Transducers Ultrasound is produced and detected with a

16076-lecture_ultrasound_beams.ppt

- Количество слайдов: 125

Transducers

Transducers

Ultrasound is produced and detected with a transducer, composed of one or more ceramic elements with electromechanical (piezoelectric) properties. The ceramic element converts electrical energy into mechanical energy to produce ultrasound and mechanical energy into electrical energy for ultrasound detection.

Ultrasound is produced and detected with a transducer, composed of one or more ceramic elements with electromechanical (piezoelectric) properties. The ceramic element converts electrical energy into mechanical energy to produce ultrasound and mechanical energy into electrical energy for ultrasound detection.

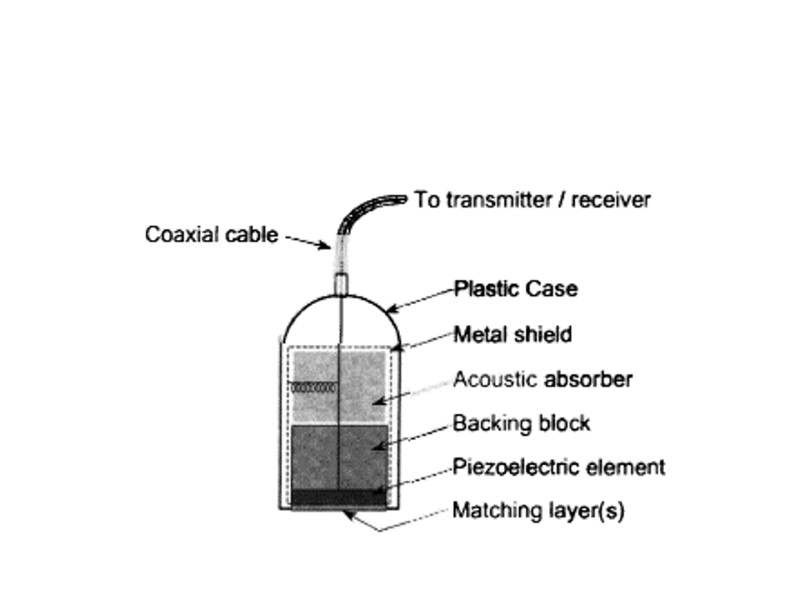

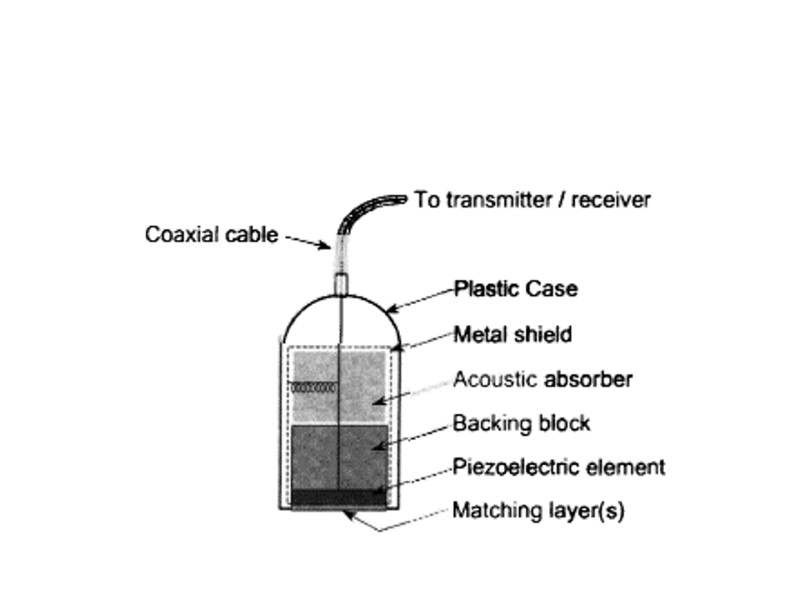

Over the past several decades, the transducer assembly has evolved considerably in design, function, and capability, from a single-element resonance crystal to a broadband transducer array of hundreds of individual elements. A simple single-element, plane-piston source transducer has major components including the piezoelectric material, marching layer, backing block, acoustic absorber, insulating cover, sensor electrodes, and transducer housing.

Over the past several decades, the transducer assembly has evolved considerably in design, function, and capability, from a single-element resonance crystal to a broadband transducer array of hundreds of individual elements. A simple single-element, plane-piston source transducer has major components including the piezoelectric material, marching layer, backing block, acoustic absorber, insulating cover, sensor electrodes, and transducer housing.

Piezoelectric Materials A piezoelectric material (often a crystal or ceramic) is the functional component of the transducer. It converts electrical energy into mechanical (sound) energy by physical deformation of the crystal structure.

Piezoelectric Materials A piezoelectric material (often a crystal or ceramic) is the functional component of the transducer. It converts electrical energy into mechanical (sound) energy by physical deformation of the crystal structure.

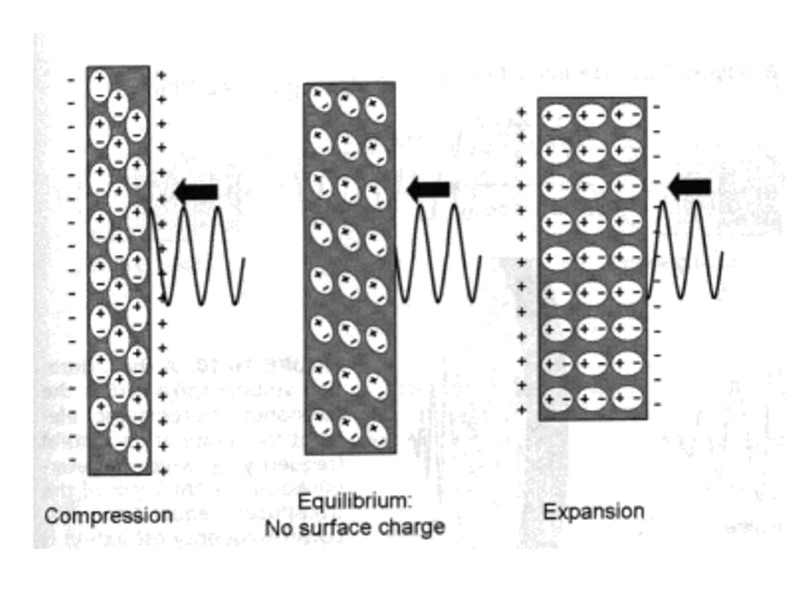

ConverseIy, mechanical pressure applied to its surface creates electrical energy. Piezoelectric materials are characterized by a well-defined molecular arrangement of electrical dipoles (Fig. 16-9).

ConverseIy, mechanical pressure applied to its surface creates electrical energy. Piezoelectric materials are characterized by a well-defined molecular arrangement of electrical dipoles (Fig. 16-9).

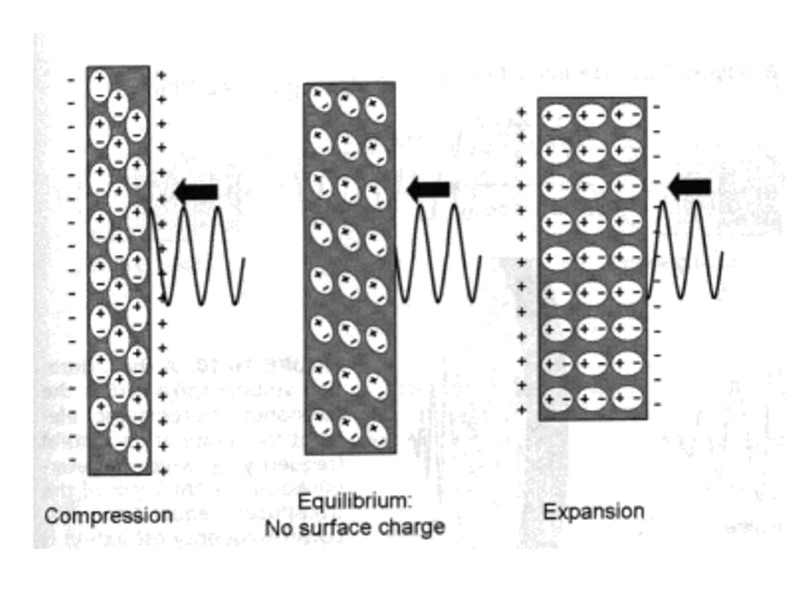

An electrical dipole is a molecular entity containing positive and negative electric charges that has no net charge. When mechanically compressed by an externally applied pressure, the alignment of the dipoles is disturbed from the equilibrium position to cause an imbalance of the charge distribution.

An electrical dipole is a molecular entity containing positive and negative electric charges that has no net charge. When mechanically compressed by an externally applied pressure, the alignment of the dipoles is disturbed from the equilibrium position to cause an imbalance of the charge distribution.

A potential difference (voltage) is created across the element with one surface maintaining a net positive charge and one surface a net negative charge. Surface electrodes measure the voltage, which is proportional to the incident mechanical pressure amplitude.

A potential difference (voltage) is created across the element with one surface maintaining a net positive charge and one surface a net negative charge. Surface electrodes measure the voltage, which is proportional to the incident mechanical pressure amplitude.

Conversely, application of an external voltage through conductors attached to the surface electrodes induces the mechanical expansion and contraction of the transducer element.

Conversely, application of an external voltage through conductors attached to the surface electrodes induces the mechanical expansion and contraction of the transducer element.

There are natural and synthetic piezoelectric materials. An example of a natural piezoelectric material is quartz crystal, commonly used in watches and other time pieces to provide a mechanical vibration source at 32.768 kHz for interval timing. This is one of several oscillation frequencies of quartz, determined by the crystal cut and machining properties.

There are natural and synthetic piezoelectric materials. An example of a natural piezoelectric material is quartz crystal, commonly used in watches and other time pieces to provide a mechanical vibration source at 32.768 kHz for interval timing. This is one of several oscillation frequencies of quartz, determined by the crystal cut and machining properties.

Ultrasound transducers for medical imaging applications employ a synthetic piezoelectric ceramic, most often lead-zirconate-titanate (PZT). The piezoelectric attributes are attained after a process of Molecular synthesis, Heating, Orientation of internal dipole structures with an applied external voltage, Cooling to permanently maintain the dipole orientation, and Cutting into a specific shape.

Ultrasound transducers for medical imaging applications employ a synthetic piezoelectric ceramic, most often lead-zirconate-titanate (PZT). The piezoelectric attributes are attained after a process of Molecular synthesis, Heating, Orientation of internal dipole structures with an applied external voltage, Cooling to permanently maintain the dipole orientation, and Cutting into a specific shape.

For PZT in its natural state, no piezoelectric properties are exhibited; however, heating the material past its “Curie temperature” (i.e., 3280 C to 3650 C) and applying an external voltage causes the dipoles to align in the ceramic. The external voltage is maintained until the material has cooled to below its Curie temperature. Once the material has cooled, the dipoles retain their alignment.

For PZT in its natural state, no piezoelectric properties are exhibited; however, heating the material past its “Curie temperature” (i.e., 3280 C to 3650 C) and applying an external voltage causes the dipoles to align in the ceramic. The external voltage is maintained until the material has cooled to below its Curie temperature. Once the material has cooled, the dipoles retain their alignment.

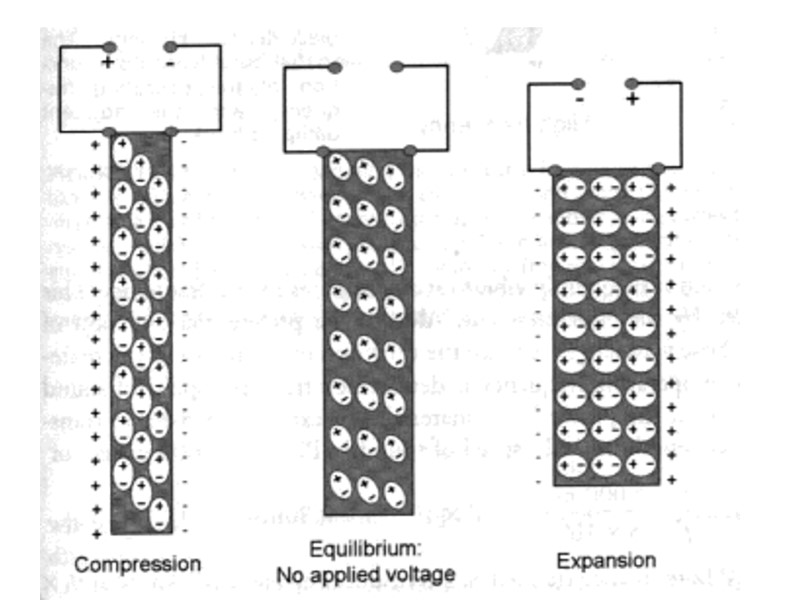

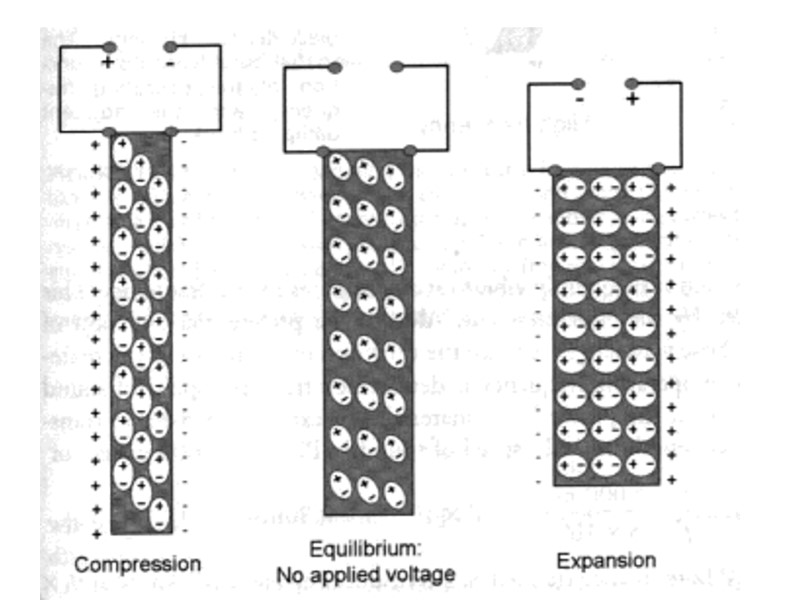

At equilibrium, there is no net charge on ceramic surfaces. When compressed, an imbalance of charge produces a voltage between the surfaces. Similarly, when a voltage is applied between electrodes attached to both surfaces, mechanical deformation occurs.

At equilibrium, there is no net charge on ceramic surfaces. When compressed, an imbalance of charge produces a voltage between the surfaces. Similarly, when a voltage is applied between electrodes attached to both surfaces, mechanical deformation occurs.

The piezoelectric element is composed of aligned molecular dipoles.

The piezoelectric element is composed of aligned molecular dipoles.

Under the influence of mechanical pressure from an adjacent medium (e.g., an ultrasound echo), the element thickness Contracts (at the peak pressure amplitude), Achieves equilibrium (with no pressure) or Expands (at the peak rarefactional pressure), This causes realignment of the electrical dipoles to produce positive and negative surface charge.

Under the influence of mechanical pressure from an adjacent medium (e.g., an ultrasound echo), the element thickness Contracts (at the peak pressure amplitude), Achieves equilibrium (with no pressure) or Expands (at the peak rarefactional pressure), This causes realignment of the electrical dipoles to produce positive and negative surface charge.

Surface electrodes (not shown) measure the voltage as a function of time.

Surface electrodes (not shown) measure the voltage as a function of time.

An external voltage source applied to the element surfaces causes compression or expansion from equilibrium by realignment of the dipoles in response to the electrical attraction or repulsion force.

