38934e864eb82bf648d7217a03ac911a.ppt

- Количество слайдов: 23

Transferring from Chabot to UC Berkeley Robert Moore May 5, 2014

Why Engineering? • Grew up around cars, always fascinated with anything with an engine • Became interested in metal fabrication • Graduated from James Logan in 2002 • Took welding and machining classes in high school and at Chabot, as well as GE • Started at Math 55 at Chabot • Went to work as a machinist for 2 years

Path to Transferring • Decided to go back to school to pursue Engineering • Started back at Chabot full time in Fall 2006 • Worked ~20 hours / week while going to school • Took 3 years to complete coursework at Chabot

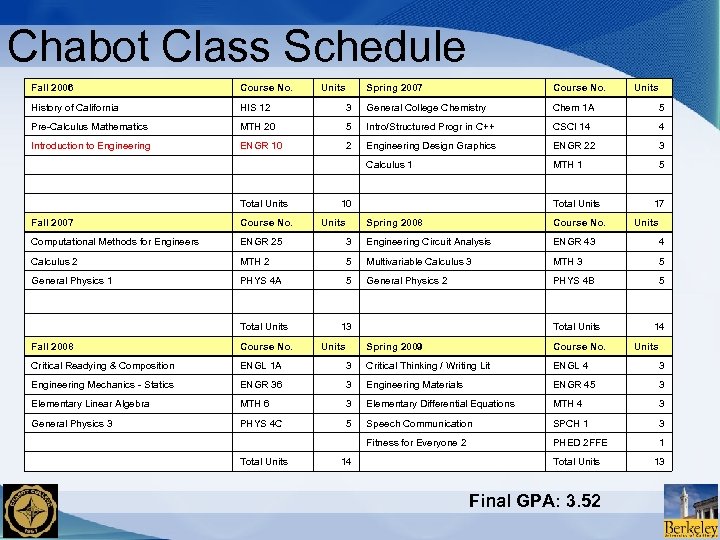

Chabot Class Schedule Fall 2006 Course No. History of California HIS 12 Pre-Calculus Mathematics Units Spring 2007 Course No. 3 General College Chemistry Chem 1 A 5 MTH 20 5 Intro/Structured Progr in C++ CSCI 14 4 Introduction to Engineering ENGR 10 2 Engineering Design Graphics ENGR 22 3 Calculus 1 MTH 1 5 Total Units Fall 2007 Course No. Spring 2008 Course No. Computational Methods for Engineers ENGR 25 3 Engineering Circuit Analysis ENGR 43 4 Calculus 2 MTH 2 5 Multivariable Calculus 3 MTH 3 5 General Physics 1 PHYS 4 A 5 General Physics 2 PHYS 4 B 5 Total Units Fall 2008 Course No. Spring 2009 Course No. Critical Readying & Composition ENGL 1 A 3 Critical Thinking / Writing Lit ENGL 4 3 Engineering Mechanics - Statics ENGR 36 3 Engineering Materials ENGR 45 3 Elementary Linear Algebra MTH 6 3 Elementary Differential Equations MTH 4 3 General Physics 3 PHYS 4 C 5 Speech Communication SPCH 1 3 Fitness for Everyone 2 PHED 2 FFE 1 Total Units 10 Units 13 Units 14 Final GPA: 3. 52 Units 17 Units 14 Units 13

Advice for Students • Work to learn all you can in your math classes, math is essential in all future classes • Take advantage of the help offered by professors • Master study skills while at Chabot • Become skilled in Matlab

Differences between Chabot and Cal • Pace at Cal is twice as fast as Chabot • Large Classes • Test are harder and very time sensitive Biggest Surprises: • Not everyone at Cal is a genius • A student that started at Cal doesn’t have an advantage

