0e7ec25fc24cd14f2b87dedb78098bde.ppt

- Количество слайдов: 45

Tools of safety management TU-E 3150 Safety management in complex sociotechnical systems Teemu Reiman

Tools of safety management TU-E 3150 Safety management in complex sociotechnical systems Teemu Reiman

17. 3. 2018 2 TU-E 3150 Safety management in complex sociotechnical systems 2. 3 Introduction and the basic concepts of safety management 9. 3 Accident models 16. 3 Accident cases + mid-term assignment 23. 3. Organizational learning and incident investigation 30. 3. Safety culture + returning the mid-term assignment 13. 4. Occupational and national cultural influences on safety 20. 4. The basic principles of safety management 27. 4. Tools of safety management 4. 5. Safety challenges today and in future 11. 5. Presentation of the study papers

17. 3. 2018 2 TU-E 3150 Safety management in complex sociotechnical systems 2. 3 Introduction and the basic concepts of safety management 9. 3 Accident models 16. 3 Accident cases + mid-term assignment 23. 3. Organizational learning and incident investigation 30. 3. Safety culture + returning the mid-term assignment 13. 4. Occupational and national cultural influences on safety 20. 4. The basic principles of safety management 27. 4. Tools of safety management 4. 5. Safety challenges today and in future 11. 5. Presentation of the study papers

17. 3. 2018 3 Potential topics for the study paper § Human error – the concept and its limitations § Accident models / causes of accidents / explaining accidents § Learning from errors / accidents – limitations and improvement possibilities § Cultural (national, organizational, occupational) influences on safety § Safety culture models and theories § Safety leadership – ways of leading, effect on safety § Organizational structures and ways of organizing – influence on safety § A systems approach to safety / systems thinking and safety § Some selected safety management tool / method § Some selected accident case § Some selected good practice, or successful case / company

17. 3. 2018 3 Potential topics for the study paper § Human error – the concept and its limitations § Accident models / causes of accidents / explaining accidents § Learning from errors / accidents – limitations and improvement possibilities § Cultural (national, organizational, occupational) influences on safety § Safety culture models and theories § Safety leadership – ways of leading, effect on safety § Organizational structures and ways of organizing – influence on safety § A systems approach to safety / systems thinking and safety § Some selected safety management tool / method § Some selected accident case § Some selected good practice, or successful case / company

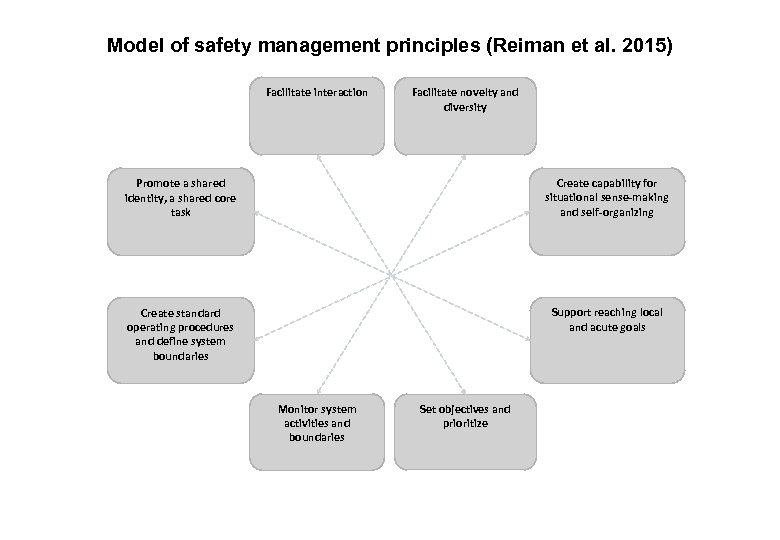

17. 3. 2018 FINAL 4 Model of safety management principles (Reiman et al. 2015) Facilitate interaction Facilitate novelty and diversity Promote a shared identity, a shared core task Create capability for situational sense-making and self-organizing Create standard operating procedures and define system boundaries Support reaching local and acute goals Monitor system activities and boundaries Set objectives and prioritize

17. 3. 2018 FINAL 4 Model of safety management principles (Reiman et al. 2015) Facilitate interaction Facilitate novelty and diversity Promote a shared identity, a shared core task Create capability for situational sense-making and self-organizing Create standard operating procedures and define system boundaries Support reaching local and acute goals Monitor system activities and boundaries Set objectives and prioritize

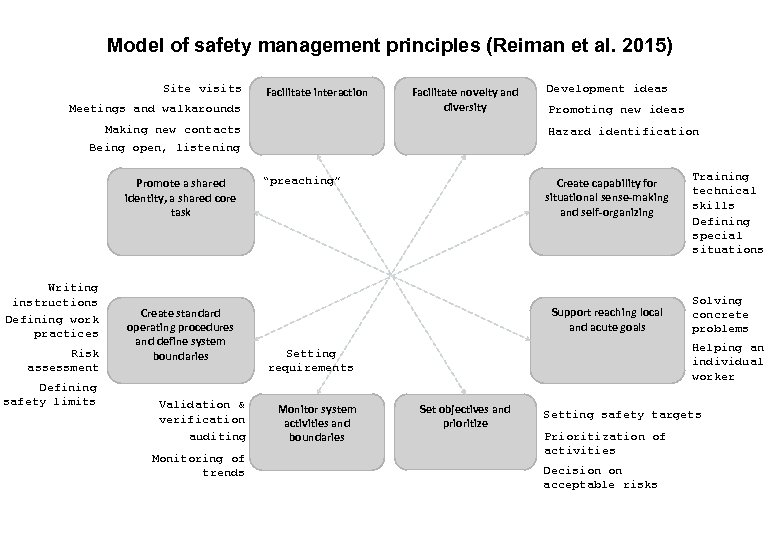

17. 3. 2018 FINAL 5 Model of safety management principles (Reiman et al. 2015) Site visits Facilitate interaction Meetings and walkarounds Facilitate novelty and diversity Making new contacts Being open, listening Promote a shared identity, a shared core task Writing instructions Defining work practices Risk assessment Defining safety limits Create standard operating procedures and define system boundaries Validation & verification auditing Monitoring of trends Development ideas Promoting new ideas Hazard identification “preaching” Create capability for situational sense-making and self-organizing Support reaching local and acute goals Solving concrete problems Helping an individual worker Setting requirements Monitor system activities and boundaries Training technical skills Defining special situations Set objectives and prioritize Setting safety targets Prioritization of activities Decision on acceptable risks

17. 3. 2018 FINAL 5 Model of safety management principles (Reiman et al. 2015) Site visits Facilitate interaction Meetings and walkarounds Facilitate novelty and diversity Making new contacts Being open, listening Promote a shared identity, a shared core task Writing instructions Defining work practices Risk assessment Defining safety limits Create standard operating procedures and define system boundaries Validation & verification auditing Monitoring of trends Development ideas Promoting new ideas Hazard identification “preaching” Create capability for situational sense-making and self-organizing Support reaching local and acute goals Solving concrete problems Helping an individual worker Setting requirements Monitor system activities and boundaries Training technical skills Defining special situations Set objectives and prioritize Setting safety targets Prioritization of activities Decision on acceptable risks

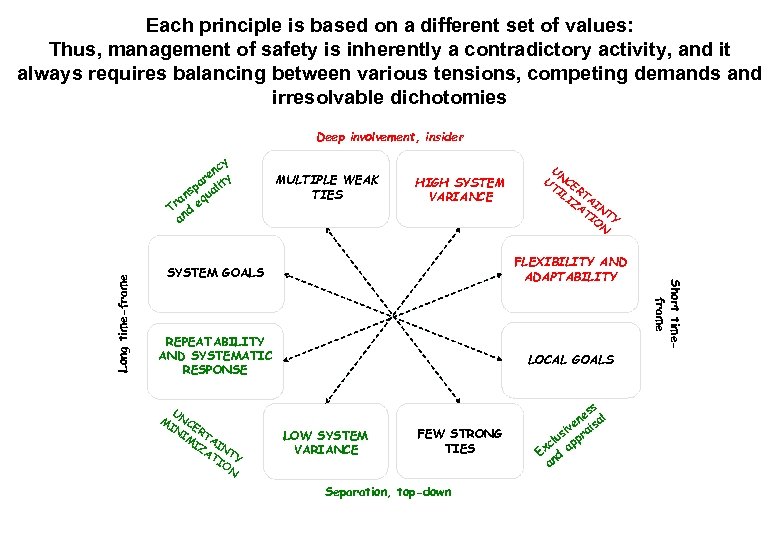

17. 3. 2018 6 Each principle is based on a different set of values: Thus, management of safety is inherently a contradictory activity, and it always requires balancing between various tensions, competing demands and irresolvable dichotomies Deep involvement, insider MULTIPLE WEAK TIES HIGH SYSTEM VARIANCE UN UT CE IL RT IZ AI AT N IO TY N SYSTEM GOALS FLEXIBILITY AND ADAPTABILITY REPEATABILITY AND SYSTEMATIC RESPONSE LOCAL GOALS U M NC IN ER IM TA IZ IN AT TY IO N LOW SYSTEM VARIANCE FEW STRONG TIES Separation, top-down ss ne sal e i siv pra lu xc ap E d an Short timeframe Long time-frame cy en y ar it sp ual n ra eq T d an

