d92053ea3e22b8fc7809819cea2a13ab.ppt

- Количество слайдов: 22

TPC Status Report Project leader: Peter Braun-Munzinger, GSI Darmstadt Deputy project leader: Johanna Stachel, Heidelberg Technical coordinator: Peter Glässel, Heidelberg TB 18. 5. 06 Peter Glässel, Heidelberg

Outline Preparations for pre-commissioning Pre-commissioning has started Gas system Laser system First events Pre-commissioning objectives and plan TB 18. 5. 06 Peter Glässel, Heidelberg

FE Cards Installation 2/2 FEE testing, round 2 ‘Dry’ sector tests completed (FEE only, no HV) TB 18. 5. 06 Peter Glässel, Heidelberg 3

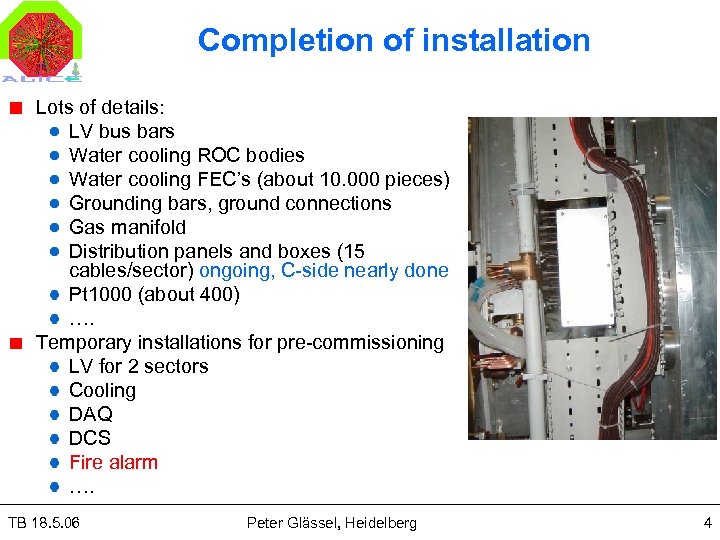

Completion of installation Lots of details: LV bus bars Water cooling ROC bodies Water cooling FEC’s (about 10. 000 pieces) Grounding bars, ground connections Gas manifold Distribution panels and boxes (15 cables/sector) ongoing, C-side nearly done Pt 1000 (about 400) …. Temporary installations for pre-commissioning LV for 2 sectors Cooling DAQ DCS Fire alarm …. TB 18. 5. 06 Peter Glässel, Heidelberg 4

Work at C-Side, now with scaffolds TB 18. 5. 06 Peter Glässel, Heidelberg 5

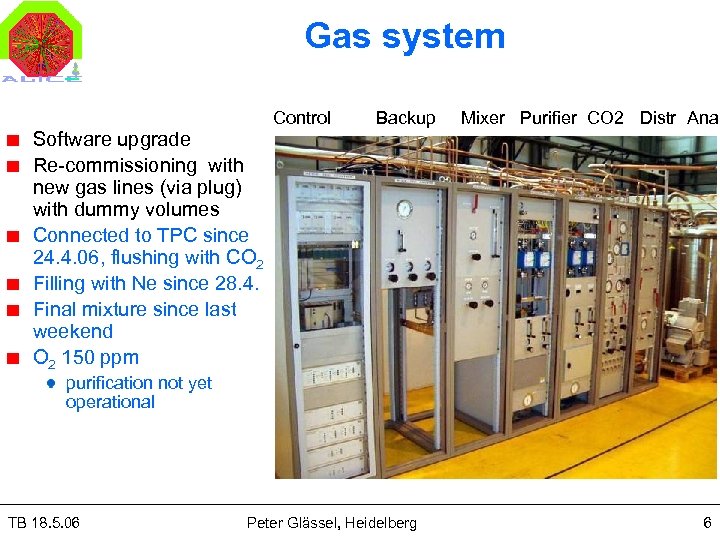

Gas system Control Backup Mixer Purifier CO 2 Distr Anal Software upgrade Re-commissioning with new gas lines (via plug) with dummy volumes Connected to TPC since 24. 4. 06, flushing with CO 2 Filling with Ne since 28. 4. Final mixture since last weekend O 2 150 ppm purification not yet operational TB 18. 5. 06 Peter Glässel, Heidelberg 6

