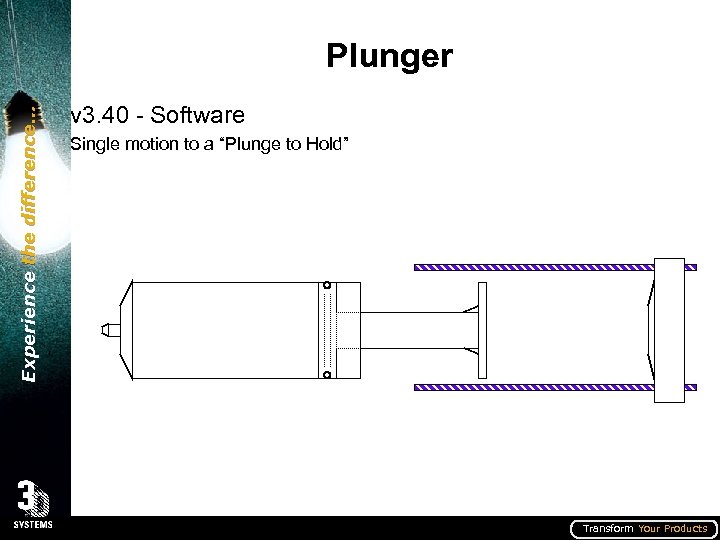

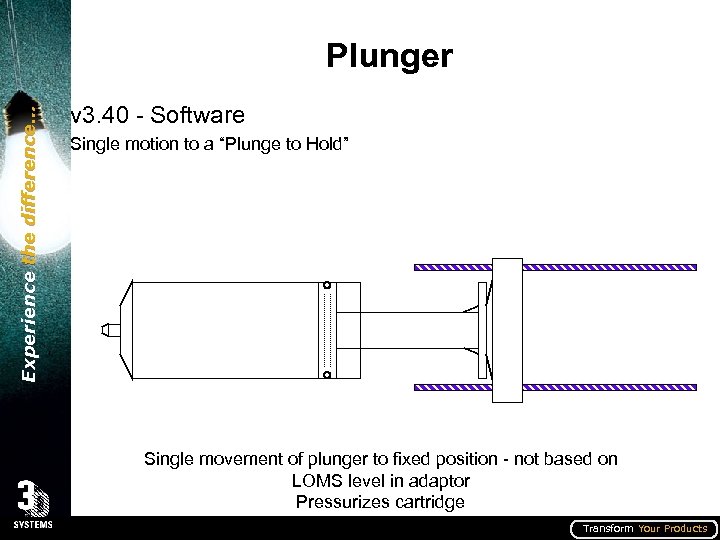

Experience the difference… Plunger v 3. 40 - Software Single motion to a “Plunge to Hold” Transform Your Products

Experience the difference… Plunger v 3. 40 - Software Single motion to a “Plunge to Hold” Transform Your Products

Experience the difference… Plunger v 3. 40 - Software Single motion to a “Plunge to Hold” Single movement of plunger to fixed position - not based on LOMS level in adaptor Pressurizes cartridge Transform Your Products

Experience the difference… Plunger v 3. 40 - Software Single motion to a “Plunge to Hold” Single movement of plunger to fixed position - not based on LOMS level in adaptor Pressurizes cartridge Transform Your Products

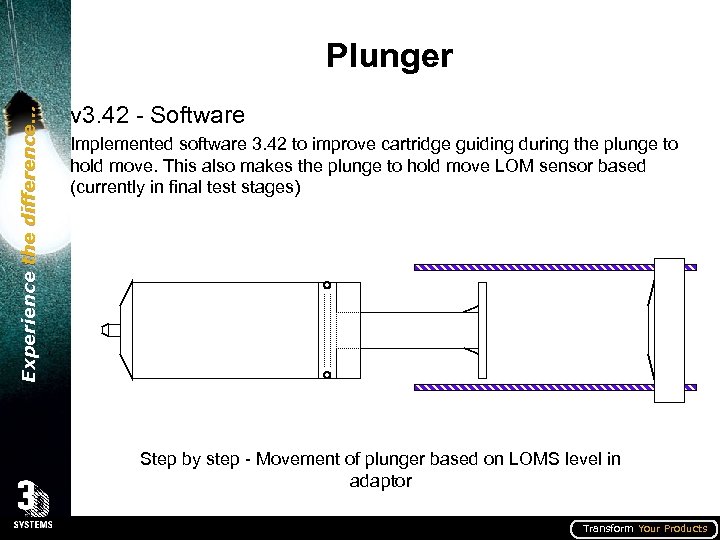

Experience the difference… Plunger v 3. 42 - Software Implemented software 3. 42 to improve cartridge guiding during the plunge to hold move. This also makes the plunge to hold move LOM sensor based (currently in final test stages) Step by step - Movement of plunger based on LOMS level in adaptor Transform Your Products