17. 3. 2018 6 Each principle is based on a different set of values: Thus, management of safety is inherently a contradictory activity, and it always requires balancing between various tensions, competing demands and irresolvable dichotomies Deep involvement, insider MULTIPLE WEAK TIES HIGH SYSTEM VARIANCE UN UT CE IL RT IZ AI AT N IO TY N SYSTEM GOALS FLEXIBILITY AND ADAPTABILITY REPEATABILITY AND SYSTEMATIC RESPONSE LOCAL GOALS U M NC IN ER IM TA IZ IN AT TY IO N LOW SYSTEM VARIANCE FEW STRONG TIES Separation, top-down ss ne sal e i siv pra lu xc ap E d an Short timeframe Long time-frame cy en y ar it sp ual n ra eq T d an

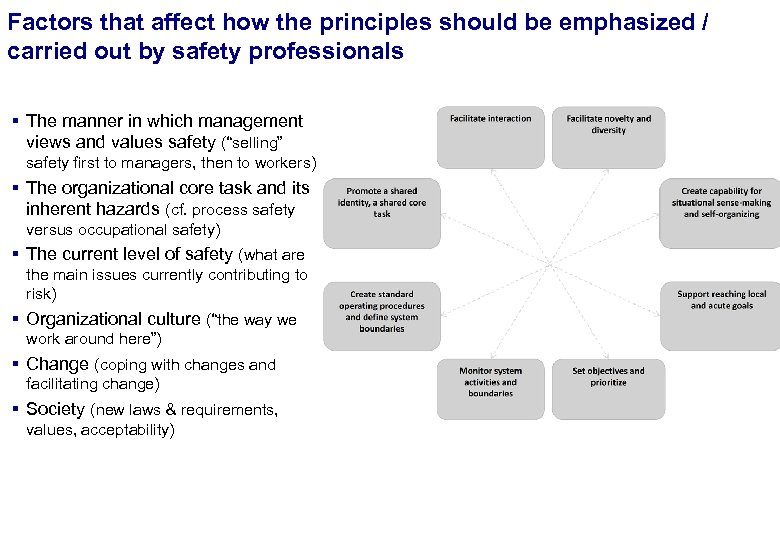

Factors that affect how the principles should be emphasized / FINAL carried out by safety professionals 17. 3. 2018 § The manner in which management views and values safety (“selling” safety first to managers, then to workers) § The organizational core task and its inherent hazards (cf. process safety versus occupational safety) § The current level of safety (what are the main issues currently contributing to risk) § Organizational culture (“the way we work around here”) § Change (coping with changes and facilitating change) § Society (new laws & requirements, values, acceptability) 7

Factors that affect how the principles should be emphasized / FINAL carried out by safety professionals 17. 3. 2018 § The manner in which management views and values safety (“selling” safety first to managers, then to workers) § The organizational core task and its inherent hazards (cf. process safety versus occupational safety) § The current level of safety (what are the main issues currently contributing to risk) § Organizational culture (“the way we work around here”) § Change (coping with changes and facilitating change) § Society (new laws & requirements, values, acceptability) 7

17. 3. 2018 Core processes of safety management 1. 2. 3. 4. 5. 6. 7. 8. Management leadership & policy setting Employee involvement Risk and hazard identification and assessment Hazard prevention and control Education and training Performance and measurement Learning from experience Continuous improvement & review 8

17. 3. 2018 Core processes of safety management 1. 2. 3. 4. 5. 6. 7. 8. Management leadership & policy setting Employee involvement Risk and hazard identification and assessment Hazard prevention and control Education and training Performance and measurement Learning from experience Continuous improvement & review 8

17. 3. 2018 Core processes of safety management 1. 2. 3. 4. 5. 6. 7. 8. Management leadership & policy setting Employee involvement Risk and hazard identification and assessment Hazard prevention and control Education and training Performance and measurement Learning from experience Continuous improvement & review 9

17. 3. 2018 Core processes of safety management 1. 2. 3. 4. 5. 6. 7. 8. Management leadership & policy setting Employee involvement Risk and hazard identification and assessment Hazard prevention and control Education and training Performance and measurement Learning from experience Continuous improvement & review 9

17. 3. 2018 10 Safety leadership § GLOBE study identified the following globally desirable leadership traits: integrity, inspirational, visionary, performance-oriented § The following traits were considered least desirable: face saver, nonparticipative, autocratic, self-centered, malevolent § Characteristics of “authentic safety leadership” (Dekker 2014, p. 154): § Having an inquisitive mindset § Genuinely wanting to learn about the work and what is going on in the organization § Ability to listen (and practice humble inquiry, see Schein) § No ego involvement: accept being proven wrong § Non-judgmental, e. g. about whether the work meets requirements, or how it should be done § Not self-protective, do not worry first and foremost about their own liability

17. 3. 2018 10 Safety leadership § GLOBE study identified the following globally desirable leadership traits: integrity, inspirational, visionary, performance-oriented § The following traits were considered least desirable: face saver, nonparticipative, autocratic, self-centered, malevolent § Characteristics of “authentic safety leadership” (Dekker 2014, p. 154): § Having an inquisitive mindset § Genuinely wanting to learn about the work and what is going on in the organization § Ability to listen (and practice humble inquiry, see Schein) § No ego involvement: accept being proven wrong § Non-judgmental, e. g. about whether the work meets requirements, or how it should be done § Not self-protective, do not worry first and foremost about their own liability

17. 3. 2018 11 1. Management leadership & policy setting § Edgar Schein (2010) has proposed the following mechanisms by which leaders embed organizational culture § Primary embedding mechanisms § § § What leaders pay attention to, measure, and control on a regular basis How leaders react to critical incidents and organizational crises How leaders allocate resources Deliberate role modelling, teaching, and coaching How leaders allocate rewards and status How leaders recruit, select, promote, and excommunicate

17. 3. 2018 11 1. Management leadership & policy setting § Edgar Schein (2010) has proposed the following mechanisms by which leaders embed organizational culture § Primary embedding mechanisms § § § What leaders pay attention to, measure, and control on a regular basis How leaders react to critical incidents and organizational crises How leaders allocate resources Deliberate role modelling, teaching, and coaching How leaders allocate rewards and status How leaders recruit, select, promote, and excommunicate

17. 3. 2018 1. Management leadership & policy setting § Edgar Schein (2010) has proposed the following mechanisms by which leaders embed organizational culture § Secondary articulation and reinforcement mechanisms § § § Organizational design and structure Organizational systems and procedures Rites and rituals of the organization Design of physical space, facades, and buildings Stories about important events and people Formal statements of organizational philosophy, creeds, and charters 12

17. 3. 2018 1. Management leadership & policy setting § Edgar Schein (2010) has proposed the following mechanisms by which leaders embed organizational culture § Secondary articulation and reinforcement mechanisms § § § Organizational design and structure Organizational systems and procedures Rites and rituals of the organization Design of physical space, facades, and buildings Stories about important events and people Formal statements of organizational philosophy, creeds, and charters 12

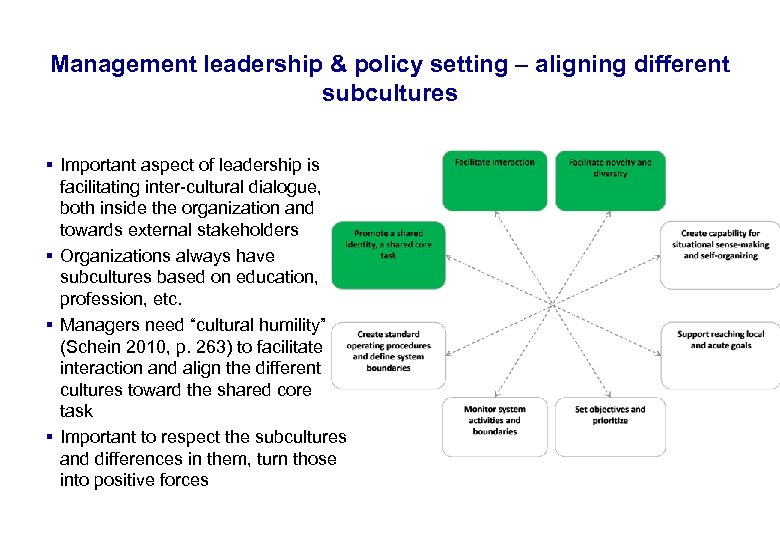

17. 3. 2018 13 Management leadership & policy setting – aligning different subcultures § Important aspect of leadership is facilitating inter-cultural dialogue, both inside the organization and towards external stakeholders § Organizations always have subcultures based on education, profession, etc. § Managers need “cultural humility” (Schein 2010, p. 263) to facilitate interaction and align the different cultures toward the shared core task § Important to respect the subcultures and differences in them, turn those into positive forces

