ca93251257dcda46ba899beccaae9083.ppt

- Количество слайдов: 37

This material is for training use only Welcome Crushed hands and arms, severed fingers, blindness the list of possible machinery related injuries is as long as it is horrifying. There seem to be as many hazards created by moving machine parts as there are types of machines. Safeguards are essential for protecting workers from needless and preventable injuries. A good rule to remember is: Any machine part, function, or process which may cause injury must be safeguarded. Where the operation of a machine or contact with it can injure the operator or others in the vicinity, the hazards must be either eliminated or controlled. This workbook overviews the various hazards of mechanical motion and actions and presents some techniques for protecting workers from these hazards. General information covered in this workbook includes where mechanical hazards occur, the hazards created by different kinds of motions and the requirements for effective safeguards, as well as a brief discussion of training guidelines. Goals ã Describe the basic hazards involving machinery including point of operation and power transmission devices ã Introduce control measures through effective machine guarding principles and methods Please Note: This material or any other material used to inform employers of compliance requirements of Oregon OSHA standards through simplification of the regulation should not be considered a substitute for any provisions of the Oregon Safe Employment Act or for any standards issued by Oregon OSHA. This workbook contains many photos which, in some cases, represent non compliance with machine guarding rules. If you reproduce these photo for training, make certain the related non compliance issue is properly addressed when referring to the photo. 1 OR OSHA 204 Machine Safeguarding

This material is for training use only Welcome Crushed hands and arms, severed fingers, blindness the list of possible machinery related injuries is as long as it is horrifying. There seem to be as many hazards created by moving machine parts as there are types of machines. Safeguards are essential for protecting workers from needless and preventable injuries. A good rule to remember is: Any machine part, function, or process which may cause injury must be safeguarded. Where the operation of a machine or contact with it can injure the operator or others in the vicinity, the hazards must be either eliminated or controlled. This workbook overviews the various hazards of mechanical motion and actions and presents some techniques for protecting workers from these hazards. General information covered in this workbook includes where mechanical hazards occur, the hazards created by different kinds of motions and the requirements for effective safeguards, as well as a brief discussion of training guidelines. Goals ã Describe the basic hazards involving machinery including point of operation and power transmission devices ã Introduce control measures through effective machine guarding principles and methods Please Note: This material or any other material used to inform employers of compliance requirements of Oregon OSHA standards through simplification of the regulation should not be considered a substitute for any provisions of the Oregon Safe Employment Act or for any standards issued by Oregon OSHA. This workbook contains many photos which, in some cases, represent non compliance with machine guarding rules. If you reproduce these photo for training, make certain the related non compliance issue is properly addressed when referring to the photo. 1 OR OSHA 204 Machine Safeguarding

This material is for training use only Welcome to this Instructor Version of our Workshop #219 Principals of Machine Guarding! The actual workbook is on the odd pages and the instructor notes are on the even pages. Another good rule to remember is: If it moves, it merits your attention! This workbook overviews * the various hazards of mechanical motion, and * presents some techniques for protecting workers from injury. Also, my thoughts on training content - page 30! NOTE: This program does not cover mechanical power presses, portable power tools, nor does it cover specific machinery individually - but rather takes a general approach. Please refer to OR-OSHA Div 2/Sub O for specific machine guarding, OR-OSHA Div 2/Sub P for portable power tool guarding, or simply give me a call. Thanks for taking a look! Craig Hamelund, OR-OSHA Public Education (503) 229 -5910 x 306 craig. hamelund@state. or. us Goals Two primary parts to this program ã hazards ã control measures Reminder - all point of operation injuries from mechanical power presses must be reported to OR-OSHA within 30 days [OR-OSHA Div 2/Sub O 29 CFR 1910. 217(g)]! This requirement is in addition to the OROSHA reporting requirement for all injuries resulting in hospitalization requiring medical treatment [OAR 437 -001 -0700(21)]. Additional References: www. orosha. org (don’t forget program directives!) www. osha. gov (Publications #3067 & #3170) www. cdc. gov/niosh (National Institute of Occupational Safety & Health) www. ccohs. ca (Canadian Centre for Occupational Health & Safety) www. ansi. org (American National Standards Institute) 2 OR OSHA 204 Machine Safeguarding

This material is for training use only Welcome to this Instructor Version of our Workshop #219 Principals of Machine Guarding! The actual workbook is on the odd pages and the instructor notes are on the even pages. Another good rule to remember is: If it moves, it merits your attention! This workbook overviews * the various hazards of mechanical motion, and * presents some techniques for protecting workers from injury. Also, my thoughts on training content - page 30! NOTE: This program does not cover mechanical power presses, portable power tools, nor does it cover specific machinery individually - but rather takes a general approach. Please refer to OR-OSHA Div 2/Sub O for specific machine guarding, OR-OSHA Div 2/Sub P for portable power tool guarding, or simply give me a call. Thanks for taking a look! Craig Hamelund, OR-OSHA Public Education (503) 229 -5910 x 306 craig. hamelund@state. or. us Goals Two primary parts to this program ã hazards ã control measures Reminder - all point of operation injuries from mechanical power presses must be reported to OR-OSHA within 30 days [OR-OSHA Div 2/Sub O 29 CFR 1910. 217(g)]! This requirement is in addition to the OROSHA reporting requirement for all injuries resulting in hospitalization requiring medical treatment [OAR 437 -001 -0700(21)]. Additional References: www. orosha. org (don’t forget program directives!) www. osha. gov (Publications #3067 & #3170) www. cdc. gov/niosh (National Institute of Occupational Safety & Health) www. ccohs. ca (Canadian Centre for Occupational Health & Safety) www. ansi. org (American National Standards Institute) 2 OR OSHA 204 Machine Safeguarding

This material is for training use only Machine Guarding Principles A good rule to remember is: Any machine part, function, or process which may cause injury must be safeguarded. Where the operation of a machine or contact with it can injure the operator or others in the vicinity, the hazards must be either eliminated or controlled. If it moves, it merits your attention! The purpose of machine guarding is to protect against and prevent injury from point of operation, in running nip points, rotating parts, flying chips, and sparks. Although some OR OSHA standards provide certain machine guarding requirements, OR OSHA’s Div 2/Sub O Machine Guarding standard provides general guarding requirements in addition to specific requirements for woodworking machinery, abrasive wheel machinery, mechanical power presses, and power transmission devices. Dangerous moving parts in three basic areas require safeguarding: 1. The point of operation That point where work is performed Cutting Turning Shaping Shearing Boring Punching Forming Bending Grinding Drilling 2. Power transmission apparatus All components of the mechanical system transmit energy to the part of the performing the work Flywheels Cams Chains Gears Couplings Spindles Cranks Shafts which machine Pulleys Belts Sprockets Rods 3. Other moving parts All parts of the machine which move while the machine is working Reciprocating Transverse Rotating Feed mechanisms 3 OR OSHA 204 Machine Safeguarding

This material is for training use only Machine Guarding Principles A good rule to remember is: Any machine part, function, or process which may cause injury must be safeguarded. Where the operation of a machine or contact with it can injure the operator or others in the vicinity, the hazards must be either eliminated or controlled. If it moves, it merits your attention! The purpose of machine guarding is to protect against and prevent injury from point of operation, in running nip points, rotating parts, flying chips, and sparks. Although some OR OSHA standards provide certain machine guarding requirements, OR OSHA’s Div 2/Sub O Machine Guarding standard provides general guarding requirements in addition to specific requirements for woodworking machinery, abrasive wheel machinery, mechanical power presses, and power transmission devices. Dangerous moving parts in three basic areas require safeguarding: 1. The point of operation That point where work is performed Cutting Turning Shaping Shearing Boring Punching Forming Bending Grinding Drilling 2. Power transmission apparatus All components of the mechanical system transmit energy to the part of the performing the work Flywheels Cams Chains Gears Couplings Spindles Cranks Shafts which machine Pulleys Belts Sprockets Rods 3. Other moving parts All parts of the machine which move while the machine is working Reciprocating Transverse Rotating Feed mechanisms 3 OR OSHA 204 Machine Safeguarding

This material is for training use only The purpose of machine guarding is to protect against and prevent injury from. … point of operation inrunning nip points rotating parts flying chips Also: noise, metal working fluids, electrical conductors, thermal exposures. sparks Where Mechanical Hazards Occur 1. The point of operation That point where work is actually performed. Cutting Shaping Grinding Boring Forming Turning Shearing Punching Bending Drilling etc……. . . 2. Power transmission apparatus All components of the mechanical system which transmit energy to the part of the machine performing the work. Flywheels Pulleys Belts Couplings Cams Spindles Chains Cranks Gears Sprockets Shafts Connecting Rods Drives Shaft ends 3. Other moving parts All parts of the machine which move while the machine is working. Reciprocating Rotating Transverse Feed mechanisms Safeguarding OR OSHA 204 Machine 4

This material is for training use only The purpose of machine guarding is to protect against and prevent injury from. … point of operation inrunning nip points rotating parts flying chips Also: noise, metal working fluids, electrical conductors, thermal exposures. sparks Where Mechanical Hazards Occur 1. The point of operation That point where work is actually performed. Cutting Shaping Grinding Boring Forming Turning Shearing Punching Bending Drilling etc……. . . 2. Power transmission apparatus All components of the mechanical system which transmit energy to the part of the machine performing the work. Flywheels Pulleys Belts Couplings Cams Spindles Chains Cranks Gears Sprockets Shafts Connecting Rods Drives Shaft ends 3. Other moving parts All parts of the machine which move while the machine is working. Reciprocating Rotating Transverse Feed mechanisms Safeguarding OR OSHA 204 Machine 4

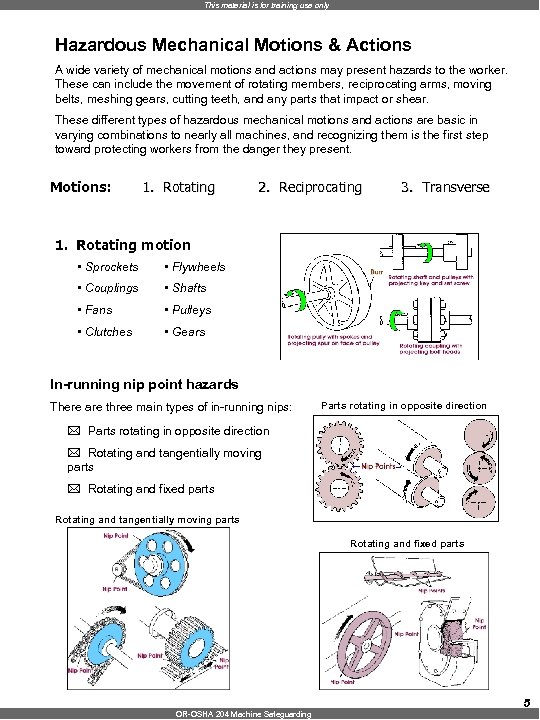

This material is for training use only Hazardous Mechanical Motions & Actions A wide variety of mechanical motions and actions may present hazards to the worker. These can include the movement of rotating members, reciprocating arms, moving belts, meshing gears, cutting teeth, and any parts that impact or shear. These different types of hazardous mechanical motions and actions are basic in varying combinations to nearly all machines, and recognizing them is the first step toward protecting workers from the danger they present. Motions: 1. Rotating 2. Reciprocating 3. Transverse 1. Rotating motion • Sprockets • Flywheels • Couplings • Shafts • Fans • Pulleys • Clutches • Gears In-running nip point hazards There are three main types of in running nips: Parts rotating in opposite direction * Rotating and tangentially moving parts * Rotating and fixed parts Rotating and tangentially moving parts Rotating and fixed parts 5 OR OSHA 204 Machine Safeguarding

