e23cc6abe4c4729ef11673e578b8016a.ppt

- Количество слайдов: 187

this ppt presentation has 187 slides, some with notes. It is much more than my short presentation. It includes sections on identification, degradation, conservation and storage and display. It is meant as an aide memoire as many of the slides are to support discussions. Should you need any help or further explanation please email me on cjw@smile-plastics. co. uk Please accept that this ppt presentation is my copyright. I am normally happy to visit collections which may include plastics materials and to give advice on identification and associated guidance. Please understand that I do not have any organisation to fund these visits so I shall have to make a charge for this service. Compared to the risks associated with degrading collections, this charge should be considered an investment! Colin Williamson, Mansion House, Ford, Shrewsbury, SY 5 9 LZ cjw@smile-plastics. co. uk

this ppt presentation has 187 slides, some with notes. It is much more than my short presentation. It includes sections on identification, degradation, conservation and storage and display. It is meant as an aide memoire as many of the slides are to support discussions. Should you need any help or further explanation please email me on cjw@smile-plastics. co. uk Please accept that this ppt presentation is my copyright. I am normally happy to visit collections which may include plastics materials and to give advice on identification and associated guidance. Please understand that I do not have any organisation to fund these visits so I shall have to make a charge for this service. Compared to the risks associated with degrading collections, this charge should be considered an investment! Colin Williamson, Mansion House, Ford, Shrewsbury, SY 5 9 LZ cjw@smile-plastics. co. uk

Plastics Colin Williamson

Plastics Colin Williamson

Plastics materials Colin Williamson

Plastics materials Colin Williamson

Plastics materials production techniques Colin Williamson

Plastics materials production techniques Colin Williamson

Plastics materials production techniques identification Colin Williamson

Plastics materials production techniques identification Colin Williamson

all you ever wanted to know about plastics

all you ever wanted to know about plastics

all you ever wanted to know about plastics in 3 x 20 minutes

all you ever wanted to know about plastics in 3 x 20 minutes

all you ever wanted to know about plastics in 3 x 20 minutes + questions +discussion

all you ever wanted to know about plastics in 3 x 20 minutes + questions +discussion

only 2 types of plastic thermosetting

only 2 types of plastic thermosetting

only 2 types of plastic thermosetting thermoplastic

only 2 types of plastic thermosetting thermoplastic

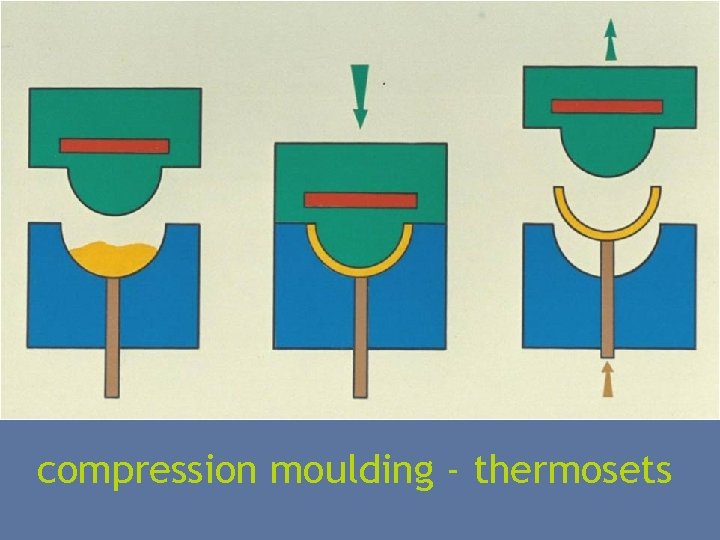

thermosets moulded whilst soft and hot ‘set’ demoulded hot once heated and ‘cured’ won’t melt again generally compression moulded

thermosets moulded whilst soft and hot ‘set’ demoulded hot once heated and ‘cured’ won’t melt again generally compression moulded

thermosets Bois Durci rubber & vulcanite phenol formaldehyde - Bakelite urea formaldehyde - Bandalasta GRP – glass fibre reinforced polyester epoxies – adhesives polyurethane

thermosets Bois Durci rubber & vulcanite phenol formaldehyde - Bakelite urea formaldehyde - Bandalasta GRP – glass fibre reinforced polyester epoxies – adhesives polyurethane

compression moulding - thermosets

compression moulding - thermosets

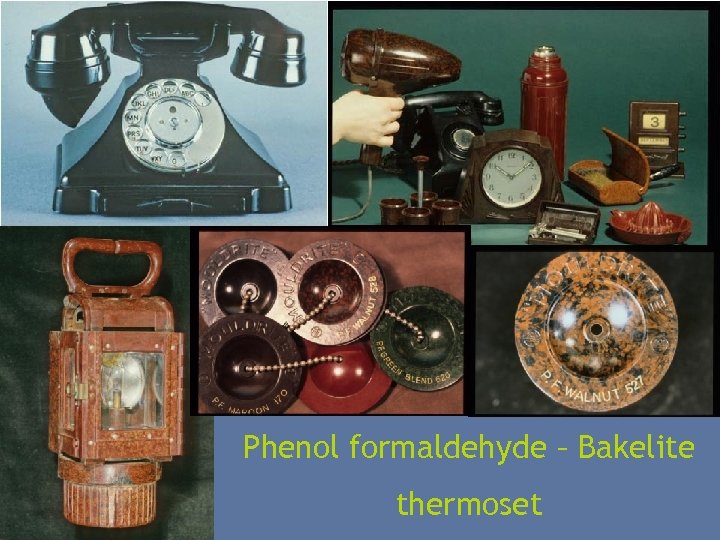

Phenol formaldehyde – Bakelite thermoset

Phenol formaldehyde – Bakelite thermoset

thermoplastics melted to form shape cooled to set in mould can be re-melted

thermoplastics melted to form shape cooled to set in mould can be re-melted

thermoplastics injection mould film blow bottle blow extrude calendar rotomould compression mould combination

thermoplastics injection mould film blow bottle blow extrude calendar rotomould compression mould combination

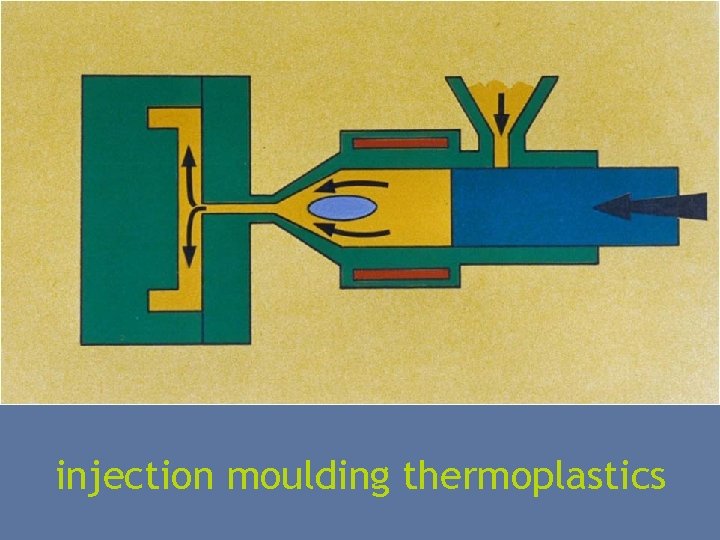

injection moulding thermoplastics

injection moulding thermoplastics

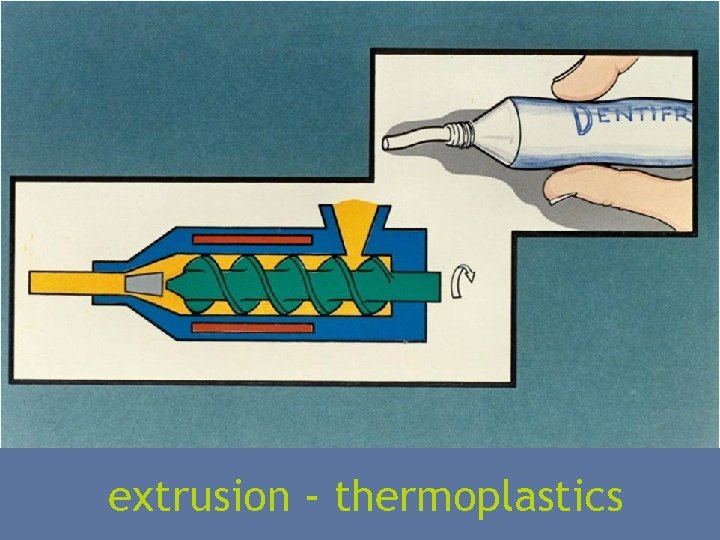

extrusion - thermoplastics

extrusion - thermoplastics

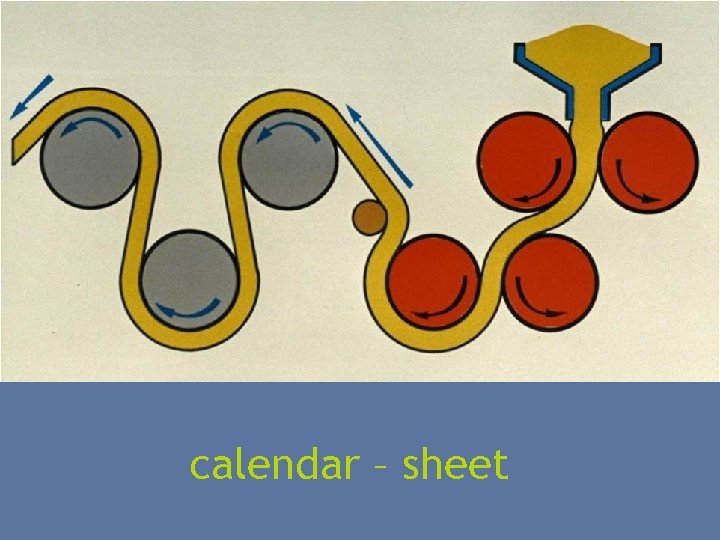

calendar – sheet

calendar – sheet

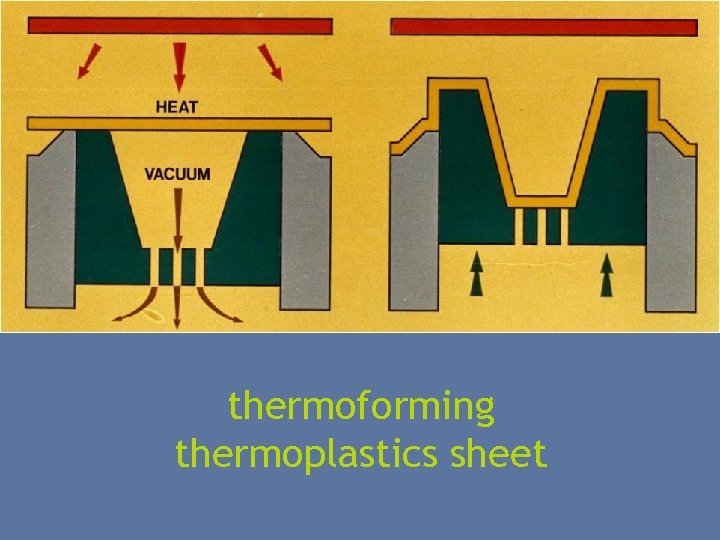

thermoforming thermoplastics sheet

thermoforming thermoplastics sheet

thermoplastic materials cellulose esters – Celluloid, CA polyethylene - polythene polypropylene polystyrene – also expanded, HIPS & ABS pvc – flexible or rigid PMMA – acrylic (Perspex)- sheet polycarbonate polyamide – nylon etc. , etc.

thermoplastic materials cellulose esters – Celluloid, CA polyethylene - polythene polypropylene polystyrene – also expanded, HIPS & ABS pvc – flexible or rigid PMMA – acrylic (Perspex)- sheet polycarbonate polyamide – nylon etc. , etc.