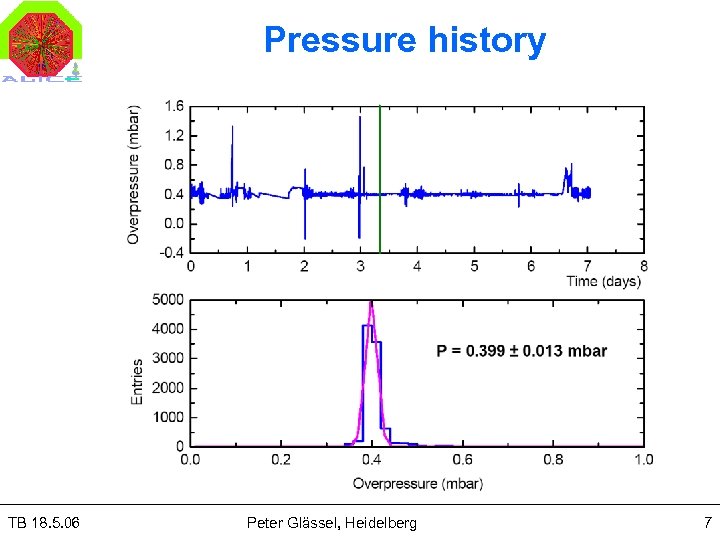

Pressure history TB 18. 5. 06 Peter Glässel, Heidelberg 7

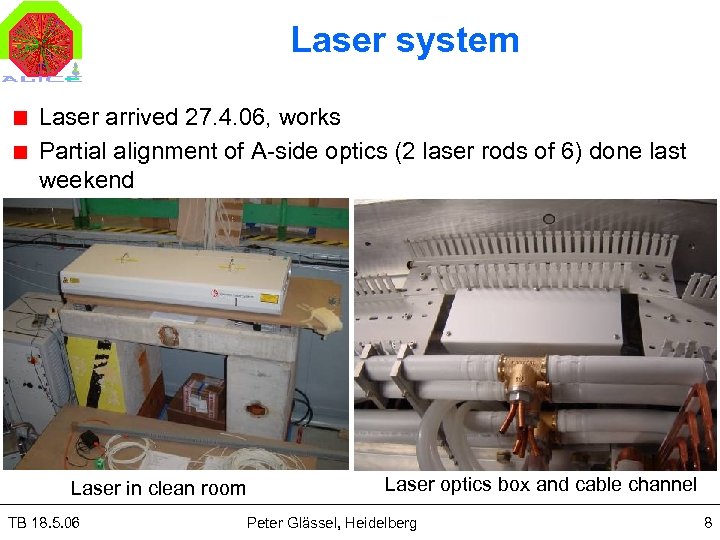

Laser system Laser arrived 27. 4. 06, works Partial alignment of A-side optics (2 laser rods of 6) done last weekend Laser in clean room TB 18. 5. 06 Laser optics box and cable channel Peter Glässel, Heidelberg 8

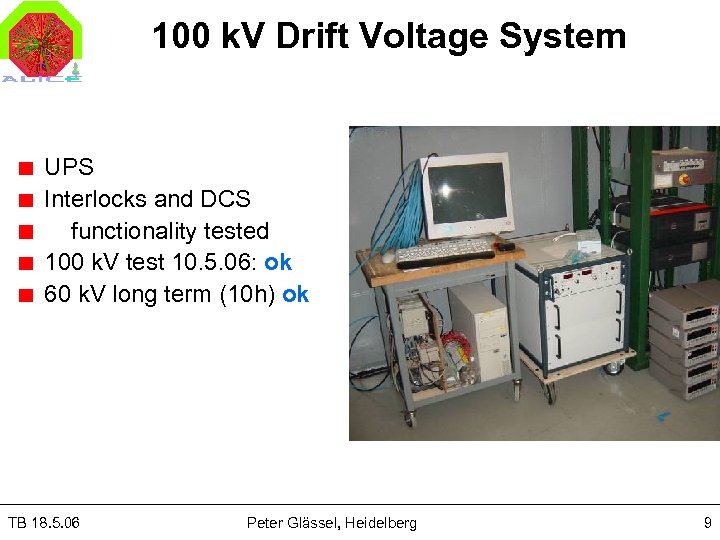

100 k. V Drift Voltage System UPS Interlocks and DCS functionality tested 100 k. V test 10. 5. 06: ok 60 k. V long term (10 h) ok TB 18. 5. 06 Peter Glässel, Heidelberg 9