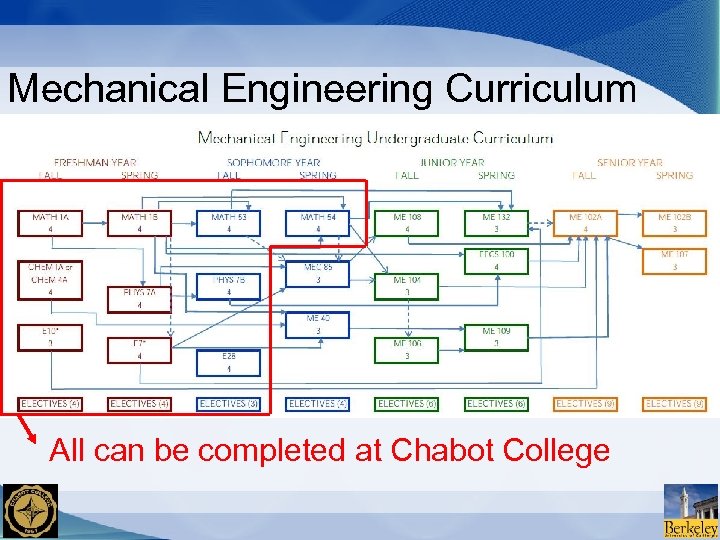

Mechanical Engineering Curriculum All can be completed at Chabot College

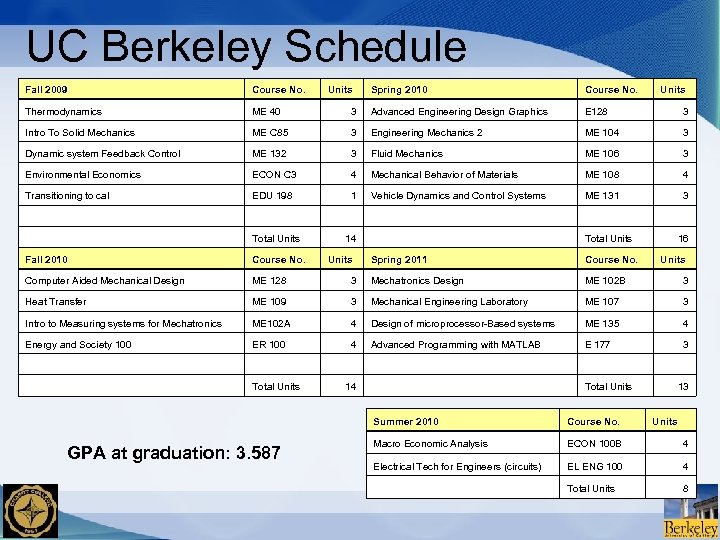

UC Berkeley Schedule Fall 2009 Course No. Thermodynamics ME 40 Intro To Solid Mechanics Units Spring 2010 Course No. 3 Advanced Engineering Design Graphics E 128 3 ME C 85 3 Engineering Mechanics 2 ME 104 3 Dynamic system Feedback Control ME 132 3 Fluid Mechanics ME 106 3 Environmental Economics ECON C 3 4 Mechanical Behavior of Materials ME 108 4 Transitioning to cal EDU 198 1 Vehicle Dynamics and Control Systems ME 131 3 Total Units Fall 2010 Course No. Spring 2011 Course No. Computer Aided Mechanical Design ME 128 3 Mechatronics Design ME 102 B 3 Heat Transfer ME 109 3 Mechanical Engineering Laboratory ME 107 3 Intro to Measuring systems for Mechatronics ME 102 A 4 Design of microprocessor-Based systems ME 135 4 Energy and Society 100 ER 100 4 Advanced Programming with MATLAB E 177 3 Total Units 14 Units 16 Units 13 Summer 2010 GPA at graduation: 3. 587 Course No. Units Macro Economic Analysis ECON 100 B 4 Electrical Tech for Engineers (circuits) EL ENG 100 4 Total Units 8

