920bca24fc0503fafce0aab962b14274.ppt

- Количество слайдов: 39

Total Quality Management 1

Total Quality Management 1

What is TQM? n n Meeting quality expectations as defined by the customer Integrated organizational effort designed to improve quality of processes at every business level 2

What is TQM? n n Meeting quality expectations as defined by the customer Integrated organizational effort designed to improve quality of processes at every business level 2

Defining Quality – 5 Ways n 1. Conformance to specs - designer based n n 2. Fitness for use - user based definition n n Does product/service meet tolerances defined by designers? E. g. 20 min wait for pizza (average) + 10 min acceptable (? ) delay. What about a customer? Is a 30 min. delay acceptable? Evaluates performance for intended use. E. g. Jeep vs. Jaguar on mountain roads? 3. Value for price paid - user based def. n Evaluation of usefulness vs. price paid. E. g. receive the same value but at a lower price 3

Defining Quality – 5 Ways n 1. Conformance to specs - designer based n n 2. Fitness for use - user based definition n n Does product/service meet tolerances defined by designers? E. g. 20 min wait for pizza (average) + 10 min acceptable (? ) delay. What about a customer? Is a 30 min. delay acceptable? Evaluates performance for intended use. E. g. Jeep vs. Jaguar on mountain roads? 3. Value for price paid - user based def. n Evaluation of usefulness vs. price paid. E. g. receive the same value but at a lower price 3

Defining Quality – 5 Ways n 4. Support services - user based def. n n Quality of support after sale. E. g. excellent warranty service 5. Psychological criteria - user based definition n e. g. ambiance, prestige, friendly staff may leave the impression of higher quality n Case: Gold Coast Advertising 4

Defining Quality – 5 Ways n 4. Support services - user based def. n n Quality of support after sale. E. g. excellent warranty service 5. Psychological criteria - user based definition n e. g. ambiance, prestige, friendly staff may leave the impression of higher quality n Case: Gold Coast Advertising 4

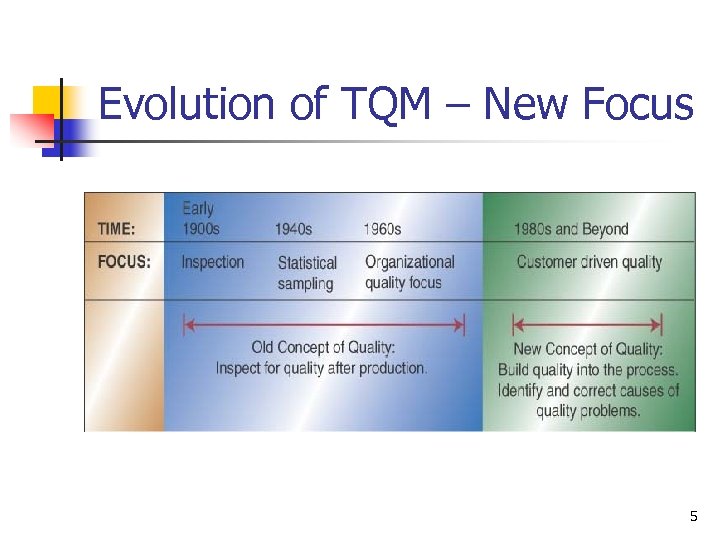

Evolution of TQM – New Focus 5

Evolution of TQM – New Focus 5

TQM Philosophy – What’s Different? n 1. Focus on Customer n n Identify and meet customer needs Stay tuned to changing needs, e. g. fashion styles n n 96% of customers do not complain (stop buying and/or tell others 9 -11 people); satisfied customers 1 person Fixing the problem after the complaint customers become more loyal than if they had not had the problem in the first place It costs more to obtain a new customer than to retain one Customers increase their spending the longer they buy from a company 6

TQM Philosophy – What’s Different? n 1. Focus on Customer n n Identify and meet customer needs Stay tuned to changing needs, e. g. fashion styles n n 96% of customers do not complain (stop buying and/or tell others 9 -11 people); satisfied customers 1 person Fixing the problem after the complaint customers become more loyal than if they had not had the problem in the first place It costs more to obtain a new customer than to retain one Customers increase their spending the longer they buy from a company 6

TQM Philosophy – What’s Different? n 2. Continuous Improvement n Continuous learning and problem solving n (jap. ) Kaizen: requires that the company continually strive to do better through learning and problem solving (“small doses of medicine are better than one large dose”) n Perfection can NEVER be achieved 7

TQM Philosophy – What’s Different? n 2. Continuous Improvement n Continuous learning and problem solving n (jap. ) Kaizen: requires that the company continually strive to do better through learning and problem solving (“small doses of medicine are better than one large dose”) n Perfection can NEVER be achieved 7