Experience the difference… Plunger v 3. 42 - Software Implemented software 3. 42 to improve cartridge guiding during the plunge to hold move. This also makes the plunge to hold move LOM sensor based (currently in final test stages) Step by step - Movement of plunger based on LOMS level in adaptor Transform Your Products

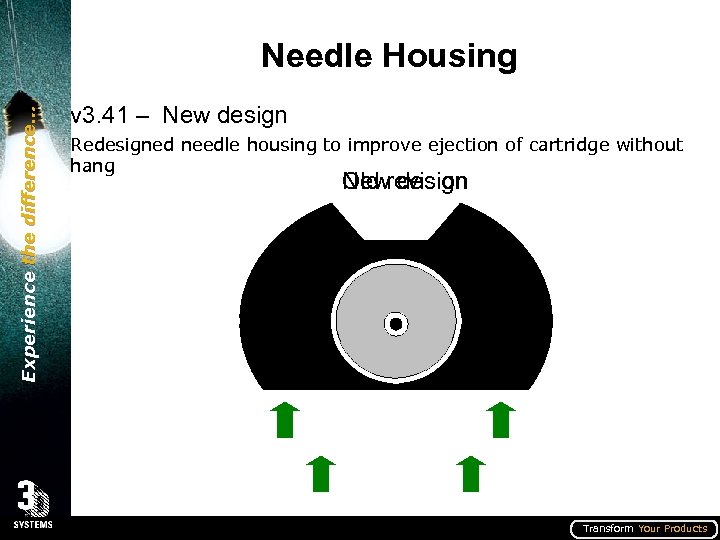

Experience the difference… Needle Housing v 3. 41 – New design Redesigned needle housing to improve ejection of cartridge without hang Old revision New design Transform Your Products

Experience the difference… Needle Housing v 3. 41 – New design Redesigned needle housing to improve ejection of cartridge without hang Old revision New design Transform Your Products

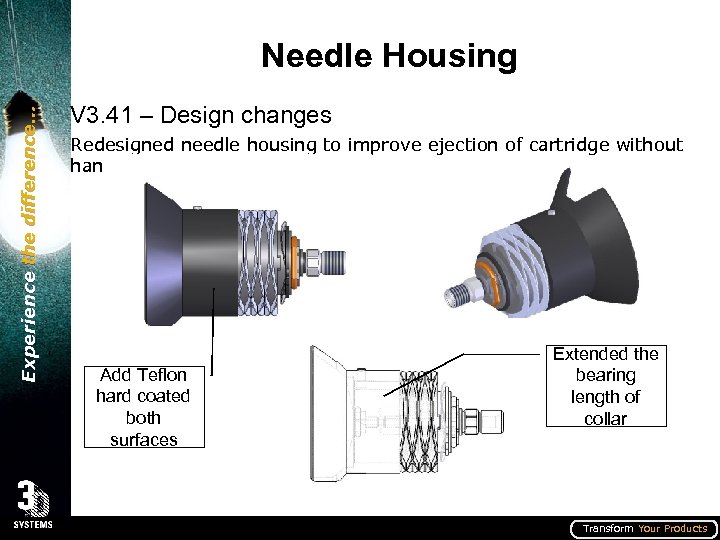

Experience the difference… Needle Housing V 3. 41 – Design changes Redesigned needle housing to improve ejection of cartridge without hang Add Teflon hard coated both surfaces Extended the bearing length of collar Transform Your Products

Experience the difference… Needle Housing V 3. 41 – Design changes Redesigned needle housing to improve ejection of cartridge without hang Add Teflon hard coated both surfaces Extended the bearing length of collar Transform Your Products

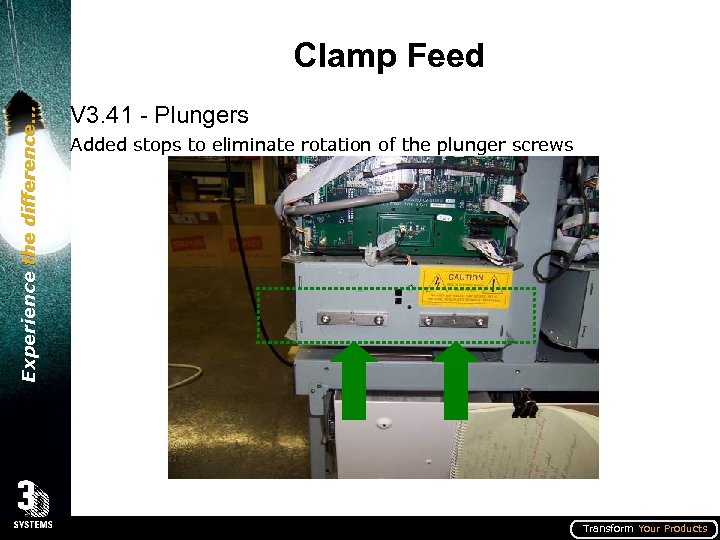

Experience the difference… Clamp Feed V 3. 41 - Plungers Added stops to eliminate rotation of the plunger screws Transform Your Products