17. 3. 2018 13 Management leadership & policy setting – aligning different subcultures § Important aspect of leadership is facilitating inter-cultural dialogue, both inside the organization and towards external stakeholders § Organizations always have subcultures based on education, profession, etc. § Managers need “cultural humility” (Schein 2010, p. 263) to facilitate interaction and align the different cultures toward the shared core task § Important to respect the subcultures and differences in them, turn those into positive forces

17. 3. 2018 Core processes of safety management 1. 2. 3. 4. 5. 6. 7. 8. Management leadership & policy setting Employee involvement Risk and hazard identification and assessment Hazard prevention and control Education and training Performance and measurement Learning from experience Continuous improvement & review 14

17. 3. 2018 Core processes of safety management 1. 2. 3. 4. 5. 6. 7. 8. Management leadership & policy setting Employee involvement Risk and hazard identification and assessment Hazard prevention and control Education and training Performance and measurement Learning from experience Continuous improvement & review 14

17. 3. 2018 15 2. Employee involvement § Occupational safety committees (työsuojelutoimikunta) § Mandatory in all organizations with more than 20 employees § Includes representatives from the employer and the employees § Safety manager (työsuojelupäällikkö) is often the employer representative § Safety representative (työsuojeluvaltuutettu) and his or her two deputies are the employees representatives automatically, both more can be, and usually are, chosen by voting § Reporting systems for development suggestions, non-conformities in product & practices and other concerns § Participation in all the other processes of safety management (e. g. hazard identification, learning, continuous improvement) § The employees’ right to decline unsafe work and the employer’s responsibility to manage the hazards connected to the work are stated in the Finnish law

17. 3. 2018 15 2. Employee involvement § Occupational safety committees (työsuojelutoimikunta) § Mandatory in all organizations with more than 20 employees § Includes representatives from the employer and the employees § Safety manager (työsuojelupäällikkö) is often the employer representative § Safety representative (työsuojeluvaltuutettu) and his or her two deputies are the employees representatives automatically, both more can be, and usually are, chosen by voting § Reporting systems for development suggestions, non-conformities in product & practices and other concerns § Participation in all the other processes of safety management (e. g. hazard identification, learning, continuous improvement) § The employees’ right to decline unsafe work and the employer’s responsibility to manage the hazards connected to the work are stated in the Finnish law

17. 3. 2018 Core processes of safety management 1. 2. 3. 4. 5. 6. 7. 8. Management leadership & policy setting Employee involvement Risk and hazard identification and assessment Hazard prevention and control Education and training Performance and measurement Learning from experience Continuous improvement & review 16

17. 3. 2018 Core processes of safety management 1. 2. 3. 4. 5. 6. 7. 8. Management leadership & policy setting Employee involvement Risk and hazard identification and assessment Hazard prevention and control Education and training Performance and measurement Learning from experience Continuous improvement & review 16

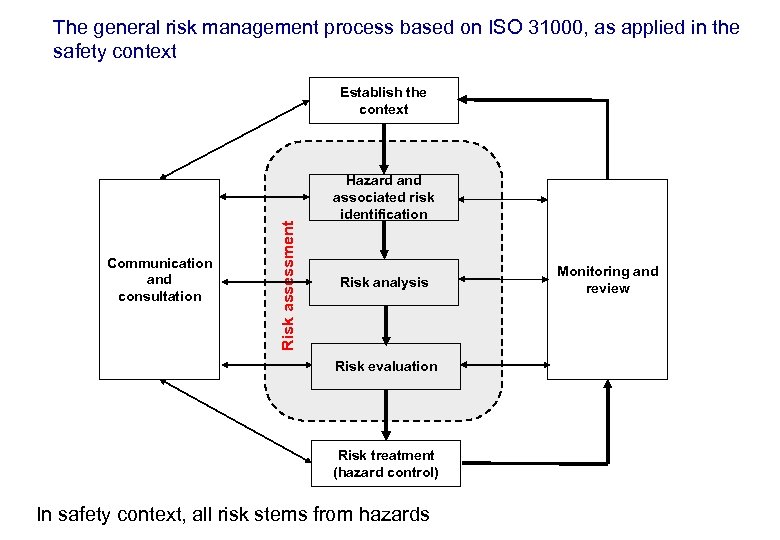

17. 3. 2018 17 The general risk management process based on ISO 31000, as applied in the safety context Communication and consultation Risk assessment Establish the context Hazard and associated risk identification Risk analysis Risk evaluation Risk treatment (hazard control) In safety context, all risk stems from hazards Monitoring and review

17. 3. 2018 17 The general risk management process based on ISO 31000, as applied in the safety context Communication and consultation Risk assessment Establish the context Hazard and associated risk identification Risk analysis Risk evaluation Risk treatment (hazard control) In safety context, all risk stems from hazards Monitoring and review

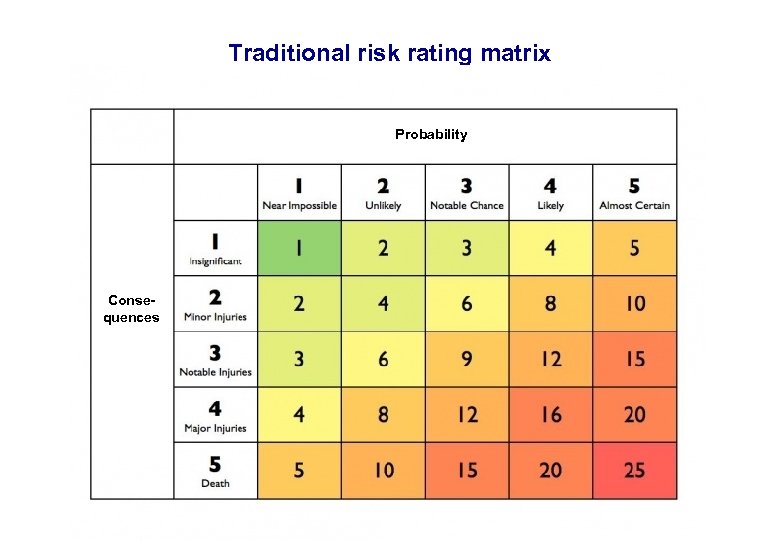

17. 3. 2018 Traditional risk rating matrix Probability Consequences 18

17. 3. 2018 Traditional risk rating matrix Probability Consequences 18

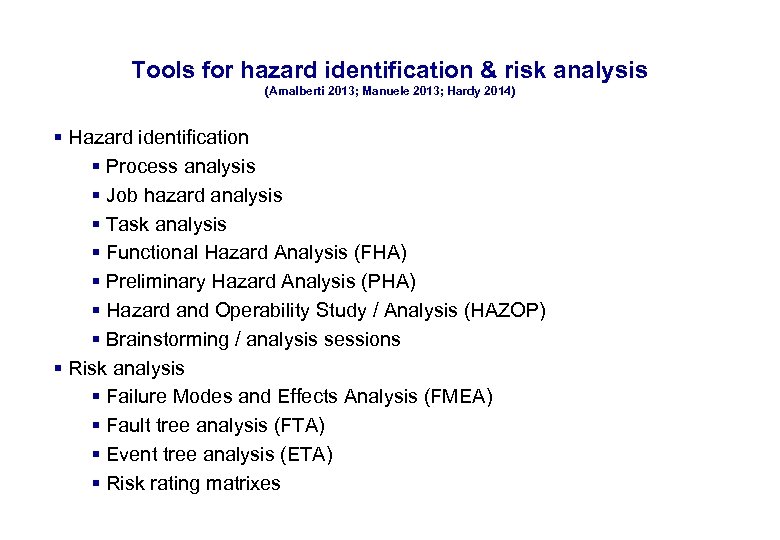

17. 3. 2018 Tools for hazard identification & risk analysis (Amalberti 2013; Manuele 2013; Hardy 2014) § Hazard identification § Process analysis § Job hazard analysis § Task analysis § Functional Hazard Analysis (FHA) § Preliminary Hazard Analysis (PHA) § Hazard and Operability Study / Analysis (HAZOP) § Brainstorming / analysis sessions § Risk analysis § Failure Modes and Effects Analysis (FMEA) § Fault tree analysis (FTA) § Event tree analysis (ETA) § Risk rating matrixes 19

17. 3. 2018 Tools for hazard identification & risk analysis (Amalberti 2013; Manuele 2013; Hardy 2014) § Hazard identification § Process analysis § Job hazard analysis § Task analysis § Functional Hazard Analysis (FHA) § Preliminary Hazard Analysis (PHA) § Hazard and Operability Study / Analysis (HAZOP) § Brainstorming / analysis sessions § Risk analysis § Failure Modes and Effects Analysis (FMEA) § Fault tree analysis (FTA) § Event tree analysis (ETA) § Risk rating matrixes 19