TQM Philosophy – What’s Different? n 2. Continuous Improvement n Continuous learning and problem solving n 6 sigma: 3. 4 defects per one million. Example: If 20 mln passengers per year pass through London’s Heathrow Airport, only 68 passengers per year will have misplaced luggage n 3 sigma: 2. 6 defects per one thousand => 2, 600 per million n 52, 000 passengers per year will have misplaced luggage 8

TQM Philosophy – What’s Different? n 2. Continuous Improvement n Continuous learning and problem solving n 6 sigma: 3. 4 defects per one million. Example: If 20 mln passengers per year pass through London’s Heathrow Airport, only 68 passengers per year will have misplaced luggage n 3 sigma: 2. 6 defects per one thousand => 2, 600 per million n 52, 000 passengers per year will have misplaced luggage 8

TQM Philosophy – What’s Different? n 3. Quality at the Source n n 4. Employee Empowerment (they are expected to seek out, identify, and correct problems) n n Inspection (before) vs. prevention & problem solving (now) Employees no longer afraid of reporting problems 5. Focus on both external (who purchase company’s goods/services) and internal customers (e. g. , packaging department is an internal customer of assembly department) 9

TQM Philosophy – What’s Different? n 3. Quality at the Source n n 4. Employee Empowerment (they are expected to seek out, identify, and correct problems) n n Inspection (before) vs. prevention & problem solving (now) Employees no longer afraid of reporting problems 5. Focus on both external (who purchase company’s goods/services) and internal customers (e. g. , packaging department is an internal customer of assembly department) 9

TQM Philosophy– What’s Different? (continued) n 6. Team Approach – Quality Circles (“two heads are better than one”) n n n 7. Benchmarking n n Teams formed around processes – 8 to 10 people Meet weekly to analyze and solve problems Studying practices at “best in class” companies; e. g. many companies use Amex to benchmark conflict resolution 8. Managing Supplier Quality n Certifying suppliers vs. receiving inspection 10

TQM Philosophy– What’s Different? (continued) n 6. Team Approach – Quality Circles (“two heads are better than one”) n n n 7. Benchmarking n n Teams formed around processes – 8 to 10 people Meet weekly to analyze and solve problems Studying practices at “best in class” companies; e. g. many companies use Amex to benchmark conflict resolution 8. Managing Supplier Quality n Certifying suppliers vs. receiving inspection 10

TQM Philosophy– What’s Different? (continued) 9. Just-in-Time n ‘Pull’ system of production/purchasing n n n Involves ‘vendor partnership programs’ to improve quality of purchased items Reduces all inventory levels n n Customer starts production with an order Inventory hides process & material problems Improves process & product quality 11

TQM Philosophy– What’s Different? (continued) 9. Just-in-Time n ‘Pull’ system of production/purchasing n n n Involves ‘vendor partnership programs’ to improve quality of purchased items Reduces all inventory levels n n Customer starts production with an order Inventory hides process & material problems Improves process & product quality 11

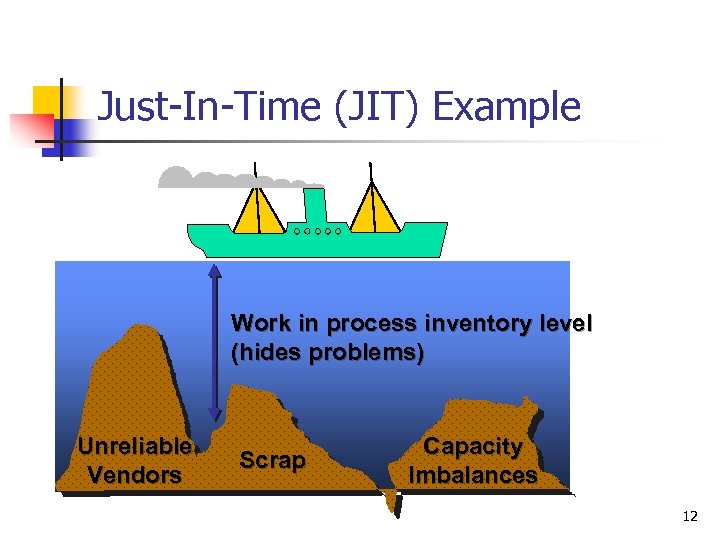

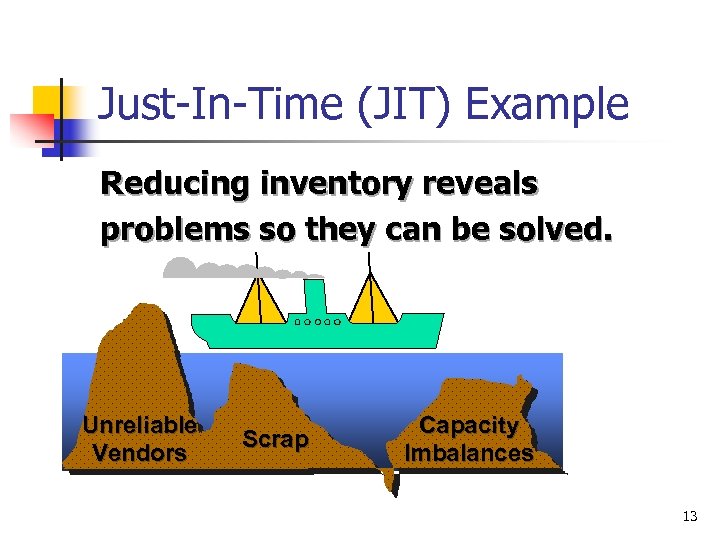

Just-In-Time (JIT) Example Work in process inventory level (hides problems) Unreliable Vendors Scrap Capacity Imbalances 12

