b1591d78d940709b84f8442215c6b1b4.ppt

- Количество слайдов: 101

Total Quality Management Chapter 16 Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Total Quality Management Chapter 16 Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

What is Quality? Quality means user satisfaction: that goods or services satisfy the needs and expectations of the user. Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

What is Quality? Quality means user satisfaction: that goods or services satisfy the needs and expectations of the user. Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality and Product Policy • Established by management • Product planning – wants and needs of the marketplace – level of product performance – price to be charged – expected sales volume Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality and Product Policy • Established by management • Product planning – wants and needs of the marketplace – level of product performance – price to be charged – expected sales volume Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality and Product Design • General specifications set by the marketplace – expected perfomance, appearance, price, volume • Product designers – materials to be used, dimensions, tolerances, product capability, service requirements Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality and Product Design • General specifications set by the marketplace – expected perfomance, appearance, price, volume • Product designers – materials to be used, dimensions, tolerances, product capability, service requirements Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

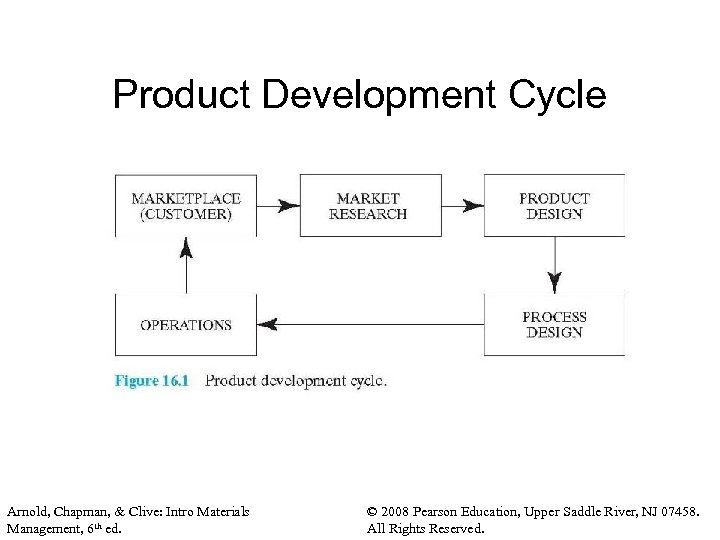

Product Development Cycle Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Product Development Cycle Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality and Manufacturing • Strive for excellence in products • All products must be within specification • The less the variation (from the nominal) the better • Tolerance – the amount of variation allowed from the desired value Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality and Manufacturing • Strive for excellence in products • All products must be within specification • The less the variation (from the nominal) the better • Tolerance – the amount of variation allowed from the desired value Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality and Use • Performance – reliability, durability, maintainability • • Features Conformance to specification Warranty Service Aesthetics Perceived quality Price Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality and Use • Performance – reliability, durability, maintainability • • Features Conformance to specification Warranty Service Aesthetics Perceived quality Price Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Total Quality Management (TQM) “TQM is based on the participation of all members of an organization in improving processes, goods, services, and the culture in which the work. ” • APICS 11 th Edition Dictionary Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Total Quality Management (TQM) “TQM is based on the participation of all members of an organization in improving processes, goods, services, and the culture in which the work. ” • APICS 11 th Edition Dictionary Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

TQM - Basic Concepts 1. A committed and involved management 2. Focus on the customer 3. Involvement of the total workforce 4. Continuous process improvement 5. Supplier partnering 6. Performance measures Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

TQM - Basic Concepts 1. A committed and involved management 2. Focus on the customer 3. Involvement of the total workforce 4. Continuous process improvement 5. Supplier partnering 6. Performance measures Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Management Commitment • Vision Statement – what the organization will be in 5 years • Mission statement – who we are, who are our customers, what we do, how we do it • Quality policy – how goods and services are provided • Strategic plan – includes TQM objectives Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Management Commitment • Vision Statement – what the organization will be in 5 years • Mission statement – who we are, who are our customers, what we do, how we do it • Quality policy – how goods and services are provided • Strategic plan – includes TQM objectives Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Customer Focus X-plicit – I want a car that will comfortably carry 5 passengers and some gear X-pected – we arrived safely at our campsite X-citing – there’s a 110 volt outlet in the back! Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Customer Focus X-plicit – I want a car that will comfortably carry 5 passengers and some gear X-pected – we arrived safely at our campsite X-citing – there’s a 110 volt outlet in the back! Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Customer Focus • Meeting and exceeding customer expectations • External customers – people we sell our goods to • Internal customers – people or departments who receive output from another person or department – treat them like a customer Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Customer Focus • Meeting and exceeding customer expectations • External customers – people we sell our goods to • Internal customers – people or departments who receive output from another person or department – treat them like a customer Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Customer Requirements 1. High quality 2. Flexibility to change in volume, etc. 3. High service level 4. Short lead times 5. Consistency in meeting targets 6. Low cost Customers expect improvements Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Customer Requirements 1. High quality 2. Flexibility to change in volume, etc. 3. High service level 4. Short lead times 5. Consistency in meeting targets 6. Low cost Customers expect improvements Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Employee Involvement • TQM is everyone’s responsibility • Employees are expected to do their jobs and to work at improving their jobs (and) other’s jobs Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Employee Involvement • TQM is everyone’s responsibility • Employees are expected to do their jobs and to work at improving their jobs (and) other’s jobs Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Commitment to TQM 1. Training – their own job skills – cross trained on other jobs – tools of continuous improvement 2. Organization – to keep close contact with customers 3. Local ownership of processes – empowerment Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Commitment to TQM 1. Training – their own job skills – cross trained on other jobs – tools of continuous improvement 2. Organization – to keep close contact with customers 3. Local ownership of processes – empowerment Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Empowerment A condition whereby employees have the authority to make decisions and take actions in their work areas without approval. For example, a customer service representative can send out a replacement product if a customer calls with a problem. • APICs 11 th Edition Dictionary Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Empowerment A condition whereby employees have the authority to make decisions and take actions in their work areas without approval. For example, a customer service representative can send out a replacement product if a customer calls with a problem. • APICs 11 th Edition Dictionary Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

TQM - Teams • Move beyond the contribution of individuals • Sum of the total effort is increased • Requires skill and training • Fundamental part of TQM Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

TQM - Teams • Move beyond the contribution of individuals • Sum of the total effort is increased • Requires skill and training • Fundamental part of TQM Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Supplier Partnerships • Used in JIT and TQM • Treat the supplier as a partner and not as an adversary – quality improvements – mutual sharing of savings – team approach Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Supplier Partnerships • Used in JIT and TQM • Treat the supplier as a partner and not as an adversary – quality improvements – mutual sharing of savings – team approach Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Performance Measures • • • “That what gets measured is that what gets done” - Anonymous Decide which processes need improvement Evaluate alternatives Compare actual to target Evaluate employees Show trends Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Performance Measures • • • “That what gets measured is that what gets done” - Anonymous Decide which processes need improvement Evaluate alternatives Compare actual to target Evaluate employees Show trends Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Measurements • Need to give useful feedback – Quantity of good parts per unit time – Cost – On time delivery – Quality • function • aesthetics • accuracy (defects/tolerance) Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Measurements • Need to give useful feedback – Quantity of good parts per unit time – Cost – On time delivery – Quality • function • aesthetics • accuracy (defects/tolerance) Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Measurements • Simple, understandable, relevant and visible to the user, preferably developed by the user, designed to promote improvement, few in number Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Measurements • Simple, understandable, relevant and visible to the user, preferably developed by the user, designed to promote improvement, few in number Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Measurements • Customer – number of complaints – on-time delivery • Production – inventory turns, scrap, cost per unit, time to delivery Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. • Suppliers – – on-time delivery rating quality performance billing accuracy • Sales – expense to revenue – new customers – sales per square foot © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Measurements • Customer – number of complaints – on-time delivery • Production – inventory turns, scrap, cost per unit, time to delivery Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. • Suppliers – – on-time delivery rating quality performance billing accuracy • Sales – expense to revenue – new customers – sales per square foot © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality Cost Concepts • Cost of failure to control quality – failure • Cost of controlling quality – prevention – appraisal Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality Cost Concepts • Cost of failure to control quality – failure • Cost of controlling quality – prevention – appraisal Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Costs of Failure • Internal failure costs – scrap – rework – spoilage – these costs diminish with improved quality Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. • External failure costs • After the customer receives the goods • Most costly – warranty costs – field service – other costs to satisfy the customer – decrese with improved quality © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Costs of Failure • Internal failure costs – scrap – rework – spoilage – these costs diminish with improved quality Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. • External failure costs • After the customer receives the goods • Most costly – warranty costs – field service – other costs to satisfy the customer – decrese with improved quality © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Costs of Controlling Quality • Prevention costs – training – statistical process control – maintenance – quality planning Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. • Appraisal costs – – inspection quality audits testing calibration © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Costs of Controlling Quality • Prevention costs – training – statistical process control – maintenance – quality planning Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. • Appraisal costs – – inspection quality audits testing calibration © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