This material is for training use only Hazardous Mechanical Motions & Actions A wide variety of mechanical motions and actions may present hazards to the worker. These can include the movement of rotating members, reciprocating arms, moving belts, meshing gears, cutting teeth, and any parts that impact or shear. These different types of hazardous mechanical motions and actions are basic in varying combinations to nearly all machines, and recognizing them is the first step toward protecting workers from the danger they present. Motions: 1. Rotating 2. Reciprocating 3. Transverse 1. Rotating motion • Sprockets • Flywheels • Couplings • Shafts • Fans • Pulleys • Clutches • Gears In-running nip point hazards There are three main types of in running nips: Parts rotating in opposite direction * Rotating and tangentially moving parts * Rotating and fixed parts Rotating and tangentially moving parts Rotating and fixed parts 5 OR OSHA 204 Machine Safeguarding

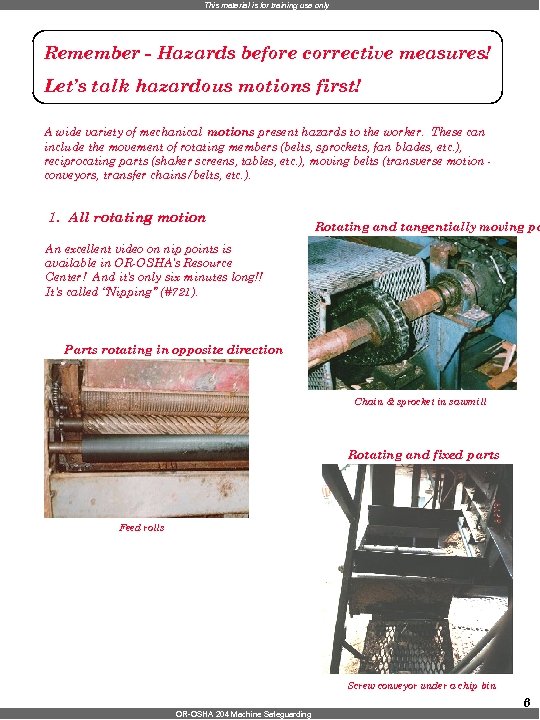

This material is for training use only Remember - Hazards before corrective measures! Let’s talk hazardous motions first! A wide variety of mechanical motions present hazards to the worker. These can include the movement of rotating members (belts, sprockets, fan blades, etc. ), reciprocating parts (shaker screens, tables, etc. ), moving belts (transverse motion conveyors, transfer chains/belts, etc. ). 1. All rotating motion Rotating and tangentially moving pa An excellent video on nip points is available in OR-OSHA’s Resource Center! And it’s only six minutes long!! It’s called “Nipping” (#721). Parts rotating in opposite direction Chain & sprocket in sawmill Rotating and fixed parts Feed rolls Screw conveyor under a chip bin 6 OR OSHA 204 Machine Safeguarding

This material is for training use only Remember - Hazards before corrective measures! Let’s talk hazardous motions first! A wide variety of mechanical motions present hazards to the worker. These can include the movement of rotating members (belts, sprockets, fan blades, etc. ), reciprocating parts (shaker screens, tables, etc. ), moving belts (transverse motion conveyors, transfer chains/belts, etc. ). 1. All rotating motion Rotating and tangentially moving pa An excellent video on nip points is available in OR-OSHA’s Resource Center! And it’s only six minutes long!! It’s called “Nipping” (#721). Parts rotating in opposite direction Chain & sprocket in sawmill Rotating and fixed parts Feed rolls Screw conveyor under a chip bin 6 OR OSHA 204 Machine Safeguarding

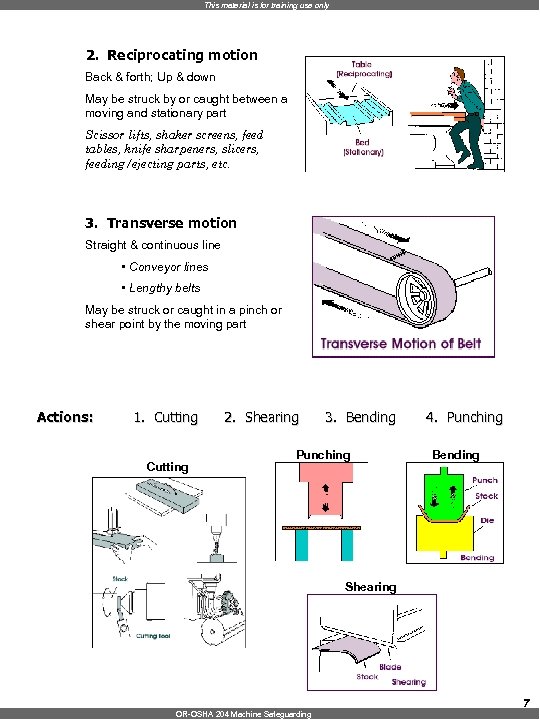

This material is for training use only 2. Reciprocating motion Back & forth; Up & down May be struck by or caught between a moving and stationary part Scissor lifts, shaker screens, feed tables, knife sharpeners, slicers, feeding/ejecting parts, etc. 3. Transverse motion Straight & continuous line • Conveyor lines • Lengthy belts May be struck or caught in a pinch or shear point by the moving part Actions: 1. Cutting 2. Shearing 3. Bending Punching 4. Punching Bending Shearing 7 OR OSHA 204 Machine Safeguarding

This material is for training use only 2. Reciprocating motion Back & forth; Up & down May be struck by or caught between a moving and stationary part Scissor lifts, shaker screens, feed tables, knife sharpeners, slicers, feeding/ejecting parts, etc. 3. Transverse motion Straight & continuous line • Conveyor lines • Lengthy belts May be struck or caught in a pinch or shear point by the moving part Actions: 1. Cutting 2. Shearing 3. Bending Punching 4. Punching Bending Shearing 7 OR OSHA 204 Machine Safeguarding

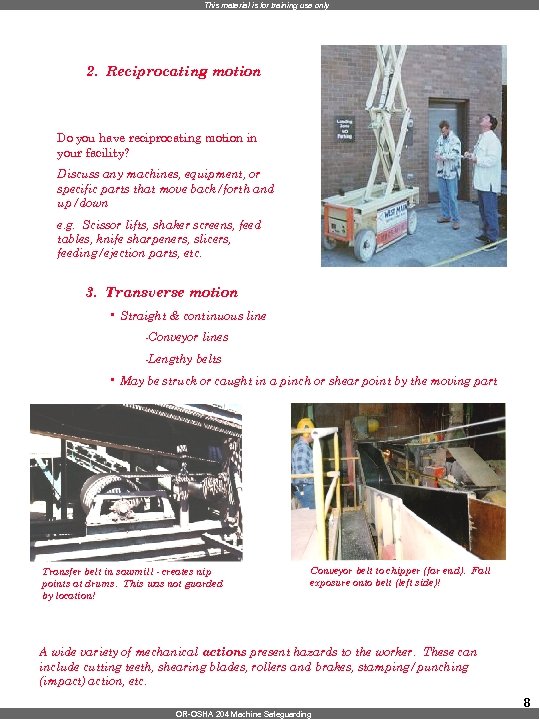

This material is for training use only 2. Reciprocating motion Do you have reciprocating motion in your facility? Discuss any machines, equipment, or specific parts that move back/forth and up/down e. g. Scissor lifts, shaker screens, feed tables, knife sharpeners, slicers, feeding/ejection parts, etc. 3. Transverse motion • Straight & continuous line Conveyor lines Lengthy belts • May be struck or caught in a pinch or shear point by the moving part Transfer belt in sawmill - creates nip points at drums. This was not guarded by location! Conveyor belt to chipper (far end). Fall exposure onto belt (left side)! A wide variety of mechanical actions present hazards to the worker. These can include cutting teeth, shearing blades, rollers and brakes, stamping/punching (impact) action, etc. 8 OR OSHA 204 Machine Safeguarding

This material is for training use only 2. Reciprocating motion Do you have reciprocating motion in your facility? Discuss any machines, equipment, or specific parts that move back/forth and up/down e. g. Scissor lifts, shaker screens, feed tables, knife sharpeners, slicers, feeding/ejection parts, etc. 3. Transverse motion • Straight & continuous line Conveyor lines Lengthy belts • May be struck or caught in a pinch or shear point by the moving part Transfer belt in sawmill - creates nip points at drums. This was not guarded by location! Conveyor belt to chipper (far end). Fall exposure onto belt (left side)! A wide variety of mechanical actions present hazards to the worker. These can include cutting teeth, shearing blades, rollers and brakes, stamping/punching (impact) action, etc. 8 OR OSHA 204 Machine Safeguarding

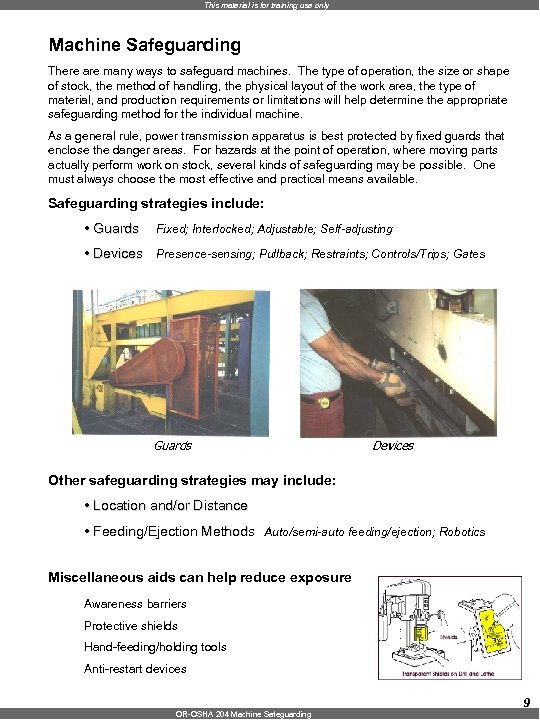

This material is for training use only Machine Safeguarding There are many ways to safeguard machines. The type of operation, the size or shape of stock, the method of handling, the physical layout of the work area, the type of material, and production requirements or limitations will help determine the appropriate safeguarding method for the individual machine. As a general rule, power transmission apparatus is best protected by fixed guards that enclose the danger areas. For hazards at the point of operation, where moving parts actually perform work on stock, several kinds of safeguarding may be possible. One must always choose the most effective and practical means available. Safeguarding strategies include: • Guards Fixed; Interlocked; Adjustable; Self-adjusting • Devices Presence-sensing; Pullback; Restraints; Controls/Trips; Gates Guards Devices Other safeguarding strategies may include: • Location and/or Distance • Feeding/Ejection Methods Auto/semi-auto feeding/ejection; Robotics Miscellaneous aids can help reduce exposure Awareness barriers Protective shields Hand feeding/holding tools Anti restart devices 9 OR OSHA 204 Machine Safeguarding

This material is for training use only Machine Safeguarding There are many ways to safeguard machines. The type of operation, the size or shape of stock, the method of handling, the physical layout of the work area, the type of material, and production requirements or limitations will help determine the appropriate safeguarding method for the individual machine. As a general rule, power transmission apparatus is best protected by fixed guards that enclose the danger areas. For hazards at the point of operation, where moving parts actually perform work on stock, several kinds of safeguarding may be possible. One must always choose the most effective and practical means available. Safeguarding strategies include: • Guards Fixed; Interlocked; Adjustable; Self-adjusting • Devices Presence-sensing; Pullback; Restraints; Controls/Trips; Gates Guards Devices Other safeguarding strategies may include: • Location and/or Distance • Feeding/Ejection Methods Auto/semi-auto feeding/ejection; Robotics Miscellaneous aids can help reduce exposure Awareness barriers Protective shields Hand feeding/holding tools Anti restart devices 9 OR OSHA 204 Machine Safeguarding

