be736c0b63563807012ff49994b22cf1.ppt

- Количество слайдов: 17

Towards the EDR Cryomodules & Cryogenics Barry Barish KEK Laboratory 12 -Sept-07 Cryomodules & Cryogenics 1

GDE – Mission Statement – Produce a design for the ILC that includes a detailed design concept, performance assessments, reliable international costing, an industrialization plan , siting analysis, as well as detector concepts and scope. – Coordinate worldwide prioritized proposal driven R & D efforts (to demonstrate and improve the performance, reduce the costs, attain the required reliability, etc. ) 12 -Sept-07 Cryomodules & Cryogenics 2

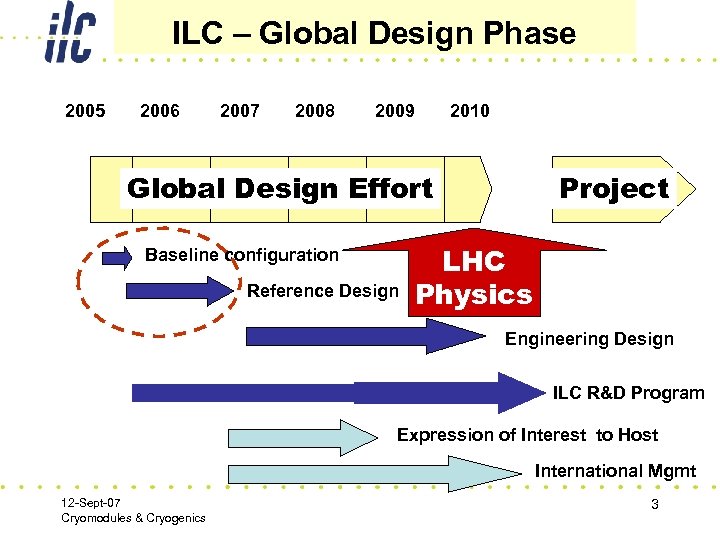

ILC – Global Design Phase 2005 2006 2007 2008 2009 2010 Global Design Effort Baseline configuration Reference Design Project LHC Physics Engineering Design ILC R&D Program Expression of Interest to Host International Mgmt 12 -Sept-07 Cryomodules & Cryogenics 3

Organizing for the EDR • Build on Successes of GDE, RDR and DCR – Be ready with solid funding proposal when exciting results begin to emerge from LHC • Project Management and Engineering Design – Re-structure and strengthen GDE to incorporate a more traditional project management structure, engineering strength and project tools. – Perform engineering design that engages industry, optimizes cost / performance, minimizes risks through R&D program, and has a realistic construction plan – Produce EDR in 2010 with project implementation plan 12 -Sept-07 Cryomodules & Cryogenics 4

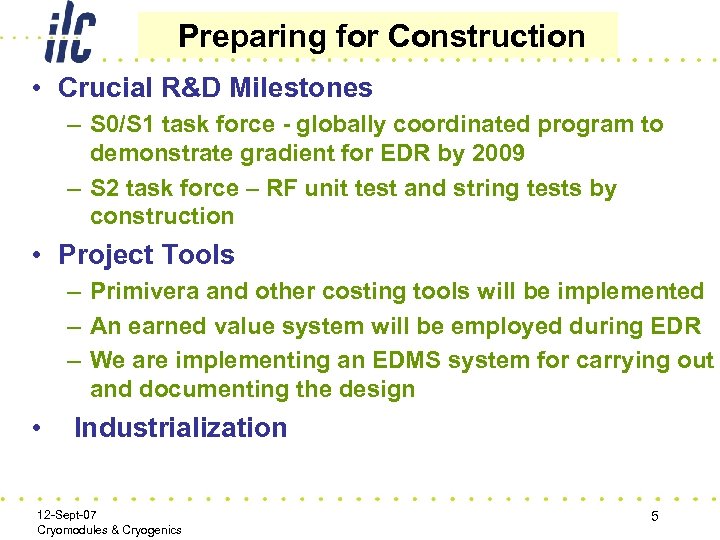

Preparing for Construction • Crucial R&D Milestones – S 0/S 1 task force - globally coordinated program to demonstrate gradient for EDR by 2009 – S 2 task force – RF unit test and string tests by construction • Project Tools – Primivera and other costing tools will be implemented – An earned value system will be employed during EDR – We are implementing an EDMS system for carrying out and documenting the design • Industrialization 12 -Sept-07 Cryomodules & Cryogenics 5