An external voltage source applied to the element surfaces causes compression or expansion from equilibrium by realignment of the dipoles in response to the electrical attraction or repulsion force.

Resonance Transducers Resonance transducers for pulse echo ultrasound imaging are manufactured to operate in a “resonance” mode, whereby a voItage (commonly 150 V) of very short duration (a voltage spike of 1 msec) is applied, causing the piezoelectric material to initially contract, and subsequently vibrate at a natural resonance frequency. This frequency is selected by the “thickness cut,” due to the preferential emission of ultrasound waves whose wavelength is twice the thickness of the piezoelectric material.

Resonance Transducers Resonance transducers for pulse echo ultrasound imaging are manufactured to operate in a “resonance” mode, whereby a voItage (commonly 150 V) of very short duration (a voltage spike of 1 msec) is applied, causing the piezoelectric material to initially contract, and subsequently vibrate at a natural resonance frequency. This frequency is selected by the “thickness cut,” due to the preferential emission of ultrasound waves whose wavelength is twice the thickness of the piezoelectric material.

The operating frequency is determined from the speed of sound in, and the thickness of, the piezoelectric material. For example, a 5-MHz transducer will have a wavelength in PZT (speed of sound in PZT is 4,000 m/sec) of

The operating frequency is determined from the speed of sound in, and the thickness of, the piezoelectric material. For example, a 5-MHz transducer will have a wavelength in PZT (speed of sound in PZT is 4,000 m/sec) of

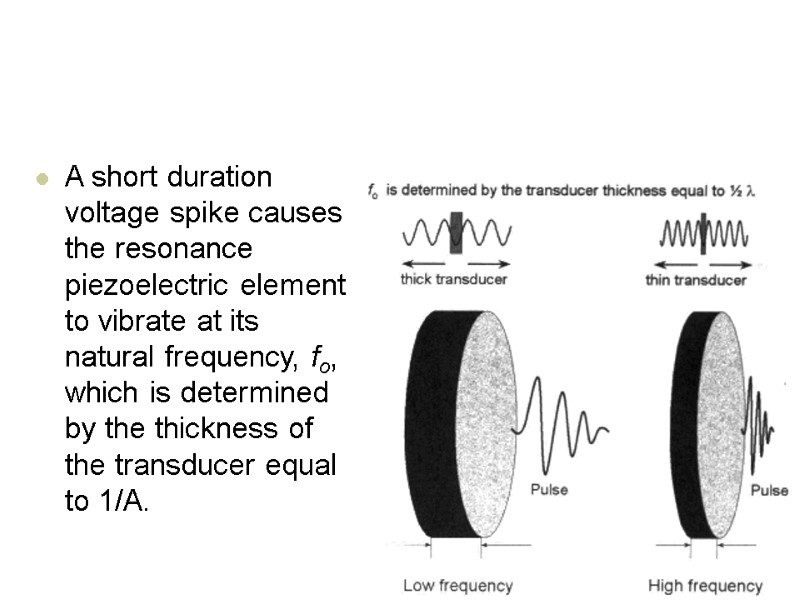

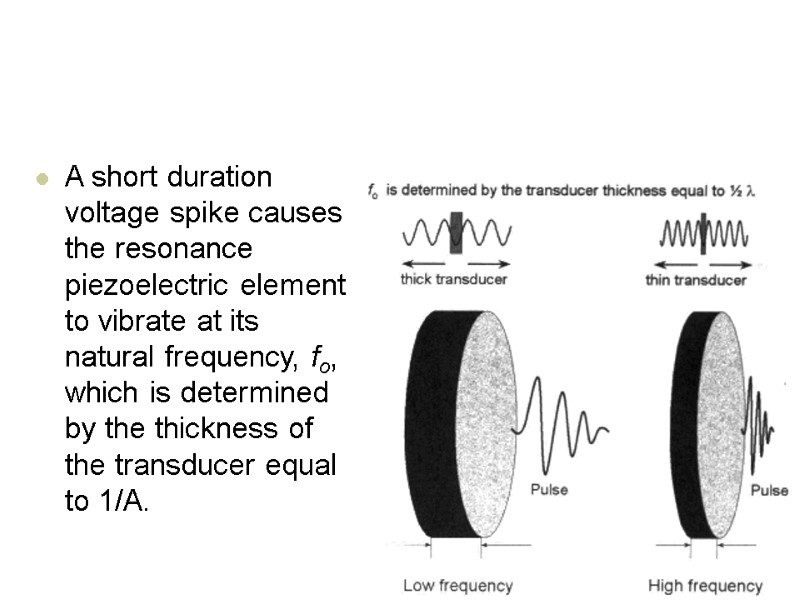

A short duration voltage spike causes the resonance piezoelectric element to vibrate at its natural frequency, fo, which is determined by the thickness of the transducer equal to 1/A.

A short duration voltage spike causes the resonance piezoelectric element to vibrate at its natural frequency, fo, which is determined by the thickness of the transducer equal to 1/A.

To achieve the 5-MHz resonance frequency, a transducer element thickness of ½ X 0.8 mm = 0.4 mm is required. Higher frequencies are achieved with thinner elements, and lower frequencies with thicker elements. Resonance transducers transmit and receive preferentially at a single “center frequency.”

To achieve the 5-MHz resonance frequency, a transducer element thickness of ½ X 0.8 mm = 0.4 mm is required. Higher frequencies are achieved with thinner elements, and lower frequencies with thicker elements. Resonance transducers transmit and receive preferentially at a single “center frequency.”

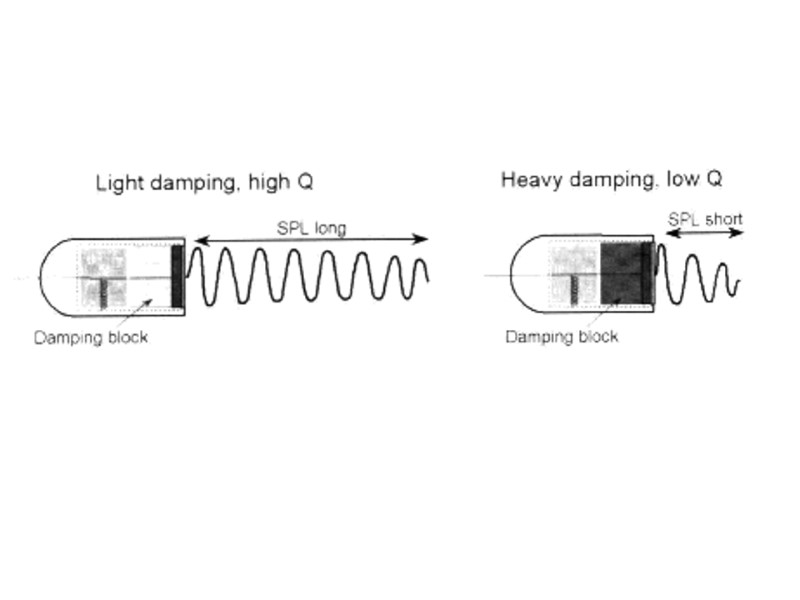

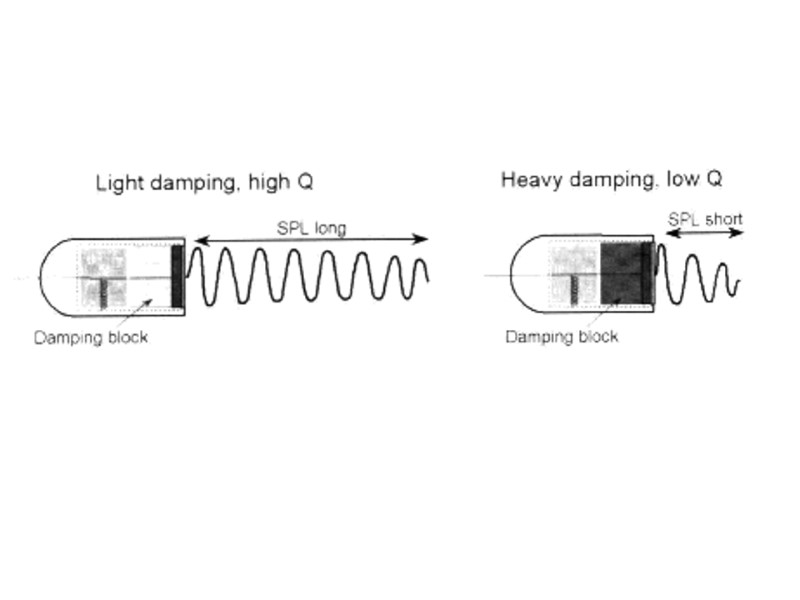

Damping Block The damping block, layered on the back of the piezoelectric element, absorbs the backward directed ultrasound energy and attenuates stray ultrasound signals from the housing. This component also dampens he transducer vibration in create an ultrasound pulse width a short spatial pulse length, which is necessary to preserve detail along he beam axis (axial resolution).

Damping Block The damping block, layered on the back of the piezoelectric element, absorbs the backward directed ultrasound energy and attenuates stray ultrasound signals from the housing. This component also dampens he transducer vibration in create an ultrasound pulse width a short spatial pulse length, which is necessary to preserve detail along he beam axis (axial resolution).

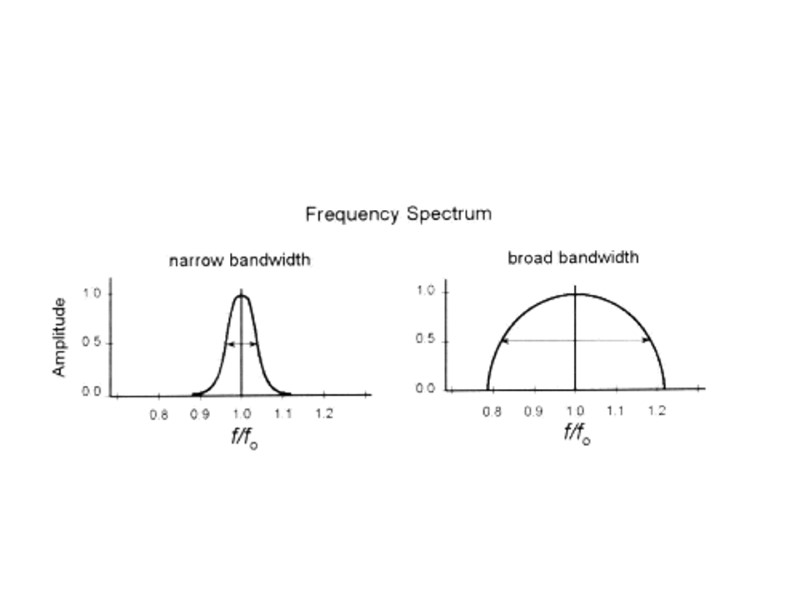

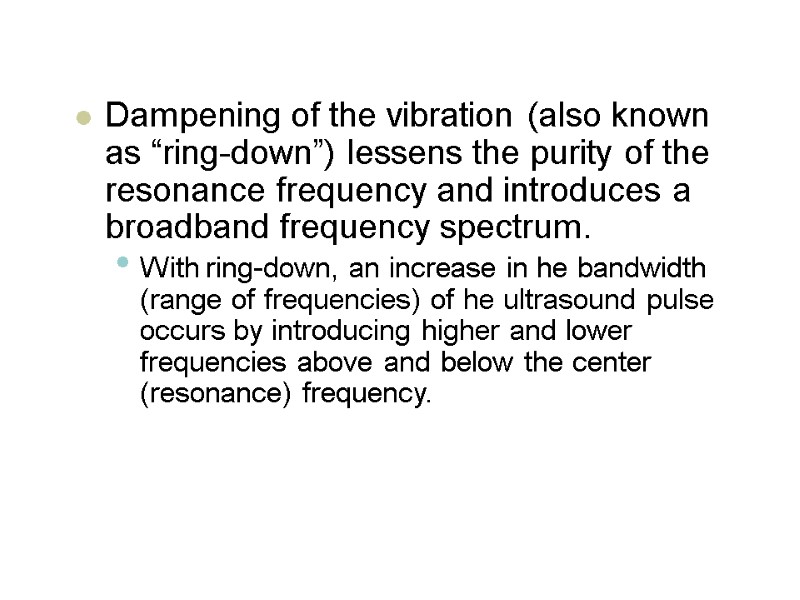

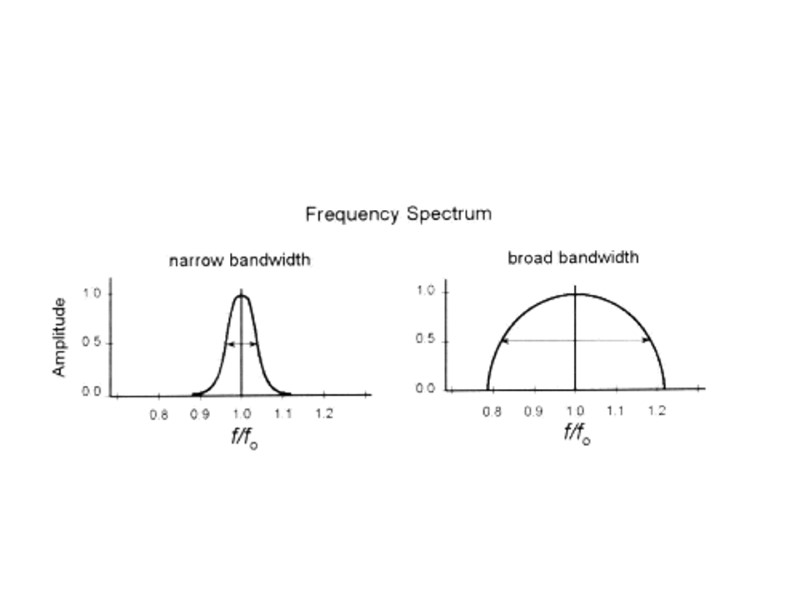

Dampening of the vibration (also known as “ring-down”) lessens the purity of the resonance frequency and introduces a broadband frequency spectrum. With ring-down, an increase in he bandwidth (range of frequencies) of he ultrasound pulse occurs by introducing higher and lower frequencies above and below the center (resonance) frequency.

Dampening of the vibration (also known as “ring-down”) lessens the purity of the resonance frequency and introduces a broadband frequency spectrum. With ring-down, an increase in he bandwidth (range of frequencies) of he ultrasound pulse occurs by introducing higher and lower frequencies above and below the center (resonance) frequency.

