98e51c5704638fbdef7fa67eded72fc1.ppt

- Количество слайдов: 13

Towards SKA-low: AAVS and Other Practicalities Peter Hall and Mark Waterson ICRAR/Curtin AAVP Workshop, Cambridge, 10 December 2010

Towards SKA-low: AAVS and Other Practicalities Peter Hall and Mark Waterson ICRAR/Curtin AAVP Workshop, Cambridge, 10 December 2010

What are the goals of AAVS? • Technology demonstrator (primarily) – Reduce risk • SKA-low ready for deployment in 2016 – Learn from LOFAR, MWA, . . . • Re-invent as little as possible – Emphasize engineering • But include a focused program of science and system learning • Design validation – for (sub)systems – Does it work? – Can it be produced in quantity? – Can it be deployed cost-effectively? Fast enough? • Collaboration demonstrator – Develop culture of collaboration • Tools, processes, management, . . .

What are the goals of AAVS? • Technology demonstrator (primarily) – Reduce risk • SKA-low ready for deployment in 2016 – Learn from LOFAR, MWA, . . . • Re-invent as little as possible – Emphasize engineering • But include a focused program of science and system learning • Design validation – for (sub)systems – Does it work? – Can it be produced in quantity? – Can it be deployed cost-effectively? Fast enough? • Collaboration demonstrator – Develop culture of collaboration • Tools, processes, management, . . .

AAVS requirements • Build functional interferometer – Validate design extensions to LOFAR, MWA • Well -defined imaging and non-imaging tests • Verify performance – Not capability (comes with adding DSP etc) • Verify scalability to SKA-low – Construction, commissioning, deployment, operation • e. g. measuring MTBF of system • Develop within institute having substantial engineering capability • AAVS will be the first dedicated SKA development! – Totally driven by SKA

AAVS requirements • Build functional interferometer – Validate design extensions to LOFAR, MWA • Well -defined imaging and non-imaging tests • Verify performance – Not capability (comes with adding DSP etc) • Verify scalability to SKA-low – Construction, commissioning, deployment, operation • e. g. measuring MTBF of system • Develop within institute having substantial engineering capability • AAVS will be the first dedicated SKA development! – Totally driven by SKA

Site impact • Ground (soil) and related issues – Finite conductivity and e. m. “mirror” • Metal ground-planes with all antenna types? – Lightning, surge considerations – Induced noise (e. g. mutual impedance coupling) – Attractiveness of galvanic isolation • Solar powered elements (PV + storage)? • Physical environment – Climate, wildlife, dust, . . . – – • Make or break issues in design Materials selection Enclosure selection Environmental conditioning (cooling, . . . ) Mechanics of deployment • Low RFI – enables cost effective aperture arrays • Engineering driver: locate AAVS (mainly) at SKA site – Site must provide AAVS infrastructure and logistical support

Site impact • Ground (soil) and related issues – Finite conductivity and e. m. “mirror” • Metal ground-planes with all antenna types? – Lightning, surge considerations – Induced noise (e. g. mutual impedance coupling) – Attractiveness of galvanic isolation • Solar powered elements (PV + storage)? • Physical environment – Climate, wildlife, dust, . . . – – • Make or break issues in design Materials selection Enclosure selection Environmental conditioning (cooling, . . . ) Mechanics of deployment • Low RFI – enables cost effective aperture arrays • Engineering driver: locate AAVS (mainly) at SKA site – Site must provide AAVS infrastructure and logistical support

ICRAR and AAVP • Moderate, but in-place resources – Euro 5 M project, 25 FTE (total), € 300 k capital for SKA-low prototyping – New radio astronomy engineering lab (€ 2 M) – Explicit resources to support MRO (desert site) prototyping – Full connectivity to MRO in next 6 months • Internet access • Innovative program for SKA-low “exploratory technology” – Single antenna 70 -450 MHz solution BUT in system context – Solar powered elements, low-power digital receiver and transport, galvanic isolation, . . – Major materials engineering, packaging, deployment focus – Links with mature industry partners • Development, site and logistical resources available to entire AAVP partnership