This material is for training use only Remember - Hazards before corrective measures! We discussed hazards - Now let’s talk corrective measures! There are many ways to safeguard machines. As a general rule, power transmission apparatus is best protected by fixed guards that enclose the danger areas. For hazards at the point of operation, where moving parts actually perform work on stock, several kinds of safeguarding may be possible. 1. Guards are always preferred and when practical…. use them! Guards PREVENT access to point of operation hazards! 2. Devices are sometimes a more practical option when safeguarding point of operation Devices CONTROL access to point of operation hazards! Other safeguarding strategies include: Safeguarding by location and/or distance - don’t forget workers may be struck by broken pieces/parts if nothing is there to capture/deflect! Feeding/Ejection Methods - designing exposure out! Don’t forget about broken parts/material becoming projectiles as well as the possibility of employees accessing the area during operation! Don’t forget safeguarding strategies also include management controls such as enforcing, training, inspecting, maintenance and repair! For example, clean and roomy work areas, lubricated self-adjusting guards, ring testing 10 abrasive stones, ensuring stable. Machine Safeguarding fixed guarding, smooth edges, etc. OR OSHA 204

This material is for training use only Remember - Hazards before corrective measures! We discussed hazards - Now let’s talk corrective measures! There are many ways to safeguard machines. As a general rule, power transmission apparatus is best protected by fixed guards that enclose the danger areas. For hazards at the point of operation, where moving parts actually perform work on stock, several kinds of safeguarding may be possible. 1. Guards are always preferred and when practical…. use them! Guards PREVENT access to point of operation hazards! 2. Devices are sometimes a more practical option when safeguarding point of operation Devices CONTROL access to point of operation hazards! Other safeguarding strategies include: Safeguarding by location and/or distance - don’t forget workers may be struck by broken pieces/parts if nothing is there to capture/deflect! Feeding/Ejection Methods - designing exposure out! Don’t forget about broken parts/material becoming projectiles as well as the possibility of employees accessing the area during operation! Don’t forget safeguarding strategies also include management controls such as enforcing, training, inspecting, maintenance and repair! For example, clean and roomy work areas, lubricated self-adjusting guards, ring testing 10 abrasive stones, ensuring stable. Machine Safeguarding fixed guarding, smooth edges, etc. OR OSHA 204

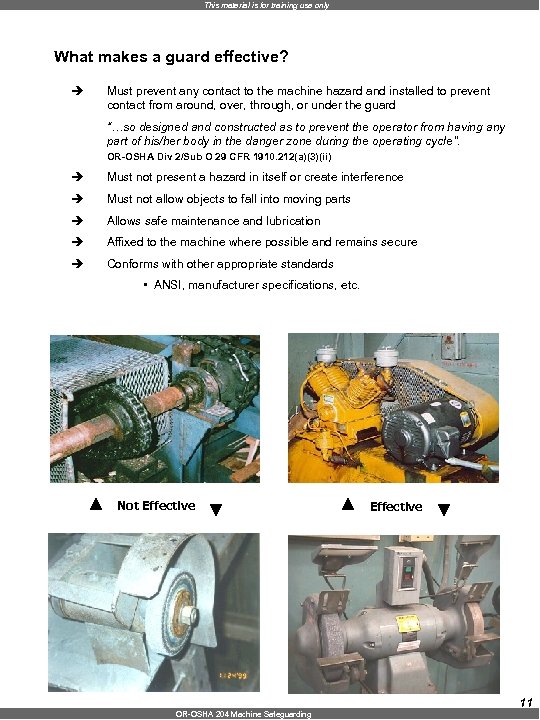

This material is for training use only What makes a guard effective? è Must prevent any contact to the machine hazard and installed to prevent contact from around, over, through, or under the guard “…so designed and constructed as to prevent the operator from having any part of his/her body in the danger zone during the operating cycle”. OR-OSHA Div 2/Sub O 29 CFR 1910. 212(a)(3)(ii) è Must not present a hazard in itself or create interference è Must not allow objects to fall into moving parts è Allows safe maintenance and lubrication è Affixed to the machine where possible and remains secure è Conforms with other appropriate standards • ANSI, manufacturer specifications, etc. Not Effective 11 OR OSHA 204 Machine Safeguarding

This material is for training use only What makes a guard effective? è Must prevent any contact to the machine hazard and installed to prevent contact from around, over, through, or under the guard “…so designed and constructed as to prevent the operator from having any part of his/her body in the danger zone during the operating cycle”. OR-OSHA Div 2/Sub O 29 CFR 1910. 212(a)(3)(ii) è Must not present a hazard in itself or create interference è Must not allow objects to fall into moving parts è Allows safe maintenance and lubrication è Affixed to the machine where possible and remains secure è Conforms with other appropriate standards • ANSI, manufacturer specifications, etc. Not Effective 11 OR OSHA 204 Machine Safeguarding

This material is for training use only What makes a guard effective? è Those six bullets are pretty much the law of the land! Remember - no guard, device, or method is fail-safe, fool-proof, or 100% effective! Anything can fail, be bypassed, or improperly maintained. Effective? No - exposed nip point Effective? Yes - common to find this “backside” area left unguarded from the manufacturer. This “backfill” guard is installed by the end user. Once the compressor is installed, the manufactured guard is against the wall, leaving the “backside” exposed. OR OSHA 204 Machine Safeguarding 12

This material is for training use only What makes a guard effective? è Those six bullets are pretty much the law of the land! Remember - no guard, device, or method is fail-safe, fool-proof, or 100% effective! Anything can fail, be bypassed, or improperly maintained. Effective? No - exposed nip point Effective? Yes - common to find this “backside” area left unguarded from the manufacturer. This “backfill” guard is installed by the end user. Once the compressor is installed, the manufactured guard is against the wall, leaving the “backside” exposed. OR OSHA 204 Machine Safeguarding 12

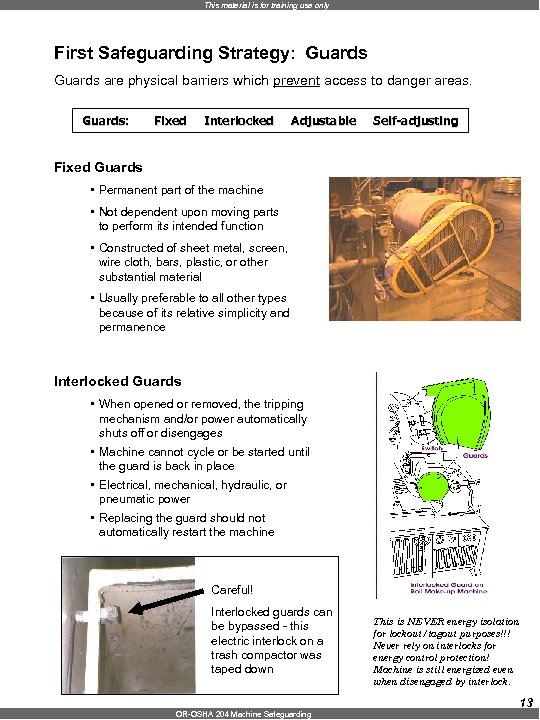

This material is for training use only First Safeguarding Strategy: Guards are physical barriers which prevent access to danger areas. Guards: Fixed Interlocked Adjustable Self-adjusting Fixed Guards • Permanent part of the machine • Not dependent upon moving parts to perform its intended function • Constructed of sheet metal, screen, wire cloth, bars, plastic, or other substantial material • Usually preferable to all other types because of its relative simplicity and permanence Interlocked Guards • When opened or removed, the tripping mechanism and/or power automatically shuts off or disengages • Machine cannot cycle or be started until the guard is back in place • Electrical, mechanical, hydraulic, or pneumatic power • Replacing the guard should not automatically restart the machine Careful! Interlocked guards can be bypassed this electric interlock on a trash compactor was taped down This is NEVER energy isolation for lockout/tagout purposes!!! Never rely on interlocks for energy control protection! Machine is still energized even when disengaged by interlock. 13 OR OSHA 204 Machine Safeguarding

This material is for training use only First Safeguarding Strategy: Guards are physical barriers which prevent access to danger areas. Guards: Fixed Interlocked Adjustable Self-adjusting Fixed Guards • Permanent part of the machine • Not dependent upon moving parts to perform its intended function • Constructed of sheet metal, screen, wire cloth, bars, plastic, or other substantial material • Usually preferable to all other types because of its relative simplicity and permanence Interlocked Guards • When opened or removed, the tripping mechanism and/or power automatically shuts off or disengages • Machine cannot cycle or be started until the guard is back in place • Electrical, mechanical, hydraulic, or pneumatic power • Replacing the guard should not automatically restart the machine Careful! Interlocked guards can be bypassed this electric interlock on a trash compactor was taped down This is NEVER energy isolation for lockout/tagout purposes!!! Never rely on interlocks for energy control protection! Machine is still energized even when disengaged by interlock. 13 OR OSHA 204 Machine Safeguarding

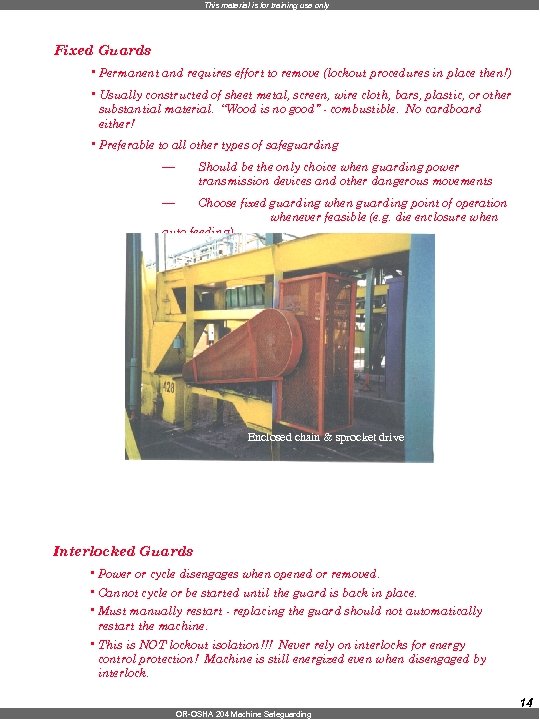

This material is for training use only Fixed Guards • Permanent and requires effort to remove (lockout procedures in place then!) • Usually constructed of sheet metal, screen, wire cloth, bars, plastic, or other substantial material. “Wood is no good” - combustible. No cardboard either! • Preferable to all other types of safeguarding — Should be the only choice when guarding power transmission devices and other dangerous movements — Choose fixed guarding when guarding point of operation whenever feasible (e. g. die enclosure when auto feeding) Enclosed chain & sprocket drive Interlocked Guards • Power or cycle disengages when opened or removed. • Cannot cycle or be started until the guard is back in place. • Must manually restart - replacing the guard should not automatically restart the machine. • This is NOT lockout isolation!!! Never rely on interlocks for energy control protection! Machine is still energized even when disengaged by interlock. 14 OR OSHA 204 Machine Safeguarding

This material is for training use only Fixed Guards • Permanent and requires effort to remove (lockout procedures in place then!) • Usually constructed of sheet metal, screen, wire cloth, bars, plastic, or other substantial material. “Wood is no good” - combustible. No cardboard either! • Preferable to all other types of safeguarding — Should be the only choice when guarding power transmission devices and other dangerous movements — Choose fixed guarding when guarding point of operation whenever feasible (e. g. die enclosure when auto feeding) Enclosed chain & sprocket drive Interlocked Guards • Power or cycle disengages when opened or removed. • Cannot cycle or be started until the guard is back in place. • Must manually restart - replacing the guard should not automatically restart the machine. • This is NOT lockout isolation!!! Never rely on interlocks for energy control protection! Machine is still energized even when disengaged by interlock. 14 OR OSHA 204 Machine Safeguarding

