63e99baa2de57f31c8690fae3fea1c78.ppt

- Количество слайдов: 27

TM SM Maximum Value for OEMs NXIO Platform from “OEMax NXIO Introduction CN rev 4. ppt” “OEMax Thomas Sugimoto Strategic Marketing Manager Maximum Value for OEMs SM

TM SM Maximum Value for OEMs NXIO Platform from “OEMax NXIO Introduction CN rev 4. ppt” “OEMax Thomas Sugimoto Strategic Marketing Manager Maximum Value for OEMs SM

Outline PLC I/O Market Trends Birth of Distributed I/O NXIO 2 nd Generation Distributed I/O Product Features Target Market How to use NXIO to reduce costs Internal Quality 2

Outline PLC I/O Market Trends Birth of Distributed I/O NXIO 2 nd Generation Distributed I/O Product Features Target Market How to use NXIO to reduce costs Internal Quality 2

PLC I/O Trends 3

PLC I/O Trends 3

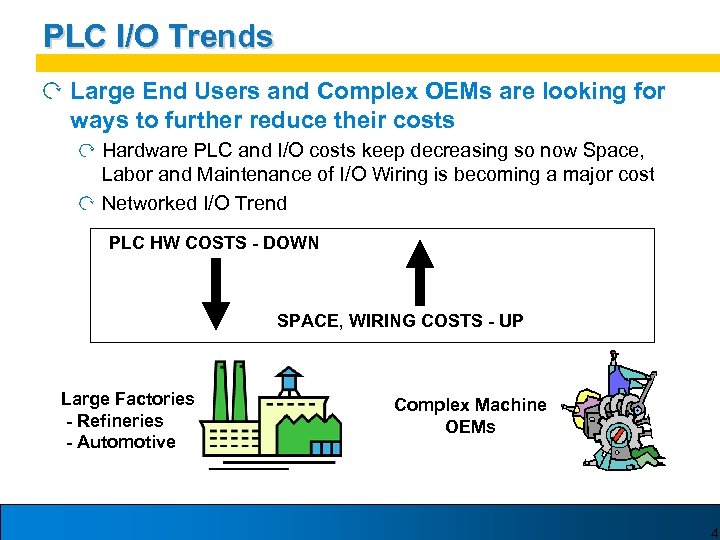

PLC I/O Trends Large End Users and Complex OEMs are looking for ways to further reduce their costs Hardware PLC and I/O costs keep decreasing so now Space, Labor and Maintenance of I/O Wiring is becoming a major cost Networked I/O Trend PLC HW COSTS - DOWN SPACE, WIRING COSTS - UP Large Factories - Refineries - Automotive Complex Machine OEMs 4

PLC I/O Trends Large End Users and Complex OEMs are looking for ways to further reduce their costs Hardware PLC and I/O costs keep decreasing so now Space, Labor and Maintenance of I/O Wiring is becoming a major cost Networked I/O Trend PLC HW COSTS - DOWN SPACE, WIRING COSTS - UP Large Factories - Refineries - Automotive Complex Machine OEMs 4

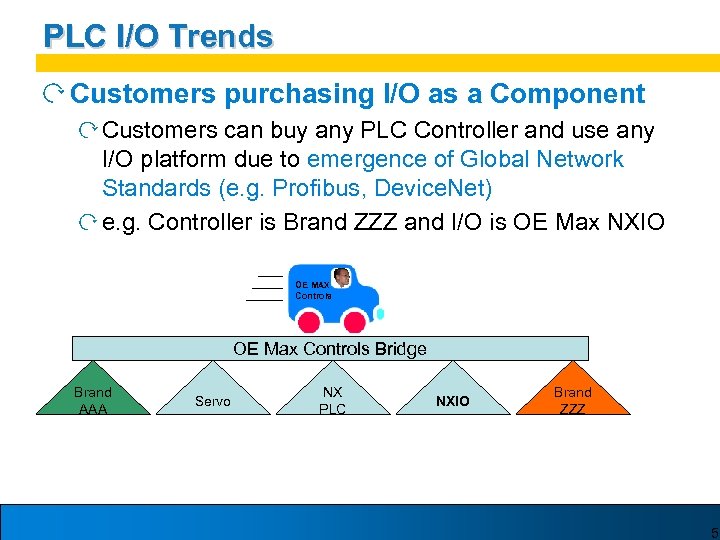

PLC I/O Trends Customers purchasing I/O as a Component Customers can buy any PLC Controller and use any I/O platform due to emergence of Global Network Standards (e. g. Profibus, Device. Net) e. g. Controller is Brand ZZZ and I/O is OE Max NXIO OE MAX Controls OE Max Controls Bridge Brand AAA Servo NX PLC NXIO Brand ZZZ 5

