d1984fca2eee436b5f95beb096c94eb8.ppt

- Количество слайдов: 101

This project is co-funded by the European Union and the Republic of Turkey Technical Assistance for Development of Regional Laboratories of Occupational Health Safety Centre (ÍSGÜM) Europe. Aid/127200/D/SER/TR

This project is co-funded by the European Union and the Republic of Turkey Occupational Exposure Limits, other reference values and interpretation of measurement results Jan Gromiec, Ph. D.

Objectives On completion of this course, participants should: • fully understand the meaning of different types of Occupational Exposure Limits • be acquainted with the procedures and the rationale for OEL derivation at the EU and national levels • be acquainted with exposure assessment criteria in the USA • have a knowledge on a possible role of DNELs (Derived. No-Effect-Levels) as the criteria of the assessment of the occupational exposure to chemicals • be able to interpret measurement results

The course outline • • • Basic terms and definitions related to Occupational Exposure Limits (OEL) OELs in the European Union OELs in individual EU countries Procedures of OEL setting OELs in the USA (OSHA, ACGIH, NIOSH) Derived-No-Effect Levels (DNELs) Comparison of OELs and DNELs Interpretation of measurement results Calculation of uncertainties

Occupational Exposure Limit (OEL) Occupational exposure is a measure of the intensity and/or extent to which the human body experiences a particular hazard. Quantitative health standard, expressed as a mean concentration over a given period of time, which an air pollutant must not exceed if the exposed workers’ health is not to be affected.

Limit value (old term) Reference figure for the concentration of a chemical in air NOTE: • set for reference periods of 8 h • temperature of 200 C • pressure of 101, 3 k. Pa. • The limit values for suspended matter are given in mg/m 3 or multiples of that for actual environmental conditions (temperature, pressure) at workplace. The limit values of fibres are given in fibres/m 3 or fibres/cm 3 for actual environmental conditions (temperature, pressure) at workplace. (EN 689: 1995)

• The effects of increasing exposure to chemical substances may be viewed as a continuum: • (1) no effects observed • (2) compensatory effects or early effects of dubious significance without adverse • health consequences • (3) early health impairment (clear adverse effects) • (4) overt disease, possibly death.

• As with systemic health effects, responses to irritants may be viewed as a continuum: • 1) no effects observed; no awareness of exposure • 2) very slight effects; awareness of exposure • (3) slight irritant effects or nuisance (e. g. smell); easily tolerable • (4) significant irritation/nuisance, overt health effects; barely tolerable • (5) serious health effects (e. g. pulmonary oedema); intolerable

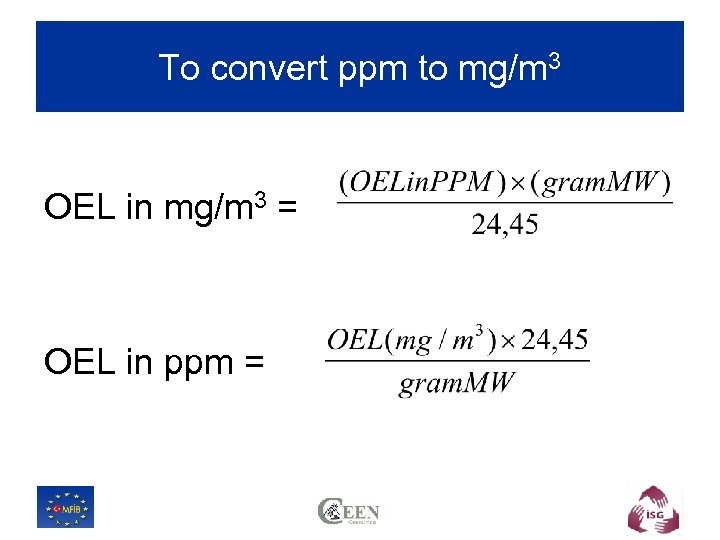

To convert ppm to mg/m 3 OEL in mg/m 3 = OEL in ppm =

Objectives of OEL setting • to prevent or limit the exposure of workers to dangerous substances at workplaces to protect the workers that are likely to be exposed to these substances OELs began to be established in order to provide criteria on the basis of which decisions could be made as to whether the airborne concentrations of given substances were sufficiently low to prevent adverse effects on health. • OELs may be used for a number of purposes. to provide standards or criteria against which measured exposure levels in existing workplaces may be compared in order to ensure that • They may also be used for design purposes

OELs at the EU level – legal aspects • Council Directive 80/1107/EEC (amended by Directive 88/642/EEC) – setting out measures for the control of risks related to chemical, physical and biological agents • Council Directive 90/394/EEC – provisions for setting up limit values for carcinogens • Framework Directive 89/391/EEC – measures to encourage improvements in the safety and health of workers at work • Council Directive 98/24/EC – legal basis for Community OELs • Commission Directive 2000/39/EC establishing the first list of indicative OELs

Scientific Committee for Occupational Exposure Limits to Chemical Agents (SCOEL) • Set up by the European Commission Decision 95/320/95 of 12 July 1995 • to supply the Commission with opinions at the latter’s request on any matter relating to the toxicological examination of the chemicals for their effects on health of workers. • to give in particular advice on the setting of OELs based on scientific data and where appropriate propose values which may include: - the eight-hour time weighted average (TWA) - short-term limits/ excursion limits (STEL) - biological limit values

Steps leading to the establishment of EU OELs • Preparation of a scientific dossier for review • Evaluation of a scientific dossier • Development of recommendation from the SCOEL (scientifically based OEL) for the Commission services • Development of a proposal for an OEL by the Commission services • Consultation of the Advisory Committee for Safety, Hygiene and Health Protection of Workers • Adoption of the implementing Directive

General procedure for setting OEL proposals by SCOEL • Assemble all available data on the hazards by the substance • Determine whether the database is adequate for the setting of an OEL • Identify the adverse effects due to exposure to the substance • Establish which adverse effect(s) is (are) considered to be crucial in deriving OEL • Identify the relevant studies which characterise these key effects (quality of of these studies) • Establish whether the substance acts via a nonthreshold or threshold mechanism (crucial for health based OELs)

Indicative Occupational Exposure Limit Values (IOELs) Commission Directive 2000/39/EC • Definition: Indicative OELs are numerical values which provide threshold level of exposure to a given substance below which no detrimental effects to workers health are expected. • Indicative OELs may be established in those cases where a review of the total available scientific data base leads to the conclusion that it is possible to identify a clear threshold dose below which exposure to the substance in question is not expected to lead to adverse effects

Indicative Occupational Exposure Limit Values (IOELs) Commission Directive 2000/39/EC, cntd • For any chemical agent for which indicative occupational exposure limit values are established at Community level, Member States are required to establish a national occupational exposure limit value, taking into account the Community limit value, determining its nature in accordance with national legislation and practice • Indicative occupational exposure limit values should be regarded as an important part of the overall approach to ensuring the protection of the health of workers at the workplace, against the risks arising from hazardous chemicals

Short-term Indicative OEL A limit value above which exposure should not occur and is related to a 15 -minute period, unless otherwise specified (COMISSION DIRECTIVE 2000/39/EC of 8 June 2000)

OEL - STEL Short-term exposure limits - peak limitations, intended as supplementary to TWA and protecting against short-time effects like annoyance, irritation, CNS depression etc. in situations where OEL-TWA values were set at levels only slightly lower than the concentrations associated with the risk of short-term exposure effects. The definition stresses that STEL is not a ceiling value, the essential difference being that no reference period is quoted for the ceiling concentration. It should be noted, however, that among the already published 90 indicative OEL values none refers to the ceiling concentration.

