bc527177623eab27b763a74c5f6cb164.ppt

- Количество слайдов: 37

Toner Transfer Method for PCBs One ham’s first attempts to make PCBs at home Jim Larsen, AL 7 FS 907 -345 -3190 AL 7 FS@AL 7 FS. us QRP Ver 1. 0 3/22/06 By Jim Larsen, AL 7 FS 1

Overview of Toner Transfer PCBs • • • QRP First attempts at Printed Circuit Boards What is toner transfer method? My approach to toner transfer Drawing the Schematic Converting to a PCB layout Preparing the Board, Laying down the Toner Removing the Paper; Leaving the Toner Etching the Board, cleanup and solder coat Drilling, shearing and building Comments and Suggestions 2

First Attempts at PCBs • Early years – sticky labels cut with a sharp blade • Sharpie permanent ink pens for resist • Results worked but were pretty simple and crude QRP 3

PCBs via Toner Transfer (TT) Why even build my own boards? Seemed like fun. Cost can be low. For over 40 years complex Boards stopped me. Manhattan Style building is good but I never seem to get started. Front-end load the hard work; finish with fun. So What is Toner Transfer Method? ? QRP 4

Toner Transfer Method • A method of creating a printed circuit board (PCB) using a copy machine or a laser printer to make apply the etchant resist pattern • Software now available to create schematic and PCB layout • No expensive equipment is required but can be helpful in the home • A simple process once the basics are mastered QRP 5

AL 7 FS Approach Equipment in the Toner Transfer Process • A computer • Free Demo Software – Up to 250 pins • Laser Printer or Copier • Various dishes for soaking or etching • A household iron or a laminator • Tarn-X, soap, scrubber, Acetone cleaner, surgical gloves, • Drill Press • Carbide drill bits • Shear or other method for cutting PCB QRP 6

AL 7 FS Approach Equipment in the Toner Transfer Process • A computer – Already had a computer • Free Demo Software – Dip. Trace demo version • Laser Printer or Copier – Decided to Buy Printer • Various dishes - Already had on hand • A household iron or a laminator – Laminator-e. Bay • Tarn-X, soap, scrubber, Acetone cleaner, surgical gloves – Had all but the scrubber • Drill Press – Decided to buy a small one • Carbide drill bits – Bought via e. Bay • Shear or other method for cutting PCB – Will use a friend’s shear QRP 7

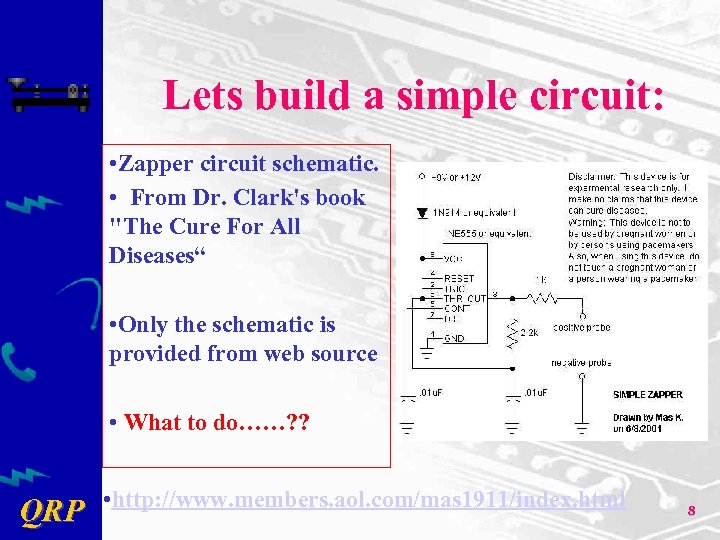

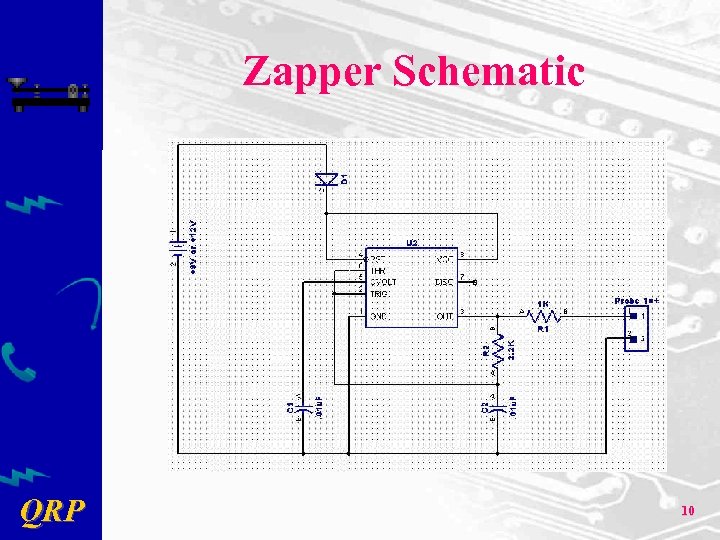

Lets build a simple circuit: • Zapper circuit schematic. • From Dr. Clark's book "The Cure For All Diseases“ • Only the schematic is provided from web source • What to do……? ? QRP • http: //www. members. aol. com/mas 1911/index. html 8