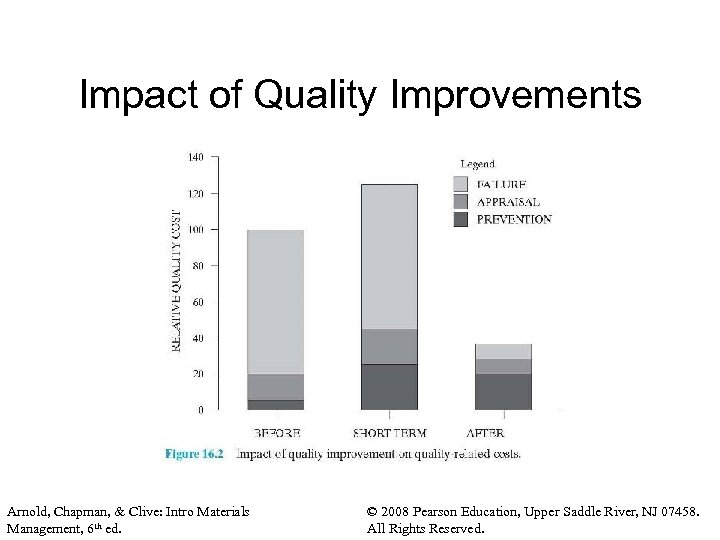

Impact of Quality Improvements Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Impact of Quality Improvements Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

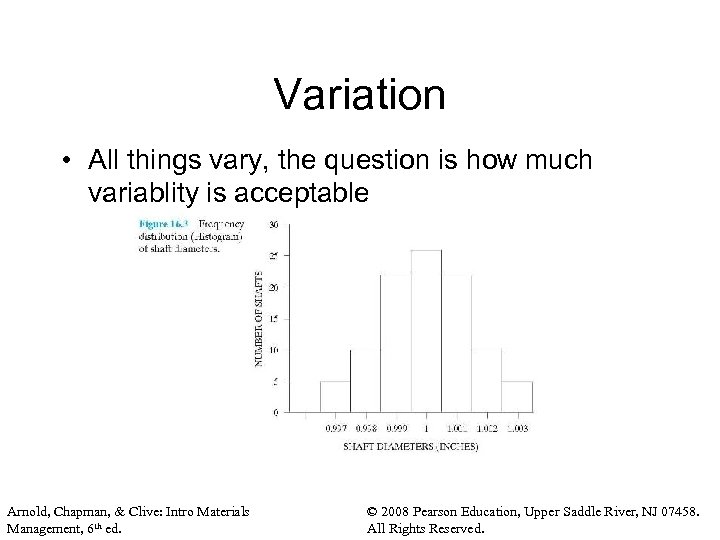

Variation • All things vary, the question is how much variablity is acceptable Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Variation • All things vary, the question is how much variablity is acceptable Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Chance Variation 1. People - poorly trained vs skilled 2. Machine - well maintained? 3. Material - should be consistent 4. Method - often by different operators 5. Environment - temperature, humidity 6. Measurement - poor adjustments Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Chance Variation 1. People - poorly trained vs skilled 2. Machine - well maintained? 3. Material - should be consistent 4. Method - often by different operators 5. Environment - temperature, humidity 6. Measurement - poor adjustments Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Chance Variation There is no way to alter chance variation except to change the process. If the process produces too many defects, then it must be changed. Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Chance Variation There is no way to alter chance variation except to change the process. If the process produces too many defects, then it must be changed. Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Assignable Variation • Where variation can be related to a given action – tool wear, movement – operator error – changes in the process Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Assignable Variation • Where variation can be related to a given action – tool wear, movement – operator error – changes in the process Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Statistical Process Control (SPC) • Attempts to find the assignable causes (so they can be eliminated) • Helps select processes that are capable of producing quality products • Monitors process to be sure it remains capable of producing quality products Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Statistical Process Control (SPC) • Attempts to find the assignable causes (so they can be eliminated) • Helps select processes that are capable of producing quality products • Monitors process to be sure it remains capable of producing quality products Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

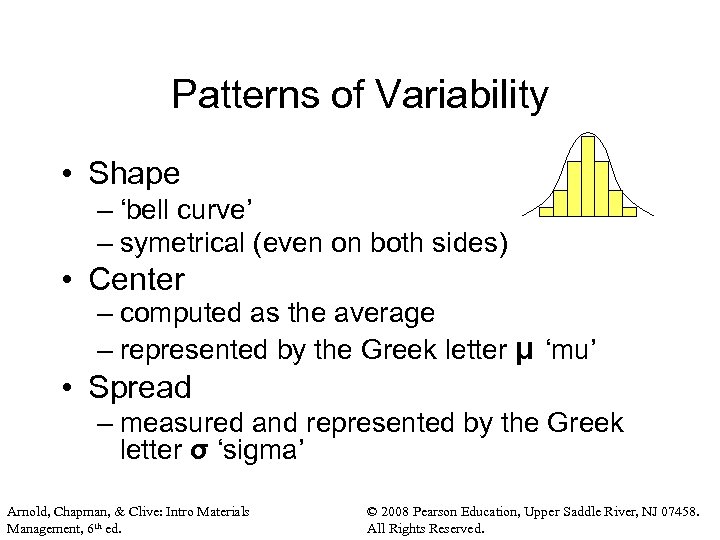

Patterns of Variability • A histogram of a number of readings gives a predictable pattern • Normal curve exists in all natural processes • If a process is studied and detects an odd shape, something is causing the change (assignable cause) Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Patterns of Variability • A histogram of a number of readings gives a predictable pattern • Normal curve exists in all natural processes • If a process is studied and detects an odd shape, something is causing the change (assignable cause) Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Patterns of Variability • Shape – ‘bell curve’ – symetrical (even on both sides) • Center – computed as the average – represented by the Greek letter μ ‘mu’ • Spread – measured and represented by the Greek letter σ ‘sigma’ Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Patterns of Variability • Shape – ‘bell curve’ – symetrical (even on both sides) • Center – computed as the average – represented by the Greek letter μ ‘mu’ • Spread – measured and represented by the Greek letter σ ‘sigma’ Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

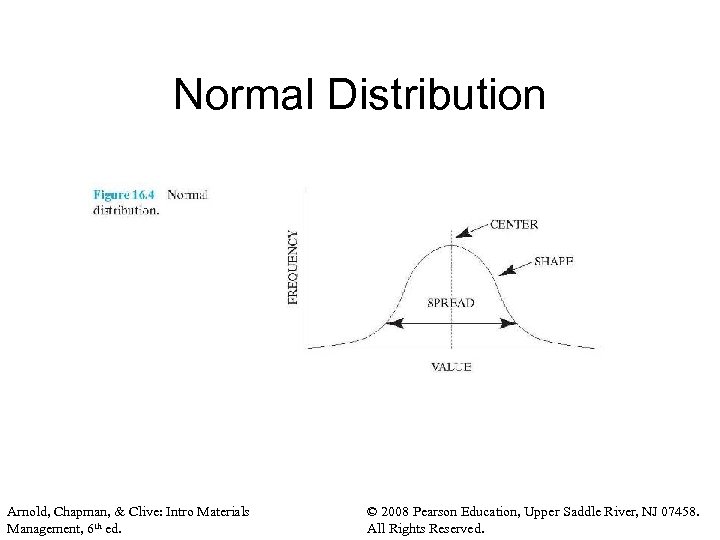

Normal Distribution Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Normal Distribution Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

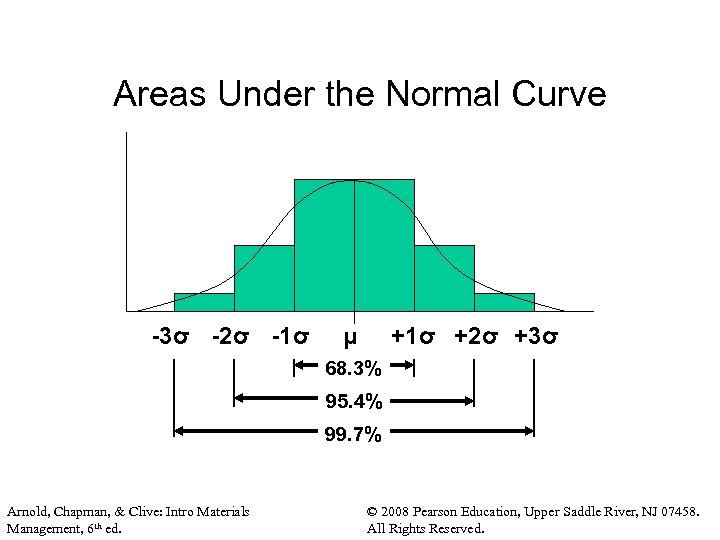

Areas Under the Normal Curve -3σ -2σ -1σ μ +1σ +2σ +3σ 68. 3% 95. 4% 99. 7% Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Areas Under the Normal Curve -3σ -2σ -1σ μ +1σ +2σ +3σ 68. 3% 95. 4% 99. 7% Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

