d32c80f0cc84dc589a51b2d329ae4ab3.ppt

- Количество слайдов: 52

Thirty Meter Space Telescope (TMST) Conceptual Mechanical Design Development J. Budinoff/544 March 2007

Thirty Meter Space Telescope (TMST) Conceptual Mechanical Design Development J. Budinoff/544 March 2007

PRE-IDC EELV Concept • EELV class packaging • How do we do this? Can we? Will they laugh?

PRE-IDC EELV Concept • EELV class packaging • How do we do this? Can we? Will they laugh?

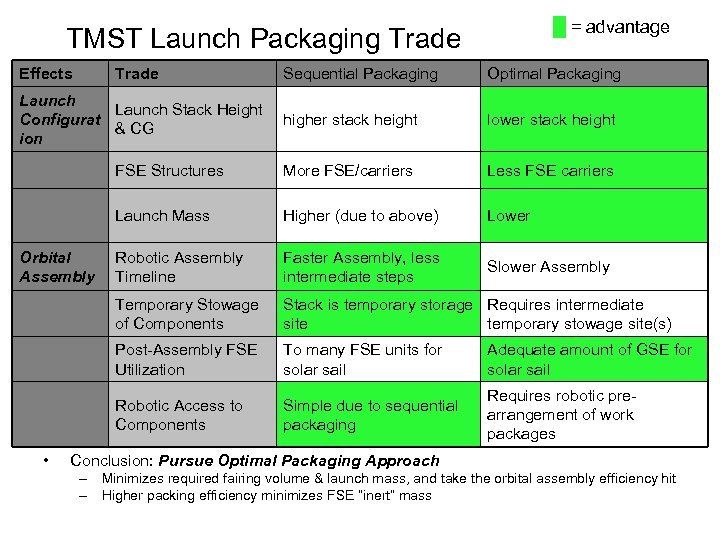

█ = advantage TMST Launch Packaging Trade Effects Trade Sequential Packaging Optimal Packaging higher stack height lower stack height FSE Structures More FSE/carriers Less FSE carriers Launch Mass Higher (due to above) Lower Robotic Assembly Timeline Faster Assembly, less intermediate steps Slower Assembly Temporary Stowage of Components Stack is temporary storage Requires intermediate site temporary stowage site(s) Post-Assembly FSE Utilization To many FSE units for solar sail Adequate amount of GSE for solar sail Robotic Access to Components Simple due to sequential packaging Requires robotic prearrangement of work packages Launch Stack Height Configurat & CG ion Orbital Assembly • Conclusion: Pursue Optimal Packaging Approach – Minimizes required fairing volume & launch mass, and take the orbital assembly efficiency hit – Higher packing efficiency minimizes FSE “inert” mass

█ = advantage TMST Launch Packaging Trade Effects Trade Sequential Packaging Optimal Packaging higher stack height lower stack height FSE Structures More FSE/carriers Less FSE carriers Launch Mass Higher (due to above) Lower Robotic Assembly Timeline Faster Assembly, less intermediate steps Slower Assembly Temporary Stowage of Components Stack is temporary storage Requires intermediate site temporary stowage site(s) Post-Assembly FSE Utilization To many FSE units for solar sail Adequate amount of GSE for solar sail Robotic Access to Components Simple due to sequential packaging Requires robotic prearrangement of work packages Launch Stack Height Configurat & CG ion Orbital Assembly • Conclusion: Pursue Optimal Packaging Approach – Minimizes required fairing volume & launch mass, and take the orbital assembly efficiency hit – Higher packing efficiency minimizes FSE “inert” mass

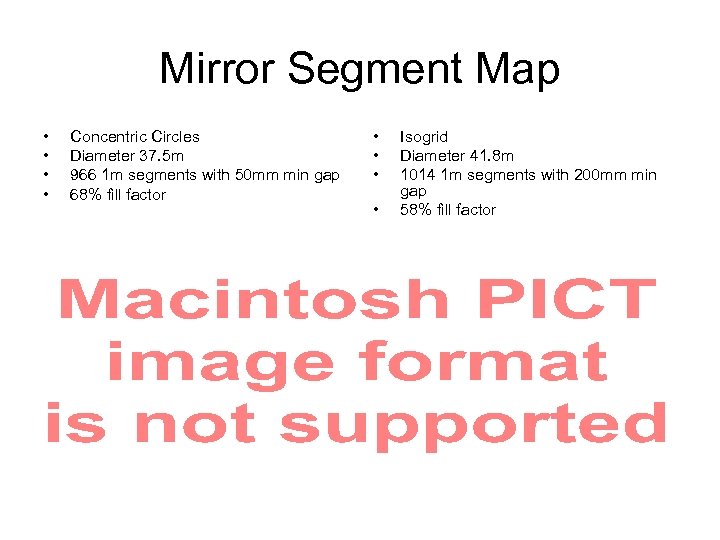

Mirror Segment Map • • Concentric Circles Diameter 37. 5 m 966 1 m segments with 50 mm min gap 68% fill factor • • Isogrid Diameter 41. 8 m 1014 1 m segments with 200 mm min gap 58% fill factor

Mirror Segment Map • • Concentric Circles Diameter 37. 5 m 966 1 m segments with 50 mm min gap 68% fill factor • • Isogrid Diameter 41. 8 m 1014 1 m segments with 200 mm min gap 58% fill factor