Just-In-Time (JIT) Example Work in process inventory level (hides problems) Unreliable Vendors Scrap Capacity Imbalances 12

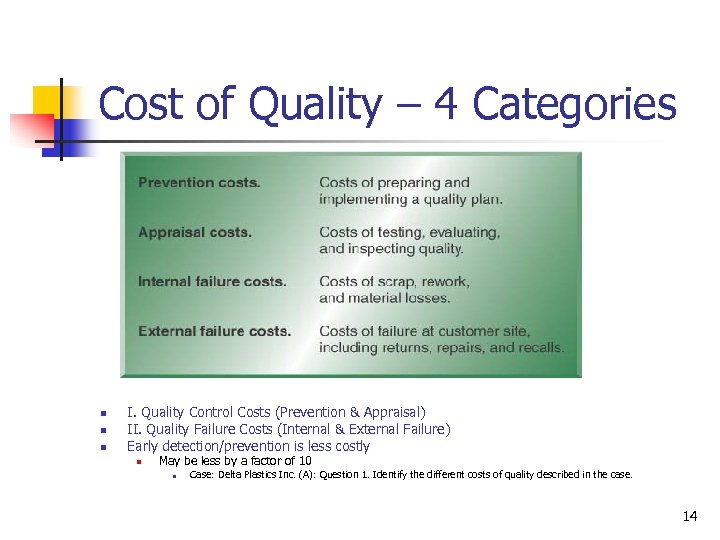

Just-In-Time (JIT) Example Reducing inventory reveals problems so they can be solved. Unreliable Vendors Scrap Capacity Imbalances 13

Just-In-Time (JIT) Example Reducing inventory reveals problems so they can be solved. Unreliable Vendors Scrap Capacity Imbalances 13

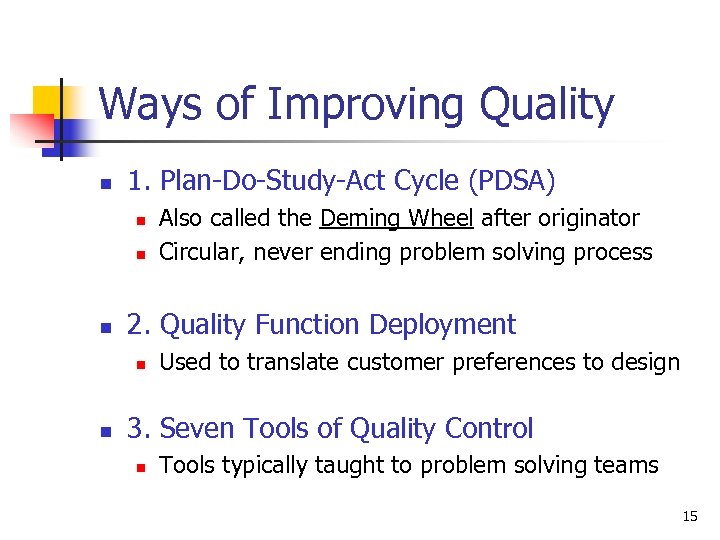

Cost of Quality – 4 Categories n n n I. Quality Control Costs (Prevention & Appraisal) II. Quality Failure Costs (Internal & External Failure) Early detection/prevention is less costly n May be less by a factor of 10 n Case: Delta Plastics Inc. (A): Question 1. Identify the different costs of quality described in the case. 14

Cost of Quality – 4 Categories n n n I. Quality Control Costs (Prevention & Appraisal) II. Quality Failure Costs (Internal & External Failure) Early detection/prevention is less costly n May be less by a factor of 10 n Case: Delta Plastics Inc. (A): Question 1. Identify the different costs of quality described in the case. 14