ICRAR and AAVP • Moderate, but in-place resources – Euro 5 M project, 25 FTE (total), € 300 k capital for SKA-low prototyping – New radio astronomy engineering lab (€ 2 M) – Explicit resources to support MRO (desert site) prototyping – Full connectivity to MRO in next 6 months • Internet access • Innovative program for SKA-low “exploratory technology” – Single antenna 70 -450 MHz solution BUT in system context – Solar powered elements, low-power digital receiver and transport, galvanic isolation, . . – Major materials engineering, packaging, deployment focus – Links with mature industry partners • Development, site and logistical resources available to entire AAVP partnership

Power • Power is a critical issue for SKA (PITF) • AAVS can be a platform for power supply innovation • AAVS must develop a culture of power demand minimization – Design against a power budget from outset, review progress – Push low-power everywhere • RF components, DSP, data transport, control systems. . – Investigate dynamic power management – sleep modes, “instant -on” to keep idle costs down – Collect and publish cost-benefit trade studies to educate all development groups • Most groups have little experience in this but there are experts around (e. g. JPL)

Power • Power is a critical issue for SKA (PITF) • AAVS can be a platform for power supply innovation • AAVS must develop a culture of power demand minimization – Design against a power budget from outset, review progress – Push low-power everywhere • RF components, DSP, data transport, control systems. . – Investigate dynamic power management – sleep modes, “instant -on” to keep idle costs down – Collect and publish cost-benefit trade studies to educate all development groups • Most groups have little experience in this but there are experts around (e. g. JPL)

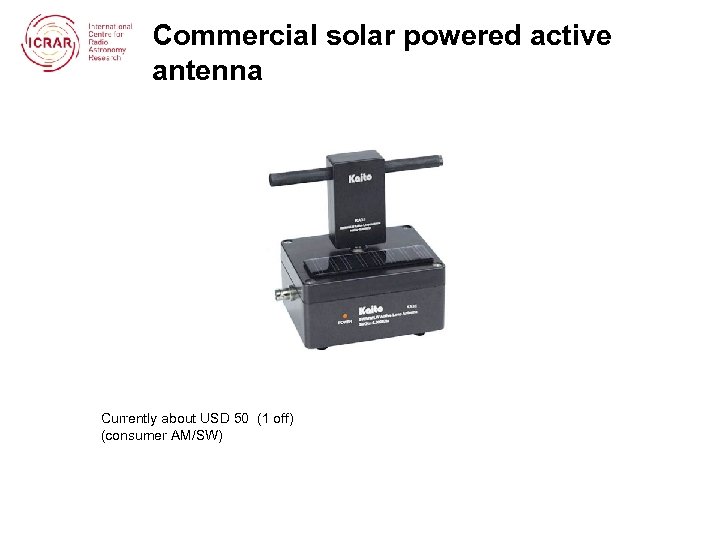

Commercial solar powered active antenna Currently about USD 50 (1 off) (consumer AM/SW)

Commercial solar powered active antenna Currently about USD 50 (1 off) (consumer AM/SW)

The MWA as an SKA engineering demonstrator • Proposed as a science-driven instrument but also a technology and operations demonstrator: – Base-band direct conversion – Reconfigurable backend processors (FPGA) – Enough dynamic range to ‘look between” terrestrial interference signals – Real-time calibration and beam solutions – Distributed system configuration and control – Deployment, operations and maintenance

The MWA as an SKA engineering demonstrator • Proposed as a science-driven instrument but also a technology and operations demonstrator: – Base-band direct conversion – Reconfigurable backend processors (FPGA) – Enough dynamic range to ‘look between” terrestrial interference signals – Real-time calibration and beam solutions – Distributed system configuration and control – Deployment, operations and maintenance

Project lessons from MWA • “Basic” project management + “SE lite” not good enough in highly distributed project – The culture of a long-term project is hard to change once started • Foster common standards and project metrics from the outset – Takes time to get the tools and infrastructure of collaborative project management working • Use AAVS to ramp up to actual SKA methodologies • One “hero” PM isn’t enough, every group must be involved so that they learn how to work in a Global team • Exchange programs really work – send team members off to work at the other group’s base for 2 -4 weeks, to understand the culture, resources a limitations