PLC I/O Trends Customers purchasing I/O as a Component Customers can buy any PLC Controller and use any I/O platform due to emergence of Global Network Standards (e. g. Profibus, Device. Net) e. g. Controller is Brand ZZZ and I/O is OE Max NXIO OE MAX Controls OE Max Controls Bridge Brand AAA Servo NX PLC NXIO Brand ZZZ 5

Birth of the Distributed I/O Concept 6

Birth of the Distributed I/O Concept 6

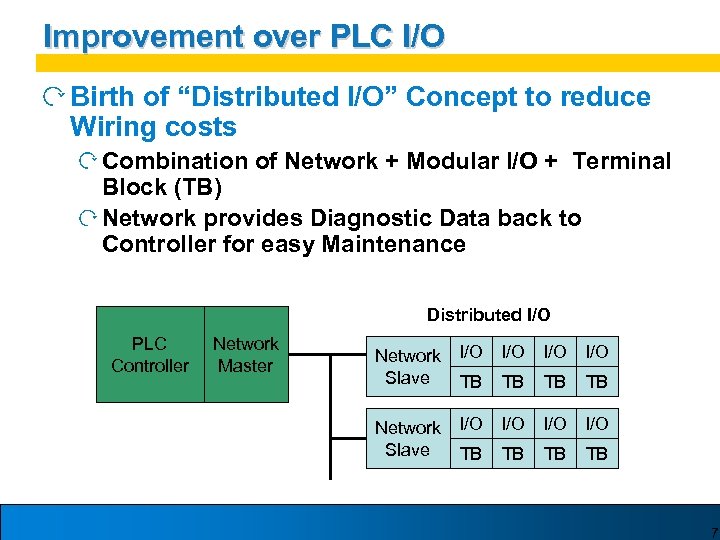

Improvement over PLC I/O Birth of “Distributed I/O” Concept to reduce Wiring costs Combination of Network + Modular I/O + Terminal Block (TB) Network provides Diagnostic Data back to Controller for easy Maintenance Distributed I/O PLC Controller Network Master Network Slave I/O I/O TB TB 7

Improvement over PLC I/O Birth of “Distributed I/O” Concept to reduce Wiring costs Combination of Network + Modular I/O + Terminal Block (TB) Network provides Diagnostic Data back to Controller for easy Maintenance Distributed I/O PLC Controller Network Master Network Slave I/O I/O TB TB 7

Improvement over PLC I/O Popular for over 10 yrs in North America and Europe where space and labor are very expensive Trend will continue into China Growing Number of Large Factories (e. g. Automotive, Food and Beverage) with Networking Requirements Labor and Space Costs will increase over time Productivity (not just low cost labor) will become a Competitive Advantage Many Terminal Block or Sensor Suppliers start to sell Distributed I/O platforms WAGO, Phoenix Contact, Beckhoff, Turck, Opto 22 but they lack a PLC background 8

Improvement over PLC I/O Popular for over 10 yrs in North America and Europe where space and labor are very expensive Trend will continue into China Growing Number of Large Factories (e. g. Automotive, Food and Beverage) with Networking Requirements Labor and Space Costs will increase over time Productivity (not just low cost labor) will become a Competitive Advantage Many Terminal Block or Sensor Suppliers start to sell Distributed I/O platforms WAGO, Phoenix Contact, Beckhoff, Turck, Opto 22 but they lack a PLC background 8

