15c0014bbce0275b1fed7a161259348d.ppt

- Количество слайдов: 46

Total Quality Management • A Great Concept. . • . . . But What is IT?

Total Quality Management • A Great Concept. . • . . . But What is IT?

Two Perspectives • Producer Definition – Conformance to specifications – Reflects priorities on consistent quality and high-performance design • Consumer Definition – Value and Fitness of Use – Hardware, support and psychological impressions

Two Perspectives • Producer Definition – Conformance to specifications – Reflects priorities on consistent quality and high-performance design • Consumer Definition – Value and Fitness of Use – Hardware, support and psychological impressions

Aspects of Quality * Manufacturing * • • Performance Features Reliability Servicability Durability Conformance Aesthetic Characteristics Perceived Quality

Aspects of Quality * Manufacturing * • • Performance Features Reliability Servicability Durability Conformance Aesthetic Characteristics Perceived Quality

Aspects of Quality * Services * • • • Reliability Responsiveness Tangibles Assurance Empathy

Aspects of Quality * Services * • • • Reliability Responsiveness Tangibles Assurance Empathy

The Quality Gurus • Deming: Management is Responsible • Crosby: Quality is Free • Juran: Quality Trilogy – Planning – Control – Improvement

The Quality Gurus • Deming: Management is Responsible • Crosby: Quality is Free • Juran: Quality Trilogy – Planning – Control – Improvement

