0c04a17ffa40865b5e646d9206e73e38.ppt

- Количество слайдов: 118

TIER 1 STEADY STATE SIMULATION PIECE Program for North American Mobility in Higher Education (NAMP) Process Integration for Environmental Control in Engineering Curricula (PIECE) PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 1

TIER 1 STEADY STATE SIMULATION PIECE Program for North American Mobility in Higher Education (NAMP) Process Integration for Environmental Control in Engineering Curricula (PIECE) PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 1

TIER 1 STEADY STATE SIMULATION PIECE Module 2 Steady State Process Simulation PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 2

TIER 1 STEADY STATE SIMULATION PIECE Module 2 Steady State Process Simulation PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 2

TIER 1 STEADY STATE SIMULATION PIECE Propose This module has been developed to help the students: ü Understand simulate processes in steady state. ü Solve technical and economic problems more quickly, efficiently and successfully. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 3

TIER 1 STEADY STATE SIMULATION PIECE Propose This module has been developed to help the students: ü Understand simulate processes in steady state. ü Solve technical and economic problems more quickly, efficiently and successfully. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 3

TIER 1 STEADY STATE SIMULATION PIECE Statement of intent The student will. ü Review basic concepts used in steady – state simulation. ü Understand the purpose of steady – state simulation. ü Develop models of a processes in steady state. ü Simulate processes with help of computer simulators. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 4

TIER 1 STEADY STATE SIMULATION PIECE Statement of intent The student will. ü Review basic concepts used in steady – state simulation. ü Understand the purpose of steady – state simulation. ü Develop models of a processes in steady state. ü Simulate processes with help of computer simulators. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 4

TIER 1 STEADY STATE SIMULATION PIECE Contents This module is divided in 3 tiers Tier 1. Introduction to simulation tool. Tier 2. How to use computer tool. Tier 3. How to apply in real world. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 5

TIER 1 STEADY STATE SIMULATION PIECE Contents This module is divided in 3 tiers Tier 1. Introduction to simulation tool. Tier 2. How to use computer tool. Tier 3. How to apply in real world. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 5

TIER 1 STEADY STATE SIMULATION PIECE Tier 1 Introduction to Steady State, Process Simulation tool PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 6

TIER 1 STEADY STATE SIMULATION PIECE Tier 1 Introduction to Steady State, Process Simulation tool PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 6

TIER 1 STEADY STATE SIMULATION PIECE Contents Tier 1 is divided in 3 sections 1. Basic concepts. 2. Steady – state simulation in a process integration context. 3. Steady – state simulation in a broader context. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 7

TIER 1 STEADY STATE SIMULATION PIECE Contents Tier 1 is divided in 3 sections 1. Basic concepts. 2. Steady – state simulation in a process integration context. 3. Steady – state simulation in a broader context. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 7

TIER 1 STEADY STATE SIMULATION PIECE 1 Basic Concepts PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 8

TIER 1 STEADY STATE SIMULATION PIECE 1 Basic Concepts PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 8

TIER 1 STEADY STATE SIMULATION PIECE Statement of intent Basic concepts ü Show the basic concepts of steady – state simulation. ü Improve process simulation skills. ü Create your own simulation flowsheets. ü Recognize why simulation is useful in the process industries. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 9

TIER 1 STEADY STATE SIMULATION PIECE Statement of intent Basic concepts ü Show the basic concepts of steady – state simulation. ü Improve process simulation skills. ü Create your own simulation flowsheets. ü Recognize why simulation is useful in the process industries. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 9

TIER 1 STEADY STATE SIMULATION PIECE Contents Basic Concepts Ø Steady – state. Ø Models and simulation. Ø Creating models. Ø Unit efficiencies. Ø Stream components. Ø Units. Ø Performing a steady – state simulation study. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 10

TIER 1 STEADY STATE SIMULATION PIECE Contents Basic Concepts Ø Steady – state. Ø Models and simulation. Ø Creating models. Ø Unit efficiencies. Ø Stream components. Ø Units. Ø Performing a steady – state simulation study. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 10

TIER 1 STEADY STATE SIMULATION PIECE Steady – state Steady – State By steady state we mean, in most systems, the conditions when nothing is changing with time. Mathematically this corresponds to having all time derivatives equal to zero, or to allowing time to become very large (go to infinity). PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 11

TIER 1 STEADY STATE SIMULATION PIECE Steady – state Steady – State By steady state we mean, in most systems, the conditions when nothing is changing with time. Mathematically this corresponds to having all time derivatives equal to zero, or to allowing time to become very large (go to infinity). PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 11

TIER 1 STEADY STATE SIMULATION PIECE Steady – state Steady – State The design of process systems requires both: ü Steady – state model. ü Dynamic models. One use for the steady – state models is in determining the possible region of steady – state operation for a process that can be limited by constraints such as safety, product quality, and equipment performance. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 12

TIER 1 STEADY STATE SIMULATION PIECE Steady – state Steady – State The design of process systems requires both: ü Steady – state model. ü Dynamic models. One use for the steady – state models is in determining the possible region of steady – state operation for a process that can be limited by constraints such as safety, product quality, and equipment performance. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 12

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Model A model is an abstraction of a process operation used to build, change, improve or control a process. Uses of a model: ü Equipment design, sizing and selection. ü Comparison of possible configurations. ü Evaluation of process performance against limits (e. g. Concentrations, effluent discharge rates). ü De-bottlenecking and optimization. ü Control strategy development and evaluation. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 13

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Model A model is an abstraction of a process operation used to build, change, improve or control a process. Uses of a model: ü Equipment design, sizing and selection. ü Comparison of possible configurations. ü Evaluation of process performance against limits (e. g. Concentrations, effluent discharge rates). ü De-bottlenecking and optimization. ü Control strategy development and evaluation. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 13

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Model The model is an abstraction of the real word ü ü ü Models vary by: Phenomena represented (energy, classifications phase change). Level of detail and granularity Assumptions (perfect mixing, zero heat loss). Kind of input required Functions performed (constraint satisfaction, optimization). Nature of output generated PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 14

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Model The model is an abstraction of the real word ü ü ü Models vary by: Phenomena represented (energy, classifications phase change). Level of detail and granularity Assumptions (perfect mixing, zero heat loss). Kind of input required Functions performed (constraint satisfaction, optimization). Nature of output generated PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 14

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Models vary by purpose and category Purpose ü Operator training simulator. ü Control strategy evaluation. ü Investment justification (e. g. new equipment purchase). ü Other… Category ü Physical (e. g. mimic panel) vs. Mathematical. ü Qualitative vs. Quantitative. ü Empirical vs. First principle based. ü Steady state vs. Dynamic state. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 15

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Models vary by purpose and category Purpose ü Operator training simulator. ü Control strategy evaluation. ü Investment justification (e. g. new equipment purchase). ü Other… Category ü Physical (e. g. mimic panel) vs. Mathematical. ü Qualitative vs. Quantitative. ü Empirical vs. First principle based. ü Steady state vs. Dynamic state. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 15

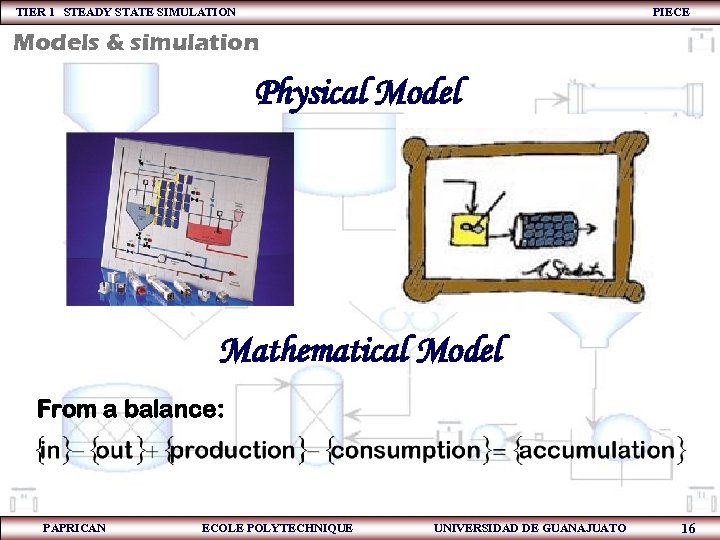

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Physical Model Mathematical Model From a balance: PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 16

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Physical Model Mathematical Model From a balance: PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 16

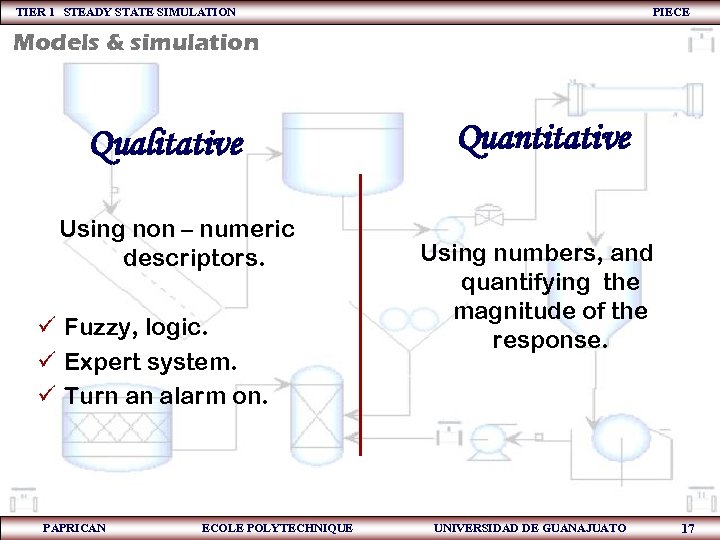

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Qualitative Using non – numeric descriptors. ü Fuzzy, logic. ü Expert system. ü Turn an alarm on. PAPRICAN ECOLE POLYTECHNIQUE Quantitative Using numbers, and quantifying the magnitude of the response. UNIVERSIDAD DE GUANAJUATO 17

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Qualitative Using non – numeric descriptors. ü Fuzzy, logic. ü Expert system. ü Turn an alarm on. PAPRICAN ECOLE POLYTECHNIQUE Quantitative Using numbers, and quantifying the magnitude of the response. UNIVERSIDAD DE GUANAJUATO 17

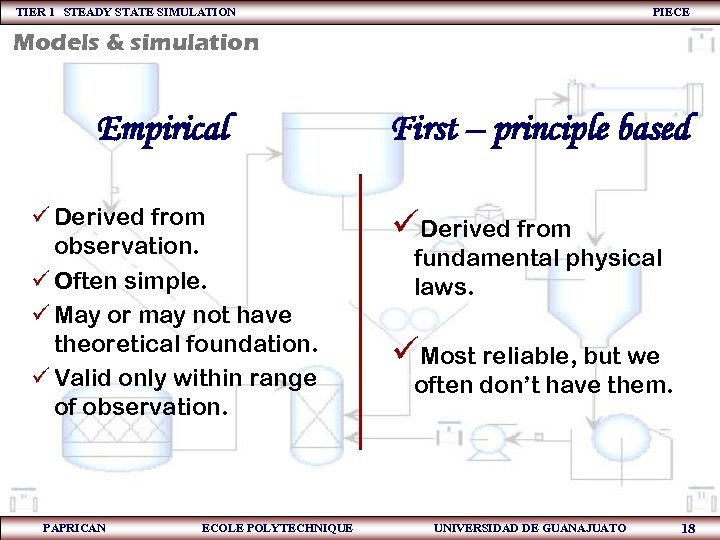

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Empirical ü Derived from observation. ü Often simple. ü May or may not have theoretical foundation. ü Valid only within range of observation. PAPRICAN ECOLE POLYTECHNIQUE First – principle based üDerived from fundamental physical laws. üMost reliable, but we often don’t have them. UNIVERSIDAD DE GUANAJUATO 18

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Empirical ü Derived from observation. ü Often simple. ü May or may not have theoretical foundation. ü Valid only within range of observation. PAPRICAN ECOLE POLYTECHNIQUE First – principle based üDerived from fundamental physical laws. üMost reliable, but we often don’t have them. UNIVERSIDAD DE GUANAJUATO 18

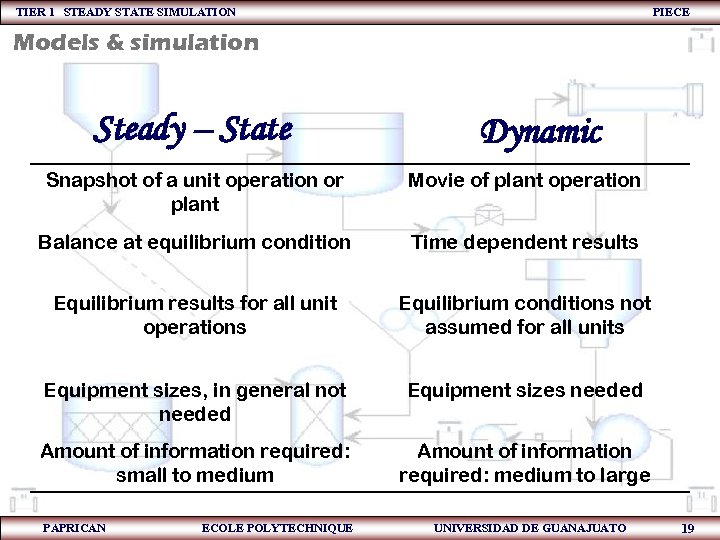

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Steady – State Dynamic Snapshot of a unit operation or plant Movie of plant operation Balance at equilibrium condition Time dependent results Equilibrium results for all unit operations Equilibrium conditions not assumed for all units Equipment sizes, in general not needed Equipment sizes needed Amount of information required: small to medium Amount of information required: medium to large PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 19