NXIO 2 nd Generation Distributed I/O Design 9

NXIO 2 nd Generation Distributed I/O Design 9

PLC I/O 市场趋势 The trend for the Semiconductor OEMs is to adopt Distributed I/O Device. Net is adopted as a Semiconductor Standard and has become very popular in Asia and North America Saves on space and wiring OE Max Controls launches NXIO in 2004 2 nd Generation Distributed I/O Design Slice-type with high granularity of I/O 10

PLC I/O 市场趋势 The trend for the Semiconductor OEMs is to adopt Distributed I/O Device. Net is adopted as a Semiconductor Standard and has become very popular in Asia and North America Saves on space and wiring OE Max Controls launches NXIO in 2004 2 nd Generation Distributed I/O Design Slice-type with high granularity of I/O 10

NXIO Specifications 11

NXIO Specifications 11

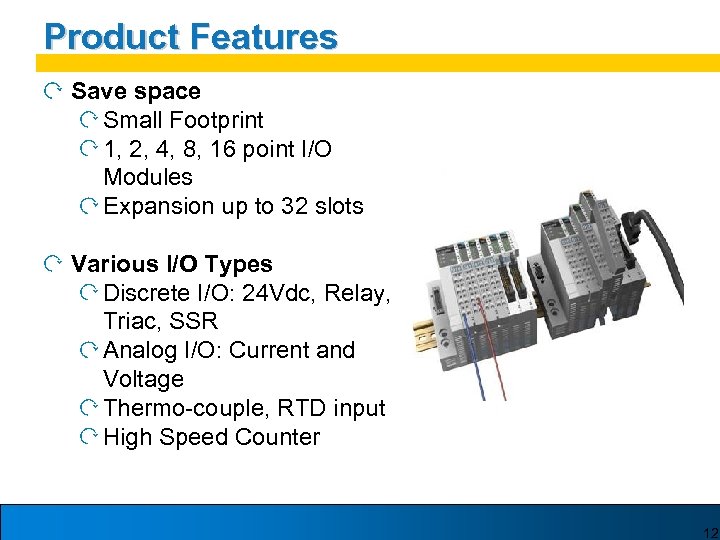

Product Features Save space Small Footprint 1, 2, 4, 8, 16 point I/O Modules Expansion up to 32 slots Various I/O Types Discrete I/O: 24 Vdc, Relay, Triac, SSR Analog I/O: Current and Voltage Thermo-couple, RTD input High Speed Counter 12

Product Features Save space Small Footprint 1, 2, 4, 8, 16 point I/O Modules Expansion up to 32 slots Various I/O Types Discrete I/O: 24 Vdc, Relay, Triac, SSR Analog I/O: Current and Voltage Thermo-couple, RTD input High Speed Counter 12

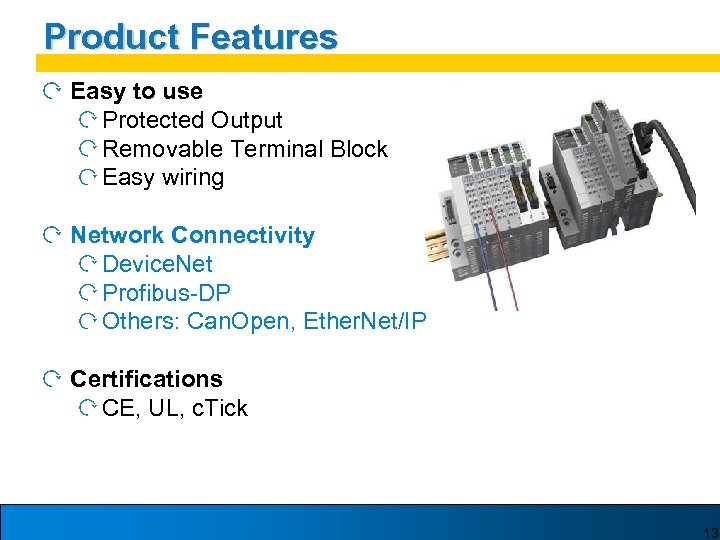

Product Features Easy to use Protected Output Removable Terminal Block Easy wiring Network Connectivity Device. Net Profibus-DP Others: Can. Open, Ether. Net/IP Certifications CE, UL, c. Tick 13

