bf11e5680f41069b86223c01cf0fe426.ppt

- Количество слайдов: 32

Thomas Aiken Marketing and Business Development Applied. Sensor, Inc. (908) 222 -1477 tom. aiken@appliedsensor. com 1 TD Aiken March 31, 2008 Developing a Safety Sensor for Fuel Cell Vehicles

2 TD Aiken March 31, 2008 Applied. Sensor provides gas sensing solutions for safety, quality, comfort and control.

Design and develop a selective safety sensor to detect hydrogen gas leaking within the confines of a hydrogen or fuel cell powered vehicle and do so – – 3 within LEL, to automotive standards, using high volume manufacturing processes and, oh by the way, make it cheap TD Aiken March 31, 2008 The Challenge

• Association of hydrogen and explosions runs deep with the consumer. • Gasoline vapor is heavy and will lie low while hydrogen will rise quickly to fill a space. • Low molecular weight allows hydrogen leaks to be a constant safety issue. 4 TD Aiken March 31, 2008 Why hydrogen but not gasoline sensing?

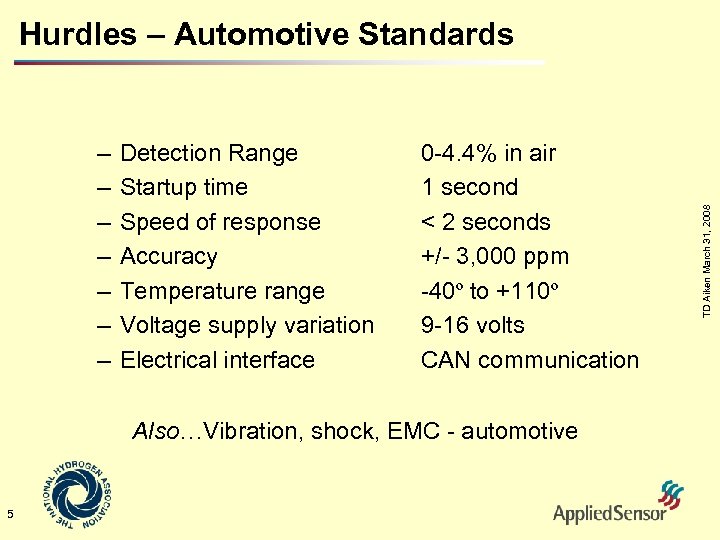

– – – – Detection Range Startup time Speed of response Accuracy Temperature range Voltage supply variation Electrical interface 0 -4. 4% in air 1 second < 2 seconds +/- 3, 000 ppm -40º to +110º 9 -16 volts CAN communication Also…Vibration, shock, EMC - automotive 5 TD Aiken March 31, 2008 Hurdles – Automotive Standards

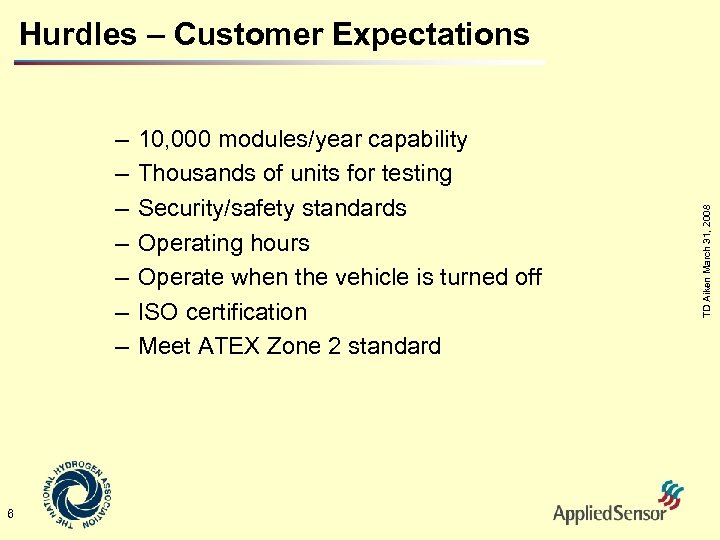

– – – – 6 10, 000 modules/year capability Thousands of units for testing Security/safety standards Operating hours Operate when the vehicle is turned off ISO certification Meet ATEX Zone 2 standard TD Aiken March 31, 2008 Hurdles – Customer Expectations