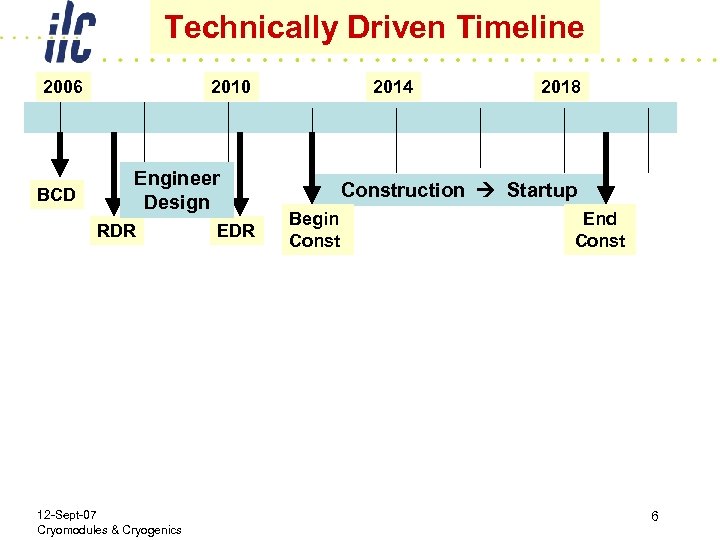

Technically Driven Timeline 2006 BCD 2010 Engineer Design RDR 12 -Sept-07 Cryomodules & Cryogenics EDR 2014 2018 Construction Startup Begin Const End Const August 6

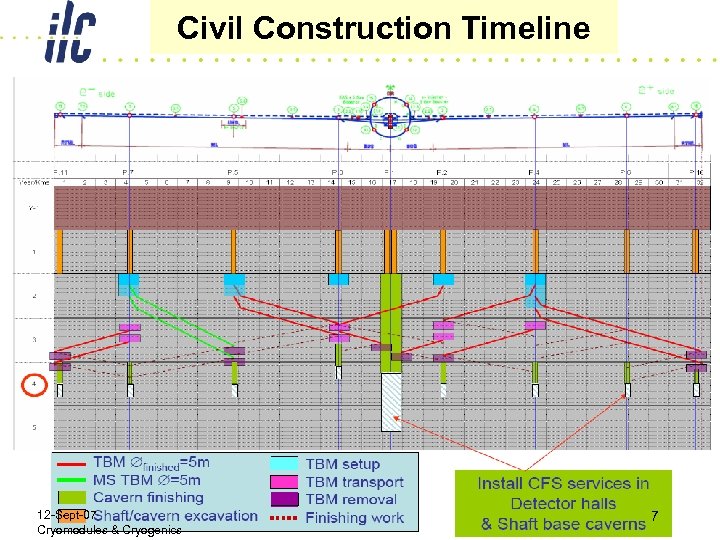

Civil Construction Timeline 12 -Sept-07 Cryomodules & Cryogenics 7

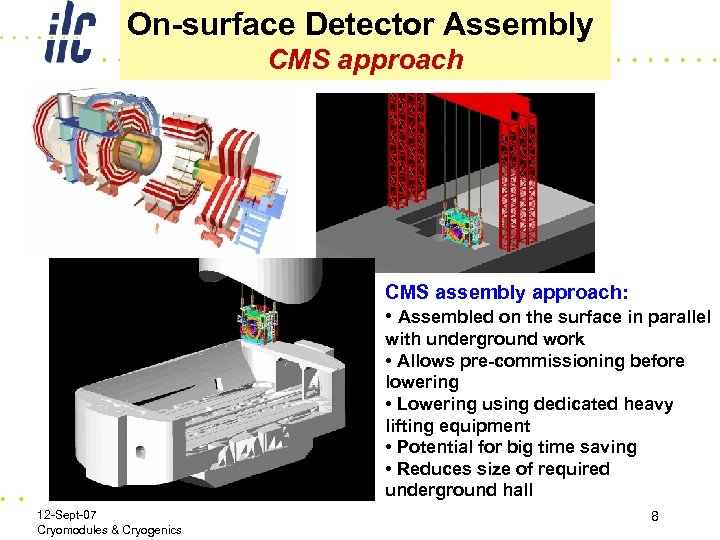

On-surface Detector Assembly CMS approach CMS assembly approach: • Assembled on the surface in parallel with underground work • Allows pre-commissioning before lowering • Lowering using dedicated heavy lifting equipment • Potential for big time saving • Reduces size of required underground hall 12 -Sept-07 Cryomodules & Cryogenics 8