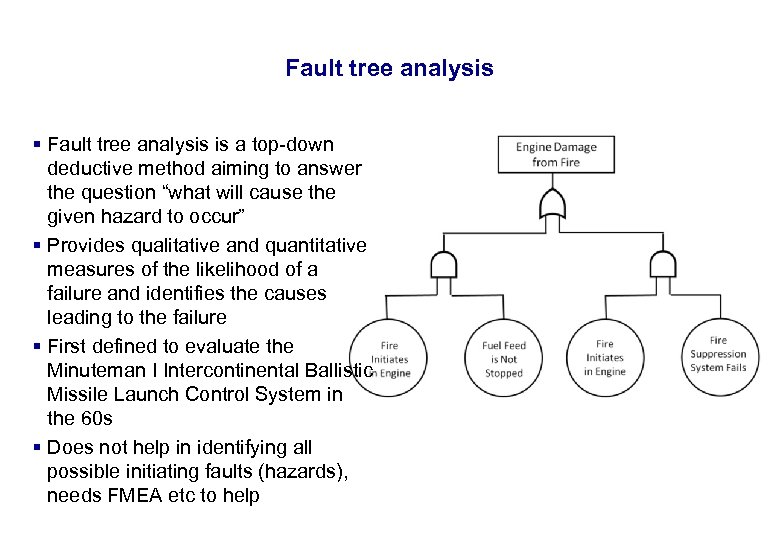

17. 3. 2018 Fault tree analysis § Fault tree analysis is a top-down deductive method aiming to answer the question “what will cause the given hazard to occur” § Provides qualitative and quantitative measures of the likelihood of a failure and identifies the causes leading to the failure § First defined to evaluate the Minuteman I Intercontinental Ballistic Missile Launch Control System in the 60 s § Does not help in identifying all possible initiating faults (hazards), needs FMEA etc to help 20

17. 3. 2018 Fault tree analysis § Fault tree analysis is a top-down deductive method aiming to answer the question “what will cause the given hazard to occur” § Provides qualitative and quantitative measures of the likelihood of a failure and identifies the causes leading to the failure § First defined to evaluate the Minuteman I Intercontinental Ballistic Missile Launch Control System in the 60 s § Does not help in identifying all possible initiating faults (hazards), needs FMEA etc to help 20

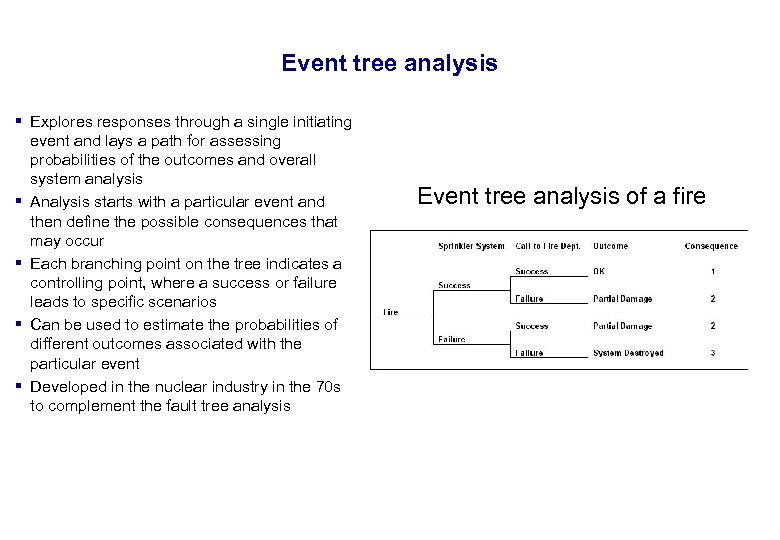

17. 3. 2018 21 Event tree analysis § Explores responses through a single initiating event and lays a path for assessing probabilities of the outcomes and overall system analysis § Analysis starts with a particular event and then define the possible consequences that may occur § Each branching point on the tree indicates a controlling point, where a success or failure leads to specific scenarios § Can be used to estimate the probabilities of different outcomes associated with the particular event § Developed in the nuclear industry in the 70 s to complement the fault tree analysis Event tree analysis of a fire

17. 3. 2018 21 Event tree analysis § Explores responses through a single initiating event and lays a path for assessing probabilities of the outcomes and overall system analysis § Analysis starts with a particular event and then define the possible consequences that may occur § Each branching point on the tree indicates a controlling point, where a success or failure leads to specific scenarios § Can be used to estimate the probabilities of different outcomes associated with the particular event § Developed in the nuclear industry in the 70 s to complement the fault tree analysis Event tree analysis of a fire

17. 3. 2018 Core processes of safety management 1. 2. 3. 4. 5. 6. 7. 8. Management leadership & policy setting Employee involvement Risk and hazard identification and assessment Hazard prevention and control Education and training Performance and measurement Learning from experience Continuous improvement & review 22

17. 3. 2018 Core processes of safety management 1. 2. 3. 4. 5. 6. 7. 8. Management leadership & policy setting Employee involvement Risk and hazard identification and assessment Hazard prevention and control Education and training Performance and measurement Learning from experience Continuous improvement & review 22

17. 3. 2018 23 Hierarchy of controls (from most effective to least effective) 1. 5. Design (or redesign) the system to reduce or eliminate hazards – inherently safe designs that have fewer hazards and smaller risks of hazards actualizing Install safety devices and safety systems to prevent hazards from actualizing or causing harm – engineering control Use cautions and warnings to indicate the presence of hazards Control through administrative means—procedures, instructions, etc. § Includes also how to deal with disturbance situations, how to minimize loss Rely on personal protective equipment (helmets, gloves) § (insure against residual risk) 2. 3. 4. Systems must be designed with humans in mind, not so that humans need to adapt to the hazardous system by having to be more careful, alter their behaviour and being constantly on guard Þnot only management level tools, but sociotechnical level tools&models are needed ÞNot only prevention of errors, but also focus on the positive organizational capabilities to control risk

17. 3. 2018 23 Hierarchy of controls (from most effective to least effective) 1. 5. Design (or redesign) the system to reduce or eliminate hazards – inherently safe designs that have fewer hazards and smaller risks of hazards actualizing Install safety devices and safety systems to prevent hazards from actualizing or causing harm – engineering control Use cautions and warnings to indicate the presence of hazards Control through administrative means—procedures, instructions, etc. § Includes also how to deal with disturbance situations, how to minimize loss Rely on personal protective equipment (helmets, gloves) § (insure against residual risk) 2. 3. 4. Systems must be designed with humans in mind, not so that humans need to adapt to the hazardous system by having to be more careful, alter their behaviour and being constantly on guard Þnot only management level tools, but sociotechnical level tools&models are needed ÞNot only prevention of errors, but also focus on the positive organizational capabilities to control risk

17. 3. 2018 24 Principles of hazard control § Hazards and best controlled at their source: when designing technology, processes, tools and practices § Controlling the hazards later in the chain is more difficult and less effective § The idea of “inherently safe design” § Work has to be designed to fit the human, not the other way around § Work planning, shifts, wokload, work practices, tool and the content of the work need to be designed so that a good quality performance is possible § Technology offers both new solutions to protect against hazards as well as new types of hazards § Hazards, and the associated countermeasures, need to be documented as standard operating procedures and emergency procedures § Proactive work needs to be done in the entire organization

17. 3. 2018 24 Principles of hazard control § Hazards and best controlled at their source: when designing technology, processes, tools and practices § Controlling the hazards later in the chain is more difficult and less effective § The idea of “inherently safe design” § Work has to be designed to fit the human, not the other way around § Work planning, shifts, wokload, work practices, tool and the content of the work need to be designed so that a good quality performance is possible § Technology offers both new solutions to protect against hazards as well as new types of hazards § Hazards, and the associated countermeasures, need to be documented as standard operating procedures and emergency procedures § Proactive work needs to be done in the entire organization

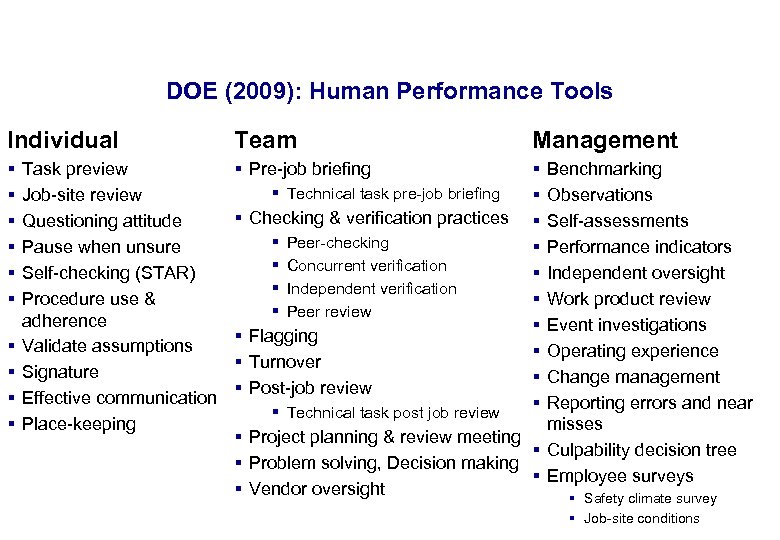

17. 3. 2018 25 DOE (2009): Human Performance Tools Individual Team Management § § § § Pre-job briefing § § § § Task preview Job-site review Questioning attitude Pause when unsure Self-checking (STAR) Procedure use & adherence Validate assumptions Signature Effective communication Place-keeping § § § § Benchmarking § Technical task pre-job briefing Observations Checking & verification practices Self-assessments § Peer-checking Performance indicators § Concurrent verification Independent oversight § Independent verification Work product review § Peer review Event investigations Flagging Operating experience Turnover Change management Post-job review Reporting errors and near § Technical task post job review misses Project planning & review meeting § Culpability decision tree Problem solving, Decision making § Employee surveys Vendor oversight § Safety climate survey § Job-site conditions