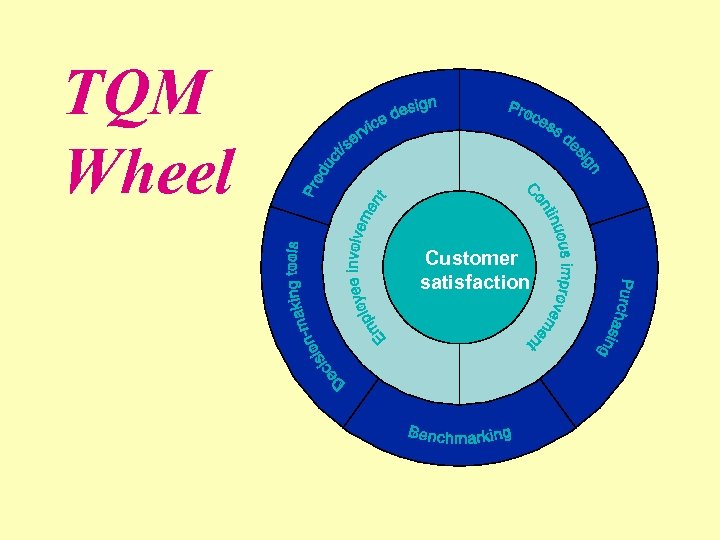

TQM Wheel Customer satisfaction

TQM Wheel Customer satisfaction

Deming Wheel Plan

Deming Wheel Plan

Deming Wheel Plan Do

Deming Wheel Plan Do

Deming Wheel Plan Do Check

Deming Wheel Plan Do Check

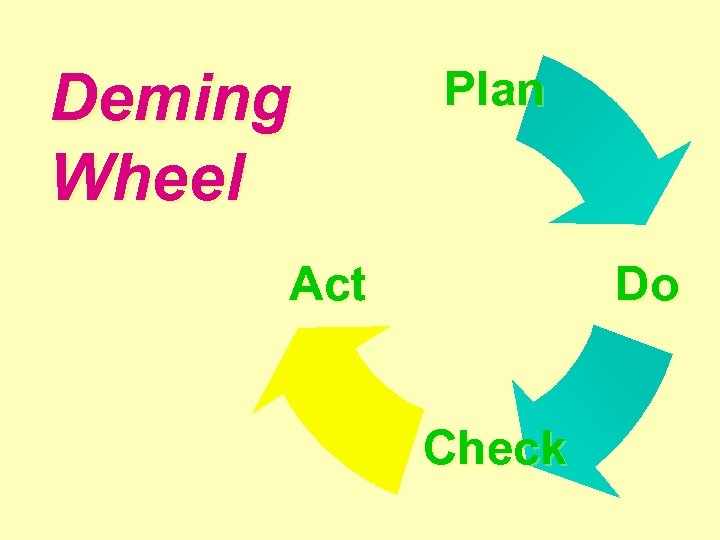

Deming Wheel Plan Act Do Check

Deming Wheel Plan Act Do Check

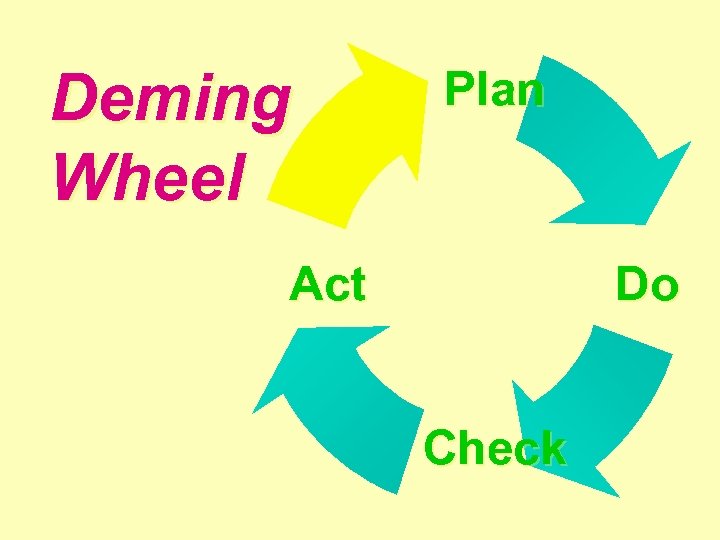

Deming Wheel Plan Act Do Check

Deming Wheel Plan Act Do Check

Deming’s 14 Points • Establish the objective of constant innovation and improvement • Adopt a new philosophy, we cannot accept the old mistakes and defects • Cease dependence on mass inspection, require statistical evidence that quality is built in • End the practice of awarding busines on the basis of price • Use statistical methods to find troublespots • Institute modern methods of training on the job • Improve supervision - do what is right for the company, don’t just turn out the required quantity

Deming’s 14 Points • Establish the objective of constant innovation and improvement • Adopt a new philosophy, we cannot accept the old mistakes and defects • Cease dependence on mass inspection, require statistical evidence that quality is built in • End the practice of awarding busines on the basis of price • Use statistical methods to find troublespots • Institute modern methods of training on the job • Improve supervision - do what is right for the company, don’t just turn out the required quantity

Deming’s 14 Points • • • Drive out FEAR. . Break down BARRIERS. . . Eliminate posters and slogans Eliminate work standards that prescribe a numerical quota Remove barriers between workers and their right to pride in workmanship • Institute a vigorous retraining program • Create top management structure that will push EVERY DAY for these points

Deming’s 14 Points • • • Drive out FEAR. . Break down BARRIERS. . . Eliminate posters and slogans Eliminate work standards that prescribe a numerical quota Remove barriers between workers and their right to pride in workmanship • Institute a vigorous retraining program • Create top management structure that will push EVERY DAY for these points

RIVETHEAD: Tales From The Assembly Line By Ben Hamper • A violation of how many of Deming’s points?

RIVETHEAD: Tales From The Assembly Line By Ben Hamper • A violation of how many of Deming’s points?

ISO 9000 • Standards for companies doing business in the EC • Certification by hearing from qualified external examiner • Certification does NOT mean anything about quality of a product. . • Instead, it means that company can provide documentation supporting their quality claims.

ISO 9000 • Standards for companies doing business in the EC • Certification by hearing from qualified external examiner • Certification does NOT mean anything about quality of a product. . • Instead, it means that company can provide documentation supporting their quality claims.

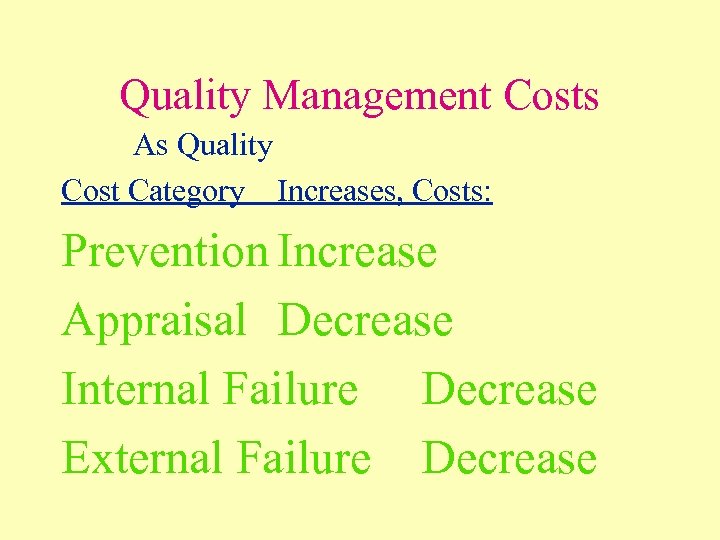

Quality Management Costs As Quality Cost Category Increases, Costs: Prevention Increase Appraisal Decrease Internal Failure Decrease External Failure Decrease