Dip Trace – Draw the Schematic http: //www. diptrace. com/ Diptrace has a Free Version: Freeware edition does not support export to DXF, Gerber and N/C Drill, max. number of pins — 250. QRP 9

Zapper Schematic QRP 10

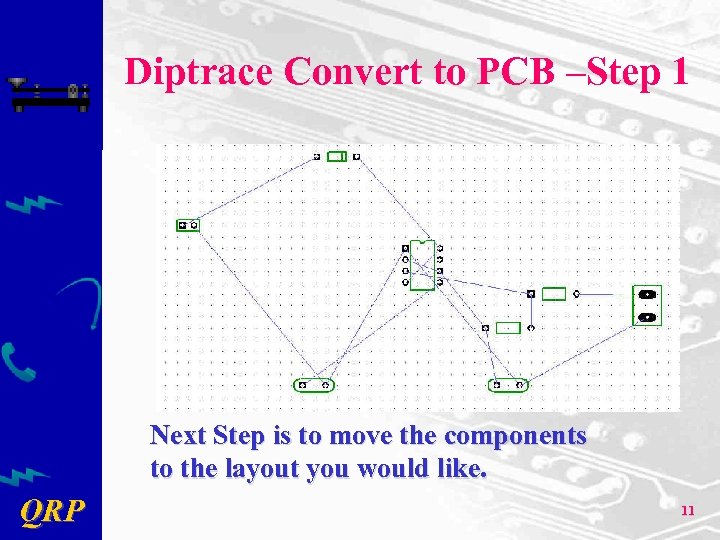

Diptrace Convert to PCB –Step 1 Next Step is to move the components to the layout you would like. QRP 11

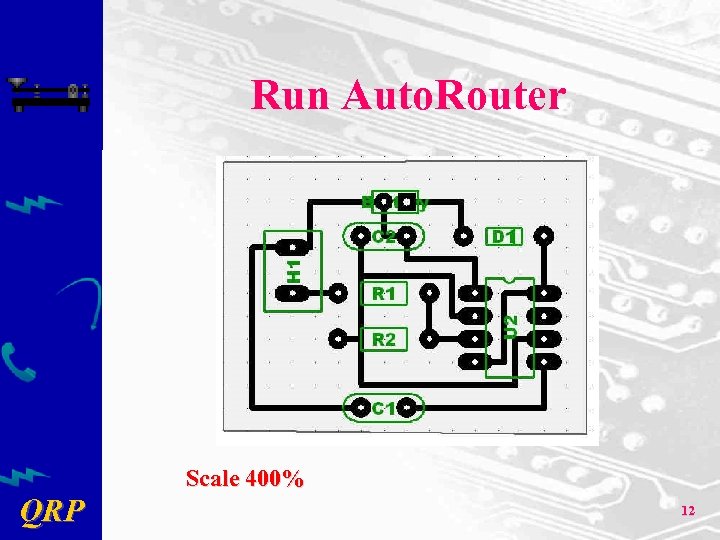

Run Auto. Router QRP Scale 400% 12

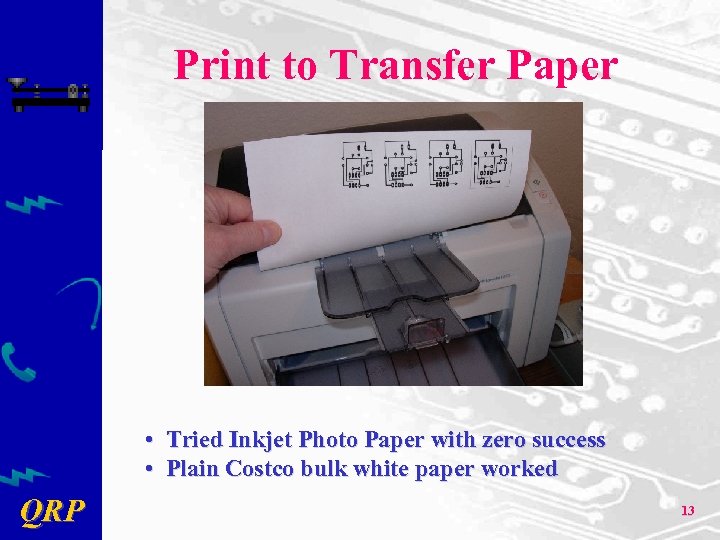

Print to Transfer Paper • Tried Inkjet Photo Paper with zero success • Plain Costco bulk white paper worked QRP 13