Product Features Easy to use Protected Output Removable Terminal Block Easy wiring Network Connectivity Device. Net Profibus-DP Others: Can. Open, Ether. Net/IP Certifications CE, UL, c. Tick 13

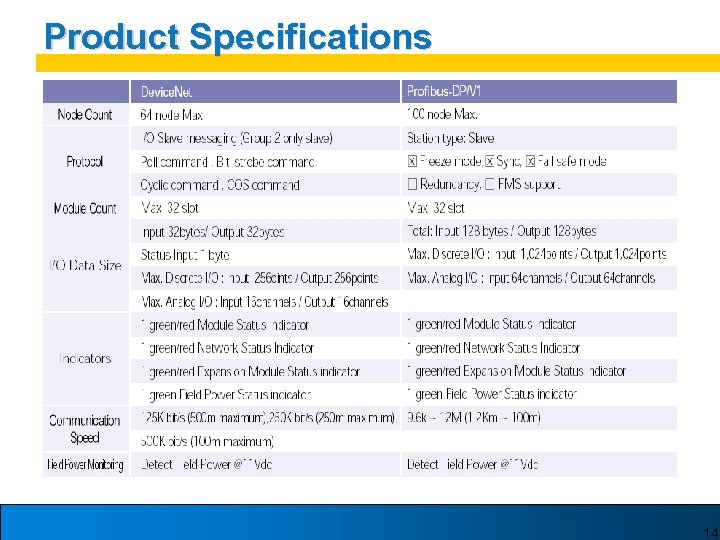

Product Specifications 14

Product Specifications 14

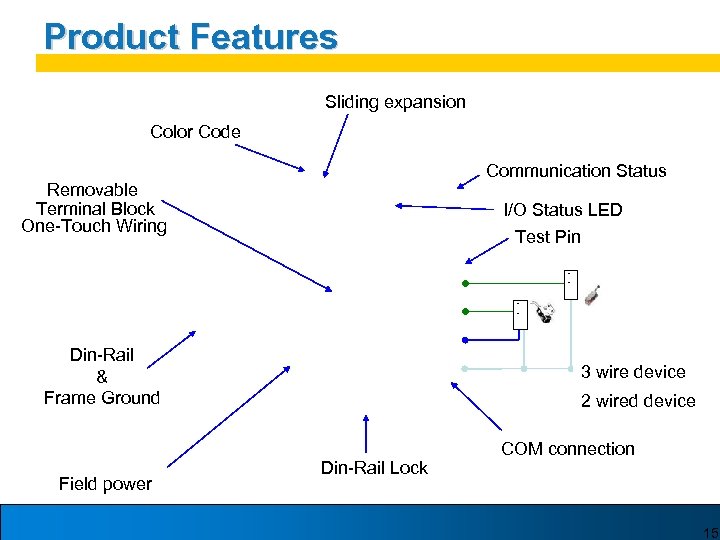

Product Features Sliding expansion Color Code Communication Status Removable Terminal Block One-Touch Wiring I/O Status LED Test Pin * * Din-Rail & Frame Ground Field power 3 wire device 2 wired device Din-Rail Lock COM connection 15

Product Features Sliding expansion Color Code Communication Status Removable Terminal Block One-Touch Wiring I/O Status LED Test Pin * * Din-Rail & Frame Ground Field power 3 wire device 2 wired device Din-Rail Lock COM connection 15