Identification

Identification

Identification education thirst for knowledge

Identification education thirst for knowledge

Identification education thirst for knowledge conservation

Identification education thirst for knowledge conservation

Identification non-destructive non-invasive

Identification non-destructive non-invasive

Identification appearance dating - style & design

Identification appearance dating - style & design

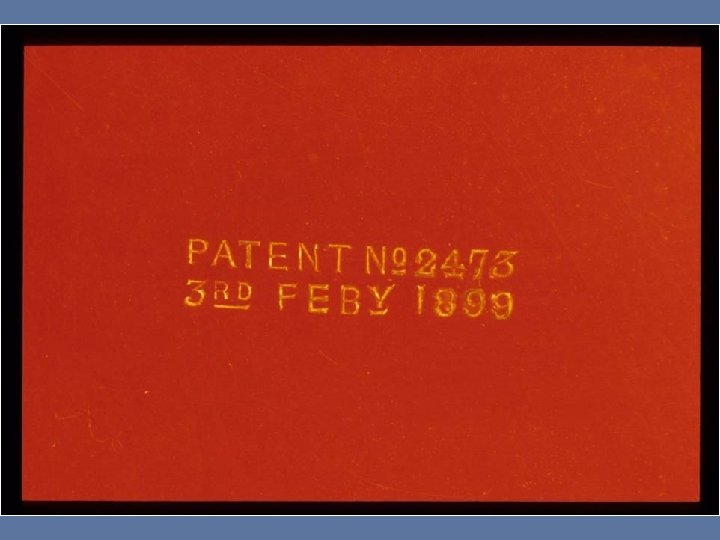

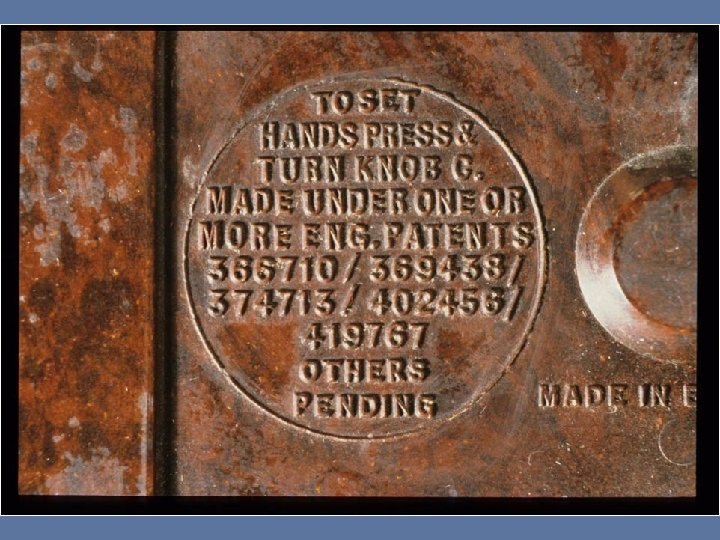

Identification appearance dating – trade marks, patents

Identification appearance dating – trade marks, patents

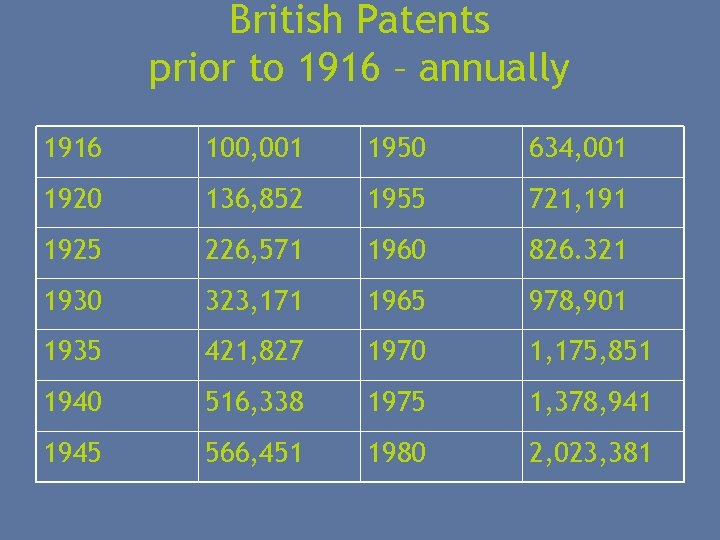

British Patents prior to 1916 – annually 1916 100, 001 1950 634, 001 1920 136, 852 1955 721, 191 1925 226, 571 1960 826. 321 1930 323, 171 1965 978, 901 1935 421, 827 1970 1, 175, 851 1940 516, 338 1975 1, 378, 941 1945 566, 451 1980 2, 023, 381

British Patents prior to 1916 – annually 1916 100, 001 1950 634, 001 1920 136, 852 1955 721, 191 1925 226, 571 1960 826. 321 1930 323, 171 1965 978, 901 1935 421, 827 1970 1, 175, 851 1940 516, 338 1975 1, 378, 941 1945 566, 451 1980 2, 023, 381

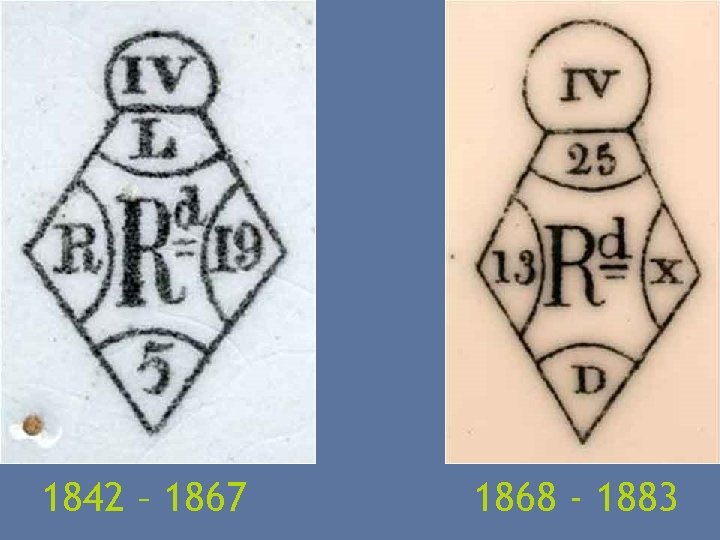

1842 – 1867 1868 - 1883

1842 – 1867 1868 - 1883

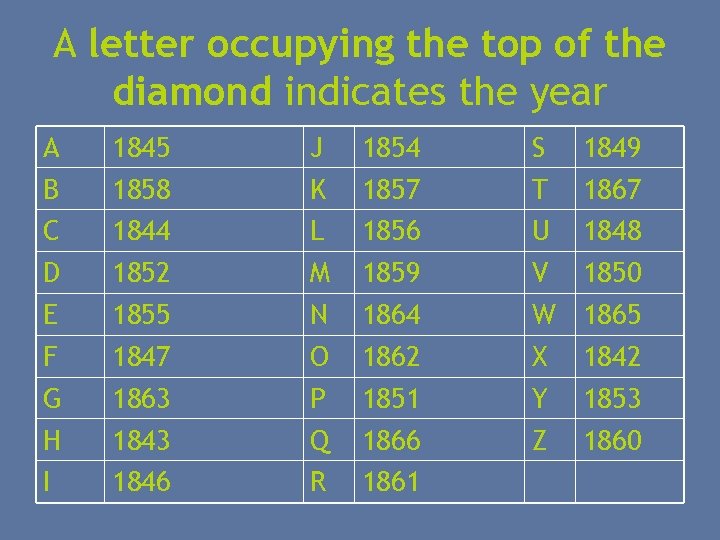

A letter occupying the top of the diamond indicates the year A B C D E F G H I 1845 1858 1844 1852 1855 1847 1863 1846 J K L M N O P Q R 1854 1857 1856 1859 1864 1862 1851 1866 1861 S T U V W X Y Z 1849 1867 1848 1850 1865 1842 1853 1860

A letter occupying the top of the diamond indicates the year A B C D E F G H I 1845 1858 1844 1852 1855 1847 1863 1846 J K L M N O P Q R 1854 1857 1856 1859 1864 1862 1851 1866 1861 S T U V W X Y Z 1849 1867 1848 1850 1865 1842 1853 1860

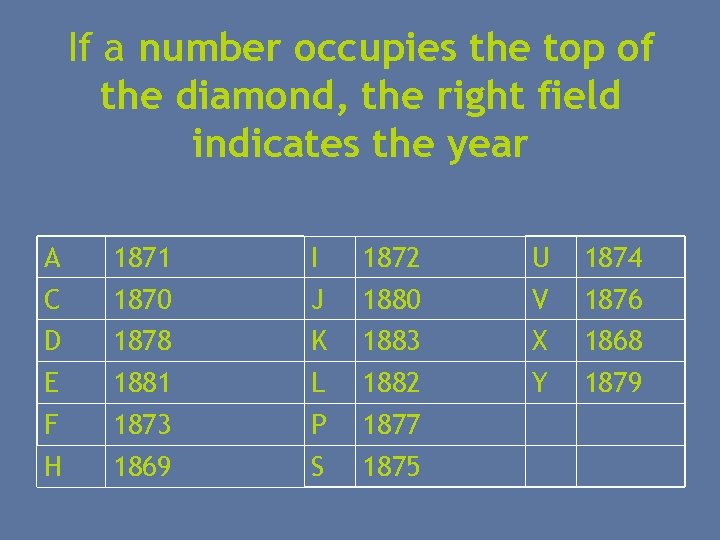

If a number occupies the top of the diamond, the right field indicates the year A C D E F H 1871 1870 1878 1881 1873 1869 I J K L P S 1872 1880 1883 1882 1877 1875 U V X Y 1874 1876 1868 1879

If a number occupies the top of the diamond, the right field indicates the year A C D E F H 1871 1870 1878 1881 1873 1869 I J K L P S 1872 1880 1883 1882 1877 1875 U V X Y 1874 1876 1868 1879

Bandalasta – urea/thiourea f

Bandalasta – urea/thiourea f

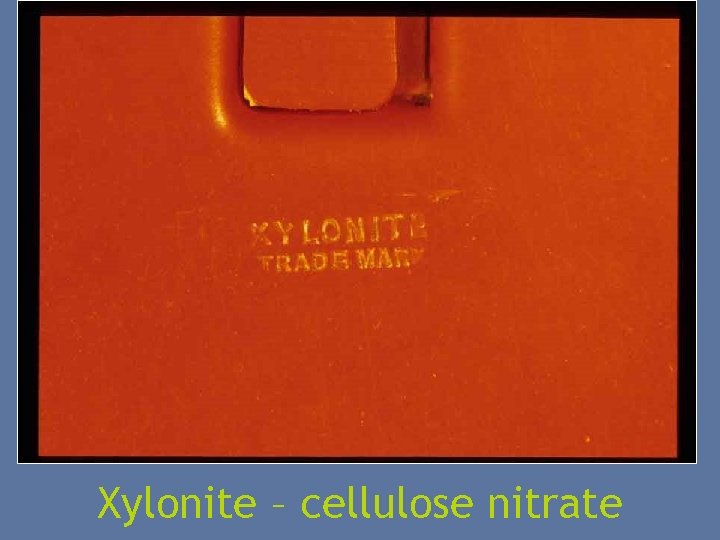

Xylonite – cellulose nitrate

Xylonite – cellulose nitrate

Identification appearance colour and transparency

Identification appearance colour and transparency

Transparent (i. e. glass clear) as thick solids (>2 mm) PMMA – acrylic, Perspex, Plexiglas polystyrene polycarbonate cast phenolic – normally tinted polyester cellulose esters silicones, polyurethane

Transparent (i. e. glass clear) as thick solids (>2 mm) PMMA – acrylic, Perspex, Plexiglas polystyrene polycarbonate cast phenolic – normally tinted polyester cellulose esters silicones, polyurethane

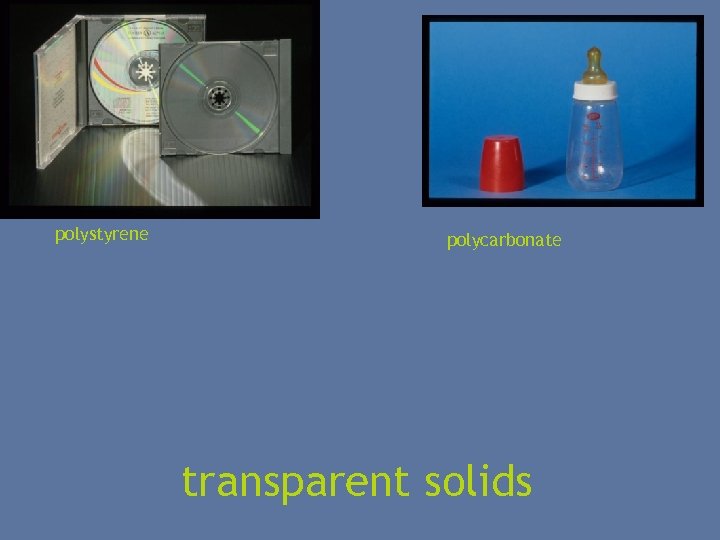

polystyrene polycarbonate transparent solids

polystyrene polycarbonate transparent solids

Transparent (i. e. glass clear) as thin film or sheet as solid + PVC both rigid and flexible polypropylene regenerated cellulose (Cellophane) polyethylene PET (polyethylene terephthalate)

Transparent (i. e. glass clear) as thin film or sheet as solid + PVC both rigid and flexible polypropylene regenerated cellulose (Cellophane) polyethylene PET (polyethylene terephthalate)

Only opaque (at best, translucent) phenol + urea formaldehyde – moulded gutta percha vulcanite Bois Durci + most compositions bitumen + cold moulded compositions composites, including GRP ABS foams

Only opaque (at best, translucent) phenol + urea formaldehyde – moulded gutta percha vulcanite Bois Durci + most compositions bitumen + cold moulded compositions composites, including GRP ABS foams

Colour phenol formaldehyde – Bakelite – dark cast pf – shades of amber pigment or compound wood or cloth fillers