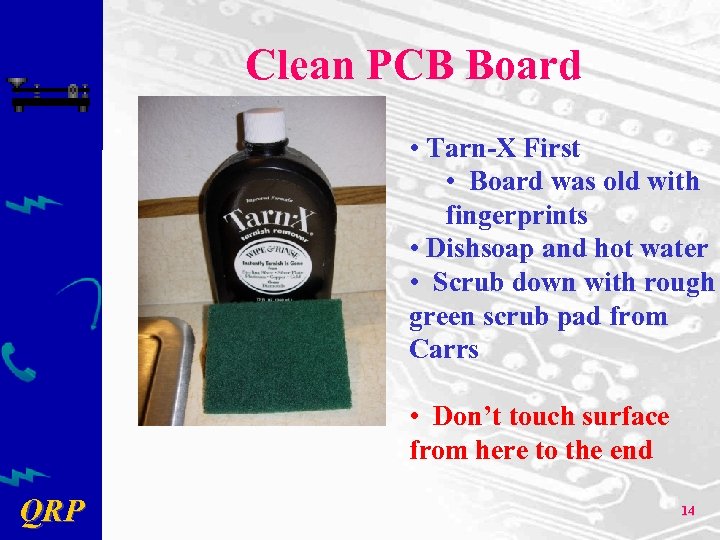

Clean PCB Board • Tarn-X First • Board was old with fingerprints • Dishsoap and hot water • Scrub down with rough green scrub pad from Carrs • Don’t touch surface from here to the end QRP 14