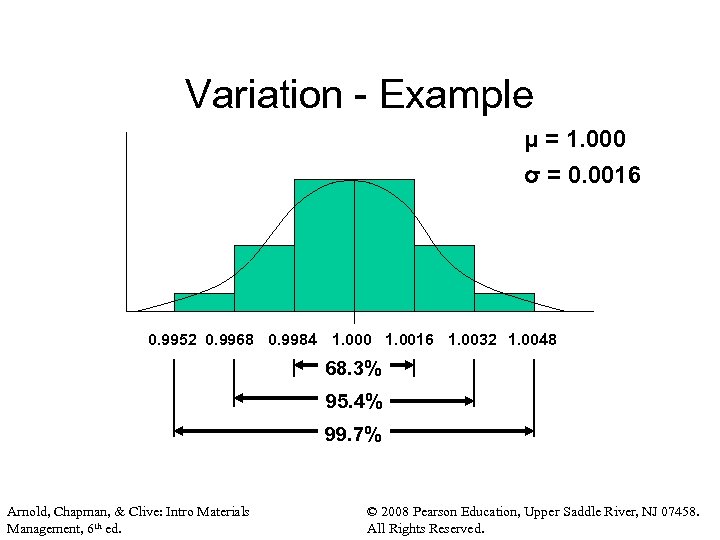

Variation - Example μ = 1. 000 σ = 0. 0016 0. 9952 0. 9968 0. 9984 1. 000 1. 0016 1. 0032 1. 0048 68. 3% 95. 4% 99. 7% Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Variation - Example μ = 1. 000 σ = 0. 0016 0. 9952 0. 9968 0. 9984 1. 000 1. 0016 1. 0032 1. 0048 68. 3% 95. 4% 99. 7% Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Tolerance “Allowable departure from a nominal value established by design engineers that is deemed acceptable for the functioning of the good or service over its life cycle. ” • APICS 11 th Edition Dictionary • Nominal value – desired value Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Tolerance “Allowable departure from a nominal value established by design engineers that is deemed acceptable for the functioning of the good or service over its life cycle. ” • APICS 11 th Edition Dictionary • Nominal value – desired value Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability “Refers to the ability of the process to produce parts that conform to (engineering) specifications. Process capability relates to the inherent variability of a process …”) • APICS 11 th Edition Dictionary Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability “Refers to the ability of the process to produce parts that conform to (engineering) specifications. Process capability relates to the inherent variability of a process …”) • APICS 11 th Edition Dictionary Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

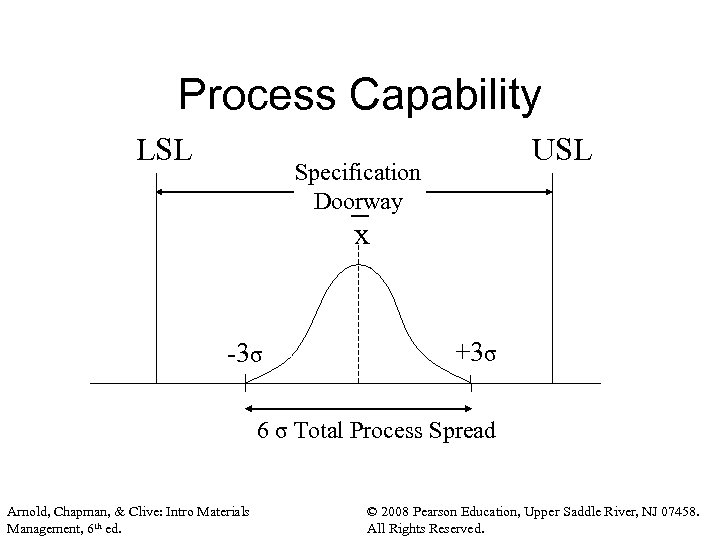

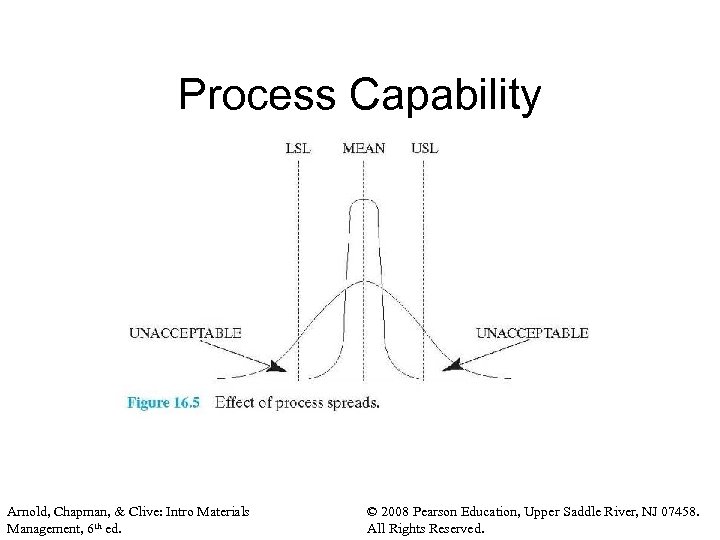

Process Capability • Compares the 6 sigma spread of a process with the specification limits – LSL - lower specification limit – USL - upper specification limit – specification doorway = USL - LSL • The 6 sigma spread of the process should be smaller than the specification doorway Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability • Compares the 6 sigma spread of a process with the specification limits – LSL - lower specification limit – USL - upper specification limit – specification doorway = USL - LSL • The 6 sigma spread of the process should be smaller than the specification doorway Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability LSL USL Specification Doorway x -3σ +3σ 6 σ Total Process Spread Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability LSL USL Specification Doorway x -3σ +3σ 6 σ Total Process Spread Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Capable? Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Capable? Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

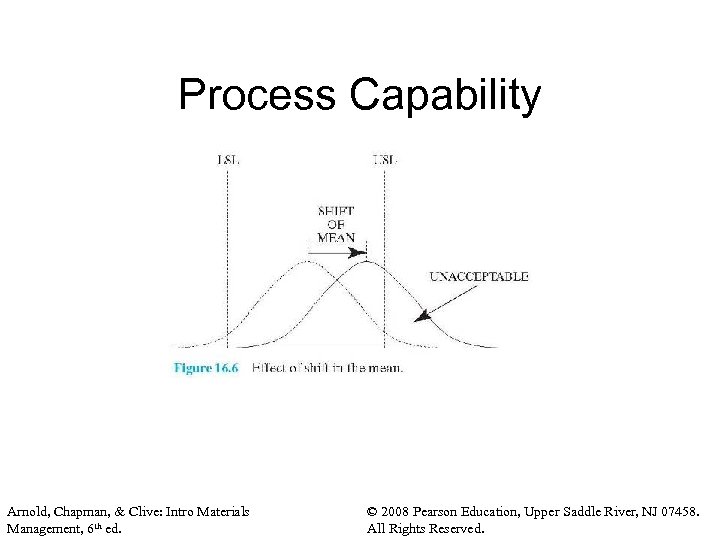

Process Capability • The process spread is not related to the product specification tolerance • A process must be selected that can meet the specifications – or defects will be produced • Processes can produce defects in one of two ways, by having too big a spread (σ) or by a shift in the average (μ) Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability • The process spread is not related to the product specification tolerance • A process must be selected that can meet the specifications – or defects will be produced • Processes can produce defects in one of two ways, by having too big a spread (σ) or by a shift in the average (μ) Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

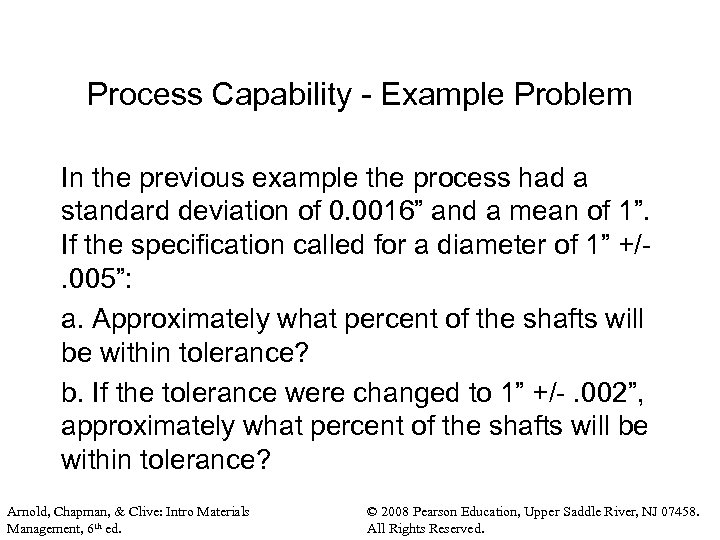

Process Capability - Example Problem In the previous example the process had a standard deviation of 0. 0016” and a mean of 1”. If the specification called for a diameter of 1” +/. 005”: a. Approximately what percent of the shafts will be within tolerance? b. If the tolerance were changed to 1” +/-. 002”, approximately what percent of the shafts will be within tolerance? Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability - Example Problem In the previous example the process had a standard deviation of 0. 0016” and a mean of 1”. If the specification called for a diameter of 1” +/. 005”: a. Approximately what percent of the shafts will be within tolerance? b. If the tolerance were changed to 1” +/-. 002”, approximately what percent of the shafts will be within tolerance? Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