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Steady – State Dynamic Snapshot of a unit operation or plant Movie of plant operation Balance at equilibrium condition Time dependent results Equilibrium results for all unit operations Equilibrium conditions not assumed for all units Equipment sizes, in general not needed Equipment sizes needed Amount of information required: small to medium Amount of information required: medium to large PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 19

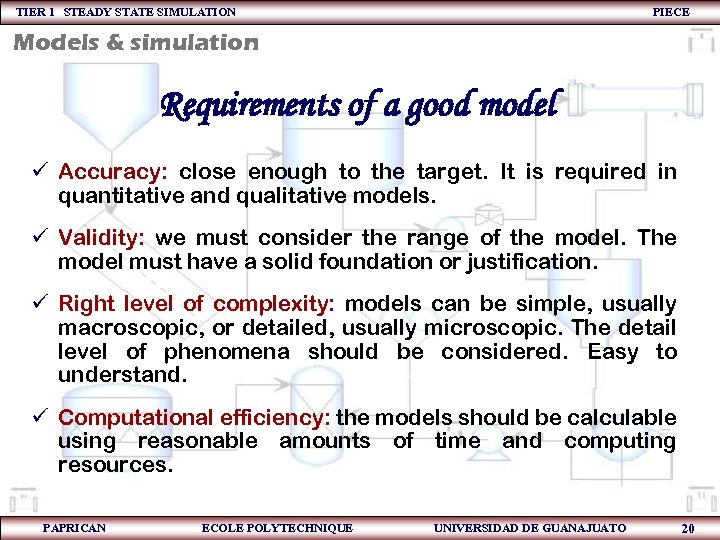

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Requirements of a good model ü Accuracy: close enough to the target. It is required in quantitative and qualitative models. ü Validity: we must consider the range of the model. The model must have a solid foundation or justification. ü Right level of complexity: models can be simple, usually macroscopic, or detailed, usually microscopic. The detail level of phenomena should be considered. Easy to understand. ü Computational efficiency: the models should be calculable using reasonable amounts of time and computing resources. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 20

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Requirements of a good model ü Accuracy: close enough to the target. It is required in quantitative and qualitative models. ü Validity: we must consider the range of the model. The model must have a solid foundation or justification. ü Right level of complexity: models can be simple, usually macroscopic, or detailed, usually microscopic. The detail level of phenomena should be considered. Easy to understand. ü Computational efficiency: the models should be calculable using reasonable amounts of time and computing resources. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 20

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Simulation Predicts the behavior of a plant by solving the mathematical relationships that describe the behavior of the plant’s constituent components. Involves performing a series of experiments with a process model. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 21

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Simulation Predicts the behavior of a plant by solving the mathematical relationships that describe the behavior of the plant’s constituent components. Involves performing a series of experiments with a process model. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 21

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Importance of steady – state simulation ü Better understanding of the process. ü Consistent set of typical mill data. ü Objective comparative evaluation of options for return on investment etc. ü Identification of bottlenecks, instabilities, etc. ü Ability to perform many experiments cheaply once model built. ü Avoidance of ineffective solutions. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 22

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Importance of steady – state simulation ü Better understanding of the process. ü Consistent set of typical mill data. ü Objective comparative evaluation of options for return on investment etc. ü Identification of bottlenecks, instabilities, etc. ü Ability to perform many experiments cheaply once model built. ü Avoidance of ineffective solutions. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 22

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Constructing a model When we try to represent a phenomena, to predict future conditions, or to know how the process will behave in certain situation, it is common to use mathematical expressions. d dt PAPRICAN ò V b d. V = - ò F × n d. S + ò B V d. V S ECOLE POLYTECHNIQUE V UNIVERSIDAD DE GUANAJUATO 23

TIER 1 STEADY STATE SIMULATION PIECE Models & simulation Constructing a model When we try to represent a phenomena, to predict future conditions, or to know how the process will behave in certain situation, it is common to use mathematical expressions. d dt PAPRICAN ò V b d. V = - ò F × n d. S + ò B V d. V S ECOLE POLYTECHNIQUE V UNIVERSIDAD DE GUANAJUATO 23

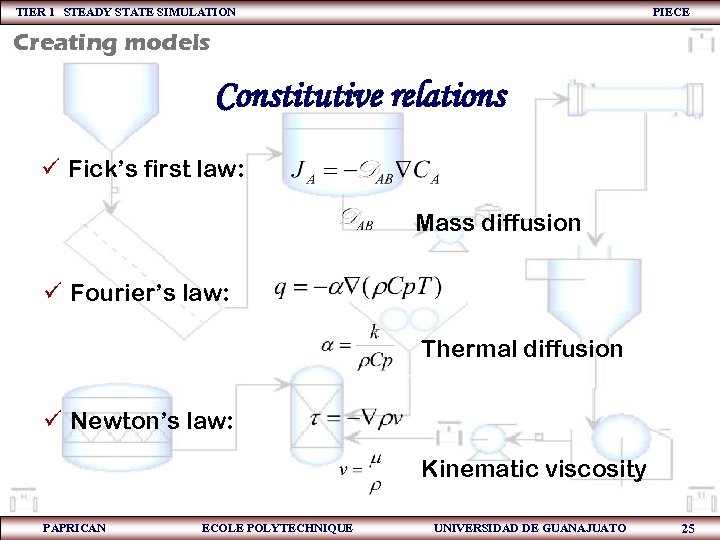

TIER 1 STEADY STATE SIMULATION PIECE Creating models Constitutive relations Relate the diffusive flux of a certain quantity with the local properties of the material and with the transport driving force. Express the movement of a certain quantity in the decreasing gradient direction of the quantity. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 24

TIER 1 STEADY STATE SIMULATION PIECE Creating models Constitutive relations Relate the diffusive flux of a certain quantity with the local properties of the material and with the transport driving force. Express the movement of a certain quantity in the decreasing gradient direction of the quantity. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 24

TIER 1 STEADY STATE SIMULATION PIECE Creating models Constitutive relations ü Fick’s first law: Mass diffusion ü Fourier’s law: Thermal diffusion ü Newton’s law: Kinematic viscosity PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 25

TIER 1 STEADY STATE SIMULATION PIECE Creating models Constitutive relations ü Fick’s first law: Mass diffusion ü Fourier’s law: Thermal diffusion ü Newton’s law: Kinematic viscosity PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 25

TIER 1 STEADY STATE SIMULATION PIECE Creating models Variation Equations Conservation Equations or Equations of change Those relate the accumulation of a quantity with the rate of entrance or formation of the same quantity in a specific volume. Those are based in fundamental principles and have universal description. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 26

TIER 1 STEADY STATE SIMULATION PIECE Creating models Variation Equations Conservation Equations or Equations of change Those relate the accumulation of a quantity with the rate of entrance or formation of the same quantity in a specific volume. Those are based in fundamental principles and have universal description. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 26

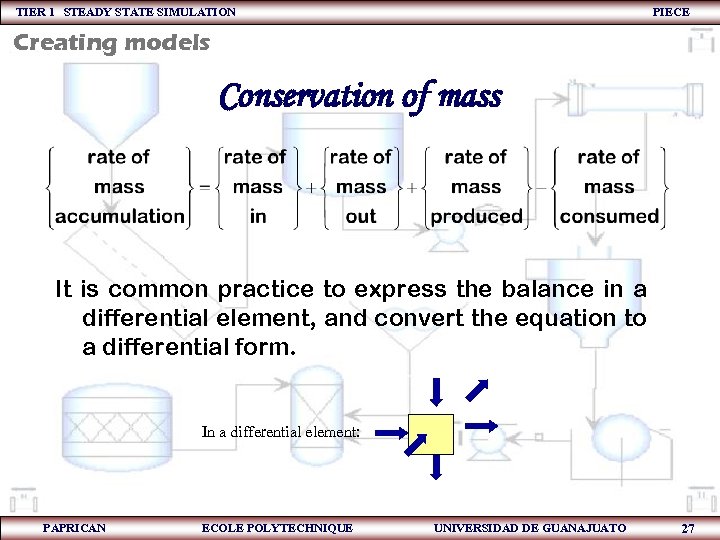

TIER 1 STEADY STATE SIMULATION PIECE Creating models Conservation of mass It is common practice to express the balance in a differential element, and convert the equation to a differential form. In a differential element: PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 27

TIER 1 STEADY STATE SIMULATION PIECE Creating models Conservation of mass It is common practice to express the balance in a differential element, and convert the equation to a differential form. In a differential element: PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 27

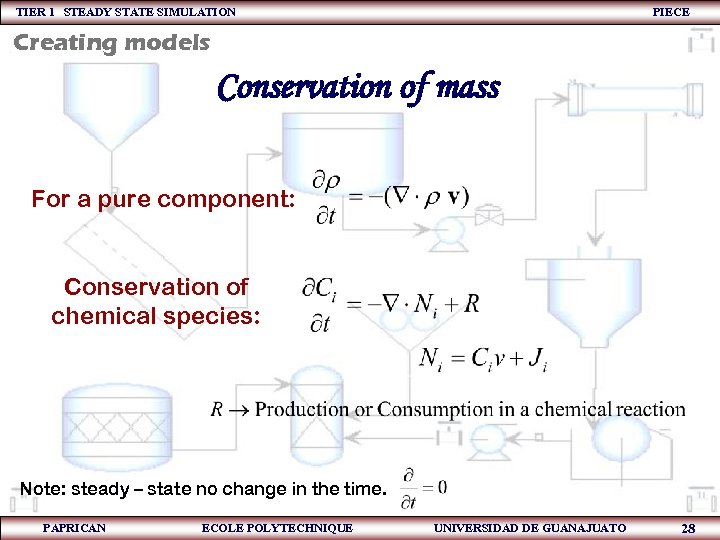

TIER 1 STEADY STATE SIMULATION PIECE Creating models Conservation of mass For a pure component: Conservation of chemical species: Note: steady – state no change in the time. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 28

TIER 1 STEADY STATE SIMULATION PIECE Creating models Conservation of mass For a pure component: Conservation of chemical species: Note: steady – state no change in the time. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 28

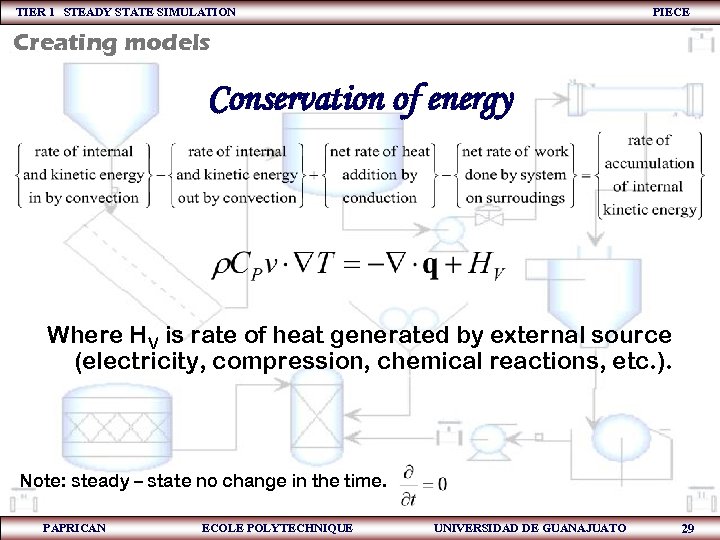

TIER 1 STEADY STATE SIMULATION PIECE Creating models Conservation of energy Where HV is rate of heat generated by external source (electricity, compression, chemical reactions, etc. ). Note: steady – state no change in the time. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 29

TIER 1 STEADY STATE SIMULATION PIECE Creating models Conservation of energy Where HV is rate of heat generated by external source (electricity, compression, chemical reactions, etc. ). Note: steady – state no change in the time. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 29

TIER 1 STEADY STATE SIMULATION PIECE Unit efficiencies An engineer may define energy efficiency in a very restrictive equipment sense. Energy efficiency has been used to describe what actually may be conservation. Energy efficiency in a more subjective sense may refer to the relative economy with which energy inputs are used to provide services. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 30

TIER 1 STEADY STATE SIMULATION PIECE Unit efficiencies An engineer may define energy efficiency in a very restrictive equipment sense. Energy efficiency has been used to describe what actually may be conservation. Energy efficiency in a more subjective sense may refer to the relative economy with which energy inputs are used to provide services. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 30

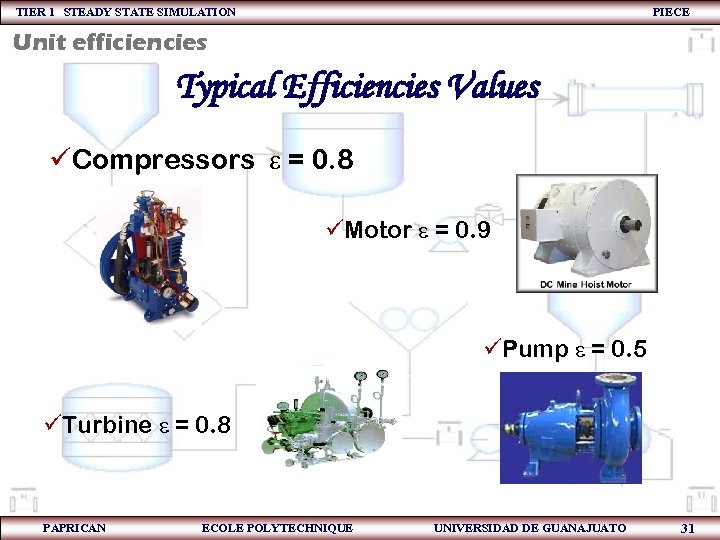

TIER 1 STEADY STATE SIMULATION PIECE Unit efficiencies Typical Efficiencies Values üCompressors e = 0. 8 üMotor e = 0. 9 üPump e = 0. 5 üTurbine e = 0. 8 PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 31