Colour phenol formaldehyde – Bakelite – dark cast pf – shades of amber pigment or compound wood or cloth fillers

phenol formaldehyde – Bakelite dark colours

phenol formaldehyde – Bakelite dark colours

Cast phenol formaldehyde – amber shades

Cast phenol formaldehyde – amber shades

Cast phenol formaldehyde – amber shades

Cast phenol formaldehyde – amber shades

pf – colour in blotches

pf – colour in blotches

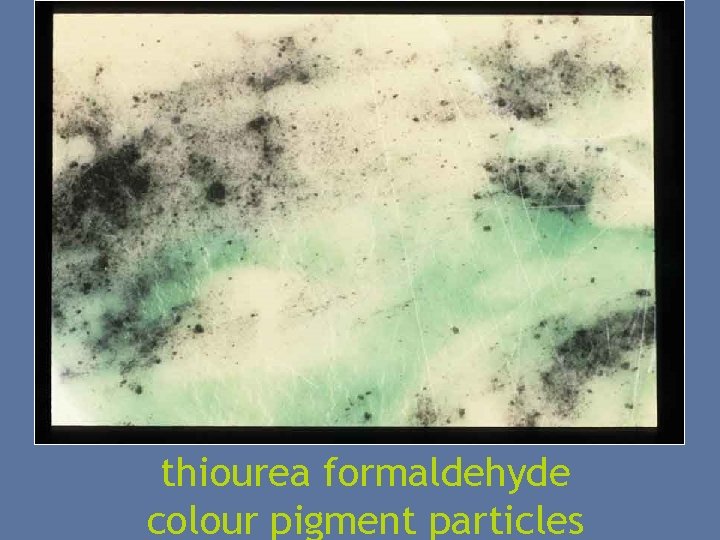

thiourea formaldehyde colour pigment particles

thiourea formaldehyde colour pigment particles

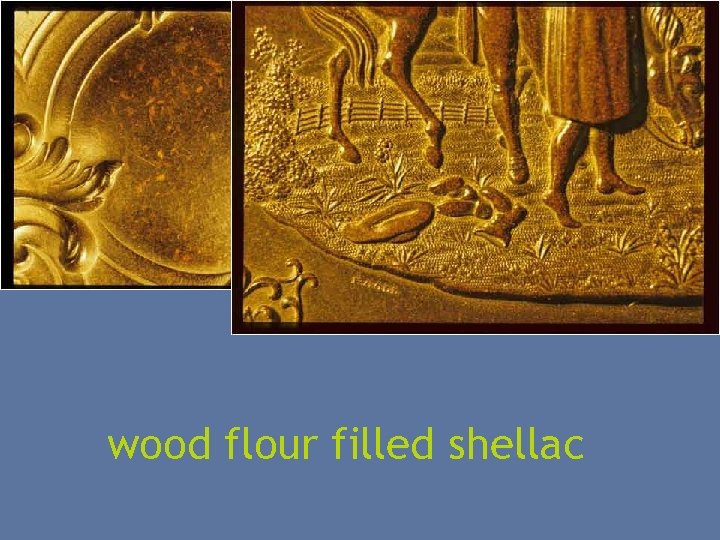

wood flour filled shellac

wood flour filled shellac

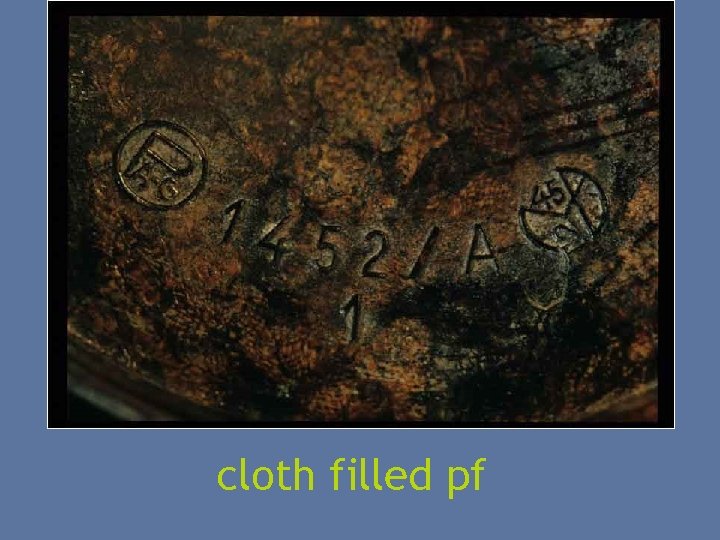

cloth filled pf

cloth filled pf

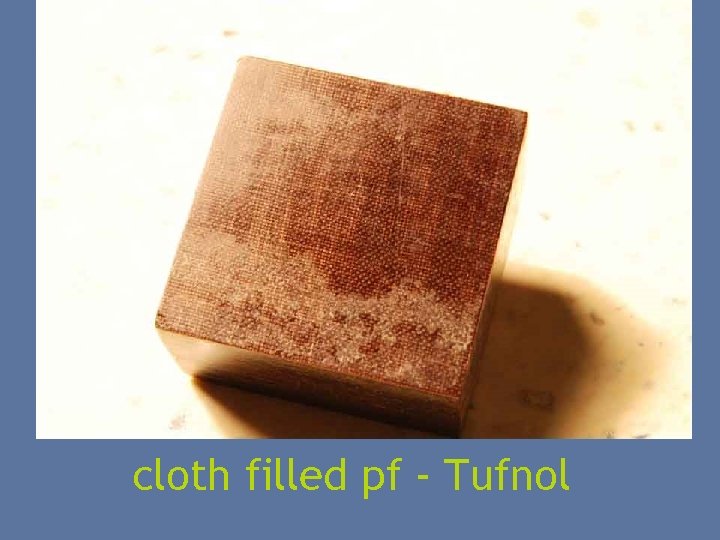

cloth filled pf - Tufnol

cloth filled pf - Tufnol

Identification appearance surface finish

Identification appearance surface finish

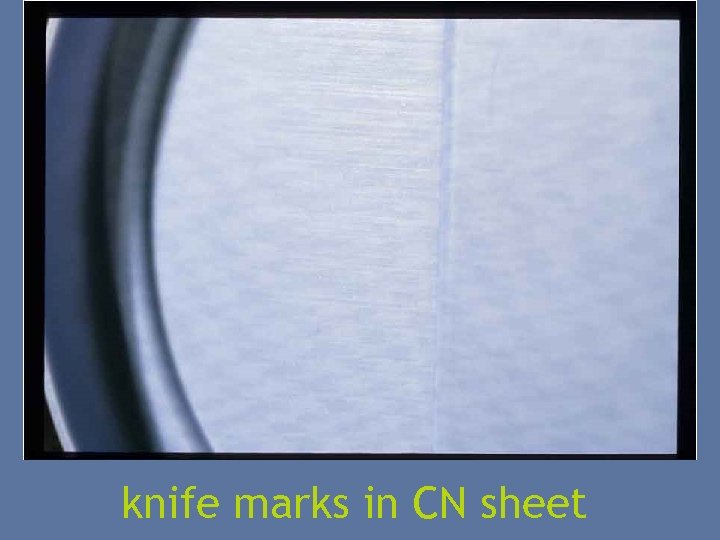

knife marks in CN sheet

knife marks in CN sheet

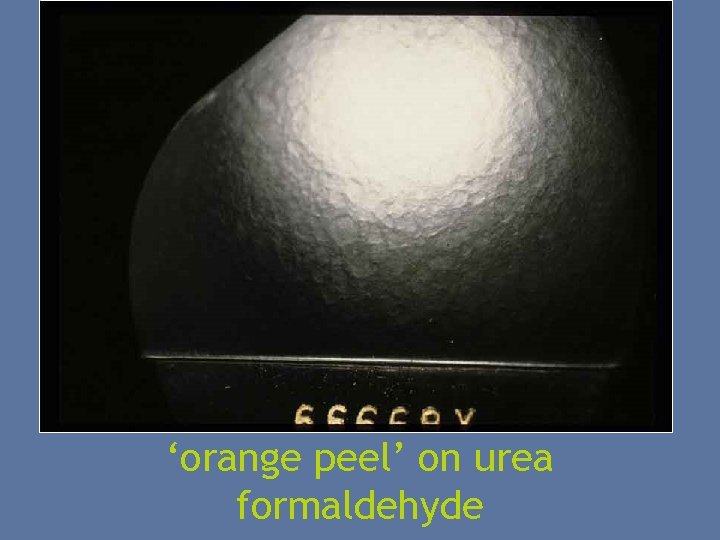

‘orange peel’ on urea formaldehyde

‘orange peel’ on urea formaldehyde

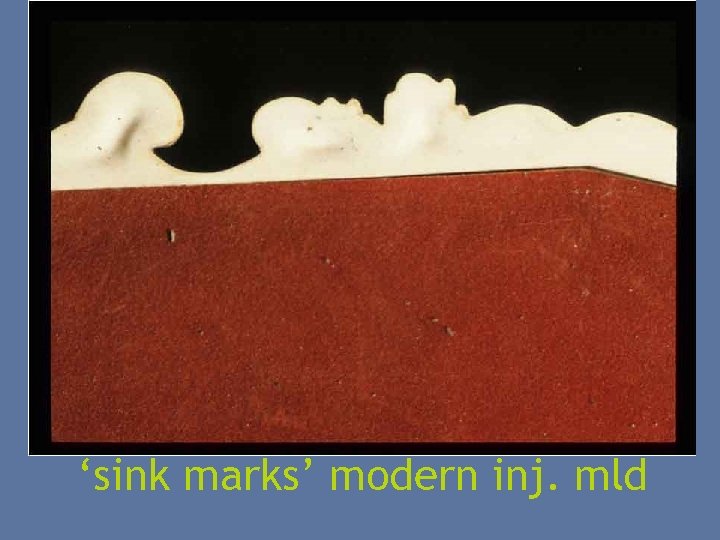

‘sink marks’ modern inj. mld

‘sink marks’ modern inj. mld

Identification appearance degradation

Identification appearance degradation

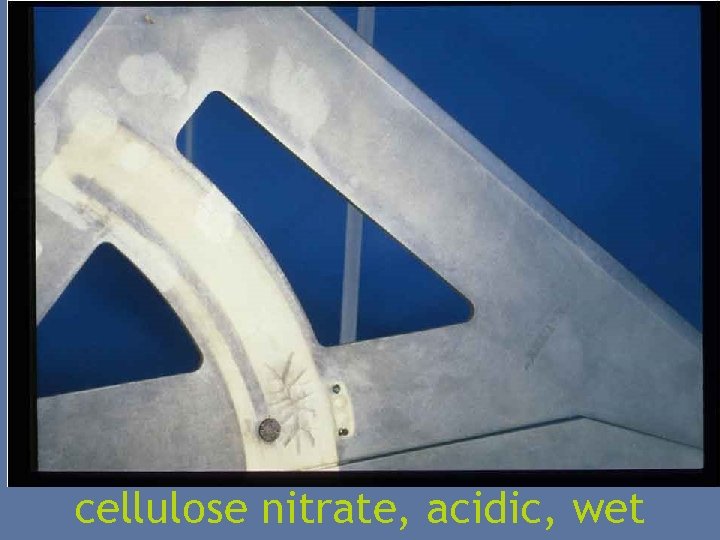

cellulose nitrate – acidic, wet

cellulose nitrate – acidic, wet

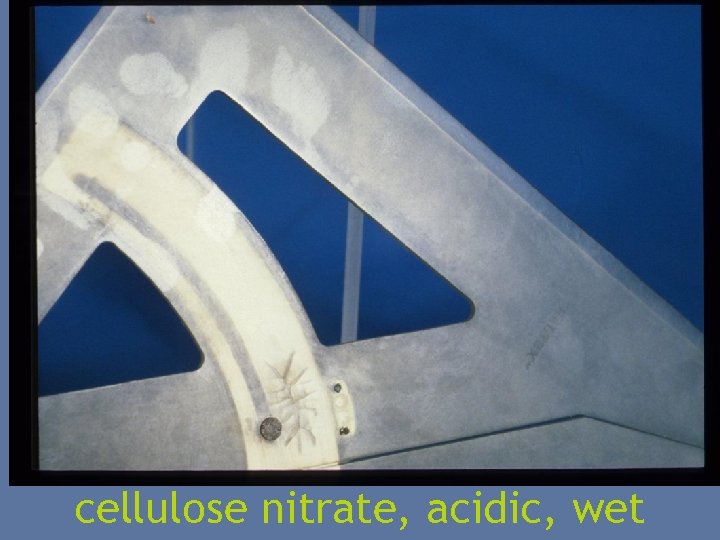

cellulose nitrate, acidic, wet

cellulose nitrate, acidic, wet