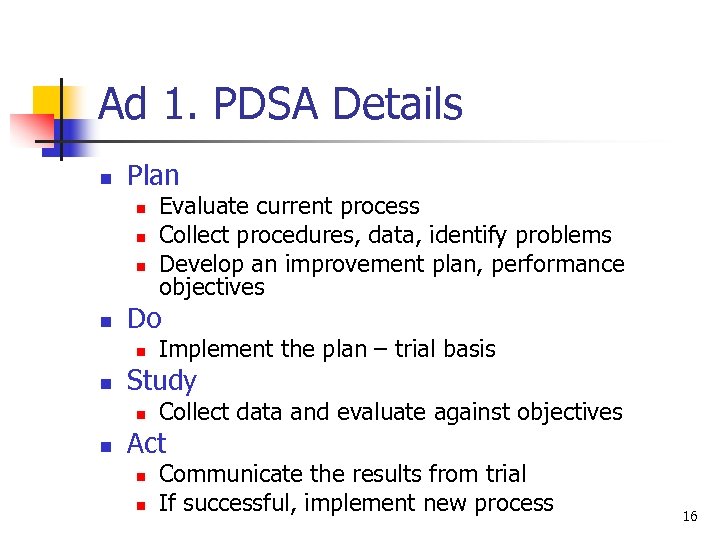

Ways of Improving Quality n 1. Plan-Do-Study-Act Cycle (PDSA) n n n 2. Quality Function Deployment n n Also called the Deming Wheel after originator Circular, never ending problem solving process Used to translate customer preferences to design 3. Seven Tools of Quality Control n Tools typically taught to problem solving teams 15

Ways of Improving Quality n 1. Plan-Do-Study-Act Cycle (PDSA) n n n 2. Quality Function Deployment n n Also called the Deming Wheel after originator Circular, never ending problem solving process Used to translate customer preferences to design 3. Seven Tools of Quality Control n Tools typically taught to problem solving teams 15

Ad 1. PDSA Details n Plan n n Do n n Implement the plan – trial basis Study n n Evaluate current process Collect procedures, data, identify problems Develop an improvement plan, performance objectives Collect data and evaluate against objectives Act n n Communicate the results from trial If successful, implement new process 16

Ad 1. PDSA Details n Plan n n Do n n Implement the plan – trial basis Study n n Evaluate current process Collect procedures, data, identify problems Develop an improvement plan, performance objectives Collect data and evaluate against objectives Act n n Communicate the results from trial If successful, implement new process 16

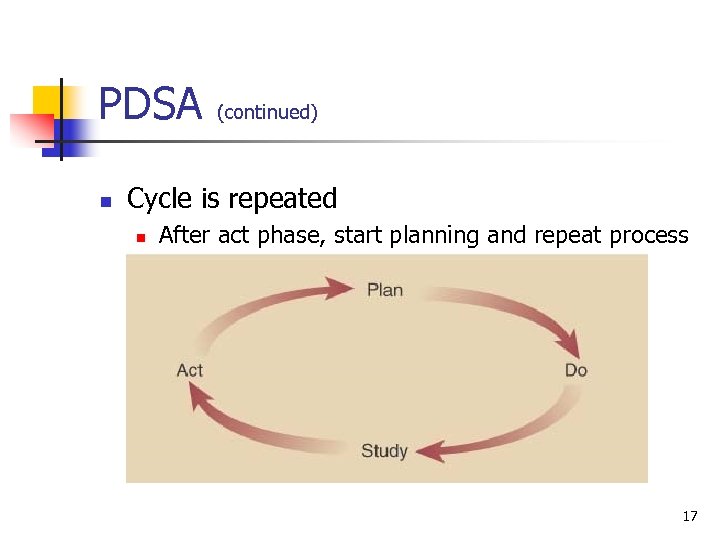

PDSA n (continued) Cycle is repeated n After act phase, start planning and repeat process 17

PDSA n (continued) Cycle is repeated n After act phase, start planning and repeat process 17

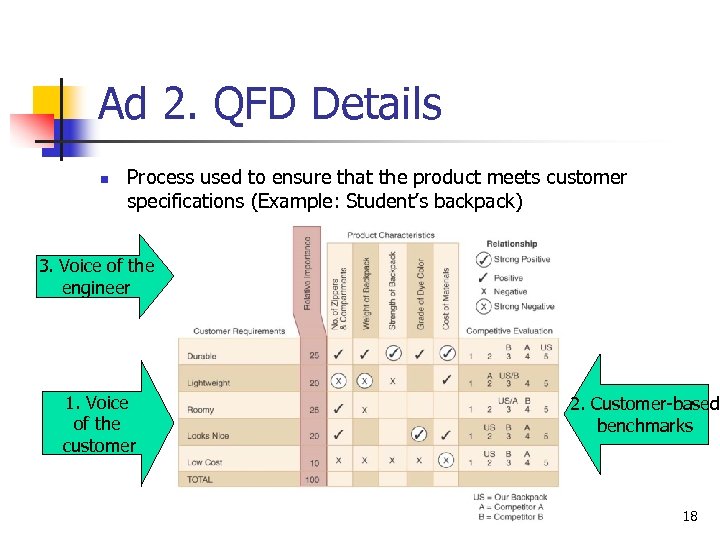

Ad 2. QFD Details n Process used to ensure that the product meets customer specifications (Example: Student’s backpack) 3. Voice of the engineer 1. Voice of the customer 2. Customer-based benchmarks 18