Binding Occupational Exposure Limits Values (BOELs) • for some adverse effects (genotoxicity, carcinogenicity, respiratory sensitization) it may not be possible on present knowledge to define a threshold of activity • „pragmatic” OELs are established at levels of sufficiently low risk • adopted by the Council of Ministers of the European Communities under the procedure laid down in Article 118 a of the Treaty. Such limit values reflect scientific data as well as socioeconomic considerations and must be transposed into national legislation as minimum requirements • if for a given substance the binding OEL has been established, the Member States are obliged to introduce into national legislation a limit value for this substance, not exceeding the agreed BOEL

EC law on Occupational Safety and Health (OSH) • EC OSH Directives contain only minimum requirements. During the necessary transposition into national legislation more stringent provisions than laid down in the EC Directives can be introduced by the Member States Legal bases: 137 Article of the EC-Treaty

Occupational Exposure Limits in Poland • Maximum Admissible Concentration (MAC) • Proposed by the MAC Commission, established by the Minister of Labour and Social Policy • Starting point: -NOAEL or LOAEL for substances with systemic activity -human data or RD 50 for irritants • Use of uncertainty factors • Ceiling MACs for substances highly irritating or dangerous to life • STEL (2 x 15 min. during a workshift) • Analytical method required • Conservative and restrictive approach

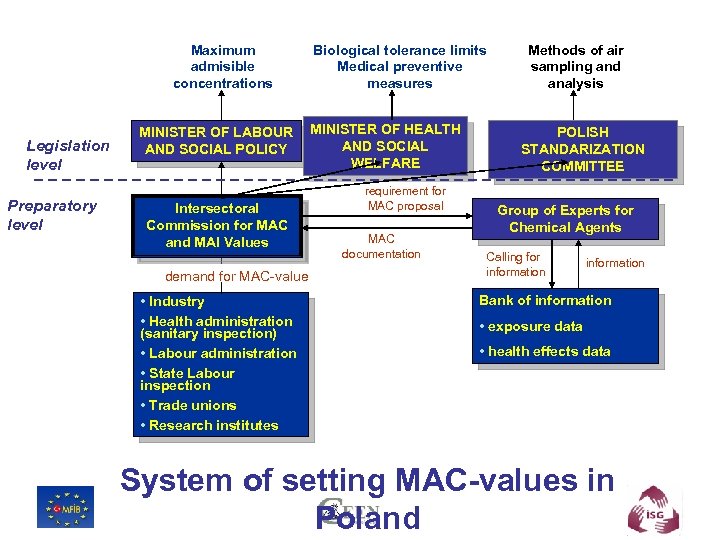

Maximum admisible concentrations Legislation level Preparatory level MINISTER OF LABOUR AND SOCIAL POLICY Intersectoral Commission for MAC and MAI Values demand for MAC-value • Industry • Health administration (sanitary inspection) • Labour administration • State Labour inspection • Trade unions • Research institutes Biological tolerance limits Medical preventive measures MINISTER OF HEALTH AND SOCIAL WELFARE requirement for MAC proposal MAC documentation Methods of air sampling and analysis POLISH STANDARIZATION COMMITTEE Group of Experts for Chemical Agents Calling for information Bank of information • exposure data • health effects data System of setting MAC-values in Poland

Number of OELs in Poland, Germany and USA

TO PREPARE DOCUMENTATIONS, THE EXPERTS UTILIZE ALL THE AVAILABLE INFORMATION WHICH USUALLY INCLUDES o original bibliography collected through the data bases (TOXLINE, MEDLINE, CANCER-CD, OSH-ROM, NIOSHTIC, CHEM-BANK, RTECS, HSDB, ANALITICAL ABSTRACTS, CCINFOdisc, IRPTC, CHEMICAL ABSTRACTS) o available documentations on exposure limits in other countries (USA, Germany, Sweden, EU) o WHO Environmental Health Criteria o IARC evaluation of the carcinogenic risk due to chemicals o other reviews o unpublished documented data

MAC Documentation Content • Summary • Substance characterization, uses and occupational exposure • Toxic effects on man • Toxic effect on experimental animals • Carcinogenicity, mutagenicity, teratogenicity, embryotoxicity and effects on reproduction • Toxicokinetics • Mechanisms of toxicity • Combined effects • Dose-effects and doseresponse relationships • Bases for existing MACvalues and biological tolerance limits • Bases for proposed MACvalues and biological tolerance limits • Methods of determination in the air and in biological material • Pre-employment and periodical examinations expsoure contraindications • References

The theoretical fundamentals for setting hygienic standards comprise: • results of epidemiological studies of a relationship between the magnitude and duration of exposure and the induced health effects; • results of medical observations of workers exposed to given toxic agent under industrial conditions; • results of experimental animal studies.

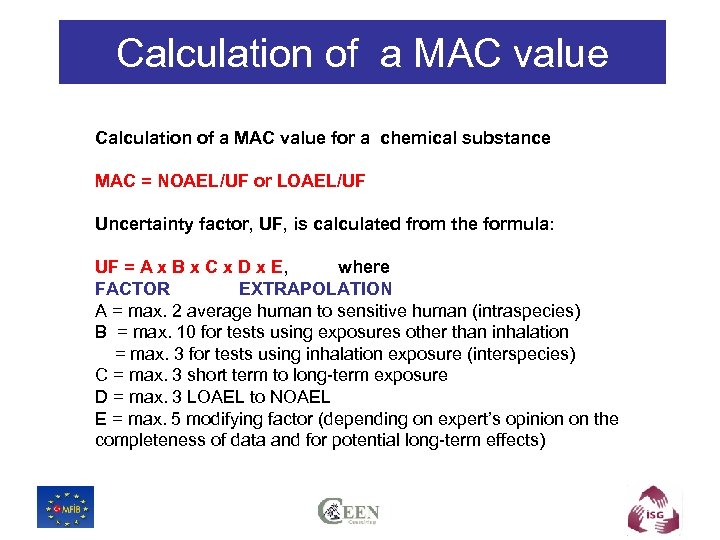

Calculation of a MAC value for a chemical substance MAC = NOAEL/UF or LOAEL/UF Uncertainty factor, UF, is calculated from the formula: UF = A x B x C x D x E, where FACTOR EXTRAPOLATION A = max. 2 average human to sensitive human (intraspecies) B = max. 10 for tests using exposures other than inhalation = max. 3 for tests using inhalation exposure (interspecies) C = max. 3 short term to long-term exposure D = max. 3 LOAEL to NOAEL E = max. 5 modifying factor (depending on expert’s opinion on the completeness of data and for potential long-term effects)

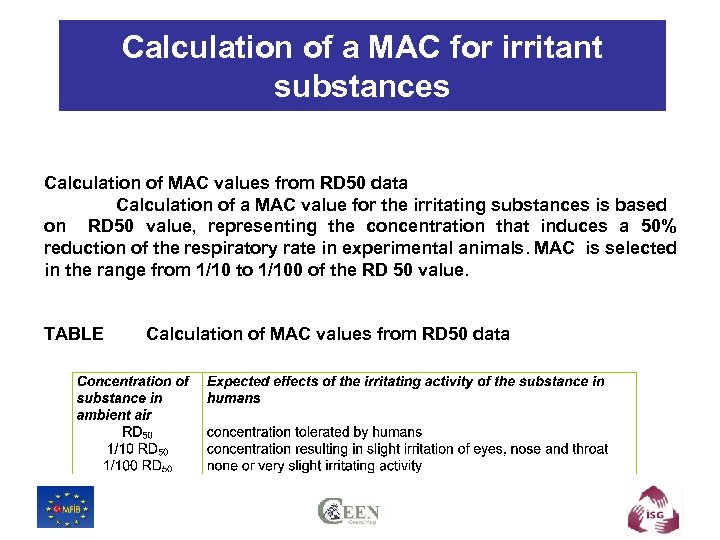

Calculation of a MAC for irritant substances Calculation of MAC values from RD 50 data Calculation of a MAC value for the irritating substances is based on RD 50 value, representing the concentration that induces a 50% reduction of the respiratory rate in experimental animals. MAC is selected in the range from 1/10 to 1/100 of the RD 50 value. TABLE Calculation of MAC values from RD 50 data

Other MAC related issues • number of MAC chemicals in Poland: 511, capacity to produce 20 documentations/yr • number of 10 t/yr MAC chemicals: 834 (2004), most of them having MAC value assigned • quality of OELs: expert assessment, multilevel process, transparency • no tradition of „private OELs” in Poland • need for analytical methods to determine compliance

Limit values in the USA • ACGIH® Threshold Limit Values (TLV®) • OSHA Permissible Exposure Limits (PEL) • NIOSH Recommended Exposure Limits (REL)

ACGIH TLVs The longest tradition is behind the hygienic standards published by ACGIH under the registered name of Threshold Limit Values (TLVs ), and annually updated since 1946. The TLVs are not obligatory under current US legal regulations; nevertheless, in view of the high ACGIH reputation, they serve as an important guide on the recommended limits of occupational exposures not only in the USA but also in other countries. • TLV-TWA (Threshold Limit Value - Time-Weighted Average) is defined as the time-weighted average concentration for a conventional 8 -hour workday and a 40 hour workweek, to which it is believed that nearly all workers may be repeatedly exposed, day after day, without adverse health effect.