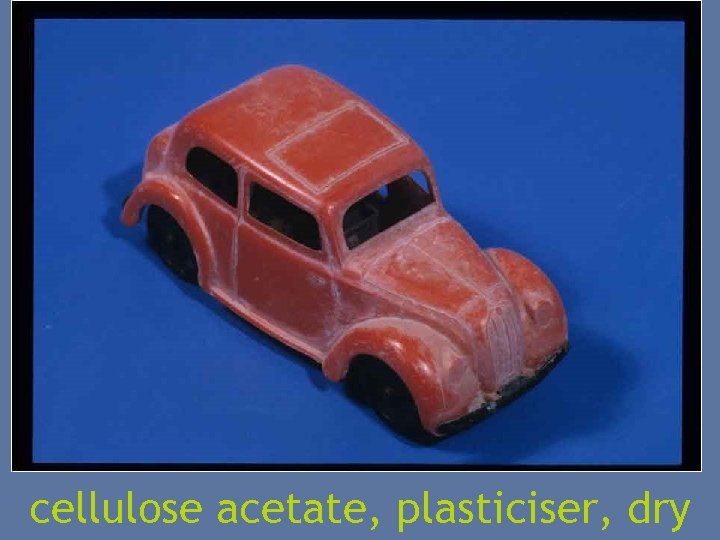

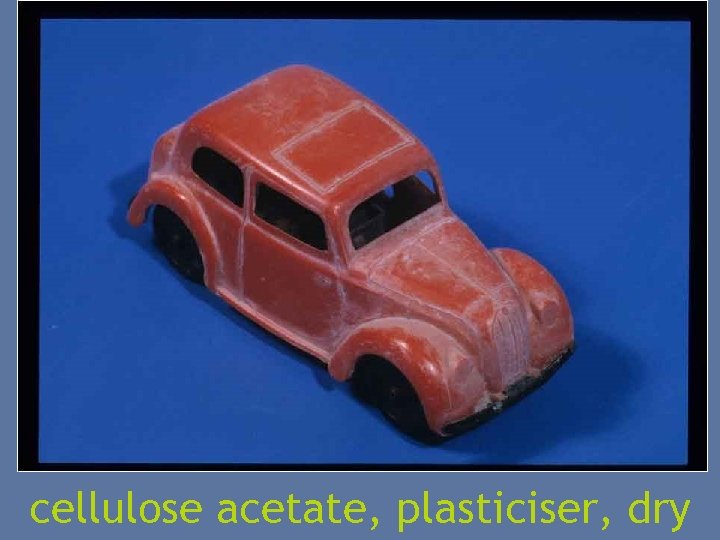

cellulose acetate, plasticiser, dry

cellulose acetate, plasticiser, dry

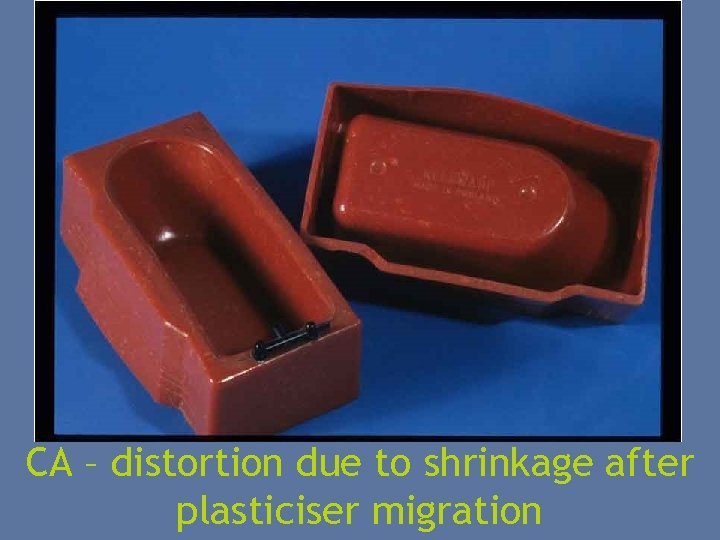

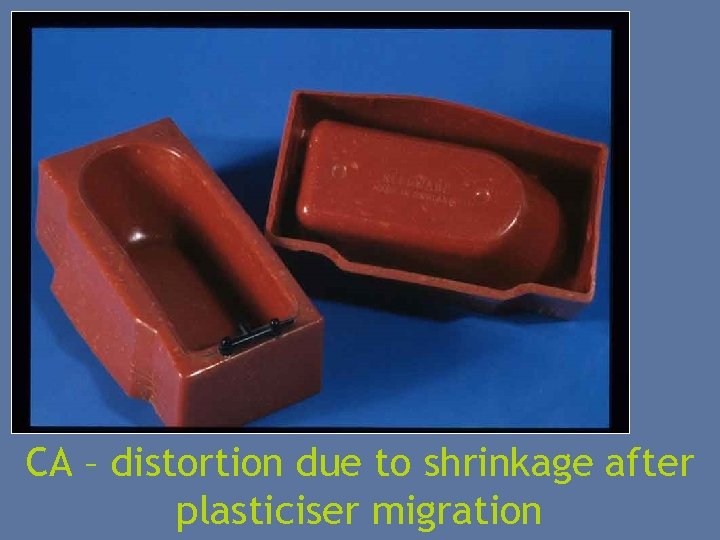

CA – distortion due to shrinkage after plasticiser migration

CA – distortion due to shrinkage after plasticiser migration

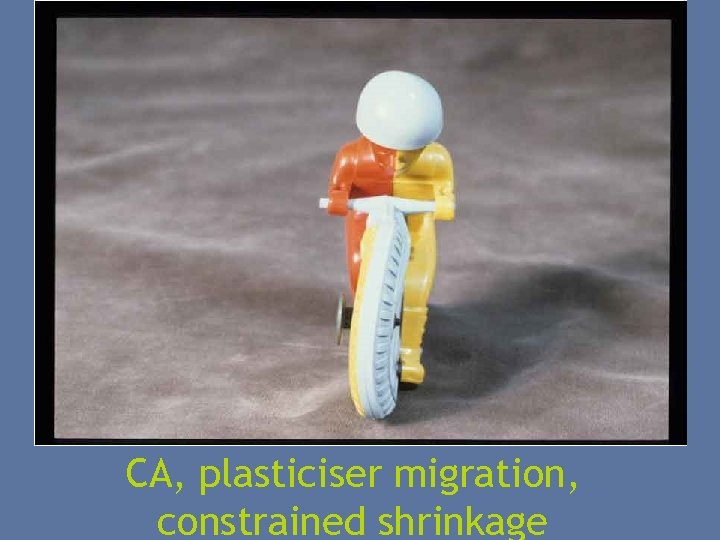

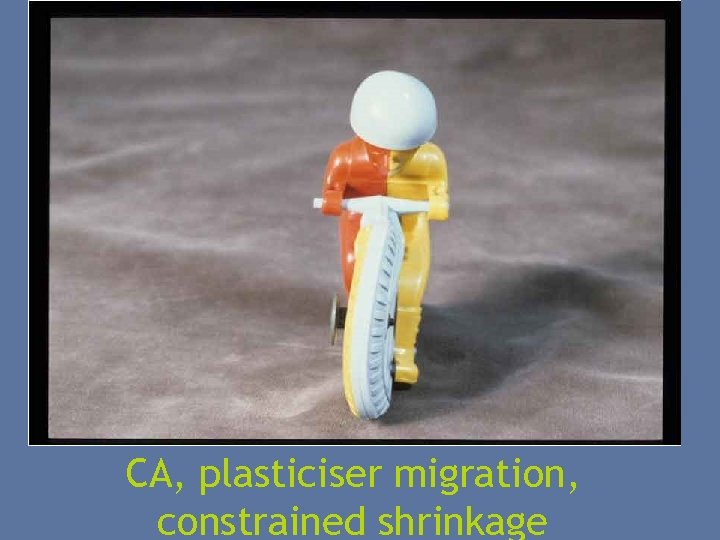

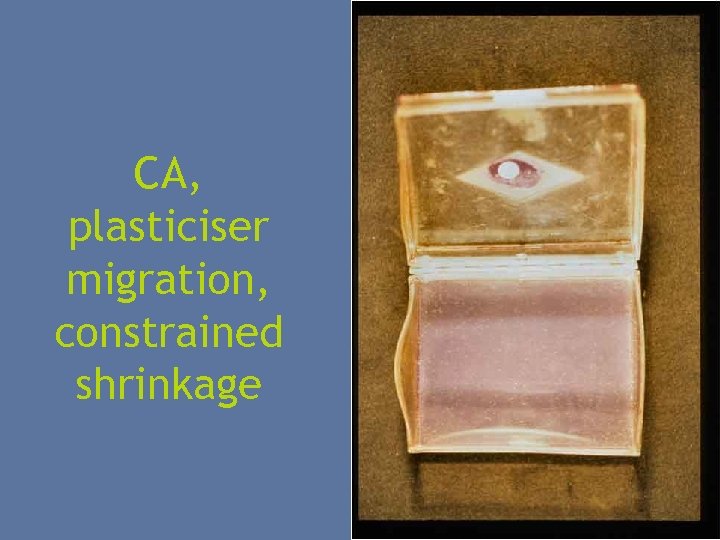

CA, plasticiser migration, constrained shrinkage

CA, plasticiser migration, constrained shrinkage

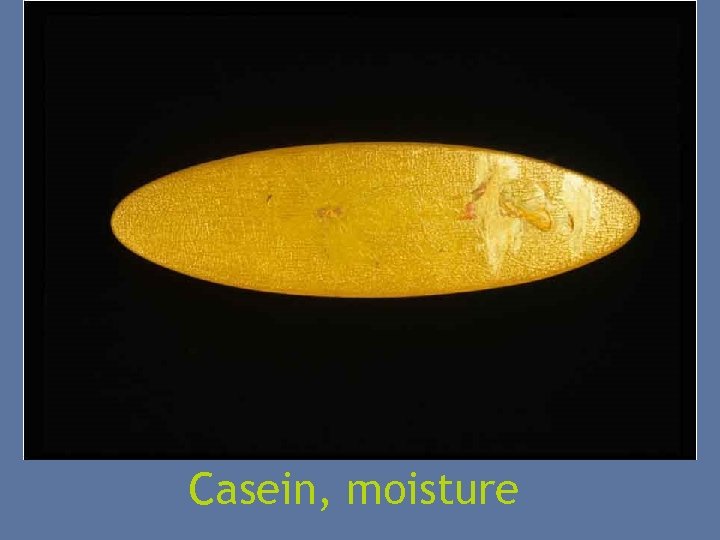

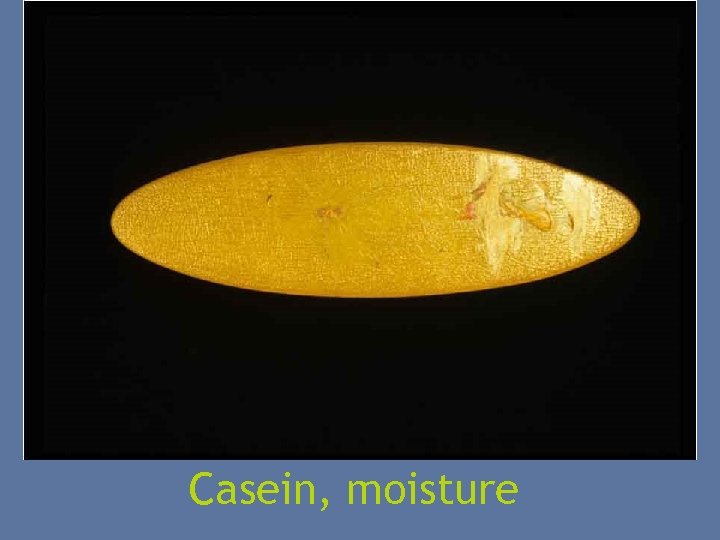

Casein, moisture

Casein, moisture

Identification appearance function

Identification appearance function

Identification appearance production method

Identification appearance production method

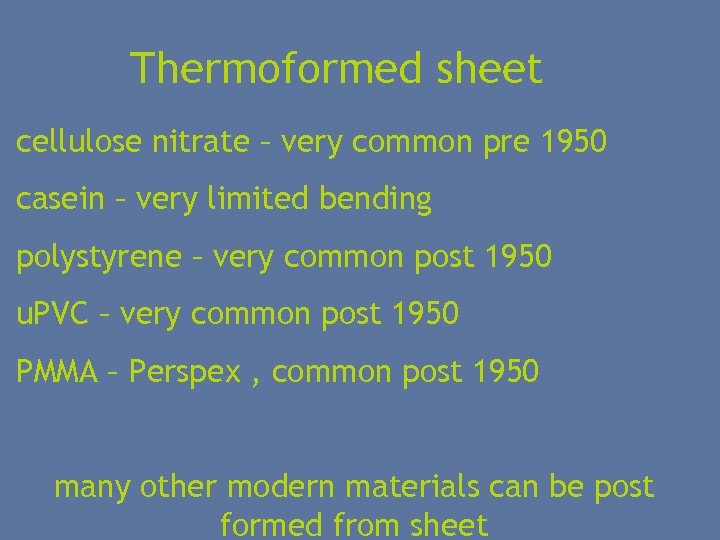

Thermoformed sheet cellulose nitrate – very common pre 1950 casein – very limited bending polystyrene – very common post 1950 u. PVC – very common post 1950 PMMA – Perspex , common post 1950 many other modern materials can be post formed from sheet

Thermoformed sheet cellulose nitrate – very common pre 1950 casein – very limited bending polystyrene – very common post 1950 u. PVC – very common post 1950 PMMA – Perspex , common post 1950 many other modern materials can be post formed from sheet

Blow moulded polyethylene – eg detergent bottles PET – eg fizzy drink bottles also u. PVC, polypropylene, polycarbonate