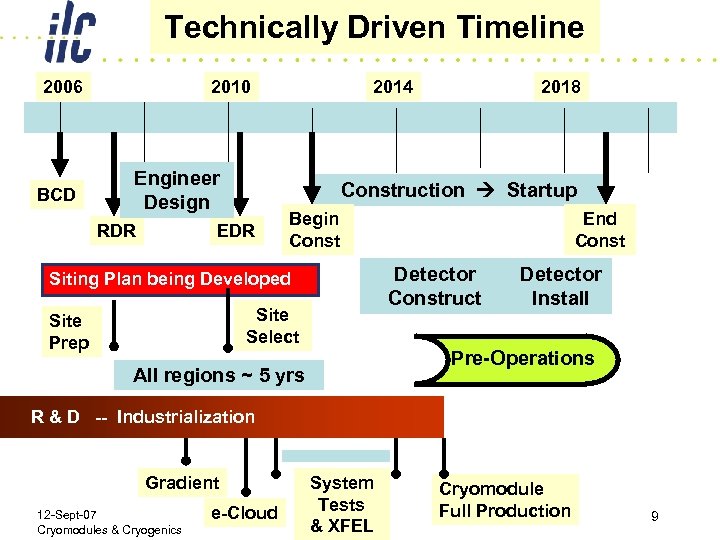

Technically Driven Timeline 2006 BCD 2010 Engineer Design RDR 2014 Construction Startup EDR Begin Const End Const Detector Construct Siting Plan being Developed Site Select Site Prep 2018 Detector Install Pre-Operations All regions ~ 5 yrs R & D -- Industrialization Gradient 12 -Sept-07 Cryomodules & Cryogenics e-Cloud System Tests & XFEL Cryomodule August Full Production 9

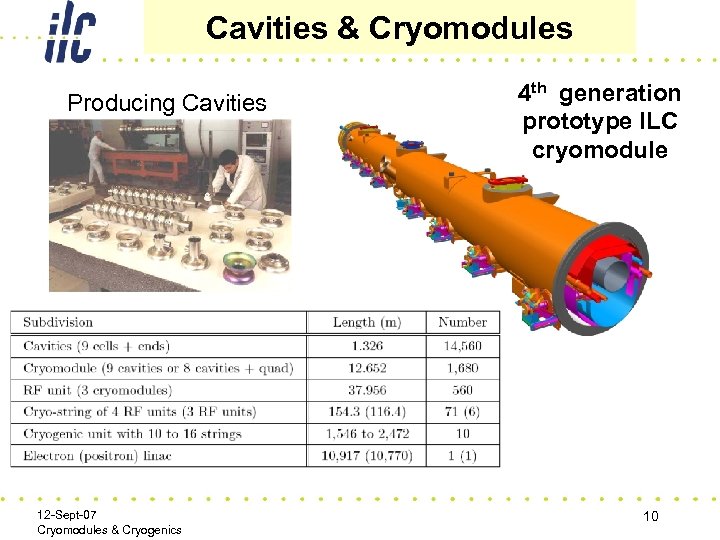

Cavities & Cryomodules Producing Cavities 12 -Sept-07 Cryomodules & Cryogenics 4 th generation prototype ILC cryomodule 10

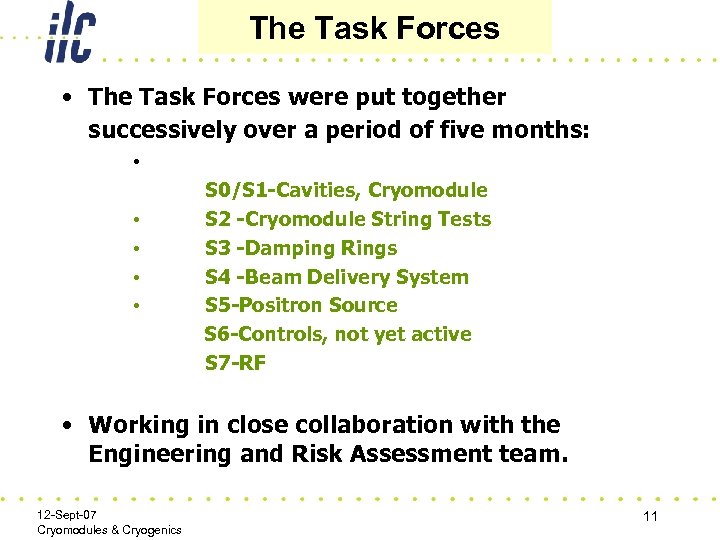

The Task Forces • The Task Forces were put together successively over a period of five months: • • • S 0/S 1 -Cavities, Cryomodule S 2 -Cryomodule String Tests S 3 -Damping Rings S 4 -Beam Delivery System S 5 -Positron Source S 6 -Controls, not yet active S 7 -RF • Working in close collaboration with the Engineering and Risk Assessment team. 12 -Sept-07 Cryomodules & Cryogenics 11