17. 3. 2018 25 DOE (2009): Human Performance Tools Individual Team Management § § § § Pre-job briefing § § § § Task preview Job-site review Questioning attitude Pause when unsure Self-checking (STAR) Procedure use & adherence Validate assumptions Signature Effective communication Place-keeping § § § § Benchmarking § Technical task pre-job briefing Observations Checking & verification practices Self-assessments § Peer-checking Performance indicators § Concurrent verification Independent oversight § Independent verification Work product review § Peer review Event investigations Flagging Operating experience Turnover Change management Post-job review Reporting errors and near § Technical task post job review misses Project planning & review meeting § Culpability decision tree Problem solving, Decision making § Employee surveys Vendor oversight § Safety climate survey § Job-site conditions

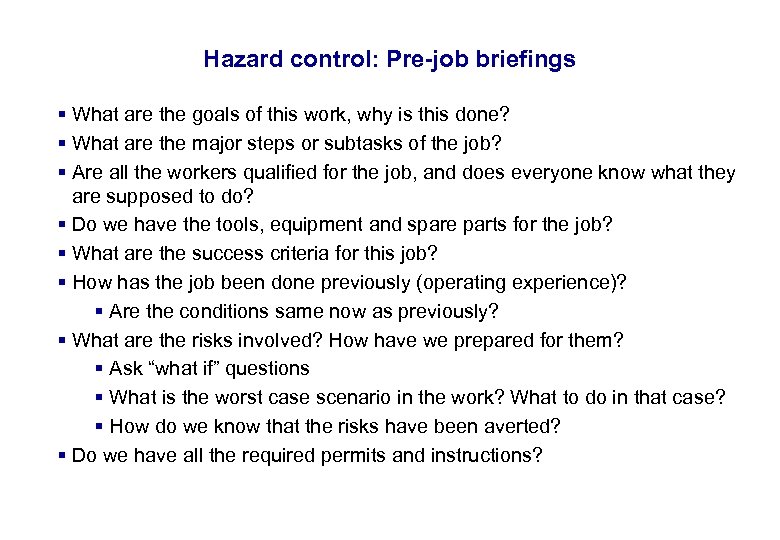

17. 3. 2018 26 Hazard control: Pre-job briefings § What are the goals of this work, why is this done? § What are the major steps or subtasks of the job? § Are all the workers qualified for the job, and does everyone know what they are supposed to do? § Do we have the tools, equipment and spare parts for the job? § What are the success criteria for this job? § How has the job been done previously (operating experience)? § Are the conditions same now as previously? § What are the risks involved? How have we prepared for them? § Ask “what if” questions § What is the worst case scenario in the work? What to do in that case? § How do we know that the risks have been averted? § Do we have all the required permits and instructions?

17. 3. 2018 26 Hazard control: Pre-job briefings § What are the goals of this work, why is this done? § What are the major steps or subtasks of the job? § Are all the workers qualified for the job, and does everyone know what they are supposed to do? § Do we have the tools, equipment and spare parts for the job? § What are the success criteria for this job? § How has the job been done previously (operating experience)? § Are the conditions same now as previously? § What are the risks involved? How have we prepared for them? § Ask “what if” questions § What is the worst case scenario in the work? What to do in that case? § How do we know that the risks have been averted? § Do we have all the required permits and instructions?

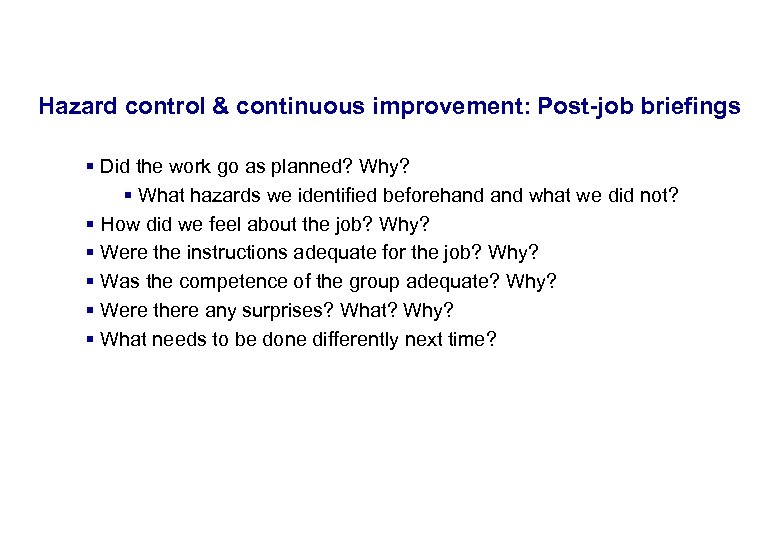

17. 3. 2018 27 Hazard control & continuous improvement: Post-job briefings § Did the work go as planned? Why? § What hazards we identified beforehand what we did not? § How did we feel about the job? Why? § Were the instructions adequate for the job? Why? § Was the competence of the group adequate? Why? § Were there any surprises? What? Why? § What needs to be done differently next time?

17. 3. 2018 27 Hazard control & continuous improvement: Post-job briefings § Did the work go as planned? Why? § What hazards we identified beforehand what we did not? § How did we feel about the job? Why? § Were the instructions adequate for the job? Why? § Was the competence of the group adequate? Why? § Were there any surprises? What? Why? § What needs to be done differently next time?

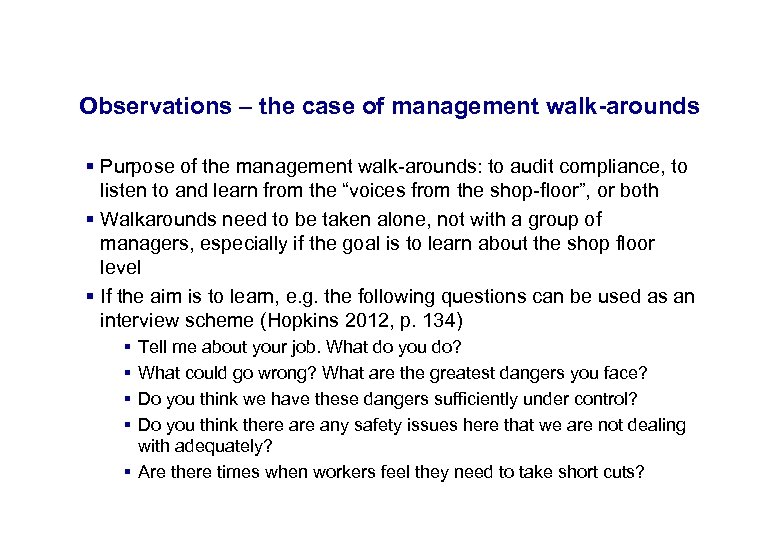

17. 3. 2018 28 Observations – the case of management walk-arounds § Purpose of the management walk-arounds: to audit compliance, to listen to and learn from the “voices from the shop-floor”, or both § Walkarounds need to be taken alone, not with a group of managers, especially if the goal is to learn about the shop floor level § If the aim is to learn, e. g. the following questions can be used as an interview scheme (Hopkins 2012, p. 134) § § Tell me about your job. What do you do? What could go wrong? What are the greatest dangers you face? Do you think we have these dangers sufficiently under control? Do you think there any safety issues here that we are not dealing with adequately? § Are there times when workers feel they need to take short cuts?

17. 3. 2018 28 Observations – the case of management walk-arounds § Purpose of the management walk-arounds: to audit compliance, to listen to and learn from the “voices from the shop-floor”, or both § Walkarounds need to be taken alone, not with a group of managers, especially if the goal is to learn about the shop floor level § If the aim is to learn, e. g. the following questions can be used as an interview scheme (Hopkins 2012, p. 134) § § Tell me about your job. What do you do? What could go wrong? What are the greatest dangers you face? Do you think we have these dangers sufficiently under control? Do you think there any safety issues here that we are not dealing with adequately? § Are there times when workers feel they need to take short cuts?

17. 3. 2018 Core processes of safety management § Management leadership & policy setting § Employee involvement § Risk and hazard identification and assessment § Hazard prevention and control § Education and training § Performance and measurement § Learning from experience § Continuous improvement & review 29

17. 3. 2018 Core processes of safety management § Management leadership & policy setting § Employee involvement § Risk and hazard identification and assessment § Hazard prevention and control § Education and training § Performance and measurement § Learning from experience § Continuous improvement & review 29

17. 3. 2018 30 Education and training – what needs to be taught (Roughton & Crutchfield 2014; Manuele 2013; Reiman 2015) § Special characteristics of the industry § The hazards that are inherent to the type of industry § Regulatory requirements § Lessons learned from past events § General hazards in any industry § Ways of identifying new hazards § Contents of the safety management system including core processes, instructions and organizing of work § Ways of working, in normal and in emergency situations § Ways of controlling the hazards § “Technical” training related to the field of industry § Work specific § General § Non-technical skills training § § Basic understanding of human factors and organizational behavior E. g. CRM, communication skills, leadership Pre-job briefings, job hazard analyses, and other tools First aid skills, extinguishing fires, etc.