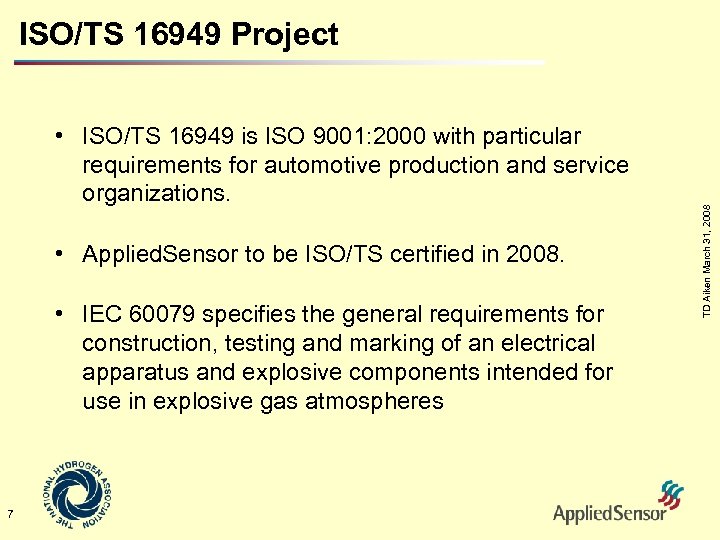

• ISO/TS 16949 is ISO 9001: 2000 with particular requirements for automotive production and service organizations. • Applied. Sensor to be ISO/TS certified in 2008. • IEC 60079 specifies the general requirements for construction, testing and marking of an electrical apparatus and explosive components intended for use in explosive gas atmospheres 7 TD Aiken March 31, 2008 ISO/TS 16949 Project

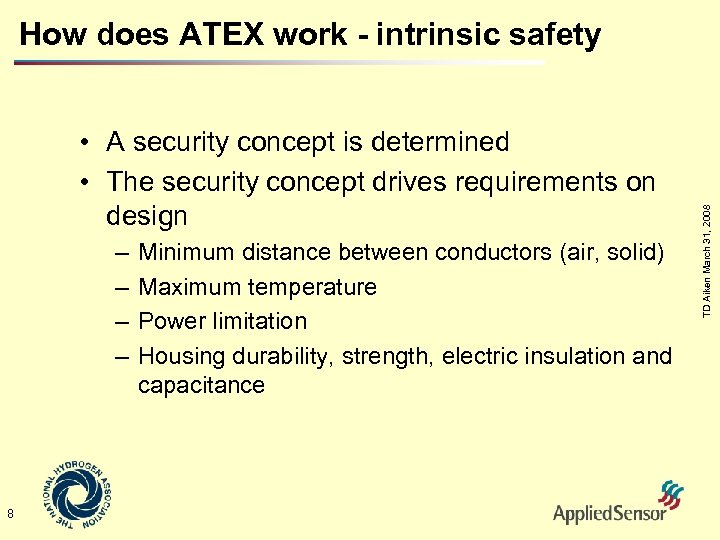

• A security concept is determined • The security concept drives requirements on design – – 8 Minimum distance between conductors (air, solid) Maximum temperature Power limitation Housing durability, strength, electric insulation and capacitance TD Aiken March 31, 2008 How does ATEX work - intrinsic safety

Zone 0 – flammable vapor exists Zone 1 – flammable vapor likely to exist Zone 2 – an explosive atmosphere consisting of a mixture of air and flammable gas vapor or mist is not likely to occur in normal operation but if it does occur will persist for a period of time. 9 TD Aiken March 31, 2008 ATEX Zone 2

Standards in general – ISO/CD 26142 - Hydrogen detection apparatus (ISO/TC 197 WG 13 ) – EU projects – UL standards, etc. … 10 TD Aiken March 31, 2008 Significant standarization efforts going on worldwide

• Early sensing technology relied on field effect principle to detect hydrogen at low levels. • Various metals investigated for sensing layer • Levels below 1, 000 ppm were achieved but this is far below the LEL of 4% in air. • Standards and customer requirements dictated an integrated solution. • Combination of field effect and thermal conductivity achieved the goal. • Wafer sub-suppliers could only be required to meet heater and temperature measurement performance. But gas characterization fell on us and is carried at our risk. 11 TD Aiken March 31, 2008 Sensor Development History