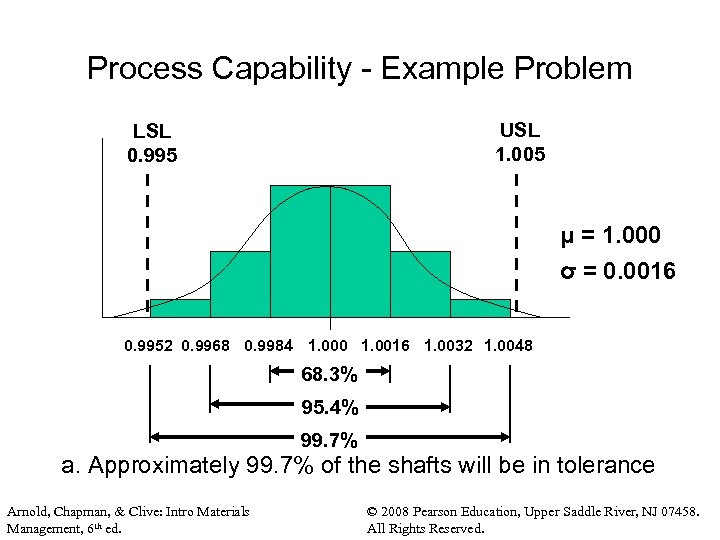

Process Capability - Example Problem USL 1. 005 LSL 0. 995 μ = 1. 000 σ = 0. 0016 0. 9952 0. 9968 0. 9984 1. 000 1. 0016 1. 0032 1. 0048 68. 3% 95. 4% 99. 7% a. Approximately 99. 7% of the shafts will be in tolerance Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability - Example Problem USL 1. 005 LSL 0. 995 μ = 1. 000 σ = 0. 0016 0. 9952 0. 9968 0. 9984 1. 000 1. 0016 1. 0032 1. 0048 68. 3% 95. 4% 99. 7% a. Approximately 99. 7% of the shafts will be in tolerance Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

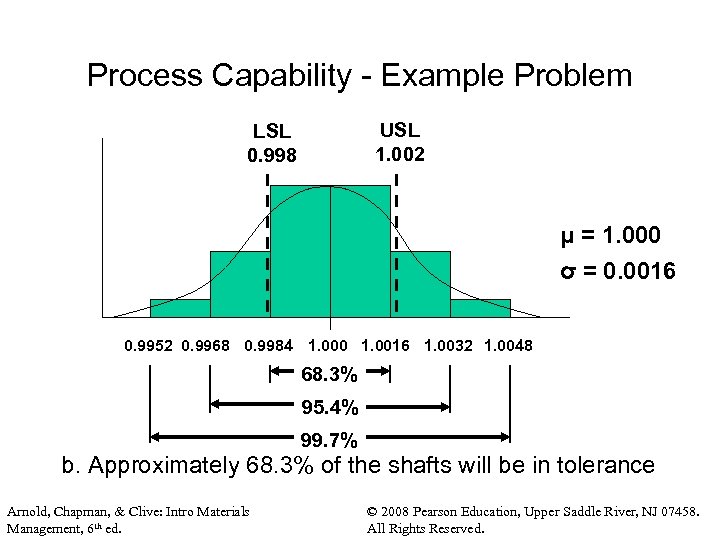

Process Capability - Example Problem USL 1. 002 LSL 0. 998 μ = 1. 000 σ = 0. 0016 0. 9952 0. 9968 0. 9984 1. 000 1. 0016 1. 0032 1. 0048 68. 3% 95. 4% 99. 7% b. Approximately 68. 3% of the shafts will be in tolerance Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability - Example Problem USL 1. 002 LSL 0. 998 μ = 1. 000 σ = 0. 0016 0. 9952 0. 9968 0. 9984 1. 000 1. 0016 1. 0032 1. 0048 68. 3% 95. 4% 99. 7% b. Approximately 68. 3% of the shafts will be in tolerance Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

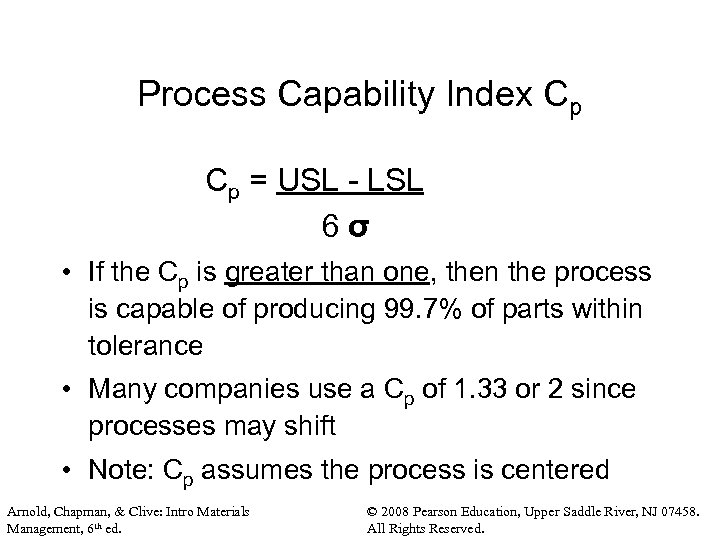

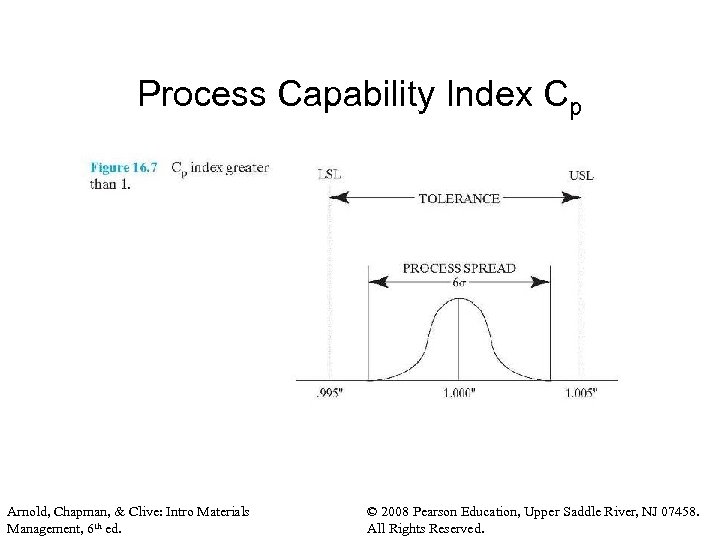

Process Capability Index Cp Cp = USL - LSL 6σ • If the Cp is greater than one, then the process is capable of producing 99. 7% of parts within tolerance • Many companies use a Cp of 1. 33 or 2 since processes may shift • Note: Cp assumes the process is centered Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability Index Cp Cp = USL - LSL 6σ • If the Cp is greater than one, then the process is capable of producing 99. 7% of parts within tolerance • Many companies use a Cp of 1. 33 or 2 since processes may shift • Note: Cp assumes the process is centered Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability Index Cp Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability Index Cp Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

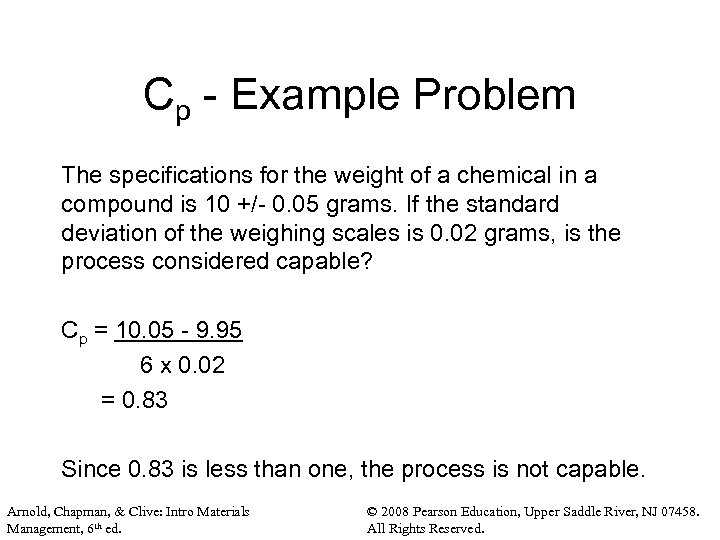

Cp - Example Problem The specifications for the weight of a chemical in a compound is 10 +/- 0. 05 grams. If the standard deviation of the weighing scales is 0. 02 grams, is the process considered capable? Cp = 10. 05 - 9. 95 6 x 0. 02 = 0. 83 Since 0. 83 is less than one, the process is not capable. Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Cp - Example Problem The specifications for the weight of a chemical in a compound is 10 +/- 0. 05 grams. If the standard deviation of the weighing scales is 0. 02 grams, is the process considered capable? Cp = 10. 05 - 9. 95 6 x 0. 02 = 0. 83 Since 0. 83 is less than one, the process is not capable. Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