Quality Management Costs As Quality Cost Category Increases, Costs: Prevention Increase Appraisal Decrease Internal Failure Decrease External Failure Decrease

Costs of Detecting a Defect Cost of Detection ($) Process Final Testing Customer

Costs of Detecting a Defect Cost of Detection ($) Process Final Testing Customer

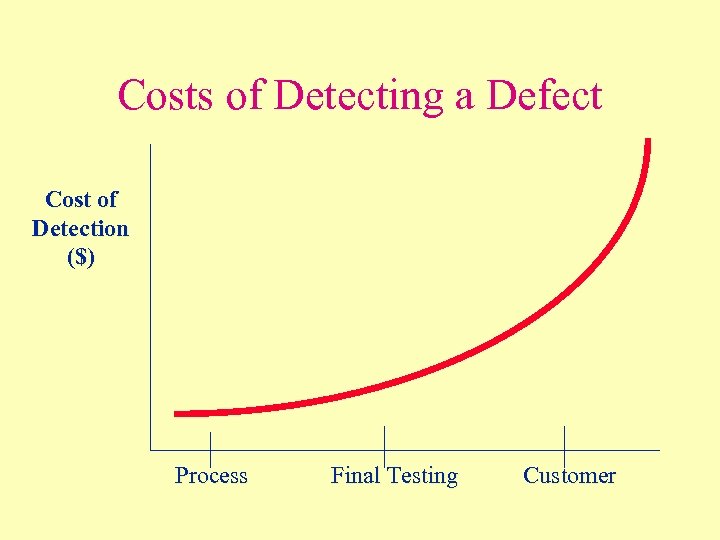

Costs of Detecting a Defect Cost of Detection ($) Process Final Testing Customer

Costs of Detecting a Defect Cost of Detection ($) Process Final Testing Customer

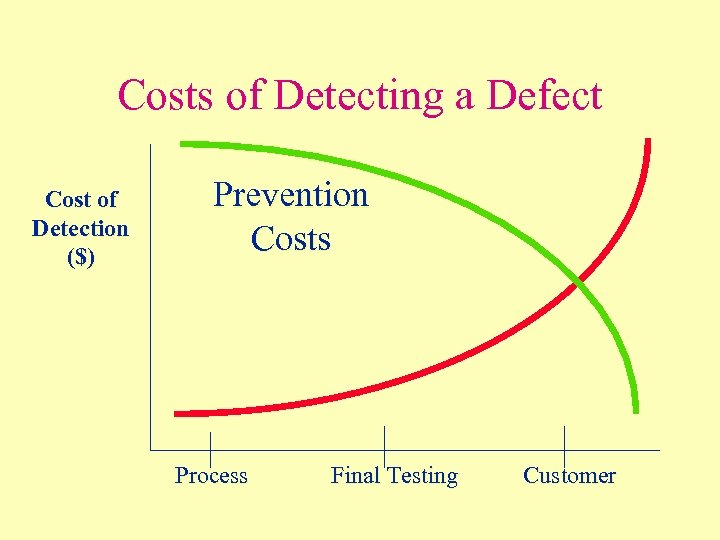

Costs of Detecting a Defect Cost of Detection ($) Prevention Costs Process Final Testing Customer

Costs of Detecting a Defect Cost of Detection ($) Prevention Costs Process Final Testing Customer

Seven Quality Tools • • Checklists Histograms Bar Charts Pareto Charts Scatter Diagrams Cause-and-Effect Diagrams Graphs

Seven Quality Tools • • Checklists Histograms Bar Charts Pareto Charts Scatter Diagrams Cause-and-Effect Diagrams Graphs