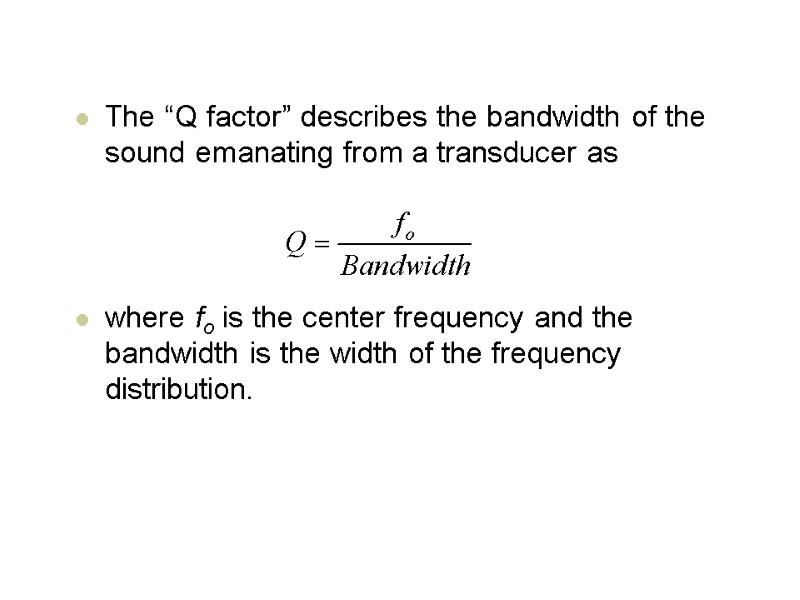

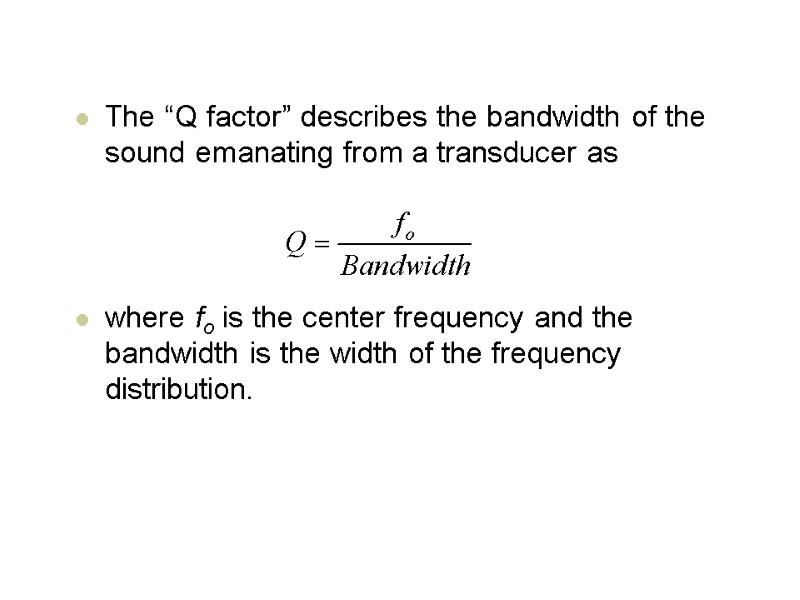

The “Q factor” describes the bandwidth of the sound emanating from a transducer as where fo is the center frequency and the bandwidth is the width of the frequency distribution.

The “Q factor” describes the bandwidth of the sound emanating from a transducer as where fo is the center frequency and the bandwidth is the width of the frequency distribution.

A “high Q” transducer has a narrow bandwidth (i.e., very little damping) and a corresponding long spatial pulse length. A “low Q” transducer has a wide bandwidth and short spatial pulse length.

A “high Q” transducer has a narrow bandwidth (i.e., very little damping) and a corresponding long spatial pulse length. A “low Q” transducer has a wide bandwidth and short spatial pulse length.

Imaging applications require a broad bandwidth transducer in order to achieve high spatial resolution along the direction of beam travel. Blood velocity measurements by Doppler instrumentation require a relatively narrow-band transducer response in order to preserve velocity information encoded by changes in the echo frequency relative to the incident frequency.

Imaging applications require a broad bandwidth transducer in order to achieve high spatial resolution along the direction of beam travel. Blood velocity measurements by Doppler instrumentation require a relatively narrow-band transducer response in order to preserve velocity information encoded by changes in the echo frequency relative to the incident frequency.

Continuous-wave ultrasound transducers have a very high Q characteristic. While the Q factor is derived from the term quality factor, a transducer with a low Q does not imply poor quality in the signal.

Continuous-wave ultrasound transducers have a very high Q characteristic. While the Q factor is derived from the term quality factor, a transducer with a low Q does not imply poor quality in the signal.

Matching Layer The matching layer provides the interface between the transducer element and the tissue and minimizes the acoustic impedance differences between the transducer and the patient. It consists of layers of materials with acoustic impedances that are intermediate to those of soft tissue and the transducer material. The thickness of each layer is equal to one-fourth the wavelength, determined from the center operating frequency of the transducer and speed of sound in the matching layer.

Matching Layer The matching layer provides the interface between the transducer element and the tissue and minimizes the acoustic impedance differences between the transducer and the patient. It consists of layers of materials with acoustic impedances that are intermediate to those of soft tissue and the transducer material. The thickness of each layer is equal to one-fourth the wavelength, determined from the center operating frequency of the transducer and speed of sound in the matching layer.

For example, the wavelength of sound in a matching layer with a speed of sound of 2,000 m/sec for a 5-MHz ultrasound beam is 0.4 mm. The optimal matching layer thickness is equal to ¼l = ¼ x 0.4 mm = 0. 1 mm. In addition to the matching layers, acoustic coupling gel (with acoustic impedance similar to soft tissue) is used between the transducer and the skin of the patient to eliminate air pockets that could attenuate and reflect the ultrasound beam.

For example, the wavelength of sound in a matching layer with a speed of sound of 2,000 m/sec for a 5-MHz ultrasound beam is 0.4 mm. The optimal matching layer thickness is equal to ¼l = ¼ x 0.4 mm = 0. 1 mm. In addition to the matching layers, acoustic coupling gel (with acoustic impedance similar to soft tissue) is used between the transducer and the skin of the patient to eliminate air pockets that could attenuate and reflect the ultrasound beam.

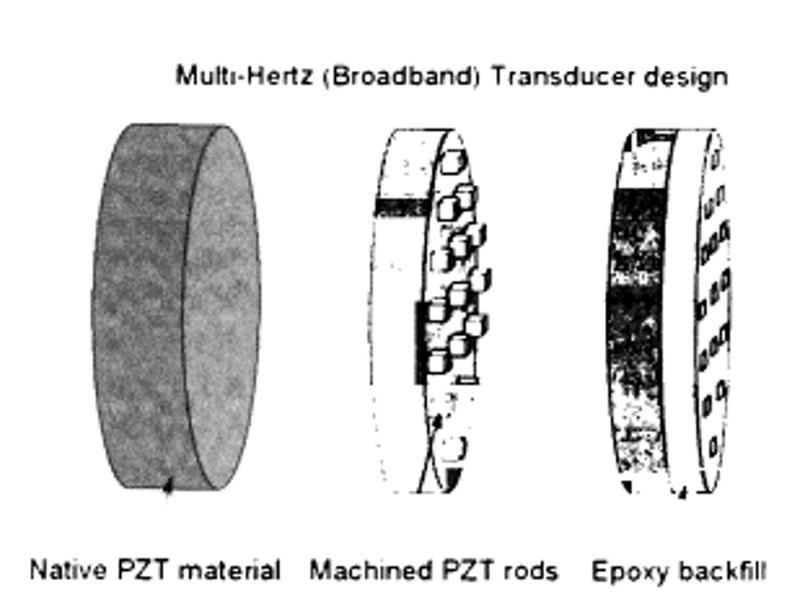

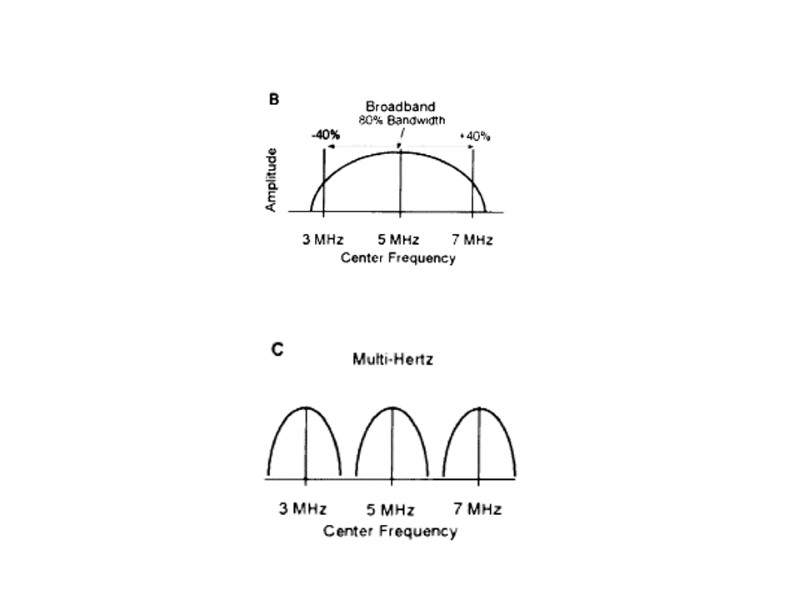

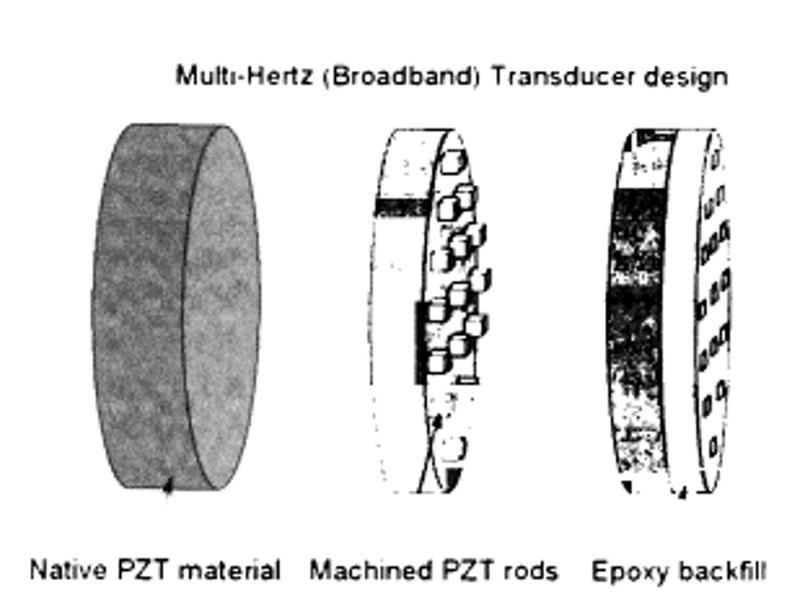

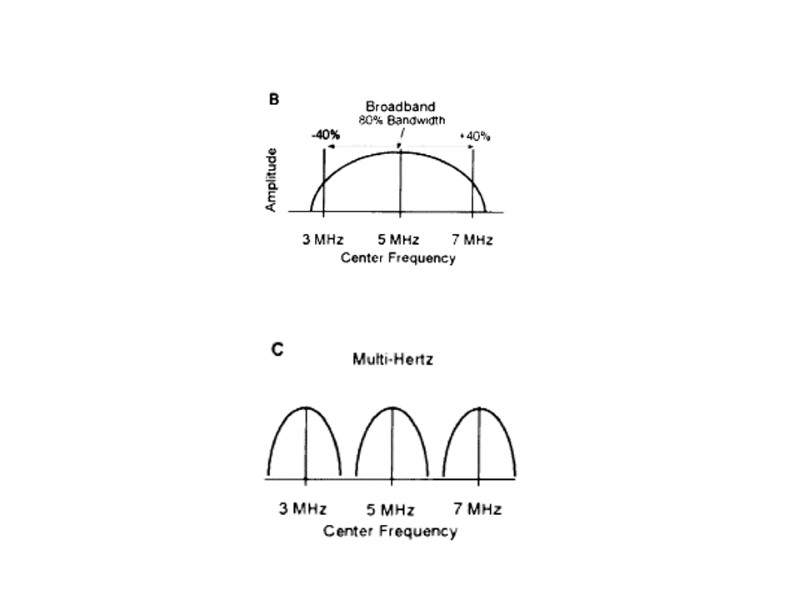

Nonresonance (Broad-Bandwidth) “Multifrequency” Transducers Modern transducer design coupled with digital signal processing enables “multifrequency or “multihertz” transducer operation, whereby rhe center frequency can be adjusted in he transmit mode. Unlike the resonance transducer design, the piezoelectric element is intricately machined into a large number of small “rods,” and then filled with an epoxy resin to create a smooth surface.

Nonresonance (Broad-Bandwidth) “Multifrequency” Transducers Modern transducer design coupled with digital signal processing enables “multifrequency or “multihertz” transducer operation, whereby rhe center frequency can be adjusted in he transmit mode. Unlike the resonance transducer design, the piezoelectric element is intricately machined into a large number of small “rods,” and then filled with an epoxy resin to create a smooth surface.

The acoustic properties are closer to issue than a pure PZT material, and thus provide a greater transmission efficiency of the ultrasound beam without resorting to multiple matching layers. Multifrequency transducers have bandwidths that exceed 80% of the center frequency.

The acoustic properties are closer to issue than a pure PZT material, and thus provide a greater transmission efficiency of the ultrasound beam without resorting to multiple matching layers. Multifrequency transducers have bandwidths that exceed 80% of the center frequency.

Excitation of the multifrequency transducer is accomplished with a short square wave burst of 150 V with one to three cycles, unlike the voltage spike used for resonance transducers. This allows the center frequency to be selected within the limits of the transducer bandwidth.

Excitation of the multifrequency transducer is accomplished with a short square wave burst of 150 V with one to three cycles, unlike the voltage spike used for resonance transducers. This allows the center frequency to be selected within the limits of the transducer bandwidth.

Likewise, the broad bandwidth response permits the reception of echoes within a wide range of frequencies. For instance, ultrasound pulses can be produced at a low frequency, and the echoes received at higher frequency.

Likewise, the broad bandwidth response permits the reception of echoes within a wide range of frequencies. For instance, ultrasound pulses can be produced at a low frequency, and the echoes received at higher frequency.

“Harmonic imaging” is a recently introduced technique that uses this ability; lower frequency ultrasound is transmitted into the patient, and the higher frequency harmonics (e.g., two times the transmitted center frequency) created from the interaction with contrast agents and tissues, are received as echoes.

“Harmonic imaging” is a recently introduced technique that uses this ability; lower frequency ultrasound is transmitted into the patient, and the higher frequency harmonics (e.g., two times the transmitted center frequency) created from the interaction with contrast agents and tissues, are received as echoes.

Native tissue harmonic imaging has certain advantages including greater depth of penetration, noise and clutter removal, and improved lateral spatial resolution.

Native tissue harmonic imaging has certain advantages including greater depth of penetration, noise and clutter removal, and improved lateral spatial resolution.

Transducer Arrays The majority of ultrasound systems employ transducers with many individual rectangular piezoelectric elements arranged in linear or curvilinear arrays. Typically, 128 to 512 individual rectangular elements compose the transducer assembly. Each element has a width typically less than half the wavelength and a length of several millimeters.

Transducer Arrays The majority of ultrasound systems employ transducers with many individual rectangular piezoelectric elements arranged in linear or curvilinear arrays. Typically, 128 to 512 individual rectangular elements compose the transducer assembly. Each element has a width typically less than half the wavelength and a length of several millimeters.