ACGIH TLVs, cntd • TLV-STEL (Short-Term Exposure Limit); this is defined as a 15 -minute TWA exposure which should not be exceeded at any time during a workday, even if the 8 hour TWA is within the TLV-TWA, Exposures above the TLV-TWA up to the TLV-STEL should not be longer than 15 minutes and should not occur more than four times per day. There should be at least 60 minutes between successive exposures in this range. • TLV -Ceiling represents a value of concentration absolutely not to be exceeded at any moment. The ceiling values refer mostly to irritant gases, and for that type of chemical substances they are the only applicable hygienic standards (no TLV -TWA are available).

ACGIH TLVs, cntd • • • Individual susceptibility Hypersensitivity Procedures and process of setting TLVs Health based criteria TLV documentations

OSHA PEL values OSHA was established in 1970 by the US Congress as an institution subordinated to the Ministry of Labor and entrusted with the task of developing and enforcing a law on the health and safety of workers. The law is understood as providing also for the hygienic standards, which should “in the most suitable and practicable way, using the best available proof, ensure that none of the workers suffers health loss or reduction of the physiological parameters even when regularly exposed to that agent at the level specified by the relevant hygienic standard throughout his/her whole working life „

OSHA PEL values establishment • history of PEL establishment • interpretation in U. S. Supreme Court rulings • a conservative approach encumbered with the risk of an error to the benefit of the worker to ensure that steps to be undertaken ensure excessive rather than insufficient protection to the concerned worker • PEL values should be based on the most recent scientific data • the results of research and recommendations prepared mainly by OSHA and NIOSH as the starting point • clinical observations (accidents, poisonings, pathologies), epidemiological data and animal test results used as the so-called “toxicological proof. ” • NOAEL or LOAEL usually employed as a starting point • uncertainty factors for individual human variability, inter-species differences, incomplete data on the chronic toxicity, and the use of a LOAEL value instead of a NOAEL value • seting STEL and Ceiling values (definitions and interpretation identical like in case of ACGIH TLVs)

OSHA PEL values establishment • proposals for setting new, or modifying the existing PEL values, together with the reasons justifying the new or revised standard published in the Federal Register as a Notice of Proposed Rulemaking • the interested parties (representatives of industry, employers, workers, federal agencies, scientific institutions, etc. ) may present their comments and suggestions in writing • public hearing of the authors of the proposals by the representatives of the commenting institutions • the participants present in writing arguments for, and against, the proposed standard in question. OSHA analyses all the notes, sets PEL values and publishes in the Federal Register the full text of the documents justifying the new or modified PEL value.

OELs in Russia • Maximum Allowable Concentartions (MAC) started in early 20’s. • Numerical values much lower than elsewhere, based on the concept of the “threshold hazardous effect” and set at the level, that was supposed to correspond to a tissue burden in exposed subjects which represent the minimum dose that triggers changes beyond the limits of physiological adaptation reactions. • Now under the auspices of the Ministry of Health (National Commission on Occupational Exposure Limits). • Based entirely on toxicological data, without reference to occupational hygiene or epidemiology (the material derived mostly from Russian sources; the existing exposure levels in industry, technical feasibility and economic implication not taken into account.

OELs in Russia, cntd • Generally considered to be the ceiling values, time weighted average concentrations are established for those substances that are highly cumulative. • In most cases established during the Soviet period, when the philosophy of hygienic standard development was quite different from that in other countries and a high coefficient of safety was usually applied. • The implementation of these standards not as strict as required. • Not revised and still used in practice despite the policy changes and other significant changes in socio-economic structure.

OELs for carcinogens • effective toxicity threshold does not exist or is impossible to be determined; each exposure to carinogenic genotoxic agent is assumed to be associated with the risk of cancer development. • not possible to determine the level of the substance concentration which does not produce adverse health effects in all the exposed individuals (a condition specified by most occupational exposure limit definitions) • for such substances the concentrations should be kept as low as possible (if their complete elimination from the production process is not feasible) • legally binding exposure limits take into consideration the socio-economic factors and are based on the concept of acceptable cancer risk

OELs for carcinogens, cntd • OELs for carcinogenic substances are based on the data on the carcinogenicity of a specific substance in humans (epidemiological data) and/or experimental animals. • Such limit may be derived from the data on unit risk or from the slope factor of the doseresponse curve; in both cases the acceptable risk serves as the criterion. • In general, in the occupational setting, the acceptable levels of cancer risk vary between 10 -2 to 10 -5

Classification of carcinogens • Classifications referring mainly to the strength of proof of their carcinogenic activity (IARC, ACGIH®, EU – Directive 2004/37/EC). • In most cases the substances and technological processes are classified as: Ø carcinogenic to humans, Ø suspected of being carcinogenic to humans, Ø carcinogenic to experimental animals, Ø not classifiable as a human carcinogen, Ø not suspected as a human carcinogen. • In some countries information on cancerogenity and/or mutagenicity included in the OEL list.

Human Health Hazard Assessment (REACH legal text) • REACH (Annex I, 1. 0. 1 ) defines the Derived No. Effect Level (DNEL), i. e. the level of exposure above which humans should not be exposed. • In the risk characterisation, the exposure of each human population known to be or likely to be exposed is compared with the appropriate DNEL • The risk to humans can be considered to be adequately controlled if the exposure levels estimated do not exceed the appropriate DNEL

Derived No Effect Level (DNEL) • Required for 10 tonnes/yr chemicals • The purpose of DNELs is to act as the reference value for determining adequate control of exposure for specific scenarios • DNELs (inhalation) for occupational exposure comparable to MACs

Steps of DNEL derivation • Collection of all available toxicity data; gathering typical dose descriptors • Decision on mode of action threshold vs. nonthreshold) • Selection of relevant dose descriptor(s) for the endpoint concerned • Modification of the dose descriptor to the correct starting point • Application of assessment factors, where necessary for the relevant exposure pattern • Selection of the critical effect

Dose descriptors for DNEL derivation • NOAEL (no observed adverse effect level) • NOAEC (no observed adverse effect concentration) • LOAEL/LOAEC (lowest observed adverse effect level/concentration) • Other dose descriptors (BMD, LD 50, LC 50, T 25 etc. ) All available hazard information needs to be evaluated (physical and chemical properties, epidemiological data, human data, acute and chronic activity, local and systemic effects etc. )

Modification of dose descriptors into the correct starting point • correction for difference in bioavailability for the same exposure route • correction for different exposure routes • correction for difference between experimental and exposure conditions • correction for differences in respiratory volumes between experimental animals and humans

Correction for difference between experimental and exposure conditions • repeated animal inhalation experiment –usually 6 hr/d • occupational exposure –usually 8 hr/d • general population exposure – 24 hr/d • effects of exposure dependant on dose, concentration or both?