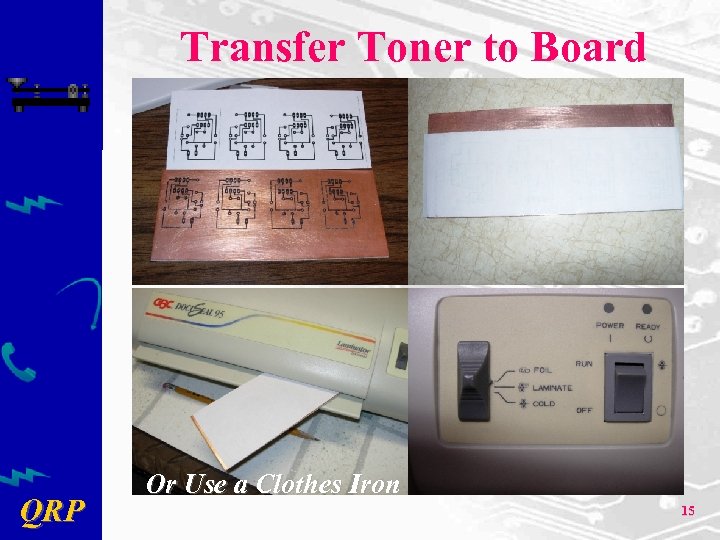

Transfer Toner to Board QRP Or Use a Clothes Iron 15

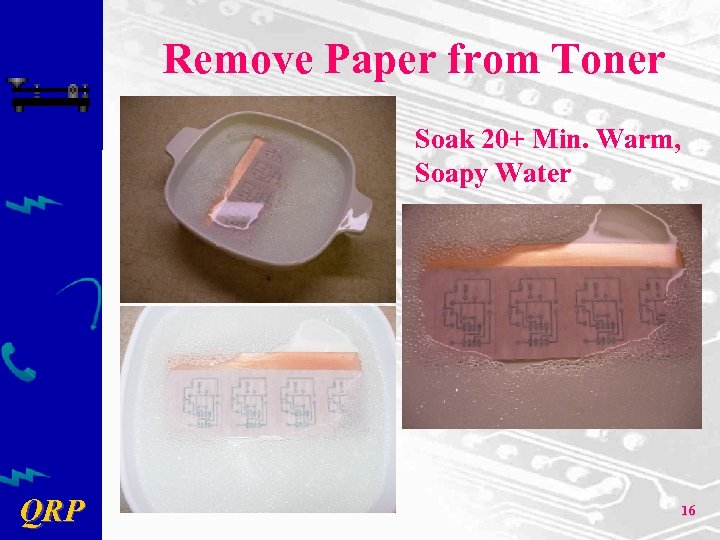

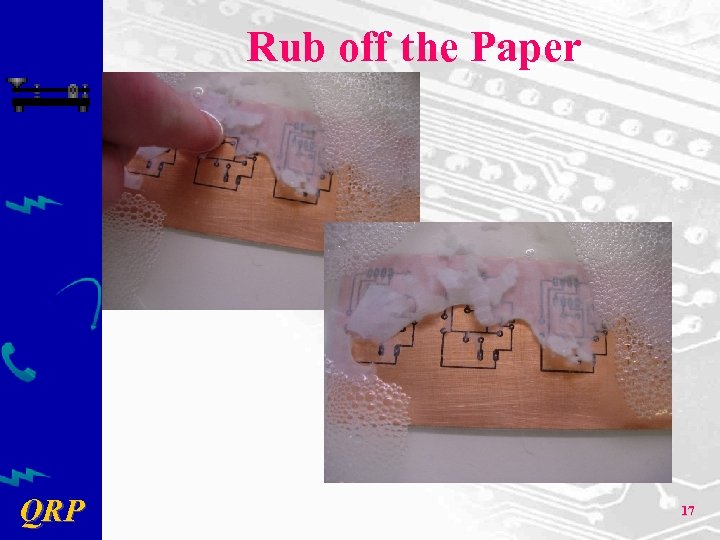

Remove Paper from Toner Soak 20+ Min. Warm, Soapy Water QRP 16

Rub off the Paper QRP 17

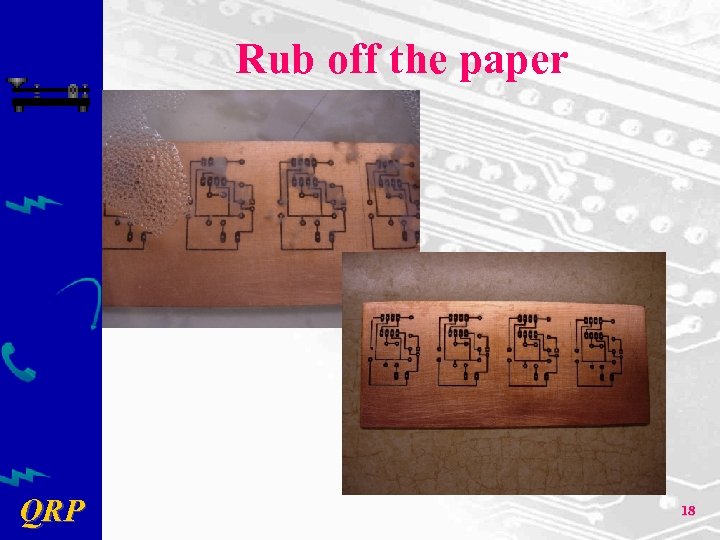

Rub off the paper QRP 18

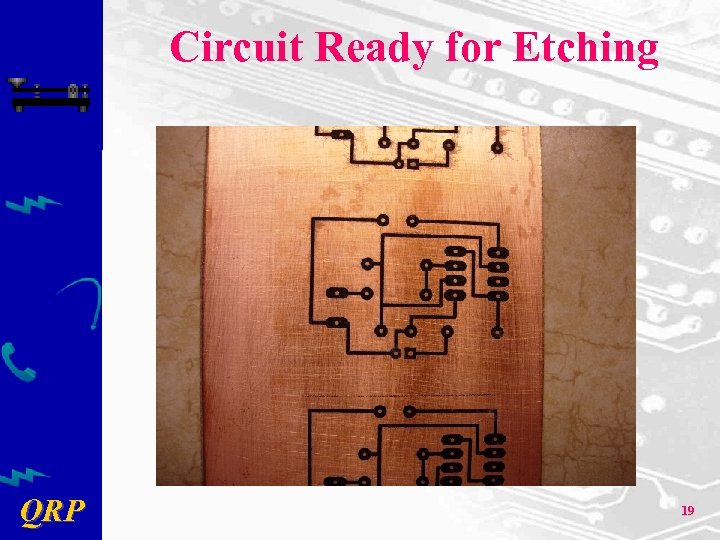

Circuit Ready for Etching QRP 19

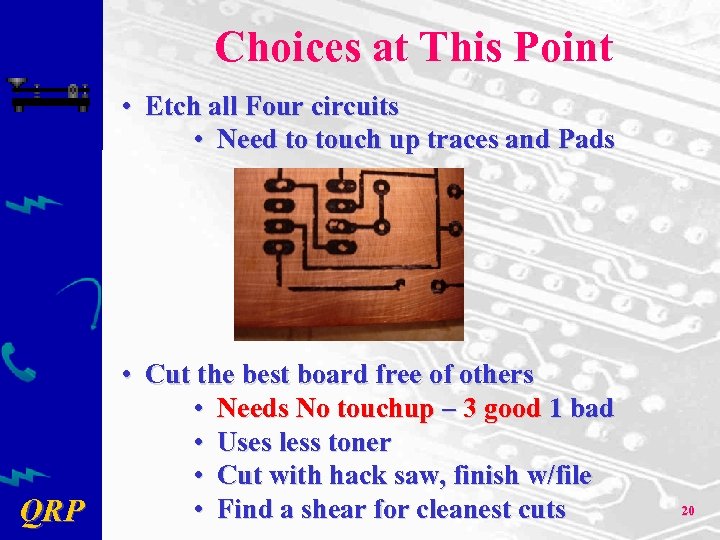

Choices at This Point • Etch all Four circuits • Need to touch up traces and Pads QRP • Cut the best board free of others • Needs No touchup – 3 good 1 bad • Uses less toner • Cut with hack saw, finish w/file • Find a shear for cleanest cuts 20