Blow moulded polyethylene – eg detergent bottles PET – eg fizzy drink bottles also u. PVC, polypropylene, polycarbonate

Rotation Moulded polyethylene, e. g. canoes, road cones plasticised pvc, e. g. footballs, dolls also nylon and polycarbonate

Rotation Moulded polyethylene, e. g. canoes, road cones plasticised pvc, e. g. footballs, dolls also nylon and polycarbonate

Injection moulded most thermoplastics except casein and cellulose nitrate thermosets after 1960

Injection moulded most thermoplastics except casein and cellulose nitrate thermosets after 1960

Compression moulded almost all plastics materials but commercially not viable for modern thermoplastics. typical of thermosets

Compression moulded almost all plastics materials but commercially not viable for modern thermoplastics. typical of thermosets

Casting polyester (especially embedding resins) PMMA (especially embedding resins) cast Phenolic polyurethane foam, e. g. shoes

Casting polyester (especially embedding resins) PMMA (especially embedding resins) cast Phenolic polyurethane foam, e. g. shoes

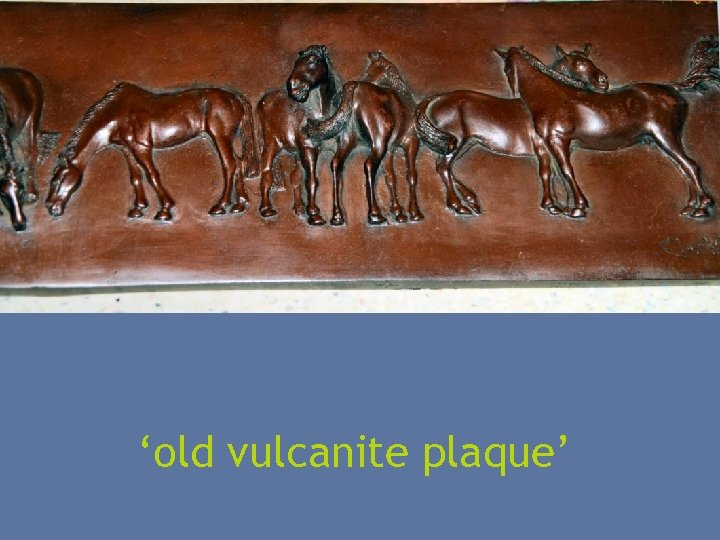

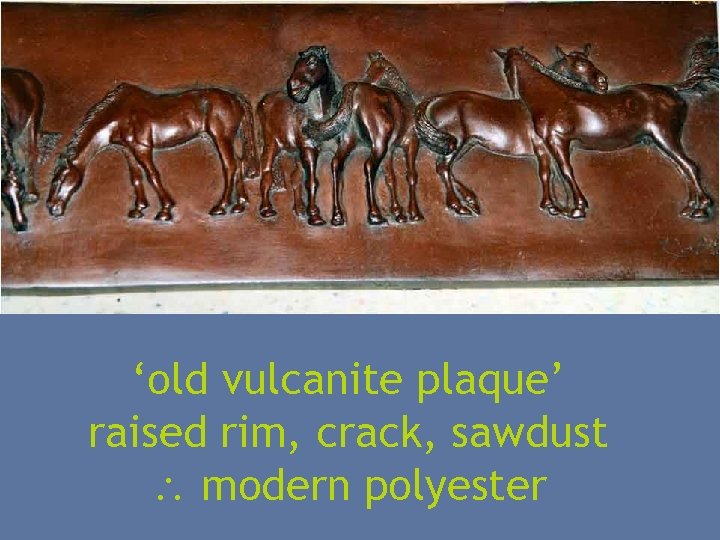

‘old vulcanite plaque’

‘old vulcanite plaque’

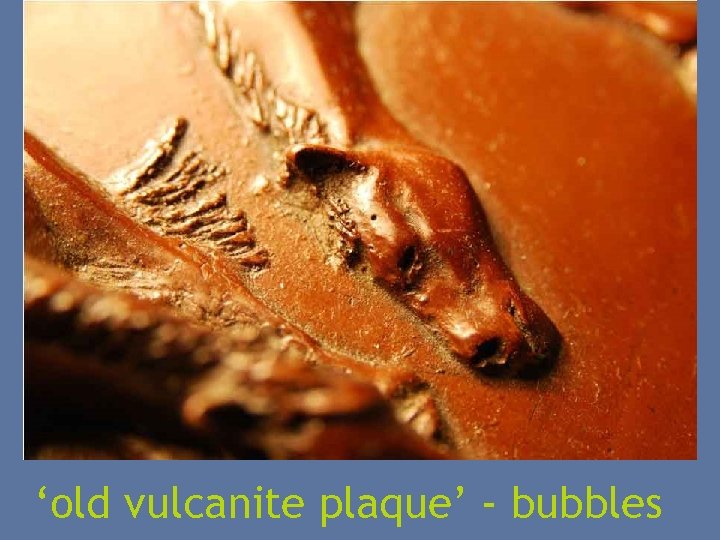

‘old vulcanite plaque’ - bubbles

‘old vulcanite plaque’ - bubbles

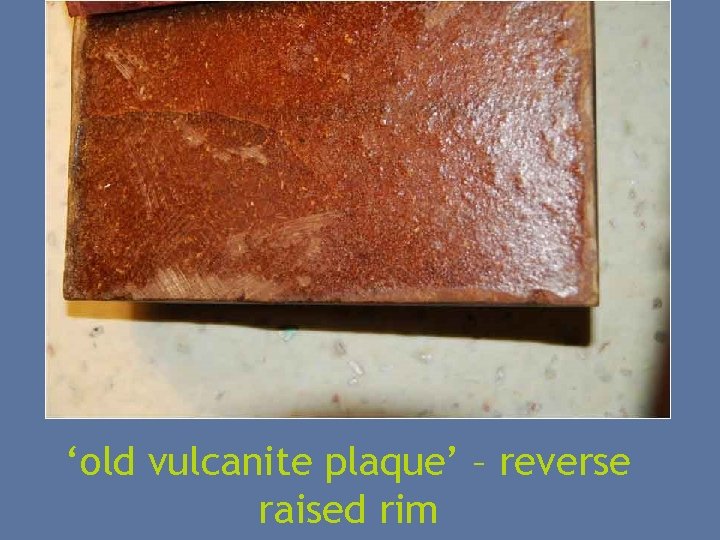

‘old vulcanite plaque’ – reverse raised rim

‘old vulcanite plaque’ – reverse raised rim

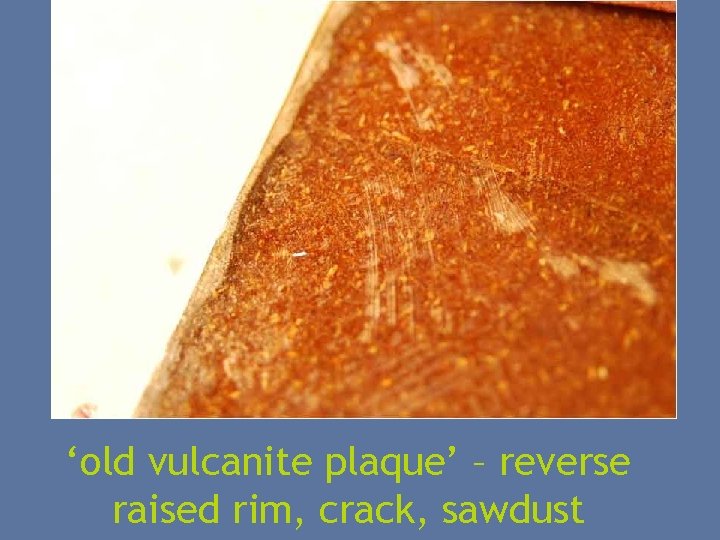

‘old vulcanite plaque’ – reverse raised rim, crack, sawdust

‘old vulcanite plaque’ – reverse raised rim, crack, sawdust

‘old vulcanite plaque’ raised rim, crack, sawdust modern polyester

‘old vulcanite plaque’ raised rim, crack, sawdust modern polyester

extrusion most thermoplastics parallel marks along the long axis film and sheet rod and profile fibres

extrusion most thermoplastics parallel marks along the long axis film and sheet rod and profile fibres

Identification physical properties

Identification physical properties

hardness some plastics are softer than a finger nail polyethylene polypropylene gutta percha (except very old) plasticised pvc polyurethane rubber

hardness some plastics are softer than a finger nail polyethylene polypropylene gutta percha (except very old) plasticised pvc polyurethane rubber

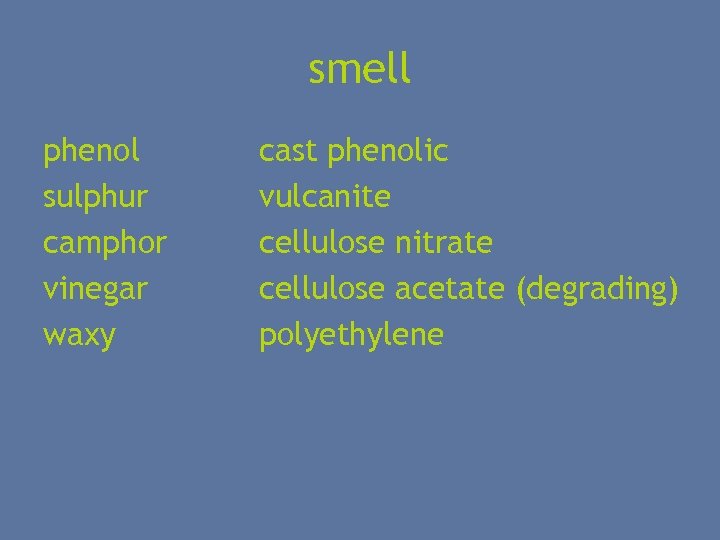

smell phenol sulphur camphor vinegar waxy cast phenolic vulcanite cellulose nitrate cellulose acetate (degrading) polyethylene

smell phenol sulphur camphor vinegar waxy cast phenolic vulcanite cellulose nitrate cellulose acetate (degrading) polyethylene

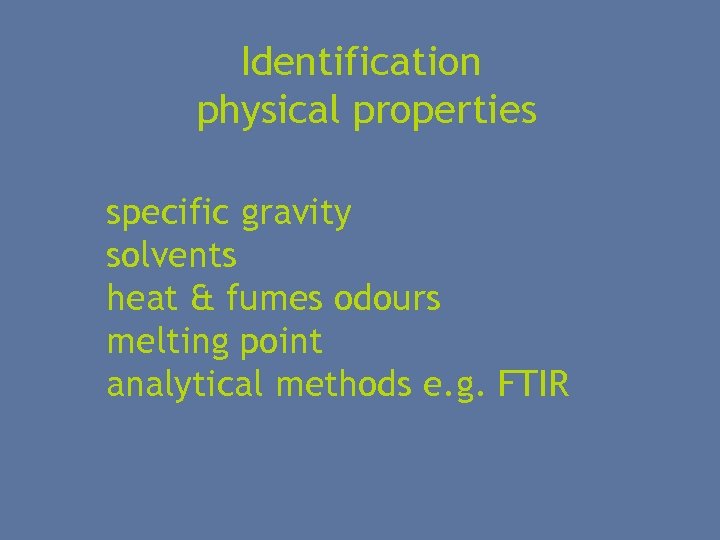

Identification physical properties specific gravity solvents heat & fumes odours melting point analytical methods e. g. FTIR

Identification physical properties specific gravity solvents heat & fumes odours melting point analytical methods e. g. FTIR

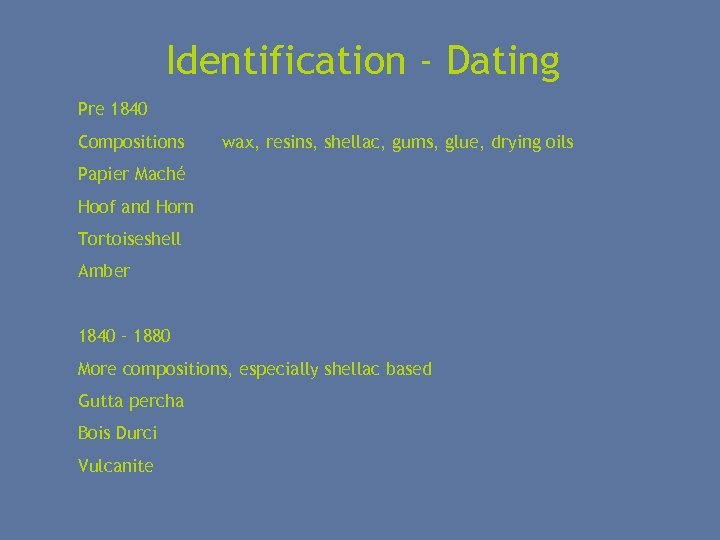

Identification - Dating Pre 1840 Compositions wax, resins, shellac, gums, glue, drying oils Papier Maché Hoof and Horn Tortoiseshell Amber 1840 – 1880 More compositions, especially shellac based Gutta percha Bois Durci Vulcanite