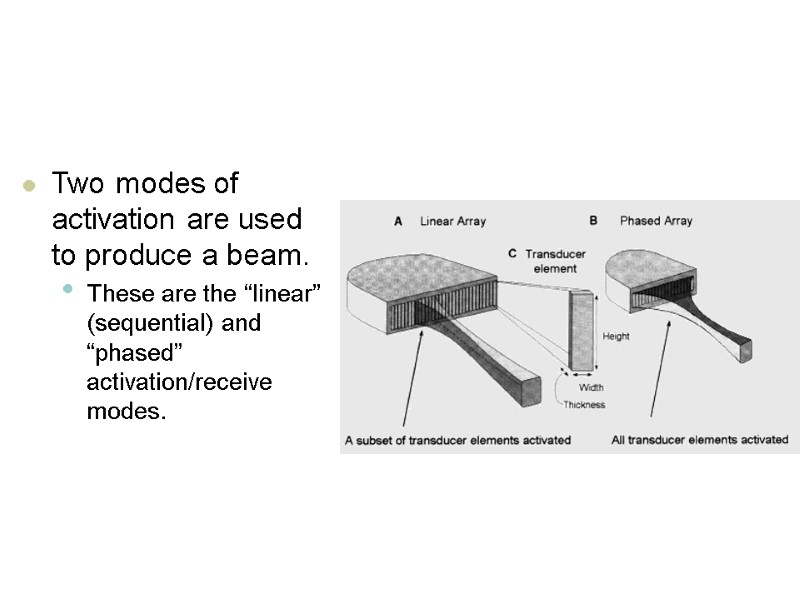

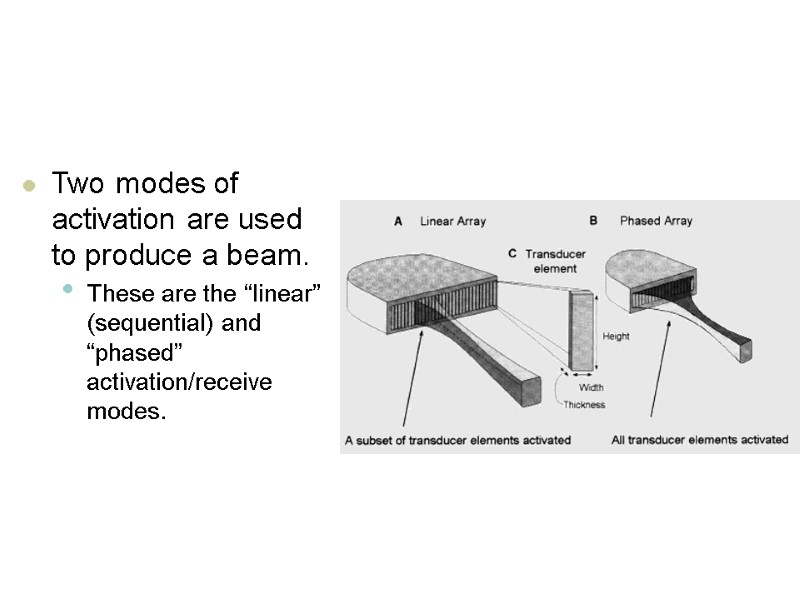

Two modes of activation are used to produce a beam. These are the “linear” (sequential) and “phased” activation/receive modes.

Two modes of activation are used to produce a beam. These are the “linear” (sequential) and “phased” activation/receive modes.

Linear Arrays Linear array transducers typically contain 256 to 512 elements; physically these are the largest transducer assemblies.

Linear Arrays Linear array transducers typically contain 256 to 512 elements; physically these are the largest transducer assemblies.

In operation, the simultaneous firing of’ a small group of 20 adjacent elements produces the ultrasound beam. The simultaneous activation produces a synthetic aperture (effetive transducer width) defined by the number of active elements.

In operation, the simultaneous firing of’ a small group of 20 adjacent elements produces the ultrasound beam. The simultaneous activation produces a synthetic aperture (effetive transducer width) defined by the number of active elements.

Echoes are detected in the receive mode by acquiring signals from most of the transducer elements. Subsequent “A-line” acquisition occurs by firing another group of transducer elements displaced by one or two elements.

Echoes are detected in the receive mode by acquiring signals from most of the transducer elements. Subsequent “A-line” acquisition occurs by firing another group of transducer elements displaced by one or two elements.

A rectangular field of view is produced with this transducer arrangement. For a curvilinear array, a trapezoidal field of view is produced.

A rectangular field of view is produced with this transducer arrangement. For a curvilinear array, a trapezoidal field of view is produced.

Phased Arrays A phased-array transducer is usually composed of 64 to 128 individual elements in a smaller package than a linear array transducer. All transducer elements are activated nearly (but not exactly) simultaneously to produce a single ultrasound beam.

Phased Arrays A phased-array transducer is usually composed of 64 to 128 individual elements in a smaller package than a linear array transducer. All transducer elements are activated nearly (but not exactly) simultaneously to produce a single ultrasound beam.

By using time delays in the electrical activation of the discrete elements across the face of the transducer, the ultrasound beam can be steered and focused electronically without moving the transducer. During ultrasound signal reception, all of the transducer elements detect the returning echoes from the beam path, and sophisticated algorithms synthesize the image from the detected data.

By using time delays in the electrical activation of the discrete elements across the face of the transducer, the ultrasound beam can be steered and focused electronically without moving the transducer. During ultrasound signal reception, all of the transducer elements detect the returning echoes from the beam path, and sophisticated algorithms synthesize the image from the detected data.

BEAM PROPERTIES The ultrasound beam propagates as a longitudinal wave from the transducer surface into the propagation medium, and exhibits two distinct beam patterns: a slightly converging beam out to a distance specified by the geometry and frequency of the transducer (the near field), and a diverging beam beyond that point (the far field).

BEAM PROPERTIES The ultrasound beam propagates as a longitudinal wave from the transducer surface into the propagation medium, and exhibits two distinct beam patterns: a slightly converging beam out to a distance specified by the geometry and frequency of the transducer (the near field), and a diverging beam beyond that point (the far field).

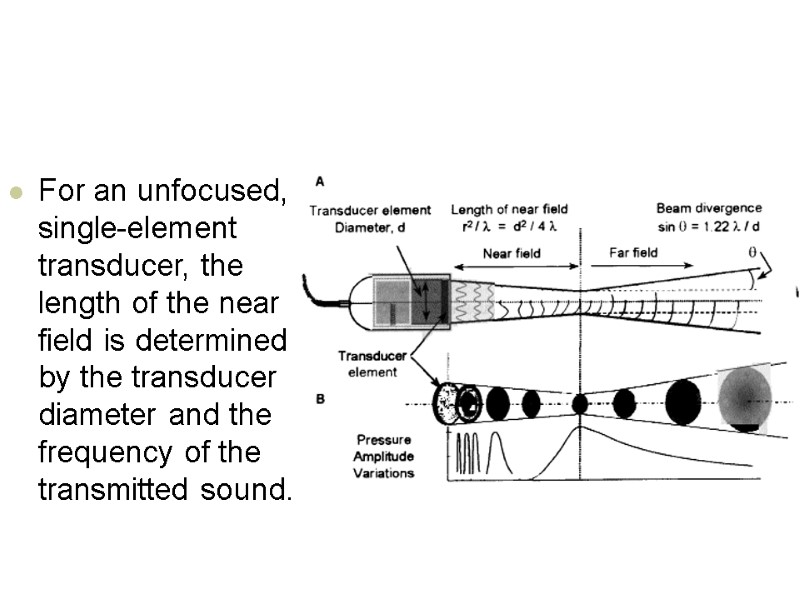

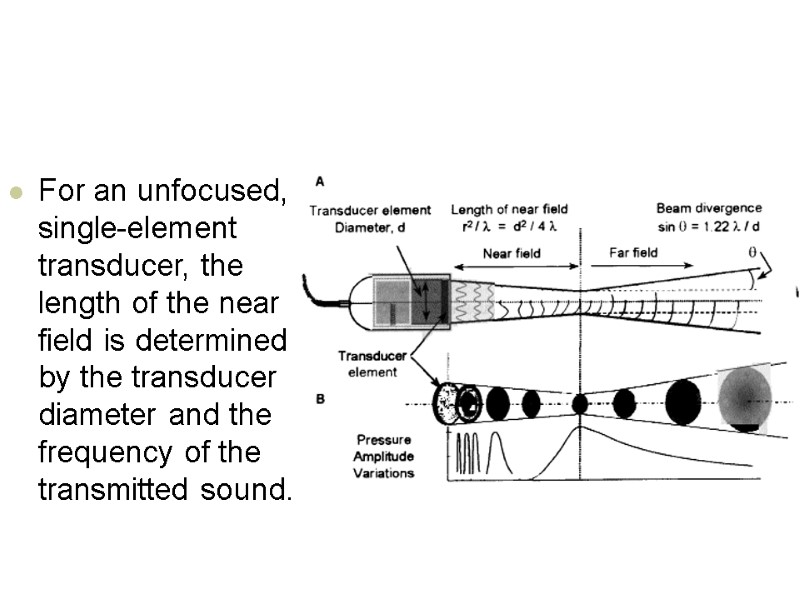

For an unfocused, single-element transducer, the length of the near field is determined by the transducer diameter and the frequency of the transmitted sound.

For an unfocused, single-element transducer, the length of the near field is determined by the transducer diameter and the frequency of the transmitted sound.

For multiple transducer element arrays, an “effective” transducer diameter is determined by the excitation of a group of’ transducer elements. Because of the interactions of each of the individual beams and the ability to focus and steer the overall beam, the formulas for a single-element, unfocused transducer are not directly applicable.

For multiple transducer element arrays, an “effective” transducer diameter is determined by the excitation of a group of’ transducer elements. Because of the interactions of each of the individual beams and the ability to focus and steer the overall beam, the formulas for a single-element, unfocused transducer are not directly applicable.

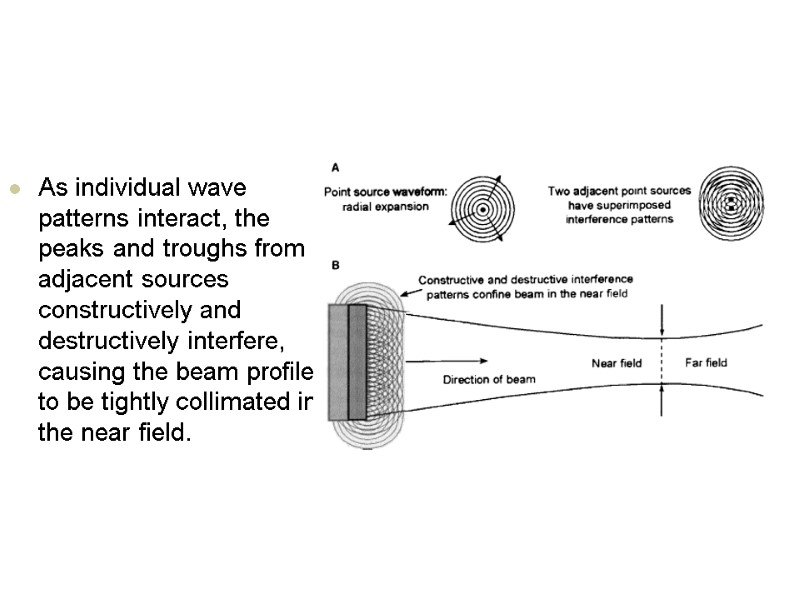

The Near Field The near field, also known as the Fresnel zone, is adjacent to the transducer face and has a converging beam profile. Beam convergence in the near field occurs because of multiple constructive and destructive interference patterns of the ultrasound waves from the transducer surface.

The Near Field The near field, also known as the Fresnel zone, is adjacent to the transducer face and has a converging beam profile. Beam convergence in the near field occurs because of multiple constructive and destructive interference patterns of the ultrasound waves from the transducer surface.

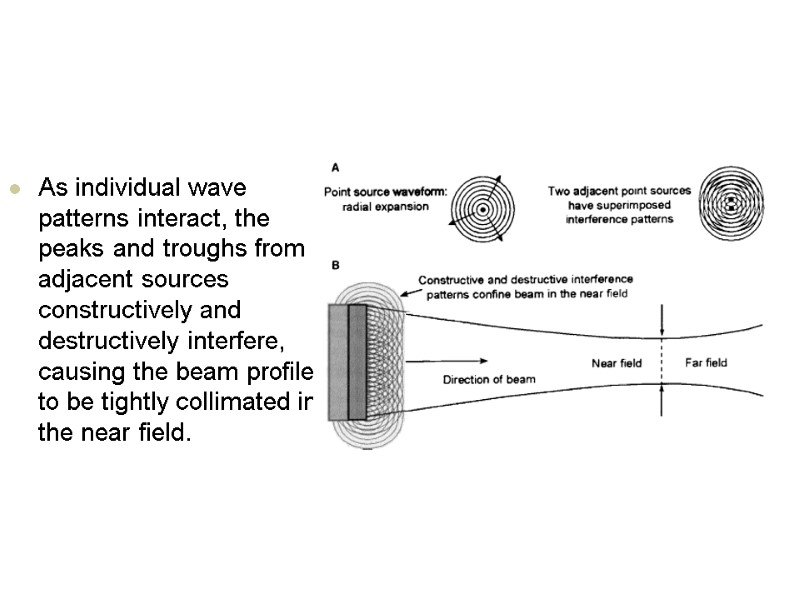

Huygen’s principle describes a large transducer surface as an infinite number of point sources of sound energy where each point is characterized as a radial emitter. By analogy, a pebble dropped in a quiet pond creates a radial wave pattern.

Huygen’s principle describes a large transducer surface as an infinite number of point sources of sound energy where each point is characterized as a radial emitter. By analogy, a pebble dropped in a quiet pond creates a radial wave pattern.

As individual wave patterns interact, the peaks and troughs from adjacent sources constructively and destructively interfere, causing the beam profile to be tightly collimated in the near field.

As individual wave patterns interact, the peaks and troughs from adjacent sources constructively and destructively interfere, causing the beam profile to be tightly collimated in the near field.

The ultrasound beam path is thus largely confined to the dimensions of the active portion of the transducer surface, with the beam diameter converging to approximately half the transducer diameter at the end of the near field.

The ultrasound beam path is thus largely confined to the dimensions of the active portion of the transducer surface, with the beam diameter converging to approximately half the transducer diameter at the end of the near field.

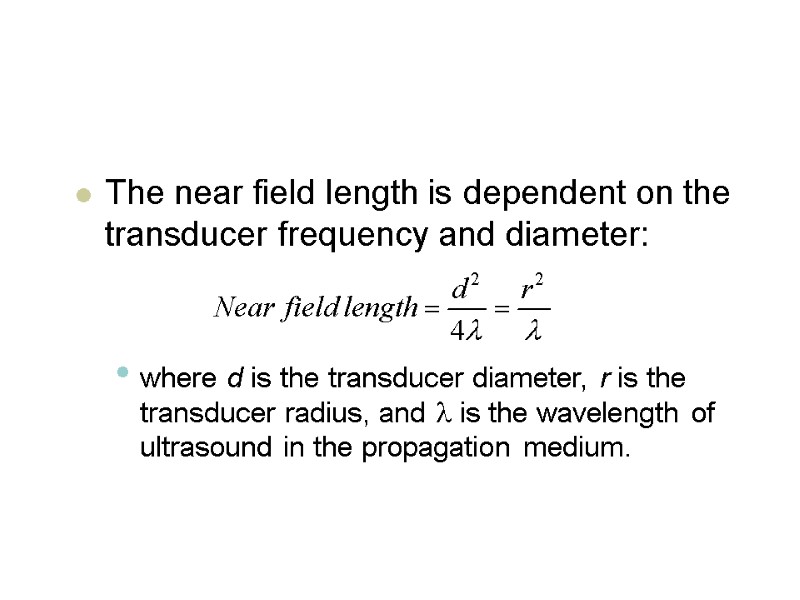

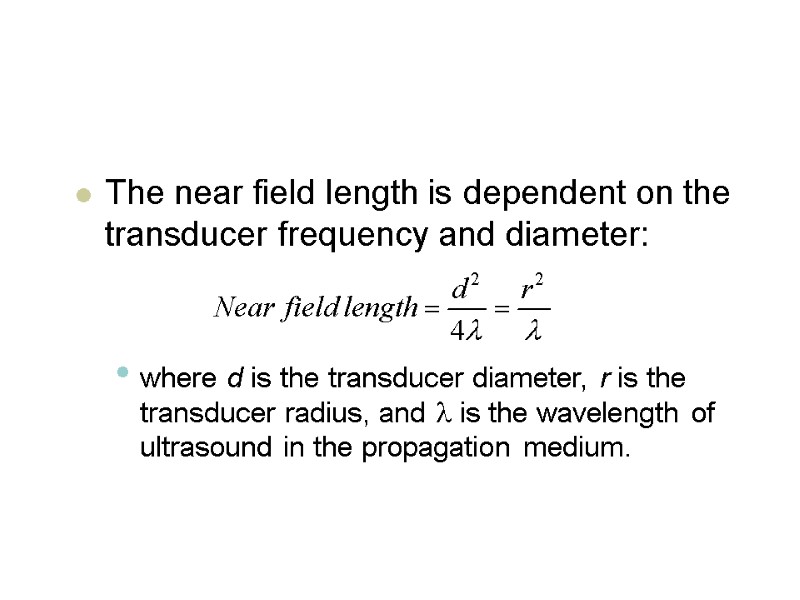

The near field length is dependent on the transducer frequency and diameter: where d is the transducer diameter, r is the transducer radius, and l is the wavelength of ultrasound in the propagation medium.