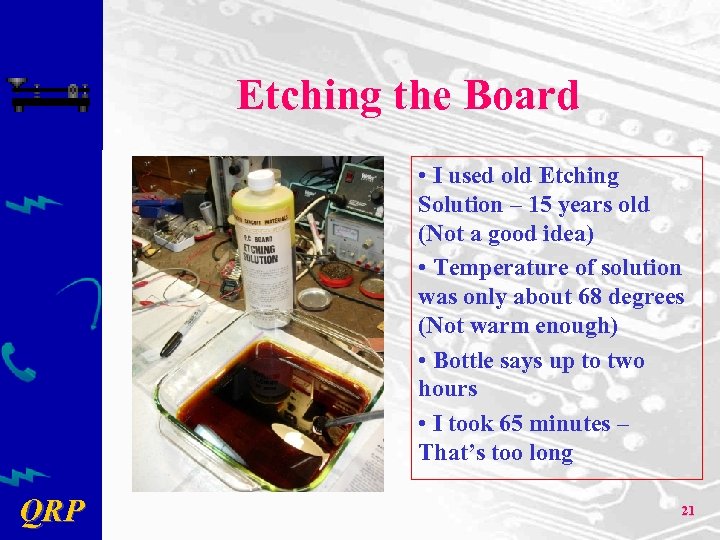

Etching the Board • I used old Etching Solution – 15 years old (Not a good idea) • Temperature of solution was only about 68 degrees (Not warm enough) • Bottle says up to two hours • I took 65 minutes – That’s too long QRP 21

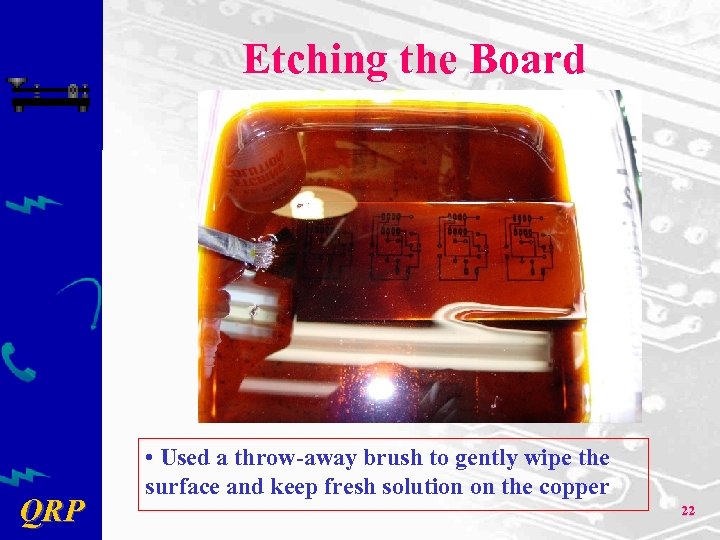

Etching the Board QRP • Used a throw-away brush to gently wipe the surface and keep fresh solution on the copper 22

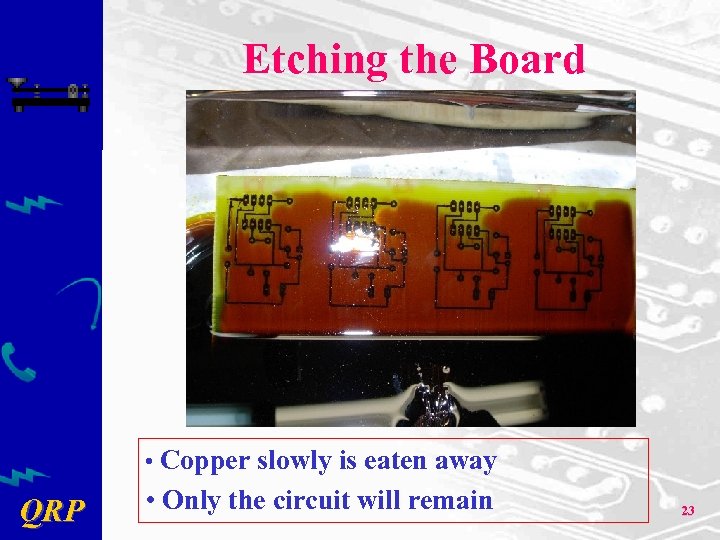

Etching the Board • Copper slowly is eaten away QRP • Only the circuit will remain 23