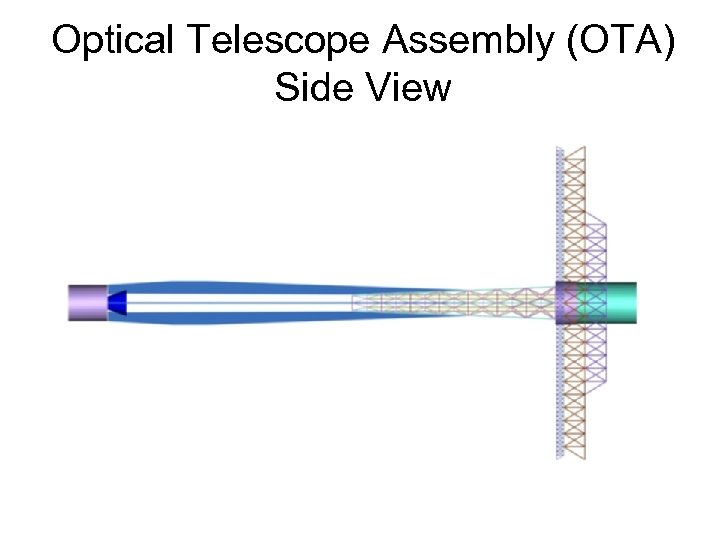

Optical Telescope Assembly (OTA) Side View

Optical Telescope Assembly (OTA) Side View

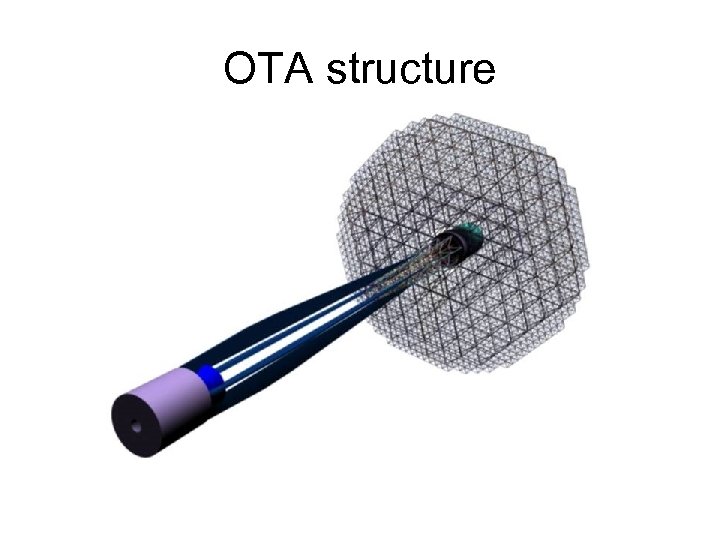

OTA structure

OTA structure

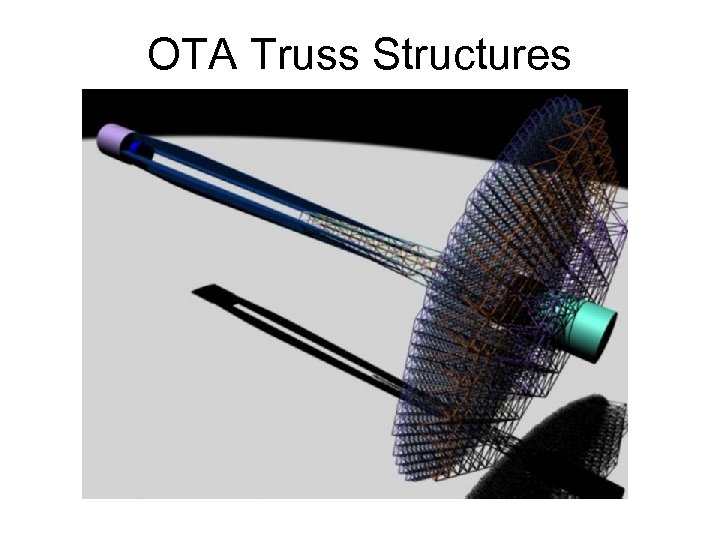

OTA Truss Structures

OTA Truss Structures

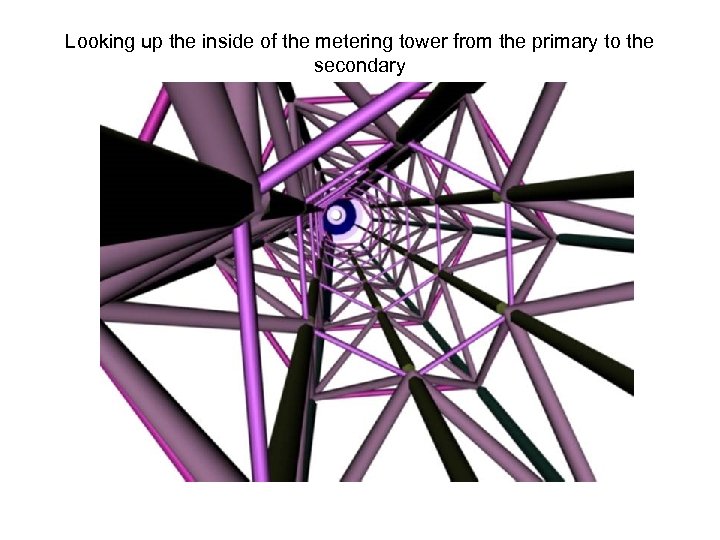

Looking up the inside of the metering tower from the primary to the secondary

Looking up the inside of the metering tower from the primary to the secondary

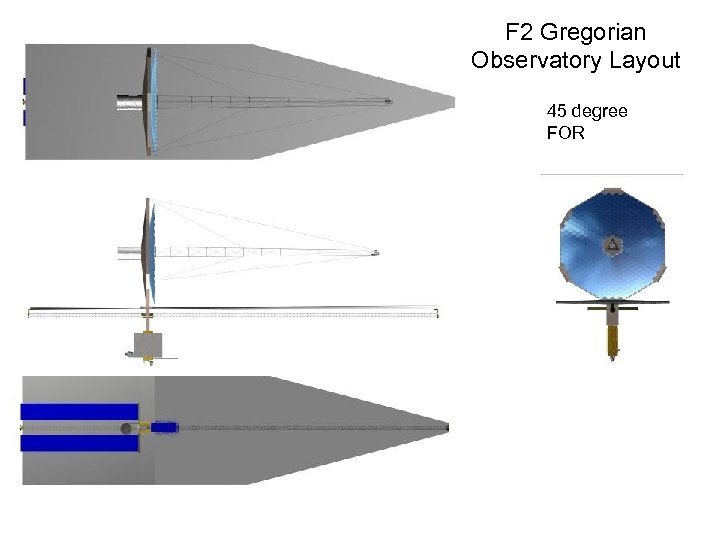

F 2 Gregorian Observatory Layout 45 degree FOR

F 2 Gregorian Observatory Layout 45 degree FOR

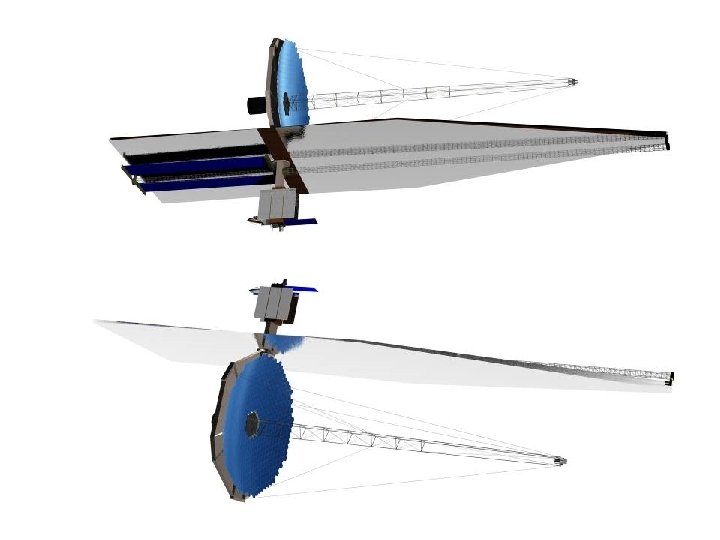

1 m lasercomm 3 m HGA Main Solar Array Radiators Early Assembly Solar Panel

1 m lasercomm 3 m HGA Main Solar Array Radiators Early Assembly Solar Panel

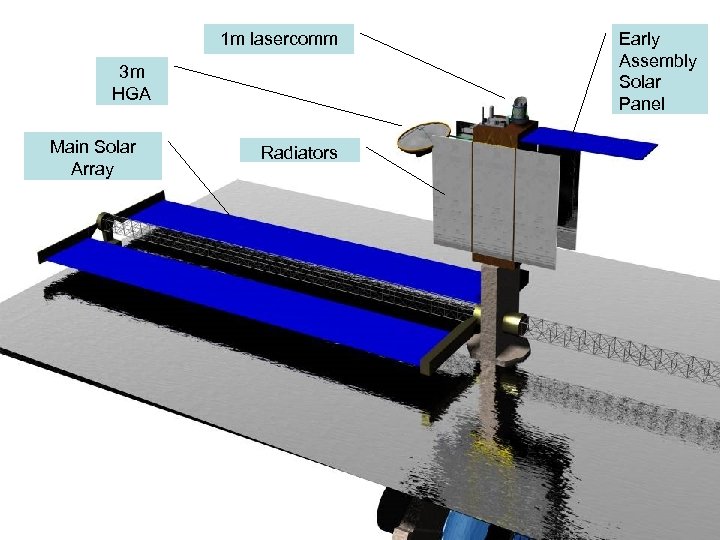

Launch Manifest • TMUST can be broken into 10 Delta IV/Atlas V (EELV-class) launch packages

Launch Manifest • TMUST can be broken into 10 Delta IV/Atlas V (EELV-class) launch packages