17. 3. 2018 30 Education and training – what needs to be taught (Roughton & Crutchfield 2014; Manuele 2013; Reiman 2015) § Special characteristics of the industry § The hazards that are inherent to the type of industry § Regulatory requirements § Lessons learned from past events § General hazards in any industry § Ways of identifying new hazards § Contents of the safety management system including core processes, instructions and organizing of work § Ways of working, in normal and in emergency situations § Ways of controlling the hazards § “Technical” training related to the field of industry § Work specific § General § Non-technical skills training § § Basic understanding of human factors and organizational behavior E. g. CRM, communication skills, leadership Pre-job briefings, job hazard analyses, and other tools First aid skills, extinguishing fires, etc.

17. 3. 2018 Core processes of safety management § Management leadership & policy setting § Employee involvement § Risk and hazard identification and assessment § Hazard prevention and control § Education and training § Performance and measurement § Learning from experience § Continuous improvement & review 31

17. 3. 2018 Core processes of safety management § Management leadership & policy setting § Employee involvement § Risk and hazard identification and assessment § Hazard prevention and control § Education and training § Performance and measurement § Learning from experience § Continuous improvement & review 31

17. 3. 2018 32 Indicators § Safety cannot be measured directly, thus several ‘proxy’ measures are needed § Safety indicators can be categorized into leading and lagging indicators § Lagging indicators § Counts of negative events that have already taken place § E. g. Recordable Injury Rate (RIR), Lost Time Injury Frequency Rate (LTIFR), number of fatal accidents § “Safety as absence of incidents” § Leading indicators § Measure what people are doing daily to promote safety and prevent accidents § Management walkarounds, safety analyses conducted, etc § Try to measure safety as presence

17. 3. 2018 32 Indicators § Safety cannot be measured directly, thus several ‘proxy’ measures are needed § Safety indicators can be categorized into leading and lagging indicators § Lagging indicators § Counts of negative events that have already taken place § E. g. Recordable Injury Rate (RIR), Lost Time Injury Frequency Rate (LTIFR), number of fatal accidents § “Safety as absence of incidents” § Leading indicators § Measure what people are doing daily to promote safety and prevent accidents § Management walkarounds, safety analyses conducted, etc § Try to measure safety as presence

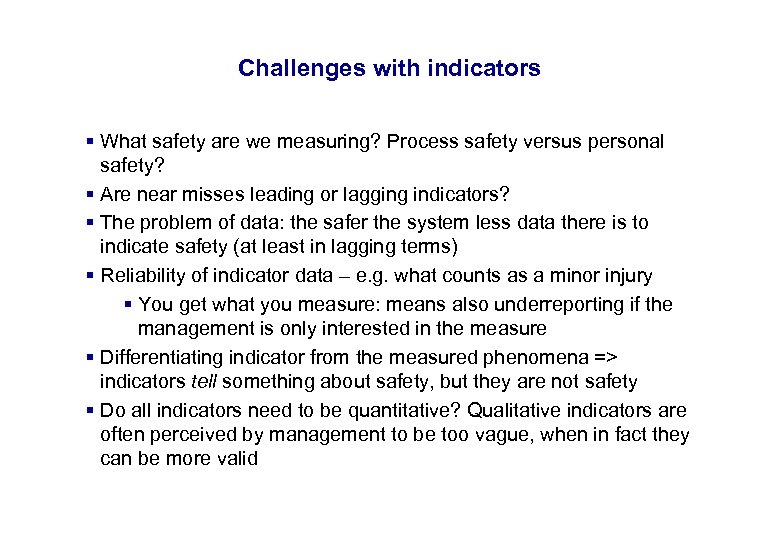

17. 3. 2018 33 Challenges with indicators § What safety are we measuring? Process safety versus personal safety? § Are near misses leading or lagging indicators? § The problem of data: the safer the system less data there is to indicate safety (at least in lagging terms) § Reliability of indicator data – e. g. what counts as a minor injury § You get what you measure: means also underreporting if the management is only interested in the measure § Differentiating indicator from the measured phenomena => indicators tell something about safety, but they are not safety § Do all indicators need to be quantitative? Qualitative indicators are often perceived by management to be too vague, when in fact they can be more valid

17. 3. 2018 33 Challenges with indicators § What safety are we measuring? Process safety versus personal safety? § Are near misses leading or lagging indicators? § The problem of data: the safer the system less data there is to indicate safety (at least in lagging terms) § Reliability of indicator data – e. g. what counts as a minor injury § You get what you measure: means also underreporting if the management is only interested in the measure § Differentiating indicator from the measured phenomena => indicators tell something about safety, but they are not safety § Do all indicators need to be quantitative? Qualitative indicators are often perceived by management to be too vague, when in fact they can be more valid

17. 3. 2018 Core processes of safety management § Management leadership & policy setting § Employee involvement § Risk and hazard identification and assessment § Hazard prevention and control § Education and training § Performance and measurement § Learning from experience § Continuous improvement & review 34

17. 3. 2018 Core processes of safety management § Management leadership & policy setting § Employee involvement § Risk and hazard identification and assessment § Hazard prevention and control § Education and training § Performance and measurement § Learning from experience § Continuous improvement & review 34

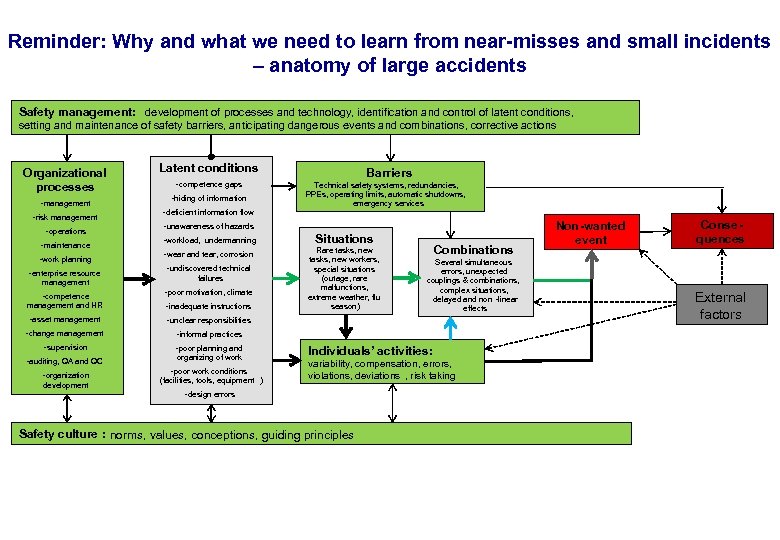

17. 3. 2018 35 Reminder: Why and what we need to learn from near-misses and small incidents – anatomy of large accidents Safety management: development of processes and technology, identification and control of latent conditions, setting and maintenance of safety barriers, anticipating dangerous events and combinations, corrective actions Organizational processes -management -risk management -operations -maintenance -work planning -enterprise resource management -competence management and HR -asset management Latent conditions -competence gaps -hiding of information Barriers Technical safety systems, redundancies, PPEs, operating limits, automatic shutdowns, emergency services -deficient information flow -unawareness of hazards -workload, undermanning -wear and tear, corrosion -undiscovered technical failures -poor motivation, climate -inadequate instructions Situations Rare tasks, new workers, special situations (outage, rare malfunctions, extreme weather, flu season) Combinations Several simultaneous errors, unexpected couplings & combinations, complex situations, delayed and non -linear effects -unclear responsibilities -change management -informal practices -supervision -poor planning and organizing of work -auditing, QA and QC -organization development -poor work conditions (facilities, tools, equipment ) Individuals’ activities: variability, compensation, errors, violations, deviations , risk taking -design errors Safety culture : norms, values, conceptions, guiding principles Non-wanted event Conse quences External factors

17. 3. 2018 35 Reminder: Why and what we need to learn from near-misses and small incidents – anatomy of large accidents Safety management: development of processes and technology, identification and control of latent conditions, setting and maintenance of safety barriers, anticipating dangerous events and combinations, corrective actions Organizational processes -management -risk management -operations -maintenance -work planning -enterprise resource management -competence management and HR -asset management Latent conditions -competence gaps -hiding of information Barriers Technical safety systems, redundancies, PPEs, operating limits, automatic shutdowns, emergency services -deficient information flow -unawareness of hazards -workload, undermanning -wear and tear, corrosion -undiscovered technical failures -poor motivation, climate -inadequate instructions Situations Rare tasks, new workers, special situations (outage, rare malfunctions, extreme weather, flu season) Combinations Several simultaneous errors, unexpected couplings & combinations, complex situations, delayed and non -linear effects -unclear responsibilities -change management -informal practices -supervision -poor planning and organizing of work -auditing, QA and QC -organization development -poor work conditions (facilities, tools, equipment ) Individuals’ activities: variability, compensation, errors, violations, deviations , risk taking -design errors Safety culture : norms, values, conceptions, guiding principles Non-wanted event Conse quences External factors