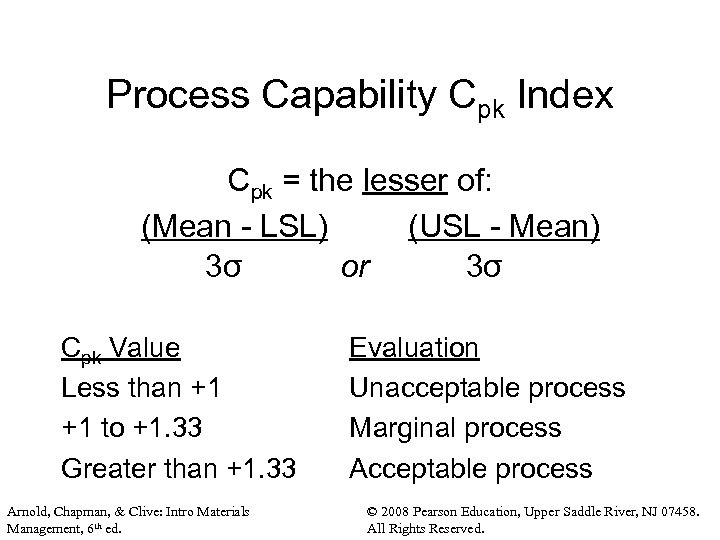

Process Capability Cpk Index Cpk = the lesser of: (Mean - LSL) (USL - Mean) 3σ or 3σ Cpk Value Less than +1 +1 to +1. 33 Greater than +1. 33 Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. Evaluation Unacceptable process Marginal process Acceptable process © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Capability Cpk Index Cpk = the lesser of: (Mean - LSL) (USL - Mean) 3σ or 3σ Cpk Value Less than +1 +1 to +1. 33 Greater than +1. 33 Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. Evaluation Unacceptable process Marginal process Acceptable process © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

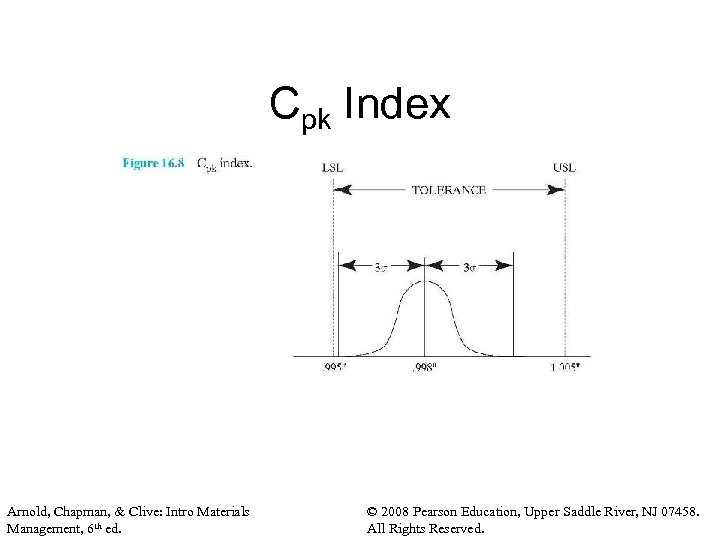

Cpk Index Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Cpk Index Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

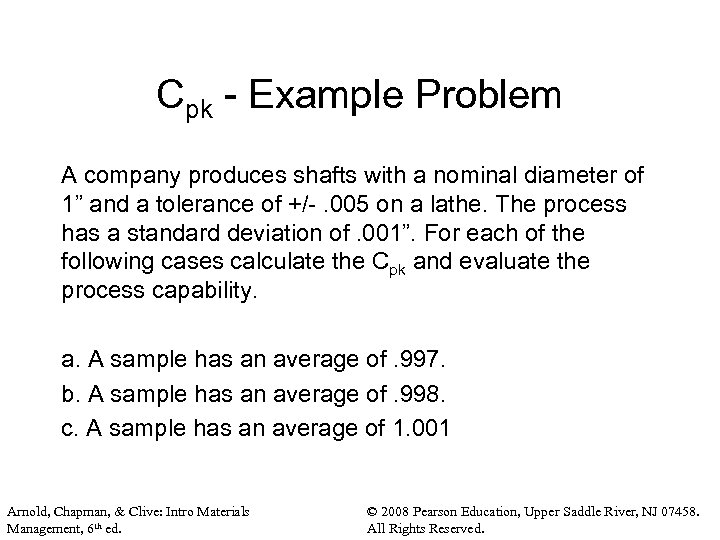

Cpk - Example Problem A company produces shafts with a nominal diameter of 1” and a tolerance of +/-. 005 on a lathe. The process has a standard deviation of. 001”. For each of the following cases calculate the Cpk and evaluate the process capability. a. A sample has an average of. 997. b. A sample has an average of. 998. c. A sample has an average of 1. 001 Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Cpk - Example Problem A company produces shafts with a nominal diameter of 1” and a tolerance of +/-. 005 on a lathe. The process has a standard deviation of. 001”. For each of the following cases calculate the Cpk and evaluate the process capability. a. A sample has an average of. 997. b. A sample has an average of. 998. c. A sample has an average of 1. 001 Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

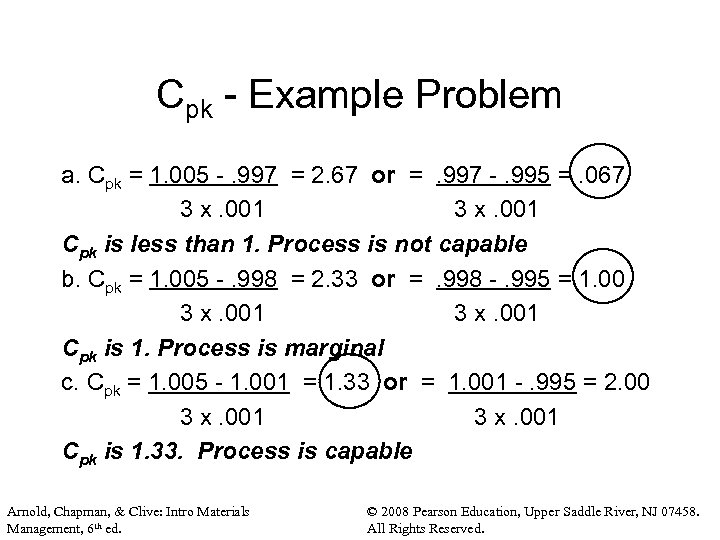

Cpk - Example Problem a. Cpk = 1. 005 -. 997 = 2. 67 or =. 997 -. 995 =. 067 3 x. 001 Cpk is less than 1. Process is not capable b. Cpk = 1. 005 -. 998 = 2. 33 or =. 998 -. 995 = 1. 00 3 x. 001 Cpk is 1. Process is marginal c. Cpk = 1. 005 - 1. 001 = 1. 33 or = 1. 001 -. 995 = 2. 00 3 x. 001 Cpk is 1. 33. Process is capable Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Cpk - Example Problem a. Cpk = 1. 005 -. 997 = 2. 67 or =. 997 -. 995 =. 067 3 x. 001 Cpk is less than 1. Process is not capable b. Cpk = 1. 005 -. 998 = 2. 33 or =. 998 -. 995 = 1. 00 3 x. 001 Cpk is 1. Process is marginal c. Cpk = 1. 005 - 1. 001 = 1. 33 or = 1. 001 -. 995 = 2. 00 3 x. 001 Cpk is 1. 33. Process is capable Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Control • Attempts to prevent defects by showing when there is assignable cause • The process should exhibit only normal variation when there is no assignable cause • This variation is monitored on a control chart Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Control • Attempts to prevent defects by showing when there is assignable cause • The process should exhibit only normal variation when there is no assignable cause • This variation is monitored on a control chart Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