TIER 1 STEADY STATE SIMULATION PIECE Unit efficiencies Typical Efficiencies Values üCompressors e = 0. 8 üMotor e = 0. 9 üPump e = 0. 5 üTurbine e = 0. 8 PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 31

TIER 1 STEADY STATE SIMULATION PIECE Stream components Stream Components Overall stream flows and components are calculated based on physical and chemical properties such as: ü Ideal gas law and equations of state. ü Solubility relations (solid in liquid and gas in liquid). ü Reaction stoichiometry and equilibrium. ü Simple vapor/liquid relationships such as Raout’s law. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 32

TIER 1 STEADY STATE SIMULATION PIECE Stream components Stream Components Overall stream flows and components are calculated based on physical and chemical properties such as: ü Ideal gas law and equations of state. ü Solubility relations (solid in liquid and gas in liquid). ü Reaction stoichiometry and equilibrium. ü Simple vapor/liquid relationships such as Raout’s law. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 32

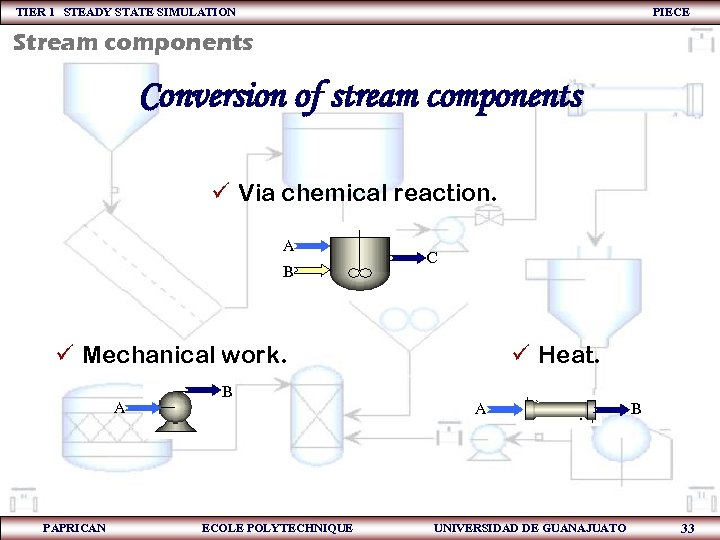

TIER 1 STEADY STATE SIMULATION PIECE Stream components Conversion of stream components ü Via chemical reaction. A B C ü Mechanical work. A PAPRICAN B ECOLE POLYTECHNIQUE ü Heat. A UNIVERSIDAD DE GUANAJUATO B 33

TIER 1 STEADY STATE SIMULATION PIECE Stream components Conversion of stream components ü Via chemical reaction. A B C ü Mechanical work. A PAPRICAN B ECOLE POLYTECHNIQUE ü Heat. A UNIVERSIDAD DE GUANAJUATO B 33

TIER 1 STEADY STATE SIMULATION Units PIECE Engineering Units The official international system of units is the SI. But older systems, particularly the centimeter – gram – second (cgs) and foot – pound – second (fps), are still in use. It was originated in France, in 1790 by the French Academy of Science. ü The units should be based on unvarying quantities in nature. ü Multiples of units should be decimal. ü The base units should be used to derive other units. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 34

TIER 1 STEADY STATE SIMULATION Units PIECE Engineering Units The official international system of units is the SI. But older systems, particularly the centimeter – gram – second (cgs) and foot – pound – second (fps), are still in use. It was originated in France, in 1790 by the French Academy of Science. ü The units should be based on unvarying quantities in nature. ü Multiples of units should be decimal. ü The base units should be used to derive other units. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 34

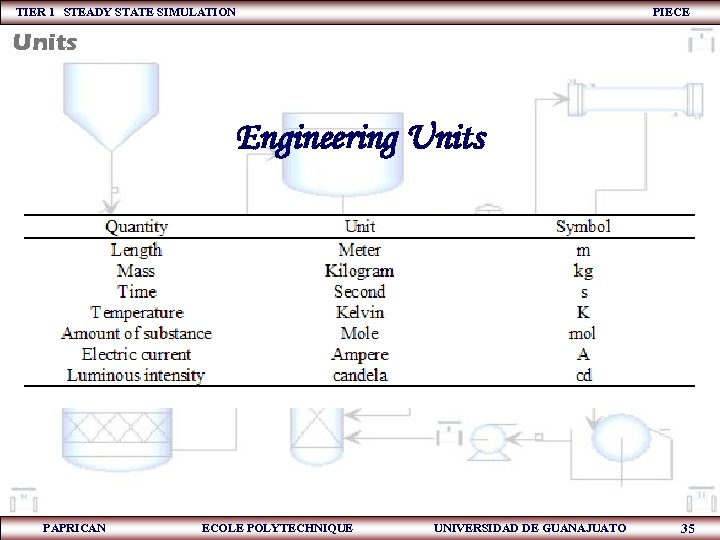

TIER 1 STEADY STATE SIMULATION PIECE Units Engineering Units PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 35

TIER 1 STEADY STATE SIMULATION PIECE Units Engineering Units PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 35

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Performing a Steady – State simulation Study ü Steady state model derivation. ü Calculation order. ü Recycle streams. ü Convergence and iteration. ü Recycle convergence methods. ü Granularity model. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 36

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Performing a Steady – State simulation Study ü Steady state model derivation. ü Calculation order. ü Recycle streams. ü Convergence and iteration. ü Recycle convergence methods. ü Granularity model. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 36

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Steady state model derivation 1. - Define Goals. a) Specific design decisions. b) Numerical values. c) Functional relationships. d) Required accuracy. 2. - Prepare information. a) Sketch process and identify system. b) Identify variables of interest. c) State assumptions and data. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 37

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Steady state model derivation 1. - Define Goals. a) Specific design decisions. b) Numerical values. c) Functional relationships. d) Required accuracy. 2. - Prepare information. a) Sketch process and identify system. b) Identify variables of interest. c) State assumptions and data. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 37

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Steady state model derivation 3. - Formulate model. a) Conservation balances. b) Constitutive equations. c) Rationalize (combine equations and collect terms). d) Check degrees of freedom. e) Dimensionless groups (Pr, Nu, Re, etc. ). 4. - Determine solution. a) Analytical. b) Numerical. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 38

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Steady state model derivation 3. - Formulate model. a) Conservation balances. b) Constitutive equations. c) Rationalize (combine equations and collect terms). d) Check degrees of freedom. e) Dimensionless groups (Pr, Nu, Re, etc. ). 4. - Determine solution. a) Analytical. b) Numerical. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 38

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Steady state model derivation 5. - Analyze results a) Check results for correctness ü Limiting and approximate answers ü Accuracy of numerical method b) Interpret results ü Plot solution ü Relate results to data and assumptions ü Evaluate sensitivity ü Answer “what if questions” PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 39

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Steady state model derivation 5. - Analyze results a) Check results for correctness ü Limiting and approximate answers ü Accuracy of numerical method b) Interpret results ü Plot solution ü Relate results to data and assumptions ü Evaluate sensitivity ü Answer “what if questions” PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 39

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Steady state model derivation 6. - Validate model. a) Select key values for validation. b) Compare with experimental results. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 40

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Steady state model derivation 6. - Validate model. a) Select key values for validation. b) Compare with experimental results. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 40

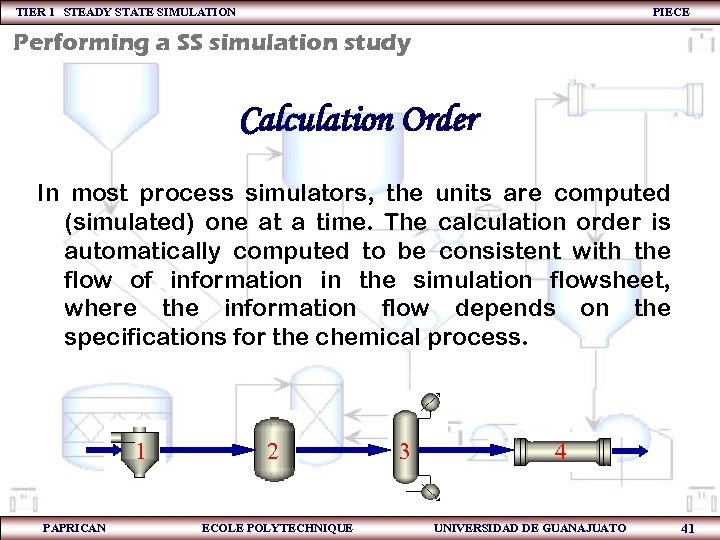

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Calculation Order In most process simulators, the units are computed (simulated) one at a time. The calculation order is automatically computed to be consistent with the flow of information in the simulation flowsheet, where the information flow depends on the specifications for the chemical process. 1 PAPRICAN 2 ECOLE POLYTECHNIQUE 3 4 UNIVERSIDAD DE GUANAJUATO 41

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Calculation Order In most process simulators, the units are computed (simulated) one at a time. The calculation order is automatically computed to be consistent with the flow of information in the simulation flowsheet, where the information flow depends on the specifications for the chemical process. 1 PAPRICAN 2 ECOLE POLYTECHNIQUE 3 4 UNIVERSIDAD DE GUANAJUATO 41

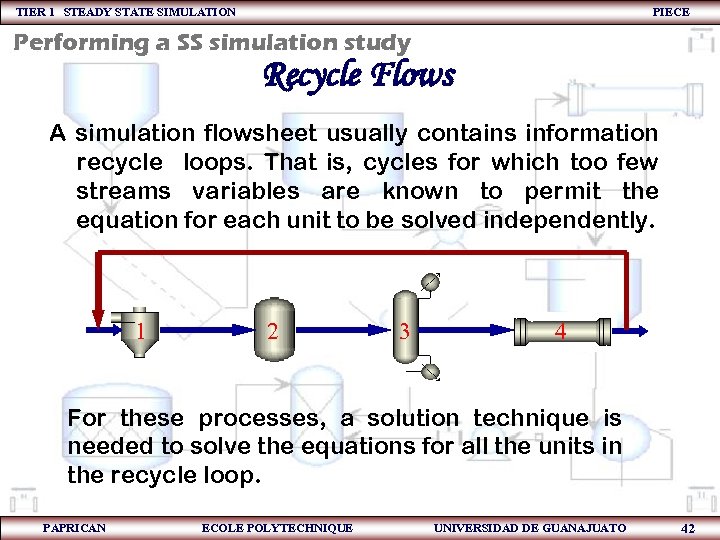

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Recycle Flows A simulation flowsheet usually contains information recycle loops. That is, cycles for which too few streams variables are known to permit the equation for each unit to be solved independently. 1 2 3 4 For these processes, a solution technique is needed to solve the equations for all the units in the recycle loop. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 42

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Recycle Flows A simulation flowsheet usually contains information recycle loops. That is, cycles for which too few streams variables are known to permit the equation for each unit to be solved independently. 1 2 3 4 For these processes, a solution technique is needed to solve the equations for all the units in the recycle loop. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 42

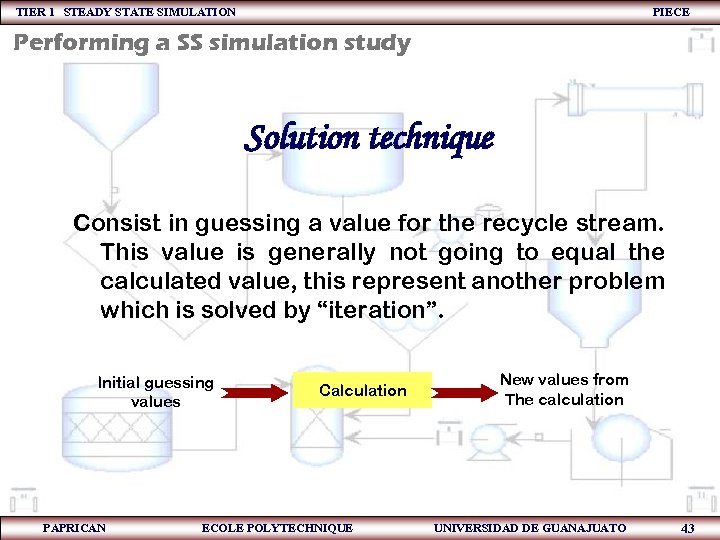

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Solution technique Consist in guessing a value for the recycle stream. This value is generally not going to equal the calculated value, this represent another problem which is solved by “iteration”. Initial guessing values PAPRICAN Calculation ECOLE POLYTECHNIQUE New values from The calculation UNIVERSIDAD DE GUANAJUATO 43

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Solution technique Consist in guessing a value for the recycle stream. This value is generally not going to equal the calculated value, this represent another problem which is solved by “iteration”. Initial guessing values PAPRICAN Calculation ECOLE POLYTECHNIQUE New values from The calculation UNIVERSIDAD DE GUANAJUATO 43

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Iteration Convergence units use convergence subroutines to compare the newly computed variables (in the feed stream to the convergence unit) with guessed values (in the product stream from the convergence unit) and to compute new guess values when the two streams are not identical to within convergence tolerances. This procedure is call iteration. It involves re – calculating the flowsheet. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 44

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Iteration Convergence units use convergence subroutines to compare the newly computed variables (in the feed stream to the convergence unit) with guessed values (in the product stream from the convergence unit) and to compute new guess values when the two streams are not identical to within convergence tolerances. This procedure is call iteration. It involves re – calculating the flowsheet. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 44