Assessment factors (AF) • Assessment factors are numerical values used to address differences between experimental data and the human situation taking into account the uncertainties in the extrapolation procedure and the available data set • Substance-specific information should be used in the establishment of appropriate values for the various assessment factors • In the absence of substance-specific or analogous data use default assessment factors • It should be remembered that the default assessment factors are based on experience and not strictly on science and they may or not may be not suitable for a given substance

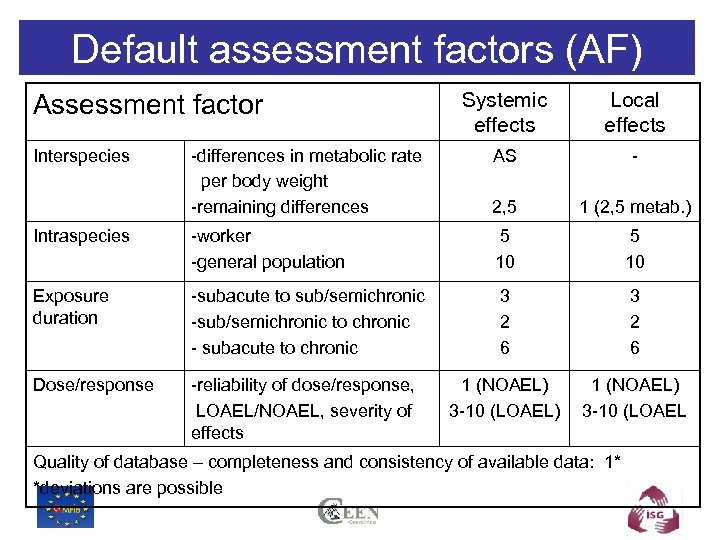

Default assessment factors (AF) Assessment factor Interspecies Systemic effects Local effects -differences in metabolic rate per body weight -remaining differences AS - 2, 5 1 (2, 5 metab. ) Intraspecies -worker -general population 5 10 Exposure duration -subacute to sub/semichronic -sub/semichronic to chronic - subacute to chronic 3 2 6 Dose/response -reliability of dose/response, LOAEL/NOAEL, severity of effects 1 (NOAEL) 3 -10 (LOAEL) 1 (NOAEL) 3 -10 (LOAEL Quality of database – completeness and consistency of available data: 1* *deviations are possible

Quality of the database • thorough analysis of available data • lacking data (long-term effects) • experimental conditions, quality of animals, control groups, etc. • consistency of data For experiments carried out according to GLP procedures and complete data, default assessment factor is 1, in other cases expert judgement

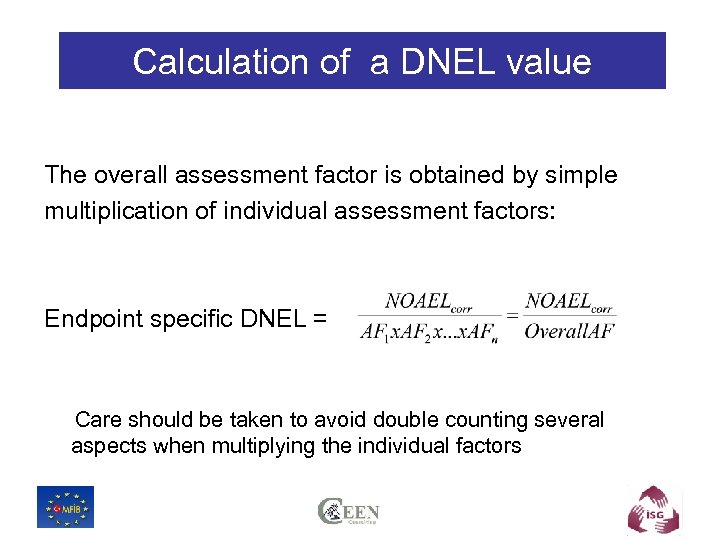

Calculation of a DNEL value The overall assessment factor is obtained by simple multiplication of individual assessment factors: Endpoint specific DNEL = Care should be taken to avoid double counting several aspects when multiplying the individual factors

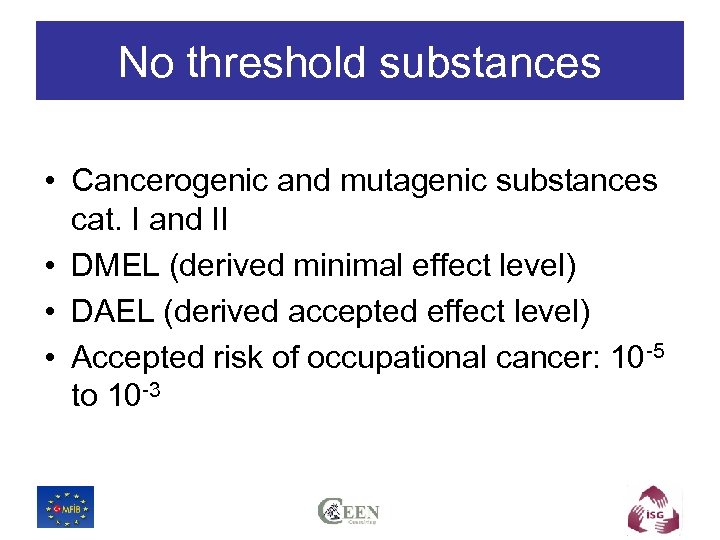

No threshold substances • Cancerogenic and mutagenic substances cat. I and II • DMEL (derived minimal effect level) • DAEL (derived accepted effect level) • Accepted risk of occupational cancer: 10 -5 to 10 -3

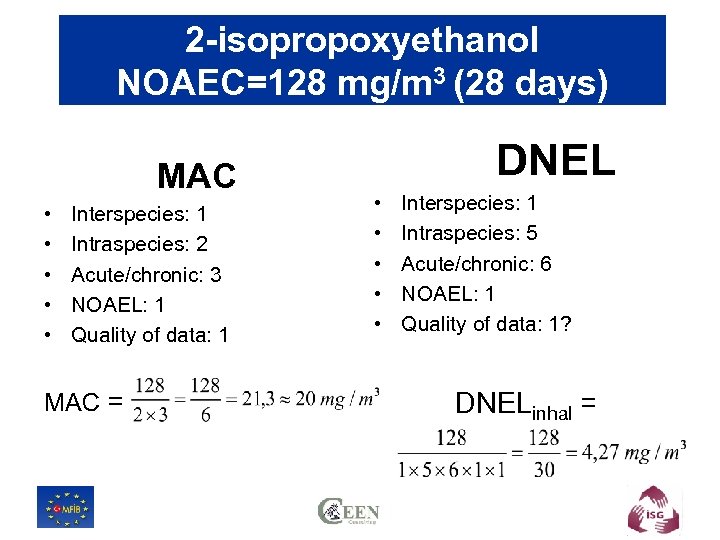

2 -isopropoxyethanol NOAEC=128 mg/m 3 (28 days) MAC • • • Interspecies: 1 Intraspecies: 2 Acute/chronic: 3 NOAEL: 1 Quality of data: 1 MAC = DNEL • • • Interspecies: 1 Intraspecies: 5 Acute/chronic: 6 NOAEL: 1 Quality of data: 1? DNELinhal =

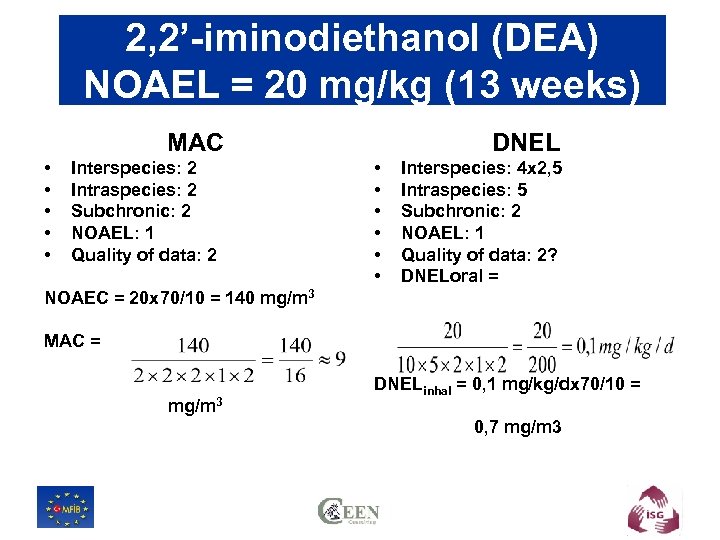

2, 2’-iminodiethanol (DEA) NOAEL = 20 mg/kg (13 weeks) MAC • • • Interspecies: 2 Intraspecies: 2 Subchronic: 2 NOAEL: 1 Quality of data: 2 DNEL • • • Interspecies: 4 x 2, 5 Intraspecies: 5 Subchronic: 2 NOAEL: 1 Quality of data: 2? DNELoral = NOAEC = 20 x 70/10 = 140 mg/m 3 MAC = mg/m 3 DNELinhal = 0, 1 mg/kg/dx 70/10 = 0, 7 mg/m 3