Identification - Dating Pre 1840 Compositions wax, resins, shellac, gums, glue, drying oils Papier Maché Hoof and Horn Tortoiseshell Amber 1840 – 1880 More compositions, especially shellac based Gutta percha Bois Durci Vulcanite

Identification - Dating 1880 – 1900 Cellulose nitrate Compositions decrease 1900 – 1920 Cellulose nitrate increases Cellulose acetate Casein Bitumen

Identification - Dating 1880 – 1900 Cellulose nitrate Compositions decrease 1900 – 1920 Cellulose nitrate increases Cellulose acetate Casein Bitumen

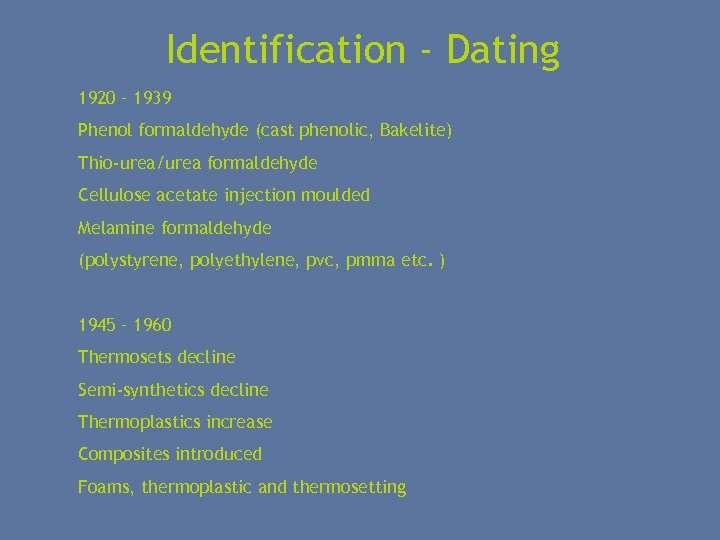

Identification - Dating 1920 – 1939 Phenol formaldehyde (cast phenolic, Bakelite) Thio-urea/urea formaldehyde Cellulose acetate injection moulded Melamine formaldehyde (polystyrene, polyethylene, pvc, pmma etc. ) 1945 – 1960 Thermosets decline Semi-synthetics decline Thermoplastics increase Composites introduced Foams, thermoplastic and thermosetting

Identification - Dating 1920 – 1939 Phenol formaldehyde (cast phenolic, Bakelite) Thio-urea/urea formaldehyde Cellulose acetate injection moulded Melamine formaldehyde (polystyrene, polyethylene, pvc, pmma etc. ) 1945 – 1960 Thermosets decline Semi-synthetics decline Thermoplastics increase Composites introduced Foams, thermoplastic and thermosetting

why identify ?

why identify ?

why identify ? to identify potential problems

why identify ? to identify potential problems

why identify ? to identify potential problems to identify problem materials

why identify ? to identify potential problems to identify problem materials

problem materials cellulose nitrate – Celluloid cellulose acetate pvc polyurethane foams

problem materials cellulose nitrate – Celluloid cellulose acetate pvc polyurethane foams

questions

questions

questions there’s no such thing as a stupid question

questions there’s no such thing as a stupid question

questions there’s no such thing as a stupid question only stupid answers

questions there’s no such thing as a stupid question only stupid answers

Degradation surface bloom distortion splitting colour change embrittlement crazing

Degradation surface bloom distortion splitting colour change embrittlement crazing

Degradation surface bloom distortion splitting colour change embrittlement crazing

Degradation surface bloom distortion splitting colour change embrittlement crazing

cellulose nitrate – acidic, wet

cellulose nitrate – acidic, wet

cellulose nitrate, acidic, wet

cellulose nitrate, acidic, wet

cellulose acetate, plasticiser, dry

cellulose acetate, plasticiser, dry

Degradation surface bloom distortion splitting colour change embrittlement crazing

Degradation surface bloom distortion splitting colour change embrittlement crazing

CA – distortion due to shrinkage after plasticiser migration

CA – distortion due to shrinkage after plasticiser migration

CA, plasticiser migration, constrained shrinkage

CA, plasticiser migration, constrained shrinkage

CA, plasticiser migration, constrained shrinkage

CA, plasticiser migration, constrained shrinkage

Degradation surface bloom distortion splitting colour change embrittlement crazing

Degradation surface bloom distortion splitting colour change embrittlement crazing

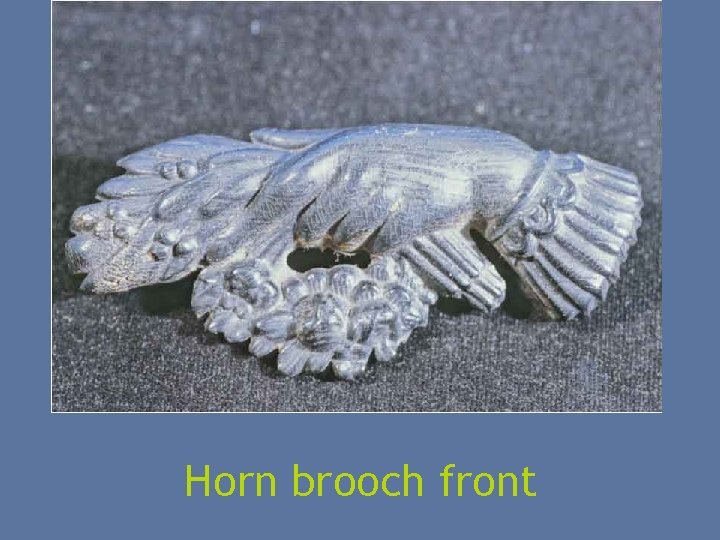

Horn brooch front

Horn brooch front

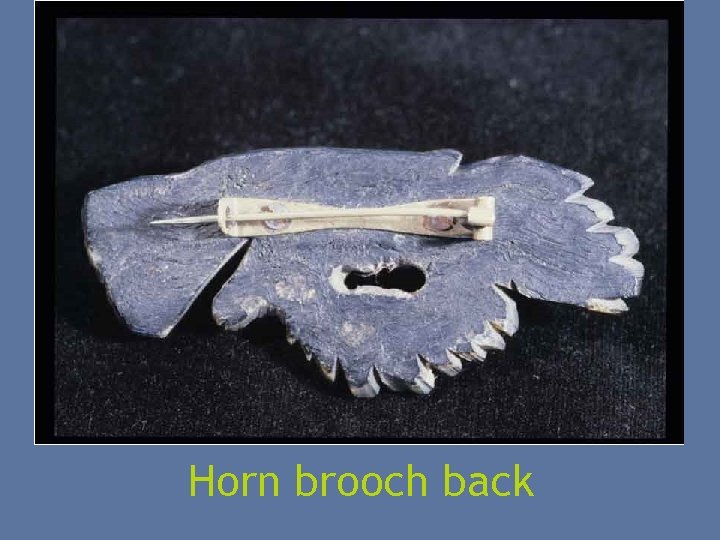

Horn brooch back

Horn brooch back

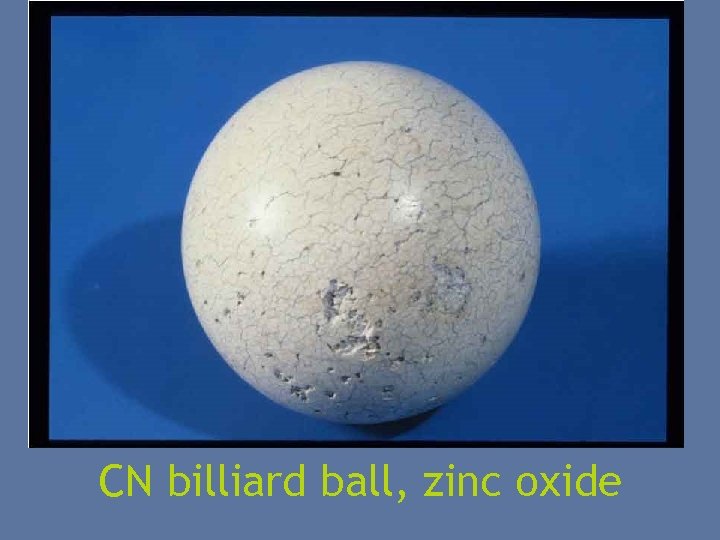

CN billiard ball, zinc oxide

CN billiard ball, zinc oxide

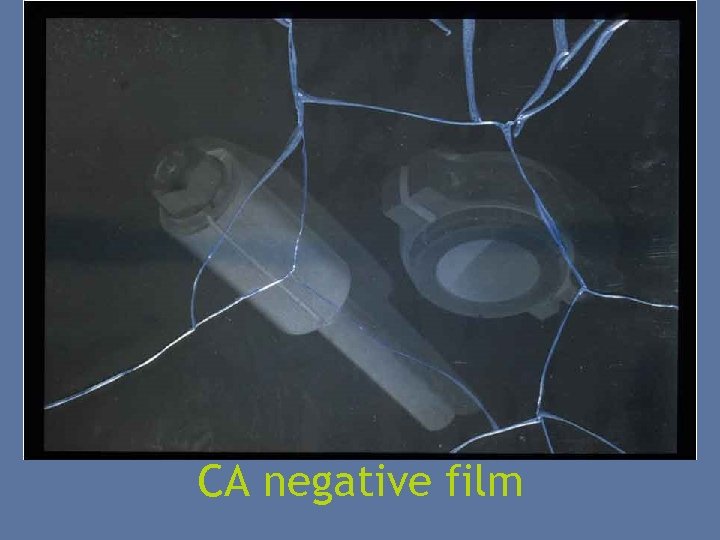

CA negative film

CA negative film

CN delamination

CN delamination

Degradation surface bloom distortion splitting colour change embrittlement crazing

Degradation surface bloom distortion splitting colour change embrittlement crazing