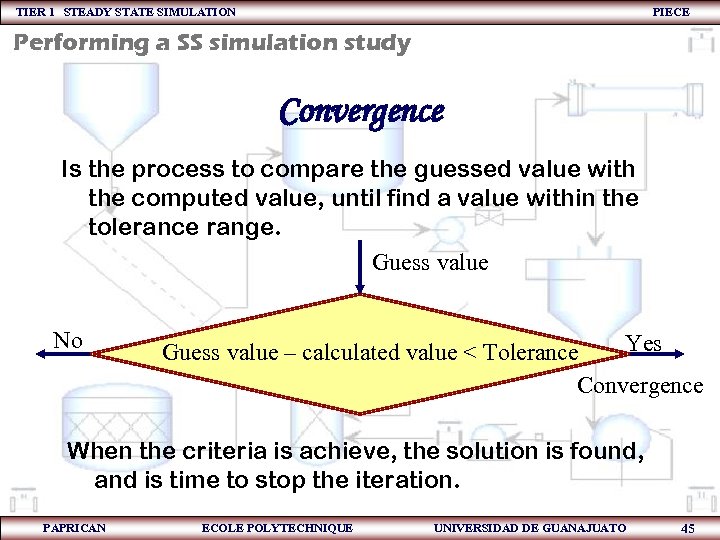

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Convergence Is the process to compare the guessed value with the computed value, until find a value within the tolerance range. Guess value No Yes Guess value – calculated value < Tolerance Convergence When the criteria is achieve, the solution is found, and is time to stop the iteration. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 45

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Convergence Is the process to compare the guessed value with the computed value, until find a value within the tolerance range. Guess value No Yes Guess value – calculated value < Tolerance Convergence When the criteria is achieve, the solution is found, and is time to stop the iteration. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 45

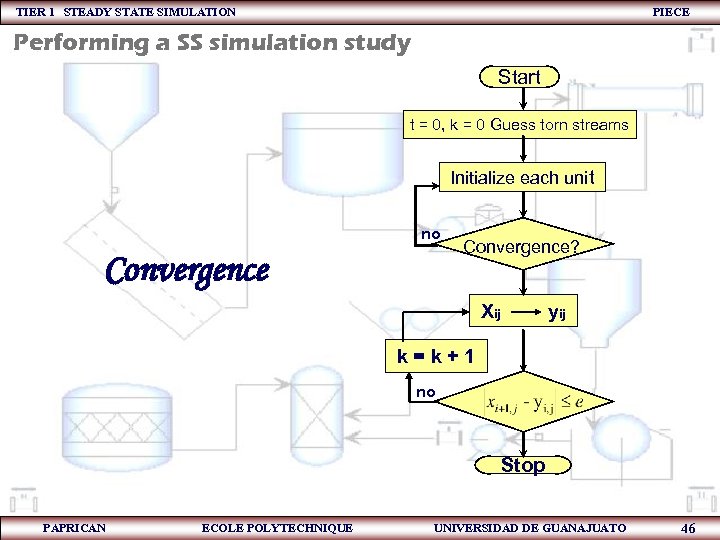

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Start t = 0, k = 0 Guess torn streams Initialize each unit no Convergence? Xij yij k=k+1 no Stop PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 46

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Start t = 0, k = 0 Guess torn streams Initialize each unit no Convergence? Xij yij k=k+1 no Stop PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 46

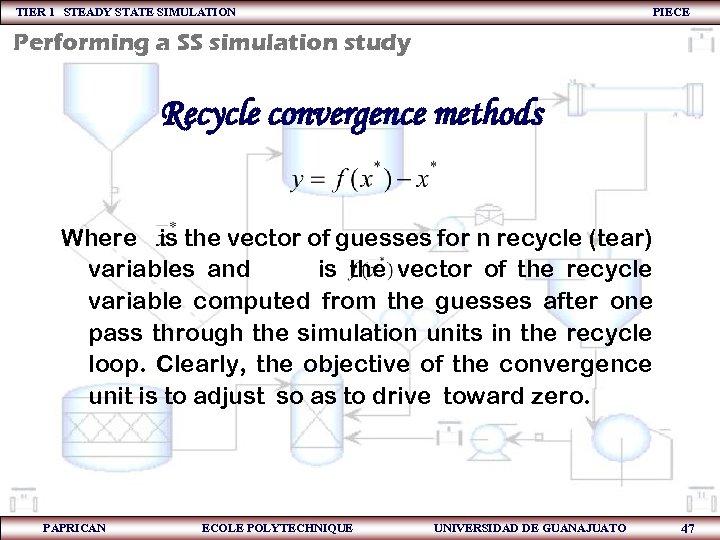

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Recycle convergence methods Where is the vector of guesses for n recycle (tear) variables and is the vector of the recycle variable computed from the guesses after one pass through the simulation units in the recycle loop. Clearly, the objective of the convergence unit is to adjust so as to drive toward zero. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 47

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Recycle convergence methods Where is the vector of guesses for n recycle (tear) variables and is the vector of the recycle variable computed from the guesses after one pass through the simulation units in the recycle loop. Clearly, the objective of the convergence unit is to adjust so as to drive toward zero. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 47

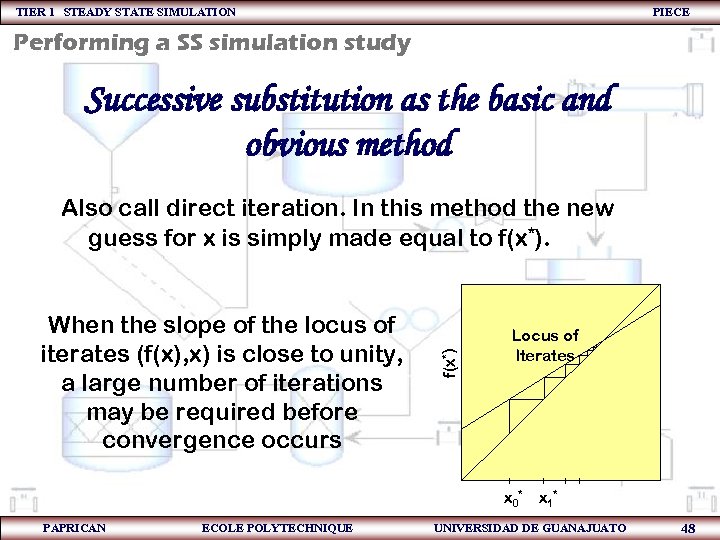

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Successive substitution as the basic and obvious method When the slope of the locus of iterates (f(x), x) is close to unity, a large number of iterations may be required before convergence occurs f(x*) Also call direct iteration. In this method the new guess for x is simply made equal to f(x*). Locus of Iterates x 0* x 1* PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 48

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Successive substitution as the basic and obvious method When the slope of the locus of iterates (f(x), x) is close to unity, a large number of iterations may be required before convergence occurs f(x*) Also call direct iteration. In this method the new guess for x is simply made equal to f(x*). Locus of Iterates x 0* x 1* PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 48

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Other convergence methods When the method of successive substitutions requires a large number of iterations, another methods are used to accelerate convergence: ü ü Wegstein’s method. Newton – Raphson method. Broyden’s quasi – Newton method. The dominant – eigenvalue method. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 49

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Other convergence methods When the method of successive substitutions requires a large number of iterations, another methods are used to accelerate convergence: ü ü Wegstein’s method. Newton – Raphson method. Broyden’s quasi – Newton method. The dominant – eigenvalue method. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 49

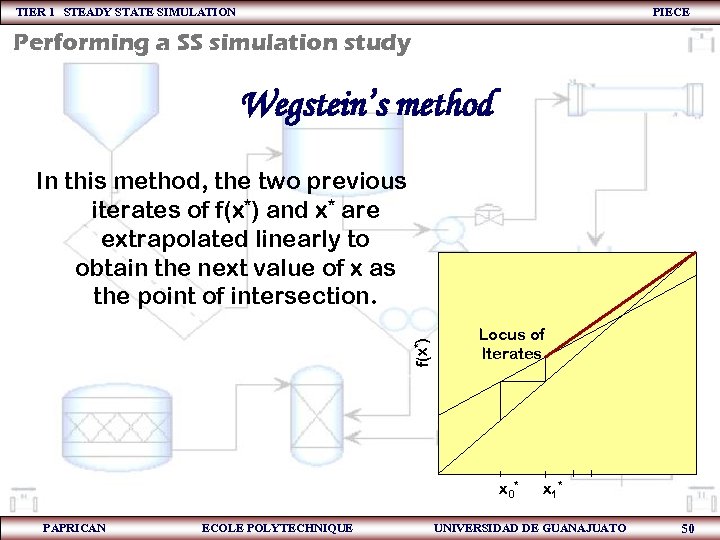

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Wegstein’s method f(x*) In this method, the two previous iterates of f(x*) and x* are extrapolated linearly to obtain the next value of x as the point of intersection. Locus of Iterates x 0* PAPRICAN ECOLE POLYTECHNIQUE x 1* UNIVERSIDAD DE GUANAJUATO 50

TIER 1 STEADY STATE SIMULATION PIECE Performing a SS simulation study Wegstein’s method f(x*) In this method, the two previous iterates of f(x*) and x* are extrapolated linearly to obtain the next value of x as the point of intersection. Locus of Iterates x 0* PAPRICAN ECOLE POLYTECHNIQUE x 1* UNIVERSIDAD DE GUANAJUATO 50

TIER 1 STEADY STATE SIMULATION PIECE Granularity of modeling Is the level of detail taken into account in a simulation. With the advance in technology, it is possible to combine on a single computer the full capability of a high fidelity simulation models. High fidelity process simulation is commonly used by many industries in the design of a process. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 51

TIER 1 STEADY STATE SIMULATION PIECE Granularity of modeling Is the level of detail taken into account in a simulation. With the advance in technology, it is possible to combine on a single computer the full capability of a high fidelity simulation models. High fidelity process simulation is commonly used by many industries in the design of a process. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 51

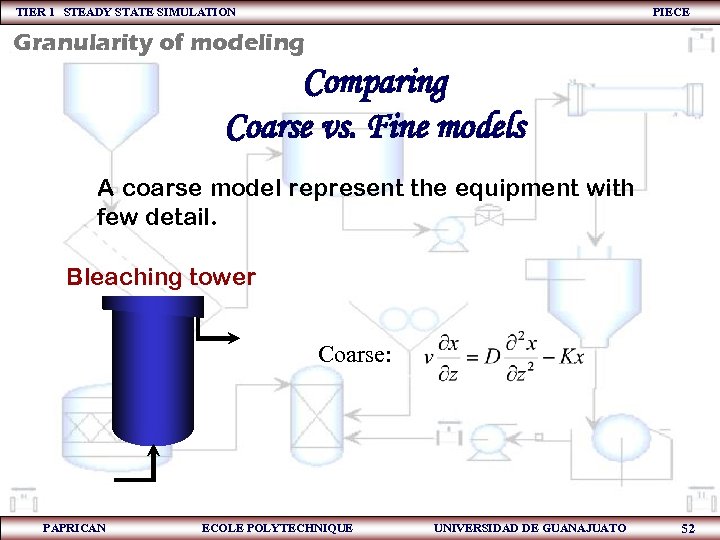

TIER 1 STEADY STATE SIMULATION PIECE Granularity of modeling Comparing Coarse vs. Fine models A coarse model represent the equipment with few detail. Bleaching tower Coarse: PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 52

TIER 1 STEADY STATE SIMULATION PIECE Granularity of modeling Comparing Coarse vs. Fine models A coarse model represent the equipment with few detail. Bleaching tower Coarse: PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 52

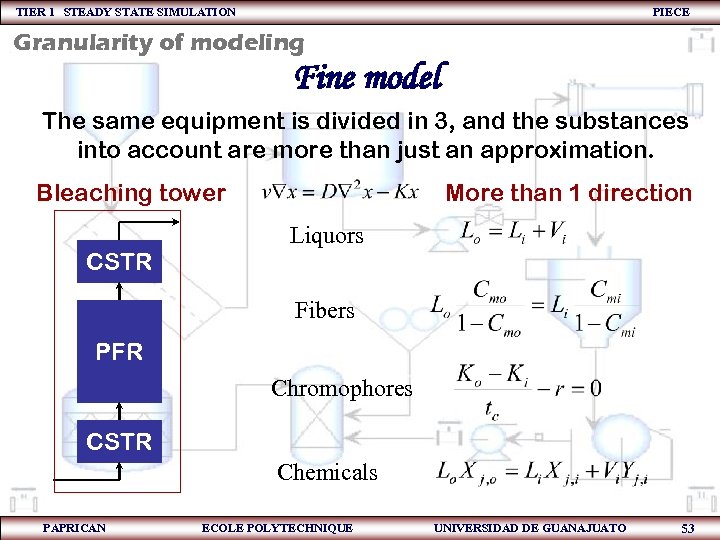

TIER 1 STEADY STATE SIMULATION PIECE Granularity of modeling Fine model The same equipment is divided in 3, and the substances into account are more than just an approximation. More than 1 direction Bleaching tower CSTR Liquors Fibers PFR Chromophores CSTR Chemicals PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 53

TIER 1 STEADY STATE SIMULATION PIECE Granularity of modeling Fine model The same equipment is divided in 3, and the substances into account are more than just an approximation. More than 1 direction Bleaching tower CSTR Liquors Fibers PFR Chromophores CSTR Chemicals PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 53