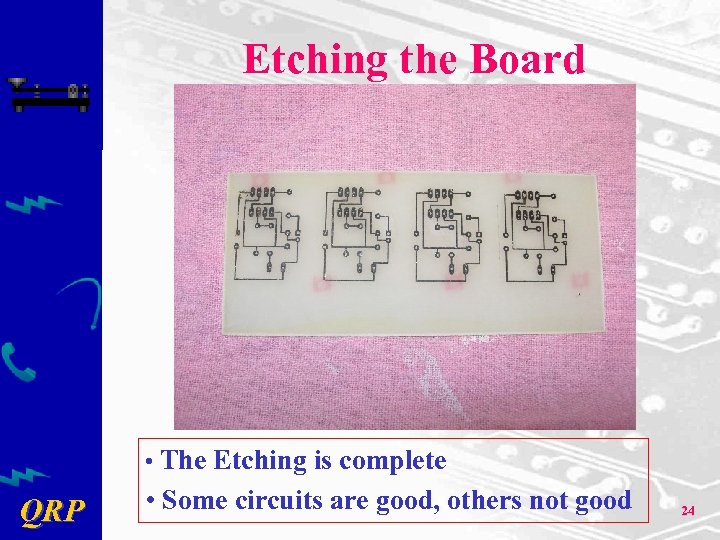

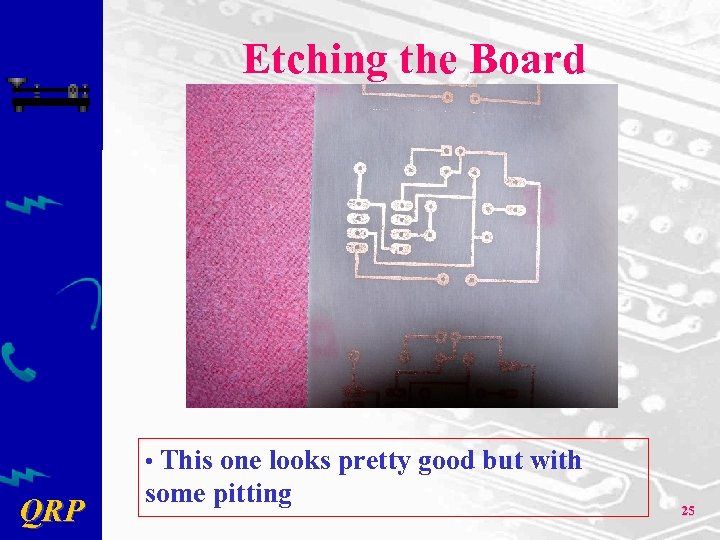

Etching the Board • The Etching is complete QRP • Some circuits are good, others not good 24

Etching the Board • This one looks pretty good but with QRP some pitting 25

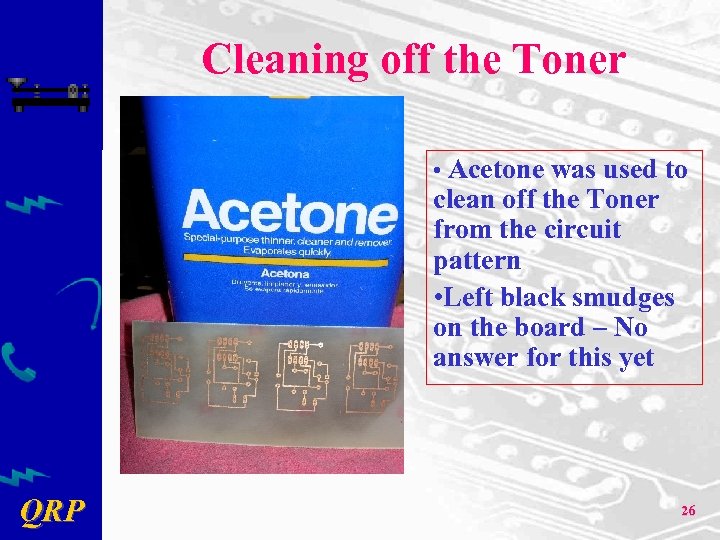

Cleaning off the Toner • Acetone was used to clean off the Toner from the circuit pattern • Left black smudges on the board – No answer for this yet QRP 26