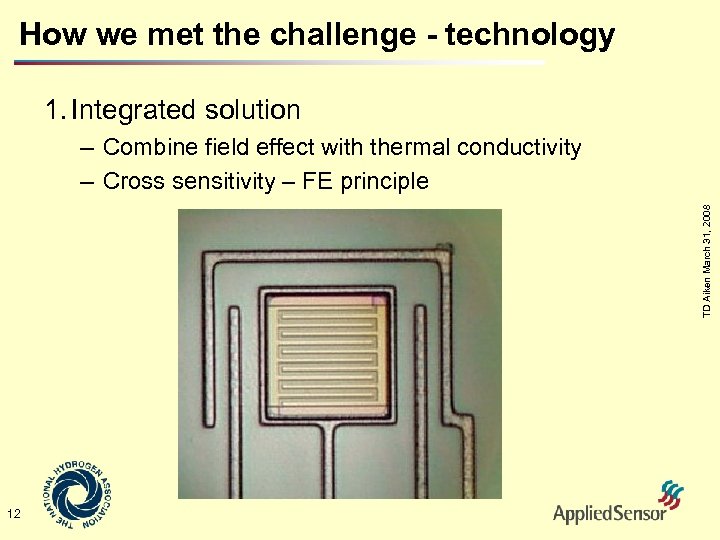

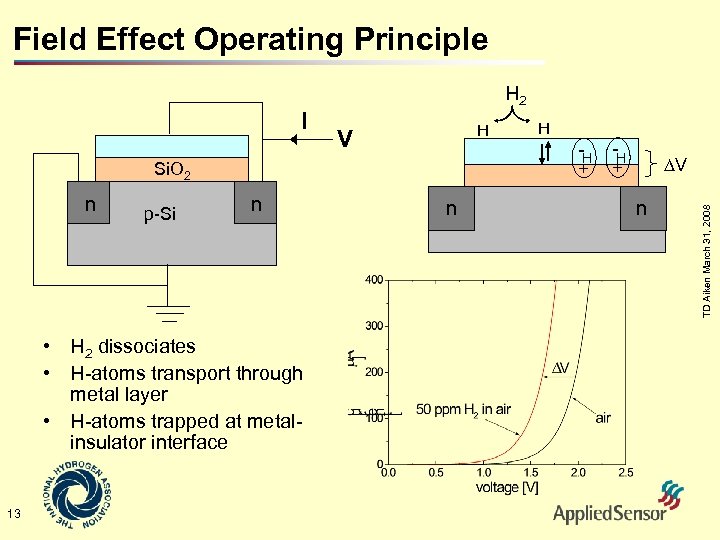

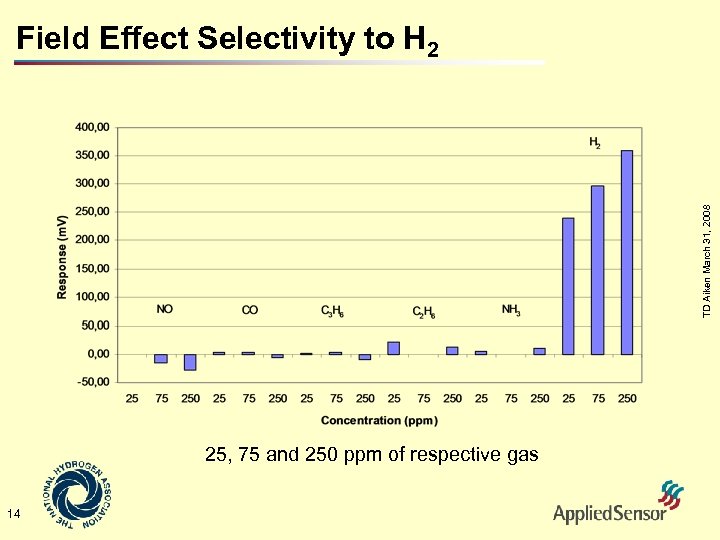

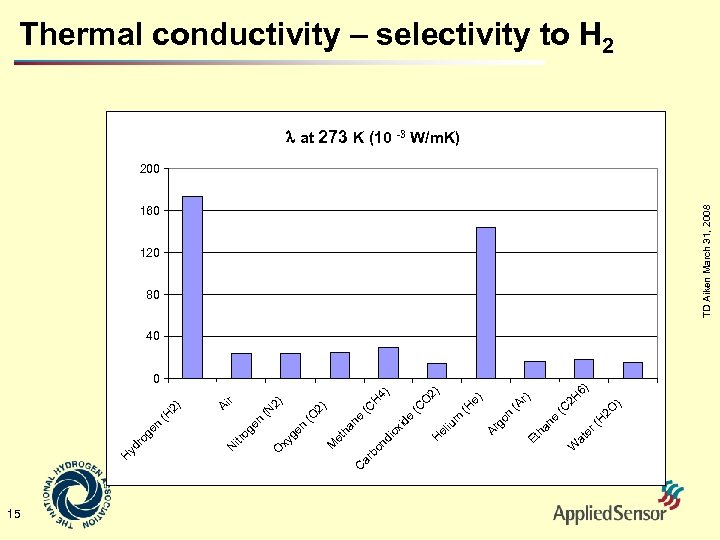

How we met the challenge - technology 1. Integrated solution TD Aiken March 31, 2008 – Combine field effect with thermal conductivity – Cross sensitivity – FE principle 12

Field Effect Operating Principle H V p-Si n • H 2 dissociates • H-atoms transport through metal layer • H-atoms trapped at metalinsulator interface 13 -H -H + Si. O 2 n H n V + n TD Aiken March 31, 2008 I H 2

TD Aiken March 31, 2008 Field Effect Selectivity to H 2 25, 75 and 250 ppm of respective gas 14

15 at er W 6) ) 2 H (C r) (A 2 O (H ne Et ha 2) e) (H O (C n Ar go el iu m H de 4) H (C 2) (O 2) Ai r 2) (N ne xi nd io ar bo C ge n et ha M xy O (H ge n itr o N ge n ro yd H 160 120 80 TD Aiken March 31, 2008 Thermal conductivity – selectivity to H 2 l at 273 K (10 -3 W/m. K) 200 40 0