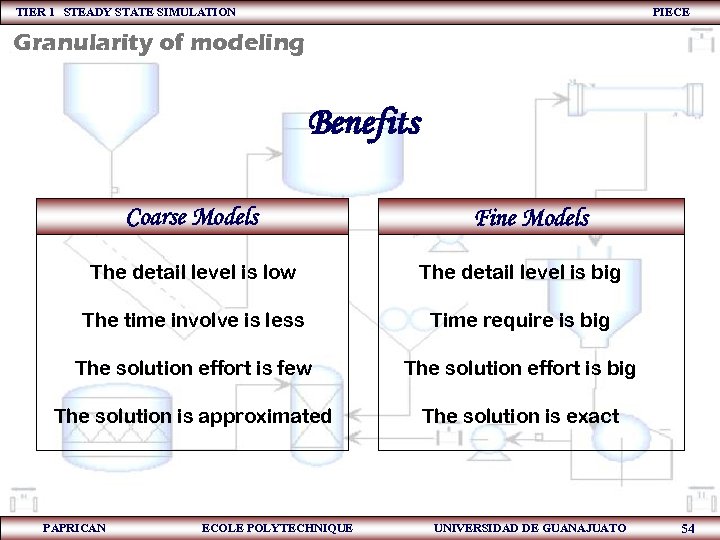

TIER 1 STEADY STATE SIMULATION PIECE Granularity of modeling Benefits Coarse Models The detail level is low The time involve is less The solution effort is few The solution is approximated PAPRICAN ECOLE POLYTECHNIQUE Fine Models The detail level is big Time require is big The solution effort is big The solution is exact UNIVERSIDAD DE GUANAJUATO 54

TIER 1 STEADY STATE SIMULATION PIECE Granularity of modeling Benefits Coarse Models The detail level is low The time involve is less The solution effort is few The solution is approximated PAPRICAN ECOLE POLYTECHNIQUE Fine Models The detail level is big Time require is big The solution effort is big The solution is exact UNIVERSIDAD DE GUANAJUATO 54

TIER 1 STEADY STATE SIMULATION PIECE 2 Steady state simulation in a process integration context PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 55

TIER 1 STEADY STATE SIMULATION PIECE 2 Steady state simulation in a process integration context PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 55

TIER 1 STEADY STATE SIMULATION PIECE Statement of intent Steady state simulation in a process integration context ü Recognize the components in a simulation flowsheet. ü Check the procedure to create a process. ü What is the importance of the computer. ü What can we obtain as a result of a simulation. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 56

TIER 1 STEADY STATE SIMULATION PIECE Statement of intent Steady state simulation in a process integration context ü Recognize the components in a simulation flowsheet. ü Check the procedure to create a process. ü What is the importance of the computer. ü What can we obtain as a result of a simulation. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 56

TIER 1 STEADY STATE SIMULATION PIECE Table of content Steady – state simulation in a process integration context Ø Ø Ø Ø Process flowsheets. Simulation flowsheets. Process synthesis methodologies. Minimal time and expense. Computer – based process. Data reconciliation. Process insights resulting from simulation. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 57

TIER 1 STEADY STATE SIMULATION PIECE Table of content Steady – state simulation in a process integration context Ø Ø Ø Ø Process flowsheets. Simulation flowsheets. Process synthesis methodologies. Minimal time and expense. Computer – based process. Data reconciliation. Process insights resulting from simulation. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 57

TIER 1 STEADY STATE SIMULATION PIECE Process flowsheets are the language of chemical processes. Like a work of art, they describe an existing process or a hypothetical process in sufficient detail to convey the essential features. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 58

TIER 1 STEADY STATE SIMULATION PIECE Process flowsheets are the language of chemical processes. Like a work of art, they describe an existing process or a hypothetical process in sufficient detail to convey the essential features. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 58

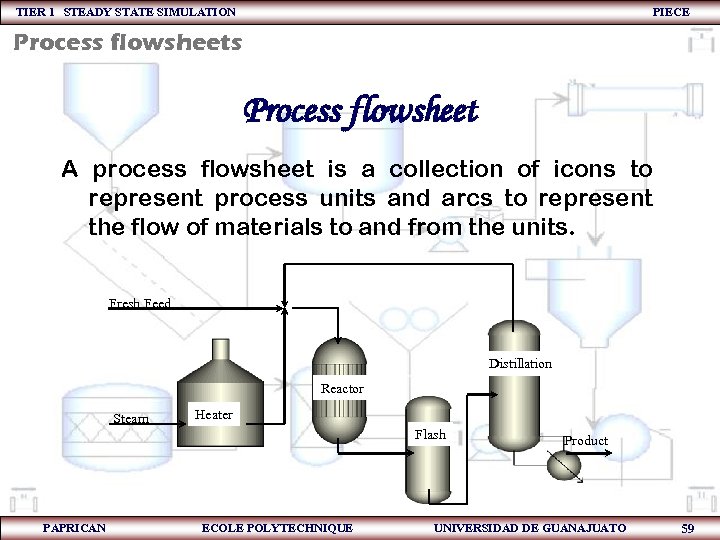

TIER 1 STEADY STATE SIMULATION PIECE Process flowsheets Process flowsheet A process flowsheet is a collection of icons to represent process units and arcs to represent the flow of materials to and from the units. Fresh Feed Distillation Reactor Steam Heater Flash PAPRICAN ECOLE POLYTECHNIQUE Product UNIVERSIDAD DE GUANAJUATO 59

TIER 1 STEADY STATE SIMULATION PIECE Process flowsheets Process flowsheet A process flowsheet is a collection of icons to represent process units and arcs to represent the flow of materials to and from the units. Fresh Feed Distillation Reactor Steam Heater Flash PAPRICAN ECOLE POLYTECHNIQUE Product UNIVERSIDAD DE GUANAJUATO 59

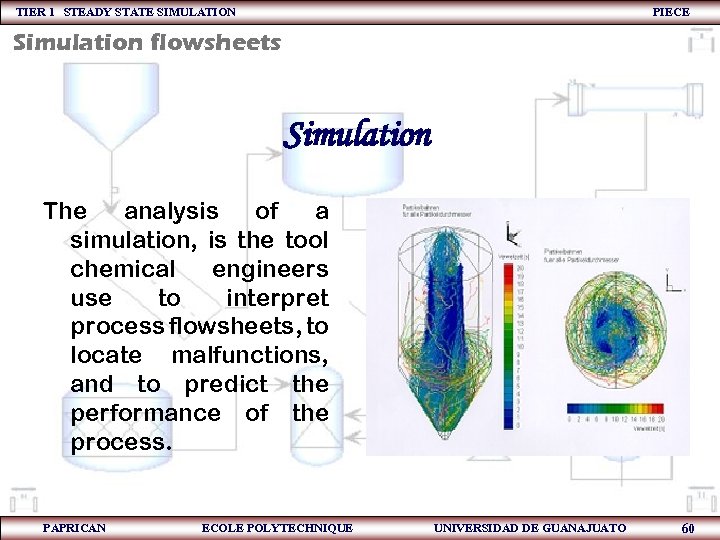

TIER 1 STEADY STATE SIMULATION PIECE Simulation flowsheets Simulation The analysis of a simulation, is the tool chemical engineers use to interpret process flowsheets, to locate malfunctions, and to predict the performance of the process. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 60

TIER 1 STEADY STATE SIMULATION PIECE Simulation flowsheets Simulation The analysis of a simulation, is the tool chemical engineers use to interpret process flowsheets, to locate malfunctions, and to predict the performance of the process. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 60

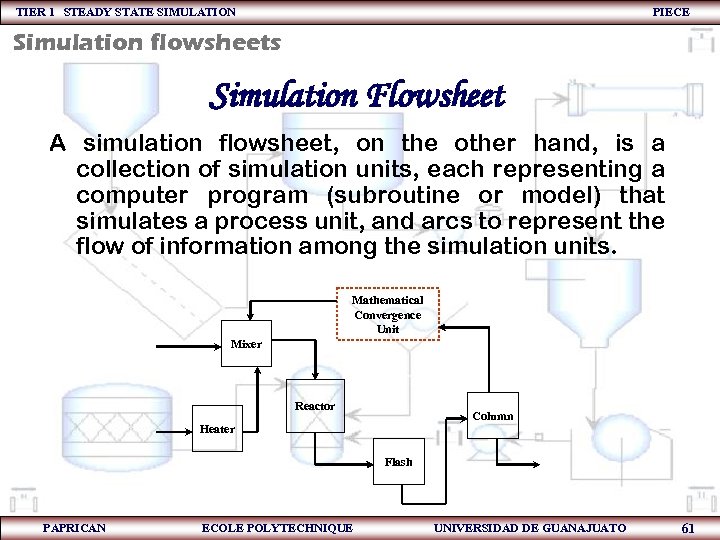

TIER 1 STEADY STATE SIMULATION PIECE Simulation flowsheets Simulation Flowsheet A simulation flowsheet, on the other hand, is a collection of simulation units, each representing a computer program (subroutine or model) that simulates a process unit, and arcs to represent the flow of information among the simulation units. Mathematical Convergence Unit Mixer Reactor Column Heater Flash PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 61

TIER 1 STEADY STATE SIMULATION PIECE Simulation flowsheets Simulation Flowsheet A simulation flowsheet, on the other hand, is a collection of simulation units, each representing a computer program (subroutine or model) that simulates a process unit, and arcs to represent the flow of information among the simulation units. Mathematical Convergence Unit Mixer Reactor Column Heater Flash PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 61

TIER 1 STEADY STATE SIMULATION PIECE Process synthesis methodologies ü Total enumeration of an explicit space: is the most obvious. Here we generate and evaluate every alternative design. We locate the better alternative by directly comparing the evaluations. ü Evolutionary methods: follow from the generation of a good base case design. Designers can then make many small changes, a few at a time, to improve the design incrementally. ü Structured Decision Making: following a plan that contains all the alternatives. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 62

TIER 1 STEADY STATE SIMULATION PIECE Process synthesis methodologies ü Total enumeration of an explicit space: is the most obvious. Here we generate and evaluate every alternative design. We locate the better alternative by directly comparing the evaluations. ü Evolutionary methods: follow from the generation of a good base case design. Designers can then make many small changes, a few at a time, to improve the design incrementally. ü Structured Decision Making: following a plan that contains all the alternatives. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 62

TIER 1 STEADY STATE SIMULATION PIECE Process synthesis methodologies ü Design to target: these have been especially useful in designing heat recovery and reactor networks. The utility requirements become the targets for the design. ü Problem abstraction: Here the search for better design alternatives begins by formulating a less detailed problem statement and attempting to solve this more abstract problem first. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 63

TIER 1 STEADY STATE SIMULATION PIECE Process synthesis methodologies ü Design to target: these have been especially useful in designing heat recovery and reactor networks. The utility requirements become the targets for the design. ü Problem abstraction: Here the search for better design alternatives begins by formulating a less detailed problem statement and attempting to solve this more abstract problem first. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 63

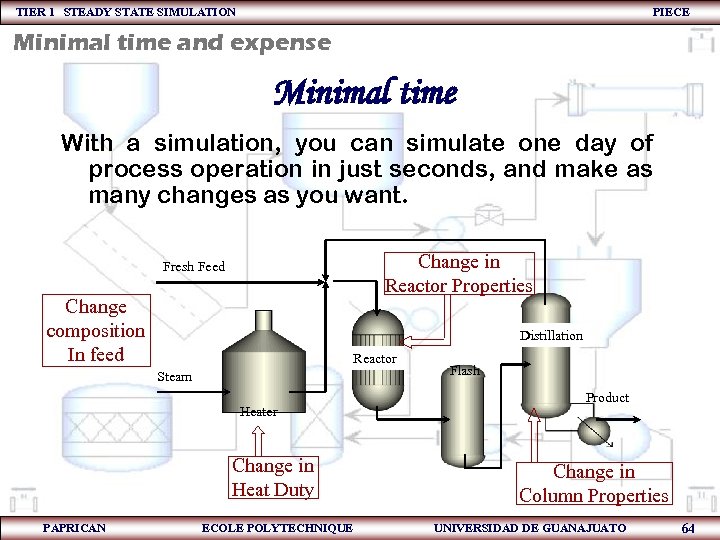

TIER 1 STEADY STATE SIMULATION PIECE Minimal time and expense Minimal time With a simulation, you can simulate one day of process operation in just seconds, and make as many changes as you want. Change in Reactor Properties Fresh Feed Change composition In feed Distillation Reactor Steam Heater Change in Heat Duty PAPRICAN ECOLE POLYTECHNIQUE Flash Product Change in Column Properties UNIVERSIDAD DE GUANAJUATO 64

TIER 1 STEADY STATE SIMULATION PIECE Minimal time and expense Minimal time With a simulation, you can simulate one day of process operation in just seconds, and make as many changes as you want. Change in Reactor Properties Fresh Feed Change composition In feed Distillation Reactor Steam Heater Change in Heat Duty PAPRICAN ECOLE POLYTECHNIQUE Flash Product Change in Column Properties UNIVERSIDAD DE GUANAJUATO 64

TIER 1 STEADY STATE SIMULATION PIECE Minimal time and expense Minimal expense Is easy to model the process with different kind of equipment without having to invest in it. Simulated “learning experiences” are much less costly than making real mistakes in the real plant. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 65

TIER 1 STEADY STATE SIMULATION PIECE Minimal time and expense Minimal expense Is easy to model the process with different kind of equipment without having to invest in it. Simulated “learning experiences” are much less costly than making real mistakes in the real plant. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 65

TIER 1 STEADY STATE SIMULATION PIECE Computer based process Computer – Based process representation which can be re - used Most of the times, there already models which can be adapted to the process under study, with minimal changes. This minimizes the time needed to set up complicated equations. Re-using models is much easier than building new ones, specially if the process is being modeled for the first time. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 66

TIER 1 STEADY STATE SIMULATION PIECE Computer based process Computer – Based process representation which can be re - used Most of the times, there already models which can be adapted to the process under study, with minimal changes. This minimizes the time needed to set up complicated equations. Re-using models is much easier than building new ones, specially if the process is being modeled for the first time. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 66