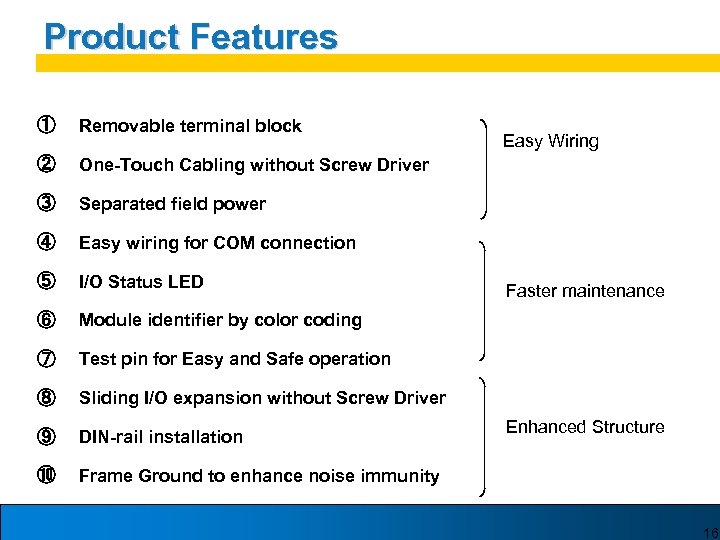

Product Features ① Removable terminal block ② One-Touch Cabling without Screw Driver ③ Separated field power ④ Easy wiring for COM connection ⑤ I/O Status LED ⑥ Module identifier by color coding ⑦ Test pin for Easy and Safe operation ⑧ Sliding I/O expansion without Screw Driver ⑨ DIN-rail installation ⑩ Frame Ground to enhance noise immunity Easy Wiring Faster maintenance Enhanced Structure 16

Product Features ① Removable terminal block ② One-Touch Cabling without Screw Driver ③ Separated field power ④ Easy wiring for COM connection ⑤ I/O Status LED ⑥ Module identifier by color coding ⑦ Test pin for Easy and Safe operation ⑧ Sliding I/O expansion without Screw Driver ⑨ DIN-rail installation ⑩ Frame Ground to enhance noise immunity Easy Wiring Faster maintenance Enhanced Structure 16

Target Market NXIO is not only for highly distributed applications. Wherever you need networked I/O, you can use NXIO 17

Target Market NXIO is not only for highly distributed applications. Wherever you need networked I/O, you can use NXIO 17

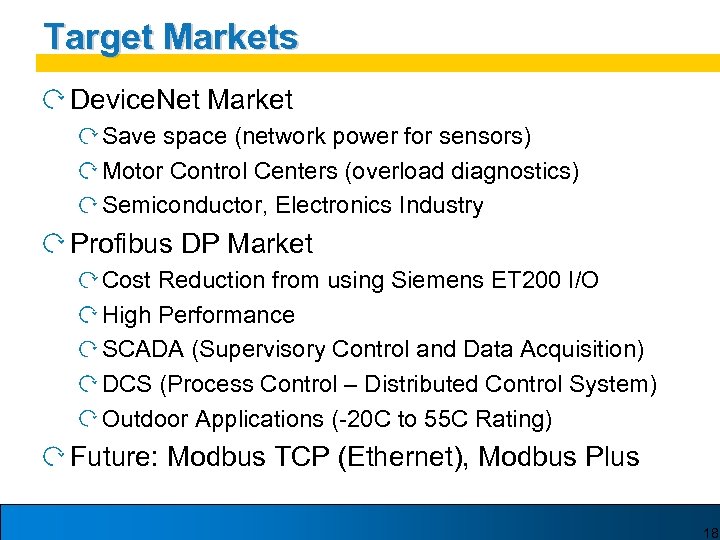

Target Markets Device. Net Market Save space (network power for sensors) Motor Control Centers (overload diagnostics) Semiconductor, Electronics Industry Profibus DP Market Cost Reduction from using Siemens ET 200 I/O High Performance SCADA (Supervisory Control and Data Acquisition) DCS (Process Control – Distributed Control System) Outdoor Applications (-20 C to 55 C Rating) Future: Modbus TCP (Ethernet), Modbus Plus 18

Target Markets Device. Net Market Save space (network power for sensors) Motor Control Centers (overload diagnostics) Semiconductor, Electronics Industry Profibus DP Market Cost Reduction from using Siemens ET 200 I/O High Performance SCADA (Supervisory Control and Data Acquisition) DCS (Process Control – Distributed Control System) Outdoor Applications (-20 C to 55 C Rating) Future: Modbus TCP (Ethernet), Modbus Plus 18