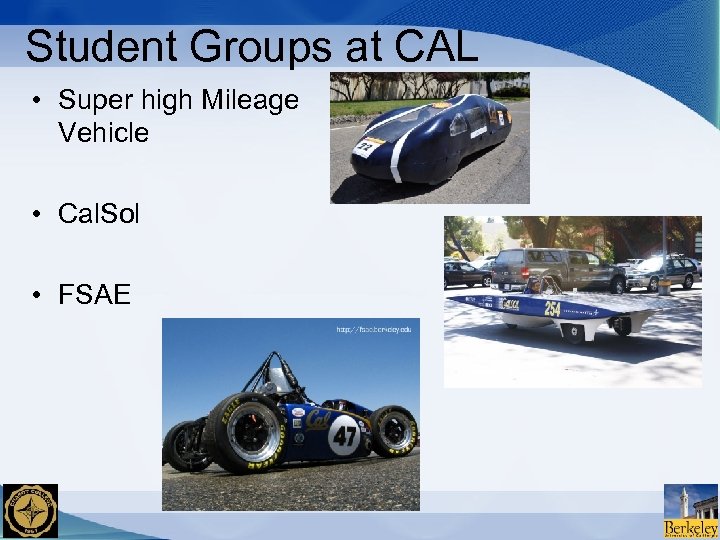

Student Groups at CAL • Super high Mileage Vehicle • Cal. Sol • FSAE

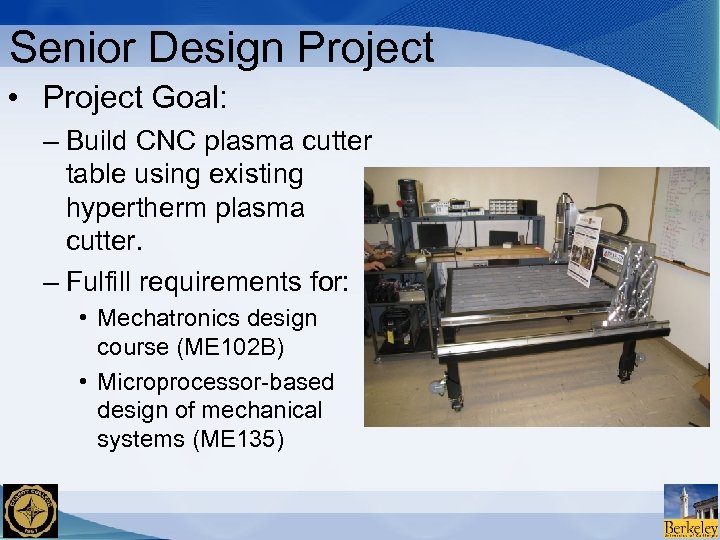

Senior Design Project • Project Goal: – Build CNC plasma cutter table using existing hypertherm plasma cutter. – Fulfill requirements for: • Mechatronics design course (ME 102 B) • Microprocessor-based design of mechanical systems (ME 135)

CNC Plasma Cutter - requirements • Requirements – Cut 4’ x 4’ sheet – Must be semi-portable – Cost not to exceed $2000 – Maximum Cutting speed 385 in/min. – Positioning accuracy to 0. 005” – Cutting tip speed must be held constant for best cutting finish

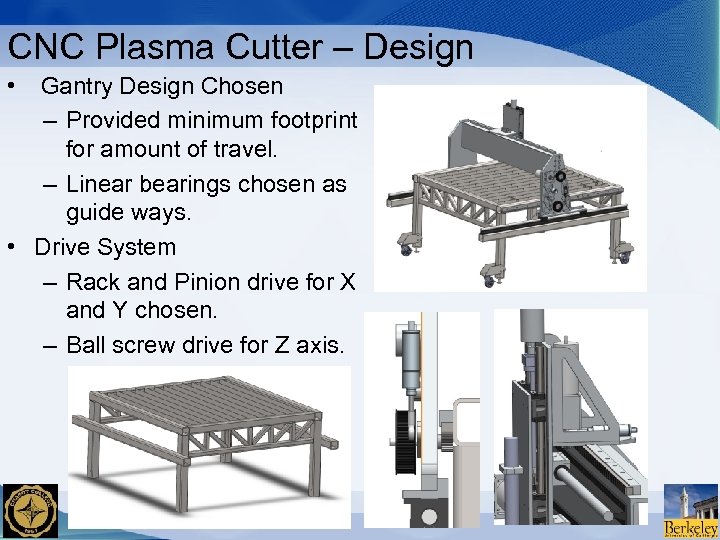

CNC Plasma Cutter – Design • Gantry Design Chosen – Provided minimum footprint for amount of travel. – Linear bearings chosen as guide ways. • Drive System – Rack and Pinion drive for X and Y chosen. – Ball screw drive for Z axis.