How we met the challenge - Production – Class 1, 000 clean room – A-B-C sample development (automotive standard) – Design validation tests 16 TD Aiken March 31, 2008 2. Establish a production process

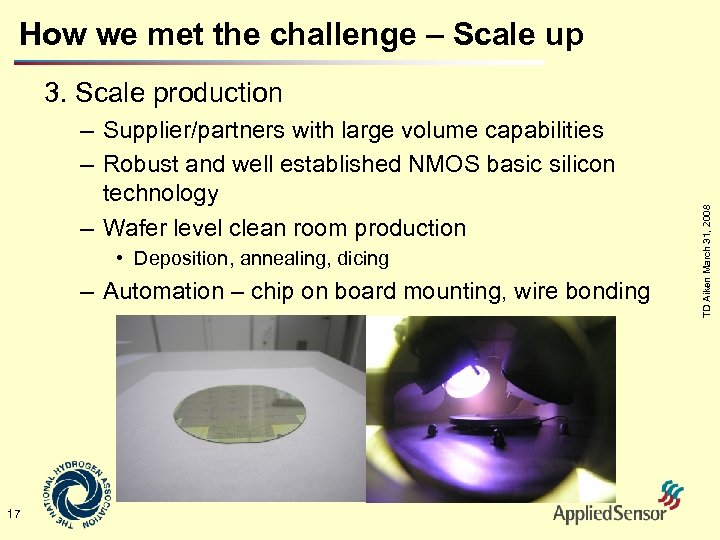

How we met the challenge – Scale up – Supplier/partners with large volume capabilities – Robust and well established NMOS basic silicon technology – Wafer level clean room production • Deposition, annealing, dicing – Automation – chip on board mounting, wire bonding 17 TD Aiken March 31, 2008 3. Scale production

How we met the challenge - Performance – – – 18 Repeatability (one sensor, time-to-time variation) Reproducibility (sensor-to-sensor variation) Accuracy Selectivity Etc…. . TD Aiken March 31, 2008 4. Testing and Validation