Pre-Commissioning plans Goal was to start with FEE/ROC mid May Commissioning of Field cage, FEE and ROCs (i) study 2 sectors thoroughly, about 2 weeks (ii) commission sector by sector @ 2 days/sector shift schedule Move to UX 25: 4. 9. 06 Delphi frame is ‘moving cradle’ Detailed planning and preparations ongoing TB 18. 5. 06 Peter Glässel, Heidelberg 10

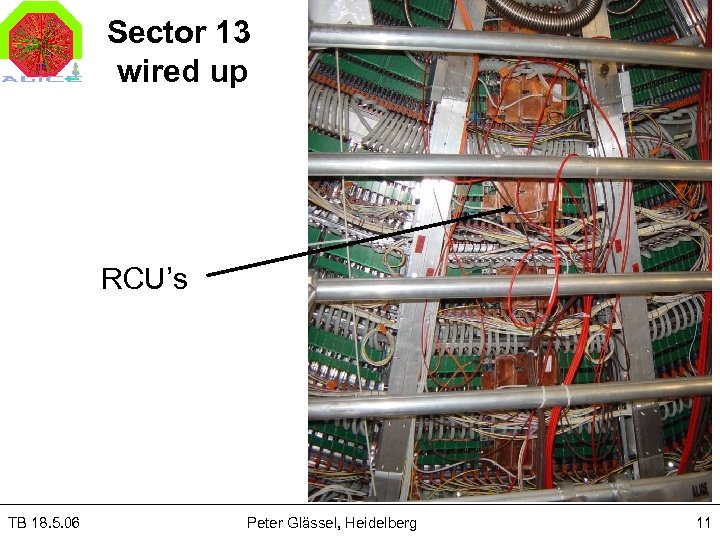

Sector 13 wired up RCU’s TB 18. 5. 06 Peter Glässel, Heidelberg 11

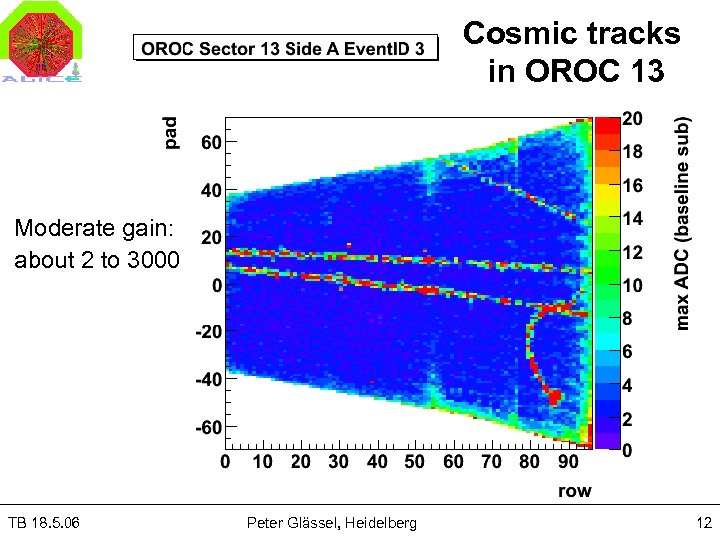

Cosmic tracks in OROC 13 Moderate gain: about 2 to 3000 TB 18. 5. 06 Peter Glässel, Heidelberg 12

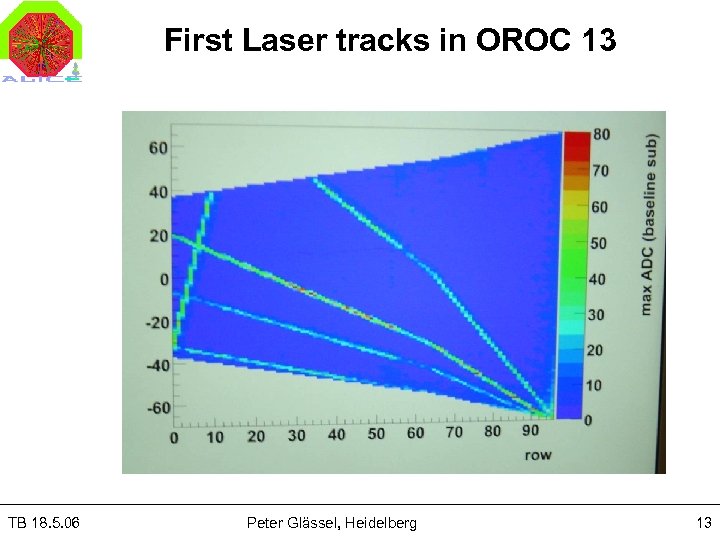

First Laser tracks in OROC 13 TB 18. 5. 06 Peter Glässel, Heidelberg 13

The Team TB 18. 5. 06 Peter Glässel, Heidelberg 14

TPC Summary Gas system working, final gas mixture Pre-commissioning of FC, ROC, FEE started Move to UX 2 Sep 06(? ) TB 18. 5. 06 Peter Glässel, Heidelberg 15