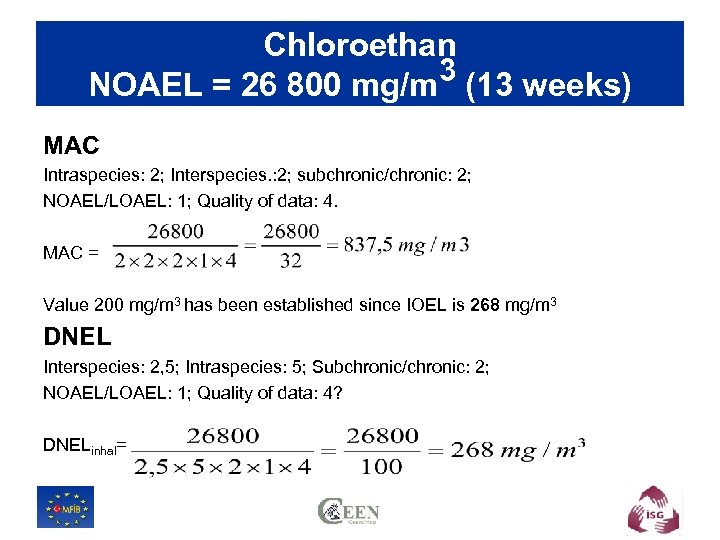

Chloroethan NOAEL = 26 800 mg/m 3 (13 weeks) MAC Intraspecies: 2; Interspecies. : 2; subchronic/chronic: 2; NOAEL/LOAEL: 1; Quality of data: 4. MAC = Value 200 mg/m 3 has been established since IOEL is 268 mg/m 3 DNEL Interspecies: 2, 5; Intraspecies: 5; Subchronic/chronic: 2; NOAEL/LOAEL: 1; Quality of data: 4? DNELinhal=

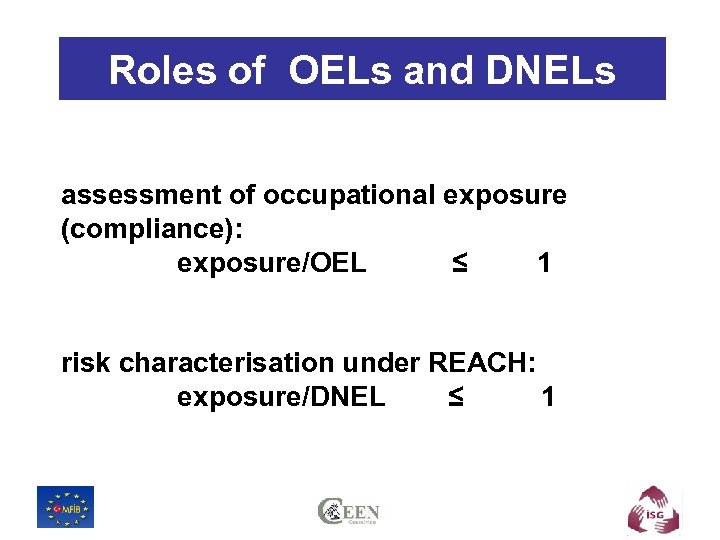

Roles of OELs and DNELs assessment of occupational exposure (compliance): exposure/OEL ≤ 1 risk characterisation under REACH: exposure/DNEL ≤ 1

OELs and DNELs: similarities • the same objective, in general: concentration, that would not result in health impairment due to exposure • the same starting point, though assessment factors are different

OELs and DNELs: differences • OELs are developed strictly for OSH purposes and have direct application as a reference tool for the systematic monitoring of exposure • DNELs primarily not intended for OSH purposes but as a tool for chemical safety assessment and selection of proper RMM • DNELs have no direct impact on workplace regulations

OELs and DNELs: differences, cntd. • OELs are legally binding (responsibility of the Government) – legal instrument of enforcement of health policy, compliance supervised by governmental agencies or institutions • DNELs introduced by companies only • Representativeness and transparency of the OEL establishment process – lack of expert judgement in the DNEL derivation • Different assessment factors; mostly default factors in DNELs vs expert judgement in OELs

Conclusion of the occupational exposure assessment in EN 689 The occupational exposure concentration is the arithmetic mean of the measurements in the same shift with the appropriate reference period of the OEL value of the agent of consideration. In the case of varying averaging times this can be accounted for by time-weighting the values (examples in Annex B). A number of schemes can be devised to compare exposures with the OELs (Annexes C and D). Whatever scheme is used, one of the three following conclusions shpuld be made: • the exposure is above the limit value: the reason should be identifiedand appropriate measures to remedy the situation should be implemented as soon as possible. The occupational exposure should be repeated b)The exposure is well below the limit value and is likely to remain so on the long-term basis due to the stability in the working conditions and the arrangement of the work process. In this case periodic measurements are not needed. Regular check is, however, required whether the conditions at workplace are unchanged. c)The exposure do not fit into categories (a) or (b). Here, even though exposure may be below OEL, periodic measurements are still required.

When the exposure may be considered acceptable • Time weighted average (TWA) concentration is below or equal to OEL. • Short term concentration (15 min) is below or equal to STEL • The sum of the ratios of concentrations of individual compounds to their OELs must be less than or equal to one

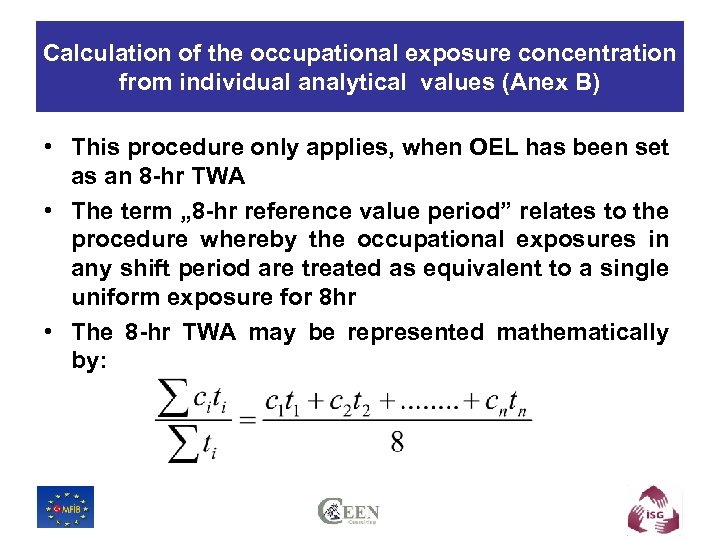

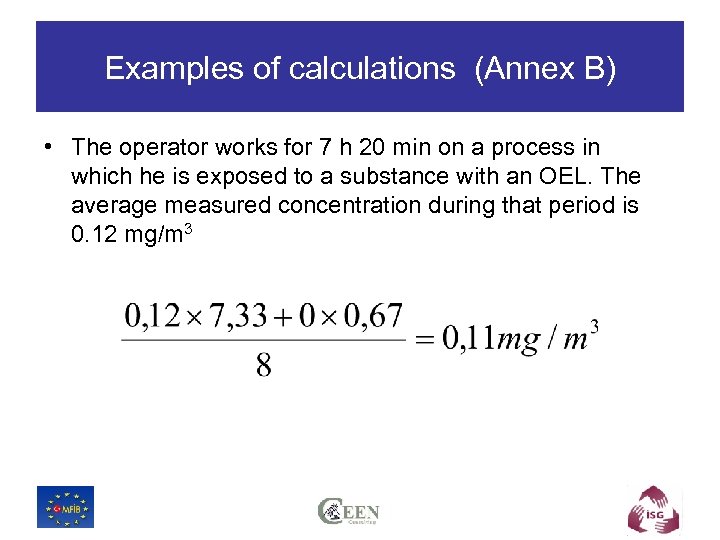

Calculation of the occupational exposure concentration from individual analytical values (Anex B) • This procedure only applies, when OEL has been set as an 8 -hr TWA • The term „ 8 -hr reference value period” relates to the procedure whereby the occupational exposures in any shift period are treated as equivalent to a single uniform exposure for 8 hr • The 8 -hr TWA may be represented mathematically by:

Examples of calculations (Annex B) • The operator works for 7 h 20 min on a process in which he is exposed to a substance with an OEL. The average measured concentration during that period is 0. 12 mg/m 3