CA, UV colour fade

CA, UV colour fade

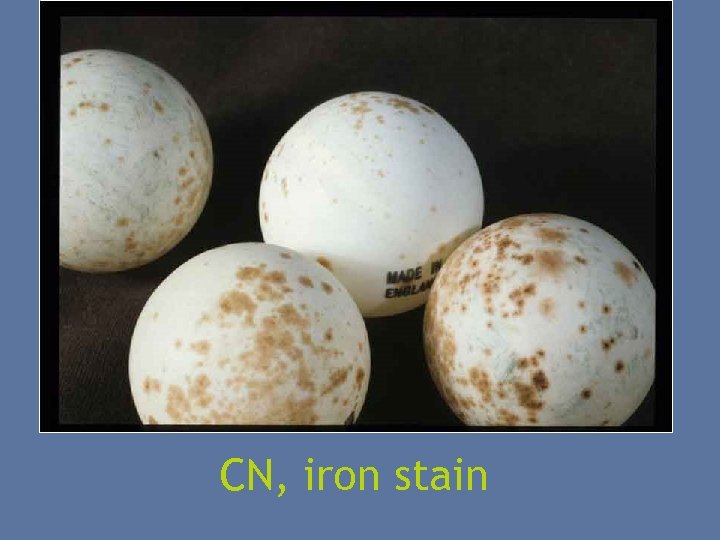

CN, iron stain

CN, iron stain

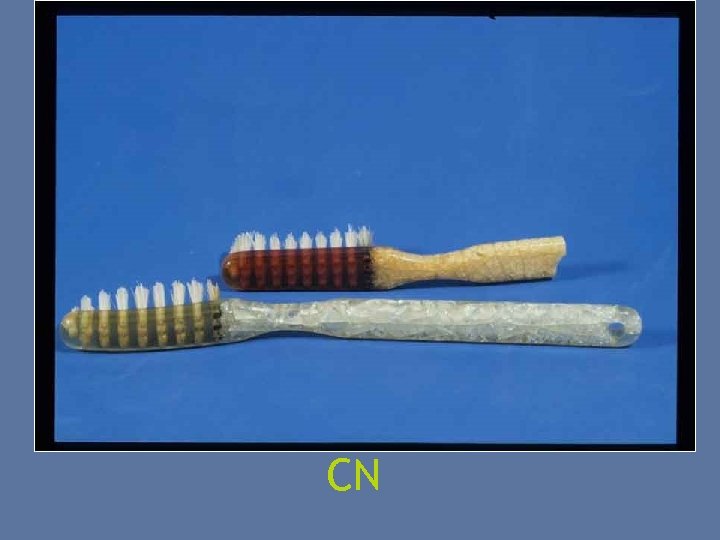

CN

CN

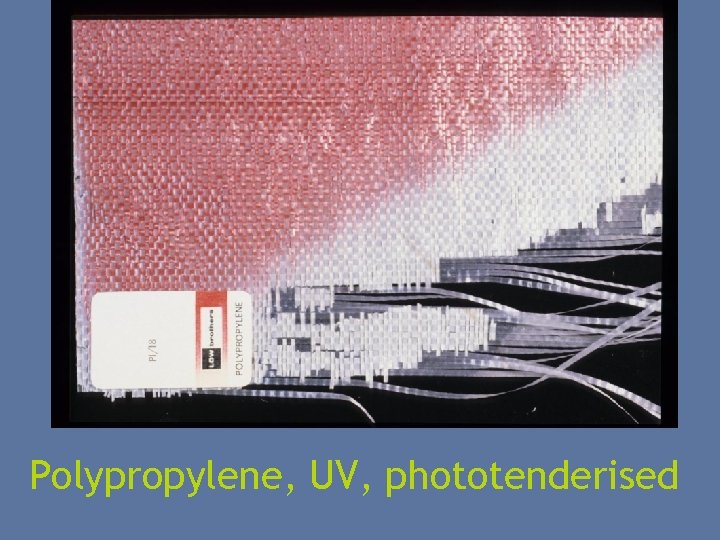

Polypropylene, UV, phototenderised

Polypropylene, UV, phototenderised

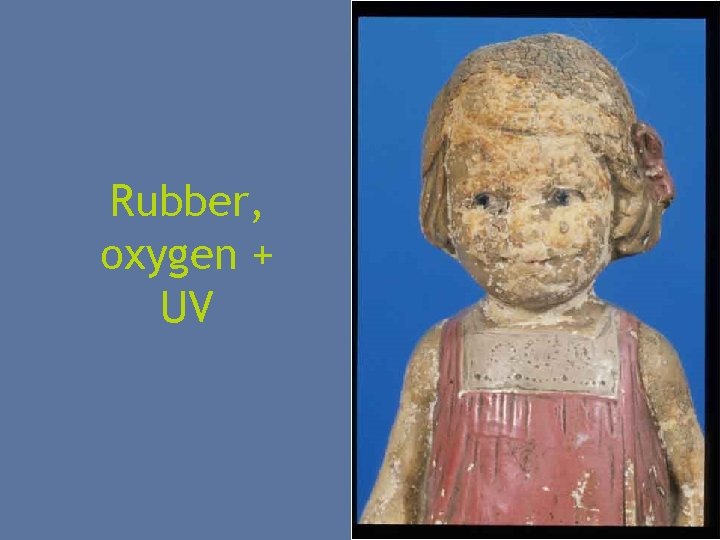

Rubber, oxygen + UV

Rubber, oxygen + UV

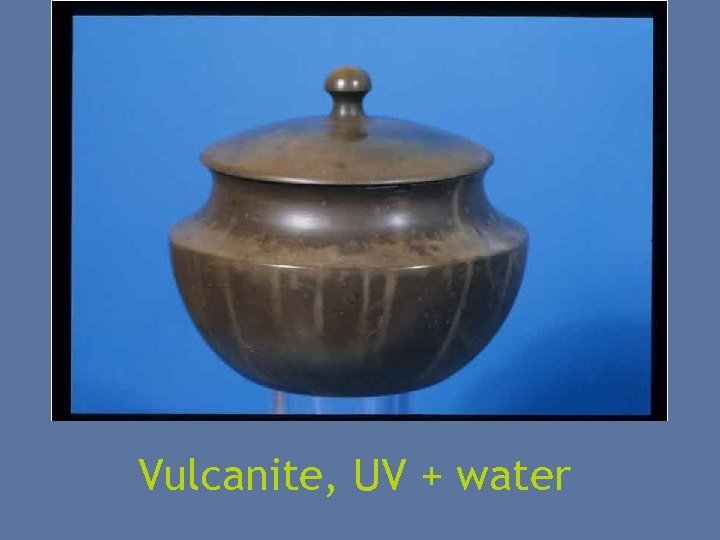

Vulcanite, UV + water

Vulcanite, UV + water

Vulcanite, UV + water

Vulcanite, UV + water

Vulcanite, UV + moisture

Vulcanite, UV + moisture

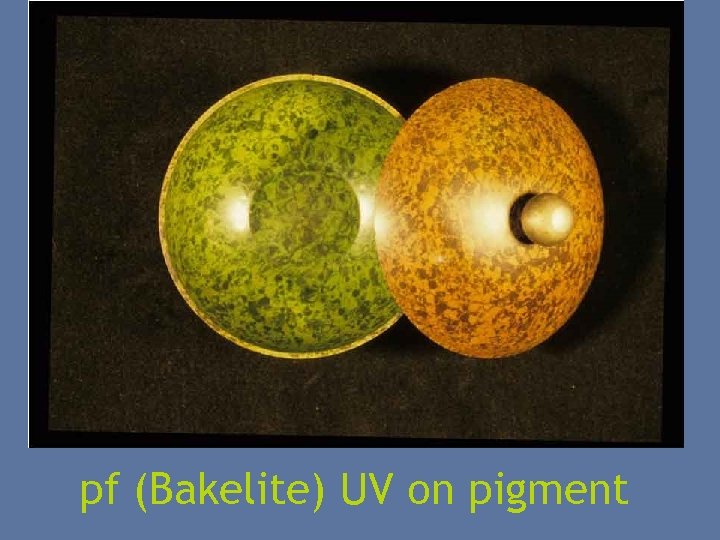

pf (Bakelite) UV

pf (Bakelite) UV

pf (Bakelite) UV on pigment

pf (Bakelite) UV on pigment

Degradation surface bloom distortion splitting colour change embrittlement crazing

Degradation surface bloom distortion splitting colour change embrittlement crazing

cn – stage 1

cn – stage 1

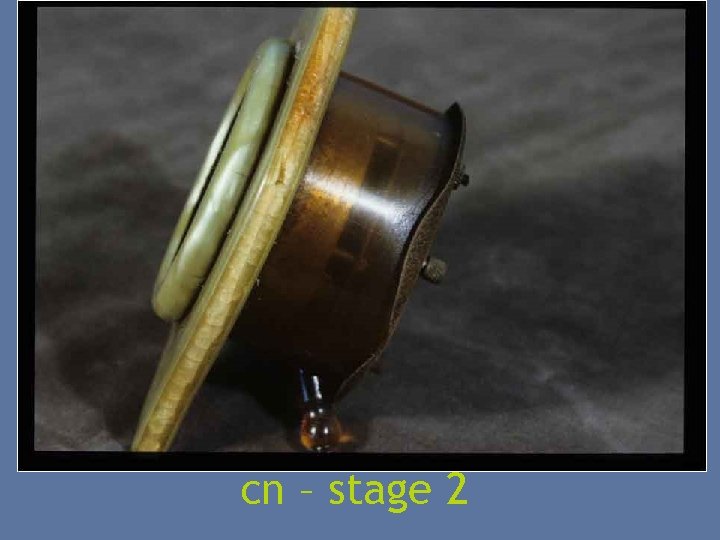

cn – stage 2

cn – stage 2

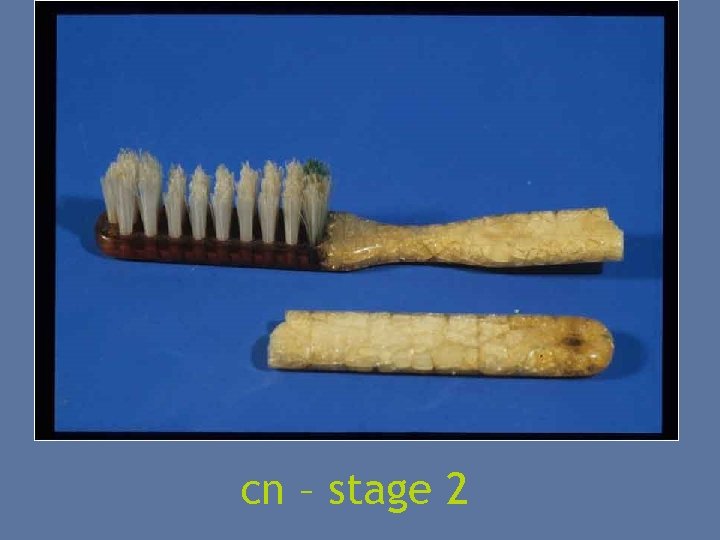

cn – stage 2

cn – stage 2

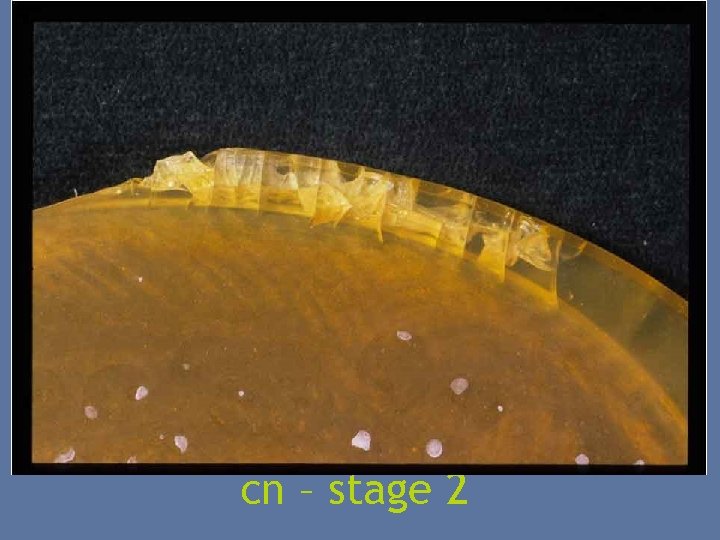

cn – stage 2

cn – stage 2

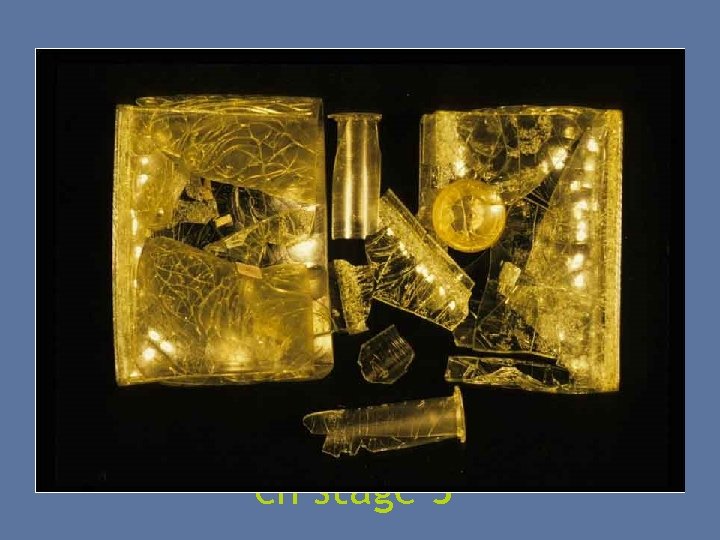

cn stage 3

cn stage 3

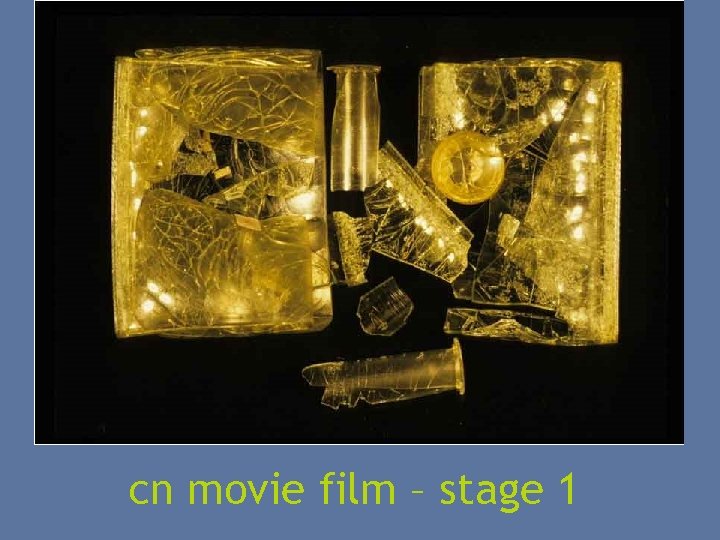

cn movie film – stage 1

cn movie film – stage 1

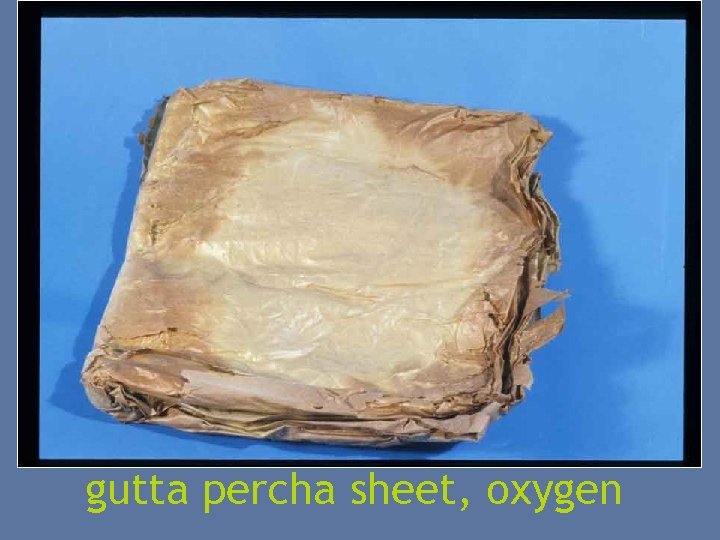

gutta percha sheet, oxygen

gutta percha sheet, oxygen

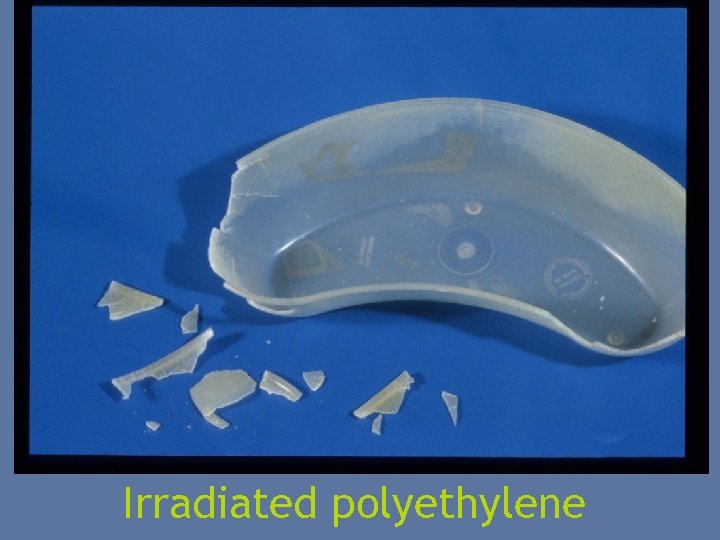

Irradiated polyethylene

Irradiated polyethylene

u. PVC, UV

u. PVC, UV

Degradation surface bloom distortion splitting colour change embrittlement crazing