The near field length is dependent on the transducer frequency and diameter: where d is the transducer diameter, r is the transducer radius, and l is the wavelength of ultrasound in the propagation medium.

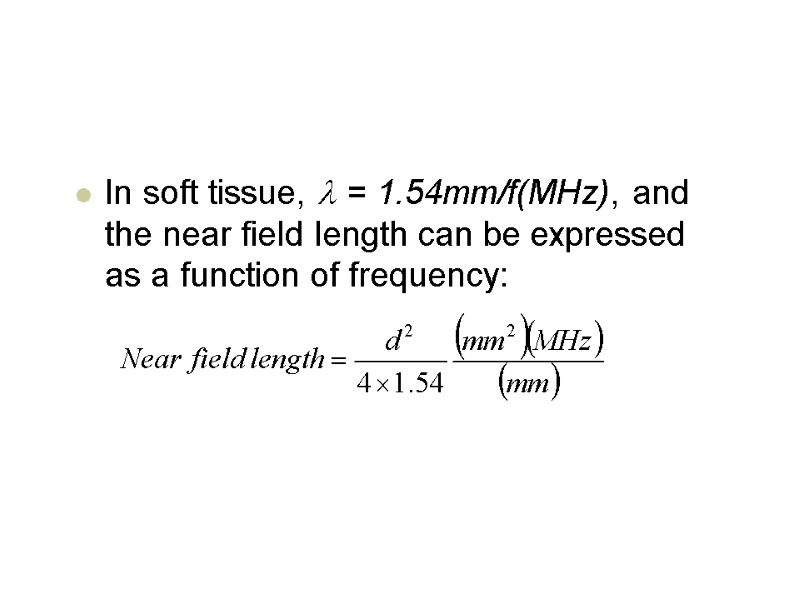

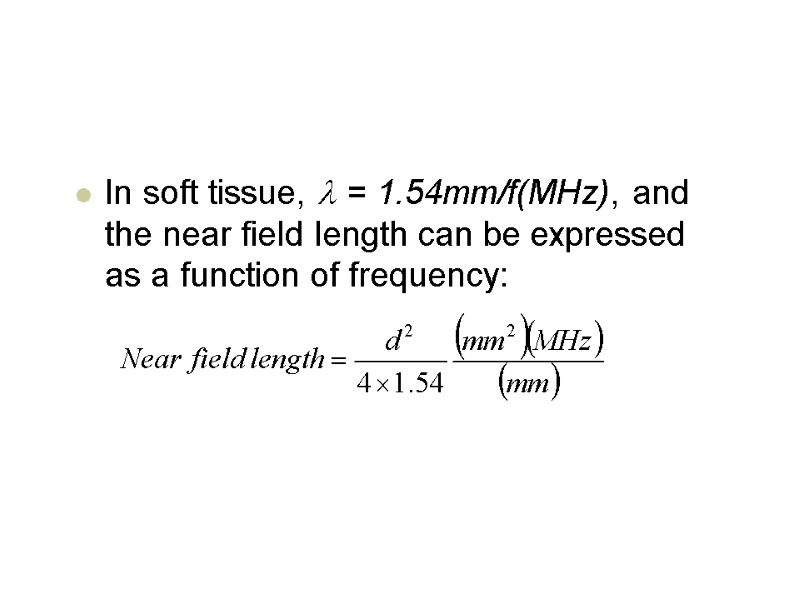

In soft tissue, l = 1.54mm/f(MHz), and the near field length can be expressed as a function of frequency:

In soft tissue, l = 1.54mm/f(MHz), and the near field length can be expressed as a function of frequency:

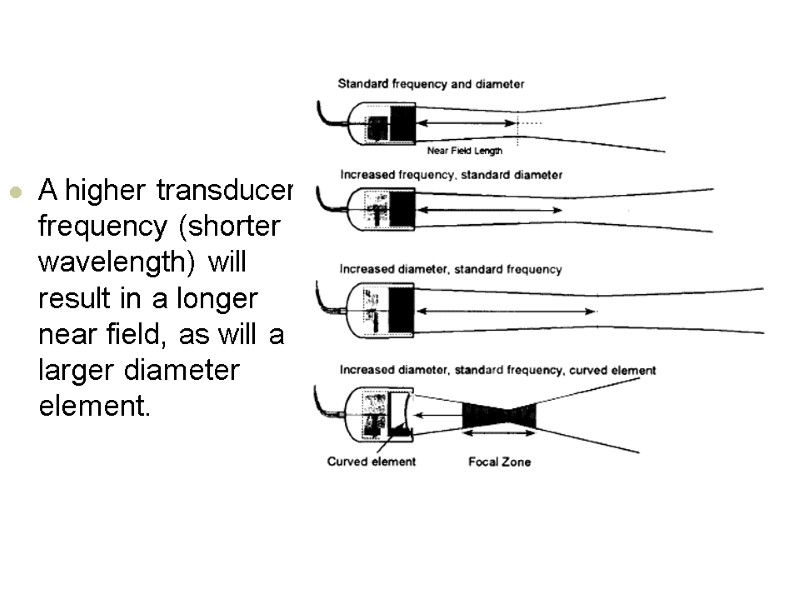

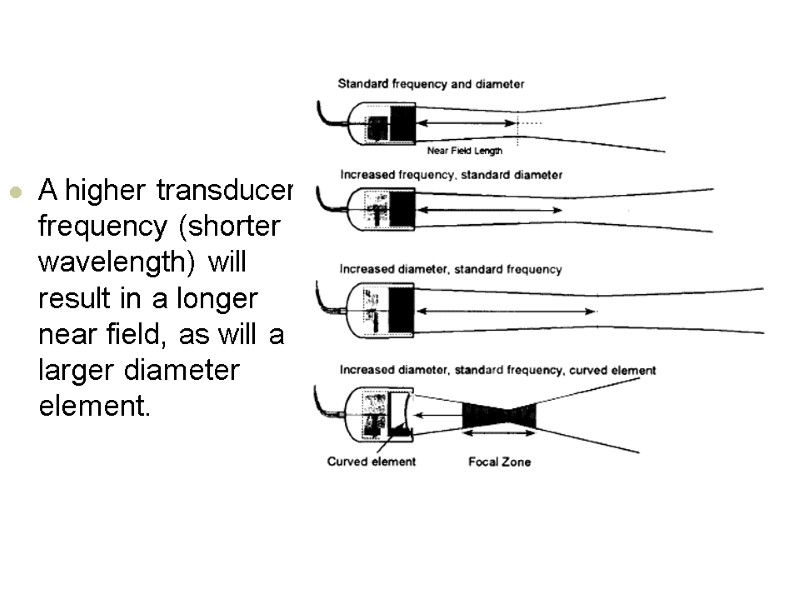

A higher transducer frequency (shorter wavelength) will result in a longer near field, as will a larger diameter element.

A higher transducer frequency (shorter wavelength) will result in a longer near field, as will a larger diameter element.

For a 10-mm-diameter transducer, the near field extends 5.7 cm at 3.5 MHz and 16.2 cm at 10 MHz in soft tissue. For a 15-mm-diameter transducer, the corresponding near field lengths are 12.8 and 36.4 cm, respectively.

For a 10-mm-diameter transducer, the near field extends 5.7 cm at 3.5 MHz and 16.2 cm at 10 MHz in soft tissue. For a 15-mm-diameter transducer, the corresponding near field lengths are 12.8 and 36.4 cm, respectively.

Lateral resolution (the ability of the system to resolve objects in a direction perpendicular to the beam direction) is dependent on the beam diameter and is best at the end of the near field for a single-element transducer. Lateral resolution is worst in areas close to and far from the transducer surface.

Lateral resolution (the ability of the system to resolve objects in a direction perpendicular to the beam direction) is dependent on the beam diameter and is best at the end of the near field for a single-element transducer. Lateral resolution is worst in areas close to and far from the transducer surface.

Pressure amplitude characteristics in the near field are very complex, caused by the constructive and destructive interference wave patterns of the ultrasound beam. Peak ultrasound pressure occurs at the end of the near field, corresponding to the minimum beam diameter for a single-element transducer.

Pressure amplitude characteristics in the near field are very complex, caused by the constructive and destructive interference wave patterns of the ultrasound beam. Peak ultrasound pressure occurs at the end of the near field, corresponding to the minimum beam diameter for a single-element transducer.

Pressures vary rapidly from peak compression to peak rarefaction several times during transit through the near field. Only when the far field is reached do the ultrasound pressure variations decrease continuously.

Pressures vary rapidly from peak compression to peak rarefaction several times during transit through the near field. Only when the far field is reached do the ultrasound pressure variations decrease continuously.

The far field is also known as the Fraunhofer zone, and is where the beam diverges. For a large-area single-element transducer, the angle of ultrasound beam divergence, 0, for the far field is given by where d is the effective diameter of the transducer and l is the wavelength; both must have the same units of distance.

The far field is also known as the Fraunhofer zone, and is where the beam diverges. For a large-area single-element transducer, the angle of ultrasound beam divergence, 0, for the far field is given by where d is the effective diameter of the transducer and l is the wavelength; both must have the same units of distance.

Less beam divergence occurs with high-frequency, large-diameter transducers. Unlike the near field, where beam intensity varies from maximum to minimum to maximum in a converging beam, ultrasound intensity in the far field decreases monotonically with distance.

Less beam divergence occurs with high-frequency, large-diameter transducers. Unlike the near field, where beam intensity varies from maximum to minimum to maximum in a converging beam, ultrasound intensity in the far field decreases monotonically with distance.

Focused Transducers Single-element transducers are focused by using a curved piezoelectric element or a curved acoustic lens to reduce the beam profile. The focal distance, the length from the transducer to the narrowest beam width, is shorter than the focal length of a non-focused transducer and is fixed.

Focused Transducers Single-element transducers are focused by using a curved piezoelectric element or a curved acoustic lens to reduce the beam profile. The focal distance, the length from the transducer to the narrowest beam width, is shorter than the focal length of a non-focused transducer and is fixed.

The focal zone is defined as the region over which the width of the beam is less than two times the width at the focal distance; Thus, the transducer frequency and dimensions should be chosen to match the depth requirements of the clinical situation.

The focal zone is defined as the region over which the width of the beam is less than two times the width at the focal distance; Thus, the transducer frequency and dimensions should be chosen to match the depth requirements of the clinical situation.

Transducer Array Beam Formation and Focusing In a transducer array, the narrow piezoelectric element width (typically less than one wavelength) produces a diverging beam at a distance very close to the transducer face. Formation and convergence of the ultrasound beam occurs with the operation of several or all of the transducer elements at the same time.

Transducer Array Beam Formation and Focusing In a transducer array, the narrow piezoelectric element width (typically less than one wavelength) produces a diverging beam at a distance very close to the transducer face. Formation and convergence of the ultrasound beam occurs with the operation of several or all of the transducer elements at the same time.

Transducer elements in a linear array that are fired simultaneously produce an effective transducer width equal to the sum of the widths of the individual elements. Individual beams interact via constructive and destructive interference to produce a collimated beam that has properties similar to the properties of a single transducer of the same size.

Transducer elements in a linear array that are fired simultaneously produce an effective transducer width equal to the sum of the widths of the individual elements. Individual beams interact via constructive and destructive interference to produce a collimated beam that has properties similar to the properties of a single transducer of the same size.

With a phased-array transducer, the beam is formed by interaction of the individual wave fronts from each transducer, each with a slight difference in excitation time. Minor phase differences of adjacent beams form constructive and destructive wave summations that steer or focus the beam profile.

With a phased-array transducer, the beam is formed by interaction of the individual wave fronts from each transducer, each with a slight difference in excitation time. Minor phase differences of adjacent beams form constructive and destructive wave summations that steer or focus the beam profile.

Transmit Focus For a single transducer or group of simultaneously fired elements in a linear array, The focal distance is a function of the transducer diameter (or the width of the group of simultaneously fired elements), The center operating frequency, and The presence of any acoustic lenses attached to the element surface.

Transmit Focus For a single transducer or group of simultaneously fired elements in a linear array, The focal distance is a function of the transducer diameter (or the width of the group of simultaneously fired elements), The center operating frequency, and The presence of any acoustic lenses attached to the element surface.

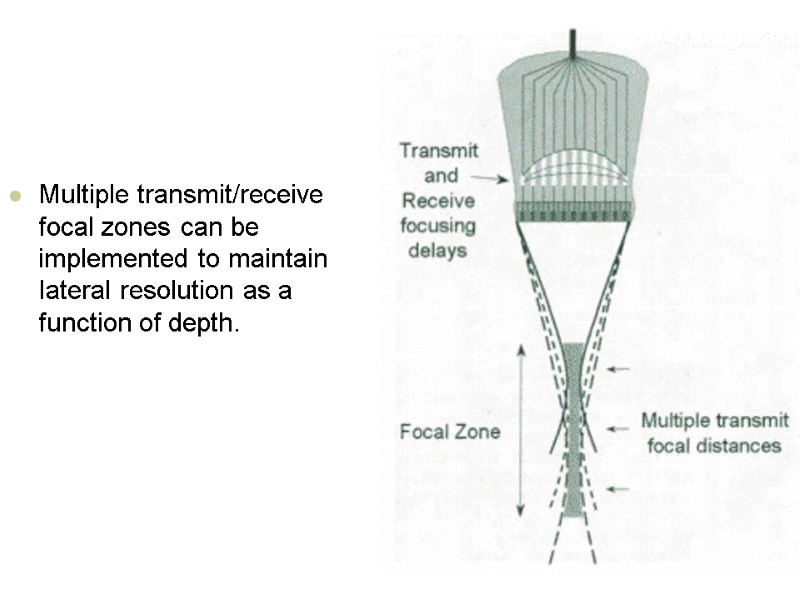

Phased array transducers and many linear array transducers allow a selectable focal distance by applying specific timing delays between transducer elements that cause the beam to converge at a specified distance.

Phased array transducers and many linear array transducers allow a selectable focal distance by applying specific timing delays between transducer elements that cause the beam to converge at a specified distance.