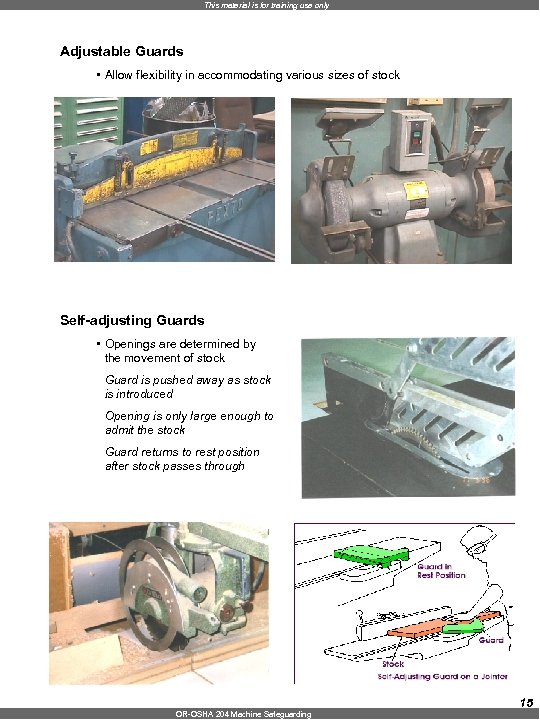

This material is for training use only Adjustable Guards • Allow flexibility in accommodating various sizes of stock Self-adjusting Guards • Openings are determined by the movement of stock Guard is pushed away as stock is introduced Opening is only large enough to admit the stock Guard returns to rest position after stock passes through 15 OR OSHA 204 Machine Safeguarding

This material is for training use only Adjustable Guards • Allow flexibility in accommodating various sizes of stock Self-adjusting Guards • Openings are determined by the movement of stock Guard is pushed away as stock is introduced Opening is only large enough to admit the stock Guard returns to rest position after stock passes through 15 OR OSHA 204 Machine Safeguarding

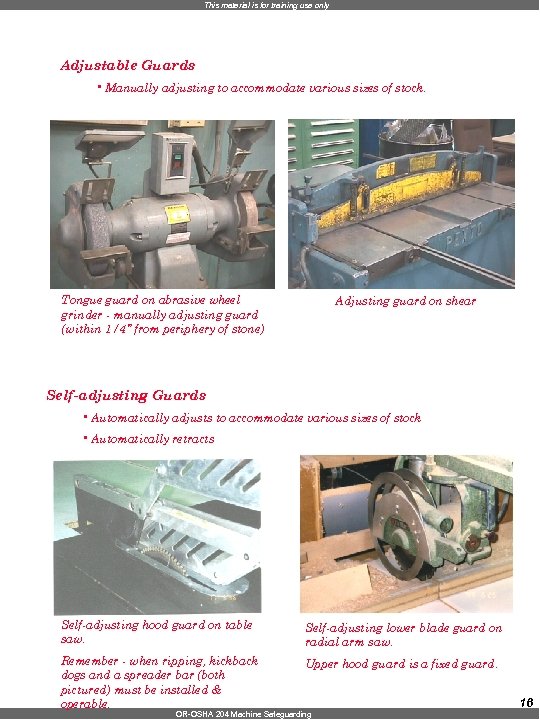

This material is for training use only Adjustable Guards • Manually adjusting to accommodate various sizes of stock. Tongue guard on abrasive wheel grinder - manually adjusting guard (within 1/4” from periphery of stone) Adjusting guard on shear Self-adjusting Guards • Automatically adjusts to accommodate various sizes of stock • Automatically retracts Self-adjusting hood guard on table saw. Self-adjusting lower blade guard on radial arm saw. Remember - when ripping, kickback dogs and a spreader bar (both pictured) must be installed & operable. Upper hood guard is a fixed guard. OR OSHA 204 Machine Safeguarding 16

This material is for training use only Adjustable Guards • Manually adjusting to accommodate various sizes of stock. Tongue guard on abrasive wheel grinder - manually adjusting guard (within 1/4” from periphery of stone) Adjusting guard on shear Self-adjusting Guards • Automatically adjusts to accommodate various sizes of stock • Automatically retracts Self-adjusting hood guard on table saw. Self-adjusting lower blade guard on radial arm saw. Remember - when ripping, kickback dogs and a spreader bar (both pictured) must be installed & operable. Upper hood guard is a fixed guard. OR OSHA 204 Machine Safeguarding 16

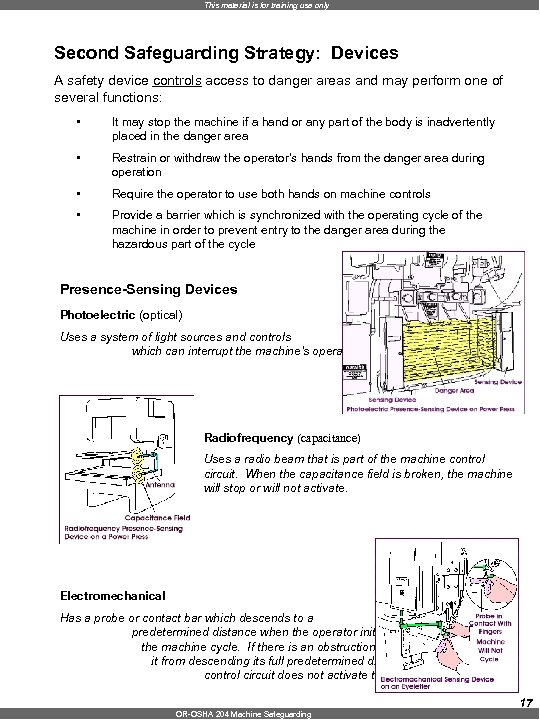

This material is for training use only Second Safeguarding Strategy: Devices A safety device controls access to danger areas and may perform one of several functions: • It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area • Restrain or withdraw the operator's hands from the danger area during operation • Require the operator to use both hands on machine controls • Provide a barrier which is synchronized with the operating cycle of the machine in order to prevent entry to the danger area during the hazardous part of the cycle Presence-Sensing Devices Photoelectric (optical) Uses a system of light sources and controls which can interrupt the machine's operating cycle. Radiofrequency (capacitance) Uses a radio beam that is part of the machine control circuit. When the capacitance field is broken, the machine will stop or will not activate. Electromechanical Has a probe or contact bar which descends to a predetermined distance when the operator initiates the machine cycle. If there is an obstruction preventing it from descending its full predetermined distance, the control circuit does not activate the machine cycle. 17 OR OSHA 204 Machine Safeguarding

This material is for training use only Second Safeguarding Strategy: Devices A safety device controls access to danger areas and may perform one of several functions: • It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area • Restrain or withdraw the operator's hands from the danger area during operation • Require the operator to use both hands on machine controls • Provide a barrier which is synchronized with the operating cycle of the machine in order to prevent entry to the danger area during the hazardous part of the cycle Presence-Sensing Devices Photoelectric (optical) Uses a system of light sources and controls which can interrupt the machine's operating cycle. Radiofrequency (capacitance) Uses a radio beam that is part of the machine control circuit. When the capacitance field is broken, the machine will stop or will not activate. Electromechanical Has a probe or contact bar which descends to a predetermined distance when the operator initiates the machine cycle. If there is an obstruction preventing it from descending its full predetermined distance, the control circuit does not activate the machine cycle. 17 OR OSHA 204 Machine Safeguarding

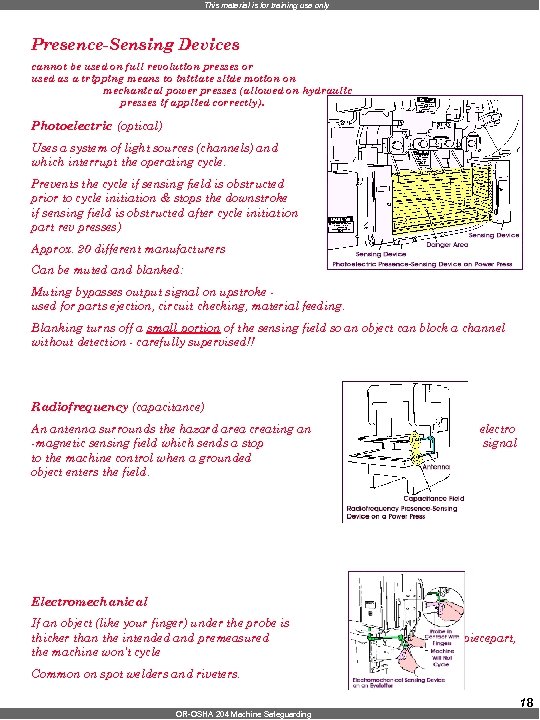

This material is for training use only Presence-Sensing Devices cannot be used on full revolution presses or used as a tripping means to initiate slide motion on mechanical power presses (allowed on hydraulic presses if applied correctly). Photoelectric (optical) Uses a system of light sources (channels) and which interrupt the operating cycle. Prevents the cycle if sensing field is obstructed prior to cycle initiation & stops the downstroke if sensing field is obstructed after cycle initiation part rev presses) controls (i. e. Approx. 20 different manufacturers Can be muted and blanked: Muting bypasses output signal on upstroke used for parts ejection, circuit checking, material feeding. Blanking turns off a small portion of the sensing field so an object can block a channel without detection - carefully supervised!! Radiofrequency (capacitance) An antenna surrounds the hazard area creating an -magnetic sensing field which sends a stop to the machine control when a grounded object enters the field. electro signal Electromechanical If an object (like your finger) under the probe is thicker than the intended and premeasured the machine won’t cycle piecepart, Common on spot welders and riveters. 18 OR OSHA 204 Machine Safeguarding

This material is for training use only Presence-Sensing Devices cannot be used on full revolution presses or used as a tripping means to initiate slide motion on mechanical power presses (allowed on hydraulic presses if applied correctly). Photoelectric (optical) Uses a system of light sources (channels) and which interrupt the operating cycle. Prevents the cycle if sensing field is obstructed prior to cycle initiation & stops the downstroke if sensing field is obstructed after cycle initiation part rev presses) controls (i. e. Approx. 20 different manufacturers Can be muted and blanked: Muting bypasses output signal on upstroke used for parts ejection, circuit checking, material feeding. Blanking turns off a small portion of the sensing field so an object can block a channel without detection - carefully supervised!! Radiofrequency (capacitance) An antenna surrounds the hazard area creating an -magnetic sensing field which sends a stop to the machine control when a grounded object enters the field. electro signal Electromechanical If an object (like your finger) under the probe is thicker than the intended and premeasured the machine won’t cycle piecepart, Common on spot welders and riveters. 18 OR OSHA 204 Machine Safeguarding