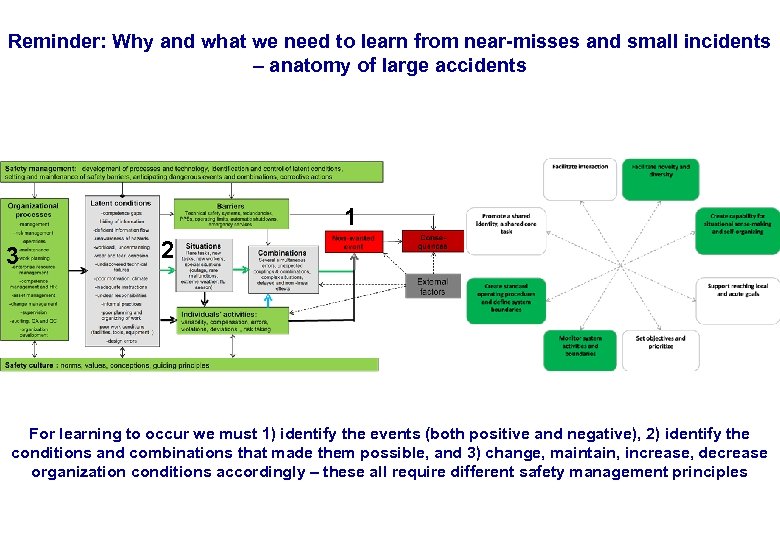

17. 3. 2018 36 Reminder: Why and what we need to learn from near-misses and small incidents – anatomy of large accidents 1 3 2 For learning to occur we must 1) identify the events (both positive and negative), 2) identify the conditions and combinations that made them possible, and 3) change, maintain, increase, decrease organization conditions accordingly – these all require different safety management principles

17. 3. 2018 36 Reminder: Why and what we need to learn from near-misses and small incidents – anatomy of large accidents 1 3 2 For learning to occur we must 1) identify the events (both positive and negative), 2) identify the conditions and combinations that made them possible, and 3) change, maintain, increase, decrease organization conditions accordingly – these all require different safety management principles

17. 3. 2018 Core processes of safety management § Management leadership & policy setting § Employee involvement § Risk and hazard identification and assessment § Hazard prevention and control § Education and training § Performance and measurement § Learning from experience § Continuous improvement & review 37

17. 3. 2018 Core processes of safety management § Management leadership & policy setting § Employee involvement § Risk and hazard identification and assessment § Hazard prevention and control § Education and training § Performance and measurement § Learning from experience § Continuous improvement & review 37

17. 3. 2018 38 Continuous improvement and organizational review § External assessments, third-party assessments § Of the management system (audits, management review) § Of culture § Of some specific issue of interest § Internal assessments, self-assessments § Of the management system § Of culture § Of some specific issue of interest

17. 3. 2018 38 Continuous improvement and organizational review § External assessments, third-party assessments § Of the management system (audits, management review) § Of culture § Of some specific issue of interest § Internal assessments, self-assessments § Of the management system § Of culture § Of some specific issue of interest

17. 3. 2018 39 Why conduct regular self-assessment and independent organizational assessments? Hazards, risks and work requirements are not always obvious Safety is often taken-for-granted but not defined, or measured very simplistically The existing culture at the organization influences how risks are perceived and what means are considered for achieving safety Culture, environment, technology, people constantly change ÞThe main reason for conducting organizational evaluations is the tendency of an organization to gradually drift into a condition where it has trouble identifying its vulnerabilities and mechanisms or practices that create or maintain these vulnerabilities (cf. Snook 2000, Rasmussen 1997) ÞBasic assumptions get stronger and more unconscious as time goes by, and at the same time espoused values, the self-image, may become disconnected and overly positive (Schein 2010, p. 289)

17. 3. 2018 39 Why conduct regular self-assessment and independent organizational assessments? Hazards, risks and work requirements are not always obvious Safety is often taken-for-granted but not defined, or measured very simplistically The existing culture at the organization influences how risks are perceived and what means are considered for achieving safety Culture, environment, technology, people constantly change ÞThe main reason for conducting organizational evaluations is the tendency of an organization to gradually drift into a condition where it has trouble identifying its vulnerabilities and mechanisms or practices that create or maintain these vulnerabilities (cf. Snook 2000, Rasmussen 1997) ÞBasic assumptions get stronger and more unconscious as time goes by, and at the same time espoused values, the self-image, may become disconnected and overly positive (Schein 2010, p. 289)

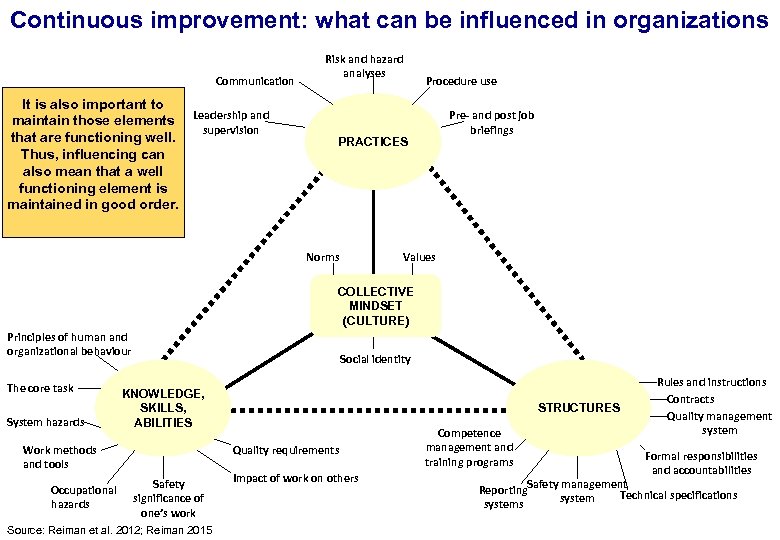

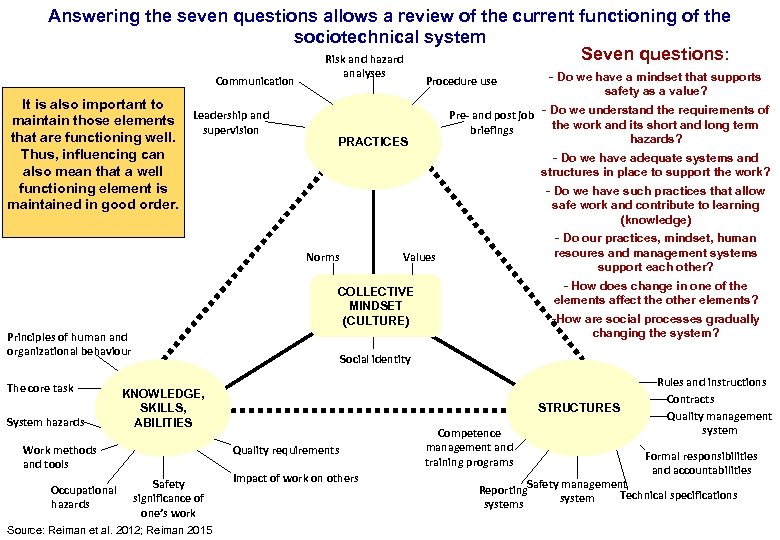

Continuous improvement: what can be influenced in organizations 17. 3. 2018 Communication It is also important to maintain those elements that are functioning well. Thus, influencing can also mean that a well functioning element is maintained in good order. Leadership and supervision Risk and hazard analyses Procedure use Pre- and post job briefings PRACTICES Norms 40 Values COLLECTIVE MINDSET (CULTURE) Principles of human and organizational behaviour The core task System hazards Social identity KNOWLEDGE, SKILLS, ABILITIES Work methods and tools Occupational hazards STRUCTURES Quality requirements Safety significance of one’s work Source: Reiman et al. 2012; Reiman 2015 Impact of work on others Competence management and training programs Rules and instructions Contracts Quality management system Formal responsibilities and accountabilities Reporting. Safety management Technical specifications systems

Continuous improvement: what can be influenced in organizations 17. 3. 2018 Communication It is also important to maintain those elements that are functioning well. Thus, influencing can also mean that a well functioning element is maintained in good order. Leadership and supervision Risk and hazard analyses Procedure use Pre- and post job briefings PRACTICES Norms 40 Values COLLECTIVE MINDSET (CULTURE) Principles of human and organizational behaviour The core task System hazards Social identity KNOWLEDGE, SKILLS, ABILITIES Work methods and tools Occupational hazards STRUCTURES Quality requirements Safety significance of one’s work Source: Reiman et al. 2012; Reiman 2015 Impact of work on others Competence management and training programs Rules and instructions Contracts Quality management system Formal responsibilities and accountabilities Reporting. Safety management Technical specifications systems