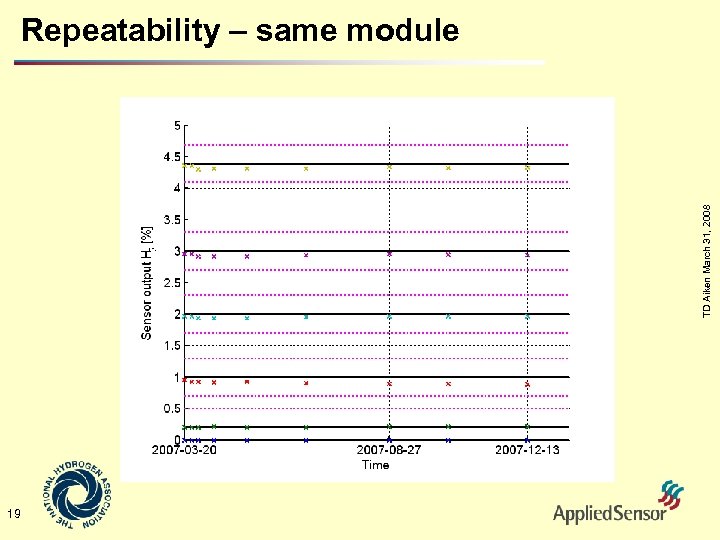

TD Aiken March 31, 2008 Repeatability – same module 19

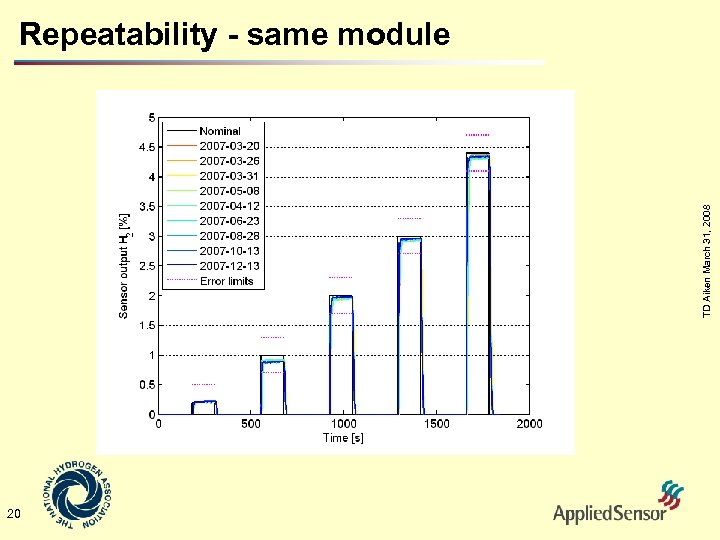

TD Aiken March 31, 2008 Repeatability - same module 20

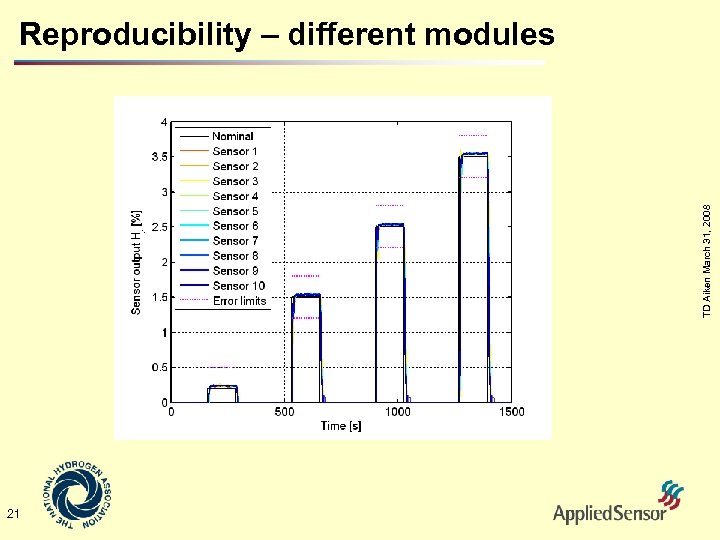

TD Aiken March 31, 2008 Reproducibility – different modules 21

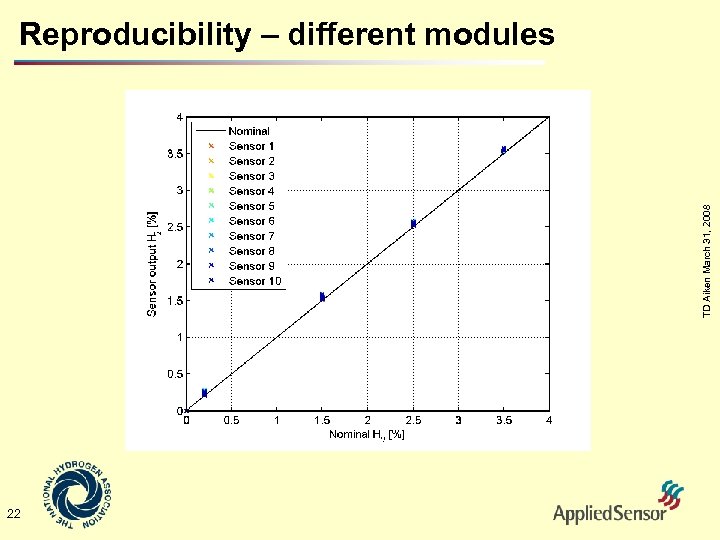