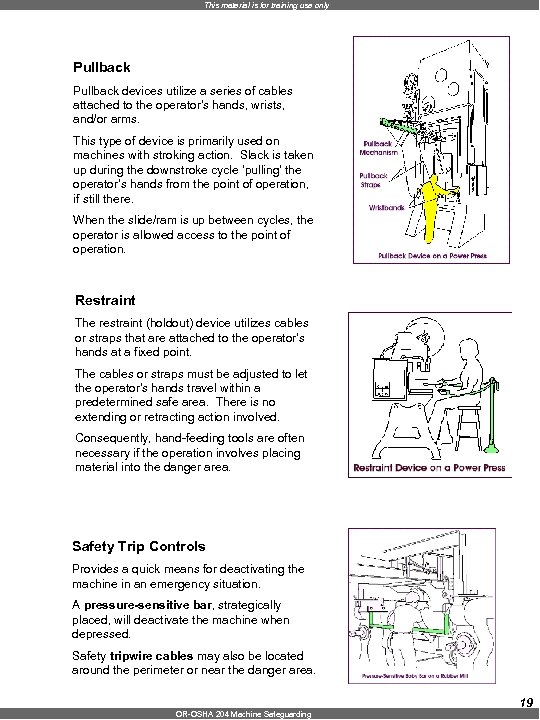

This material is for training use only Pullback devices utilize a series of cables attached to the operator's hands, wrists, and/or arms. This type of device is primarily used on machines with stroking action. Slack is taken up during the downstroke cycle ‘pulling’ the operator’s hands from the point of operation, if still there. When the slide/ram is up between cycles, the operator is allowed access to the point of operation. Restraint The restraint (holdout) device utilizes cables or straps that are attached to the operator's hands at a fixed point. The cables or straps must be adjusted to let the operator's hands travel within a predetermined safe area. There is no extending or retracting action involved. Consequently, hand feeding tools are often necessary if the operation involves placing material into the danger area. Safety Trip Controls Provides a quick means for deactivating the machine in an emergency situation. A pressure-sensitive bar, strategically placed, will deactivate the machine when depressed. Safety tripwire cables may also be located around the perimeter or near the danger area. 19 OR OSHA 204 Machine Safeguarding

This material is for training use only Pullback devices utilize a series of cables attached to the operator's hands, wrists, and/or arms. This type of device is primarily used on machines with stroking action. Slack is taken up during the downstroke cycle ‘pulling’ the operator’s hands from the point of operation, if still there. When the slide/ram is up between cycles, the operator is allowed access to the point of operation. Restraint The restraint (holdout) device utilizes cables or straps that are attached to the operator's hands at a fixed point. The cables or straps must be adjusted to let the operator's hands travel within a predetermined safe area. There is no extending or retracting action involved. Consequently, hand feeding tools are often necessary if the operation involves placing material into the danger area. Safety Trip Controls Provides a quick means for deactivating the machine in an emergency situation. A pressure-sensitive bar, strategically placed, will deactivate the machine when depressed. Safety tripwire cables may also be located around the perimeter or near the danger area. 19 OR OSHA 204 Machine Safeguarding

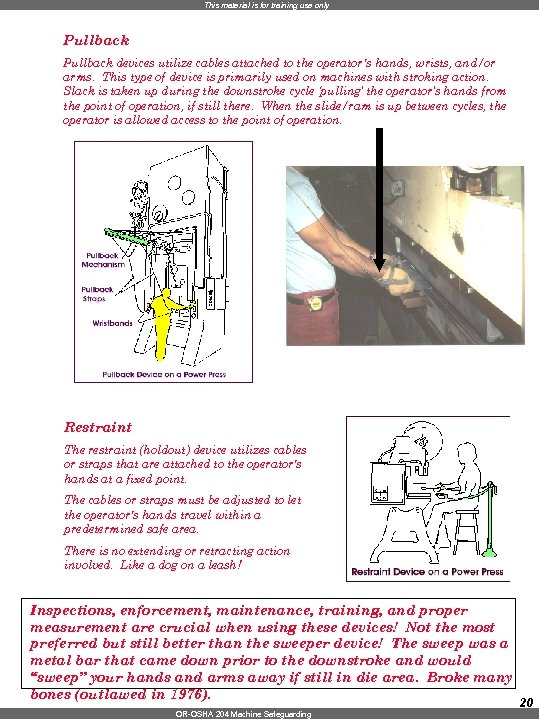

This material is for training use only Pullback devices utilize cables attached to the operator's hands, wrists, and/or arms. This type of device is primarily used on machines with stroking action. Slack is taken up during the downstroke cycle ‘pulling’ the operator’s hands from the point of operation, if still there. When the slide/ram is up between cycles, the operator is allowed access to the point of operation. Restraint The restraint (holdout) device utilizes cables or straps that are attached to the operator's hands at a fixed point. The cables or straps must be adjusted to let the operator's hands travel within a predetermined safe area. There is no extending or retracting action involved. Like a dog on a leash! Inspections, enforcement, maintenance, training, and proper measurement are crucial when using these devices! Not the most preferred but still better than the sweeper device! The sweep was a metal bar that came down prior to the downstroke and would “sweep” your hands and arms away if still in die area. Broke many bones (outlawed in 1976). OR OSHA 204 Machine Safeguarding 20

This material is for training use only Pullback devices utilize cables attached to the operator's hands, wrists, and/or arms. This type of device is primarily used on machines with stroking action. Slack is taken up during the downstroke cycle ‘pulling’ the operator’s hands from the point of operation, if still there. When the slide/ram is up between cycles, the operator is allowed access to the point of operation. Restraint The restraint (holdout) device utilizes cables or straps that are attached to the operator's hands at a fixed point. The cables or straps must be adjusted to let the operator's hands travel within a predetermined safe area. There is no extending or retracting action involved. Like a dog on a leash! Inspections, enforcement, maintenance, training, and proper measurement are crucial when using these devices! Not the most preferred but still better than the sweeper device! The sweep was a metal bar that came down prior to the downstroke and would “sweep” your hands and arms away if still in die area. Broke many bones (outlawed in 1976). OR OSHA 204 Machine Safeguarding 20

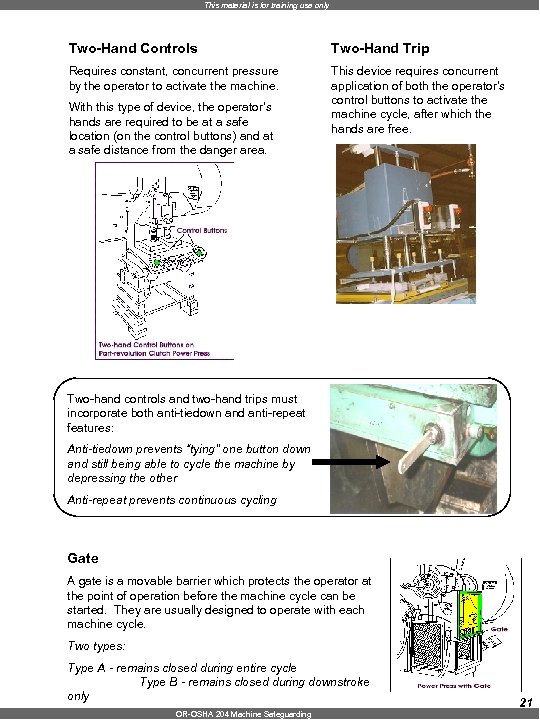

This material is for training use only Two-Hand Controls Two-Hand Trip Requires constant, concurrent pressure by the operator to activate the machine. This device requires concurrent application of both the operator’s control buttons to activate the machine cycle, after which the hands are free. With this type of device, the operator’s hands are required to be at a safe location (on the control buttons) and at a safe distance from the danger area. Two hand controls and two hand trips must incorporate both anti tiedown and anti repeat features: Anti-tiedown prevents “tying” one button down and still being able to cycle the machine by depressing the other Anti-repeat prevents continuous cycling Gate A gate is a movable barrier which protects the operator at the point of operation before the machine cycle can be started. They are usually designed to operate with each machine cycle. Two types: Type A - remains closed during entire cycle Type B - remains closed during downstroke only OR OSHA 204 Machine Safeguarding 21

This material is for training use only Two-Hand Controls Two-Hand Trip Requires constant, concurrent pressure by the operator to activate the machine. This device requires concurrent application of both the operator’s control buttons to activate the machine cycle, after which the hands are free. With this type of device, the operator’s hands are required to be at a safe location (on the control buttons) and at a safe distance from the danger area. Two hand controls and two hand trips must incorporate both anti tiedown and anti repeat features: Anti-tiedown prevents “tying” one button down and still being able to cycle the machine by depressing the other Anti-repeat prevents continuous cycling Gate A gate is a movable barrier which protects the operator at the point of operation before the machine cycle can be started. They are usually designed to operate with each machine cycle. Two types: Type A - remains closed during entire cycle Type B - remains closed during downstroke only OR OSHA 204 Machine Safeguarding 21

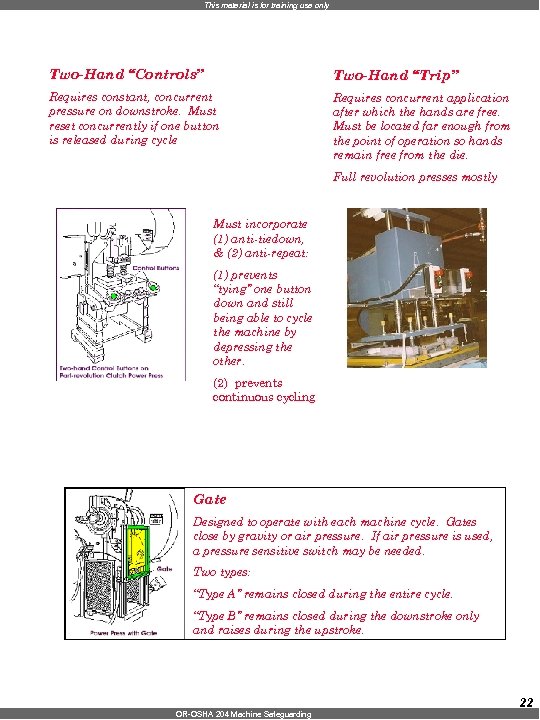

This material is for training use only Two-Hand “Controls” Two-Hand “Trip” Requires constant, concurrent pressure on downstroke. Must reset concurrently if one button is released during cycle Requires concurrent application after which the hands are free. Must be located far enough from the point of operation so hands remain free from the die. Full revolution presses mostly Must incorporate (1) anti-tiedown, & (2) anti-repeat: (1) prevents “tying” one button down and still being able to cycle the machine by depressing the other. (2) prevents continuous cycling Gate Designed to operate with each machine cycle. Gates close by gravity or air pressure. If air pressure is used, a pressure sensitive switch may be needed. Two types: “Type A” remains closed during the entire cycle. “Type B” remains closed during the downstroke only and raises during the upstroke. 22 OR OSHA 204 Machine Safeguarding

This material is for training use only Two-Hand “Controls” Two-Hand “Trip” Requires constant, concurrent pressure on downstroke. Must reset concurrently if one button is released during cycle Requires concurrent application after which the hands are free. Must be located far enough from the point of operation so hands remain free from the die. Full revolution presses mostly Must incorporate (1) anti-tiedown, & (2) anti-repeat: (1) prevents “tying” one button down and still being able to cycle the machine by depressing the other. (2) prevents continuous cycling Gate Designed to operate with each machine cycle. Gates close by gravity or air pressure. If air pressure is used, a pressure sensitive switch may be needed. Two types: “Type A” remains closed during the entire cycle. “Type B” remains closed during the downstroke only and raises during the upstroke. 22 OR OSHA 204 Machine Safeguarding