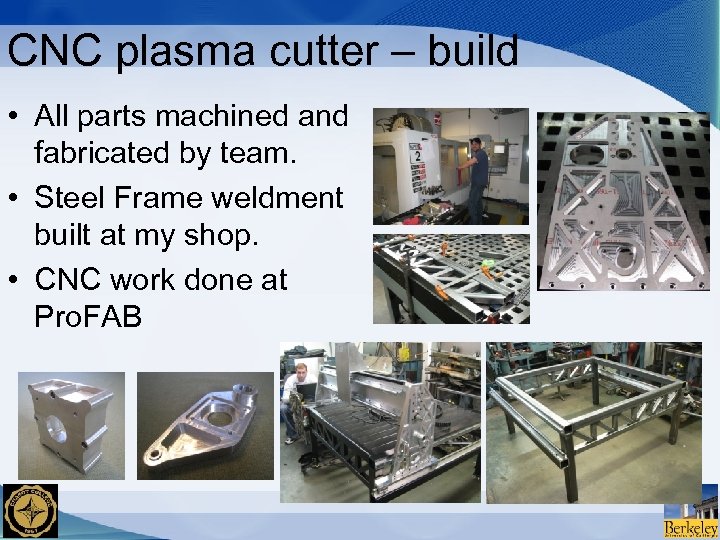

CNC plasma cutter – build • All parts machined and fabricated by team. • Steel Frame weldment built at my shop. • CNC work done at Pro. FAB

CNC plasma cutter - results • Project won best design award for spring 2011.

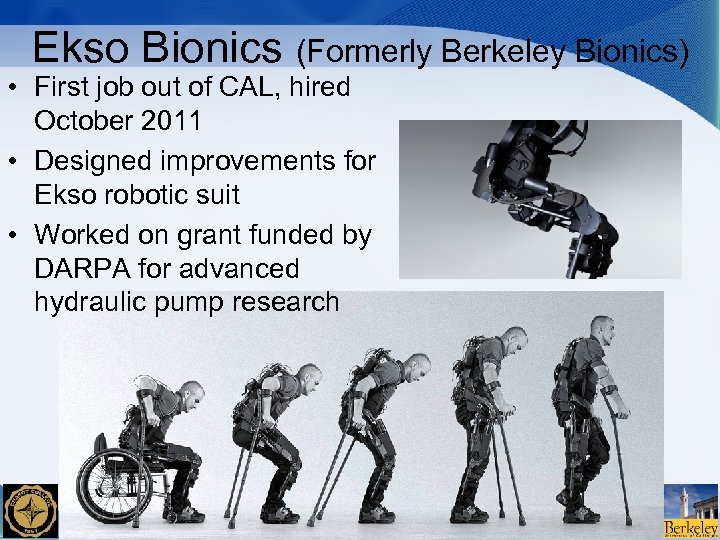

Ekso Bionics (Formerly Berkeley Bionics) • First job out of CAL, hired October 2011 • Designed improvements for Ekso robotic suit • Worked on grant funded by DARPA for advanced hydraulic pump research

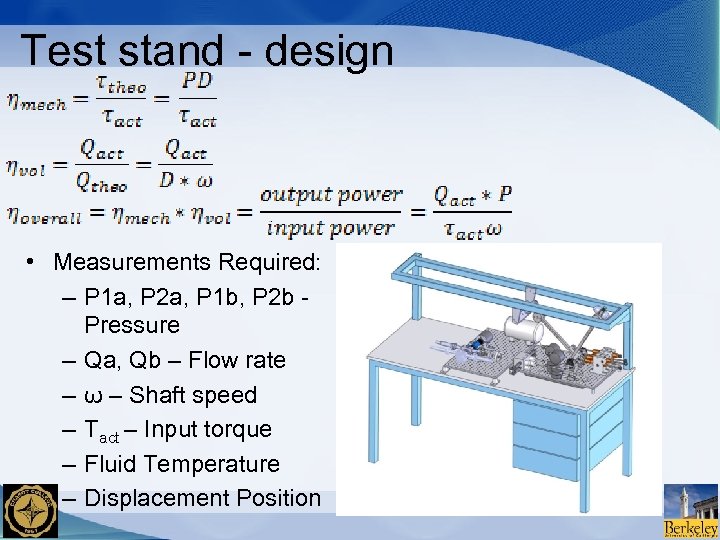

Hyd pump & test stand • Project Overview – DARPA grant funded project to build low-noise high efficiency mobile hydraulic system. – Worked with subcontractor to design hydraulic pump. All actuation designed in house. • Project required a test stand to be designed to evaluate performance of new pumps versus existing technology.