EELV Launch Kits 10 ISIM 09 Edge Panels & 2 ndry 08 Edge Panels & cables 07 Mirror & Met. Truss 06 Mirror & Met. Truss 05 Mirror & Met. Truss 04 Mirror & Met. Truss 03 Mirror & Met. Truss 02 Solar Array & Shield 01 Bus

EELV Launch Kits 10 ISIM 09 Edge Panels & 2 ndry 08 Edge Panels & cables 07 Mirror & Met. Truss 06 Mirror & Met. Truss 05 Mirror & Met. Truss 04 Mirror & Met. Truss 03 Mirror & Met. Truss 02 Solar Array & Shield 01 Bus

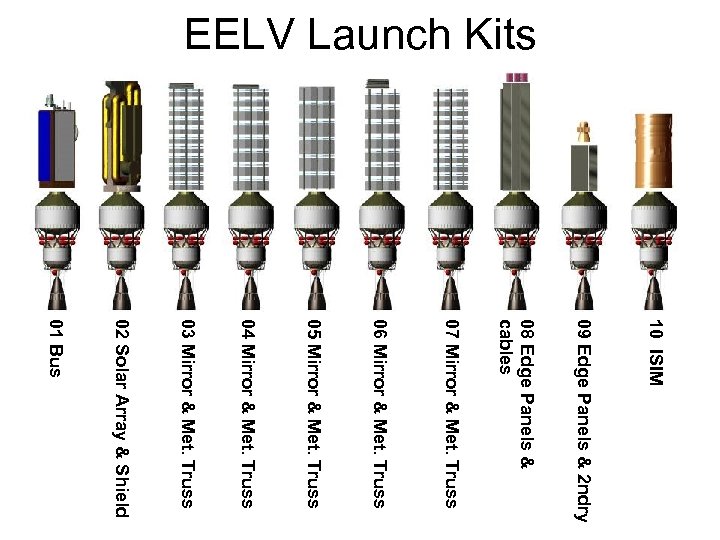

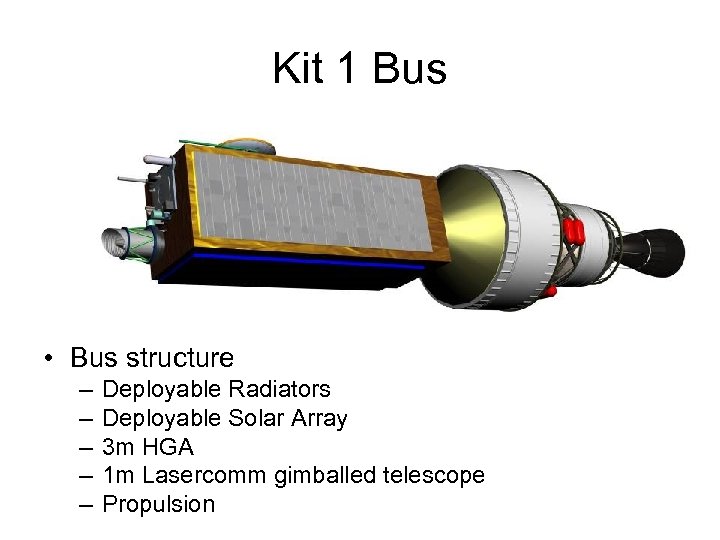

Kit 1 Bus • Bus structure – – – Deployable Radiators Deployable Solar Array 3 m HGA 1 m Lasercomm gimballed telescope Propulsion

Kit 1 Bus • Bus structure – – – Deployable Radiators Deployable Solar Array 3 m HGA 1 m Lasercomm gimballed telescope Propulsion

Kit 2 Sunshield, Main Solar Array • • Mated to bus Able mast deploys sunshield & main solar array using bus power Thermal Isolation interface Backplane Edge Panels

Kit 2 Sunshield, Main Solar Array • • Mated to bus Able mast deploys sunshield & main solar array using bus power Thermal Isolation interface Backplane Edge Panels