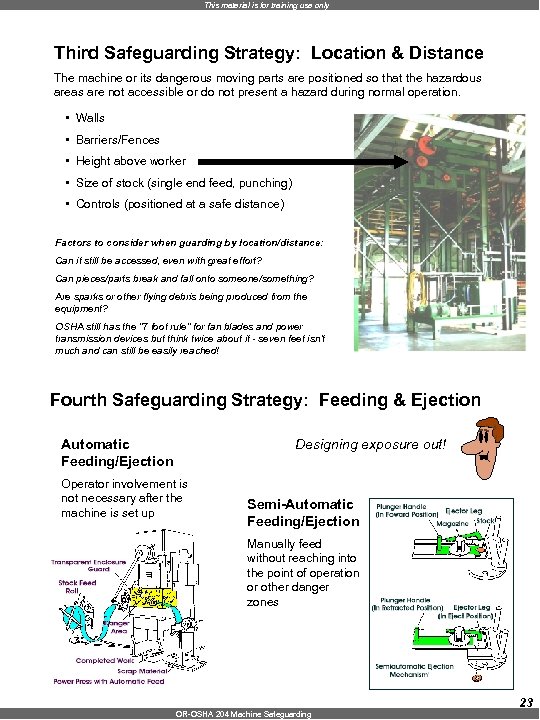

This material is for training use only Third Safeguarding Strategy: Location & Distance The machine or its dangerous moving parts are positioned so that the hazardous areas are not accessible or do not present a hazard during normal operation. • Walls • Barriers/Fences • Height above worker • Size of stock (single end feed, punching) • Controls (positioned at a safe distance) Factors to consider when guarding by location/distance: Can it still be accessed, even with great effort? Can pieces/parts break and fall onto someone/something? Are sparks or other flying debris being produced from the equipment? OSHA still has the “ 7 foot rule” for fan blades and power transmission devices but think twice about it - seven feet isn’t much and can still be easily reached! Fourth Safeguarding Strategy: Feeding & Ejection Automatic Feeding/Ejection Designing exposure out! Operator involvement is not necessary after the machine is set up Semi-Automatic Feeding/Ejection Manually feed without reaching into the point of operation or other danger zones 23 OR OSHA 204 Machine Safeguarding

This material is for training use only Third Safeguarding Strategy: Location & Distance The machine or its dangerous moving parts are positioned so that the hazardous areas are not accessible or do not present a hazard during normal operation. • Walls • Barriers/Fences • Height above worker • Size of stock (single end feed, punching) • Controls (positioned at a safe distance) Factors to consider when guarding by location/distance: Can it still be accessed, even with great effort? Can pieces/parts break and fall onto someone/something? Are sparks or other flying debris being produced from the equipment? OSHA still has the “ 7 foot rule” for fan blades and power transmission devices but think twice about it - seven feet isn’t much and can still be easily reached! Fourth Safeguarding Strategy: Feeding & Ejection Automatic Feeding/Ejection Designing exposure out! Operator involvement is not necessary after the machine is set up Semi-Automatic Feeding/Ejection Manually feed without reaching into the point of operation or other danger zones 23 OR OSHA 204 Machine Safeguarding

This material is for training use only Big time judgment call! If there is opportunity for exposure (can still reach into, around, climb to, being struck by, etc. ) - do not consider it guarded by location or distance! An effective lockout program must be utilized during any service or repair! What are some concerns when considering guarding by location and/or distance? Can it still be accessed, even with great effort? Can pieces/parts break and fall onto someone/something? Are sparks or other flying debris being produced from the equipment? OSHA still has the “ 7 foot rule” for fan blades and power transmission devices but think twice about it - seven feet isn’t much and can still be easily reached! Can break and fall onto an employee! Feeding/Ejection Still accessible! OR OSHA 204 Machine Safeguarding Whether it’s fully automated or partially automated, consider exposures from projectiles, sparks, noise, solvents, etc. Also, can employees still access the point of operation area (e. g. offbearing), feeding system (transverse motion), and ejection points (projectiles, magazines, 24 noise).

This material is for training use only Big time judgment call! If there is opportunity for exposure (can still reach into, around, climb to, being struck by, etc. ) - do not consider it guarded by location or distance! An effective lockout program must be utilized during any service or repair! What are some concerns when considering guarding by location and/or distance? Can it still be accessed, even with great effort? Can pieces/parts break and fall onto someone/something? Are sparks or other flying debris being produced from the equipment? OSHA still has the “ 7 foot rule” for fan blades and power transmission devices but think twice about it - seven feet isn’t much and can still be easily reached! Can break and fall onto an employee! Feeding/Ejection Still accessible! OR OSHA 204 Machine Safeguarding Whether it’s fully automated or partially automated, consider exposures from projectiles, sparks, noise, solvents, etc. Also, can employees still access the point of operation area (e. g. offbearing), feeding system (transverse motion), and ejection points (projectiles, magazines, 24 noise).

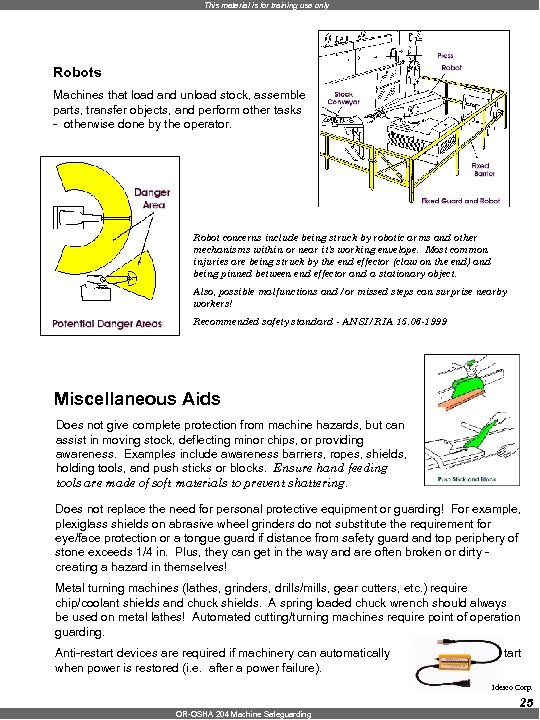

This material is for training use only Robots Machines that load and unload stock, assemble parts, transfer objects, and perform other tasks otherwise done by the operator. Robot concerns include being struck by robotic arms and other mechanisms within or near it’s working envelope. Most common injuries are being struck by the end effector (claw on the end) and being pinned between end effector and a stationary object. Also, possible malfunctions and/or missed steps can surprise nearby workers! Recommended safety standard - ANSI/RIA 15. 06 -1999 Miscellaneous Aids Does not give complete protection from machine hazards, but can assist in moving stock, deflecting minor chips, or providing awareness. Examples include awareness barriers, ropes, shields, holding tools, and push sticks or blocks. Ensure hand feeding tools are made of soft materials to prevent shattering. Does not replace the need for personal protective equipment or guarding! For example, plexiglass shields on abrasive wheel grinders do not substitute the requirement for eye/face protection or a tongue guard if distance from safety guard and top periphery of stone exceeds 1/4 in. Plus, they can get in the way and are often broken or dirty creating a hazard in themselves! Metal turning machines (lathes, grinders, drills/mills, gear cutters, etc. ) require chip/coolant shields and chuck shields. A spring loaded chuck wrench should always be used on metal lathes! Automated cutting/turning machines require point of operation guarding. Anti restart devices are required if machinery can automatically when power is restored (i. e. after a power failure). restart Idesco Corp. 25 OR OSHA 204 Machine Safeguarding

This material is for training use only Robots Machines that load and unload stock, assemble parts, transfer objects, and perform other tasks otherwise done by the operator. Robot concerns include being struck by robotic arms and other mechanisms within or near it’s working envelope. Most common injuries are being struck by the end effector (claw on the end) and being pinned between end effector and a stationary object. Also, possible malfunctions and/or missed steps can surprise nearby workers! Recommended safety standard - ANSI/RIA 15. 06 -1999 Miscellaneous Aids Does not give complete protection from machine hazards, but can assist in moving stock, deflecting minor chips, or providing awareness. Examples include awareness barriers, ropes, shields, holding tools, and push sticks or blocks. Ensure hand feeding tools are made of soft materials to prevent shattering. Does not replace the need for personal protective equipment or guarding! For example, plexiglass shields on abrasive wheel grinders do not substitute the requirement for eye/face protection or a tongue guard if distance from safety guard and top periphery of stone exceeds 1/4 in. Plus, they can get in the way and are often broken or dirty creating a hazard in themselves! Metal turning machines (lathes, grinders, drills/mills, gear cutters, etc. ) require chip/coolant shields and chuck shields. A spring loaded chuck wrench should always be used on metal lathes! Automated cutting/turning machines require point of operation guarding. Anti restart devices are required if machinery can automatically when power is restored (i. e. after a power failure). restart Idesco Corp. 25 OR OSHA 204 Machine Safeguarding

This material is for training use only Robots Concerns include being struck by robotic arms and other mechanisms within or near it’s working envelope. Most common injuries are being struck by the end effector (claw on the end) and being pinned between end effector and a stationary object. Also, possible malfunctions and/or missed steps can surprise nearby workers! ANSI RIA 15. 06 -1999 is the best of the best! Supplemental only! Provides awareness (chains, signs), deflects minor projections (shields), and assists in moving stock (hand-feeding tools, jigs, push sticks, etc. ). Ensure hand feeding tools are made of soft materials to prevent shattering. Does not replace the need for personal protective equipment or guarding! For example, plexiglass shields on abrasive wheel grinders do not substitute the requirement for eye/face protection or a tongue guard if distance from safety guard and top periphery of stone exceeds 1/4”. Plus, they get in the way and are broken or dirty - creating a hazard in themselves! Metal turning machines (lathes, grinders, drills/mills, gear cutters, etc. ) require chip/coolant shields and chuck shields. A spring loaded chuck wrench should always be used on metal lathes! Automated cutting/turning machines require point of operation guarding. Important Points: Training in proper use and understanding limitations! Also, don’t forget personal disabilities (i. e. color blindness, hearing impaired) if relying on visual warnings (colors) and/or audible warnings (machine startup). 26 OR OSHA 204 Machine Safeguarding

This material is for training use only Robots Concerns include being struck by robotic arms and other mechanisms within or near it’s working envelope. Most common injuries are being struck by the end effector (claw on the end) and being pinned between end effector and a stationary object. Also, possible malfunctions and/or missed steps can surprise nearby workers! ANSI RIA 15. 06 -1999 is the best of the best! Supplemental only! Provides awareness (chains, signs), deflects minor projections (shields), and assists in moving stock (hand-feeding tools, jigs, push sticks, etc. ). Ensure hand feeding tools are made of soft materials to prevent shattering. Does not replace the need for personal protective equipment or guarding! For example, plexiglass shields on abrasive wheel grinders do not substitute the requirement for eye/face protection or a tongue guard if distance from safety guard and top periphery of stone exceeds 1/4”. Plus, they get in the way and are broken or dirty - creating a hazard in themselves! Metal turning machines (lathes, grinders, drills/mills, gear cutters, etc. ) require chip/coolant shields and chuck shields. A spring loaded chuck wrench should always be used on metal lathes! Automated cutting/turning machines require point of operation guarding. Important Points: Training in proper use and understanding limitations! Also, don’t forget personal disabilities (i. e. color blindness, hearing impaired) if relying on visual warnings (colors) and/or audible warnings (machine startup). 26 OR OSHA 204 Machine Safeguarding

This material is for training use only The final exa……er, Quick Review! 1. Machine guarding protects operators and prevents injury from…… P____ __ _____ F______ C_______ R____ P_____ S______ N___ P_______ 2. Three basic area require machine safeguarding. Circle three: Other danger areas Point of operation Power transmission apparatus 3. What are three types of equipment/machine motions that present hazards to the worker? R________________ T________ 4. What are three types of in-running nip points? Parts rotating in o_____ direction Rotating and t______ moving parts Rotating and f______ parts 5. What are the four types of equipment/machine actions that can injure the worker? A. Cutting B. Shearing C. Punching D. Bending E. All of the above 6. List the four general types of guards. F_____ I______ A______ S____ A_____ 6. List at least two types of safeguard devices. 7. What are the requirements for effective guards? 27 OR OSHA 204 Machine Safeguarding