TIER 1 STEADY STATE SIMULATION PIECE Data reconciliation is a technique for improving the quality of measured plant data. These measurements are inherently inaccurate due to instrument failures, limitations of measurement techniques, etc. As a result, data are obtained that violate mass and energy balance constraints of describe a physically infeasible process. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 67

TIER 1 STEADY STATE SIMULATION PIECE Data reconciliation is a technique for improving the quality of measured plant data. These measurements are inherently inaccurate due to instrument failures, limitations of measurement techniques, etc. As a result, data are obtained that violate mass and energy balance constraints of describe a physically infeasible process. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 67

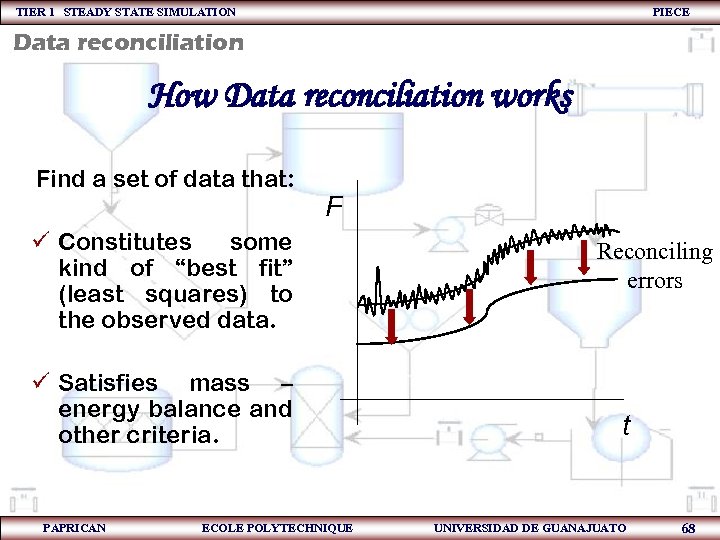

TIER 1 STEADY STATE SIMULATION PIECE Data reconciliation How Data reconciliation works Find a set of data that: F ü Constitutes some kind of “best fit” (least squares) to the observed data. ü Satisfies mass – energy balance and other criteria. PAPRICAN ECOLE POLYTECHNIQUE Reconciling errors t UNIVERSIDAD DE GUANAJUATO 68

TIER 1 STEADY STATE SIMULATION PIECE Data reconciliation How Data reconciliation works Find a set of data that: F ü Constitutes some kind of “best fit” (least squares) to the observed data. ü Satisfies mass – energy balance and other criteria. PAPRICAN ECOLE POLYTECHNIQUE Reconciling errors t UNIVERSIDAD DE GUANAJUATO 68

TIER 1 STEADY STATE SIMULATION PIECE Data reconciliation Opportunity to do data reconciliation This amounts to validation of the process data using knowledge of the plant structure and the plant measurement system PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 69

TIER 1 STEADY STATE SIMULATION PIECE Data reconciliation Opportunity to do data reconciliation This amounts to validation of the process data using knowledge of the plant structure and the plant measurement system PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 69

TIER 1 STEADY STATE SIMULATION PIECE Process insights resulting from modeling 1. MODEL 2. 2. 3. PAPRICAN Identification: We can find the structure and parameters in the model. Estimation: If the internal structure of model is known, we can find the internal states in model. Design: If the structure and internal states of model are known, we can study the parameters in the model. ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 70

TIER 1 STEADY STATE SIMULATION PIECE Process insights resulting from modeling 1. MODEL 2. 2. 3. PAPRICAN Identification: We can find the structure and parameters in the model. Estimation: If the internal structure of model is known, we can find the internal states in model. Design: If the structure and internal states of model are known, we can study the parameters in the model. ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 70

TIER 1 STEADY STATE SIMULATION PIECE Process insights resulting from modeling If the model is known, we have two uses for our model: 1. Direct: input is specified, output is studied (simulation). 2. Inverse: output is specified, input is studied. Used when an objective must be met (production, composition). PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 71

TIER 1 STEADY STATE SIMULATION PIECE Process insights resulting from modeling If the model is known, we have two uses for our model: 1. Direct: input is specified, output is studied (simulation). 2. Inverse: output is specified, input is studied. Used when an objective must be met (production, composition). PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 71

TIER 1 STEADY STATE SIMULATION PIECE 3 Steady – State Simulation in a Broader Context PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 72

TIER 1 STEADY STATE SIMULATION PIECE 3 Steady – State Simulation in a Broader Context PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 72

TIER 1 STEADY STATE SIMULATION PIECE Statement of intent Steady – State Simulation in a Broader Context ü Show to take a decision to create a process. ü Know if the process is viable, in terms of stability and economic. ü Taking in count security aspects. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 73

TIER 1 STEADY STATE SIMULATION PIECE Statement of intent Steady – State Simulation in a Broader Context ü Show to take a decision to create a process. ü Know if the process is viable, in terms of stability and economic. ü Taking in count security aspects. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 73

TIER 1 STEADY STATE SIMULATION PIECE Table of content Aspects of Process Design Ø Process design. Ø Stability and sensitivity. Ø Process optimization. Ø Economic evaluation of alternatives. Ø Operator training. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 74

TIER 1 STEADY STATE SIMULATION PIECE Table of content Aspects of Process Design Ø Process design. Ø Stability and sensitivity. Ø Process optimization. Ø Economic evaluation of alternatives. Ø Operator training. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 74

TIER 1 STEADY STATE SIMULATION PIECE Process design The design of chemical products begins with the identification and creation of potential opportunities to satisfy societal needs and to generate profit. The scope of chemical product is extremely broad. They can be roughly classified as: 1. 2. 3. PAPRICAN basic chemical products. Industrial products. Consumer products. ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 75

TIER 1 STEADY STATE SIMULATION PIECE Process design The design of chemical products begins with the identification and creation of potential opportunities to satisfy societal needs and to generate profit. The scope of chemical product is extremely broad. They can be roughly classified as: 1. 2. 3. PAPRICAN basic chemical products. Industrial products. Consumer products. ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 75

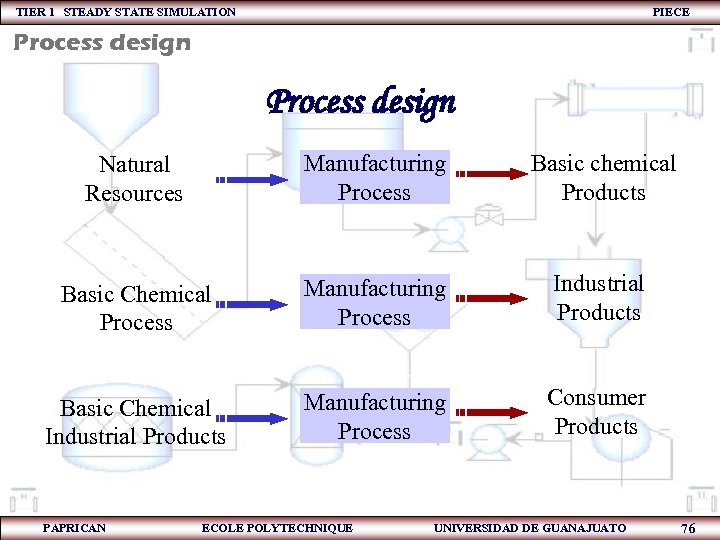

TIER 1 STEADY STATE SIMULATION PIECE Process design Natural Resources Manufacturing Process Basic chemical Products Basic Chemical Process Manufacturing Process Industrial Products Basic Chemical Industrial Products Manufacturing Process Consumer Products PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 76

TIER 1 STEADY STATE SIMULATION PIECE Process design Natural Resources Manufacturing Process Basic chemical Products Basic Chemical Process Manufacturing Process Industrial Products Basic Chemical Industrial Products Manufacturing Process Consumer Products PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 76

TIER 1 STEADY STATE SIMULATION PIECE Process design Motivation for design projects 1. Desires of customers for chemicals with improved properties for many applications. 2. New inexpensive source of a raw material with new reaction paths and methods of separation. 3. New markets are discovered. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 77

TIER 1 STEADY STATE SIMULATION PIECE Process design Motivation for design projects 1. Desires of customers for chemicals with improved properties for many applications. 2. New inexpensive source of a raw material with new reaction paths and methods of separation. 3. New markets are discovered. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 77

TIER 1 STEADY STATE SIMULATION PIECE Process design Steps in a Process Design 1. Process Design – Questions to Answer ü ü Is the chemical structure known? Is a process required to produce the chemicals? Is the gross profit favorable? Is the process still promising after further elaboration? Is the process and/or product feasible? ü ü ü PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 78

TIER 1 STEADY STATE SIMULATION PIECE Process design Steps in a Process Design 1. Process Design – Questions to Answer ü ü Is the chemical structure known? Is a process required to produce the chemicals? Is the gross profit favorable? Is the process still promising after further elaboration? Is the process and/or product feasible? ü ü ü PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 78

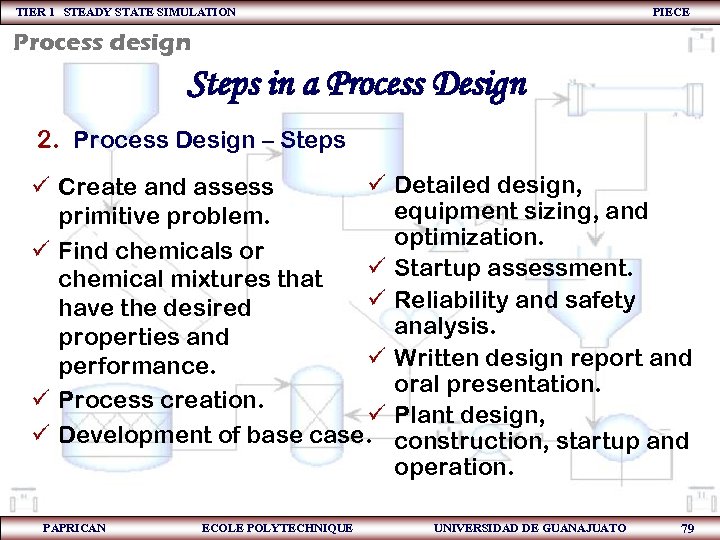

TIER 1 STEADY STATE SIMULATION PIECE Process design Steps in a Process Design 2. Process Design – Steps ü ü Create and assess primitive problem. ü Find chemicals or ü chemical mixtures that ü have the desired properties and ü performance. ü Process creation. ü ü Development of base case. PAPRICAN ECOLE POLYTECHNIQUE Detailed design, equipment sizing, and optimization. Startup assessment. Reliability and safety analysis. Written design report and oral presentation. Plant design, construction, startup and operation. UNIVERSIDAD DE GUANAJUATO 79

TIER 1 STEADY STATE SIMULATION PIECE Process design Steps in a Process Design 2. Process Design – Steps ü ü Create and assess primitive problem. ü Find chemicals or ü chemical mixtures that ü have the desired properties and ü performance. ü Process creation. ü ü Development of base case. PAPRICAN ECOLE POLYTECHNIQUE Detailed design, equipment sizing, and optimization. Startup assessment. Reliability and safety analysis. Written design report and oral presentation. Plant design, construction, startup and operation. UNIVERSIDAD DE GUANAJUATO 79

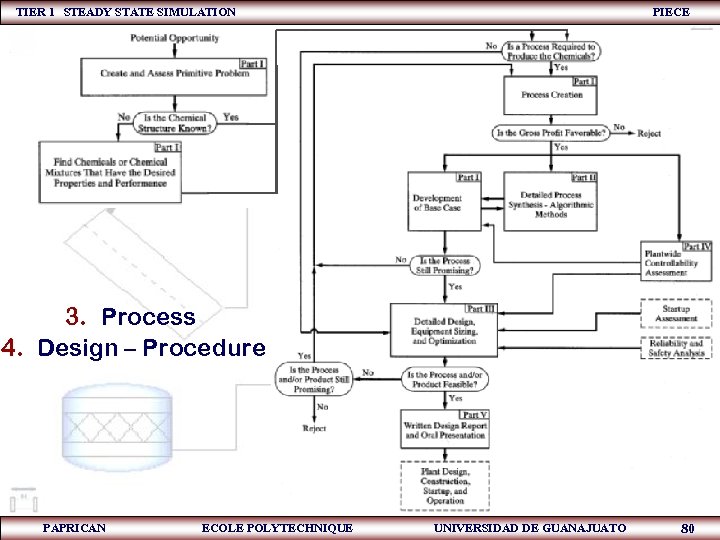

TIER 1 STEADY STATE SIMULATION PIECE 3. Process 4. Design – Procedure PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 80

TIER 1 STEADY STATE SIMULATION PIECE 3. Process 4. Design – Procedure PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 80

TIER 1 STEADY STATE SIMULATION PIECE Process design Detailed Process Synthesis Using Algorithmic Methods ü Create and evaluate chemical reactor networks for conversion of feed to product chemicals. • Separation trains for recovering species in multicomponent mixture. • Reactor separator recycle networks. ü Locate and reduce energy usage. • Create and evaluate efficient networks of heat exchangers with turbines for power recovery. • Networks of mass exchangers to reduce waste. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 81

TIER 1 STEADY STATE SIMULATION PIECE Process design Detailed Process Synthesis Using Algorithmic Methods ü Create and evaluate chemical reactor networks for conversion of feed to product chemicals. • Separation trains for recovering species in multicomponent mixture. • Reactor separator recycle networks. ü Locate and reduce energy usage. • Create and evaluate efficient networks of heat exchangers with turbines for power recovery. • Networks of mass exchangers to reduce waste. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 81