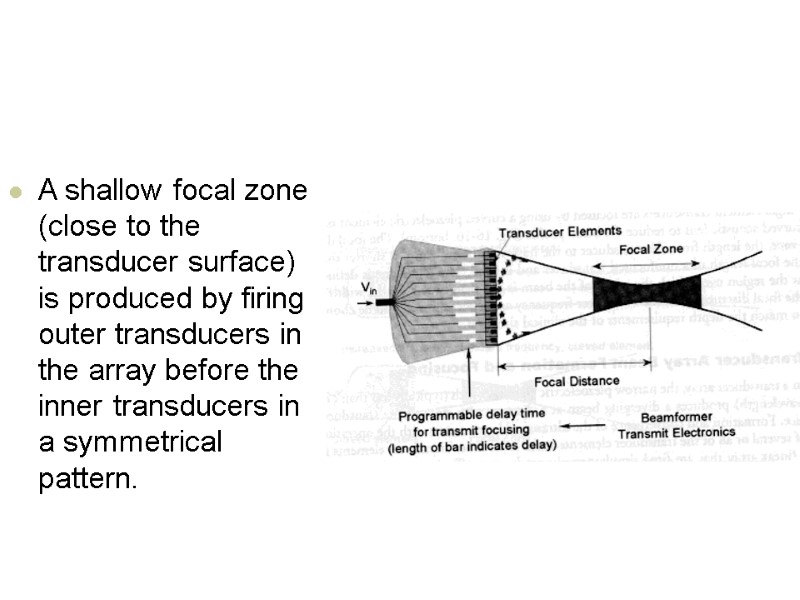

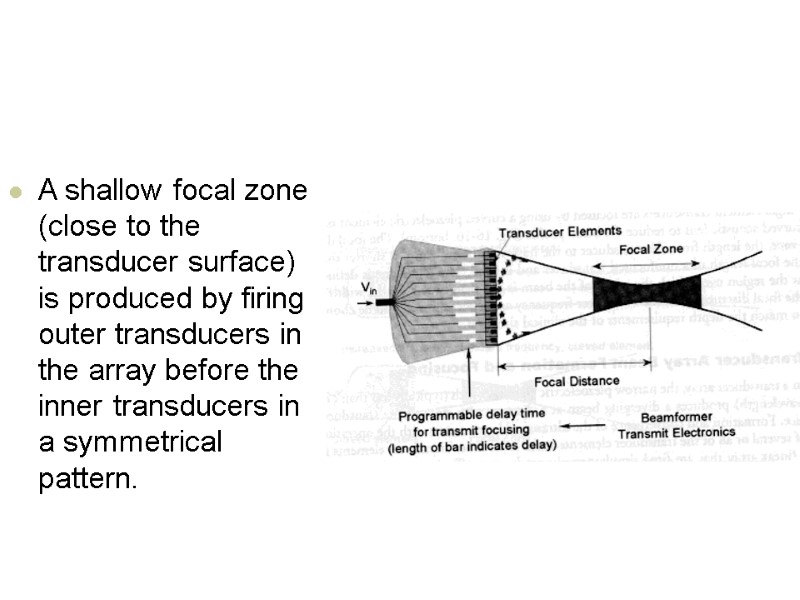

A shallow focal zone (close to the transducer surface) is produced by firing outer transducers in the array before the inner transducers in a symmetrical pattern.

A shallow focal zone (close to the transducer surface) is produced by firing outer transducers in the array before the inner transducers in a symmetrical pattern.

Greater focal distances are achieved by reducing the delay time differences among the transducer elements, resulting in more distal beam convergence. Multiple transmit focal zones are created by repeatedly acquiring data over the same volume, but with different phase timing of the transducer array elements.

Greater focal distances are achieved by reducing the delay time differences among the transducer elements, resulting in more distal beam convergence. Multiple transmit focal zones are created by repeatedly acquiring data over the same volume, but with different phase timing of the transducer array elements.

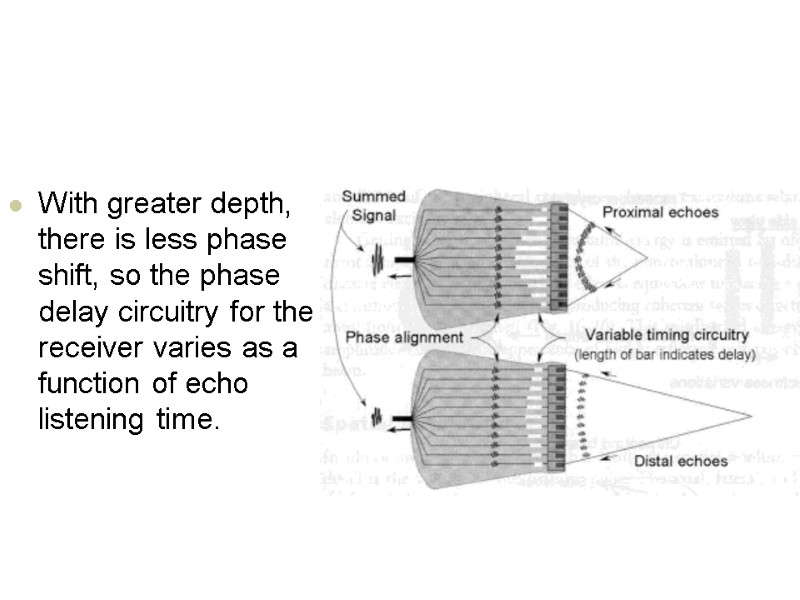

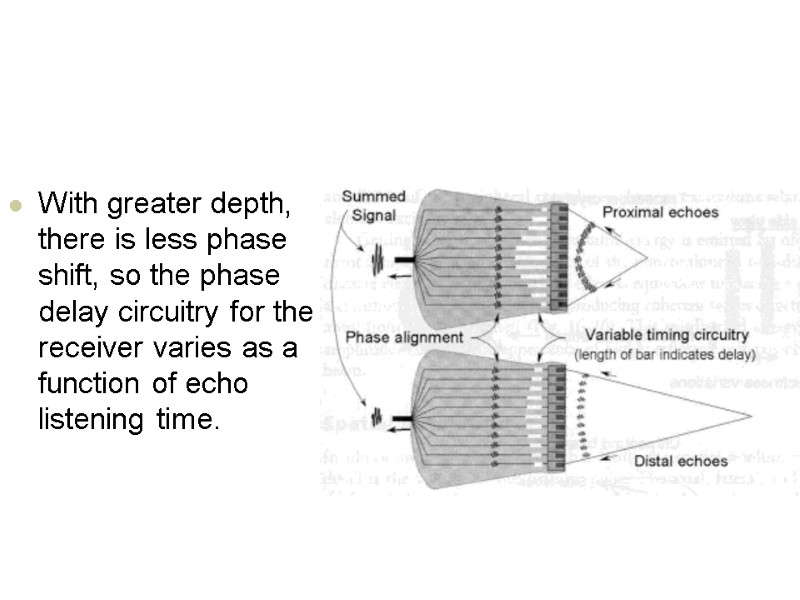

Receive Focus In a phased array transducer, the echoes received by all of the individual transducer elements are summed together to create the ultrasound signal from a given depth. Echoes received at the edge of the element array travel a slightly longer distance than those received at the center of the array, particularly at shallow depths.

Receive Focus In a phased array transducer, the echoes received by all of the individual transducer elements are summed together to create the ultrasound signal from a given depth. Echoes received at the edge of the element array travel a slightly longer distance than those received at the center of the array, particularly at shallow depths.

Signals from individual transducer elements therefore must be rephased to avoid a loss of resolution when the individual signals are synthesized into an image. Dynamic receive focusing is a method to rephase the signals by dynamically introducing electronic delays as a function of depth (time).

Signals from individual transducer elements therefore must be rephased to avoid a loss of resolution when the individual signals are synthesized into an image. Dynamic receive focusing is a method to rephase the signals by dynamically introducing electronic delays as a function of depth (time).

At shallow depths, rephasing delays between adjacent transducer elements are greatest.

At shallow depths, rephasing delays between adjacent transducer elements are greatest.

With greater depth, there is less phase shift, so the phase delay circuitry for the receiver varies as a function of echo listening time.

With greater depth, there is less phase shift, so the phase delay circuitry for the receiver varies as a function of echo listening time.

In addition to phased array transducers, many linear array transducers permit dynamic receive focusing among the active element group.

In addition to phased array transducers, many linear array transducers permit dynamic receive focusing among the active element group.

Dynamic Aperture The lateral spatial resolution of the linear array beam varies with depth, dependent on the total width of the simultaneously fired elements (aperture). A process termed dynamic aperture increases the number of active receiving elements in the array with reflector depth so that the lateral resolution does not degrade with depth of propagation.

Dynamic Aperture The lateral spatial resolution of the linear array beam varies with depth, dependent on the total width of the simultaneously fired elements (aperture). A process termed dynamic aperture increases the number of active receiving elements in the array with reflector depth so that the lateral resolution does not degrade with depth of propagation.

Side Lobes and Grating Lobes

Side Lobes and Grating Lobes

Side lobes are unwanted emissions of ultrasound energy directed away from the main pulse, caused by the radial expansion and contraction of the transducer element during thickness contraction and expansion. In the receive mode of transducer operation, echoes generated from the side lobes are unavoidably remapped along the main beam, which can introduce artifacts in the image.

Side lobes are unwanted emissions of ultrasound energy directed away from the main pulse, caused by the radial expansion and contraction of the transducer element during thickness contraction and expansion. In the receive mode of transducer operation, echoes generated from the side lobes are unavoidably remapped along the main beam, which can introduce artifacts in the image.

In continuous mode operation, the narrow frequency bandwidth of the transducer (high Q) causes the side lobe energy to be a significant fraction of the total beam. In pulsed mode operation. the low Q broadband ultrasound beam produces a spectrum of acoustic wavelengths chat reduces the emission of side lobe energy.

In continuous mode operation, the narrow frequency bandwidth of the transducer (high Q) causes the side lobe energy to be a significant fraction of the total beam. In pulsed mode operation. the low Q broadband ultrasound beam produces a spectrum of acoustic wavelengths chat reduces the emission of side lobe energy.

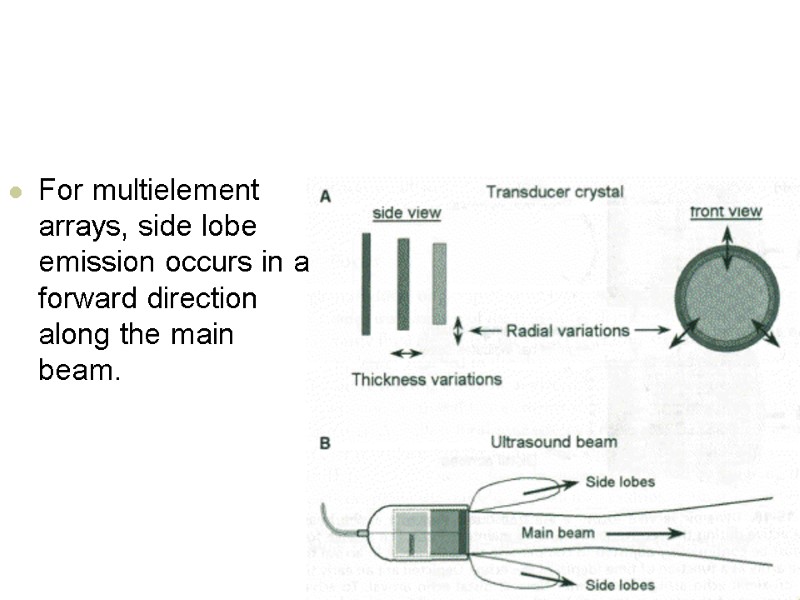

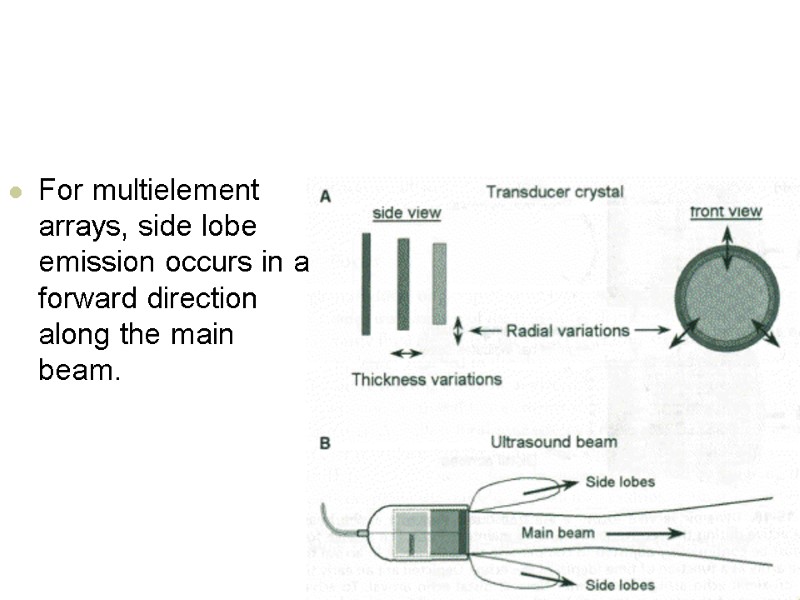

For multielement arrays, side lobe emission occurs in a forward direction along the main beam.

For multielement arrays, side lobe emission occurs in a forward direction along the main beam.

By keeping the individual transducer element widths small (less than half the wavelength) the side lobe emissions are reduced. Another method to minimize side lobes with array transducers is to reduce the amplitude of the peripheral transducer element excitations relative to the central element excitations.

By keeping the individual transducer element widths small (less than half the wavelength) the side lobe emissions are reduced. Another method to minimize side lobes with array transducers is to reduce the amplitude of the peripheral transducer element excitations relative to the central element excitations.

Grating lobes result when ultrasound energy is emitted far off-axis by multielement arrays, and are a consequence of the noncontinuous transducer surface of the discrete elements. The grating lobe effect is equivalent to placing a grating in front of a continuous transducer element, producing coherent waves directed at a large angle away from the main beam.

Grating lobes result when ultrasound energy is emitted far off-axis by multielement arrays, and are a consequence of the noncontinuous transducer surface of the discrete elements. The grating lobe effect is equivalent to placing a grating in front of a continuous transducer element, producing coherent waves directed at a large angle away from the main beam.

This misdirected energy of relatively low amplitude results in the appearance of highly reflective, off-axis objects in the main beam.

This misdirected energy of relatively low amplitude results in the appearance of highly reflective, off-axis objects in the main beam.

Spatial Resolution

Spatial Resolution

In ultrasound, the major factor that limits the spatial resolution and visibility of detail is the volume of the acoustic pulse.

In ultrasound, the major factor that limits the spatial resolution and visibility of detail is the volume of the acoustic pulse.

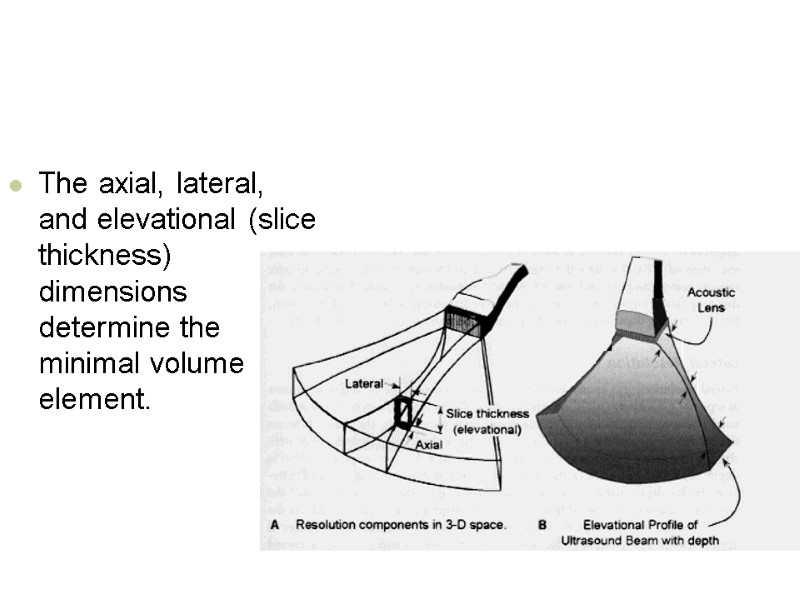

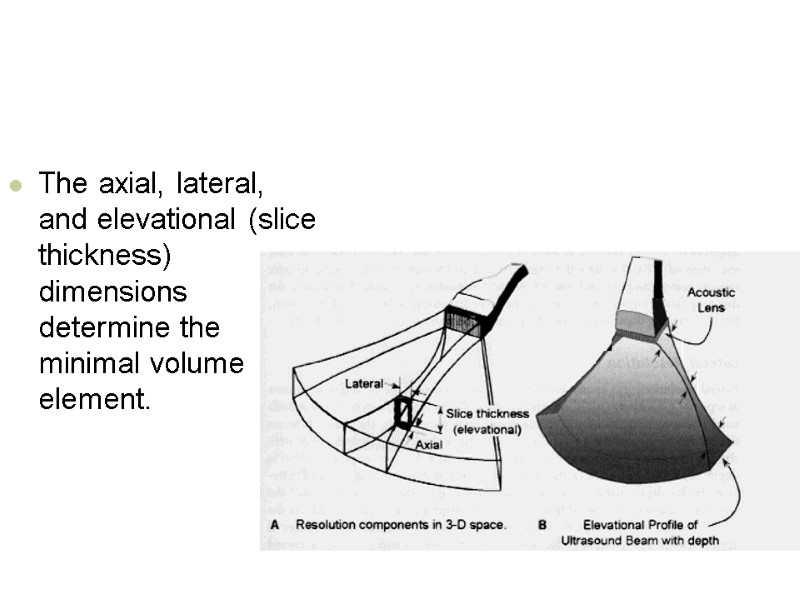

The axial, lateral, and elevational (slice thickness) dimensions determine the minimal volume element.