Ad 2. QFD Details n Process used to ensure that the product meets customer specifications (Example: Student’s backpack) 3. Voice of the engineer 1. Voice of the customer 2. Customer-based benchmarks 18

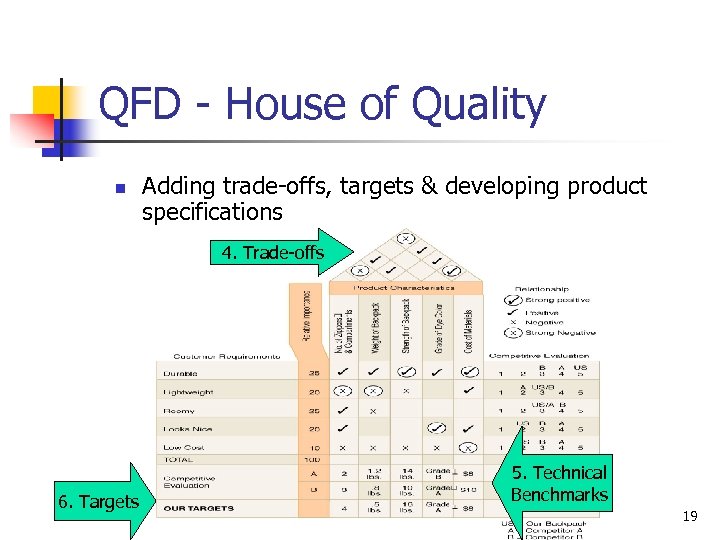

QFD - House of Quality n Adding trade-offs, targets & developing product specifications 4. Trade-offs 6. Targets 5. Technical Benchmarks 19

QFD - House of Quality n Adding trade-offs, targets & developing product specifications 4. Trade-offs 6. Targets 5. Technical Benchmarks 19

Ad 3. Seven Problem Solving Tools n n n n (i) Cause-and-Effect Diagrams (ii) Flowcharts (iii) Checklists (iv) Control Charts (v) Scatter Diagrams (vi) Pareto Analysis (vii) Histograms 20

Ad 3. Seven Problem Solving Tools n n n n (i) Cause-and-Effect Diagrams (ii) Flowcharts (iii) Checklists (iv) Control Charts (v) Scatter Diagrams (vi) Pareto Analysis (vii) Histograms 20

Cause-and-Effect Diagrams n n Called Fishbone Diagram Focused on solving identified quality problem Used to find problem sources/solutions Steps n n n Identify the problem to correct Draw main causes for problem as ‘bones’ Ask ‘What could have caused problems in these areas? ’ Repeat for each sub-area. 21

Cause-and-Effect Diagrams n n Called Fishbone Diagram Focused on solving identified quality problem Used to find problem sources/solutions Steps n n n Identify the problem to correct Draw main causes for problem as ‘bones’ Ask ‘What could have caused problems in these areas? ’ Repeat for each sub-area. 21

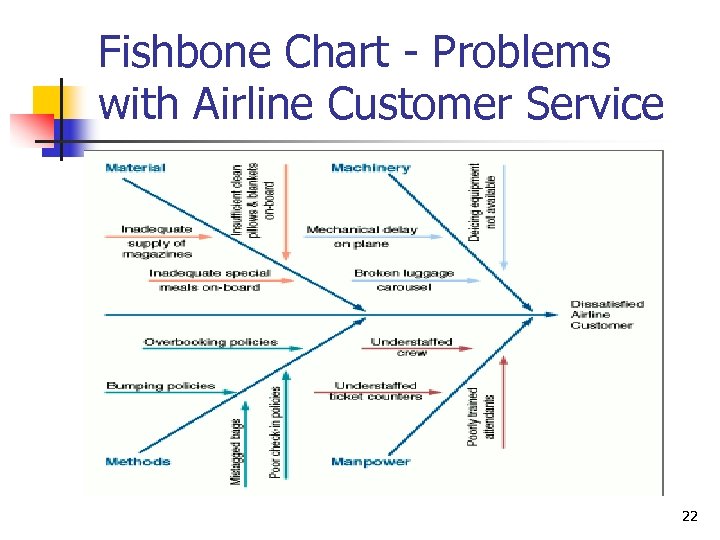

Fishbone Chart - Problems with Airline Customer Service 22

Fishbone Chart - Problems with Airline Customer Service 22

Fishbone Chart - Problems with Getting to Work on Time n n Consider the everyday task of getting to work on time or arriving at your first class on time in the morning. Draw a fish-bone chart showing reasons why you might arrive late in the morning. 4 M: Method, Material, Machinery, Manpower 23

Fishbone Chart - Problems with Getting to Work on Time n n Consider the everyday task of getting to work on time or arriving at your first class on time in the morning. Draw a fish-bone chart showing reasons why you might arrive late in the morning. 4 M: Method, Material, Machinery, Manpower 23