Experience the difference… Clamp Feed V 3. 41 - Plungers Added stops to eliminate rotation of the plunger screws Transform Your Products

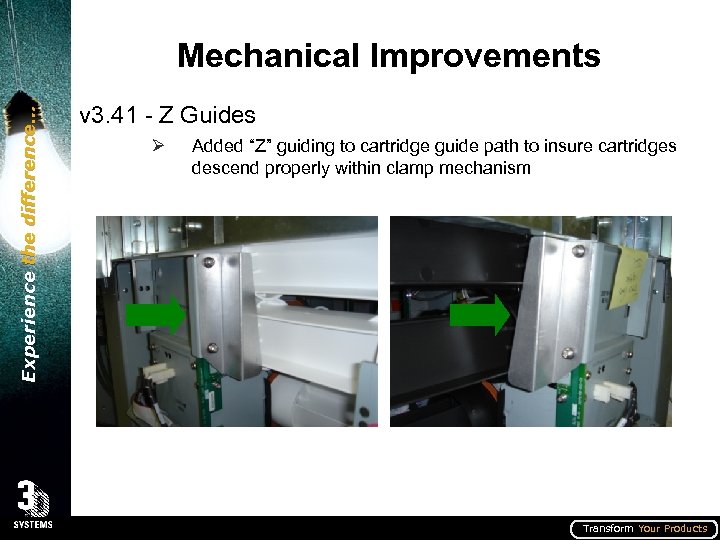

Experience the difference… Mechanical Improvements v 3. 41 - Z Guides Ø Added “Z” guiding to cartridge guide path to insure cartridges descend properly within clamp mechanism Transform Your Products

Experience the difference… Mechanical Improvements v 3. 41 - Z Guides Ø Added “Z” guiding to cartridge guide path to insure cartridges descend properly within clamp mechanism Transform Your Products

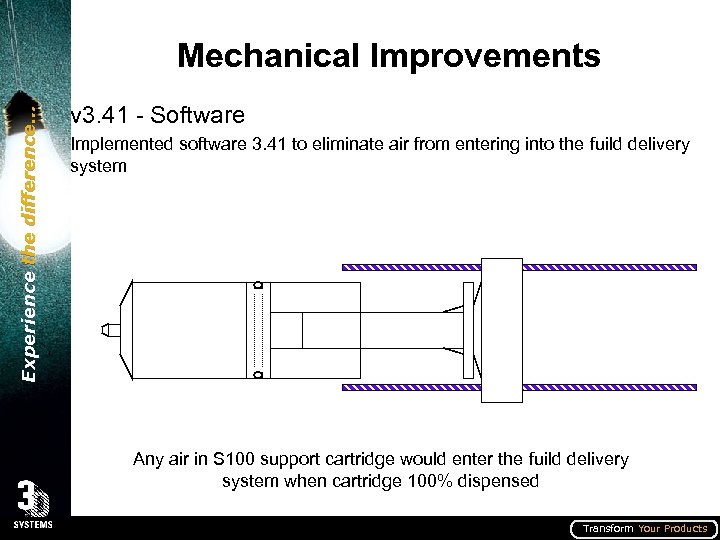

Experience the difference… Mechanical Improvements v 3. 41 - Software Implemented software 3. 41 to eliminate air from entering into the fuild delivery system Any air in S 100 support cartridge would enter the fuild delivery system when cartridge 100% dispensed Transform Your Products

Experience the difference… Mechanical Improvements v 3. 41 - Software Implemented software 3. 41 to eliminate air from entering into the fuild delivery system Any air in S 100 support cartridge would enter the fuild delivery system when cartridge 100% dispensed Transform Your Products