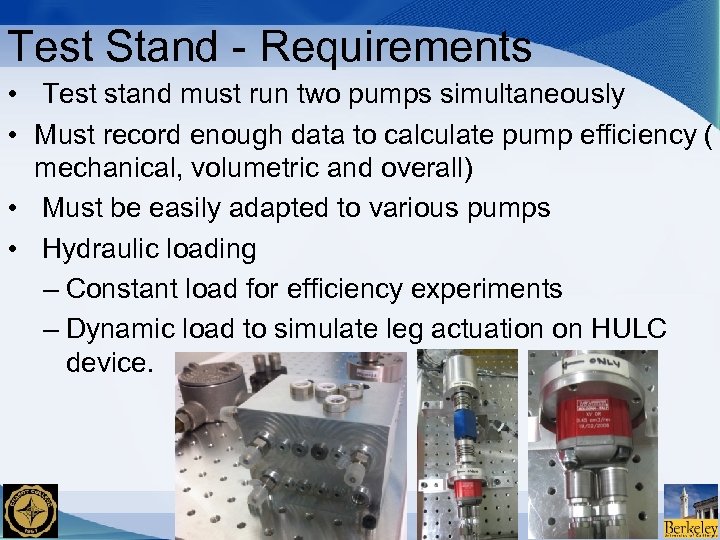

Test Stand - Requirements • Test stand must run two pumps simultaneously • Must record enough data to calculate pump efficiency ( mechanical, volumetric and overall) • Must be easily adapted to various pumps • Hydraulic loading – Constant load for efficiency experiments – Dynamic load to simulate leg actuation on HULC device.

Test stand - design • Measurements Required: – P 1 a, P 2 a, P 1 b, P 2 b - Pressure – Qa, Qb – Flow rate – ω – Shaft speed – Τact – Input torque – Fluid Temperature – Displacement Position

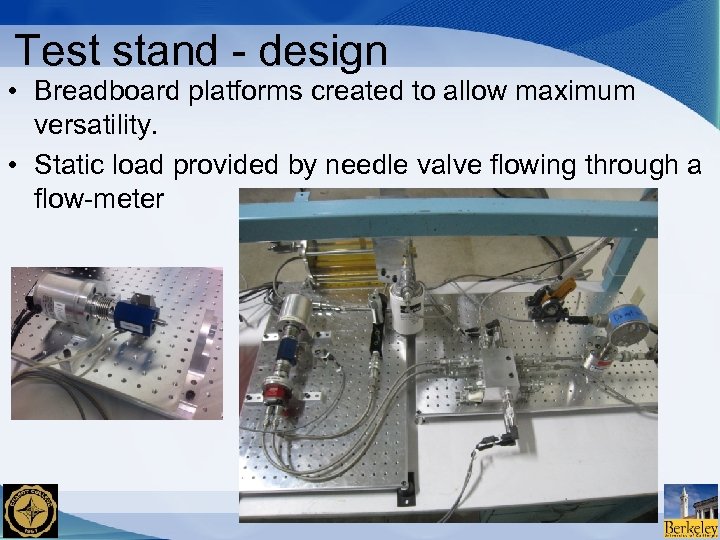

Test stand - design • Breadboard platforms created to allow maximum versatility. • Static load provided by needle valve flowing through a flow-meter