Flowcharts n n Used to document the detailed steps in a process Often the first step in Process Re-Engineering 24

Flowcharts n n Used to document the detailed steps in a process Often the first step in Process Re-Engineering 24

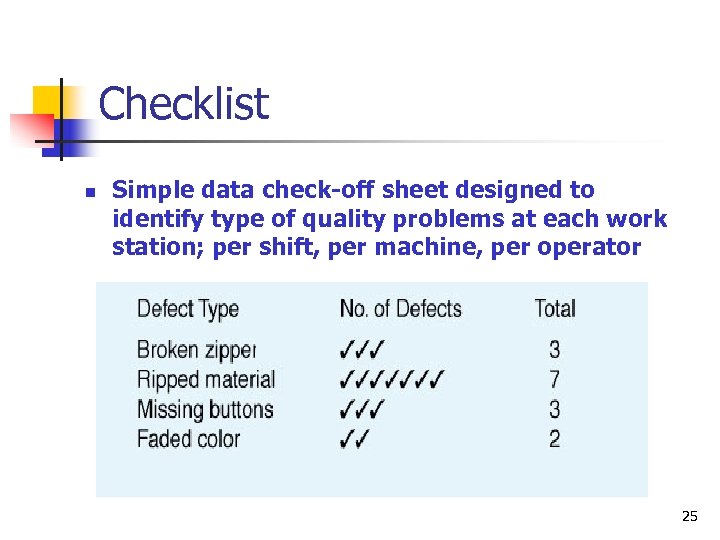

Checklist n Simple data check-off sheet designed to identify type of quality problems at each work station; per shift, per machine, per operator 25

Checklist n Simple data check-off sheet designed to identify type of quality problems at each work station; per shift, per machine, per operator 25

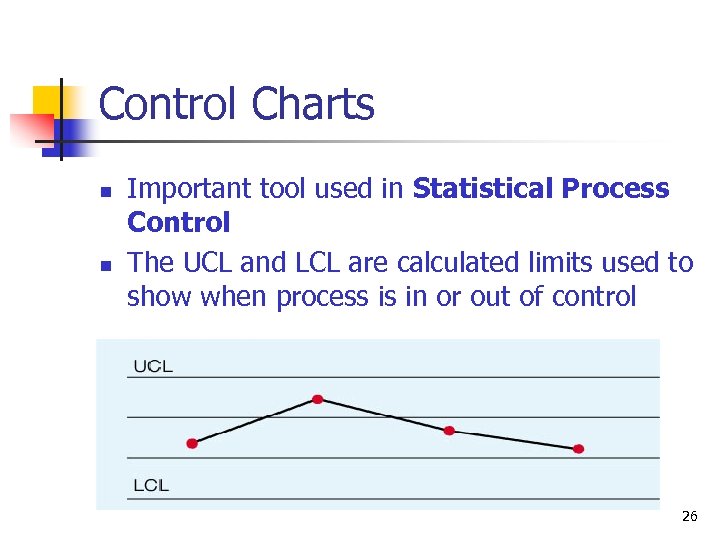

Control Charts n n Important tool used in Statistical Process Control The UCL and LCL are calculated limits used to show when process is in or out of control 26

Control Charts n n Important tool used in Statistical Process Control The UCL and LCL are calculated limits used to show when process is in or out of control 26

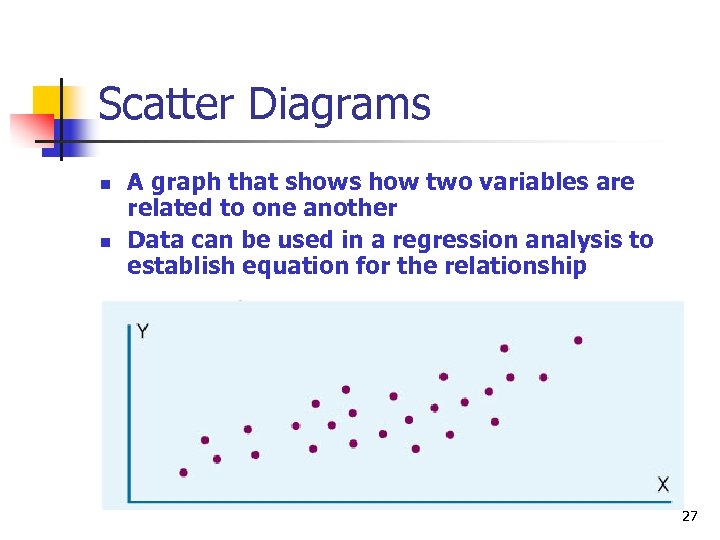

Scatter Diagrams n n A graph that shows how two variables are related to one another Data can be used in a regression analysis to establish equation for the relationship 27

Scatter Diagrams n n A graph that shows how two variables are related to one another Data can be used in a regression analysis to establish equation for the relationship 27