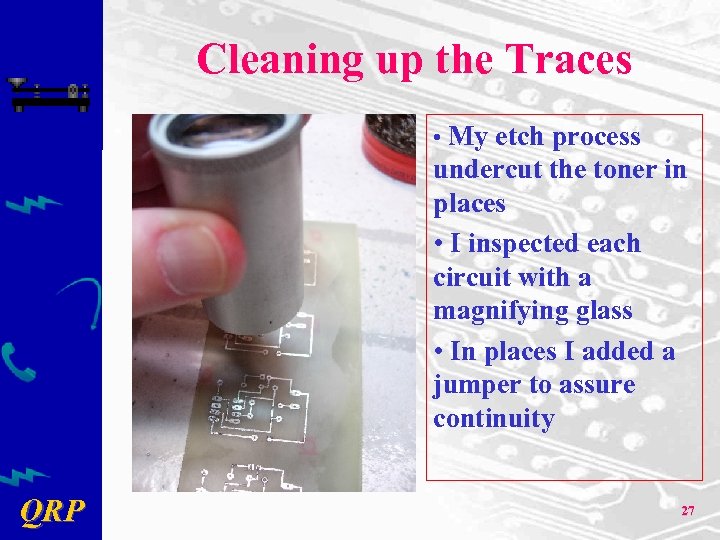

Cleaning up the Traces • My etch process undercut the toner in places • I inspected each circuit with a magnifying glass • In places I added a jumper to assure continuity QRP 27

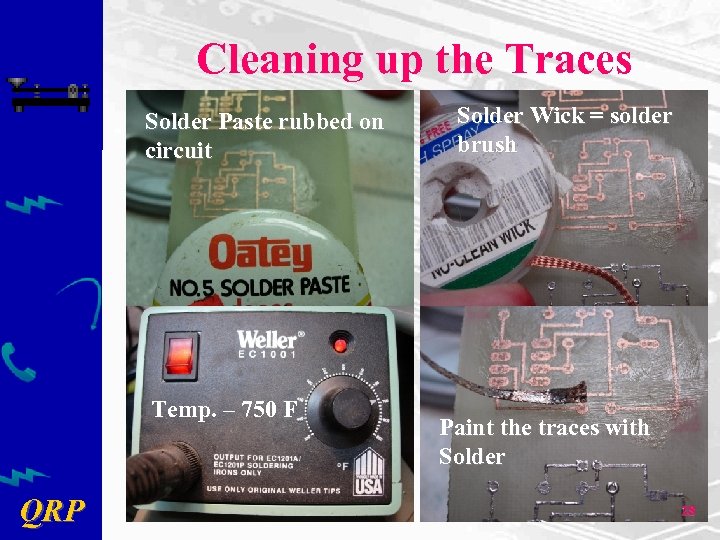

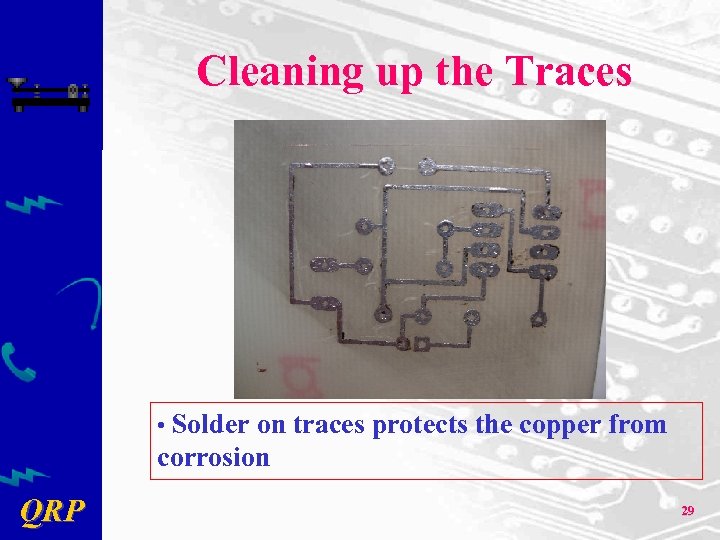

Cleaning up the Traces Solder Paste rubbed on circuit Temp. – 750 F QRP Solder Wick = solder brush Paint the traces with Solder 28

Cleaning up the Traces • Solder on traces protects the copper from corrosion QRP 29

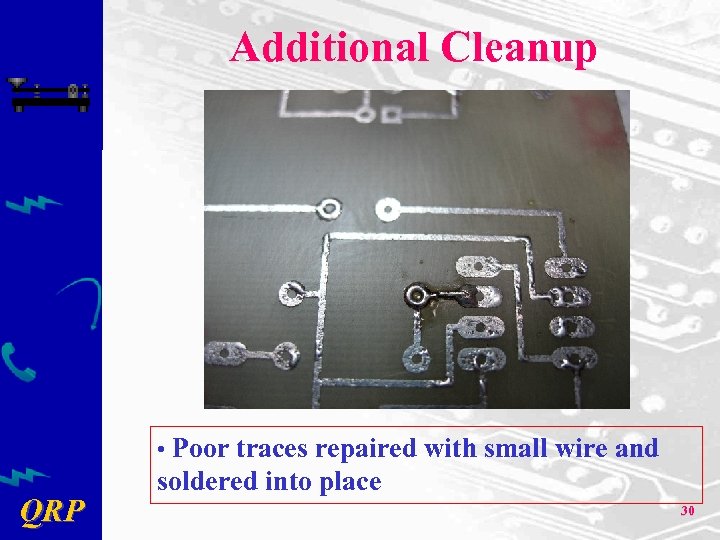

Additional Cleanup • Poor traces repaired with small wire and QRP soldered into place 30