Quality Function Deployment The House of Quality

Quality Function Deployment The House of Quality

Voice of the Customer

Voice of the Customer

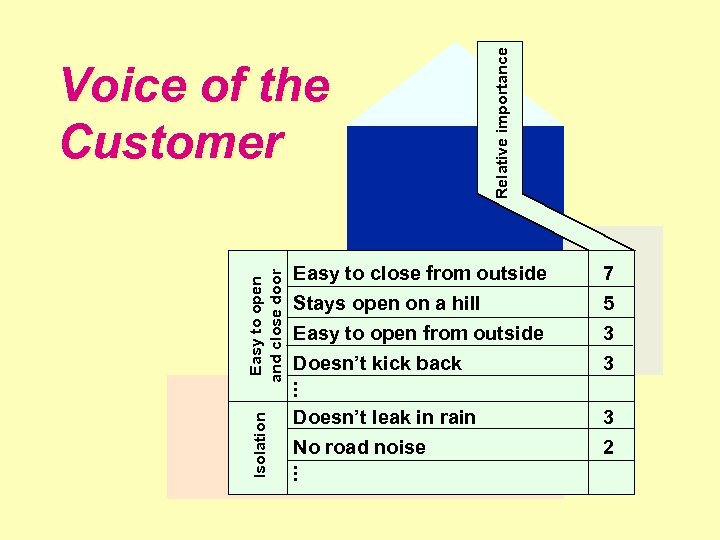

Isolation Easy to open and close door Relative importance Voice of the Customer Easy to close from outside Stays open on a hill 7 5 Easy to open from outside Doesn’t kick back. . . Doesn’t leak in rain No road noise. . . 3 3 3 2

Isolation Easy to open and close door Relative importance Voice of the Customer Easy to close from outside Stays open on a hill 7 5 Easy to open from outside Doesn’t kick back. . . Doesn’t leak in rain No road noise. . . 3 3 3 2