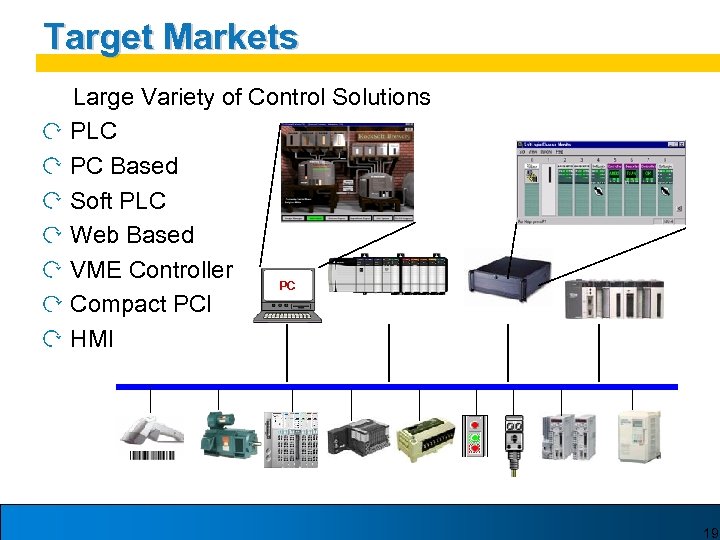

Target Markets Large Variety of Control Solutions PLC PC Based Soft PLC Web Based VME Controller PC Compact PCI HMI 19

Target Markets Large Variety of Control Solutions PLC PC Based Soft PLC Web Based VME Controller PC Compact PCI HMI 19

Advantages of using NXIO How to use NXIO to reduce costs - At the same time improve the overall value of your system. 20

Advantages of using NXIO How to use NXIO to reduce costs - At the same time improve the overall value of your system. 20

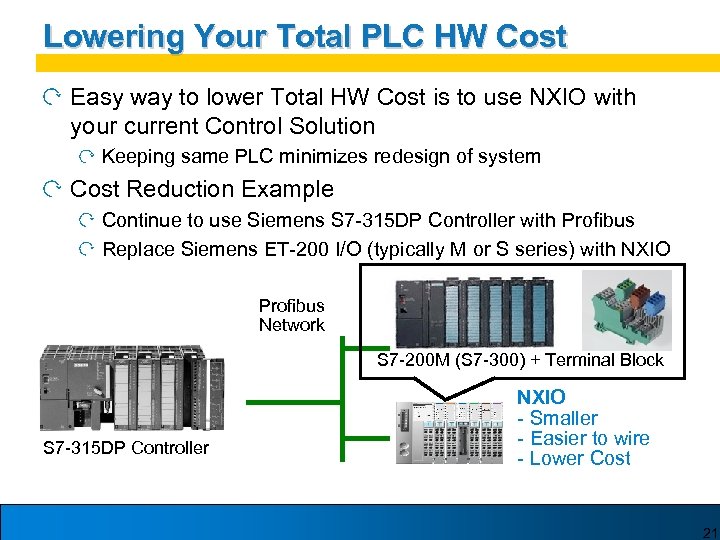

Lowering Your Total PLC HW Cost Easy way to lower Total HW Cost is to use NXIO with your current Control Solution Keeping same PLC minimizes redesign of system Cost Reduction Example Continue to use Siemens S 7 -315 DP Controller with Profibus Replace Siemens ET-200 I/O (typically M or S series) with NXIO Profibus Network S 7 -200 M (S 7 -300) + Terminal Block S 7 -315 DP Controller NXIO - Smaller - Easier to wire - Lower Cost 21

Lowering Your Total PLC HW Cost Easy way to lower Total HW Cost is to use NXIO with your current Control Solution Keeping same PLC minimizes redesign of system Cost Reduction Example Continue to use Siemens S 7 -315 DP Controller with Profibus Replace Siemens ET-200 I/O (typically M or S series) with NXIO Profibus Network S 7 -200 M (S 7 -300) + Terminal Block S 7 -315 DP Controller NXIO - Smaller - Easier to wire - Lower Cost 21