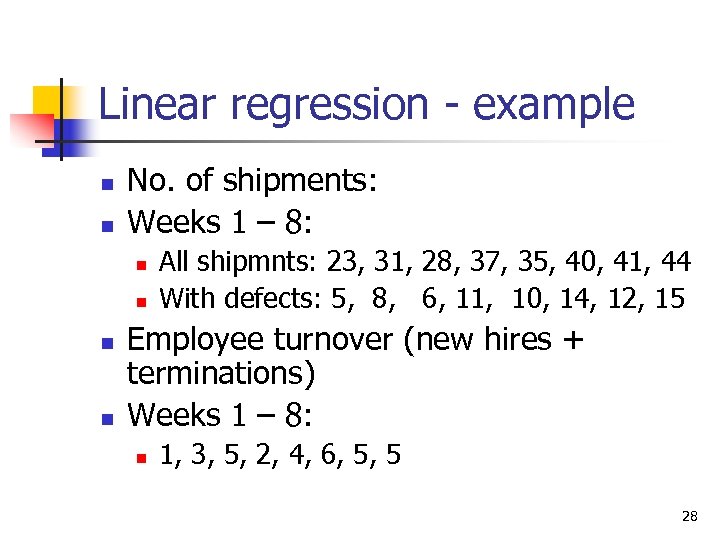

Linear regression - example n n No. of shipments: Weeks 1 – 8: n n All shipmnts: 23, 31, 28, 37, 35, 40, 41, 44 With defects: 5, 8, 6, 11, 10, 14, 12, 15 Employee turnover (new hires + terminations) Weeks 1 – 8: n 1, 3, 5, 2, 4, 6, 5, 5 28

Linear regression - example n n No. of shipments: Weeks 1 – 8: n n All shipmnts: 23, 31, 28, 37, 35, 40, 41, 44 With defects: 5, 8, 6, 11, 10, 14, 12, 15 Employee turnover (new hires + terminations) Weeks 1 – 8: n 1, 3, 5, 2, 4, 6, 5, 5 28

Pareto Analysis n Technique that displays the degree of importance for each element n Named after the 19 th century Italian economist n Often called the 80 -20 Rule n Principle is that quality problems are the result of only a few problems e. g. 80% of the problems caused by 20% of causes 29

Pareto Analysis n Technique that displays the degree of importance for each element n Named after the 19 th century Italian economist n Often called the 80 -20 Rule n Principle is that quality problems are the result of only a few problems e. g. 80% of the problems caused by 20% of causes 29

Pareto Analysis n n Develop a Pareto analysis of the following reasons of delay in a production process. What do you conclude? Reason for Delay Frequency n Awaiting engineering decision 11 n No schematic available 10 n Test equipment down 22 n Delay in inspection 15 n Inadequate parts 40 n Lack of personnel available 3 30

Pareto Analysis n n Develop a Pareto analysis of the following reasons of delay in a production process. What do you conclude? Reason for Delay Frequency n Awaiting engineering decision 11 n No schematic available 10 n Test equipment down 22 n Delay in inspection 15 n Inadequate parts 40 n Lack of personnel available 3 30