Voice of the Customer

Voice of the Customer

Competitive Analysis

Competitive Analysis

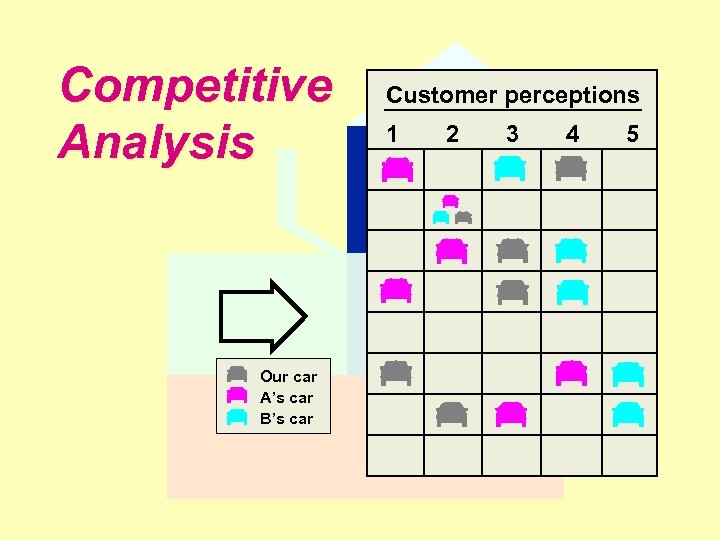

Competitive Analysis Our car A’s car B’s car Customer perceptions 1 2 3 4 5

Competitive Analysis Our car A’s car B’s car Customer perceptions 1 2 3 4 5

Competitive Analysis

Competitive Analysis

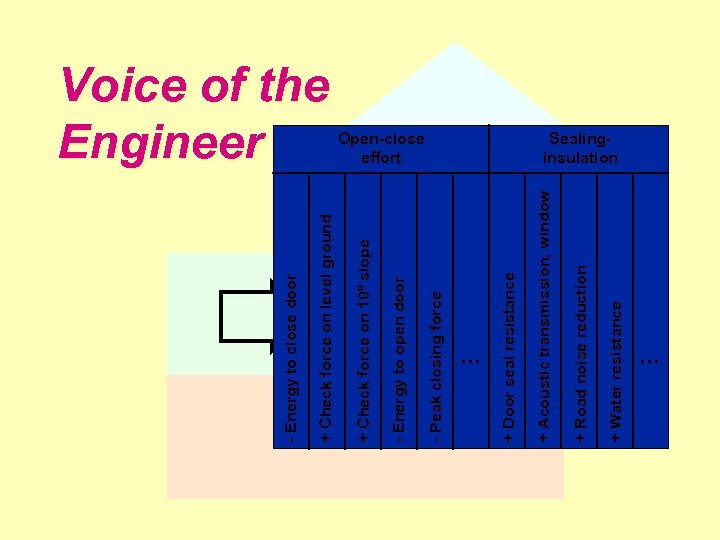

Voice of the Engineer

Voice of the Engineer

- Peak closing force - Energy to open door + Check force on 10º slope + Check force on level ground - Energy to close door . . . + Water resistance + Road noise reduction Open-close effort + Acoustic transmission, window + Door seal resistance Voice of the Engineer Sealinginsulation . . .

- Peak closing force - Energy to open door + Check force on 10º slope + Check force on level ground - Energy to close door . . . + Water resistance + Road noise reduction Open-close effort + Acoustic transmission, window + Door seal resistance Voice of the Engineer Sealinginsulation . . .

Voice of the Engineer

Voice of the Engineer

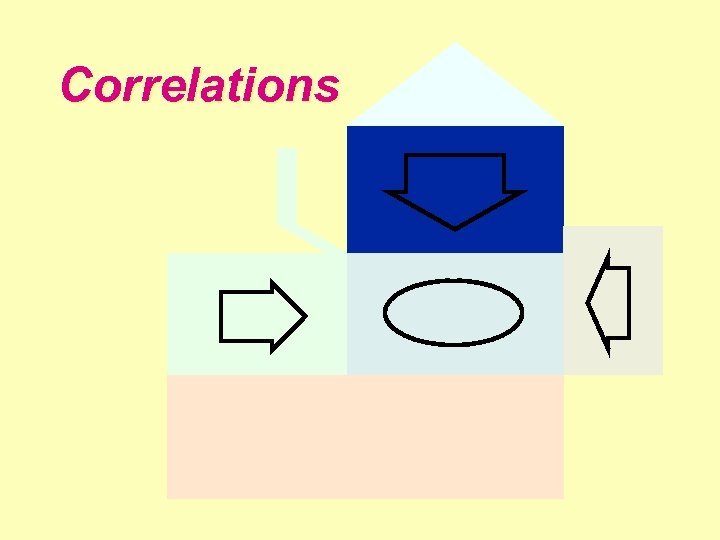

Correlations

Correlations

Correlations X Relationships Strong positive Medium positive X Medium negative X Strong negative X

Correlations X Relationships Strong positive Medium positive X Medium negative X Strong negative X

Correlations

Correlations

Technical Comparison

Technical Comparison

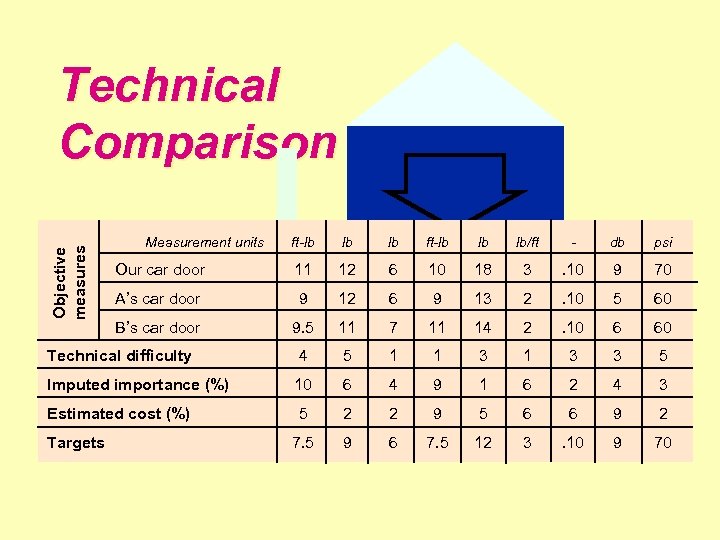

Technical Comparison lb lb ft-lb lb lb/ft - db psi Our car door 11 12 6 10 18 3 . 10 9 70 A’s car door 9 12 6 9 13 2 . 10 5 60 B’s car door 9. 5 11 7 11 14 2 . 10 6 60 Technical difficulty 4 5 1 1 3 3 5 Imputed importance (%) 10 6 4 9 1 6 2 4 3 Estimated cost (%) 5 2 2 9 5 6 6 9 2 7. 5 9 6 7. 5 12 3 . 10 9 70 Objective measures ft-lb Targets Measurement units