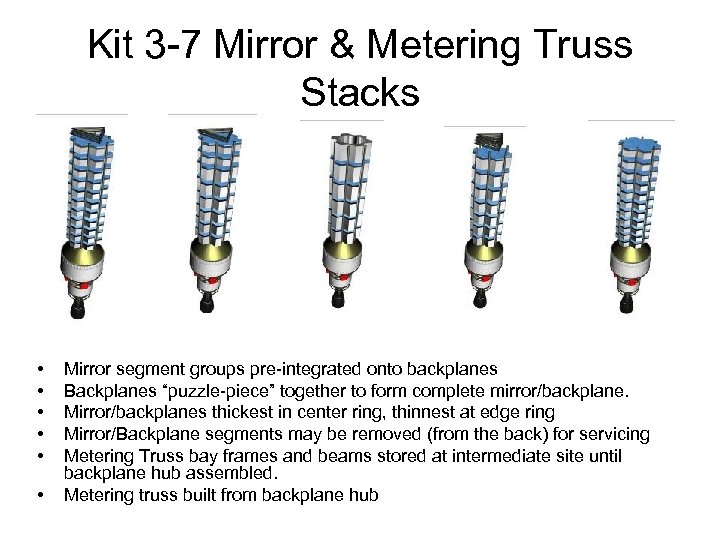

Kit 3 -7 Mirror & Metering Truss Stacks • • • Mirror segment groups pre-integrated onto backplanes Backplanes “puzzle-piece” together to form complete mirror/backplane. Mirror/backplanes thickest in center ring, thinnest at edge ring Mirror/Backplane segments may be removed (from the back) for servicing Metering Truss bay frames and beams stored at intermediate site until backplane hub assembled. Metering truss built from backplane hub

Kit 3 -7 Mirror & Metering Truss Stacks • • • Mirror segment groups pre-integrated onto backplanes Backplanes “puzzle-piece” together to form complete mirror/backplane. Mirror/backplanes thickest in center ring, thinnest at edge ring Mirror/Backplane segments may be removed (from the back) for servicing Metering Truss bay frames and beams stored at intermediate site until backplane hub assembled. Metering truss built from backplane hub

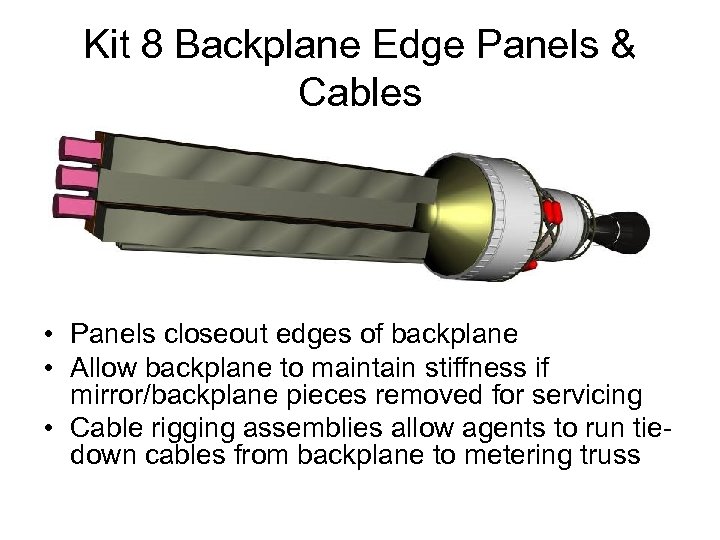

Kit 8 Backplane Edge Panels & Cables • Panels closeout edges of backplane • Allow backplane to maintain stiffness if mirror/backplane pieces removed for servicing • Cable rigging assemblies allow agents to run tiedown cables from backplane to metering truss

Kit 8 Backplane Edge Panels & Cables • Panels closeout edges of backplane • Allow backplane to maintain stiffness if mirror/backplane pieces removed for servicing • Cable rigging assemblies allow agents to run tiedown cables from backplane to metering truss

Kit 9 Backplane Edge Short Panels & Secondary Mirror Assembly • Delta IV Medium Fairing • Brings remaining Short Edge Closeout panels – first short panels brought in kit 2 • Integrated secondary mirror assembly placed at end of metering truss

Kit 9 Backplane Edge Short Panels & Secondary Mirror Assembly • Delta IV Medium Fairing • Brings remaining Short Edge Closeout panels – first short panels brought in kit 2 • Integrated secondary mirror assembly placed at end of metering truss

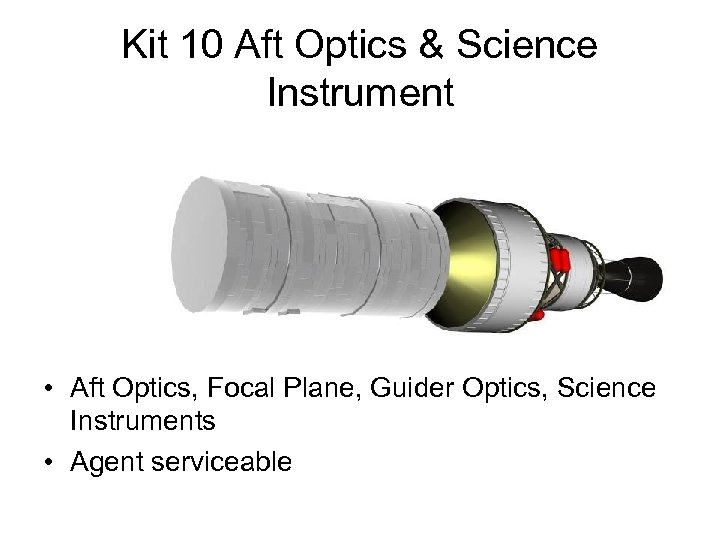

Kit 10 Aft Optics & Science Instrument • Aft Optics, Focal Plane, Guider Optics, Science Instruments • Agent serviceable

Kit 10 Aft Optics & Science Instrument • Aft Optics, Focal Plane, Guider Optics, Science Instruments • Agent serviceable

IDC Concept • EELV or notional large launch vehicles • Develop observatory bus concept (IMDC) • Further detail the OTA (ISAL)

IDC Concept • EELV or notional large launch vehicles • Develop observatory bus concept (IMDC) • Further detail the OTA (ISAL)