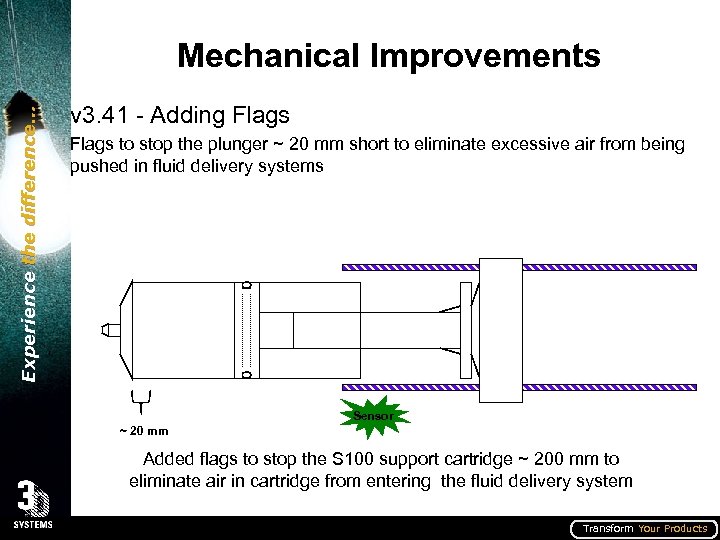

Experience the difference… Mechanical Improvements v 3. 41 - Adding Flags to stop the plunger ~ 20 mm short to eliminate excessive air from being pushed in fluid delivery systems Sensor ~ 20 mm Added flags to stop the S 100 support cartridge ~ 200 mm to eliminate air in cartridge from entering the fluid delivery system Transform Your Products

Experience the difference… Mechanical Improvements v 3. 41 - Adding Flags to stop the plunger ~ 20 mm short to eliminate excessive air from being pushed in fluid delivery systems Sensor ~ 20 mm Added flags to stop the S 100 support cartridge ~ 200 mm to eliminate air in cartridge from entering the fluid delivery system Transform Your Products

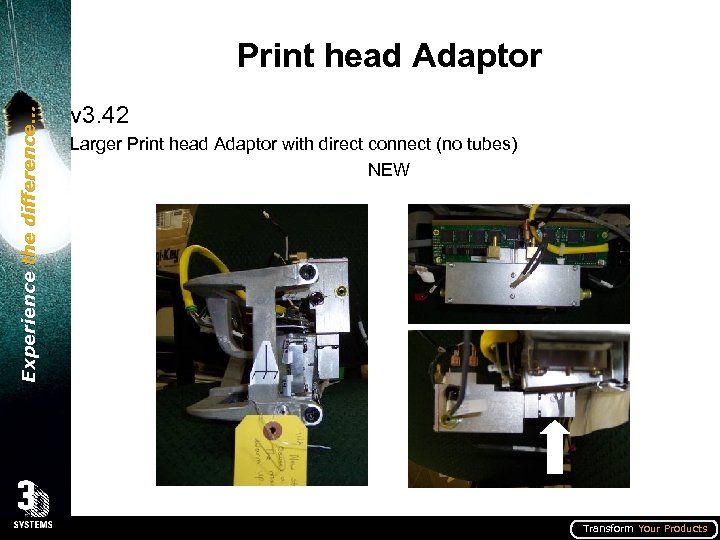

Experience the difference… Print head Adaptor v 3. 42 Larger Print head Adaptor with direct connect (no tubes) NEW Transform Your Products

Experience the difference… Print head Adaptor v 3. 42 Larger Print head Adaptor with direct connect (no tubes) NEW Transform Your Products

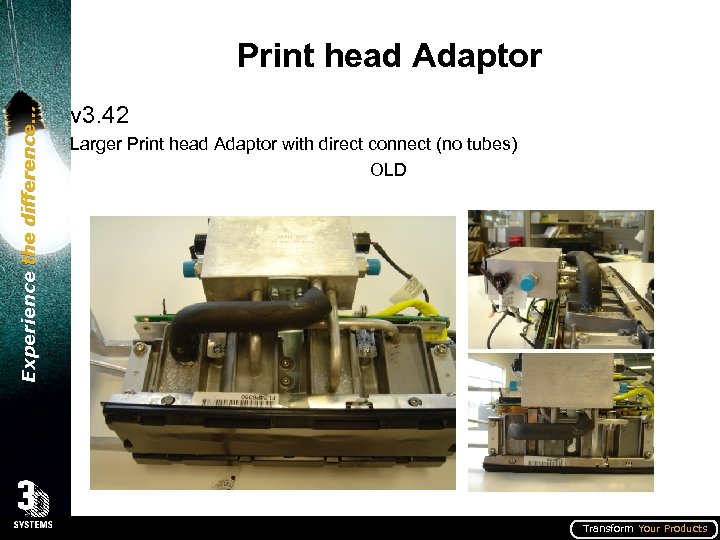

Experience the difference… Print head Adaptor v 3. 42 Larger Print head Adaptor with direct connect (no tubes) OLD Transform Your Products