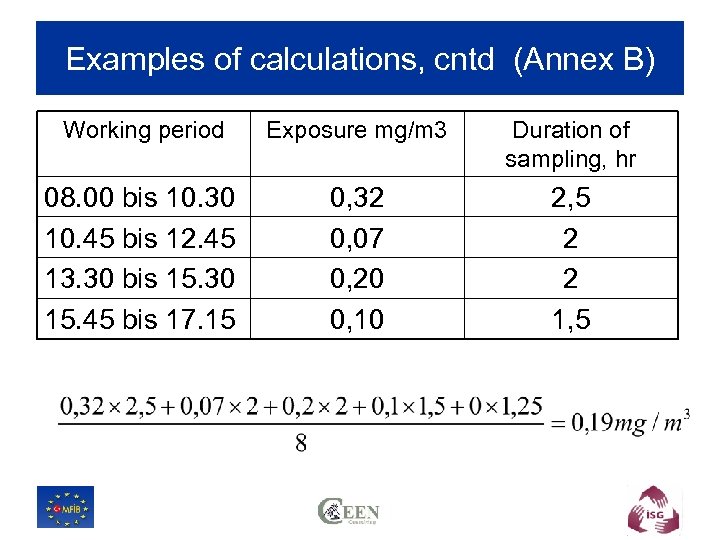

Examples of calculations, cntd (Annex B) Working period Exposure mg/m 3 Duration of sampling, hr 08. 00 bis 10. 30 10. 45 bis 12. 45 13. 30 bis 15. 30 15. 45 bis 17. 15 0, 32 0, 07 0, 20 0, 10 2, 5 2 2 1, 5

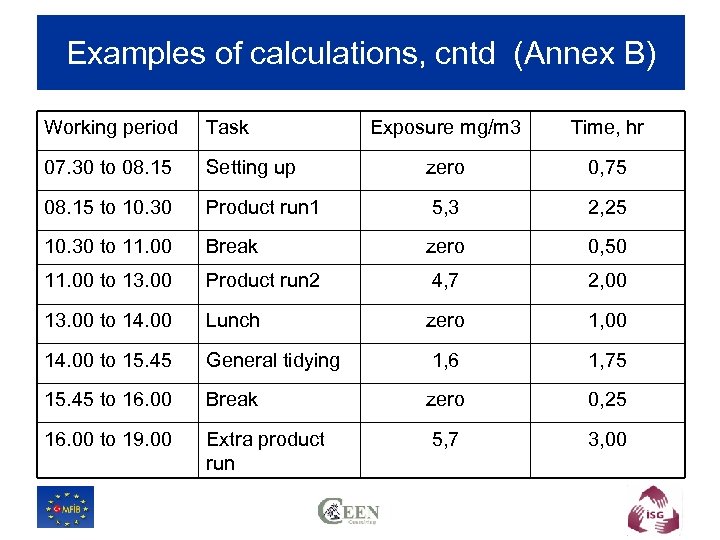

Examples of calculations, cntd (Annex B) Working period Task Exposure mg/m 3 Time, hr 07. 30 to 08. 15 Setting up zero 0, 75 08. 15 to 10. 30 Product run 1 5, 3 2, 25 10. 30 to 11. 00 Break zero 0, 50 11. 00 to 13. 00 Product run 2 4, 7 2, 00 13. 00 to 14. 00 Lunch zero 1, 00 14. 00 to 15. 45 General tidying 1, 6 1, 75 15. 45 to 16. 00 Break zero 0, 25 16. 00 to 19. 00 Extra product run 5, 7 3, 00

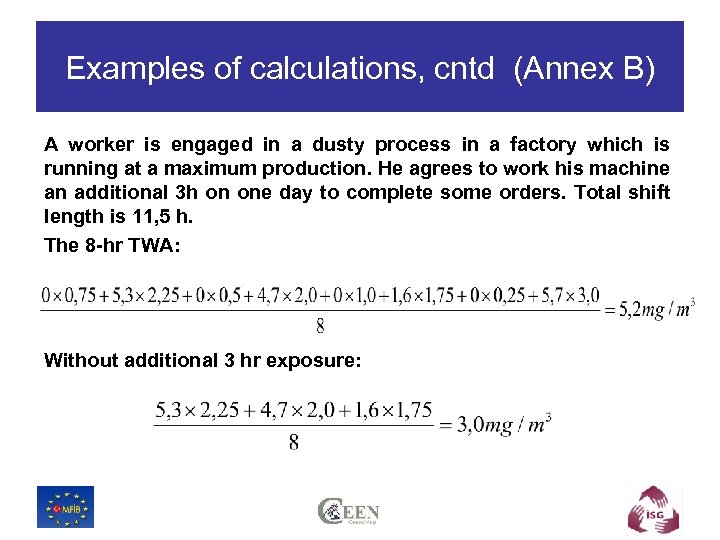

Examples of calculations, cntd (Annex B) A worker is engaged in a dusty process in a factory which is running at a maximum production. He agrees to work his machine an additional 3 h on one day to complete some orders. Total shift length is 11, 5 h. The 8 -hr TWA: Without additional 3 hr exposure:

Probability plot (Annex G) This approach is the percentile method of expressing exposure measurements, which uses a statistical analysis of the data in the form of lognormal probability or cumulative frequency plot To construct a lognormal probability plot: 1. Rank exposure data from rhe lowest to the highest. 2. Count the number of results and obtain the appropriate plotting positions as shown in the examples in tables G. 1, G. 2. and G. 3 of Annex G. 3. Select log probability graph paper having a Y-axis capable of covering the range of the exposure data. 4. Plot each exposure value against the corresponding plotting point on the log probability paper, as shown in figure G. 2 for the raw data in table G. 3.

Probability plot (Annex G), cntd 5. Fit the straight line to the data points, disregarding all points outside the bounds of 1% and 99% probability. For all remaining data give preference to those nearest the central 50% position, that is in the 20% to 80% region; 6. If the data do not follow the straight line then the underlying distribution may not be lognormally distributed, or may comprise more than one sample population; 7. The geometric mean value is the 50% probability value and may be read directly from the intersection of the fitted line with the 50% probability line; 8. The geometric standard deviation (GSD) is the slope of the lognormal plot and a measure of variability or dispersion of the data

Example of a probability plot (EN 689, Annex G

Probability plot (Annex G), cntd The geometric standard deviation is given by: • The GSD can, together with the geometric mean be used, if required to draw theoretical „best fit” line for the data. • Good for extrapolation to higher exposure levels or % probabilities • Two statistical parameters characterise lognormal probability plot: -the geometric mean (50% of results are below and above the value) -the GSD (the slope of the cumulative exposure plot (measure of variability of the results). • The plot can be used to compare exposure data with OEL at any probability level, or to estimate the percentage of exposures likely to exceed a particular value. • Normally not less than 7 data points are required for such comparisons or estimates.

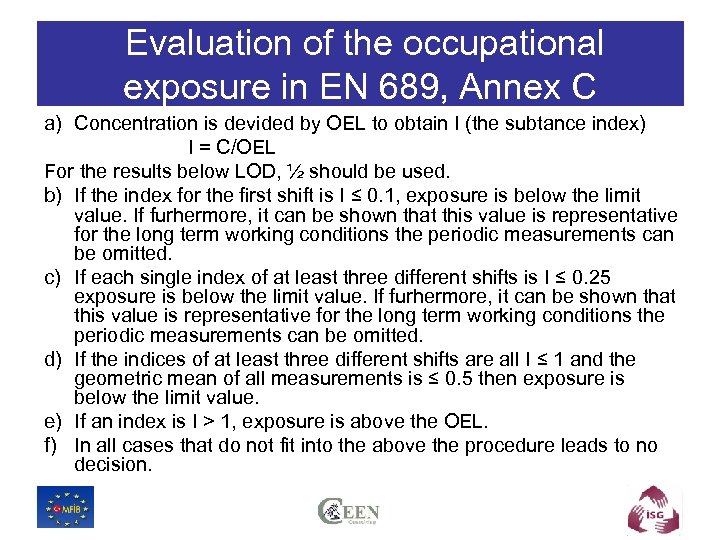

Evaluation of the occupational exposure in EN 689, Annex C a) Concentration is devided by OEL to obtain I (the subtance index) I = C/OEL For the results below LOD, ½ should be used. b) If the index for the first shift is I ≤ 0. 1, exposure is below the limit value. If furhermore, it can be shown that this value is representative for the long term working conditions the periodic measurements can be omitted. c) If each single index of at least three different shifts is I ≤ 0. 25 exposure is below the limit value. If furhermore, it can be shown that this value is representative for the long term working conditions the periodic measurements can be omitted. d) If the indices of at least three different shifts are all I ≤ 1 and the geometric mean of all measurements is ≤ 0. 5 then exposure is below the limit value. e) If an index is I > 1, exposure is above the OEL. f) In all cases that do not fit into the above the procedure leads to no decision.