The axial, lateral, and elevational (slice thickness) dimensions determine the minimal volume element.

Each dimension has an effect on the resolvability of objects in the image.

Each dimension has an effect on the resolvability of objects in the image.

Axial Resolution Axial resolution (also known as linear, range, longitudinal, or depth resolution) refers to the ability to discern two closely spaced objects in the direction of the beam. Achieving good axial resolution requires that the returning echoes be distinct without overlap.

Axial Resolution Axial resolution (also known as linear, range, longitudinal, or depth resolution) refers to the ability to discern two closely spaced objects in the direction of the beam. Achieving good axial resolution requires that the returning echoes be distinct without overlap.

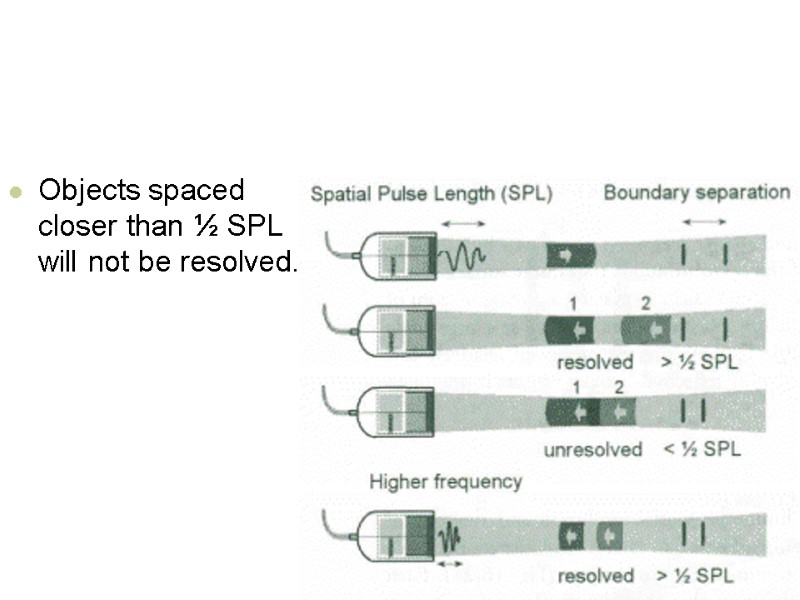

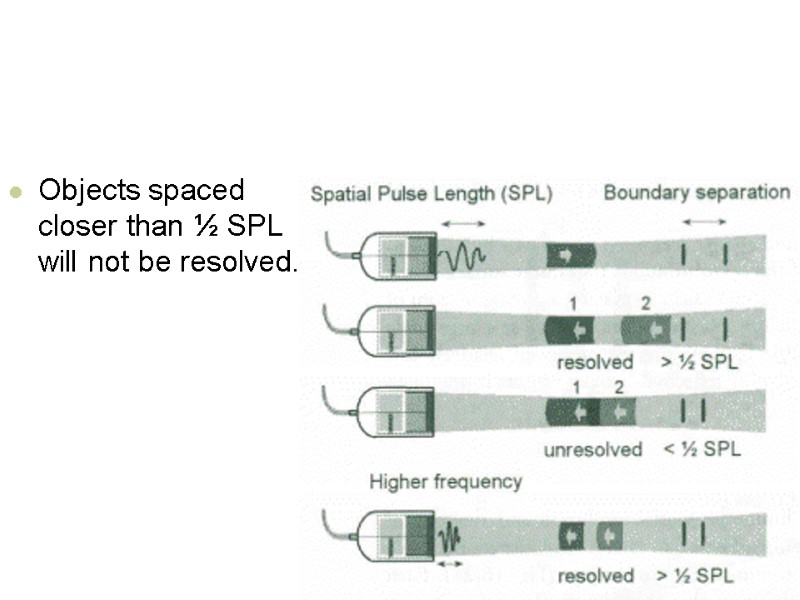

The minimal required separation distance between two reflectors is one-half of the spatial pulse length (SPL) to avoid the overlap of returning echoes, as the distance traveled between two reflectors is twice the separation distance.

The minimal required separation distance between two reflectors is one-half of the spatial pulse length (SPL) to avoid the overlap of returning echoes, as the distance traveled between two reflectors is twice the separation distance.

Objects spaced closer than ½ SPL will not be resolved.

Objects spaced closer than ½ SPL will not be resolved.

The SPL is the number of cycles emitted per pulse by the transducer multiplied by the wavelength. Shorter pulses, producing better axial resolution, can be achieved with greater damping of the transducer element (to reduce the pulse duration and number of cycles) or with higher frequency (to reduce wavelength).

The SPL is the number of cycles emitted per pulse by the transducer multiplied by the wavelength. Shorter pulses, producing better axial resolution, can be achieved with greater damping of the transducer element (to reduce the pulse duration and number of cycles) or with higher frequency (to reduce wavelength).

For imaging applications, the ultrasound pulse typically consists of three cycles. At 5 MHz (wavelength of 0.31 mm), the SPL is about 3 x 0.31 0.93 mm, which provides an axial resolution of /2(0.93 mm) = 0.47 mm.

For imaging applications, the ultrasound pulse typically consists of three cycles. At 5 MHz (wavelength of 0.31 mm), the SPL is about 3 x 0.31 0.93 mm, which provides an axial resolution of /2(0.93 mm) = 0.47 mm.

At a given frequency, shorter pulse lengths require heavy damping and low Q, broad-bandwidth operation. For a constant damping factor, higher frequencies (shorter wavelengths) give better axial resolution, but the imaging depth is reduced. Axial resolution remains constant with depth.

At a given frequency, shorter pulse lengths require heavy damping and low Q, broad-bandwidth operation. For a constant damping factor, higher frequencies (shorter wavelengths) give better axial resolution, but the imaging depth is reduced. Axial resolution remains constant with depth.

Lateral Resolution Lateral resolution, also known as azimuthal resolution, refers to the ability to discern as separate two closely spaced objects perpendicular to the beam direction.

Lateral Resolution Lateral resolution, also known as azimuthal resolution, refers to the ability to discern as separate two closely spaced objects perpendicular to the beam direction.

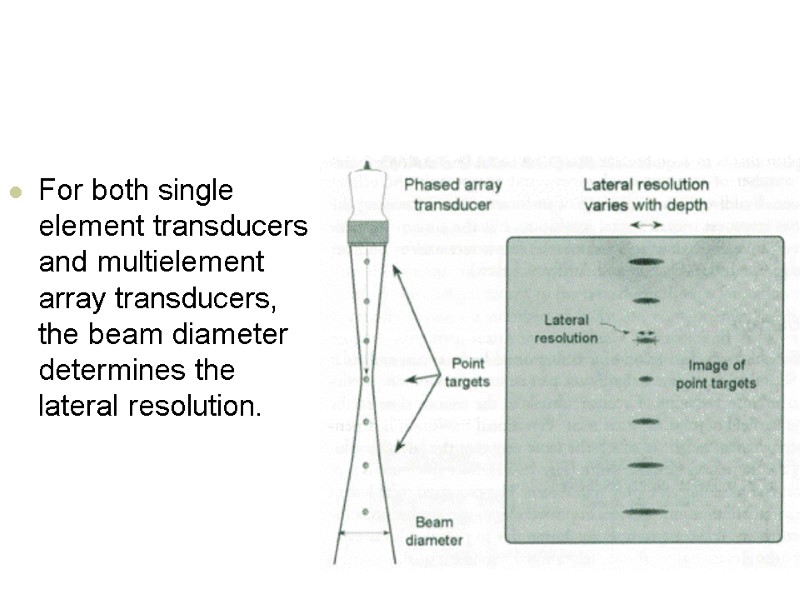

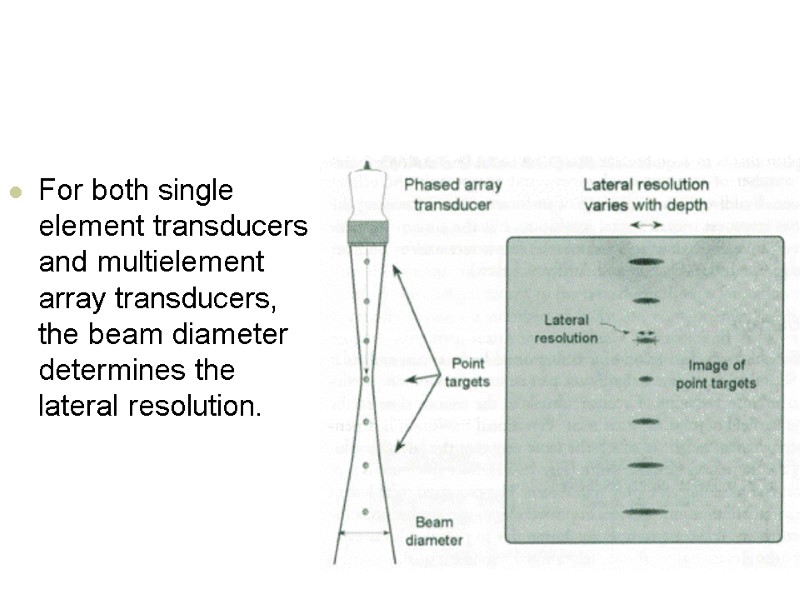

For both single element transducers and multielement array transducers, the beam diameter determines the lateral resolution.

For both single element transducers and multielement array transducers, the beam diameter determines the lateral resolution.

Since the beam diameter varies with the distance from the transducer in the near and far field, the lateral resolution is depth dependent. The best lateral resolution occurs at the near field—far field face.

Since the beam diameter varies with the distance from the transducer in the near and far field, the lateral resolution is depth dependent. The best lateral resolution occurs at the near field—far field face.

At this depth, the effective beam diameter is approximately equal to half the transducer diameter. In the far field, the beam diverges and substantially reduces the lateral resolution.

At this depth, the effective beam diameter is approximately equal to half the transducer diameter. In the far field, the beam diverges and substantially reduces the lateral resolution.

The typical lateral resolution for an unfocused transducer is approximately 2 to 5 mm. A focused transducer uses an acoustic lens (a curved acoustic material analogous to an optical lens) to decrease the beam diameter at a specified distance from the transducer.

The typical lateral resolution for an unfocused transducer is approximately 2 to 5 mm. A focused transducer uses an acoustic lens (a curved acoustic material analogous to an optical lens) to decrease the beam diameter at a specified distance from the transducer.

With an acoustic lens, lateral resolution at the near field-far field interface is traded for better lateral resolution at a shorter depth, but the far field beam divergence is substantially increased. The lateral resolution of linear and curvilinear array transducers can be varied.

With an acoustic lens, lateral resolution at the near field-far field interface is traded for better lateral resolution at a shorter depth, but the far field beam divergence is substantially increased. The lateral resolution of linear and curvilinear array transducers can be varied.

The number of elements simultaneously activated in a group defines an “effective” transducer width that has similar behavior to a single transducer element of the same width. Transmit and receive focusing can produce focal at varying depths along each line.

The number of elements simultaneously activated in a group defines an “effective” transducer width that has similar behavior to a single transducer element of the same width. Transmit and receive focusing can produce focal at varying depths along each line.

For the phased array transducer, focusing to a specific depth is achieved by both beam steering and transmit/receive focusing to reduce the effective beam width and improve lateral resolution, especially in the near field.

For the phased array transducer, focusing to a specific depth is achieved by both beam steering and transmit/receive focusing to reduce the effective beam width and improve lateral resolution, especially in the near field.

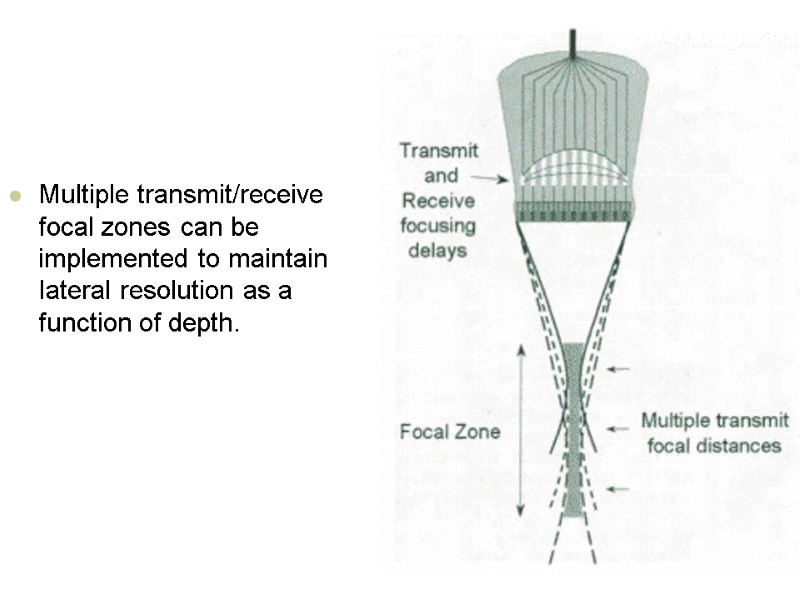

Multiple transmit/receive focal zones can be implemented to maintain Iateral resolution as a function of depth.

Multiple transmit/receive focal zones can be implemented to maintain Iateral resolution as a function of depth.

Each focal zone requires separate pulse echo sequences to acquire data.

Each focal zone requires separate pulse echo sequences to acquire data.

One way to accomplish this is to acquire data along one beam line multiple times (depending on the number of transmit focal zones), and accept only the echoes within each focal zone, building up a single line of in-focus zones. Increasing the number of focal zones improves overall lateral resolution, but the amount of time required to produce an image increases and reduces the frame rate and/or number of scan lines per image.

One way to accomplish this is to acquire data along one beam line multiple times (depending on the number of transmit focal zones), and accept only the echoes within each focal zone, building up a single line of in-focus zones. Increasing the number of focal zones improves overall lateral resolution, but the amount of time required to produce an image increases and reduces the frame rate and/or number of scan lines per image.