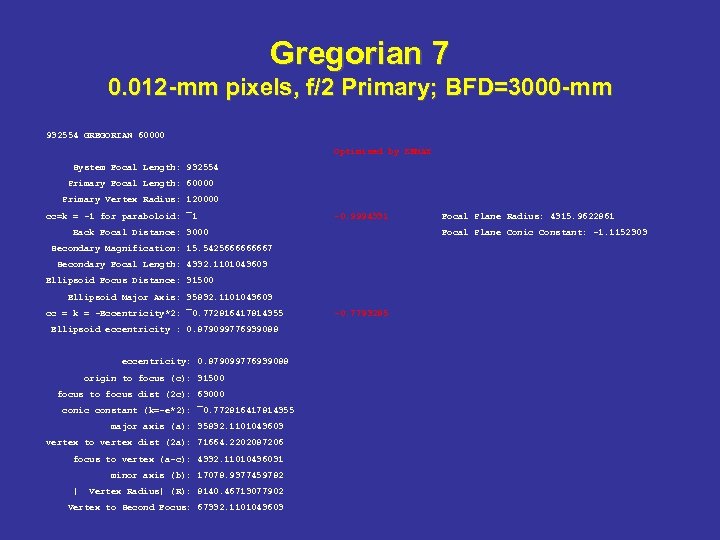

Gregorian 7 0. 012 -mm pixels, f/2 Primary; BFD=3000 -mm 932554 GREGORIAN 60000 Optimized by ZEMAX System Focal Length: 932554 Primary Focal Length: 60000 Primary Vertex Radius: 120000 cc=k = -1 for paraboloid: ¯ 1 -0. 9994331 Back Focal Distance: 3000 Focal Plane Conic Constant: -1. 1152303 Secondary Magnification: 15. 542566667 Secondary Focal Length: 4332. 1101043603 Ellipsoid Focus Distance: 31500 Ellipsoid Major Axis: 35832. 1101043603 cc = k = -Eccentricity*2: ¯ 0. 772816417814355 Ellipsoid eccentricity : 0. 879099776939088 eccentricity: 0. 879099776939088 origin to focus (c): 31500 focus to focus dist (2 c): 63000 conic constant (k=-e*2): ¯ 0. 772816417814355 major axis (a): 35832. 1101043603 vertex to vertex dist (2 a): 71664. 2202087206 focus to vertex (a-c): 4332. 11010436031 minor axis (b): 17078. 9377459782 | Vertex Radius| (R): 8140. 46713077902 Vertex to Second Focus: 67332. 1101043603 Focal Plane Radius: 4315. 9622861 -0. 7793285

Gregorian 7 0. 012 -mm pixels, f/2 Primary; BFD=3000 -mm 932554 GREGORIAN 60000 Optimized by ZEMAX System Focal Length: 932554 Primary Focal Length: 60000 Primary Vertex Radius: 120000 cc=k = -1 for paraboloid: ¯ 1 -0. 9994331 Back Focal Distance: 3000 Focal Plane Conic Constant: -1. 1152303 Secondary Magnification: 15. 542566667 Secondary Focal Length: 4332. 1101043603 Ellipsoid Focus Distance: 31500 Ellipsoid Major Axis: 35832. 1101043603 cc = k = -Eccentricity*2: ¯ 0. 772816417814355 Ellipsoid eccentricity : 0. 879099776939088 eccentricity: 0. 879099776939088 origin to focus (c): 31500 focus to focus dist (2 c): 63000 conic constant (k=-e*2): ¯ 0. 772816417814355 major axis (a): 35832. 1101043603 vertex to vertex dist (2 a): 71664. 2202087206 focus to vertex (a-c): 4332. 11010436031 minor axis (b): 17078. 9377459782 | Vertex Radius| (R): 8140. 46713077902 Vertex to Second Focus: 67332. 1101043603 Focal Plane Radius: 4315. 9622861 -0. 7793285

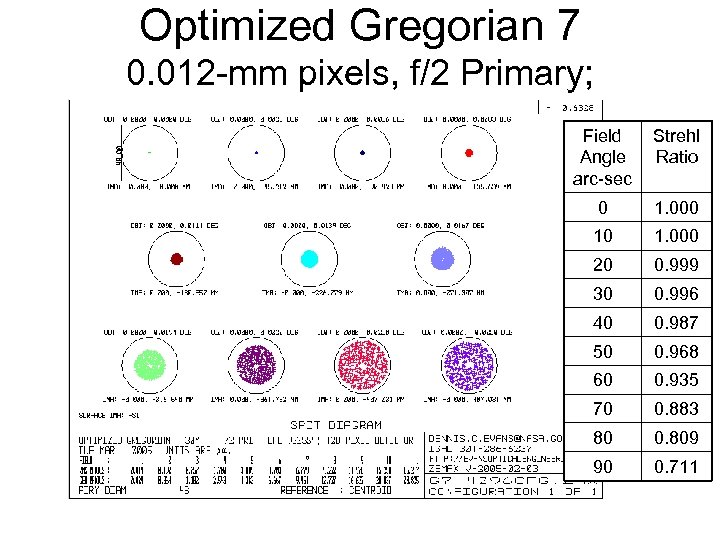

Optimized Gregorian 7 0. 012 -mm pixels, f/2 Primary; BFD=3000 -mm Field 10 0 30 20 Angle arc-sec Strehl Ratio 0 10 70 80 60 90 20 0. 999 30 0. 996 0. 987 50 50 1. 000 40 40 1. 000 0. 968 -90 ARC-SEC 60 0. 935 70 0. 883 80 0. 809 90 0. 711

Optimized Gregorian 7 0. 012 -mm pixels, f/2 Primary; BFD=3000 -mm Field 10 0 30 20 Angle arc-sec Strehl Ratio 0 10 70 80 60 90 20 0. 999 30 0. 996 0. 987 50 50 1. 000 40 40 1. 000 0. 968 -90 ARC-SEC 60 0. 935 70 0. 883 80 0. 809 90 0. 711