This material is for training use only The final exa……er, Quick Review! 1. Machine guarding protects operators and prevents injury from…… P____ __ _____ F______ C_______ R____ P_____ S______ N___ P_______ 2. Three basic area require machine safeguarding. Circle three: Other danger areas Point of operation Power transmission apparatus 3. What are three types of equipment/machine motions that present hazards to the worker? R________________ T________ 4. What are three types of in-running nip points? Parts rotating in o_____ direction Rotating and t______ moving parts Rotating and f______ parts 5. What are the four types of equipment/machine actions that can injure the worker? A. Cutting B. Shearing C. Punching D. Bending E. All of the above 6. List the four general types of guards. F_____ I______ A______ S____ A_____ 6. List at least two types of safeguard devices. 7. What are the requirements for effective guards? 27 OR OSHA 204 Machine Safeguarding

This material is for training use only The final exa……er, Quick Review! 1. Machine guarding protects operators and prevents injury from…… Point of operation Flying chips Rotating parts Sparks Nip points 2. Three basic area require machine safeguarding. Circle three: Other danger areas Point of operation Power transmission apparatus 3. What are three types of equipment/machine motions that present hazards to the worker? Rotating Reciprocating Transverse 4. What are three types of in-running nip points? Parts rotating in opposite direction Rotating and tangentially moving parts Rotating and fixed parts 5. What are the four types of equipment/machine actions that can injure the worker? A. Cutting B. Shearing C. Punching D. Bending E. All of the above 6. List the four general types of guards. Fixed Interlock Adjusting Self adjusting 6. List at least two types of safeguard devices. Presence sensing Two Hand Trips Pullbacks/Restraints Trip controls Two Hand Controls Gates 7. What are the requirements for effective guards? Pages 11 & 12 of this Inst Manual 28 OR OSHA 204 Machine Safeguarding

This material is for training use only The final exa……er, Quick Review! 1. Machine guarding protects operators and prevents injury from…… Point of operation Flying chips Rotating parts Sparks Nip points 2. Three basic area require machine safeguarding. Circle three: Other danger areas Point of operation Power transmission apparatus 3. What are three types of equipment/machine motions that present hazards to the worker? Rotating Reciprocating Transverse 4. What are three types of in-running nip points? Parts rotating in opposite direction Rotating and tangentially moving parts Rotating and fixed parts 5. What are the four types of equipment/machine actions that can injure the worker? A. Cutting B. Shearing C. Punching D. Bending E. All of the above 6. List the four general types of guards. Fixed Interlock Adjusting Self adjusting 6. List at least two types of safeguard devices. Presence sensing Two Hand Trips Pullbacks/Restraints Trip controls Two Hand Controls Gates 7. What are the requirements for effective guards? Pages 11 & 12 of this Inst Manual 28 OR OSHA 204 Machine Safeguarding

This material is for training use only Appendix Training guidelines Guard Opening Scale Checklist ANSI references 29 OR OSHA 204 Machine Safeguarding

This material is for training use only Appendix Training guidelines Guard Opening Scale Checklist ANSI references 29 OR OSHA 204 Machine Safeguarding

This material is for training use only Training Guidelines An extremely important step in machine safeguarding a step which oftentimes is overlooked is providing safety instruction and training on the various types of equipment the worker is expected to operate and the safeguarding the worker is expected to use. At a minimum, this education should include: * Discussion of hazardous exposures and control measures • Hazardous motions • Hazardous actions • Potential of flying/ejected material • Effective guarding methods and/or other control measures • Ergonomics • Fire/combustion potential • Appropriate personal protective equipment and clothing • Health hazards Air quality Noise & vibration Metal working fluids * Equipment specific training (hands on) • Properation of safeguards Limitations Maintenance & care Inspection Adjustment/placement • Clarification of manufacturer requirements • Instruction on when safeguard is discovered damaged, missing, etc. Retraining? Training, and relevant retraining, must be provided for new operators and maintenance/setup employees. Also, retrain affected employees when new or altered safeguards are used, when the employee(s) is assigned to a new machine or operation, and whenever worker deficiencies are discovered. 30 OR OSHA 204 Machine Safeguarding

This material is for training use only Training Guidelines An extremely important step in machine safeguarding a step which oftentimes is overlooked is providing safety instruction and training on the various types of equipment the worker is expected to operate and the safeguarding the worker is expected to use. At a minimum, this education should include: * Discussion of hazardous exposures and control measures • Hazardous motions • Hazardous actions • Potential of flying/ejected material • Effective guarding methods and/or other control measures • Ergonomics • Fire/combustion potential • Appropriate personal protective equipment and clothing • Health hazards Air quality Noise & vibration Metal working fluids * Equipment specific training (hands on) • Properation of safeguards Limitations Maintenance & care Inspection Adjustment/placement • Clarification of manufacturer requirements • Instruction on when safeguard is discovered damaged, missing, etc. Retraining? Training, and relevant retraining, must be provided for new operators and maintenance/setup employees. Also, retrain affected employees when new or altered safeguards are used, when the employee(s) is assigned to a new machine or operation, and whenever worker deficiencies are discovered. 30 OR OSHA 204 Machine Safeguarding

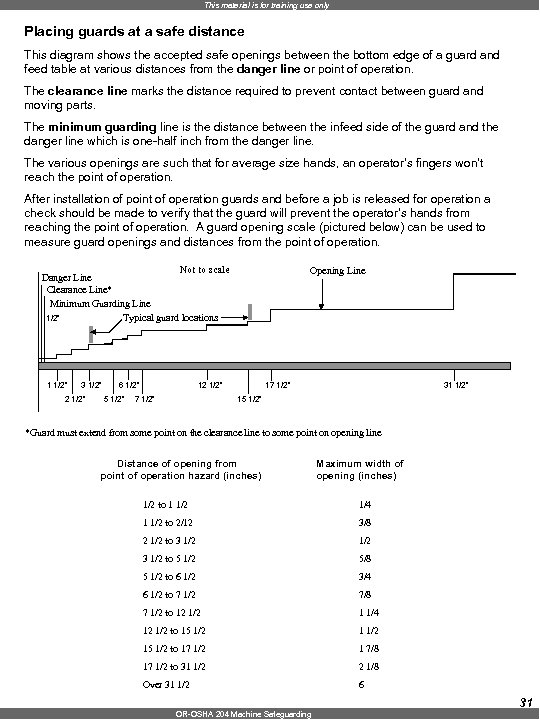

This material is for training use only Placing guards at a safe distance This diagram shows the accepted safe openings between the bottom edge of a guard and feed table at various distances from the danger line or point of operation. The clearance line marks the distance required to prevent contact between guard and moving parts. The minimum guarding line is the distance between the infeed side of the guard and the danger line which is one half inch from the danger line. The various openings are such that for average size hands, an operator’s fingers won’t reach the point of operation. After installation of point of operation guards and before a job is released for operation a check should be made to verify that the guard will prevent the operator’s hands from reaching the point of operation. A guard opening scale (pictured below) can be used to measure guard openings and distances from the point of operation. Not to scale Danger Line Clearance Line* Minimum Guarding Line Typical guard locations 1/2” 1 1/2” 3 1/2” 2 1/2” 6 1/2” 5 1/2” Opening Line 12 1/2” 7 1/2” 17 1/2” 31 1/2” 15 1/2” *Guard must extend from some point on the clearance line to some point on opening line Distance of opening from point of operation hazard (inches) Maximum width of opening (inches) 1/2 to 1 1/2 1/4 1 1/2 to 2/12 3/8 2 1/2 to 3 1/2 to 5 1/2 5/8 5 1/2 to 6 1/2 3/4 6 1/2 to 7 1/2 7/8 7 1/2 to 12 1/2 1 1/4 12 1/2 to 15 1/2 to 17 1/2 1 7/8 17 1/2 to 31 1/2 2 1/8 Over 31 1/2 6 31 OR OSHA 204 Machine Safeguarding

This material is for training use only Placing guards at a safe distance This diagram shows the accepted safe openings between the bottom edge of a guard and feed table at various distances from the danger line or point of operation. The clearance line marks the distance required to prevent contact between guard and moving parts. The minimum guarding line is the distance between the infeed side of the guard and the danger line which is one half inch from the danger line. The various openings are such that for average size hands, an operator’s fingers won’t reach the point of operation. After installation of point of operation guards and before a job is released for operation a check should be made to verify that the guard will prevent the operator’s hands from reaching the point of operation. A guard opening scale (pictured below) can be used to measure guard openings and distances from the point of operation. Not to scale Danger Line Clearance Line* Minimum Guarding Line Typical guard locations 1/2” 1 1/2” 3 1/2” 2 1/2” 6 1/2” 5 1/2” Opening Line 12 1/2” 7 1/2” 17 1/2” 31 1/2” 15 1/2” *Guard must extend from some point on the clearance line to some point on opening line Distance of opening from point of operation hazard (inches) Maximum width of opening (inches) 1/2 to 1 1/2 1/4 1 1/2 to 2/12 3/8 2 1/2 to 3 1/2 to 5 1/2 5/8 5 1/2 to 6 1/2 3/4 6 1/2 to 7 1/2 7/8 7 1/2 to 12 1/2 1 1/4 12 1/2 to 15 1/2 to 17 1/2 1 7/8 17 1/2 to 31 1/2 2 1/8 Over 31 1/2 6 31 OR OSHA 204 Machine Safeguarding

This material is for training use only Machine Guarding Checklist Answers to the following questions should help the interested reader determine the safeguarding needs of his or her own workplace, by drawing attention to hazardous conditions or practices requiring correction. Yes No ____ 1. Do the safeguards provided meet the minimum OSHA requirements? ____ 2. Do the safeguards prevent workers' hands, arms, and other body parts for making contact with dangerous moving parts? ____ 3. Are the safeguards firmly secured and not easily removable? ____ 4. Do the safeguards ensure that no object will fall into the moving parts? ____ 5. Do the safeguards permit safe, comfortable, and relatively easy operation of the machine? ____ 6. Can the machine be oiled without removing the safeguard? ____ 7. Is there a system for shutting down the machinery before safeguards are removed? ____ 8. Can the existing safeguards be improved? Mechanical Hazards Yes No The point of operation: ____ 1. Is there a point of operation safeguard provided for the machine? ____ 2. Does it keep the operator's hands, fingers, body out of the danger area? ____ 3. Is there evidence that the safeguards have been tampered with or removed? ____ 4. Could you suggest a more practical, effective safeguard? ____ 5. Could changes be made on the machine to eliminate the point of operation hazard entirely? 32 OR OSHA 204 Machine Safeguarding

This material is for training use only Machine Guarding Checklist Answers to the following questions should help the interested reader determine the safeguarding needs of his or her own workplace, by drawing attention to hazardous conditions or practices requiring correction. Yes No ____ 1. Do the safeguards provided meet the minimum OSHA requirements? ____ 2. Do the safeguards prevent workers' hands, arms, and other body parts for making contact with dangerous moving parts? ____ 3. Are the safeguards firmly secured and not easily removable? ____ 4. Do the safeguards ensure that no object will fall into the moving parts? ____ 5. Do the safeguards permit safe, comfortable, and relatively easy operation of the machine? ____ 6. Can the machine be oiled without removing the safeguard? ____ 7. Is there a system for shutting down the machinery before safeguards are removed? ____ 8. Can the existing safeguards be improved? Mechanical Hazards Yes No The point of operation: ____ 1. Is there a point of operation safeguard provided for the machine? ____ 2. Does it keep the operator's hands, fingers, body out of the danger area? ____ 3. Is there evidence that the safeguards have been tampered with or removed? ____ 4. Could you suggest a more practical, effective safeguard? ____ 5. Could changes be made on the machine to eliminate the point of operation hazard entirely? 32 OR OSHA 204 Machine Safeguarding