Experience the difference… Print head Adaptor v 3. 42 Larger Print head Adaptor with direct connect (no tubes) OLD Transform Your Products

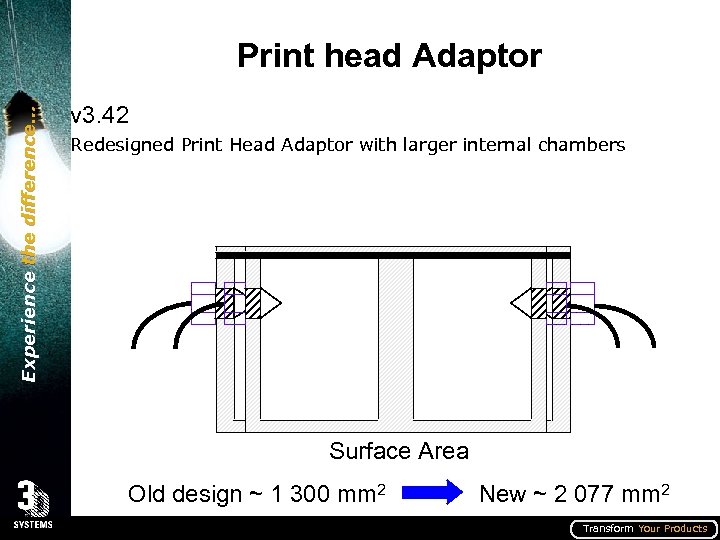

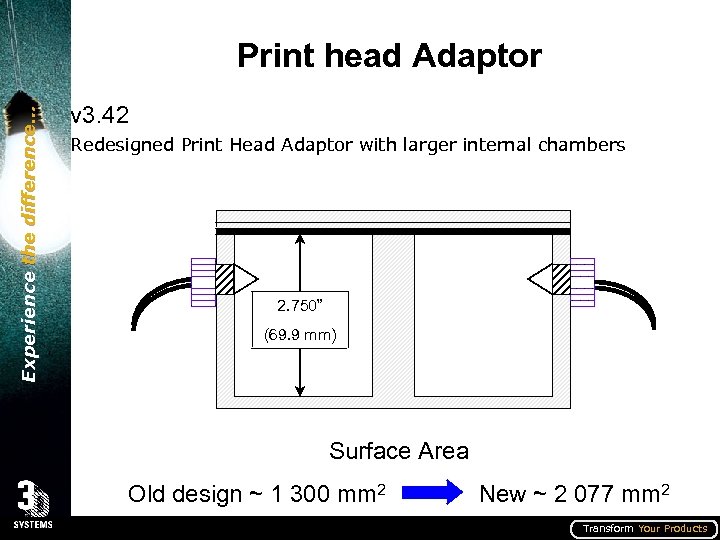

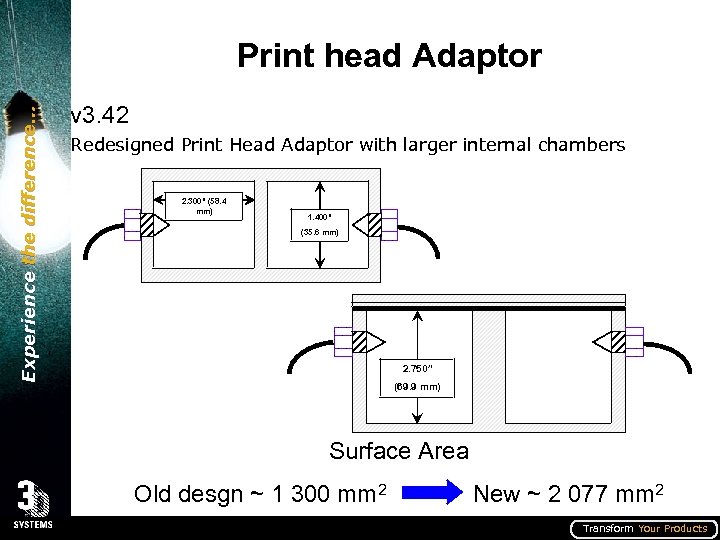

Experience the difference… Print head Adaptor v 3. 42 Redesigned Print Head Adaptor with larger internal chambers Surface Area Old design ~ 1 300 mm 2 New ~ 2 077 mm 2 Transform Your Products

Experience the difference… Print head Adaptor v 3. 42 Redesigned Print Head Adaptor with larger internal chambers Surface Area Old design ~ 1 300 mm 2 New ~ 2 077 mm 2 Transform Your Products