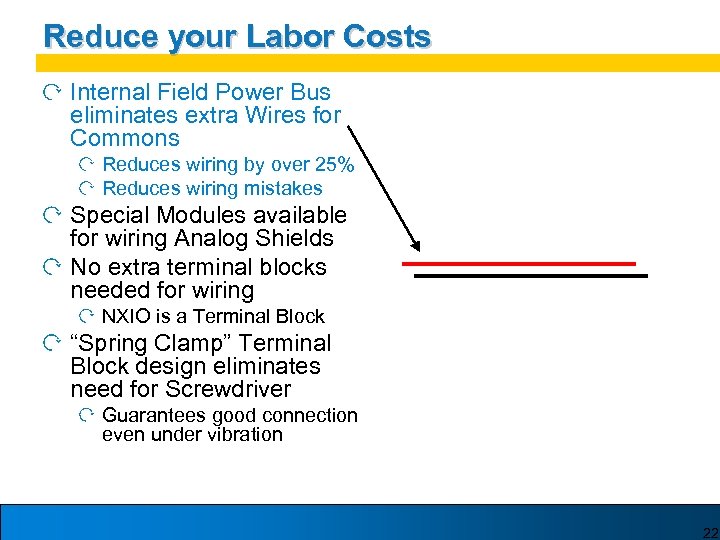

Reduce your Labor Costs Internal Field Power Bus eliminates extra Wires for Commons Reduces wiring by over 25% Reduces wiring mistakes Special Modules available for wiring Analog Shields No extra terminal blocks needed for wiring NXIO is a Terminal Block “Spring Clamp” Terminal Block design eliminates need for Screwdriver Guarantees good connection even under vibration 22

Reduce your Labor Costs Internal Field Power Bus eliminates extra Wires for Commons Reduces wiring by over 25% Reduces wiring mistakes Special Modules available for wiring Analog Shields No extra terminal blocks needed for wiring NXIO is a Terminal Block “Spring Clamp” Terminal Block design eliminates need for Screwdriver Guarantees good connection even under vibration 22

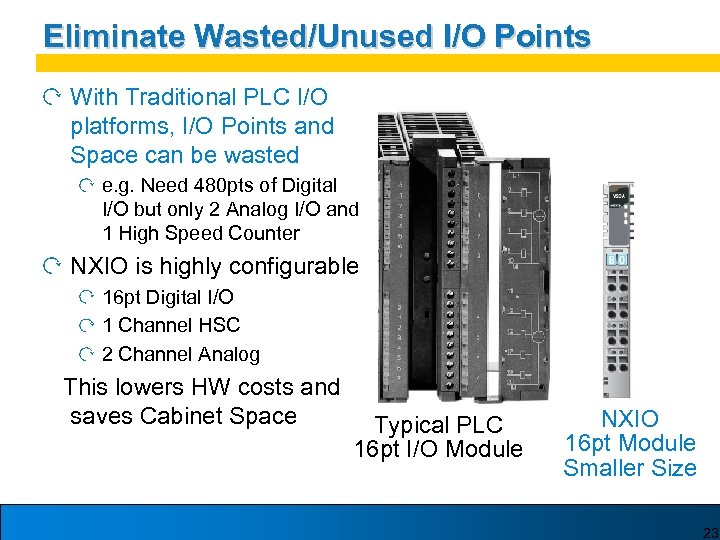

Eliminate Wasted/Unused I/O Points With Traditional PLC I/O platforms, I/O Points and Space can be wasted e. g. Need 480 pts of Digital I/O but only 2 Analog I/O and 1 High Speed Counter NXIO is highly configurable 16 pt Digital I/O 1 Channel HSC 2 Channel Analog This lowers HW costs and saves Cabinet Space Typical PLC 16 pt I/O Module NXIO 16 pt Module Smaller Size 23

Eliminate Wasted/Unused I/O Points With Traditional PLC I/O platforms, I/O Points and Space can be wasted e. g. Need 480 pts of Digital I/O but only 2 Analog I/O and 1 High Speed Counter NXIO is highly configurable 16 pt Digital I/O 1 Channel HSC 2 Channel Analog This lowers HW costs and saves Cabinet Space Typical PLC 16 pt I/O Module NXIO 16 pt Module Smaller Size 23