This material is for training use only Requirements for all Safeguards (continued) Yes No Power transmission apparatus: ____ 1. Are there any unguarded gears, sprockets, pulleys, or flywheels on the apparatus? ____ 2. Are there any exposed belts or chain drives? ____ 3. Are there any exposed set screws, key ways, collars, etc. ? ____ 4. Are starting and stopping controls within easy reach of the operator? ____ 5. If there is more than one operator, are separate controls provided? Other moving parts: ____ 1. Are safeguards provided for all hazardous moving parts of the machine including auxiliary parts? Nonmechanical Hazards ____ 1. Have appropriate measures been taken to safeguard workers against noise hazards? ____ 2. Have special guards, enclosures, or personal protective equipment been provided, where necessary, to protect workers from exposure to harmful substances used in machine operation? Electric Hazards ____ 1. Is the machine installed in accordance with National Fire Protection Association and National Electrical Code requirements? ____ 2. Are there loose conduit fittings? ____ 3. Is the machine properly grounded? ____ 4. Is the power supply correctly fused and protected? ____ 5. Do workers occasionally receive minor shocks while operating any of the machines? 33 OR OSHA 204 Machine Safeguarding

This material is for training use only Requirements for all Safeguards (continued) Yes No Power transmission apparatus: ____ 1. Are there any unguarded gears, sprockets, pulleys, or flywheels on the apparatus? ____ 2. Are there any exposed belts or chain drives? ____ 3. Are there any exposed set screws, key ways, collars, etc. ? ____ 4. Are starting and stopping controls within easy reach of the operator? ____ 5. If there is more than one operator, are separate controls provided? Other moving parts: ____ 1. Are safeguards provided for all hazardous moving parts of the machine including auxiliary parts? Nonmechanical Hazards ____ 1. Have appropriate measures been taken to safeguard workers against noise hazards? ____ 2. Have special guards, enclosures, or personal protective equipment been provided, where necessary, to protect workers from exposure to harmful substances used in machine operation? Electric Hazards ____ 1. Is the machine installed in accordance with National Fire Protection Association and National Electrical Code requirements? ____ 2. Are there loose conduit fittings? ____ 3. Is the machine properly grounded? ____ 4. Is the power supply correctly fused and protected? ____ 5. Do workers occasionally receive minor shocks while operating any of the machines? 33 OR OSHA 204 Machine Safeguarding

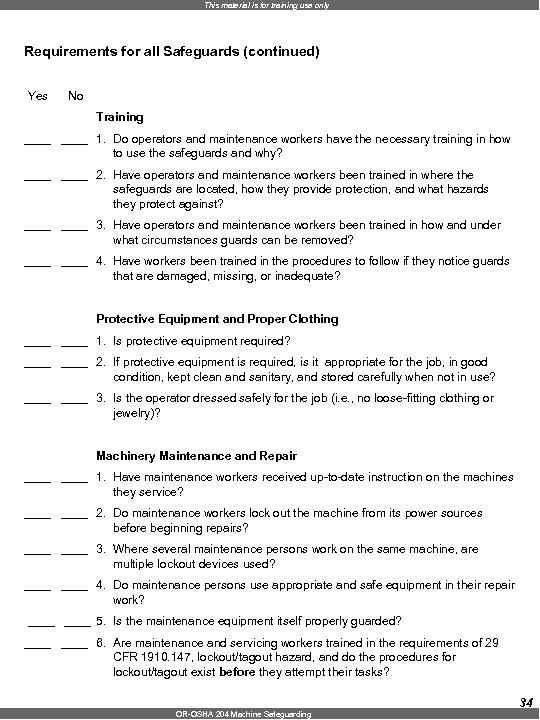

This material is for training use only Requirements for all Safeguards (continued) Yes No Training ____ 1. Do operators and maintenance workers have the necessary training in how to use the safeguards and why? ____ 2. Have operators and maintenance workers been trained in where the safeguards are located, how they provide protection, and what hazards they protect against? ____ 3. Have operators and maintenance workers been trained in how and under what circumstances guards can be removed? ____ 4. Have workers been trained in the procedures to follow if they notice guards that are damaged, missing, or inadequate? Protective Equipment and Proper Clothing ____ 1. Is protective equipment required? ____ 2. If protective equipment is required, is it appropriate for the job, in good condition, kept clean and sanitary, and stored carefully when not in use? ____ 3. Is the operator dressed safely for the job (i. e. , no loose fitting clothing or jewelry)? Machinery Maintenance and Repair ____ 1. Have maintenance workers received up to date instruction on the machines they service? ____ 2. Do maintenance workers lock out the machine from its power sources before beginning repairs? ____ 3. Where several maintenance persons work on the same machine, are multiple lockout devices used? ____ 4. Do maintenance persons use appropriate and safe equipment in their repair work? ____ 5. Is the maintenance equipment itself properly guarded? ____ 6. Are maintenance and servicing workers trained in the requirements of 29 CFR 1910. 147, lockout/tagout hazard, and do the procedures for lockout/tagout exist before they attempt their tasks? 34 OR OSHA 204 Machine Safeguarding

This material is for training use only Requirements for all Safeguards (continued) Yes No Training ____ 1. Do operators and maintenance workers have the necessary training in how to use the safeguards and why? ____ 2. Have operators and maintenance workers been trained in where the safeguards are located, how they provide protection, and what hazards they protect against? ____ 3. Have operators and maintenance workers been trained in how and under what circumstances guards can be removed? ____ 4. Have workers been trained in the procedures to follow if they notice guards that are damaged, missing, or inadequate? Protective Equipment and Proper Clothing ____ 1. Is protective equipment required? ____ 2. If protective equipment is required, is it appropriate for the job, in good condition, kept clean and sanitary, and stored carefully when not in use? ____ 3. Is the operator dressed safely for the job (i. e. , no loose fitting clothing or jewelry)? Machinery Maintenance and Repair ____ 1. Have maintenance workers received up to date instruction on the machines they service? ____ 2. Do maintenance workers lock out the machine from its power sources before beginning repairs? ____ 3. Where several maintenance persons work on the same machine, are multiple lockout devices used? ____ 4. Do maintenance persons use appropriate and safe equipment in their repair work? ____ 5. Is the maintenance equipment itself properly guarded? ____ 6. Are maintenance and servicing workers trained in the requirements of 29 CFR 1910. 147, lockout/tagout hazard, and do the procedures for lockout/tagout exist before they attempt their tasks? 34 OR OSHA 204 Machine Safeguarding

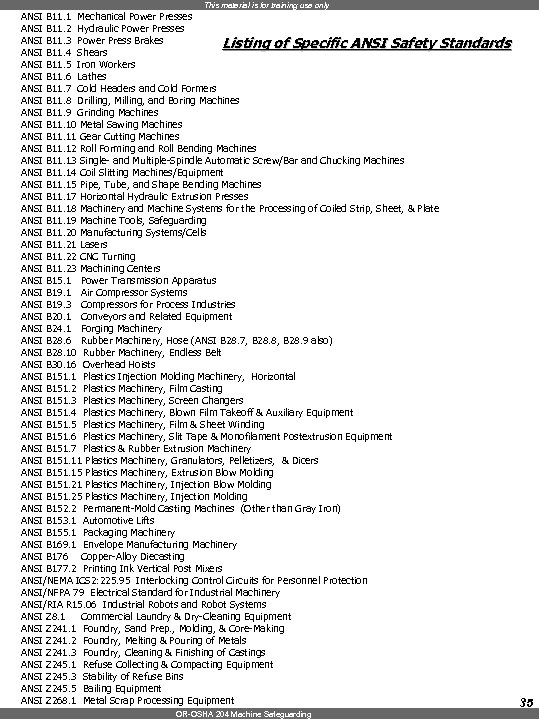

This material is for training use only ANSI B 11. 1 Mechanical Power Presses ANSI B 11. 2 Hydraulic Power Presses ANSI B 11. 3 Power Press Brakes Listing of Specific ANSI Safety Standards ANSI B 11. 4 Shears ANSI B 11. 5 Iron Workers ANSI B 11. 6 Lathes ANSI B 11. 7 Cold Headers and Cold Formers ANSI B 11. 8 Drilling, Milling, and Boring Machines ANSI B 11. 9 Grinding Machines ANSI B 11. 10 Metal Sawing Machines ANSI B 11. 11 Gear Cutting Machines ANSI B 11. 12 Roll Forming and Roll Bending Machines ANSI B 11. 13 Single- and Multiple-Spindle Automatic Screw/Bar and Chucking Machines ANSI B 11. 14 Coil Slitting Machines/Equipment ANSI B 11. 15 Pipe, Tube, and Shape Bending Machines ANSI B 11. 17 Horizontal Hydraulic Extrusion Presses ANSI B 11. 18 Machinery and Machine Systems for the Processing of Coiled Strip, Sheet, & Plate ANSI B 11. 19 Machine Tools, Safeguarding ANSI B 11. 20 Manufacturing Systems/Cells ANSI B 11. 21 Lasers ANSI B 11. 22 CNC Turning ANSI B 11. 23 Machining Centers ANSI B 15. 1 Power Transmission Apparatus ANSI B 19. 1 Air Compressor Systems ANSI B 19. 3 Compressors for Process Industries ANSI B 20. 1 Conveyors and Related Equipment ANSI B 24. 1 Forging Machinery ANSI B 28. 6 Rubber Machinery, Hose (ANSI B 28. 7, B 28. 8, B 28. 9 also) ANSI B 28. 10 Rubber Machinery, Endless Belt ANSI B 30. 16 Overhead Hoists ANSI B 151. 1 Plastics Injection Molding Machinery, Horizontal ANSI B 151. 2 Plastics Machinery, Film Casting ANSI B 151. 3 Plastics Machinery, Screen Changers ANSI B 151. 4 Plastics Machinery, Blown Film Takeoff & Auxiliary Equipment ANSI B 151. 5 Plastics Machinery, Film & Sheet Winding ANSI B 151. 6 Plastics Machinery, Slit Tape & Monofilament Postextrusion Equipment ANSI B 151. 7 Plastics & Rubber Extrusion Machinery ANSI B 151. 11 Plastics Machinery, Granulators, Pelletizers, & Dicers ANSI B 151. 15 Plastics Machinery, Extrusion Blow Molding ANSI B 151. 21 Plastics Machinery, Injection Blow Molding ANSI B 151. 25 Plastics Machinery, Injection Molding ANSI B 152. 2 Permanent-Mold Casting Machines (Other than Gray Iron) ANSI B 153. 1 Automotive Lifts ANSI B 155. 1 Packaging Machinery ANSI B 169. 1 Envelope Manufacturing Machinery ANSI B 176 Copper-Alloy Diecasting ANSI B 177. 2 Printing Ink Vertical Post Mixers ANSI/NEMA ICS 2: 225. 95 Interlocking Control Circuits for Personnel Protection ANSI/NFPA 79 Electrical Standard for Industrial Machinery ANSI/RIA R 15. 06 Industrial Robots and Robot Systems ANSI Z 8. 1 Commercial Laundry & Dry-Cleaning Equipment ANSI Z 241. 1 Foundry, Sand Prep. , Molding, & Core-Making ANSI Z 241. 2 Foundry, Melting & Pouring of Metals ANSI Z 241. 3 Foundry, Cleaning & Finishing of Castings ANSI Z 245. 1 Refuse Collecting & Compacting Equipment ANSI Z 245. 3 Stability of Refuse Bins ANSI Z 245. 5 Bailing Equipment ANSI Z 268. 1 Metal Scrap Processing Equipment OR OSHA 204 Machine Safeguarding 35