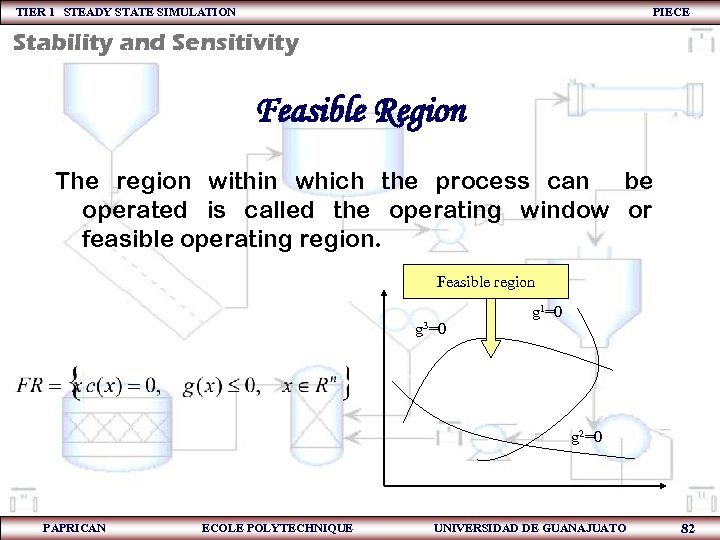

TIER 1 STEADY STATE SIMULATION PIECE Stability and Sensitivity Feasible Region The region within which the process can be operated is called the operating window or feasible operating region. Feasible region g 3=0 g 1=0 g 2=0 PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 82

TIER 1 STEADY STATE SIMULATION PIECE Stability and Sensitivity Feasible Region The region within which the process can be operated is called the operating window or feasible operating region. Feasible region g 3=0 g 1=0 g 2=0 PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 82

TIER 1 STEADY STATE SIMULATION PIECE Stability and Sensitivity Feasible Region One can not in general say a priori how a thermodynamic model will behave when extrapolated beyond the region in which data were available for determining its empirical parameters. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 83

TIER 1 STEADY STATE SIMULATION PIECE Stability and Sensitivity Feasible Region One can not in general say a priori how a thermodynamic model will behave when extrapolated beyond the region in which data were available for determining its empirical parameters. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 83

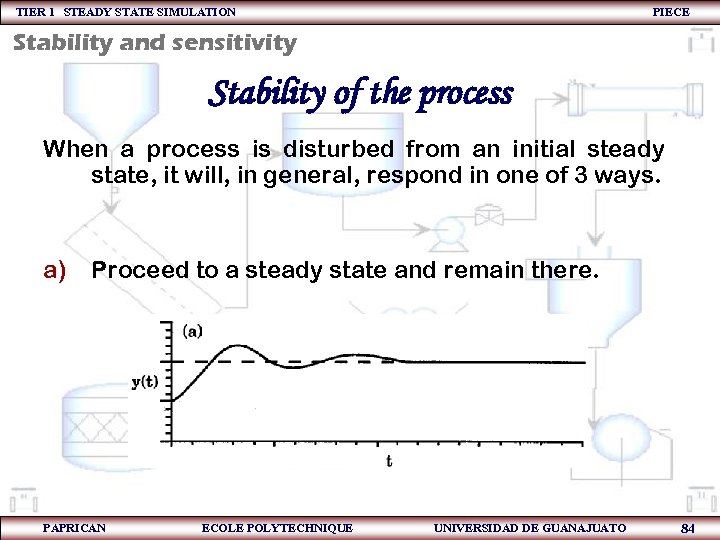

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Stability of the process When a process is disturbed from an initial steady state, it will, in general, respond in one of 3 ways. a) Proceed to a steady state and remain there. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 84

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Stability of the process When a process is disturbed from an initial steady state, it will, in general, respond in one of 3 ways. a) Proceed to a steady state and remain there. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 84

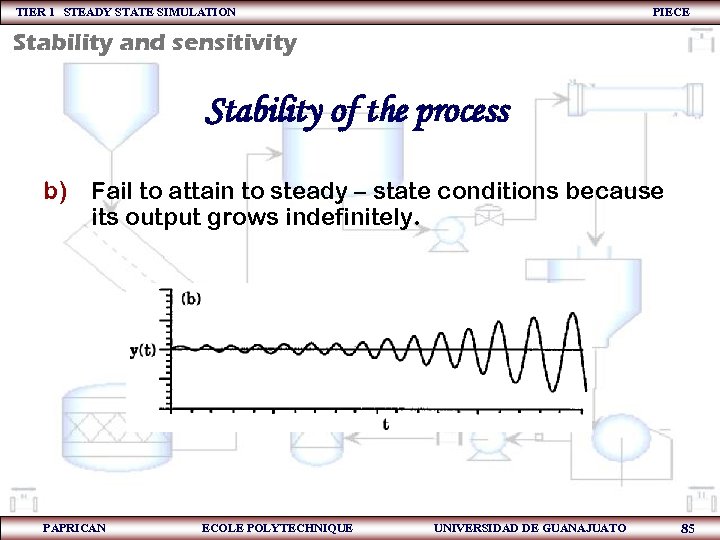

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Stability of the process b) Fail to attain to steady – state conditions because its output grows indefinitely. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 85

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Stability of the process b) Fail to attain to steady – state conditions because its output grows indefinitely. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 85

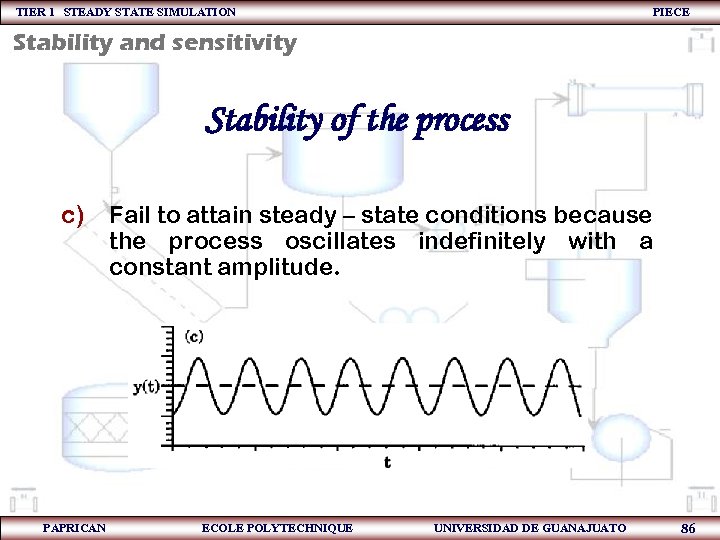

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Stability of the process c) PAPRICAN Fail to attain steady – state conditions because the process oscillates indefinitely with a constant amplitude. ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 86

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Stability of the process c) PAPRICAN Fail to attain steady – state conditions because the process oscillates indefinitely with a constant amplitude. ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 86

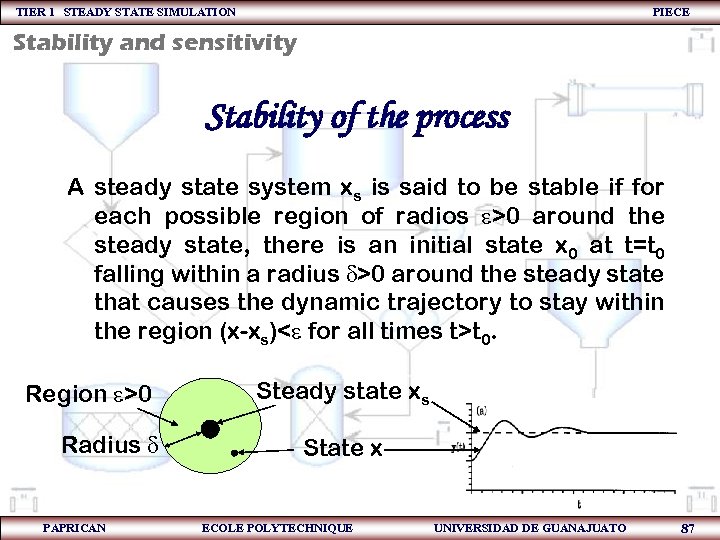

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Stability of the process A steady state system xs is said to be stable if for each possible region of radios e>0 around the steady state, there is an initial state x 0 at t=t 0 falling within a radius d>0 around the steady state that causes the dynamic trajectory to stay within the region (x-xs)

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Stability of the process A steady state system xs is said to be stable if for each possible region of radios e>0 around the steady state, there is an initial state x 0 at t=t 0 falling within a radius d>0 around the steady state that causes the dynamic trajectory to stay within the region (x-xs)

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Sensitivity analysis In many cases, it is useful to know how a chemical process respond when a equipment parameter or stream variable is varied, rather than running simulation only in few parameters. The sensitivity analysis permits the tabulation of output variables at equal increments over a specified range of parameter or variable values. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 88

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Sensitivity analysis In many cases, it is useful to know how a chemical process respond when a equipment parameter or stream variable is varied, rather than running simulation only in few parameters. The sensitivity analysis permits the tabulation of output variables at equal increments over a specified range of parameter or variable values. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 88

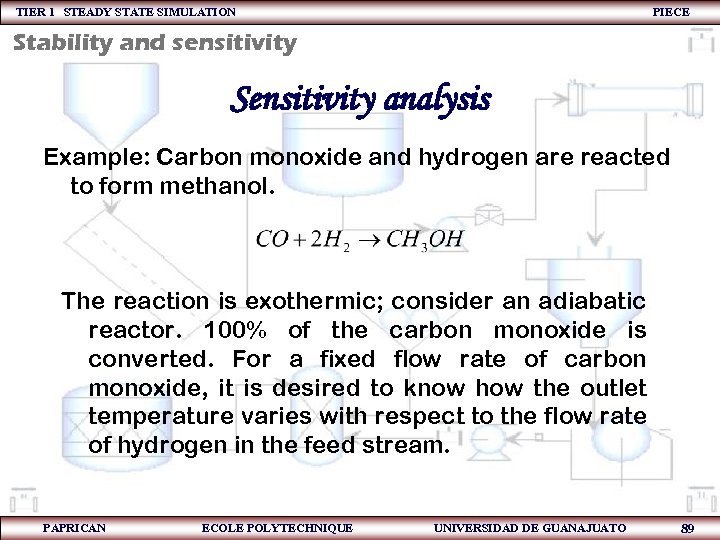

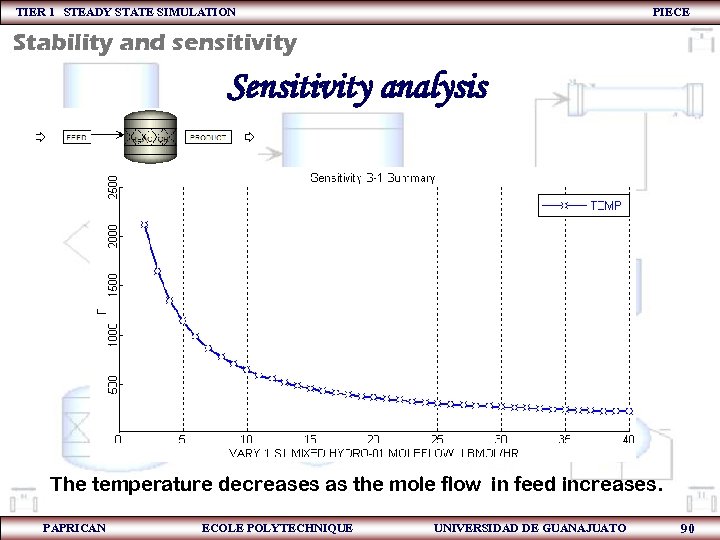

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Sensitivity analysis Example: Carbon monoxide and hydrogen are reacted to form methanol. The reaction is exothermic; consider an adiabatic reactor. 100% of the carbon monoxide is converted. For a fixed flow rate of carbon monoxide, it is desired to know how the outlet temperature varies with respect to the flow rate of hydrogen in the feed stream. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 89

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Sensitivity analysis Example: Carbon monoxide and hydrogen are reacted to form methanol. The reaction is exothermic; consider an adiabatic reactor. 100% of the carbon monoxide is converted. For a fixed flow rate of carbon monoxide, it is desired to know how the outlet temperature varies with respect to the flow rate of hydrogen in the feed stream. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 89

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Sensitivity analysis The temperature decreases as the mole flow in feed increases. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 90

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Sensitivity analysis The temperature decreases as the mole flow in feed increases. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 90

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Sensitivity analysis One of the most important contributions of sensitivity analysis is that it allows one to identify those variables which, when changed, have the greatest impact on the process output. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 91

TIER 1 STEADY STATE SIMULATION PIECE Stability and sensitivity Sensitivity analysis One of the most important contributions of sensitivity analysis is that it allows one to identify those variables which, when changed, have the greatest impact on the process output. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 91

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Optimization From a Mathematical point of view, chemical engineers encounter 3 situations when solving equations. ü Completely specified case. ü Over-specified case. ü Under-specified. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 92

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Optimization From a Mathematical point of view, chemical engineers encounter 3 situations when solving equations. ü Completely specified case. ü Over-specified case. ü Under-specified. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 92

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Completely specified case Nequations = Nvariables When the number of equations is equal to the number of variables, then we can proceed to solve the problem. 3 x – 2 y + 9 z = 3 6 x – 11 y + z = 7 x – 15 y + 4 z = 25 PAPRICAN ECOLE POLYTECHNIQUE In this case, we have 3 equations with 3 unknowns. UNIVERSIDAD DE GUANAJUATO 93

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Completely specified case Nequations = Nvariables When the number of equations is equal to the number of variables, then we can proceed to solve the problem. 3 x – 2 y + 9 z = 3 6 x – 11 y + z = 7 x – 15 y + 4 z = 25 PAPRICAN ECOLE POLYTECHNIQUE In this case, we have 3 equations with 3 unknowns. UNIVERSIDAD DE GUANAJUATO 93