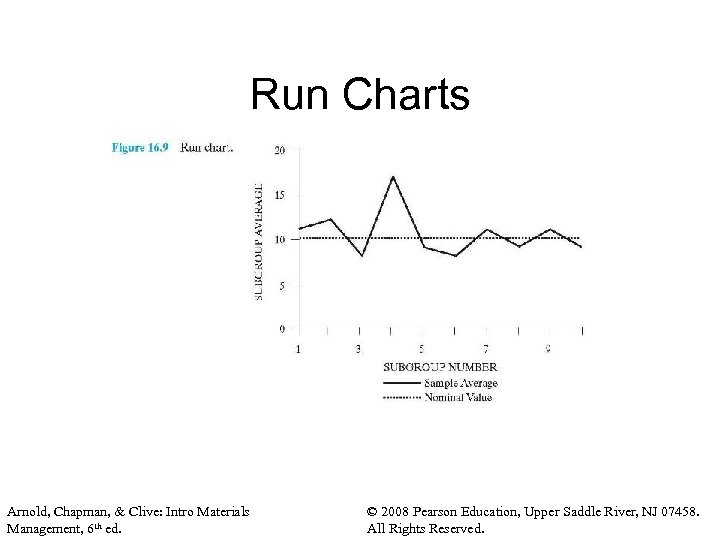

Control Charts Run chart: A graphical technique that illustrates how a process is performing over time. X-bar (averages) chart: A control chart in which the subgroup average, X-bar, is used to evaluate the stability of the process level. R chart: A control chart in which the subgroup range, R, is used to evaluate the stability or variability within a process. • APICS 11 th Edition Dictionary Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Control Charts Run chart: A graphical technique that illustrates how a process is performing over time. X-bar (averages) chart: A control chart in which the subgroup average, X-bar, is used to evaluate the stability of the process level. R chart: A control chart in which the subgroup range, R, is used to evaluate the stability or variability within a process. • APICS 11 th Edition Dictionary Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Run Charts Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Run Charts Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

X (X-bar) and R Charts • Small samples (3 - 9 pieces) are taken on a regular basis to find the average (X) and range (R) of the sample • These values are then plotted on a chart – X-bar chart – R chart Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

X (X-bar) and R Charts • Small samples (3 - 9 pieces) are taken on a regular basis to find the average (X) and range (R) of the sample • These values are then plotted on a chart – X-bar chart – R chart Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Control Limits • Lines on a control chart showing the normal (99. 7%) of expected variation of a process • Readings (X-bar or R) outside of these limits indicates assignable cause of variation Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Control Limits • Lines on a control chart showing the normal (99. 7%) of expected variation of a process • Readings (X-bar or R) outside of these limits indicates assignable cause of variation Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

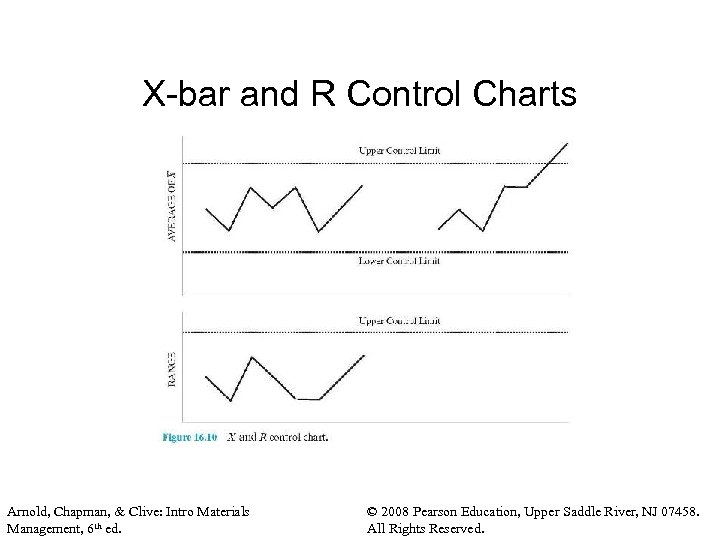

X-bar and R Control Charts Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

X-bar and R Control Charts Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Interpretting Control Charts • A shift in the average (X-bar) – something has moved – change in method or material – worn tools • A change in the range (R) – loose tools – change in method or material Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Interpretting Control Charts • A shift in the average (X-bar) – something has moved – change in method or material – worn tools • A change in the range (R) – loose tools – change in method or material Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Action on Out of Control Points • Out-of-control points indicate that something unusual has occurred • Current conditions should be recorded • The operator is probably the most aware of what has ‘changed’ • The sooner an investigation is conducted the better Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Action on Out of Control Points • Out-of-control points indicate that something unusual has occurred • Current conditions should be recorded • The operator is probably the most aware of what has ‘changed’ • The sooner an investigation is conducted the better Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Attributes • Items that do not conform to specification (difficult to measure) – scratches, dents – light bulbs – go-no-go inspection – sterility – dissatsified customers – missing items Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Attributes • Items that do not conform to specification (difficult to measure) – scratches, dents – light bulbs – go-no-go inspection – sterility – dissatsified customers – missing items Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Attribute Charts • “p-chart” • Frequency of defects are charted • Investigation is made of unusual changes in number of defects • After-the-fact and do not prevent defects Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Attribute Charts • “p-chart” • Frequency of defects are charted • Investigation is made of unusual changes in number of defects • After-the-fact and do not prevent defects Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Other Quality Tools 1. Pareto charts 2. Checksheets 3. Process flow charts 4. Scatterplots 5. Cause and effect (fishbone) diagrams Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Other Quality Tools 1. Pareto charts 2. Checksheets 3. Process flow charts 4. Scatterplots 5. Cause and effect (fishbone) diagrams Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Pareto Charts • Histograms arranged in decending order – typically: problems or defects (scrap, customer complaints) • Identifies most significant area to start investigation Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Pareto Charts • Histograms arranged in decending order – typically: problems or defects (scrap, customer complaints) • Identifies most significant area to start investigation Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Checksheets • Lists source of quality problems – customer complaints – missing parts, defects • Occurances are simpy checked on the sheet • Totals should show where the most problems occur Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Checksheets • Lists source of quality problems – customer complaints – missing parts, defects • Occurances are simpy checked on the sheet • Totals should show where the most problems occur Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Flow Charts • Show in detail the steps required to produce the product or service • Can show where problems occur – delays – wasted activity – excess travelling Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Process Flow Charts • Show in detail the steps required to produce the product or service • Can show where problems occur – delays – wasted activity – excess travelling Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Scatterplots • Shows the relationship between two variables • temperature and strength • length of stay and satisfaction • price and number sold • study hours and grade Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Scatterplots • Shows the relationship between two variables • temperature and strength • length of stay and satisfaction • price and number sold • study hours and grade Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

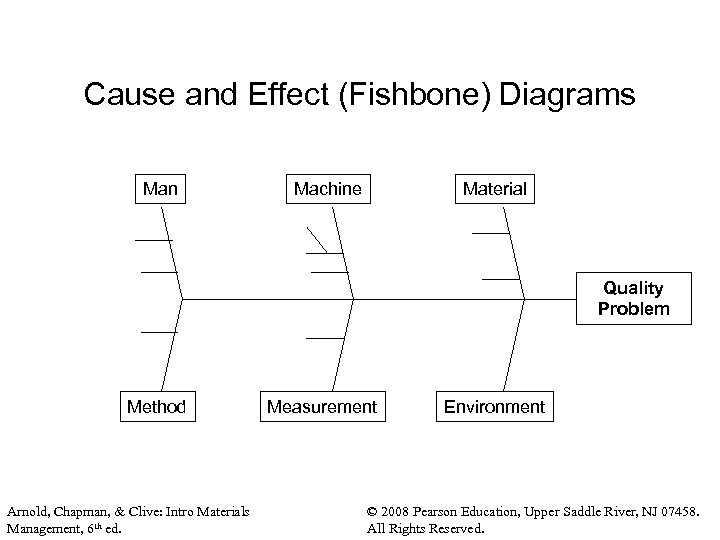

Cause and Effect (Fishbone) Diagrams • Plots potential • Sorts by category causes of a quality – People problem – Machine – Method • Encourages input – Material from group members – Measurement – Environment Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Cause and Effect (Fishbone) Diagrams • Plots potential • Sorts by category causes of a quality – People problem – Machine – Method • Encourages input – Material from group members – Measurement – Environment Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Cause and Effect (Fishbone) Diagrams Man Machine Material Quality Problem Method Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. Measurement Environment © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Cause and Effect (Fishbone) Diagrams Man Machine Material Quality Problem Method Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. Measurement Environment © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Sampling Inspection • 100% inspection – inspect every part – when the consequence of failure is critical – when its easy to do – medical, aeronautics – tends to be expensive • Acceptance sampling – take a sample of parts – accept or reject the entire batch Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Sampling Inspection • 100% inspection – inspect every part – when the consequence of failure is critical – when its easy to do – medical, aeronautics – tends to be expensive • Acceptance sampling – take a sample of parts – accept or reject the entire batch Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

When to Use Acceptance Sampling • Testing is destructive – ultimate pull strength of chain, sterility, firecrackers • Not enough time to sample – election polls • It is too expensive to test the whole batch – machine output, market surveys • Human error will be in the sampling – as high as 3% – judgement is involved Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