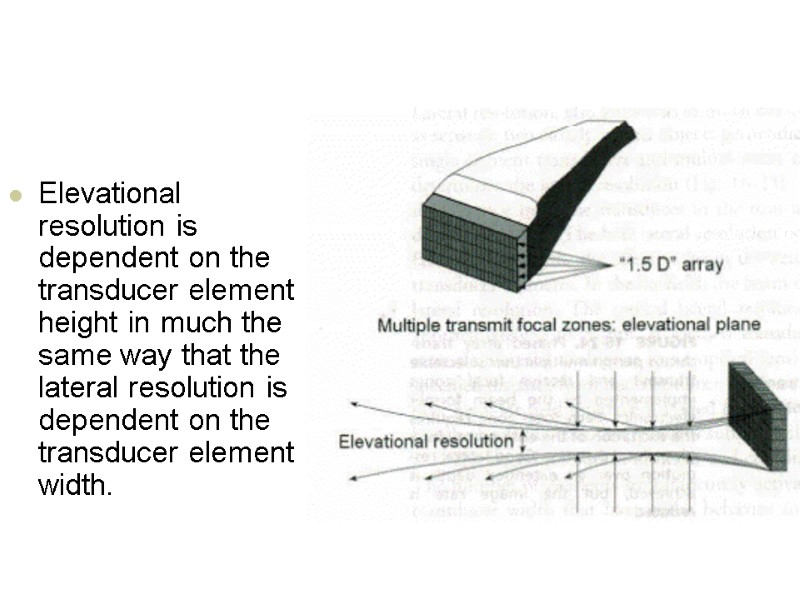

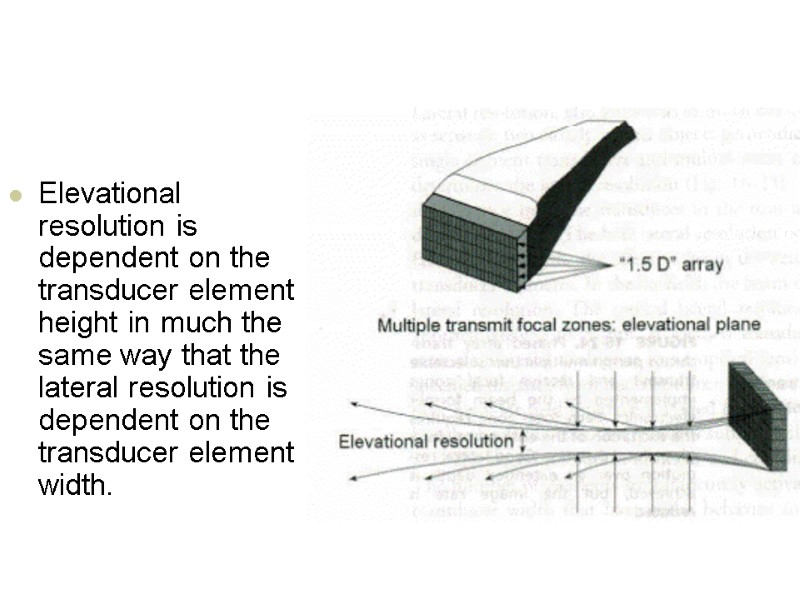

Elevational Resolution The elevational or slice-thickness dimension of the ultrasound beam is perpendicular to the image plane. Slice thickness plays a significant part in image resolution, particularly with respect to volume averaging of acoustic details in the regions dose to the transducer and in the far field beyond the focal zone.

Elevational Resolution The elevational or slice-thickness dimension of the ultrasound beam is perpendicular to the image plane. Slice thickness plays a significant part in image resolution, particularly with respect to volume averaging of acoustic details in the regions dose to the transducer and in the far field beyond the focal zone.

Elevational resolution is dependent on the transducer element height in much the same way that the lateral resolution is dependent on the transducer element width.

Elevational resolution is dependent on the transducer element height in much the same way that the lateral resolution is dependent on the transducer element width.

Slice thickness is typically the worst measure of resolution for array transducers. Use of a fixed focaI length lens across the entire surface of the array provides improved elevational resolution at the focal distance.

Slice thickness is typically the worst measure of resolution for array transducers. Use of a fixed focaI length lens across the entire surface of the array provides improved elevational resolution at the focal distance.

Unfortunately, this compromises resolution due to partial volume averaging before and after the elevational focal zone (elevational resolution quality control phantom image shows the effects of variable resolution with depth.

Unfortunately, this compromises resolution due to partial volume averaging before and after the elevational focal zone (elevational resolution quality control phantom image shows the effects of variable resolution with depth.

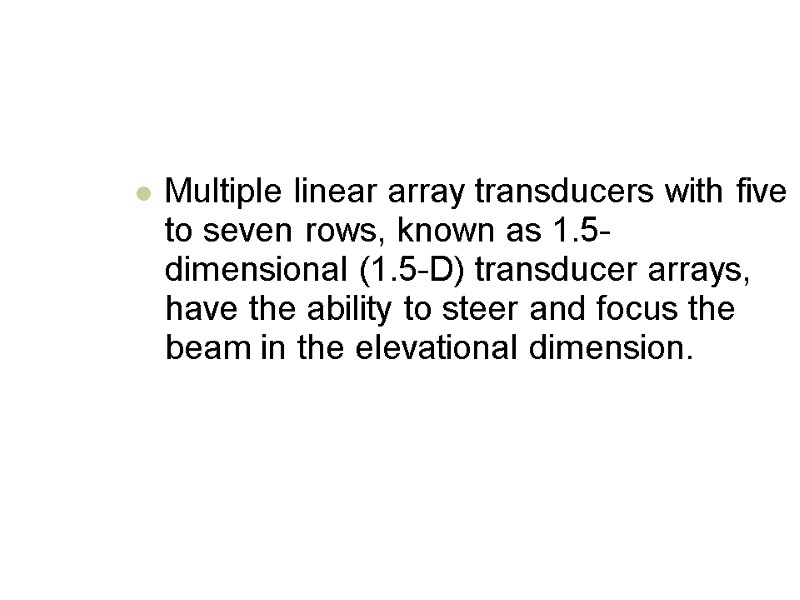

Multiple linear array transducers with five to seven rows, known as 1.5-dimensional (1.5-D) transducer arrays, have the ability to steer and focus the beam in the elevational dimension.

Multiple linear array transducers with five to seven rows, known as 1.5-dimensional (1.5-D) transducer arrays, have the ability to steer and focus the beam in the elevational dimension.

Elevational focusing is implemented with phased excitation of the outer to inner arrays to minimize the slice thickness dimension at a given depth (Fig. 16-25).

Elevational focusing is implemented with phased excitation of the outer to inner arrays to minimize the slice thickness dimension at a given depth (Fig. 16-25).

By using subsequent excitations with different focusing distances, multiple transmit focusing can produce smaller slice thickness over a range of tissue depths. A disadvantage of elevational focusing is a frame rate reduction penalty required for multiple excitations to build one image.

By using subsequent excitations with different focusing distances, multiple transmit focusing can produce smaller slice thickness over a range of tissue depths. A disadvantage of elevational focusing is a frame rate reduction penalty required for multiple excitations to build one image.

The increased width of the transducer array also limits positioning flexibility. Extension to full 2D transducer arrays with enhancements in computational power will allow 3D imaging with uniform resolution throughout the image volume.

The increased width of the transducer array also limits positioning flexibility. Extension to full 2D transducer arrays with enhancements in computational power will allow 3D imaging with uniform resolution throughout the image volume.

IMAGE DATA ACQUISITION Understanding ultrasonic image formation requires knowledge of ultrasound production, propagation, and interactions. Images are created using a pulse echo method of ultrasound production and detection.

IMAGE DATA ACQUISITION Understanding ultrasonic image formation requires knowledge of ultrasound production, propagation, and interactions. Images are created using a pulse echo method of ultrasound production and detection.

Each pulse transmits directionally into the patient, and then experiences partial reflections from tissue interfaces that create echoes, which return to the transducer.

Each pulse transmits directionally into the patient, and then experiences partial reflections from tissue interfaces that create echoes, which return to the transducer.

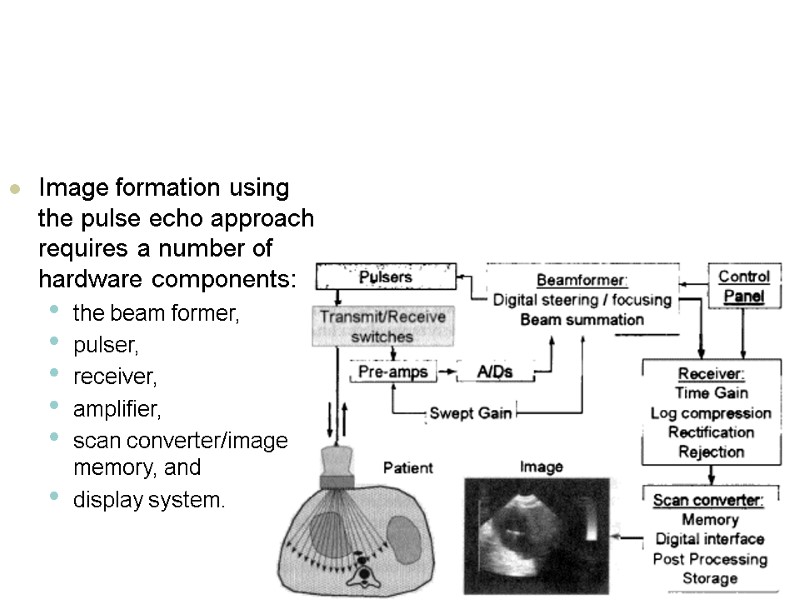

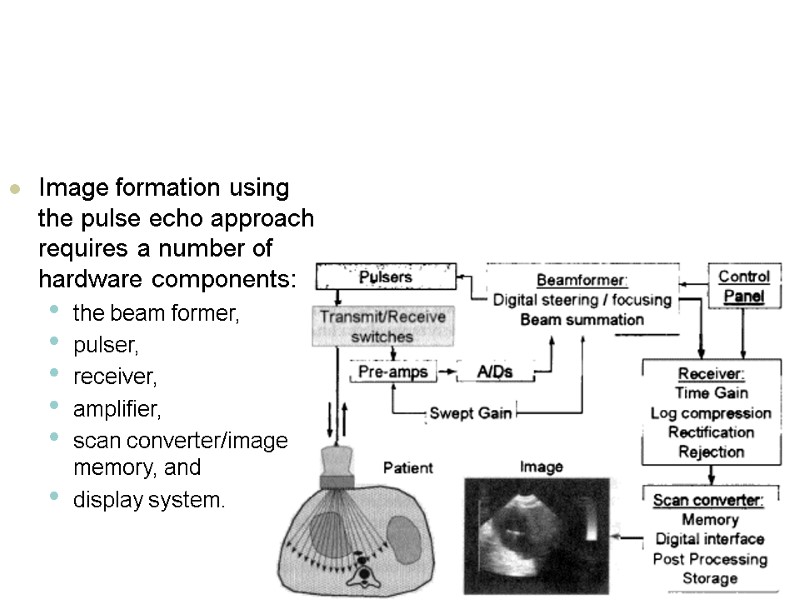

Image formation using the pulse echo approach requires a number of hardware components: the beam former, pulser, receiver, amplifier, scan converter/image memory, and display system.

Image formation using the pulse echo approach requires a number of hardware components: the beam former, pulser, receiver, amplifier, scan converter/image memory, and display system.

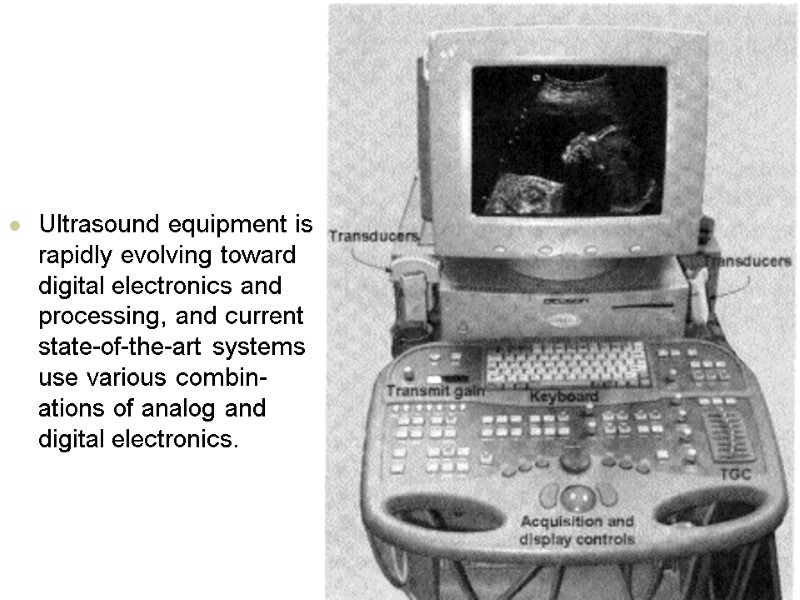

Ultrasound equipment is rapidly evolving toward digital electronics and processing, and current state-of-the-art systems use various combin-ations of analog and digital electronics.

Ultrasound equipment is rapidly evolving toward digital electronics and processing, and current state-of-the-art systems use various combin-ations of analog and digital electronics.

Beam Formers The beam former is responsible for generating the electronic delays for individual transducer elements in an array to achieve transmit and receive focusing and, in phased arrays, beam steering. Most modern, high-end ultrasound equipment incorporates a digital beam former and digital electronics for both transmit and receive functions.

Beam Formers The beam former is responsible for generating the electronic delays for individual transducer elements in an array to achieve transmit and receive focusing and, in phased arrays, beam steering. Most modern, high-end ultrasound equipment incorporates a digital beam former and digital electronics for both transmit and receive functions.

A digital beam former controls application-specific integrated circuits (ASICs) that provide transmit/receive switches, digital-to-analog and analog-to-digital converters, and preamplification and time gain compensation circuitry for each of the transducer elements in the array.

A digital beam former controls application-specific integrated circuits (ASICs) that provide transmit/receive switches, digital-to-analog and analog-to-digital converters, and preamplification and time gain compensation circuitry for each of the transducer elements in the array.

Major advantages of digital acquisition and processing include the flexibility to introduce new ultrasound capabilities by programmable software algorithms and to enhance control of the acoustic beam.

Major advantages of digital acquisition and processing include the flexibility to introduce new ultrasound capabilities by programmable software algorithms and to enhance control of the acoustic beam.

Pulser The pulser (also known as the transmitter) provides the electrical voltage for exciting the piezoelectric transducer elcnwnts, and controls the output transmit power by adjustment of the applied voltage. In digital beam-former systems, a digital-to analog-converter determines the amplitude of the voltage. An increase in transmit amplitude creates higher intensity sound and improves echo detection from weaker reflectors.

Pulser The pulser (also known as the transmitter) provides the electrical voltage for exciting the piezoelectric transducer elcnwnts, and controls the output transmit power by adjustment of the applied voltage. In digital beam-former systems, a digital-to analog-converter determines the amplitude of the voltage. An increase in transmit amplitude creates higher intensity sound and improves echo detection from weaker reflectors.

A direct consequence is higher signal-to-noise ratio in the images, but also higher power deposition to the patient. User controls of the output power are labeled “output,” “power,” “dB,” or “transmit” by the manufacturer. In some systems, a low power setting for obstetric imaging is available to reduce power deposition to the fetus. A method for indicating output power in terms of a thermal index (TI) and mechanical index (MI) is usually provided (see section 16.1 1).

A direct consequence is higher signal-to-noise ratio in the images, but also higher power deposition to the patient. User controls of the output power are labeled “output,” “power,” “dB,” or “transmit” by the manufacturer. In some systems, a low power setting for obstetric imaging is available to reduce power deposition to the fetus. A method for indicating output power in terms of a thermal index (TI) and mechanical index (MI) is usually provided (see section 16.1 1).