Evaluation of the occupational exposure in EN 689, Annex C, cntd • If any of the conditions of b), c), or d) apply, then the occupational exposure assessment can be terminated. . • In the cases c), or d) the concentration can be interpreted as the first periodic measurement. Its result then may determine the time interval for the next periodic measurement. If the workers are exposed simultaneously or consecutively to more than one agent during the same workshift, this fact needs to be taken into consideration.

Types of Mixture • • • Natural mixtures Petroleum based mixtures Formulated mixtures Processing mixtures Combined mixtures

Natural mixtures • Source – extraction and/or processing naturally occurring substances (mineral ores, vegetable oils, tea etc. ) • Composition may be not known and vary depending on source and season • Defined by mostly by their physical properties or technological processes • In most cases no OELs assigned • Specific ill-efects usually well documented

Petroleum based mixtures • Sub-group of „natural mixtures” • Relates to distillation fractions of oil (white spirit, fuels, naphtas etc. ) • Defined by by physical properties (e. g. boiling range) • Composition may vary depending on origin and processing • The mixture and/or its components may have been assignrd OELs

Formulated mixtures • Produced by mixing components to a predefined formula to give products for specific applications (paints, adhesives, cleaning preparations) • The composition is usually known; some components may be already natural mixtures • Composition is controlled • No OEL for the mixture, individual components may have been assigned OELs

Processing mixtures • Arise from the technological processes (plastic fumes, welding fumes, rubber fumes etc) • Composition changes with process parameters (temperature, pressure, oxygen supply etc) • Contain both identified and unidentified compounds • Some compounds may have or may have not OELs assigned • Some of the process mixtures may have been assigned OELs

What to measure? • All, or many of the individual components (require knowledge of the mixture components and availability of the appropriate analytical method) • The „total mixture” (if OEL is for the mixture or if the total mixture exposure serves as a measure of control) • A single substance, as a guide to exposure and control

A single substance as a measure of exposure • Measurement methods not available for all the pollutants • Many components without OELs • There are unidentified components • Quantification of all components would be excessively expensive

Selection of the key components to be measured • The existence of OELs • Concentration in the mixture • The toxicity of the individual substances

Categories of possible joint toxic effects • Independent action – each component acts in an individual way in the human body which is different from, and unaffected by, the effects of other components • Additive action - the combined toxic effects are the simple sum of toxic effects of each component acting alone • Synergistic action – the combined toxic effects are greater than the simple sum of the toxic effects of the single components acting alone • Antagonistic effect – the combined toxic effects are less than the simple sum of the toxic effects of each component acting alone

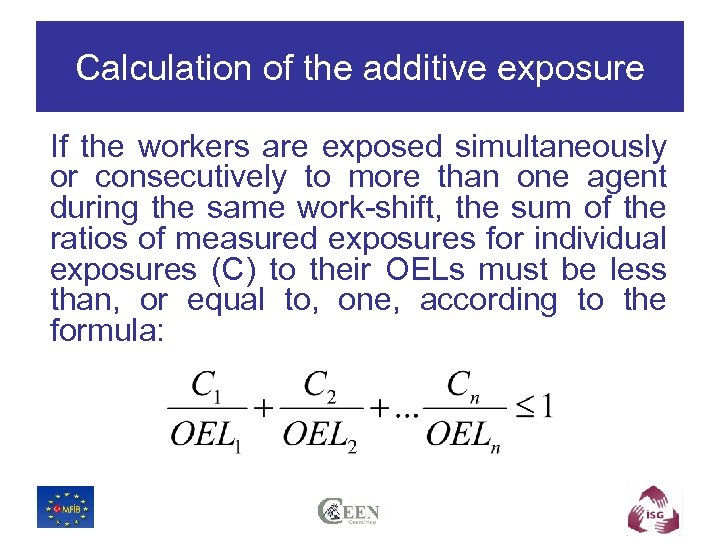

Calculation of the additive exposure If the workers are exposed simultaneously or consecutively to more than one agent during the same work-shift, the sum of the ratios of measured exposures for individual exposures (C) to their OELs must be less than, or equal to, one, according to the formula:

Test report Reports shall be written of the occupational exposure assessment and of any periodic measurement. According to EN 689, the report has to contain: § the name of the person(s) or institutions undertaking the assessment and the measurements; § the name of the substance considered; § name and address of company; § the description of workplace factors including the workplace conditions during the measurements § the purpose of the measurement procedure; § the measuring procedure; § the time schedule ((date, beginning and end of sampling) § the occupational exposure concentrations; § all events and factors liable to influence appreciably the results; § details of quality assurance, if any; § result of the comparison with the limit value (OEL).

Calculation of the expanded uncertainty

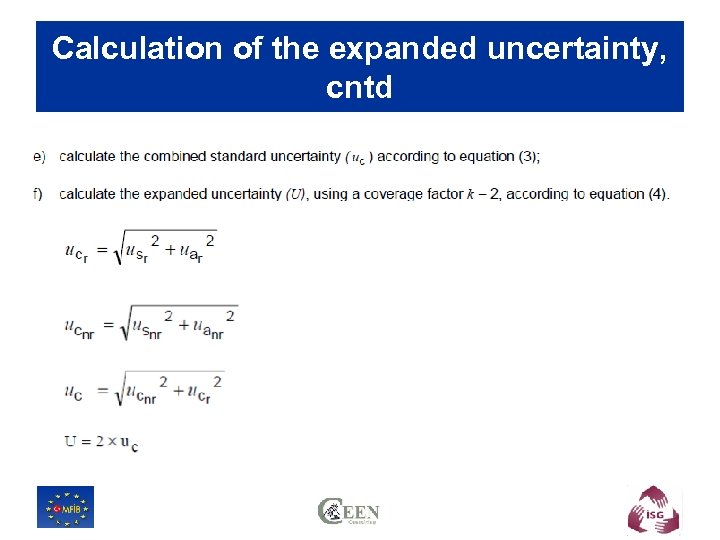

Calculation of the expanded uncertainty, cntd

Uncertainty components in workplace air measurement methods • sampling: -uncertainty associated with sampled air volume -uncertainty associated with sampling efficiency -uncertainty associated with sample storage and transportation, if any • analysis: -uncertainty associated with method recovery -uncertainty associated with analytical variability -uncertainty associated with the calibration -uncertainty associated with instrument drift The uncertainty of each of those components is estimated and calculated and then combined to obtain an estimate of the uncertainty of the measurement method as a whole.