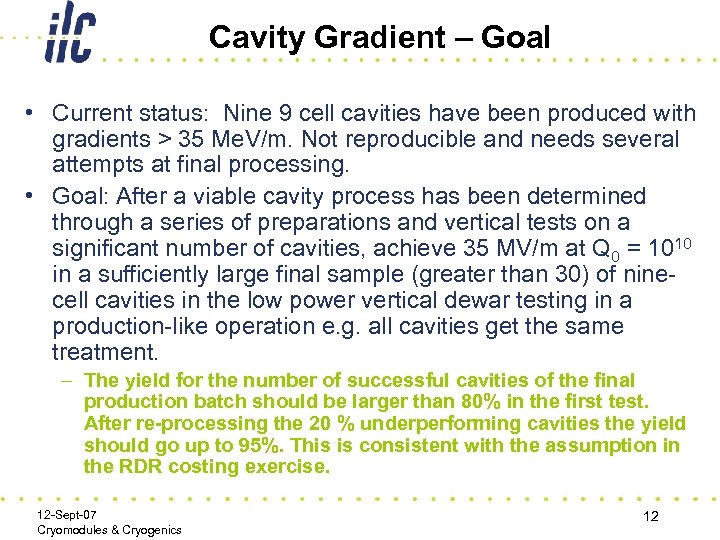

Cavity Gradient – Goal • Current status: Nine 9 cell cavities have been produced with gradients > 35 Me. V/m. Not reproducible and needs several attempts at final processing. • Goal: After a viable cavity process has been determined through a series of preparations and vertical tests on a significant number of cavities, achieve 35 MV/m at Q 0 = 1010 in a sufficiently large final sample (greater than 30) of ninecell cavities in the low power vertical dewar testing in a production-like operation e. g. all cavities get the same treatment. – The yield for the number of successful cavities of the final production batch should be larger than 80% in the first test. After re-processing the 20 % underperforming cavities the yield should go up to 95%. This is consistent with the assumption in the RDR costing exercise. 12 -Sept-07 Cryomodules & Cryogenics 12

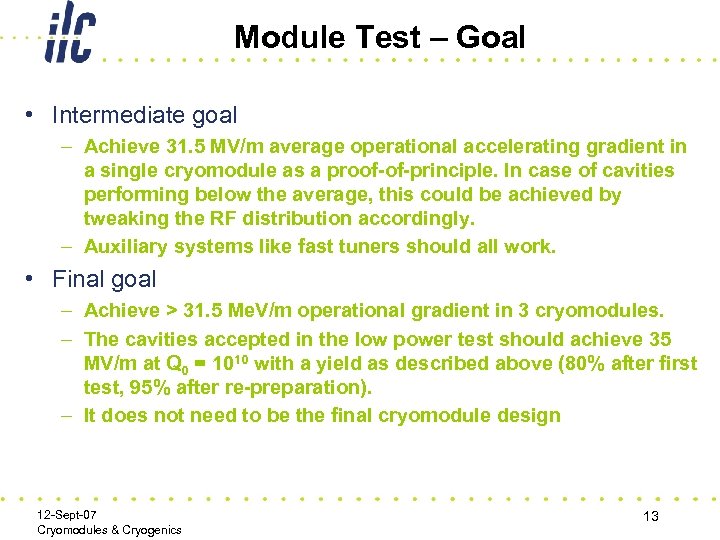

Module Test – Goal • Intermediate goal – Achieve 31. 5 MV/m average operational accelerating gradient in a single cryomodule as a proof-of-principle. In case of cavities performing below the average, this could be achieved by tweaking the RF distribution accordingly. – Auxiliary systems like fast tuners should all work. • Final goal – Achieve > 31. 5 Me. V/m operational gradient in 3 cryomodules. – The cavities accepted in the low power test should achieve 35 MV/m at Q 0 = 1010 with a yield as described above (80% after first test, 95% after re-preparation). – It does not need to be the final cryomodule design 12 -Sept-07 Cryomodules & Cryogenics 13