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Over – specified case Many variables are determined in >1 way – values must be reconciled Nvariables < Nequations which is commonly referred to as the reconciliation (data reconciliation and rectification) problem. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 94

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Over – specified case Many variables are determined in >1 way – values must be reconciled Nvariables < Nequations which is commonly referred to as the reconciliation (data reconciliation and rectification) problem. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 94

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Under – specified case Some variables are undetermined – can be manipulated to optimize the process. Nvariables > Nequations Also called optimization problems. The optimization is used to maximize or minimize a specified objective function by manipulating decision variables (feed stream, block input, or other input variables). PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 95

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Under – specified case Some variables are undetermined – can be manipulated to optimize the process. Nvariables > Nequations Also called optimization problems. The optimization is used to maximize or minimize a specified objective function by manipulating decision variables (feed stream, block input, or other input variables). PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 95

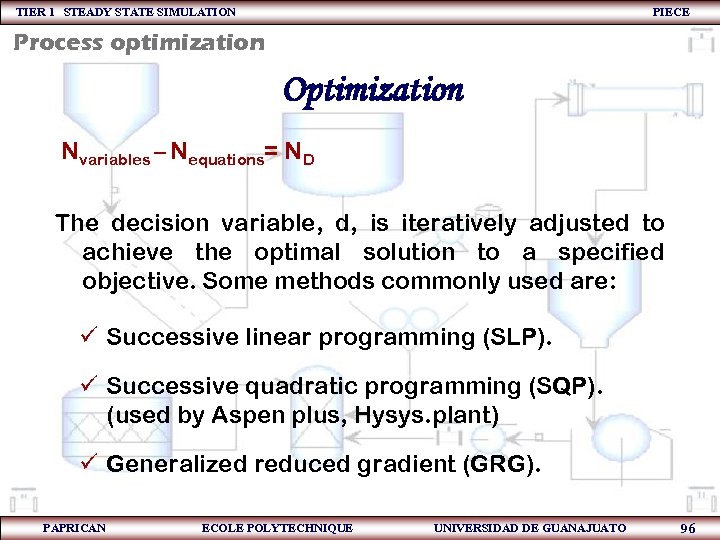

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Optimization Nvariables – Nequations= ND The decision variable, d, is iteratively adjusted to achieve the optimal solution to a specified objective. Some methods commonly used are: ü Successive linear programming (SLP). ü Successive quadratic programming (SQP). (used by Aspen plus, Hysys. plant) ü Generalized reduced gradient (GRG). PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 96

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Optimization Nvariables – Nequations= ND The decision variable, d, is iteratively adjusted to achieve the optimal solution to a specified objective. Some methods commonly used are: ü Successive linear programming (SLP). ü Successive quadratic programming (SQP). (used by Aspen plus, Hysys. plant) ü Generalized reduced gradient (GRG). PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 96

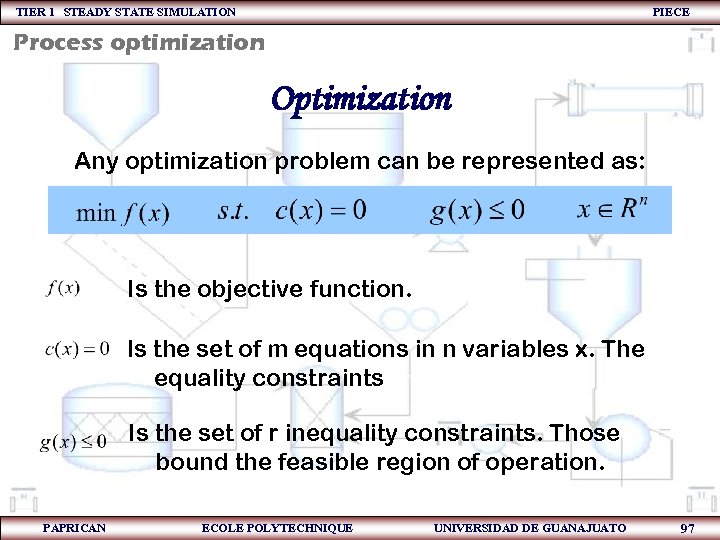

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Optimization Any optimization problem can be represented as: Is the objective function. Is the set of m equations in n variables x. The equality constraints Is the set of r inequality constraints. Those bound the feasible region of operation. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 97

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Optimization Any optimization problem can be represented as: Is the objective function. Is the set of m equations in n variables x. The equality constraints Is the set of r inequality constraints. Those bound the feasible region of operation. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 97

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Optimize on multiple criteria Some common objectives in optimization of an industrial process are: ü ü ü Achieve lower capital cost design. Increase production. Reduce unit operation cost. Reduce environmental impact. Reduce energy consumption. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 98

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Optimize on multiple criteria Some common objectives in optimization of an industrial process are: ü ü ü Achieve lower capital cost design. Increase production. Reduce unit operation cost. Reduce environmental impact. Reduce energy consumption. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 98

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Degrees of freedom A degree of freedom analysis is incorporated in the development of each subroutine that simulate a process unit. These subroutines solve sets of Nequations involving Nvariables. ND = Nequations – Nvariables. Degrees of freedom are the number of input variables you need to specify. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 99

TIER 1 STEADY STATE SIMULATION PIECE Process optimization Degrees of freedom A degree of freedom analysis is incorporated in the development of each subroutine that simulate a process unit. These subroutines solve sets of Nequations involving Nvariables. ND = Nequations – Nvariables. Degrees of freedom are the number of input variables you need to specify. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 99

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Quantitative comparison of alternatives In almost every case encountered by chemical engineer, there are several alternative methods which can be used for any given process or operation. Formaldehyde production: 1. By catalytic dehydrogenation of methanol. (By controlled oxidation of natural gas) 2. By direct reaction between CO and H 2 (under special conditions of catalyst, temperature, and pressure) PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 100

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Quantitative comparison of alternatives In almost every case encountered by chemical engineer, there are several alternative methods which can be used for any given process or operation. Formaldehyde production: 1. By catalytic dehydrogenation of methanol. (By controlled oxidation of natural gas) 2. By direct reaction between CO and H 2 (under special conditions of catalyst, temperature, and pressure) PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 100

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Optimum Economic Design If there are two or more methods for obtaining exactly equivalent final results, the preferred method would be the one involving the least total cost. $ Alternative designs do not give final products or results that are exactly equivalent. It then becomes necessary to consider the quality of the product or the operation as well as the total cost. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 101

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Optimum Economic Design If there are two or more methods for obtaining exactly equivalent final results, the preferred method would be the one involving the least total cost. $ Alternative designs do not give final products or results that are exactly equivalent. It then becomes necessary to consider the quality of the product or the operation as well as the total cost. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 101

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Throughout the design process, estimates of the cost of equipment and other costs related to the capital investment play a crucial role in selecting from among the design alternatives. ü The total capital investment (TCI). ü The annual cost of manufacture (COM). PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 102

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Throughout the design process, estimates of the cost of equipment and other costs related to the capital investment play a crucial role in selecting from among the design alternatives. ü The total capital investment (TCI). ü The annual cost of manufacture (COM). PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 102

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Total capital investment Is a one – time expense for the design, construction, and start – up of a new plant or a revamp of an existing plant. Estimation of the total capital investment 1. Order – of magnitude estimate based on bench – scale laboratory experiments. 2. Study estimate based on a preliminary process design. 3. Preliminary estimate based on detailed process design studies lading to an optimized process design. 4. Definitive estimate based on a detailed plant design. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 103

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Total capital investment Is a one – time expense for the design, construction, and start – up of a new plant or a revamp of an existing plant. Estimation of the total capital investment 1. Order – of magnitude estimate based on bench – scale laboratory experiments. 2. Study estimate based on a preliminary process design. 3. Preliminary estimate based on detailed process design studies lading to an optimized process design. 4. Definitive estimate based on a detailed plant design. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 103

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Investment justification Objective: to evaluate the costs and benefits of investment in process modifications. ü Inputs and outputs with costs attached must be accurately represented. ü Differences between candidate solutions must be accurately modelled. ü Level of detail just enough to enable costbenefit calculations. ü Other parts of the process can be a “black box”. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 104

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Investment justification Objective: to evaluate the costs and benefits of investment in process modifications. ü Inputs and outputs with costs attached must be accurately represented. ü Differences between candidate solutions must be accurately modelled. ü Level of detail just enough to enable costbenefit calculations. ü Other parts of the process can be a “black box”. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 104

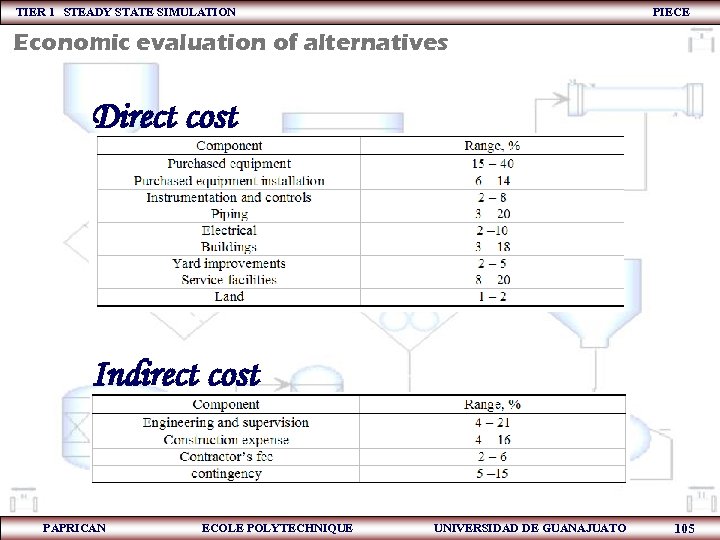

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Direct cost Indirect cost PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 105

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Direct cost Indirect cost PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 105

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Quantify cost – benefit of various possibilities When designing a greenfield plant, there are many possibilities which can be evaluated to get the best cost – benefit ratio. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 106

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Quantify cost – benefit of various possibilities When designing a greenfield plant, there are many possibilities which can be evaluated to get the best cost – benefit ratio. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 106

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Cost sensitivity analysis Sensitivity analysis is important in order to avoid information overload: It usually is best to do an initial analysis using only the data you have, being careful about indicating where the data is weak or you are using best guesses. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 107

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Cost sensitivity analysis Sensitivity analysis is important in order to avoid information overload: It usually is best to do an initial analysis using only the data you have, being careful about indicating where the data is weak or you are using best guesses. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 107

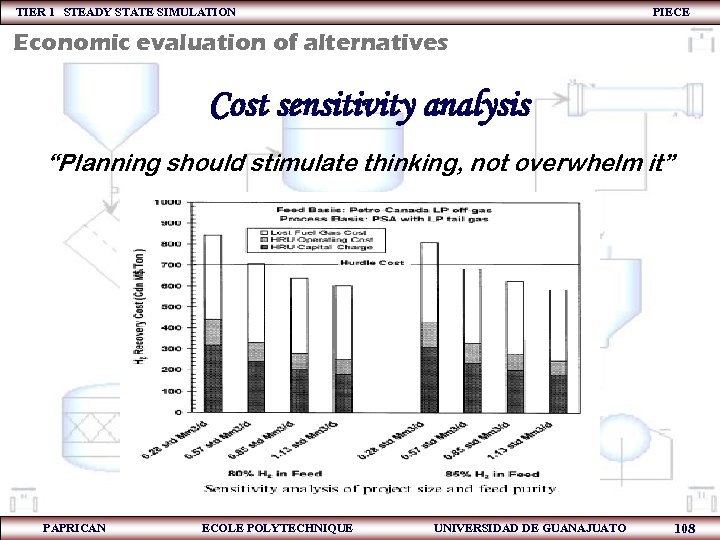

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Cost sensitivity analysis “Planning should stimulate thinking, not overwhelm it” PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 108

TIER 1 STEADY STATE SIMULATION PIECE Economic evaluation of alternatives Cost sensitivity analysis “Planning should stimulate thinking, not overwhelm it” PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 108

TIER 1 STEADY STATE SIMULATION PIECE Operator training Today, cheap computer power allows virtually any operator to have enough capability to simulate large flowsheets with considerable detail on the desktop. Process flowsheet simulators now have a sophisticated user interface, large physical properties databanks, and many thermodynamic models. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 109

TIER 1 STEADY STATE SIMULATION PIECE Operator training Today, cheap computer power allows virtually any operator to have enough capability to simulate large flowsheets with considerable detail on the desktop. Process flowsheet simulators now have a sophisticated user interface, large physical properties databanks, and many thermodynamic models. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 109

TIER 1 STEADY STATE SIMULATION PIECE Operator training Running sophisticated process simulations does not guarantee correct results. You need to understand thermodynamic assumptions underlying the program and how to ensure proper application. The personnel using the simulators, should be trained beforehand, and be aware of problems that may appear. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 110

TIER 1 STEADY STATE SIMULATION PIECE Operator training Running sophisticated process simulations does not guarantee correct results. You need to understand thermodynamic assumptions underlying the program and how to ensure proper application. The personnel using the simulators, should be trained beforehand, and be aware of problems that may appear. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 110

TIER 1 STEADY STATE SIMULATION PIECE Operator training Operator Training simulation Objective: to mimic response of displays to simulate process excursion and operator inputs. ü integration with physical operator console. ü simplified process representation, just enough to generate appropriate responses. ü progressive series of exercises as part of system. ü trainee evaluation as part of system. PAPRICAN ECOLE POLYTECHNIQUE UNIVERSIDAD DE GUANAJUATO 111