Project lessons from MWA • “Basic” project management + “SE lite” not good enough in highly distributed project – The culture of a long-term project is hard to change once started • Foster common standards and project metrics from the outset – Takes time to get the tools and infrastructure of collaborative project management working • Use AAVS to ramp up to actual SKA methodologies • One “hero” PM isn’t enough, every group must be involved so that they learn how to work in a Global team • Exchange programs really work – send team members off to work at the other group’s base for 2 -4 weeks, to understand the culture, resources a limitations

Recommendations from MWA • Lab “mock-up” is critical • Test everything before going to site – and if it doesn’t work, DON’T GO! • Enforce transparency – especially out-oforganization reviews, personnel exchanges • Separate project status reports/meetings from design workshops • Look at other data-heavy projects for development priorities – eg LHC, Pan. STARRS, LSST, …

Recommendations from MWA • Lab “mock-up” is critical • Test everything before going to site – and if it doesn’t work, DON’T GO! • Enforce transparency – especially out-oforganization reviews, personnel exchanges • Separate project status reports/meetings from design workshops • Look at other data-heavy projects for development priorities – eg LHC, Pan. STARRS, LSST, …

More specific to SKA-low • Don’t underestimate the cost of complexity – High unit counts make simple things complicated – Include studies of maintenance cost (and time) – Even a simple thing is hard if you have to do it 16 000 times! • Include real failure handling functions in designs – Ability to isolate, and turn off, malfunctioning elements at acceptably sized sections – Include transparent restart capability • Be aware of cumulative MTBFs • Analyze cumulative failure degradation carefully – How often will maintenance really be required? – What is the maintenance model (within SKA operations plan)?

More specific to SKA-low • Don’t underestimate the cost of complexity – High unit counts make simple things complicated – Include studies of maintenance cost (and time) – Even a simple thing is hard if you have to do it 16 000 times! • Include real failure handling functions in designs – Ability to isolate, and turn off, malfunctioning elements at acceptably sized sections – Include transparent restart capability • Be aware of cumulative MTBFs • Analyze cumulative failure degradation carefully – How often will maintenance really be required? – What is the maintenance model (within SKA operations plan)?

Industry and SKA-low • Industry will make and deploy our systems • Design for manufacture, design for deployment – Combine pathfinder experience with site-knowledgeable industry know-how • Many Global industries with relevant experience – Construction and operation of remote facilities in AU, RSA • e. g. mining, resource, communications, . . . – Infrastructure provision rests squarely with industry • Commissioning is where industry is most deficient – We need a commissioning plan and international commissioning crew • Constructors will not wait for leisurely sign-off large commissioning crew • Cross-disciplinary (astronomy + engineering) • Mobile (significant time at, or near, site) – Likely to grow out of AAVP team

Industry and SKA-low • Industry will make and deploy our systems • Design for manufacture, design for deployment – Combine pathfinder experience with site-knowledgeable industry know-how • Many Global industries with relevant experience – Construction and operation of remote facilities in AU, RSA • e. g. mining, resource, communications, . . . – Infrastructure provision rests squarely with industry • Commissioning is where industry is most deficient – We need a commissioning plan and international commissioning crew • Constructors will not wait for leisurely sign-off large commissioning crew • Cross-disciplinary (astronomy + engineering) • Mobile (significant time at, or near, site) – Likely to grow out of AAVP team

Conclusion • Use Pathfinders for “active learning” • Use phased resourcing within AAVP wisely • Push for maximum SKA site-specific learning • From this point, integrate SKA-low and SKA-mid system design • Keep an open mind but require timely demonstration – Innovation important, but 2016 timescale imposes real limits • Accept that we now entering a major engineering project and be prepared to make hard decisions on specifications

Conclusion • Use Pathfinders for “active learning” • Use phased resourcing within AAVP wisely • Push for maximum SKA site-specific learning • From this point, integrate SKA-low and SKA-mid system design • Keep an open mind but require timely demonstration – Innovation important, but 2016 timescale imposes real limits • Accept that we now entering a major engineering project and be prepared to make hard decisions on specifications