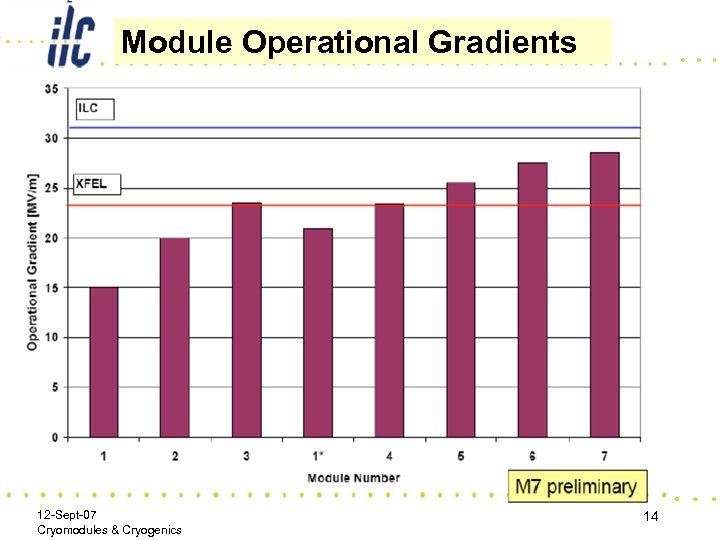

Module Operational Gradients 12 -Sept-07 Cryomodules & Cryogenics 14

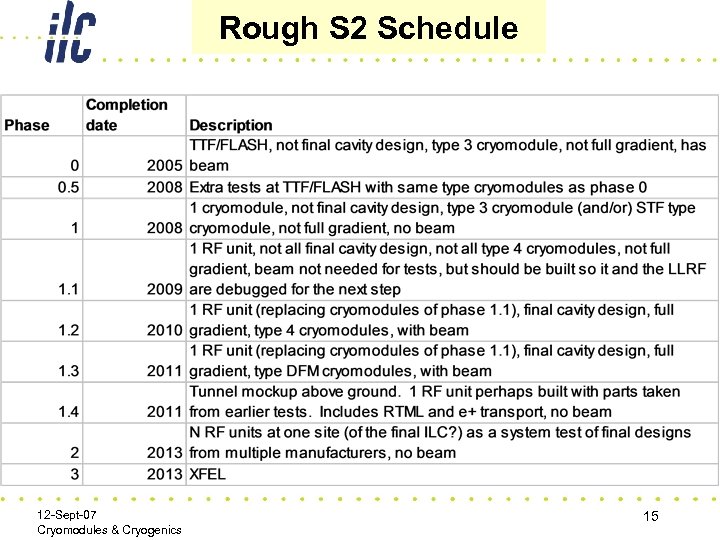

Rough S 2 Schedule 12 -Sept-07 Cryomodules & Cryogenics 15

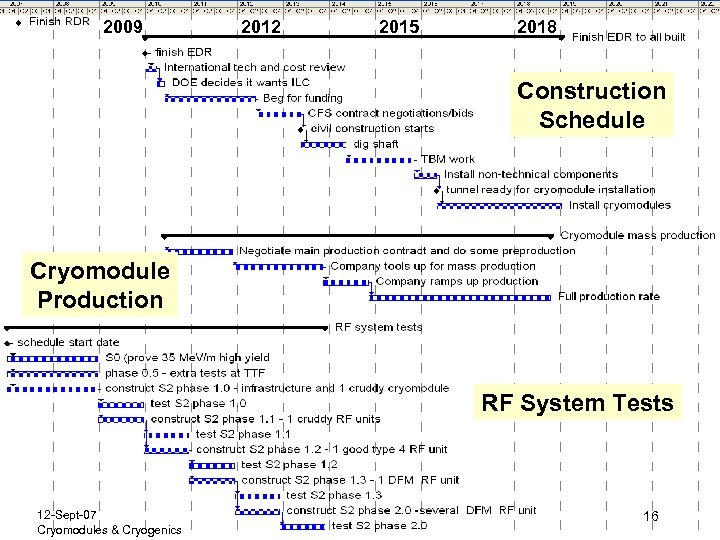

2009 2012 2015 2018 Schedule in Graphical Form Construction Schedule Cryomodule Production RF System Tests 12 -Sept-07 Cryomodules & Cryogenics 16

Cryo – Kickoff Discussions • Gradient ? – Demonstrate 31. 5 MV/m before EDR or reduce the gradient or adjust the design or ? ? (We need a vital program of both R&D and demonstrations) • Mass production ? – Industrialize, multiple vendors, economies of mass production etc • How to maintain a global design ? – Maintaining a baseline – Unified design and plug compatible designs 12 -Sept-07 Cryomodules & Cryogenics 17

be736c0b63563807012ff49994b22cf1.ppt