Technical Comparison lb lb ft-lb lb lb/ft - db psi Our car door 11 12 6 10 18 3 . 10 9 70 A’s car door 9 12 6 9 13 2 . 10 5 60 B’s car door 9. 5 11 7 11 14 2 . 10 6 60 Technical difficulty 4 5 1 1 3 3 5 Imputed importance (%) 10 6 4 9 1 6 2 4 3 Estimated cost (%) 5 2 2 9 5 6 6 9 2 7. 5 9 6 7. 5 12 3 . 10 9 70 Objective measures ft-lb Targets Measurement units

Technical Comparison

Technical Comparison

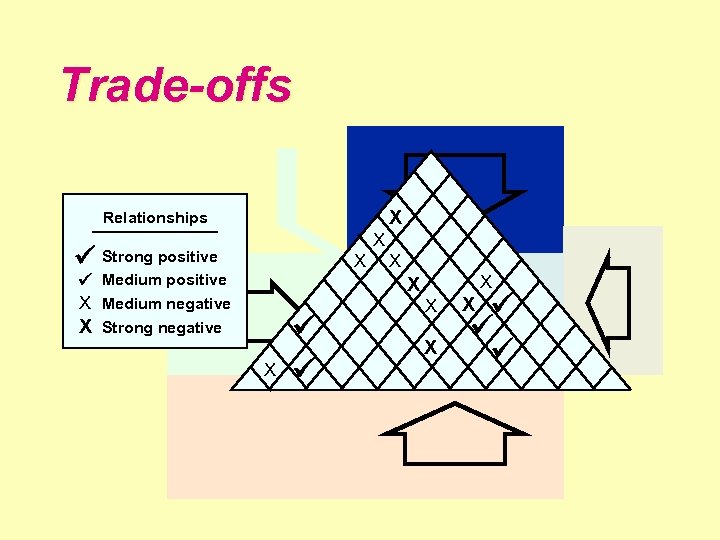

Trade-offs

Trade-offs

Trade-offs X Relationships X Strong positive Medium positive X Medium negative X Strong negative X X X X

Trade-offs X Relationships X Strong positive Medium positive X Medium negative X Strong negative X X X X