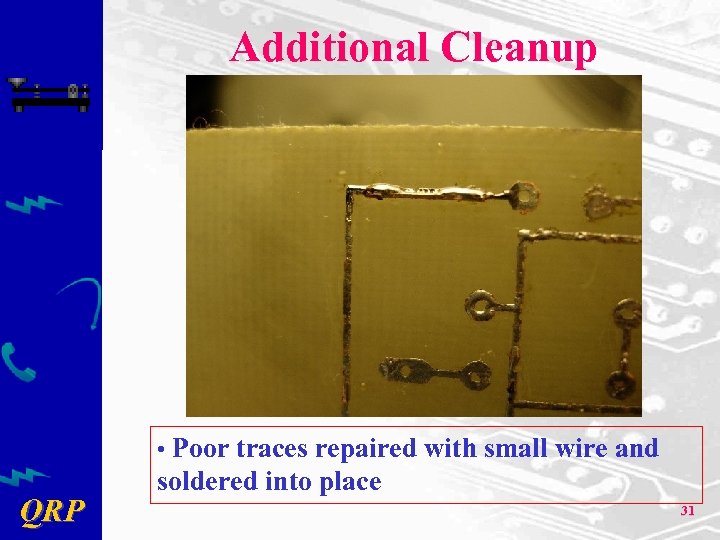

Additional Cleanup • Poor traces repaired with small wire and QRP soldered into place 31

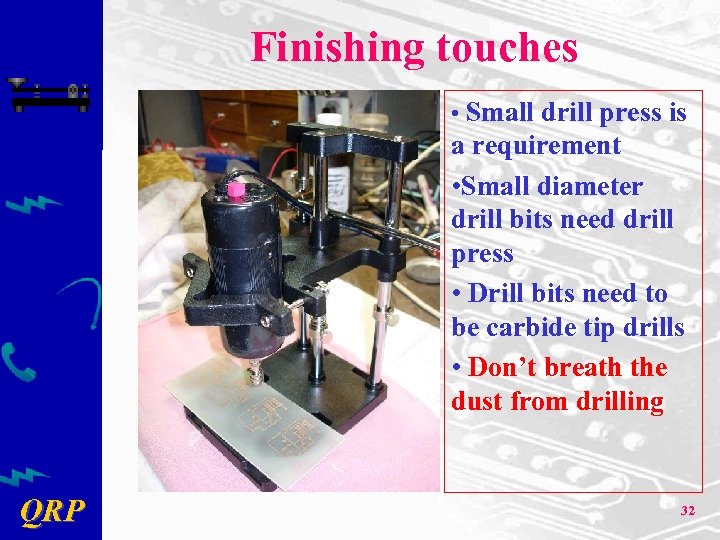

Finishing touches • Small drill press is a requirement • Small diameter drill bits need drill press • Drill bits need to be carbide tip drills • Don’t breath the dust from drilling QRP 32

Final Touches • May Use toner transfer method again to add component outlines on the top of the board. Can use household iron or laminator to fix the toner • Solder in the components • Test the circuit • Install in a chassis as desired QRP 33

Final Comments • This is my first attempt at toner transfer. • I offer my observations as a learning tool • I plan to keep trying new techniques • There are Many variations on this technique • Board cleaning methods used by me not best. (e. g. , the acetone black smears) • My etching technique undercut some traces (Needs major improvement) • Great potential with this technique QRP Give it a try Yourself !! 34

Links for Toner Transfer • http: //www. diptrace. com/ Home. Page for Dip. Trace software • http: //groups. yahoo. com/group/diptr/ Mail List for Dip. Trace • http: //groups. yahoo. com/group/Homebrew_PCBs Mail List for homebrew PCBs • http: //max 8888. orcon. net. nz/pcbs. htm another step by step example • http: //www. Google. com/ search on “toner transfer method” QRP 35

Alaska QRP Club • No officers, no directors, no constitution & No dues. • Meets the Third Friday of every month - 7: 00 PM (Some show for dinner at 6 PM) • Meet at Dennys (in the back room) on De. Barr near Bragaw. • Contact is Jim Larsen, AL 7 FS, 907 -345 -3190. AL 7 FS@AL 7 FS. us • http: //www. qsl. net/kl 7 aqc/ QRP 36

Questions? QRP 37

bc527177623eab27b763a74c5f6cb164.ppt