The Quality Inside Let’s look inside NXIO 24

The Quality Inside Let’s look inside NXIO 24

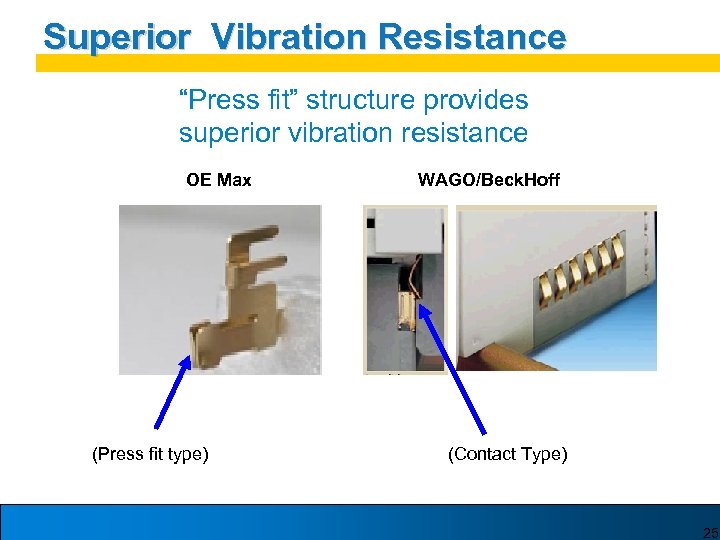

Superior Vibration Resistance “Press fit” structure provides superior vibration resistance OE Max (Press fit type) WAGO/Beck. Hoff (Contact Type) 25

Superior Vibration Resistance “Press fit” structure provides superior vibration resistance OE Max (Press fit type) WAGO/Beck. Hoff (Contact Type) 25

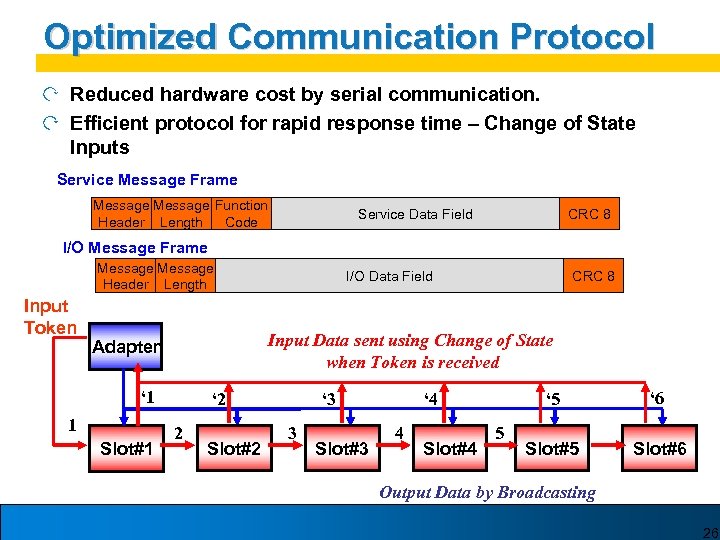

Optimized Communication Protocol Reduced hardware cost by serial communication. Efficient protocol for rapid response time – Change of State Inputs Service Message Frame Message Function Header Length Code Service Data Field CRC 8 I/O Message Frame Message Header Length Input Token ‘ 1 Slot#1 CRC 8 Input Data sent using Change of State when Token is received Adapter 1 I/O Data Field ‘ 2 2 Slot#2 ‘ 3 3 Slot#3 ‘ 5 ‘ 4 4 Slot#4 5 ‘ 6 Slot#5 Slot#6 Output Data by Broadcasting 26

Optimized Communication Protocol Reduced hardware cost by serial communication. Efficient protocol for rapid response time – Change of State Inputs Service Message Frame Message Function Header Length Code Service Data Field CRC 8 I/O Message Frame Message Header Length Input Token ‘ 1 Slot#1 CRC 8 Input Data sent using Change of State when Token is received Adapter 1 I/O Data Field ‘ 2 2 Slot#2 ‘ 3 3 Slot#3 ‘ 5 ‘ 4 4 Slot#4 5 ‘ 6 Slot#5 Slot#6 Output Data by Broadcasting 26

TM Maximum Value for OEMs SM 27

TM Maximum Value for OEMs SM 27