-- Spares -- TB 18. 5. 06 Peter Glässel, Heidelberg 16

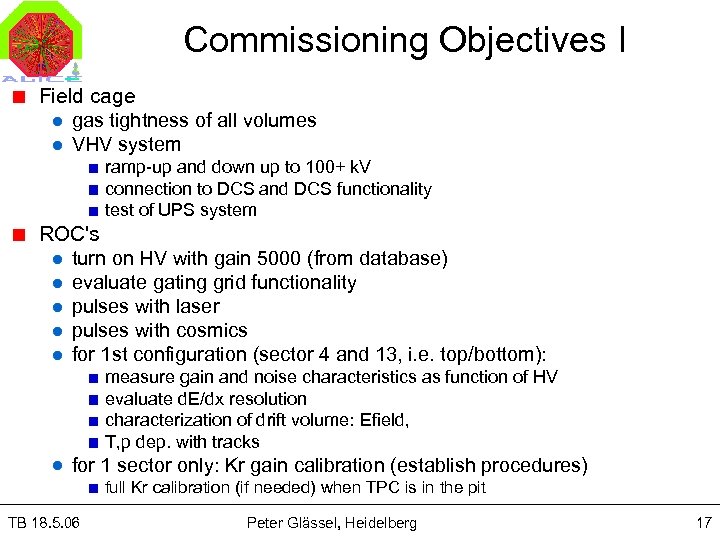

Commissioning Objectives I Field cage gas tightness of all volumes VHV system ramp-up and down up to 100+ k. V connection to DCS and DCS functionality test of UPS system ROC's turn on HV with gain 5000 (from database) evaluate gating grid functionality pulses with laser pulses with cosmics for 1 st configuration (sector 4 and 13, i. e. top/bottom): measure gain and noise characteristics as function of HV evaluate d. E/dx resolution characterization of drift volume: Efield, T, p dep. with tracks for 1 sector only: Kr gain calibration (establish procedures) full Kr calibration (if needed) when TPC is in the pit TB 18. 5. 06 Peter Glässel, Heidelberg 17

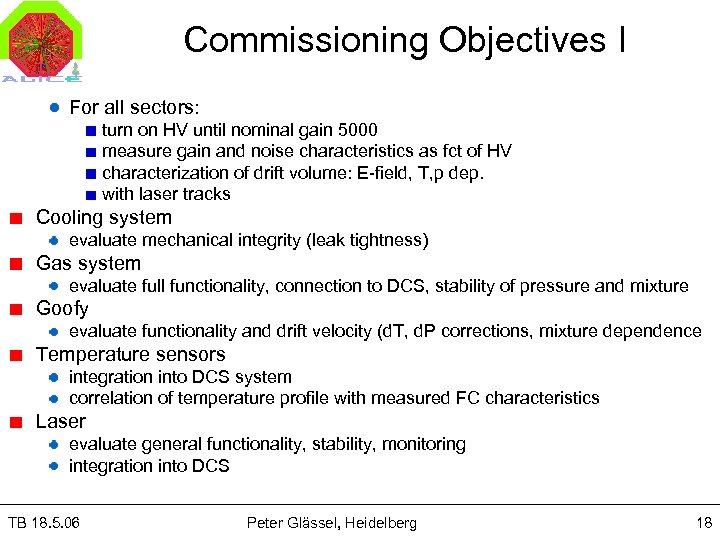

Commissioning Objectives I For all sectors: turn on HV until nominal gain 5000 measure gain and noise characteristics as fct of HV characterization of drift volume: E-field, T, p dep. with laser tracks Cooling system evaluate mechanical integrity (leak tightness) Gas system evaluate full functionality, connection to DCS, stability of pressure and mixture Goofy evaluate functionality and drift velocity (d. T, d. P corrections, mixture dependence Temperature sensors integration into DCS system correlation of temperature profile with measured FC characteristics Laser evaluate general functionality, stability, monitoring integration into DCS TB 18. 5. 06 Peter Glässel, Heidelberg 18