41 17. 3. 2018 Answering the seven questions allows a review of the current functioning of the sociotechnical system Seven questions: Risk and hazard analyses Communication It is also important to maintain those elements that are functioning well. Thus, influencing can also mean that a well functioning element is maintained in good order. Leadership and supervision PRACTICES Norms Values COLLECTIVE MINDSET (CULTURE) Principles of human and organizational behaviour The core task System hazards Social identity KNOWLEDGE, SKILLS, ABILITIES Work methods and tools Occupational hazards - Do we have a mindset that supports safety as a value? Pre- and post job - Do we understand the requirements of the work and its short and long term briefings hazards? - Do we have adequate systems and structures in place to support the work? - Do we have such practices that allow safe work and contribute to learning (knowledge) - Do our practices, mindset, human resoures and management systems support each other? - How does change in one of the elements affect the other elements? -How are social processes gradually changing the system? Procedure use STRUCTURES Quality requirements Safety significance of one’s work Source: Reiman et al. 2012; Reiman 2015 Impact of work on others Competence management and training programs Rules and instructions Contracts Quality management system Formal responsibilities and accountabilities Reporting. Safety management Technical specifications systems

41 17. 3. 2018 Answering the seven questions allows a review of the current functioning of the sociotechnical system Seven questions: Risk and hazard analyses Communication It is also important to maintain those elements that are functioning well. Thus, influencing can also mean that a well functioning element is maintained in good order. Leadership and supervision PRACTICES Norms Values COLLECTIVE MINDSET (CULTURE) Principles of human and organizational behaviour The core task System hazards Social identity KNOWLEDGE, SKILLS, ABILITIES Work methods and tools Occupational hazards - Do we have a mindset that supports safety as a value? Pre- and post job - Do we understand the requirements of the work and its short and long term briefings hazards? - Do we have adequate systems and structures in place to support the work? - Do we have such practices that allow safe work and contribute to learning (knowledge) - Do our practices, mindset, human resoures and management systems support each other? - How does change in one of the elements affect the other elements? -How are social processes gradually changing the system? Procedure use STRUCTURES Quality requirements Safety significance of one’s work Source: Reiman et al. 2012; Reiman 2015 Impact of work on others Competence management and training programs Rules and instructions Contracts Quality management system Formal responsibilities and accountabilities Reporting. Safety management Technical specifications systems

17. 3. 2018 Other important processes / functions § Management of change § Organizing of work § Supply chain management / management of contractor safety § Emergency management / contingency management § Configuration management § Safety case management § Risk management § Etc. => integrated management system 42

17. 3. 2018 Other important processes / functions § Management of change § Organizing of work § Supply chain management / management of contractor safety § Emergency management / contingency management § Configuration management § Safety case management § Risk management § Etc. => integrated management system 42

17. 3. 2018 43 Global trends affect safety and its management § Trends in work § § § Increase in flexi-work and remote work Increase in temporary work Increase in the autonomy of work for the highly educated Fragmentation of work tasks – specialization to specific aspects of job, not to the entire job Changes in the type of industry in Finland – from heavy industry to knowledge industry § Trends in the society § § § Ageing workforce Globalization Economic shifts, from depression to economic boost to depression again Smart phones, tablets etc make people and information available and usable 24/7 New technological innovations Concentrations of energy, people and power (Perrow 2007) § Trends in management § Increased use of subcontractors § Specialization § Management fads

17. 3. 2018 43 Global trends affect safety and its management § Trends in work § § § Increase in flexi-work and remote work Increase in temporary work Increase in the autonomy of work for the highly educated Fragmentation of work tasks – specialization to specific aspects of job, not to the entire job Changes in the type of industry in Finland – from heavy industry to knowledge industry § Trends in the society § § § Ageing workforce Globalization Economic shifts, from depression to economic boost to depression again Smart phones, tablets etc make people and information available and usable 24/7 New technological innovations Concentrations of energy, people and power (Perrow 2007) § Trends in management § Increased use of subcontractors § Specialization § Management fads

17. 3. 2018 Final lecture § START 16. 30 § Short summary § Brief status report of the final papers § Feedback 44

17. 3. 2018 Final lecture § START 16. 30 § Short summary § Brief status report of the final papers § Feedback 44

17. 3. 2018 45 References § § § § § Amalberti, R. (2013). Navigating safety. Necessary compromises and trade-offs – Theory and practice. Springer. Aven, T. (2010). Misconceptions of risk. Wiley. Dekker S. (2014). The field guide to understanding ‘human error’. Third edition. Farnham: Ashgate. DOE. (2009). Human performance improvement handbook. Volume 2: human performance tools for individuals, work teams, and management. DOE-HDBK-1028 -2009. Hardy, T. L. (2014). The system safety skeptic. Lessons learned in safety management and engineering. Second edition. Book. Locker. Hollnagel, E. (2014). Safety-I and safety-II: The past and future of safety management. Ashgate. Hopkins, A. (2009). Thinking about process safety indicators. Safety Science 47, 460 -465. Manuele FA. (2013). On the practice of safety. Fourth edition. New Jersey: John Wiley & Sons. Perrow, C. (2007). The next catastrophe. Reducing our vulnerabilities to natural, industrial, and terrorist disasters. New Jersey: Princeton University Press. Rasmussen, J. (1997). Risk management in a dynamic society: A modelling problem. Safety Science, 27, 183 -213. Reiman, T. (2015). Turvallisuusasiantuntijoiden roolit, toimintatavat ja tarvittavat kyvyt ja taidot. VTT Technology 198. Espoo, VTT. Reiman, T. , Pietikäinen, E. , Oedewald, P. , & Gotcheva, N. (2012). System modeling with the DISC framework: evidence from safety-critical domains. Work, 41, 3018 -3025. Reiman, T. & Pietikäinen, E. (2014). Organizational safety professionals’ work roles and safety management principles based on an in-depth study of nine safety professionals’ work in three companies. Workingonsafety. net, 7 th international conference, 30 September - 03 October 2014, Glasgow, Scotland, UK. Reiman, T. , Rollenhagen, C. , Pietikäinen, E. & Heikkilä, J. (2015). Principles of adaptive management in complex safety critical organizations. Safety Science 71, 80 -92. Roughton, J. & Crutchfield, N. (2014). Safety culture. An innovative leadership approach. Oxford: Butterworth-Heinemann. Snook, S. A. (2000). Friendly fire. The accidental shootdown of U. S. Black Hawks over Northern Iraq. New Jersey: Princeton University Press. Sagan, S. D. (1993). The limits of safety. Organizations, accidents, and nuclear weapons. Princeton University Press. Schein, E. H. (2010). Organizational culture and leadership. 4 th Edition. Jossey-Bass: San Francisco.

17. 3. 2018 45 References § § § § § Amalberti, R. (2013). Navigating safety. Necessary compromises and trade-offs – Theory and practice. Springer. Aven, T. (2010). Misconceptions of risk. Wiley. Dekker S. (2014). The field guide to understanding ‘human error’. Third edition. Farnham: Ashgate. DOE. (2009). Human performance improvement handbook. Volume 2: human performance tools for individuals, work teams, and management. DOE-HDBK-1028 -2009. Hardy, T. L. (2014). The system safety skeptic. Lessons learned in safety management and engineering. Second edition. Book. Locker. Hollnagel, E. (2014). Safety-I and safety-II: The past and future of safety management. Ashgate. Hopkins, A. (2009). Thinking about process safety indicators. Safety Science 47, 460 -465. Manuele FA. (2013). On the practice of safety. Fourth edition. New Jersey: John Wiley & Sons. Perrow, C. (2007). The next catastrophe. Reducing our vulnerabilities to natural, industrial, and terrorist disasters. New Jersey: Princeton University Press. Rasmussen, J. (1997). Risk management in a dynamic society: A modelling problem. Safety Science, 27, 183 -213. Reiman, T. (2015). Turvallisuusasiantuntijoiden roolit, toimintatavat ja tarvittavat kyvyt ja taidot. VTT Technology 198. Espoo, VTT. Reiman, T. , Pietikäinen, E. , Oedewald, P. , & Gotcheva, N. (2012). System modeling with the DISC framework: evidence from safety-critical domains. Work, 41, 3018 -3025. Reiman, T. & Pietikäinen, E. (2014). Organizational safety professionals’ work roles and safety management principles based on an in-depth study of nine safety professionals’ work in three companies. Workingonsafety. net, 7 th international conference, 30 September - 03 October 2014, Glasgow, Scotland, UK. Reiman, T. , Rollenhagen, C. , Pietikäinen, E. & Heikkilä, J. (2015). Principles of adaptive management in complex safety critical organizations. Safety Science 71, 80 -92. Roughton, J. & Crutchfield, N. (2014). Safety culture. An innovative leadership approach. Oxford: Butterworth-Heinemann. Snook, S. A. (2000). Friendly fire. The accidental shootdown of U. S. Black Hawks over Northern Iraq. New Jersey: Princeton University Press. Sagan, S. D. (1993). The limits of safety. Organizations, accidents, and nuclear weapons. Princeton University Press. Schein, E. H. (2010). Organizational culture and leadership. 4 th Edition. Jossey-Bass: San Francisco.