TD Aiken March 31, 2008 Reproducibility – different modules 22

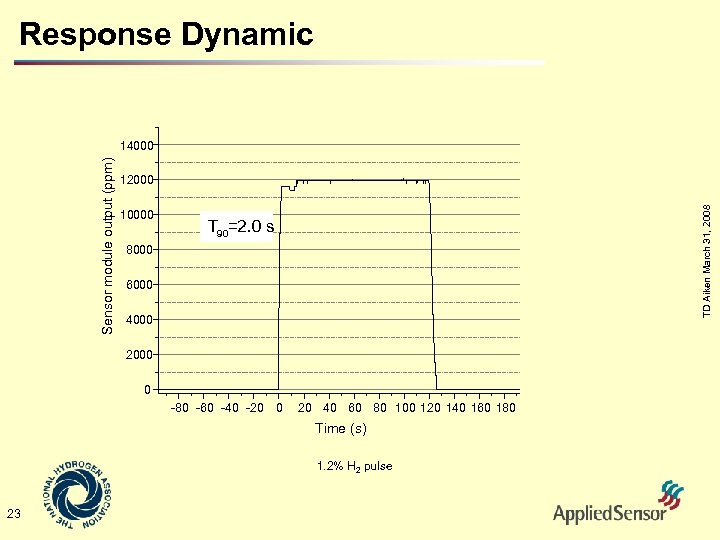

Response Dynamic 12000 10000 TD Aiken March 31, 2008 Sensor module output (ppm) 14000 T 90=2. 0 s 8000 6000 4000 2000 0 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160 180 Time (s) 1. 2% H 2 pulse 23