Degradation surface bloom distortion splitting colour change embrittlement crazing

Casein, moisture

Casein, moisture

Casein, moisture

Casein, moisture

Degradation surface bloom distortion splitting colour change embrittlement crazing weeping

Degradation surface bloom distortion splitting colour change embrittlement crazing weeping

Degradation Weeping – typically CA plasticiser loss

Degradation Weeping – typically CA plasticiser loss

Stability of Plastics

Stability of Plastics

Cellulose Nitrate (Celluloid) hydrolysis Nitrogen oxides off gas Nitrous and nitric acids

Cellulose Nitrate (Celluloid) hydrolysis Nitrogen oxides off gas Nitrous and nitric acids

Cellulose Nitrate (Celluloid) off gassing - corrosion moist haze acidic surface cuboid cracking movie film dry deepfreeze

Cellulose Nitrate (Celluloid) off gassing - corrosion moist haze acidic surface cuboid cracking movie film dry deepfreeze

Cellulose Acetate hydrolysis acetic acid - vinegar plasticiser migration

Cellulose Acetate hydrolysis acetic acid - vinegar plasticiser migration

Cellulose Acetate smell of vinegar weeping dry plasticiser on surface distortion blisters

Cellulose Acetate smell of vinegar weeping dry plasticiser on surface distortion blisters

PVC originally unstable but UV and ΔH stabilisers added plasticiser migration rigid – darkens & embrittles flexible – stiffens/liquefies

PVC originally unstable but UV and ΔH stabilisers added plasticiser migration rigid – darkens & embrittles flexible – stiffens/liquefies

Polyurethanes unstable as foam as high surface area and O 2 exposure darken, powder, crumbling

Polyurethanes unstable as foam as high surface area and O 2 exposure darken, powder, crumbling

Other polymers all UV sensitive transparent worse than opaque amorphous (e. g. PMMA, P’s, Polycarb) – solvent sensitivity

Other polymers all UV sensitive transparent worse than opaque amorphous (e. g. PMMA, P’s, Polycarb) – solvent sensitivity

Caring basic considerations storage inc. passive cons. cleaning handling degradation indicators display

Caring basic considerations storage inc. passive cons. cleaning handling degradation indicators display

Caring basic considerations storage inc. passive cons. cleaning handling degradation indicators display

Caring basic considerations storage inc. passive cons. cleaning handling degradation indicators display

Basic considerations identify the material before acquisition

Basic considerations identify the material before acquisition

Basic considerations identify the material before acquisition only acquire non-degrading items

Basic considerations identify the material before acquisition only acquire non-degrading items

Basic considerations identify the material before acquisition only acquire non-degrading items physical damage better than chemical

Basic considerations identify the material before acquisition only acquire non-degrading items physical damage better than chemical

Basic considerations identify the material before acquisition only acquire non-degrading items physical damage better than chemical exposure stress, labels, paint, adhesive

Basic considerations identify the material before acquisition only acquire non-degrading items physical damage better than chemical exposure stress, labels, paint, adhesive

Caring basic considerations storage inc. passive cons. cleaning handling degradation indicators display

Caring basic considerations storage inc. passive cons. cleaning handling degradation indicators display

storage no sunlight, heat, & damp no lights in stores 30 -50% RH <5 o C < 30% slows degradation

storage no sunlight, heat, & damp no lights in stores 30 -50% RH <5 o C < 30% slows degradation

storage no sunlight, heat, & damp no enclosed wrappings allow off gassing except for passive conservation

storage no sunlight, heat, & damp no enclosed wrappings allow off gassing except for passive conservation

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue not touching other items

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue not touching other items

storage not touching other items plasticiser migration degradation bi-products colour bleed

storage not touching other items plasticiser migration degradation bi-products colour bleed

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue not touching other items supported

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue not touching other items supported

storage supported stress sculpted bed cushion strongest points open framework check materials (cf display)

storage supported stress sculpted bed cushion strongest points open framework check materials (cf display)

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue not touching other items supported indicators

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue not touching other items supported indicators

storage indicators cresol paper cresol string

storage indicators cresol paper cresol string

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue not touching other items supported indicators passive conservation

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue not touching other items supported indicators passive conservation

storage passive conservation scavengers activated charcoal – poss CN CA Zeolites – ok CA film long term Ageless – ok for rubber NOT CN CA

storage passive conservation scavengers activated charcoal – poss CN CA Zeolites – ok CA film long term Ageless – ok for rubber NOT CN CA

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue not touching other items supported indicators passive conservation gloves

storage no sunlight, heat, & damp no enclosed wrappings acid free tissue not touching other items supported indicators passive conservation gloves

storage gloves lint free - snagging non-absorbent (acids)

storage gloves lint free - snagging non-absorbent (acids)

Caring basic considerations storage inc. passive cons. cleaning

Caring basic considerations storage inc. passive cons. cleaning

Caring cleaning advisable for conservation but curatorial ?

Caring cleaning advisable for conservation but curatorial ?

Caring cleaning water (sparingly) generally safe BUT

Caring cleaning water (sparingly) generally safe BUT

water generally safe BUT not immersion ? surface dyed casein not vulcanite not foam not degrading CN

water generally safe BUT not immersion ? surface dyed casein not vulcanite not foam not degrading CN

Caring cleaning olive oil ok for sticky labels BUT beware ESC

Caring cleaning olive oil ok for sticky labels BUT beware ESC

Caring cleaning wax polish ?

Caring cleaning wax polish ?

Caring basic considerations storage inc. passive cons. cleaning handling degradation indicators display

Caring basic considerations storage inc. passive cons. cleaning handling degradation indicators display

Caring display 50 lux max 30 -50% RH constant 200 C clean(ed) air acid fumes, organic vapours

Caring display 50 lux max 30 -50% RH constant 200 C clean(ed) air acid fumes, organic vapours

Caring display suitable plastics for direct contact polyolefines (check stability and creep) polyethylene foam PET – polyester eg, Melinex, Mylar nylons

Caring display suitable plastics for direct contact polyolefines (check stability and creep) polyethylene foam PET – polyester eg, Melinex, Mylar nylons

Caring display un-suitable plastics for display/support cellulose esters e. g. celluloid plasticised PVC polyurethane foam paint – esp solvent

Caring display un-suitable plastics for display/support cellulose esters e. g. celluloid plasticised PVC polyurethane foam paint – esp solvent

So, you’ve got plastics in the collection ? ? ?

So, you’ve got plastics in the collection ? ? ?

So, you’ve got plastics in the collection ? ? ? What to do

So, you’ve got plastics in the collection ? ? ? What to do

Survey identify materials

Survey identify materials

Survey identify materials identify degradation

Survey identify materials identify degradation

Survey identify materials identify degradation determine risk

Survey identify materials identify degradation determine risk

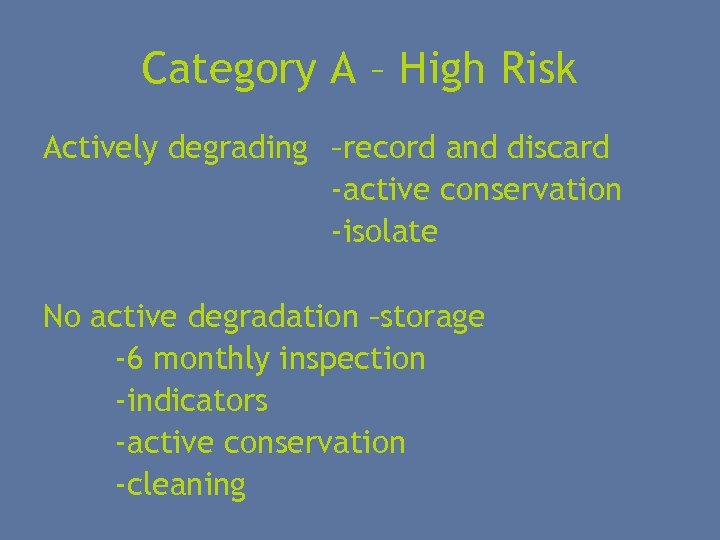

Category A – High Risk Degradation started Likely to affect other materials

Category A – High Risk Degradation started Likely to affect other materials

Category A – High Risk Degradation started Likely to affect other materials Cellulose Nitrate – ‘celluloid disease’ Attacked metals, wrapping

Category A – High Risk Degradation started Likely to affect other materials Cellulose Nitrate – ‘celluloid disease’ Attacked metals, wrapping

Category A – High Risk Actively degrading –record and discard -active conservation -isolate No active degradation –storage -6 monthly inspection -indicators -active conservation -cleaning

Category A – High Risk Actively degrading –record and discard -active conservation -isolate No active degradation –storage -6 monthly inspection -indicators -active conservation -cleaning

Category B – Medium Risk Likely to degrade but products of degradation inoffensive

Category B – Medium Risk Likely to degrade but products of degradation inoffensive

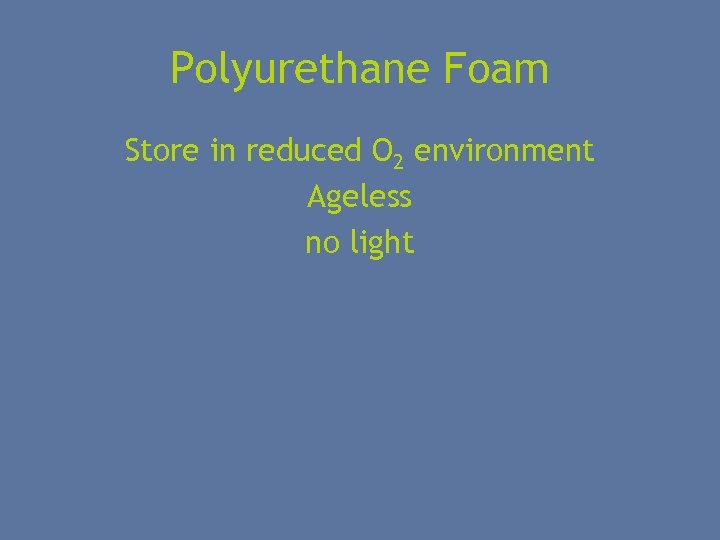

Polyurethane Foam Store in reduced O 2 environment Ageless no light

Polyurethane Foam Store in reduced O 2 environment Ageless no light

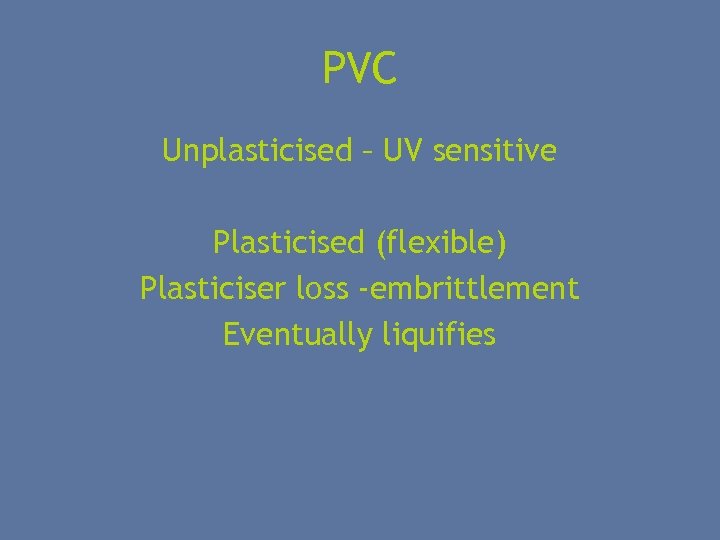

PVC Unplasticised – UV sensitive Plasticised (flexible) Plasticiser loss -embrittlement Eventually liquifies

PVC Unplasticised – UV sensitive Plasticised (flexible) Plasticiser loss -embrittlement Eventually liquifies