When to Use Acceptance Sampling • Testing is destructive – ultimate pull strength of chain, sterility, firecrackers • Not enough time to sample – election polls • It is too expensive to test the whole batch – machine output, market surveys • Human error will be in the sampling – as high as 3% – judgement is involved Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Conditions Necessary for Sampling • All items are processed under the same conditions – same machine, same load of corn • Samples must be random – inspectors are not allowed to choose • The lot should be homogeneous – start, middle and end of the batch • Batches are large – need enough samples to be significant Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Conditions Necessary for Sampling • All items are processed under the same conditions – same machine, same load of corn • Samples must be random – inspectors are not allowed to choose • The lot should be homogeneous – start, middle and end of the batch • Batches are large – need enough samples to be significant Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Sampling Plans • Establish a level of acceptance – “if more than 2% defects are found, reject” • AQL - Acceptable Quality Level • Requires a pre-determined number of samples • Procedures are set down to keep sampling methods consistant Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Sampling Plans • Establish a level of acceptance – “if more than 2% defects are found, reject” • AQL - Acceptable Quality Level • Requires a pre-determined number of samples • Procedures are set down to keep sampling methods consistant Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

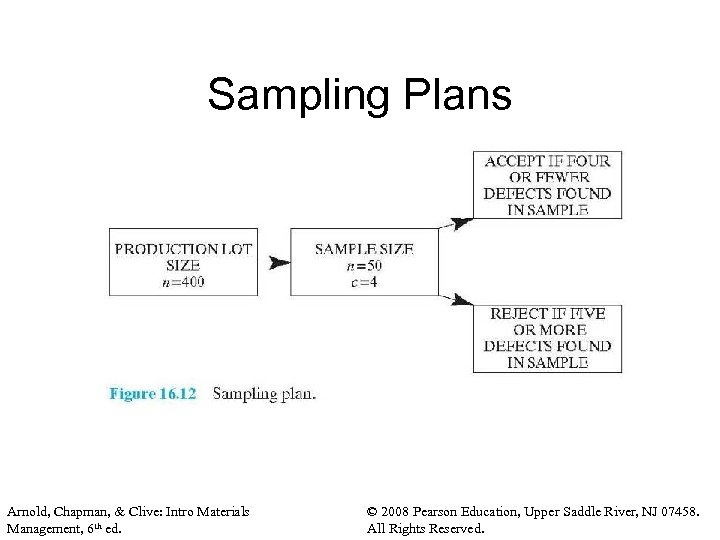

Sampling Plans Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Sampling Plans Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Sampling Plans • Consumer’s risk – the probability of accepting a batch which is actually worse than the value found in the sample • Producer’s risk – the probability of a rejecting a batch that is actually better than the sample indicates • Larger samples help to reduce these risks Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Sampling Plans • Consumer’s risk – the probability of accepting a batch which is actually worse than the value found in the sample • Producer’s risk – the probability of a rejecting a batch that is actually better than the sample indicates • Larger samples help to reduce these risks Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

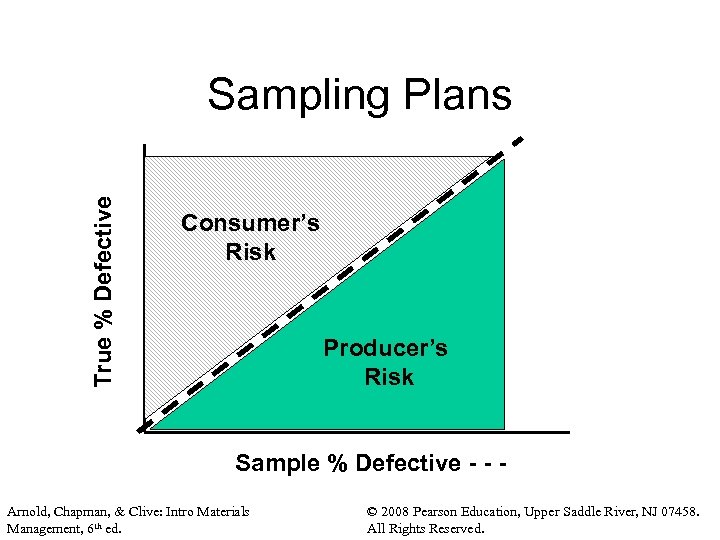

True % Defective Sampling Plans Consumer’s Risk Producer’s Risk Sample % Defective - - - Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

True % Defective Sampling Plans Consumer’s Risk Producer’s Risk Sample % Defective - - - Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Sampling Plans - Cost • Inspection costs money – employees time – destroyed product • Need to balance the cost of sampling between the consumer’s risk and the producer’s risk Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Sampling Plans - Cost • Inspection costs money – employees time – destroyed product • Need to balance the cost of sampling between the consumer’s risk and the producer’s risk Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

ISO Certification • International Organization for Standardization - Geneva Switzerland • “Iso” Greek for equality • Management standards • May be a requirement of doing business • Most recent standard - ISO 9000: 2000 Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

ISO Certification • International Organization for Standardization - Geneva Switzerland • “Iso” Greek for equality • Management standards • May be a requirement of doing business • Most recent standard - ISO 9000: 2000 Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Third Party Registration System • Registrar Accreditation Board • American Society for Quality - ASQ • Registers and regularly audits – quality system is in place – it is being followed – documentation is provided Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Third Party Registration System • Registrar Accreditation Board • American Society for Quality - ASQ • Registers and regularly audits – quality system is in place – it is being followed – documentation is provided Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

ISO 9000: 2000 8 Principles 1. Customer focus 2. Leadership 3. Involvement of people 4. Process approach Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. 5. System approach to management 6. Continuous improvement 7. Factual approach to decision making 8. Mutually beneficial supplier relations © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

ISO 9000: 2000 8 Principles 1. Customer focus 2. Leadership 3. Involvement of people 4. Process approach Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. 5. System approach to management 6. Continuous improvement 7. Factual approach to decision making 8. Mutually beneficial supplier relations © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

ISO 9000: 2000 • Product realization – bringing the product or service into reality • Applies to services as well as manufacturing Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

ISO 9000: 2000 • Product realization – bringing the product or service into reality • Applies to services as well as manufacturing Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

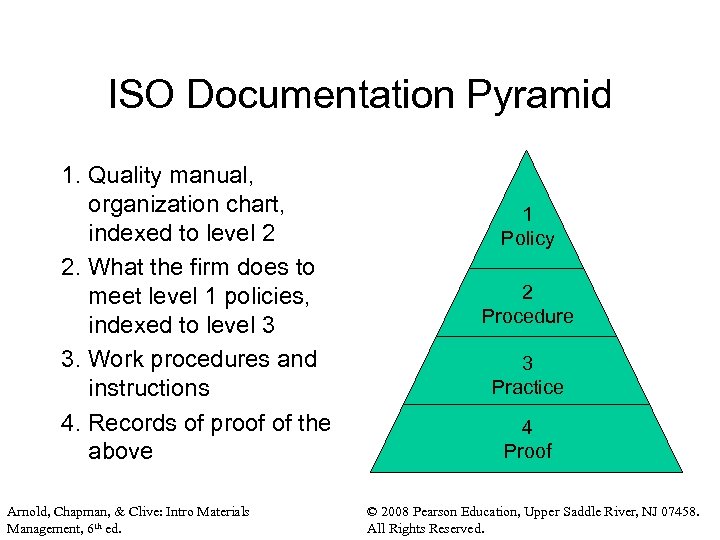

ISO Documentation Pyramid 1. Quality manual, organization chart, indexed to level 2 2. What the firm does to meet level 1 policies, indexed to level 3 3. Work procedures and instructions 4. Records of proof of the above Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. 1 Policy 2 Procedure 3 Practice 4 Proof © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

ISO Documentation Pyramid 1. Quality manual, organization chart, indexed to level 2 2. What the firm does to meet level 1 policies, indexed to level 3 3. Work procedures and instructions 4. Records of proof of the above Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. 1 Policy 2 Procedure 3 Practice 4 Proof © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

ISO Certification • Management standard • Process approach • Audited by third party • Consistency in doing business • Continuous improvement Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