Experience the difference… Print head Adaptor v 3. 42 Redesigned Print Head Adaptor with larger internal chambers 2. 300” (58. 4 mm) 1. 400” (35. 6 mm) 2. 750” (69. 9 mm) Surface Area Old design ~ 1 300 mm 2 New ~ 2 077 mm 2 Transform Your Products

Experience the difference… Print head Adaptor v 3. 42 Redesigned Print Head Adaptor with larger internal chambers 2. 300” (58. 4 mm) 1. 400” (35. 6 mm) 2. 750” (69. 9 mm) Surface Area Old design ~ 1 300 mm 2 New ~ 2 077 mm 2 Transform Your Products

Experience the difference… Print head Adaptor v 3. 42 Redesigned Print Head Adaptor with larger internal chambers 2. 300” (58. 4 mm) 1. 400” (35. 6 mm) 2. 300” (58. 4 mm) 2. 750” (69. 9 mm) 1. 400” (35. 6 mm) Surface Area Old desgn ~ 1 300 mm 2 New ~ 2 077 mm 2 Transform Your Products

Experience the difference… Print head Adaptor v 3. 42 Redesigned Print Head Adaptor with larger internal chambers 2. 300” (58. 4 mm) 1. 400” (35. 6 mm) 2. 300” (58. 4 mm) 2. 750” (69. 9 mm) 1. 400” (35. 6 mm) Surface Area Old desgn ~ 1 300 mm 2 New ~ 2 077 mm 2 Transform Your Products

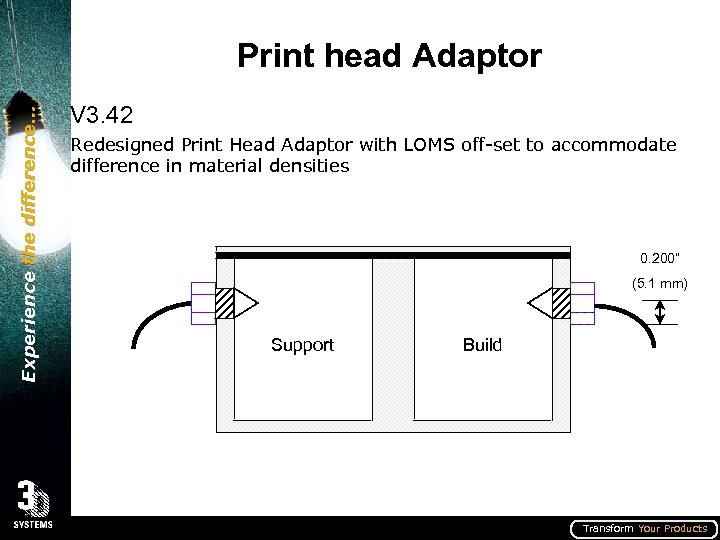

Experience the difference… Print head Adaptor V 3. 42 Redesigned Print Head Adaptor with LOMS off-set to accommodate difference in material densities 0. 200” (5. 1 mm) Support Build Transform Your Products

Experience the difference… Print head Adaptor V 3. 42 Redesigned Print Head Adaptor with LOMS off-set to accommodate difference in material densities 0. 200” (5. 1 mm) Support Build Transform Your Products