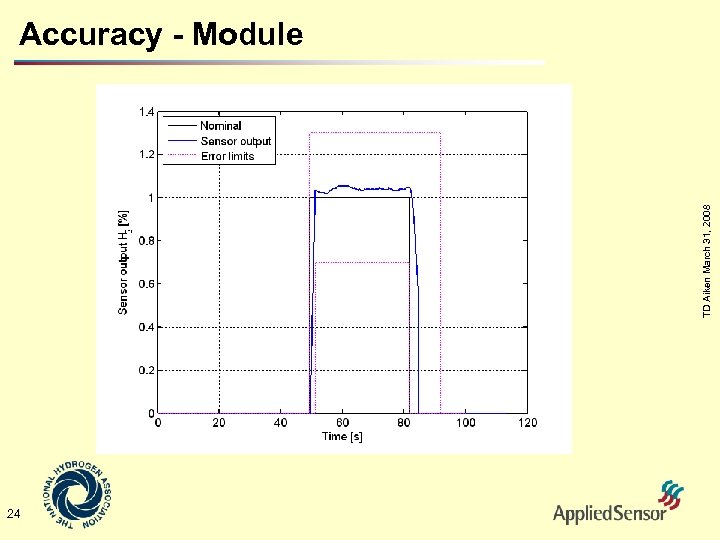

TD Aiken March 31, 2008 Accuracy - Module 24

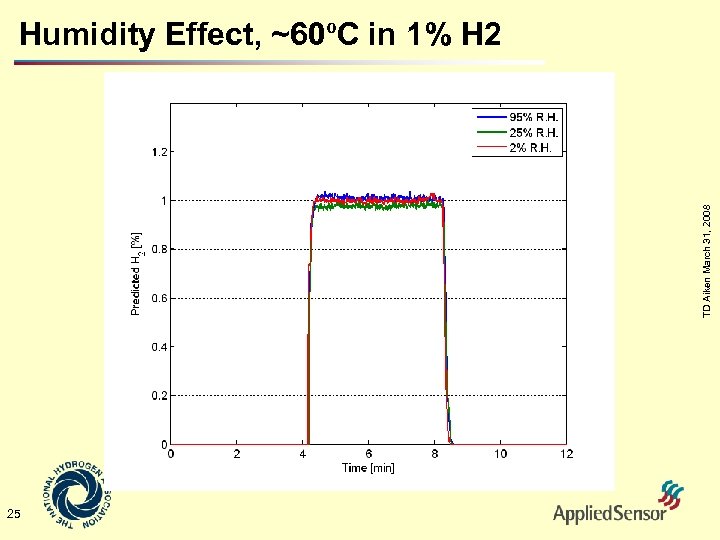

TD Aiken March 31, 2008 Humidity Effect, ~60ºC in 1% H 2 25

Hydrogen Safety Module TD Aiken March 31, 2008 HSS-440 26

TD Aiken March 31, 2008 BMW Hydrogen 7 27

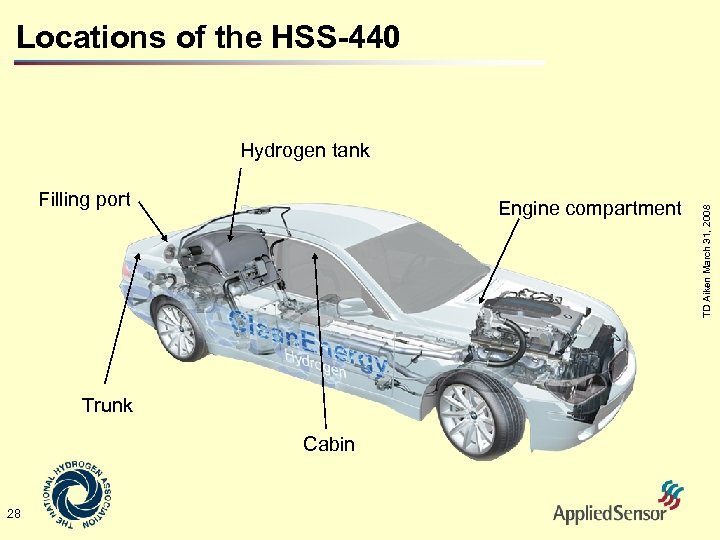

Locations of the HSS-440 Filling port Engine compartment Trunk Cabin 28 TD Aiken March 31, 2008 Hydrogen tank

GENERAL MOTORS TD Aiken March 31, 2008 Chevrolet Equinox Fuel Cell Chevrolet is committed to bringing you drivable and practical vehicles that decrease our energy dependence and reduce our emissions. 29

Mercedes- Benz B-Class F-Cell TD Aiken March 31, 2008 Launch of the first series-production fuel cell The engine for this innovative vehicle will be a new generation of fuel-cell engine that is much more compact and yet at the same time more powerful and completely practicable for everyday use. 30 Source – Daimler AG

Ramping up Commercialization • Ability to detect leaks rapidly is now commercially available for automotive and non-automotive applications. • Tough automotive standards have been met and may exceed other application requirements. 31 TD Aiken March 31, 2008 • Designing for H 2 gas leaks is critical in product development.

Applied. Sensor, Inc. Booth 510 32 TD Aiken March 31, 2008 Developing a Safety Sensor for Fuel Cell Vehicles

bf11e5680f41069b86223c01cf0fe426.ppt