ISO Certification • Management standard • Process approach • Audited by third party • Consistency in doing business • Continuous improvement Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Benchmarking • Compares an organization to the best in class – not necessarily in the same business • Looks outward for ideas on improvement Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Benchmarking • Compares an organization to the best in class – not necessarily in the same business • Looks outward for ideas on improvement Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Benchmarking 1. Select the process 2. Identify an organization that is “best in class” – for that process i. e. accounts receivable 3. Study the benchmarked organization 4. Analyze the data – metrics, a measure of performance • quality, response time, cost per order Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Benchmarking 1. Select the process 2. Identify an organization that is “best in class” – for that process i. e. accounts receivable 3. Study the benchmarked organization 4. Analyze the data – metrics, a measure of performance • quality, response time, cost per order Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma • Focus on improving all business functions • Initiated by upper management • Tasked by middle management • Projects • Project managers Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma • Focus on improving all business functions • Initiated by upper management • Tasked by middle management • Projects • Project managers Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma • Striving for failure rates less than 3. 4 out of one million possibilities • Applied to all business processes • Customer focus Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma • Striving for failure rates less than 3. 4 out of one million possibilities • Applied to all business processes • Customer focus Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma • Scope: Systemic reduction of variability • Quality Definition: Defects per million • Purpose: Reduce variation - increase profits • Measurement: Defects per million • Focus: Locate and eliminate sources of process error Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma • Scope: Systemic reduction of variability • Quality Definition: Defects per million • Purpose: Reduce variation - increase profits • Measurement: Defects per million • Focus: Locate and eliminate sources of process error Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma Projects DMAIC – Design – Measure – Analyze – Improve – Control Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma Projects DMAIC – Design – Measure – Analyze – Improve – Control Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma Project 1. Select the appropriate metrics 2. Determine how metrics will be tracked 3. Determine current baseline 4. Determine input variables 5. Determine changes needed 6. Make the changes 7. Did changes have a positive effect? 8. Establish controls at the new level Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma Project 1. Select the appropriate metrics 2. Determine how metrics will be tracked 3. Determine current baseline 4. Determine input variables 5. Determine changes needed 6. Make the changes 7. Did changes have a positive effect? 8. Establish controls at the new level Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma • Achieved when process capability is equal to or greater than 2 • The process variation consumes less than half the specification doorway Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma • Achieved when process capability is equal to or greater than 2 • The process variation consumes less than half the specification doorway Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Project Managers • Green Belts – specific amount of training – project savings of $10, 000 • Black Belts – more training – project savings of $100, 000 • Master Black Belts – Masters Degree – savings of $1, 000 Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Project Managers • Green Belts – specific amount of training – project savings of $10, 000 • Black Belts – more training – project savings of $100, 000 • Master Black Belts – Masters Degree – savings of $1, 000 Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma • Extension of SPC to business processes • Continuous improvement – reduced waste – decreased costs – improved opportunities • Customer benefits Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Six Sigma • Extension of SPC to business processes • Continuous improvement – reduced waste – decreased costs – improved opportunities • Customer benefits Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality Function Deployment • Decision making method • Voice of the customer • Helps incorporate customer wants and needs into design features Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

Quality Function Deployment • Decision making method • Voice of the customer • Helps incorporate customer wants and needs into design features Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

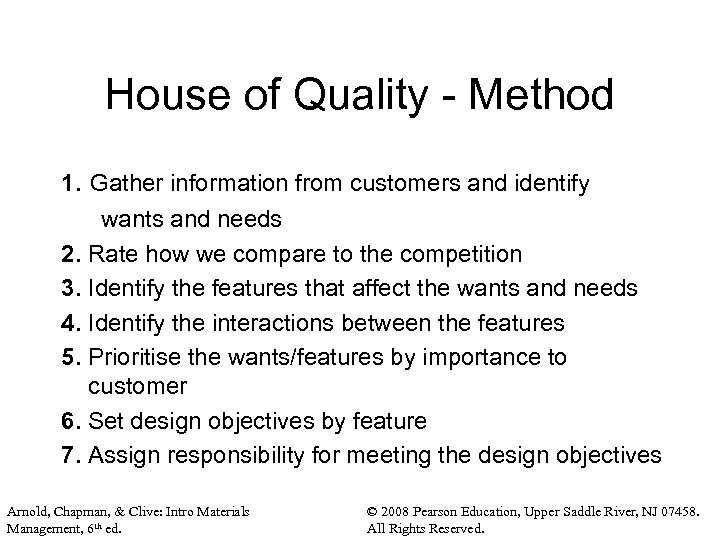

House of Quality - Method 1. Gather information from customers and identify wants and needs 2. Rate how we compare to the competition 3. Identify the features that affect the wants and needs 4. Identify the interactions between the features 5. Prioritise the wants/features by importance to customer 6. Set design objectives by feature 7. Assign responsibility for meeting the design objectives Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

House of Quality - Method 1. Gather information from customers and identify wants and needs 2. Rate how we compare to the competition 3. Identify the features that affect the wants and needs 4. Identify the interactions between the features 5. Prioritise the wants/features by importance to customer 6. Set design objectives by feature 7. Assign responsibility for meeting the design objectives Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

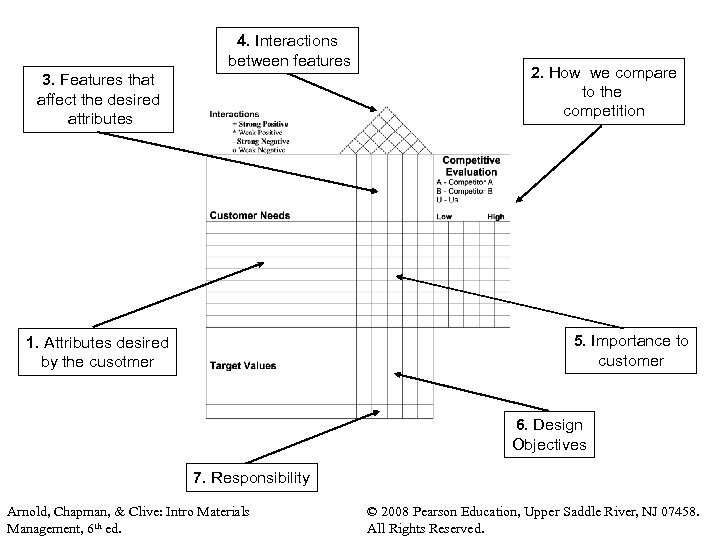

4. Interactions between features 3. Features that affect the desired attributes 2. How we compare to the competition 5. Importance to customer 1. Attributes desired by the cusotmer 6. Design Objectives 7. Responsibility Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

4. Interactions between features 3. Features that affect the desired attributes 2. How we compare to the competition 5. Importance to customer 1. Attributes desired by the cusotmer 6. Design Objectives 7. Responsibility Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

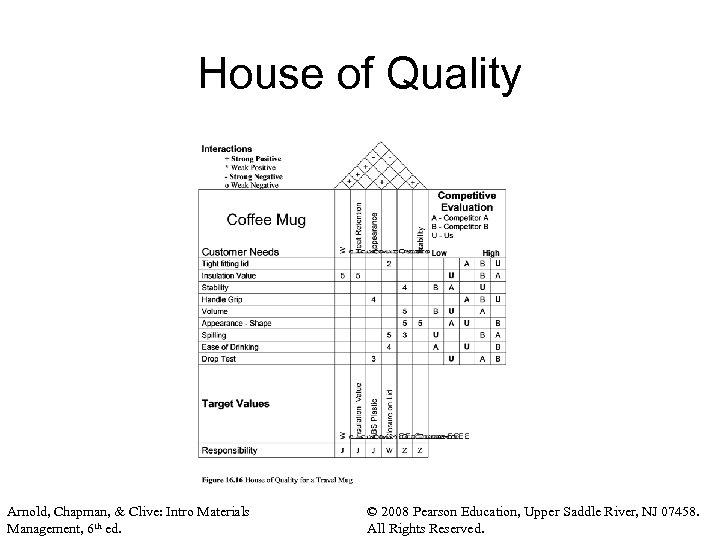

House of Quality Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

House of Quality Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

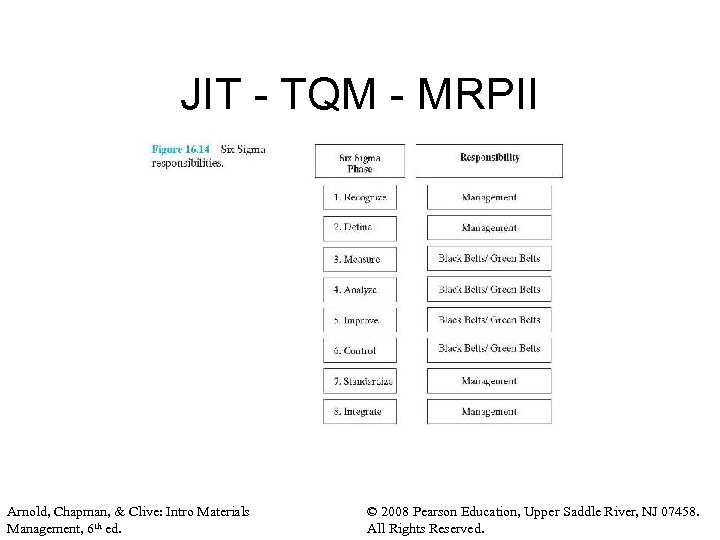

JIT - TQM - MRPII • JIT seeks to eliminate waste – inward looking • TQM emphasis on customer satisfaction – outward looking • MRPII manages resources • All are involved in satisfying the customer Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

JIT - TQM - MRPII • JIT seeks to eliminate waste – inward looking • TQM emphasis on customer satisfaction – outward looking • MRPII manages resources • All are involved in satisfying the customer Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

JIT - TQM - MRPII Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.

JIT - TQM - MRPII Arnold, Chapman, & Clive: Intro Materials Management, 6 th ed. © 2008 Pearson Education, Upper Saddle River, NJ 07458. All Rights Reserved.