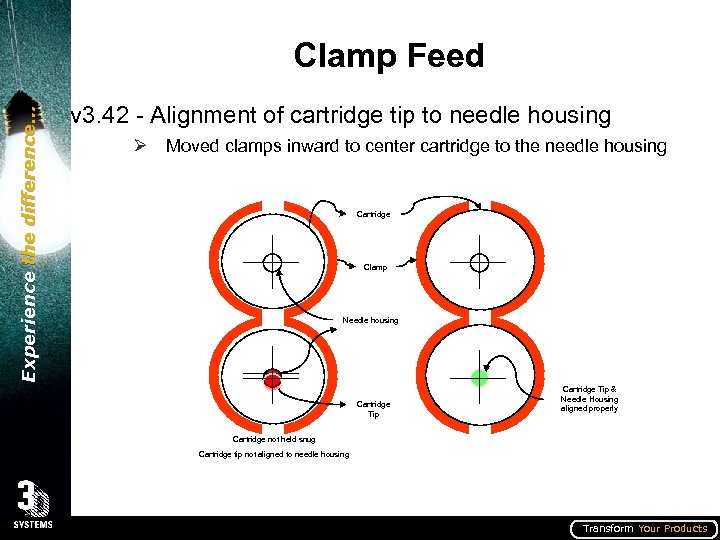

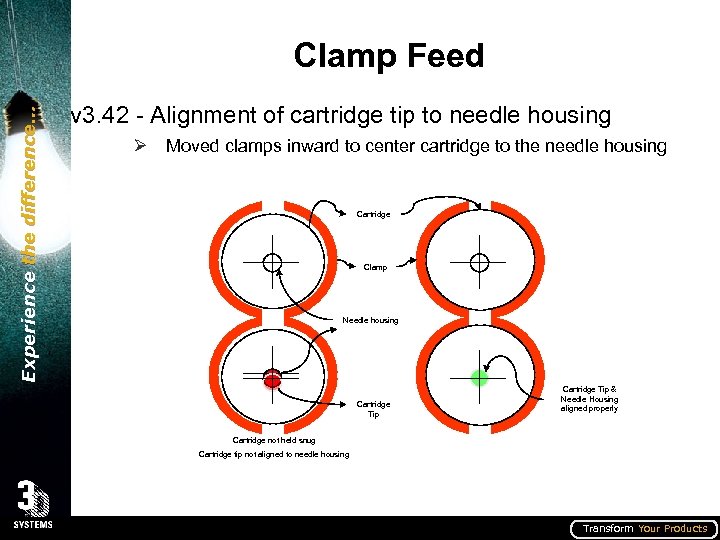

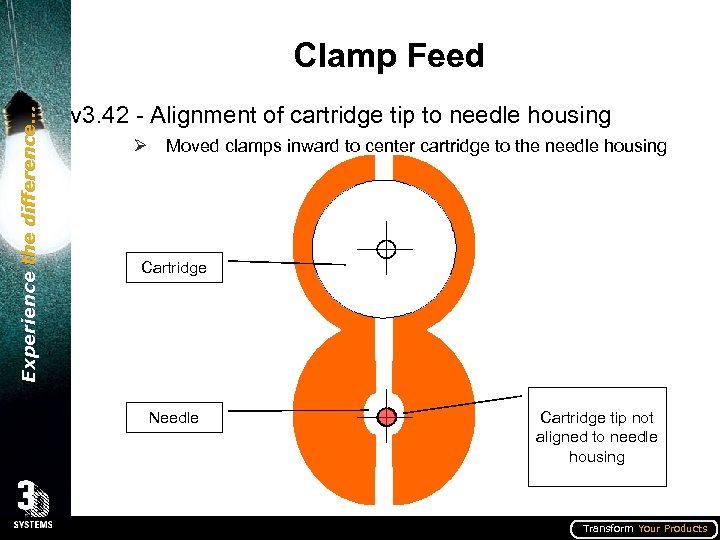

Experience the difference… Clamp Feed v 3. 42 - Alignment of cartridge tip to needle housing Ø Moved clamps inward to center cartridge to the needle housing Cartridge Clamp Needle housing Cartridge Tip & Needle Housing aligned properly Cartridge not held snug Cartridge tip not aligned to needle housing Transform Your Products

Experience the difference… Clamp Feed v 3. 42 - Alignment of cartridge tip to needle housing Ø Moved clamps inward to center cartridge to the needle housing Cartridge Clamp Needle housing Cartridge Tip & Needle Housing aligned properly Cartridge not held snug Cartridge tip not aligned to needle housing Transform Your Products

Experience the difference… Clamp Feed v 3. 42 - Alignment of cartridge tip to needle housing Ø Moved clamps inward to center cartridge to the needle housing Cartridge Clamp Needle housing Cartridge Tip & Needle Housing aligned properly Cartridge not held snug Cartridge tip not aligned to needle housing Transform Your Products

Experience the difference… Clamp Feed v 3. 42 - Alignment of cartridge tip to needle housing Ø Moved clamps inward to center cartridge to the needle housing Cartridge Clamp Needle housing Cartridge Tip & Needle Housing aligned properly Cartridge not held snug Cartridge tip not aligned to needle housing Transform Your Products

Experience the difference… Clamp Feed v 3. 42 - Alignment of cartridge tip to needle housing Ø Moved clamps inward to center cartridge to the needle housing Cartridge Needle Cartridge tip not aligned to needle housing Transform Your Products

Experience the difference… Clamp Feed v 3. 42 - Alignment of cartridge tip to needle housing Ø Moved clamps inward to center cartridge to the needle housing Cartridge Needle Cartridge tip not aligned to needle housing Transform Your Products