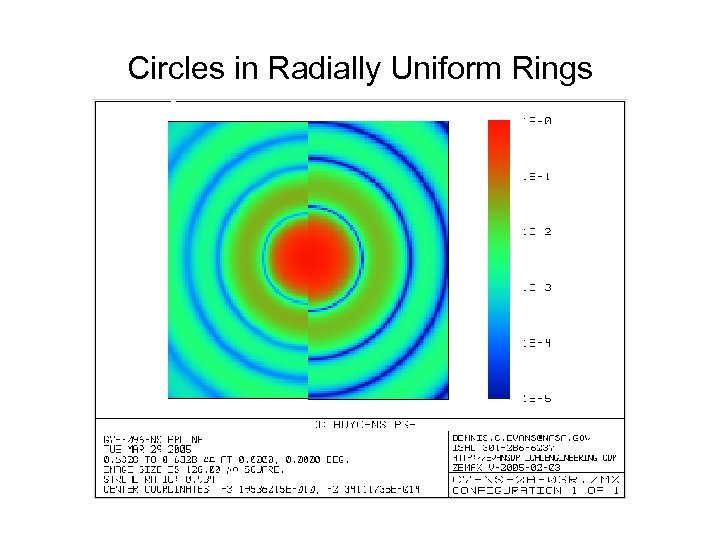

Circles in Radially Uniform Rings Segmented 35. 0 m Monolithic 30 m

Circles in Radially Uniform Rings Segmented 35. 0 m Monolithic 30 m

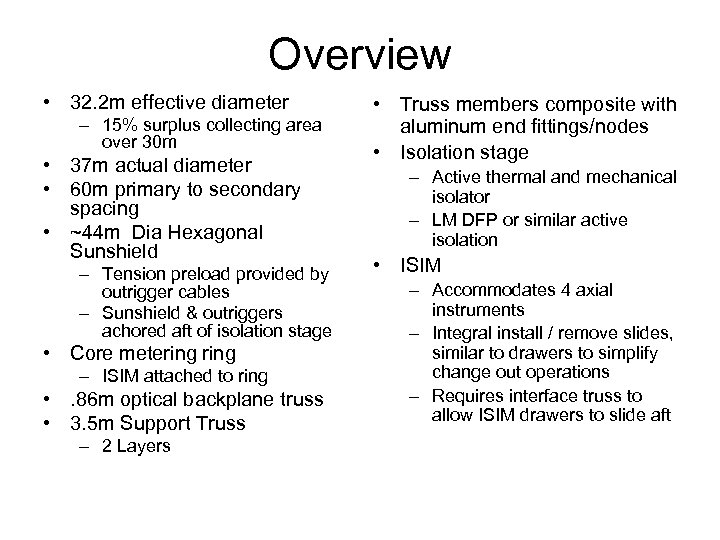

Overview • 32. 2 m effective diameter – 15% surplus collecting area over 30 m • 37 m actual diameter • 60 m primary to secondary spacing • ~44 m Dia Hexagonal Sunshield – Tension preload provided by outrigger cables – Sunshield & outriggers achored aft of isolation stage • Core metering – ISIM attached to ring • . 86 m optical backplane truss • 3. 5 m Support Truss – 2 Layers • Truss members composite with aluminum end fittings/nodes • Isolation stage – Active thermal and mechanical isolator – LM DFP or similar active isolation • ISIM – Accommodates 4 axial instruments – Integral install / remove slides, similar to drawers to simplify change out operations – Requires interface truss to allow ISIM drawers to slide aft

Overview • 32. 2 m effective diameter – 15% surplus collecting area over 30 m • 37 m actual diameter • 60 m primary to secondary spacing • ~44 m Dia Hexagonal Sunshield – Tension preload provided by outrigger cables – Sunshield & outriggers achored aft of isolation stage • Core metering – ISIM attached to ring • . 86 m optical backplane truss • 3. 5 m Support Truss – 2 Layers • Truss members composite with aluminum end fittings/nodes • Isolation stage – Active thermal and mechanical isolator – LM DFP or similar active isolation • ISIM – Accommodates 4 axial instruments – Integral install / remove slides, similar to drawers to simplify change out operations – Requires interface truss to allow ISIM drawers to slide aft

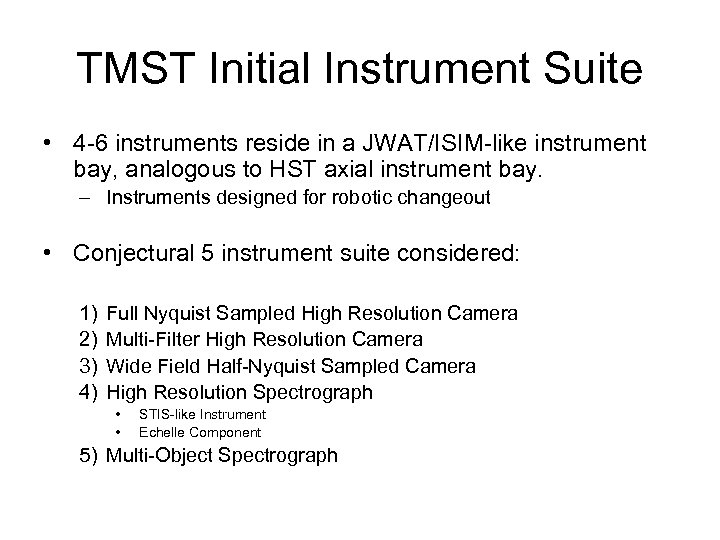

TMST Initial Instrument Suite • 4 -6 instruments reside in a JWAT/ISIM-like instrument bay, analogous to HST axial instrument bay. – Instruments designed for robotic changeout • Conjectural 5 instrument suite considered: 1) 2) 3) 4) Full Nyquist Sampled High Resolution Camera Multi-Filter High Resolution Camera Wide Field Half-Nyquist Sampled Camera High Resolution Spectrograph • • STIS-like Instrument Echelle Component 5) Multi-Object Spectrograph

TMST Initial Instrument Suite • 4 -6 instruments reside in a JWAT/ISIM-like instrument bay, analogous to HST axial instrument bay. – Instruments designed for robotic changeout • Conjectural 5 instrument suite considered: 1) 2) 3) 4) Full Nyquist Sampled High Resolution Camera Multi-Filter High Resolution Camera Wide Field Half-Nyquist Sampled Camera High Resolution Spectrograph • • STIS-like Instrument Echelle Component 5) Multi-Object Spectrograph

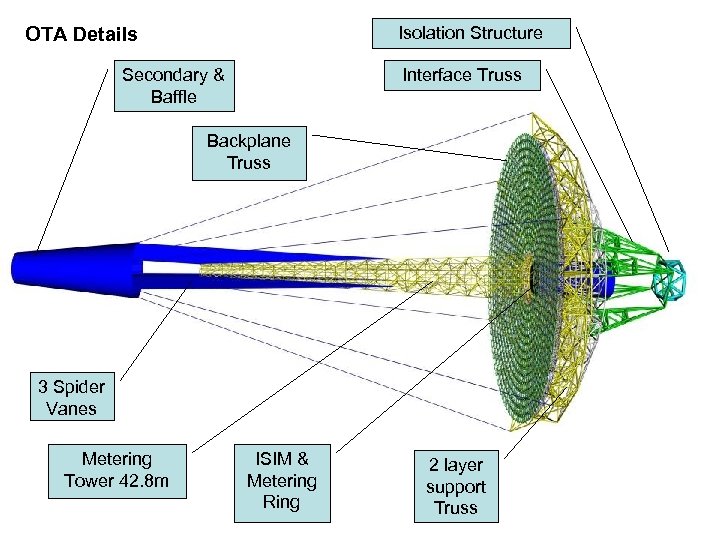

Isolation Structure OTA Details Secondary & Baffle Interface Truss Backplane Truss 3 Spider Vanes Metering Tower 42. 8 m ISIM & Metering Ring 2 layer support Truss

Isolation Structure OTA Details Secondary & Baffle Interface Truss Backplane Truss 3 Spider Vanes Metering Tower 42. 8 m ISIM & Metering Ring 2 layer support Truss