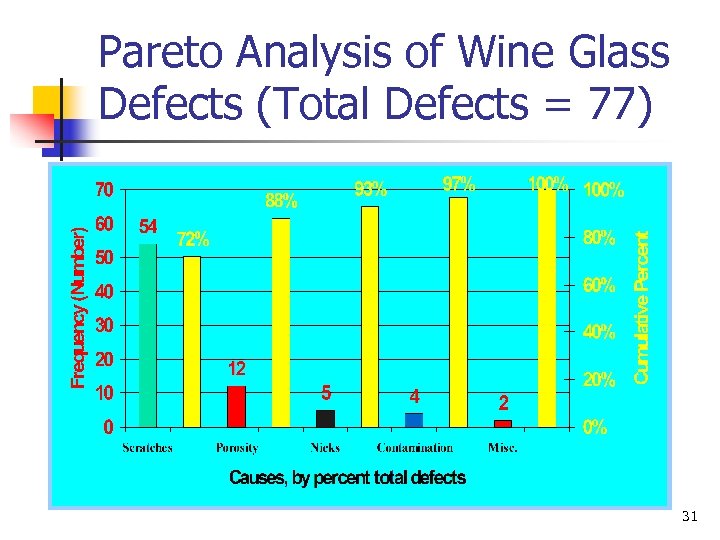

Pareto Analysis of Wine Glass Defects (Total Defects = 77) 31

Pareto Analysis of Wine Glass Defects (Total Defects = 77) 31

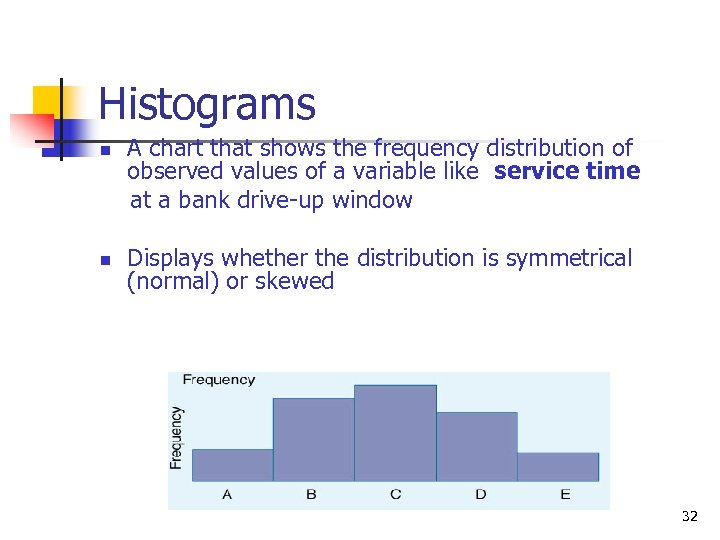

Histograms n n A chart that shows the frequency distribution of observed values of a variable like service time at a bank drive-up window Displays whether the distribution is symmetrical (normal) or skewed 32

Histograms n n A chart that shows the frequency distribution of observed values of a variable like service time at a bank drive-up window Displays whether the distribution is symmetrical (normal) or skewed 32

Quality Awards and Standards n Malcolm Baldrige National Quality Award n The Deming Prize n ISO 9000 Certification n ISO 14000 Standards 33

Quality Awards and Standards n Malcolm Baldrige National Quality Award n The Deming Prize n ISO 9000 Certification n ISO 14000 Standards 33

MBNQA- What Is It? n n n Award named after the former Secretary of Commerce – Reagan Administration Intended to reward and stimulate quality initiatives Given to no more that two companies in each of three categories; manufacturing, service, and small business Past winners; Fed. Ex, 3 M, IBM, Ritz-Carlton Typical winners have scored around 700 points 34

MBNQA- What Is It? n n n Award named after the former Secretary of Commerce – Reagan Administration Intended to reward and stimulate quality initiatives Given to no more that two companies in each of three categories; manufacturing, service, and small business Past winners; Fed. Ex, 3 M, IBM, Ritz-Carlton Typical winners have scored around 700 points 34

The Deming Prize n Given by the Union of Japanese Scientists and Engineers since 1951 n Named after W. Edwards Deming who worked to improve Japanese quality after WWII n Not open to foreign companies until 1984 n Florida Power & Light was first US company winner 35

The Deming Prize n Given by the Union of Japanese Scientists and Engineers since 1951 n Named after W. Edwards Deming who worked to improve Japanese quality after WWII n Not open to foreign companies until 1984 n Florida Power & Light was first US company winner 35

ISO Standards n ISO 9000 Standards (published in 1987): n n n n Certification developed by International Organization for Standardization Set of internationally recognized quality standards Companies are periodically audited & certified ISO 9000: 2000 Quality Management Systems (QMS) – Fundamentals and Standards ISO 9001: 2000 QMS – Requirements (customer) ISO 9004: 2000 QMS - Guidelines for Performance ISO 14000: Focuses on a company’s environmental responsibility 36

ISO Standards n ISO 9000 Standards (published in 1987): n n n n Certification developed by International Organization for Standardization Set of internationally recognized quality standards Companies are periodically audited & certified ISO 9000: 2000 Quality Management Systems (QMS) – Fundamentals and Standards ISO 9001: 2000 QMS – Requirements (customer) ISO 9004: 2000 QMS - Guidelines for Performance ISO 14000: Focuses on a company’s environmental responsibility 36

ISO Standards n (1) Design/Development -> (2) Procurement -> (3) Production -> (4) Installation -> (5) Servicing n n n ISO 9001: 2000 (1) (5) ISO 9002, ISO 9003: withdrawn, incorporated into ISO 9001: 2000 ISO 10011: Guidelines for Auditing & Quality Management 37

ISO Standards n (1) Design/Development -> (2) Procurement -> (3) Production -> (4) Installation -> (5) Servicing n n n ISO 9001: 2000 (1) (5) ISO 9002, ISO 9003: withdrawn, incorporated into ISO 9001: 2000 ISO 10011: Guidelines for Auditing & Quality Management 37

Quality Gurus n n n n Walter A. Shewhart W. Edwards Deming Joseph M. Juran Armand V. Feigenbaum Phillip Crosby Kaoru Ishikawa Genichi Taguchi 38

Quality Gurus n n n n Walter A. Shewhart W. Edwards Deming Joseph M. Juran Armand V. Feigenbaum Phillip Crosby Kaoru Ishikawa Genichi Taguchi 38

Why TQM Efforts Fail n n n Lack of a genuine quality culture Lack of top management support and commitment Over- and under-reliance on SPC methods 39

Why TQM Efforts Fail n n n Lack of a genuine quality culture Lack of top management support and commitment Over- and under-reliance on SPC methods 39