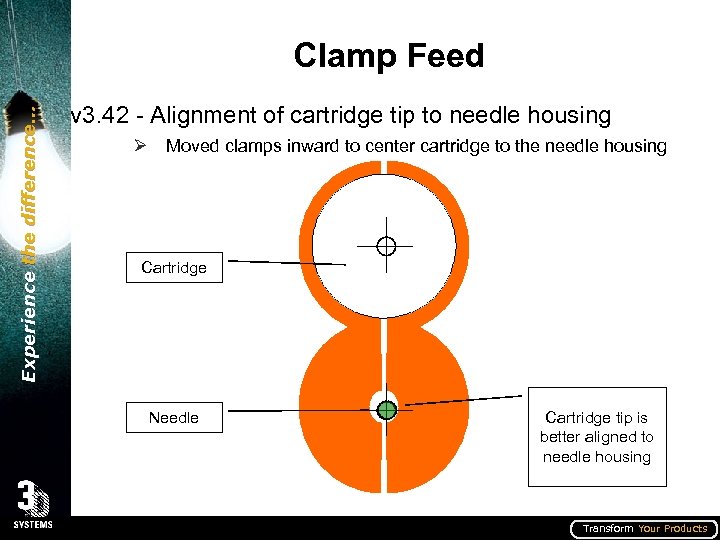

Experience the difference… Clamp Feed v 3. 42 - Alignment of cartridge tip to needle housing Ø Moved clamps inward to center cartridge to the needle housing Cartridge Needle Cartridge tip is better aligned to needle housing Transform Your Products

Experience the difference… Clamp Feed v 3. 42 - Alignment of cartridge tip to needle housing Ø Moved clamps inward to center cartridge to the needle housing Cartridge Needle Cartridge tip is better aligned to needle housing Transform Your Products

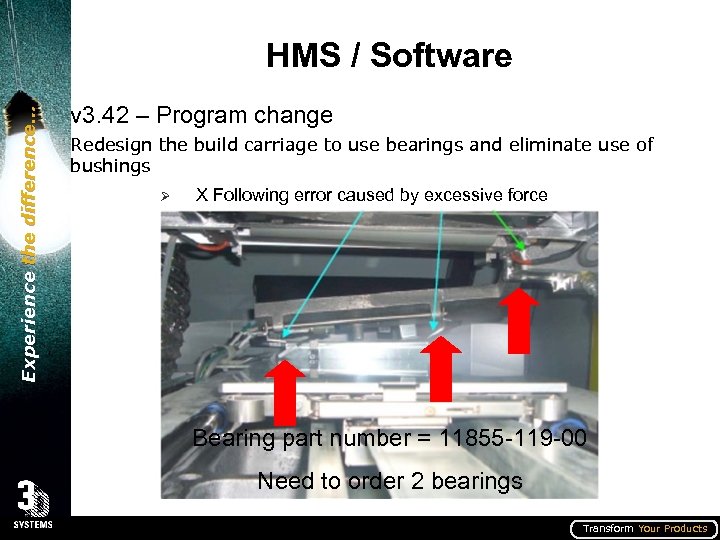

Experience the difference… HMS / Software v 3. 42 – Program change Redesign the build carriage to use bearings and eliminate use of bushings Ø X Following error caused by excessive force Ø Print head homes while the HMS engaged Bearing part number = 11855 -119 -00 Need to order 2 bearings Transform Your Products

Experience the difference… HMS / Software v 3. 42 – Program change Redesign the build carriage to use bearings and eliminate use of bushings Ø X Following error caused by excessive force Ø Print head homes while the HMS engaged Bearing part number = 11855 -119 -00 Need to order 2 bearings Transform Your Products

Experience the difference… Material Improvements SR 200/HR 200/DP 200 2 year expiration date build material manufactured after 01 -Jan-2007 Ø Eliminate unnecessary RMA / Returned material Ø Customer complaints on receipt of material with < 6 months expiry date Ø Software v 3. 42 will accommodate material produced prior to 01 -Jan-2007 Added stabilizer to eliminate clogged jets, waste tanks and waste umbilical when build and support materials reacting when co-mixing Transform Your Products

Experience the difference… Material Improvements SR 200/HR 200/DP 200 2 year expiration date build material manufactured after 01 -Jan-2007 Ø Eliminate unnecessary RMA / Returned material Ø Customer complaints on receipt of material with < 6 months expiry date Ø Software v 3. 42 will accommodate material produced prior to 01 -Jan-2007 Added stabilizer to eliminate clogged jets, waste tanks and waste umbilical when build and support materials reacting when co-mixing Transform Your Products

Experience the difference… RMA / Returns Ø All part returns should be coordinated with Frank Vullhorst Ø Non-conforming parts should be returned to UPS Col. Using a RMA # Transform Your Products

Experience the difference… RMA / Returns Ø All part returns should be coordinated with Frank Vullhorst Ø Non-conforming parts should be returned to UPS Col. Using a RMA # Transform Your Products