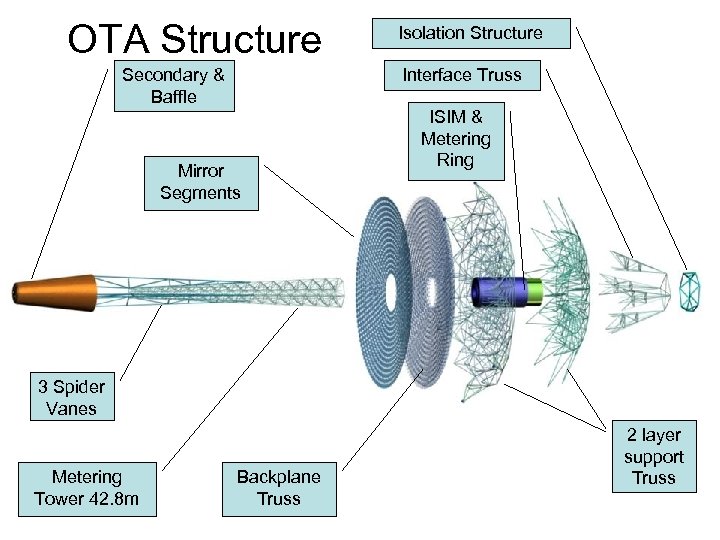

OTA Structure Secondary & Baffle Isolation Structure Interface Truss Mirror Segments ISIM & Metering Ring 3 Spider Vanes Metering Tower 42. 8 m Backplane Truss 2 layer support Truss

OTA Structure Secondary & Baffle Isolation Structure Interface Truss Mirror Segments ISIM & Metering Ring 3 Spider Vanes Metering Tower 42. 8 m Backplane Truss 2 layer support Truss

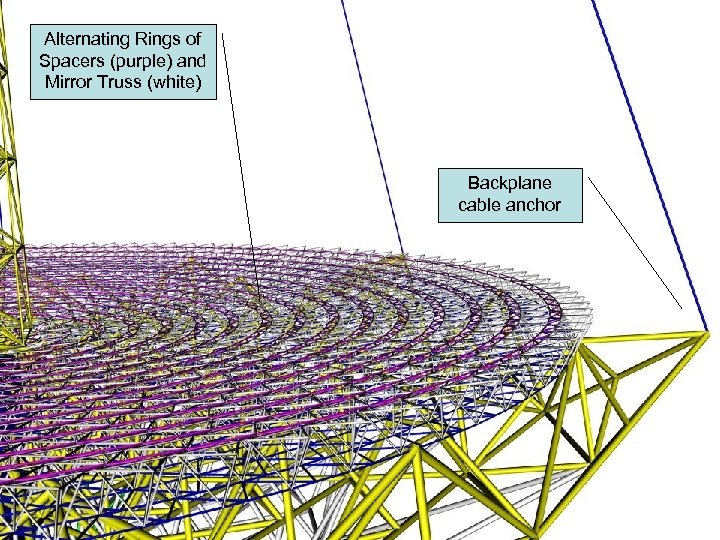

Alternating Rings of Spacers (purple) and Mirror Truss (white) Backplane cable anchor

Alternating Rings of Spacers (purple) and Mirror Truss (white) Backplane cable anchor

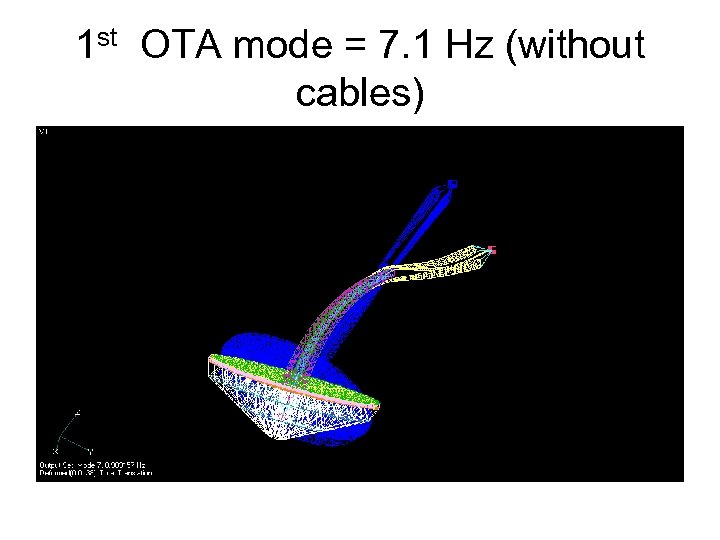

1 st OTA mode = 7. 1 Hz (without cables)

1 st OTA mode = 7. 1 Hz (without cables)

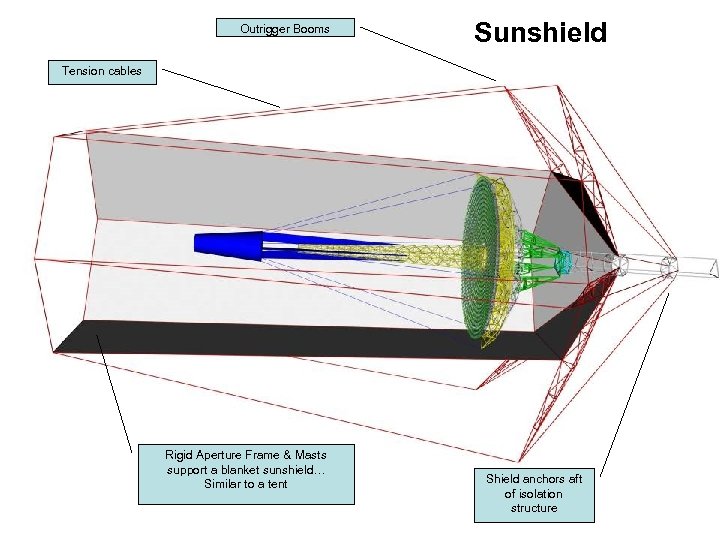

Outrigger Booms Sunshield Tension cables Rigid Aperture Frame & Masts support a blanket sunshield… Similar to a tent Shield anchors aft of isolation structure

Outrigger Booms Sunshield Tension cables Rigid Aperture Frame & Masts support a blanket sunshield… Similar to a tent Shield anchors aft of isolation structure