Sources of uncertainty in pumped sampling • Flow rate measurement - the calibration of the flow meter (random error), the reading of the flow meter (random error) and, where appropriate, correction of the flow rate reading to ambient pressure and temperature. The uncertainty of flow rate calibration should be calculated from the data given on the flow meter test certificate. The uncertainty of the flow rate reading should be calculated from measurements carried out under repeatability conditions. • Pump flow stability • Sampling time

Flow rate measurements

Uncertainty of the flow rate measurement for different types of flow meters

Flow rate stability • Pumps for personal air sampling are usually selfregulating and maintain the set flow independent of variation in back pressure • EN 1232 and EN 12319 require that the flow rate is maintained within ± 5% of the set value throughout the sampling period • Assuming a rectangular probability distribution, the maximum acceptable value for a nonrandomuncertainty component for the pump flow stability is 5/√ 3

Uncertainty components associated with sampling, cntd • Sampling time may be measured very exactly with a radio controlled clock, a quartz clock or stopwatch. The major source of uncertainty in measurement of sampling time is the accuracy with which the reading is taken, i. e. to the nearest minute or second. The non-random uncertainty component is very small in the case of long term measurements (e. g. > 2 h) and can be disregarded, but for short term measurements it needs to be taken into account. (for a 15 minute sample, if time is recorded to the nearest minute, the RSD is 3. 8%, assuming a rectangular probability distribution)

Uncertainty associated with sampling efficiency • Influence of ambient conditions (temperature, pressure, humidity) • Influence of a flow rate • Breakthrough volume (EN 1076) • Efficiency when sampling with bubblers/impingers and impregnated filters

Uncertainty associated with sample storage and transportation • Non-random uncertainty component for storage can be estimated by analysis of samples collected from a test atmosphere or prepared by spiking sampling media with a chemical agent. Calculated from the difference between the mean results of replicate samples analysed immediately after sampling/spiking and after the maximum storage period specified in the method. • Storage tests described in detail in EN 838 (passive dosimetry) or EN 1076 (pumped methods) • No need to take into consideration for gas and vapour samples if transported in an appropriate manner as specified in the method. • The transport of aerosol samples has a component of uncertainty associated with material losses from the sample substrate or substrate contamination The upper limit for the loading of the collection substrate can be determined as described in EN 838 or ISO 15767.

Uncertainty asssociated with analytical recovery • May be carried out following the tests described in EN 1076 and EN 838 by the use of standard test atmospheres. • Results for vapour and gases methods are normally corrected for desorption efficiency. It can be calculated using spiked sampling media. When the influence of ambient conditions and other factors are not significant and results are corrected for desorption efficiency, only the uncertainty component associated with this correction is taken into account.

Uncertainty asssociated with analytical recovery, cntd • Bias can be estimated from: Øresults obtained by analysing a suitable number of replicate samples of certified reference materials Øresults obtained from replicate samples taken in the test gas atmospheres Øresults from interlaboratory comparisons Øresults from recovery tests carried out on spiked sampling media Desorption efficiency can be calculated from the results of replicate analyses of certified reference material or of sampling media spiked at several levels covering the range of the application of the method, dividing the mass of analyte recovered by the mass applied, as specified in EN 838 and EN 1076.

Desorption efficiency When desorption efficiency does not vary significantly with the concentration (general case) and the results are corrected for desorption efficiency, the random uncertainty component associated with this correction is estimated and treated as an uncertainty component. The random uncertainty component associated with incomplete desorption is estimated as the relative standard deviation of the mean of the desorption efficiencies for all levels. If desorption efficiency correction is not applied to the results, the bias component is estimated and treated as an uncertainty component. The non-random uncertainty component associated with incomplete desorption is estimated as the difference of the mean of the desorption efficiency at all concentrations from unity and converted to a standard uncertainty. In some cases desorption efficiency varies with concentration. In this case the random and non-random uncertainty components will be estimated from the function relating the desorption efficiency to concentration.

Uncertainty asssociated with analytical variability In general, the uncertainty associated with analytical variability may be estimated either from data obtained under repeatability conditions or from data obtained under reproducibility conditions. When the analytical precision is determined from withinlaboratory reproducibility data, i. e. using quality control data, most random and randomized uncertainty components are included. The uncertainty associated with the analytical precision is determined by analysing calibration standards of the same composition under repeatability conditions. In vapour and gases methods this contribution is already incorporated in contributions from the determination of the desorption efficiency and it does not need to be taken into account. If applicable, the random uncertainty component associated with blank subtraction, or non-random uncertaintycomponent when no blank subtraction is performed, need to be included.

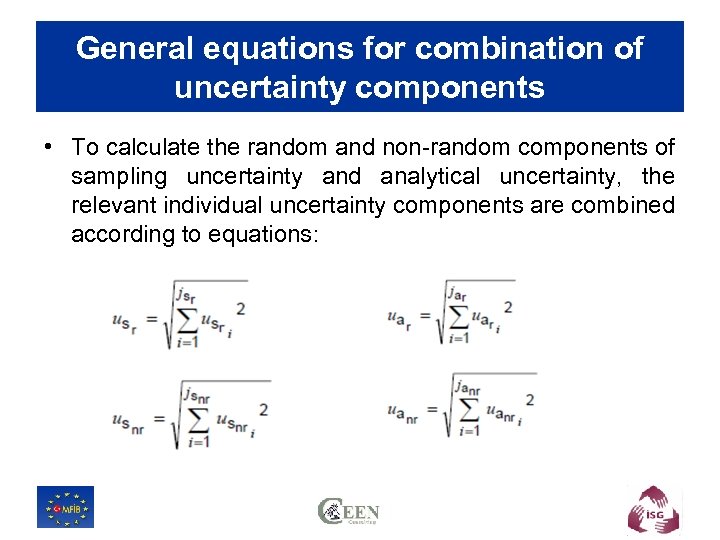

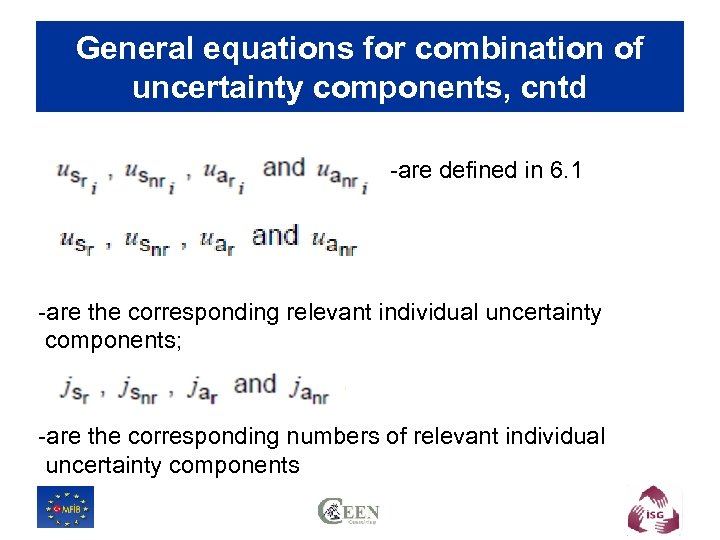

General equations for combination of uncertainty components • To calculate the random and non-random components of sampling uncertainty and analytical uncertainty, the relevant individual uncertainty components are combined according to equations:

General equations for combination of uncertainty components, cntd -are defined in 6. 1 -are the corresponding relevant individual uncertainty components; -are the corresponding numbers of relevant individual uncertainty components

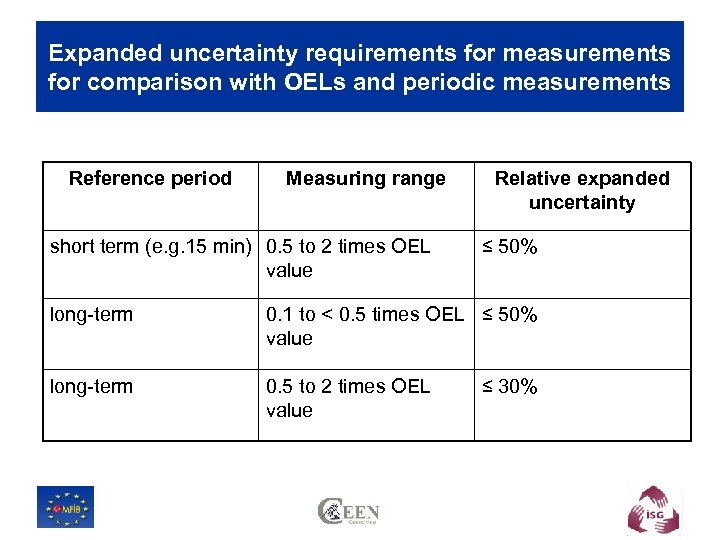

Expanded uncertainty requirements for measurements for comparison with OELs and periodic measurements Reference period Measuring range short term (e. g. 15 min) 0. 5 to 2 times OEL value Relative expanded uncertainty ≤ 50% long-term 0. 1 to < 0. 5 times OEL ≤ 50% value long-term 0. 5 to 2 times OEL value ≤ 30%

Thank you for your attention

d1984fca2eee436b5f95beb096c94eb8.ppt