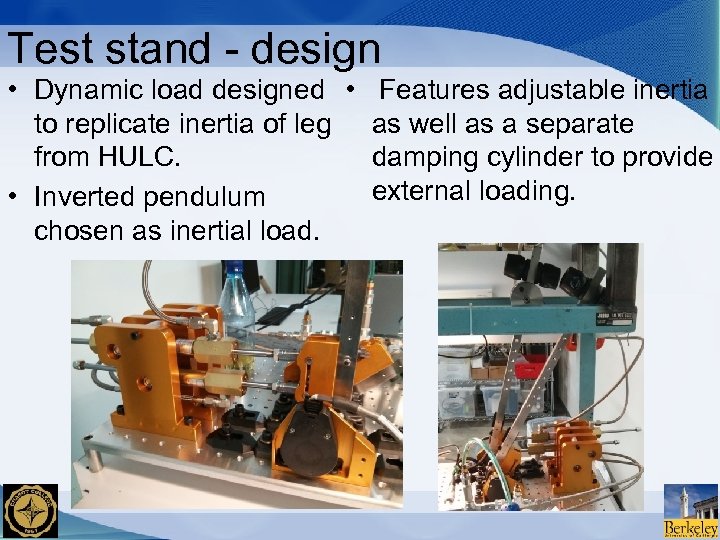

Test stand - design • Dynamic load designed • to replicate inertia of leg from HULC. • Inverted pendulum chosen as inertial load. Features adjustable inertia as well as a separate damping cylinder to provide external loading.

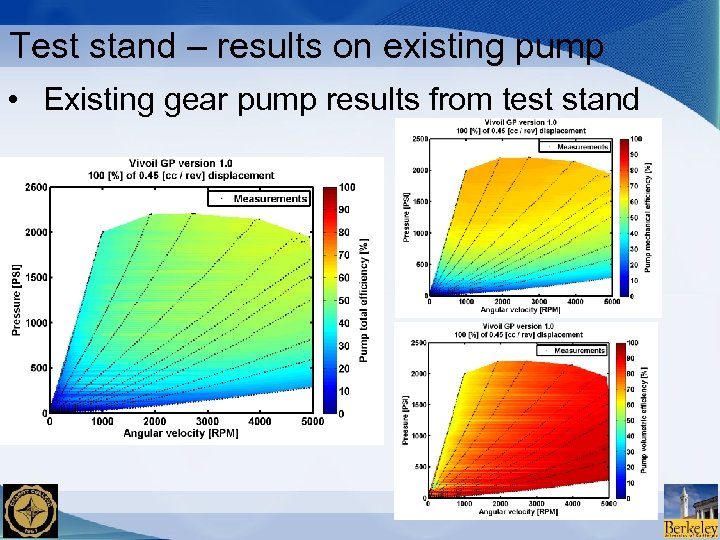

Test stand – results on existing pump • Existing gear pump results from test stand

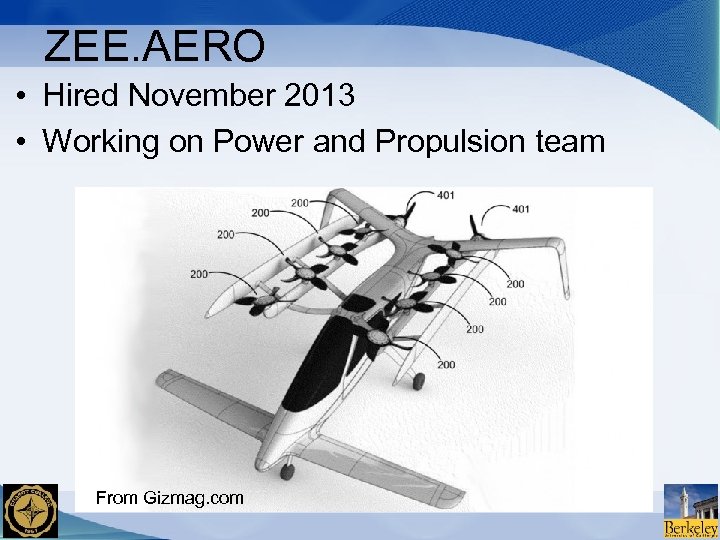

ZEE. AERO • Hired November 2013 • Working on Power and Propulsion team From Gizmag. com

Any Questions? • e-mail me any questions: robertwmoore 17@gmail. com Information: fsae. berkeley. edu me. berkeley. edu coe. berkeley. edu

38934e864eb82bf648d7217a03ac911a.ppt