Trade-offs

Trade-offs

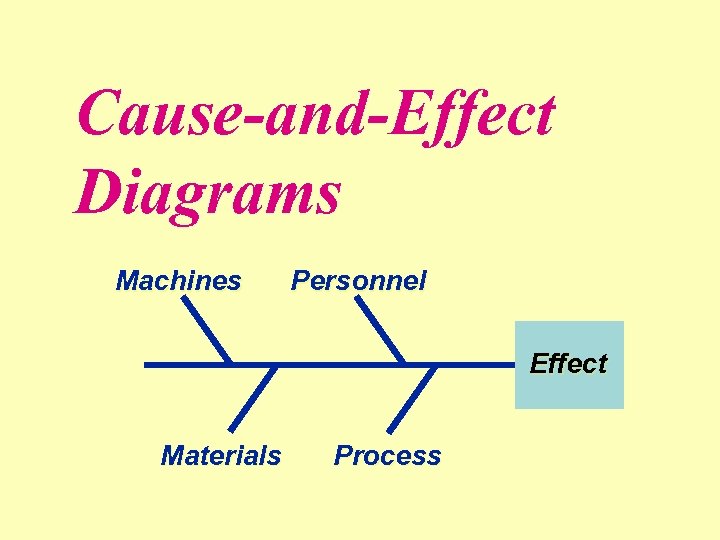

Cause-and-Effect Diagrams Machines Personnel Effect Materials Process

Cause-and-Effect Diagrams Machines Personnel Effect Materials Process

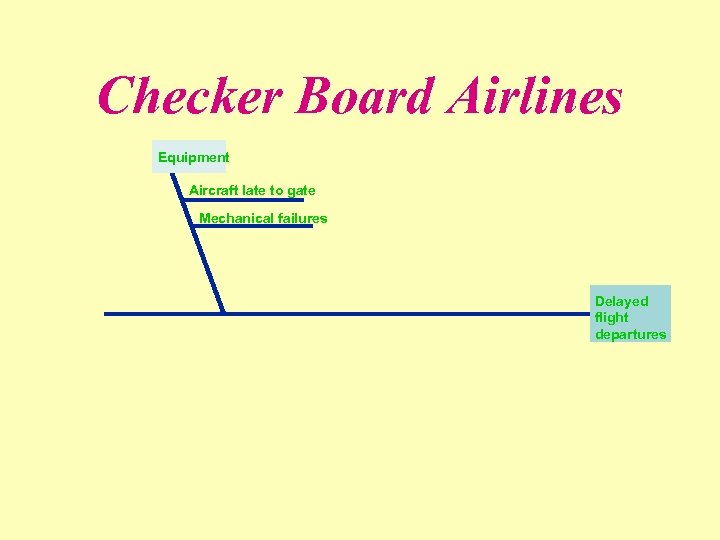

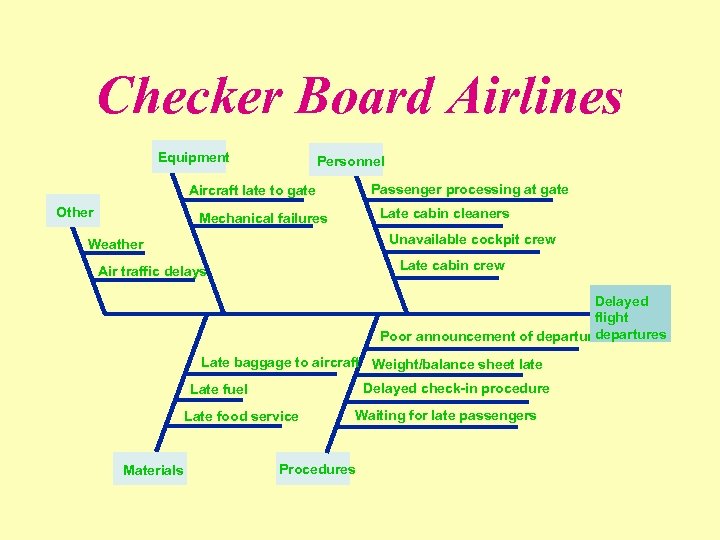

Checker Board Airlines Delayed flight departures

Checker Board Airlines Delayed flight departures

Checker Board Airlines Equipment Aircraft late to gate Mechanical failures Delayed flight departures

Checker Board Airlines Equipment Aircraft late to gate Mechanical failures Delayed flight departures

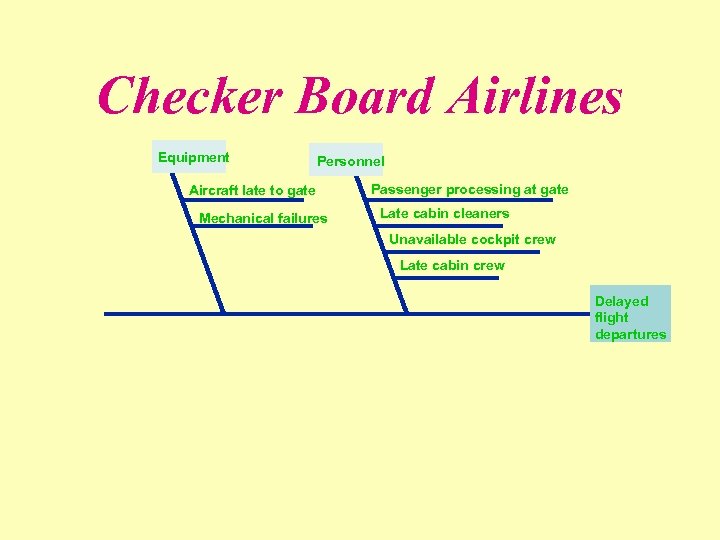

Checker Board Airlines Equipment Personnel Aircraft late to gate Mechanical failures Passenger processing at gate Late cabin cleaners Unavailable cockpit crew Late cabin crew Delayed flight departures

Checker Board Airlines Equipment Personnel Aircraft late to gate Mechanical failures Passenger processing at gate Late cabin cleaners Unavailable cockpit crew Late cabin crew Delayed flight departures