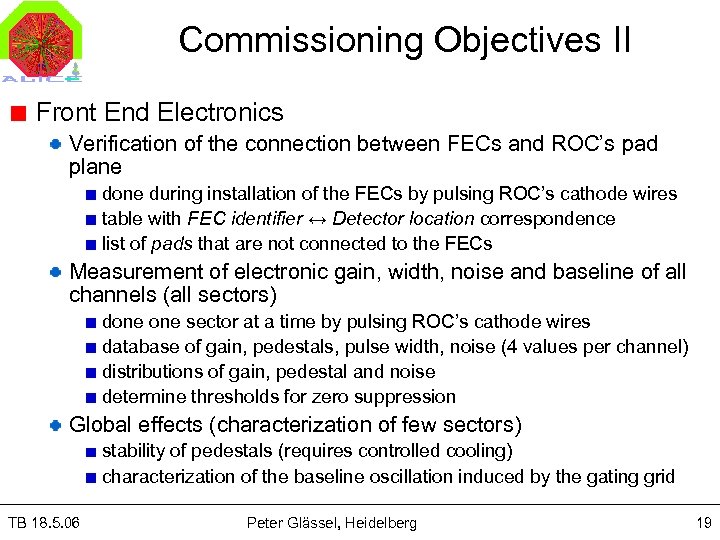

Commissioning Objectives II Front End Electronics Verification of the connection between FECs and ROC’s pad plane done during installation of the FECs by pulsing ROC’s cathode wires table with FEC identifier ↔ Detector location correspondence list of pads that are not connected to the FECs Measurement of electronic gain, width, noise and baseline of all channels (all sectors) done sector at a time by pulsing ROC’s cathode wires database of gain, pedestals, pulse width, noise (4 values per channel) distributions of gain, pedestal and noise determine thresholds for zero suppression Global effects (characterization of few sectors) stability of pedestals (requires controlled cooling) characterization of the baseline oscillation induced by the gating grid TB 18. 5. 06 Peter Glässel, Heidelberg 19

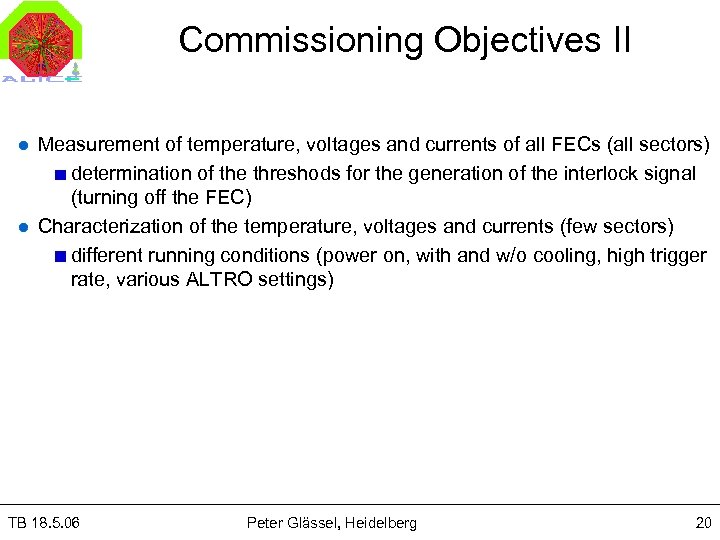

Commissioning Objectives II Measurement of temperature, voltages and currents of all FECs (all sectors) determination of the threshods for the generation of the interlock signal (turning off the FEC) Characterization of the temperature, voltages and currents (few sectors) different running conditions (power on, with and w/o cooling, high trigger rate, various ALTRO settings) TB 18. 5. 06 Peter Glässel, Heidelberg 20

Commissioning Objectives III Readout Electronics and Backend Systems FEE Configuration Creation of a set of basic Configuration Files (black events, zero suppressionevents, readout path test, etc. ) FEE Command Coder Configuration of FEE via DCS development of the supervisory layer completion of the field layer (DCS board) application integration of field layer, intercom layer and supervisory layer Configuration of FEE via DDL FEE monitoring via DCS development of the supervisory layer completion and test of the intercom layer and field layer application TB 18. 5. 06 Peter Glässel, Heidelberg 21

Commissioning Objectives III TPC Data Monitor review and integration of the various visual monitoring packages (MOOD, HLT, Expert Monitor, Offline) development of automated data quality monitor (what and where) Integration of FEE, ECS, DAQ, HLT, Trigger, Offline define standard run and calibration procedures and operations verify procedures for detection and recovery from errors (e. g. illegal trigger sequence) TB 18. 5. 06 Peter Glässel, Heidelberg 22

d92053ea3e22b8fc7809819cea2a13ab.ppt