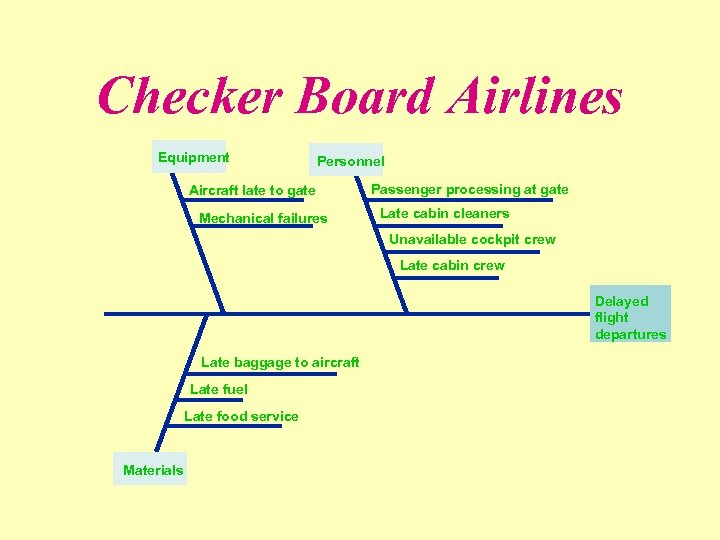

Checker Board Airlines Equipment Personnel Aircraft late to gate Mechanical failures Passenger processing at gate Late cabin cleaners Unavailable cockpit crew Late cabin crew Delayed flight departures Late baggage to aircraft Late fuel Late food service Materials

Checker Board Airlines Equipment Personnel Aircraft late to gate Mechanical failures Passenger processing at gate Late cabin cleaners Unavailable cockpit crew Late cabin crew Delayed flight departures Late baggage to aircraft Late fuel Late food service Materials

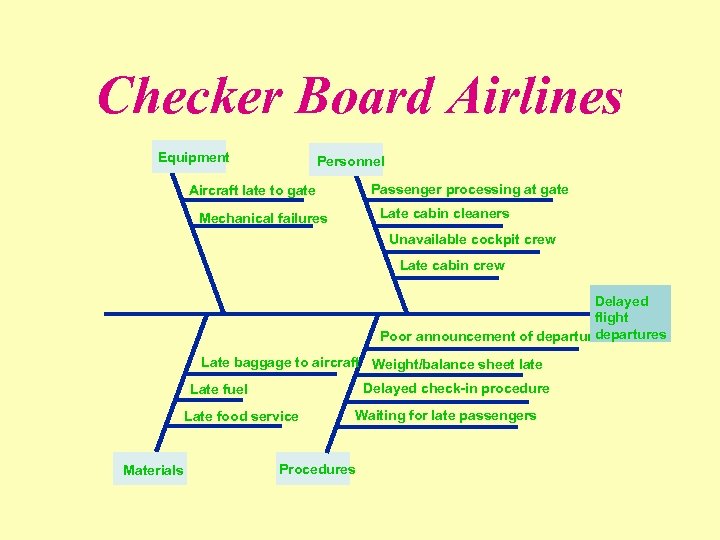

Checker Board Airlines Equipment Personnel Passenger processing at gate Aircraft late to gate Late cabin cleaners Mechanical failures Unavailable cockpit crew Late cabin crew Delayed flight departures Poor announcement of departures Late baggage to aircraft Weight/balance sheet late Delayed check-in procedure Late fuel Late food service Materials Waiting for late passengers Procedures

Checker Board Airlines Equipment Personnel Passenger processing at gate Aircraft late to gate Late cabin cleaners Mechanical failures Unavailable cockpit crew Late cabin crew Delayed flight departures Poor announcement of departures Late baggage to aircraft Weight/balance sheet late Delayed check-in procedure Late fuel Late food service Materials Waiting for late passengers Procedures

Checker Board Airlines Equipment Personnel Passenger processing at gate Aircraft late to gate Other Late cabin cleaners Mechanical failures Unavailable cockpit crew Weather Late cabin crew Air traffic delays Delayed flight departures Poor announcement of departures Late baggage to aircraft Weight/balance sheet late Delayed check-in procedure Late fuel Late food service Materials Waiting for late passengers Procedures

Checker Board Airlines Equipment Personnel Passenger processing at gate Aircraft late to gate Other Late cabin cleaners Mechanical failures Unavailable cockpit crew Weather Late cabin crew Air traffic delays Delayed flight departures Poor announcement of departures Late baggage to aircraft Weight/balance sheet late Delayed check-in procedure Late fuel Late food service Materials Waiting for late passengers Procedures