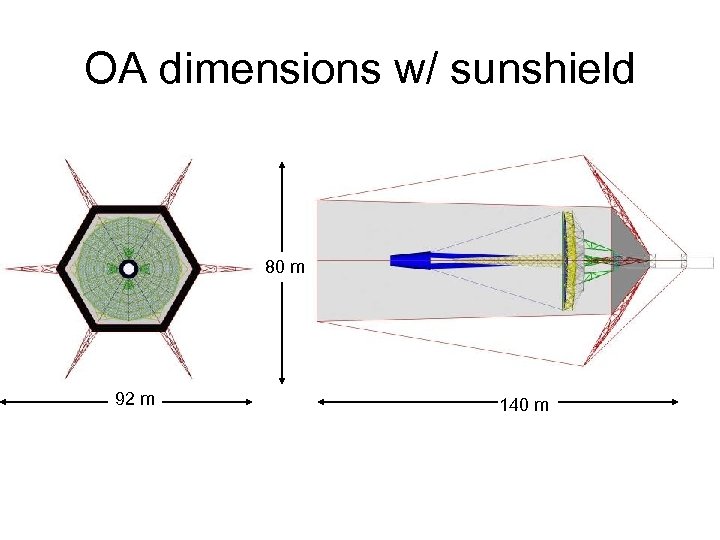

OA dimensions w/ sunshield 80 m 92 m 140 m

OA dimensions w/ sunshield 80 m 92 m 140 m

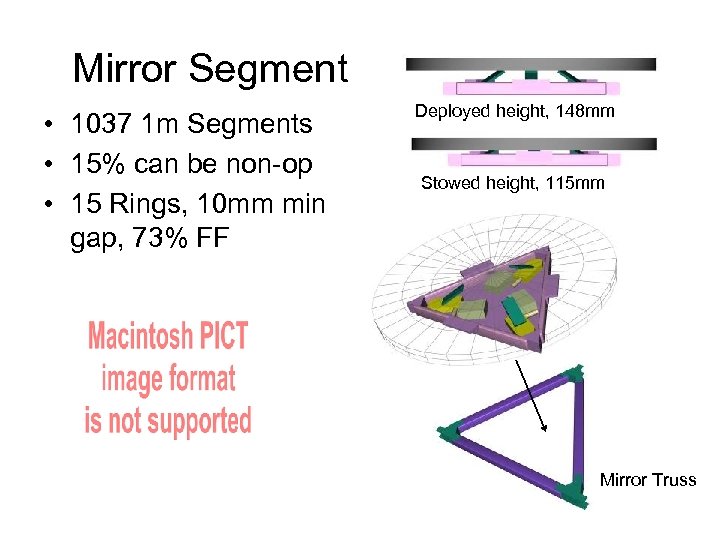

Mirror Segment • 1037 1 m Segments • 15% can be non-op • 15 Rings, 10 mm min gap, 73% FF Deployed height, 148 mm Stowed height, 115 mm Mirror Truss

Mirror Segment • 1037 1 m Segments • 15% can be non-op • 15 Rings, 10 mm min gap, 73% FF Deployed height, 148 mm Stowed height, 115 mm Mirror Truss

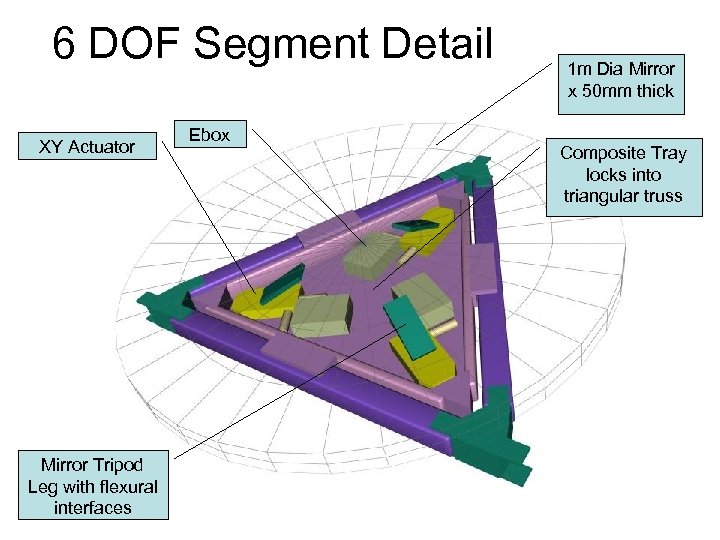

6 DOF Segment Detail XY Actuator Mirror Tripod Leg with flexural interfaces Ebox 1 m Dia Mirror x 50 mm thick Composite Tray locks into triangular truss

6 DOF Segment Detail XY Actuator Mirror Tripod Leg with flexural interfaces Ebox 1 m Dia Mirror x 50 mm thick Composite Tray locks into triangular truss

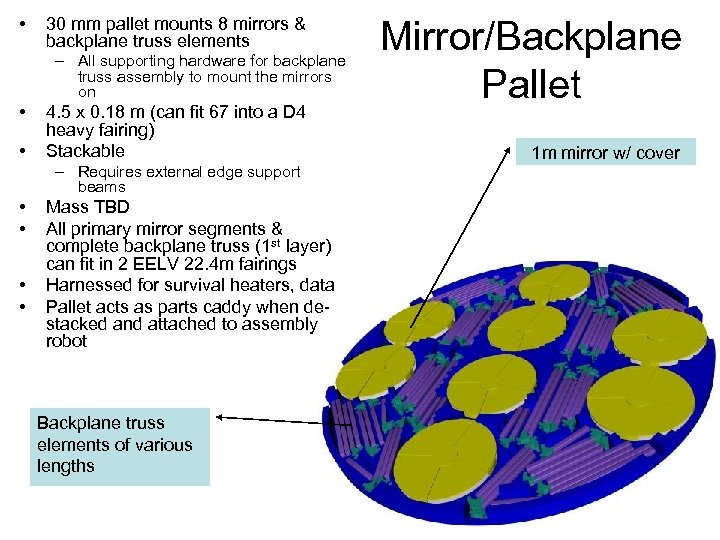

• 30 mm pallet mounts 8 mirrors & backplane truss elements – All supporting hardware for backplane truss assembly to mount the mirrors on • • 4. 5 x 0. 18 m (can fit 67 into a D 4 heavy fairing) Stackable – Requires external edge support beams • • Mass TBD All primary mirror segments & complete backplane truss (1 st layer) can fit in 2 EELV 22. 4 m fairings Harnessed for survival heaters, data Pallet acts as parts caddy when destacked and attached to assembly robot Backplane truss elements of various lengths Mirror/Backplane Pallet 1 m mirror w/ cover

• 30 mm pallet mounts 8 mirrors & backplane truss elements – All supporting hardware for backplane truss assembly to mount the mirrors on • • 4. 5 x 0. 18 m (can fit 67 into a D 4 heavy fairing) Stackable – Requires external edge support beams • • Mass TBD All primary mirror segments & complete backplane truss (1 st layer) can fit in 2 EELV 22. 4 m fairings Harnessed for survival heaters, data Pallet acts as parts caddy when destacked and attached to assembly robot Backplane truss elements of various lengths Mirror/Backplane Pallet 1 m mirror w/ cover

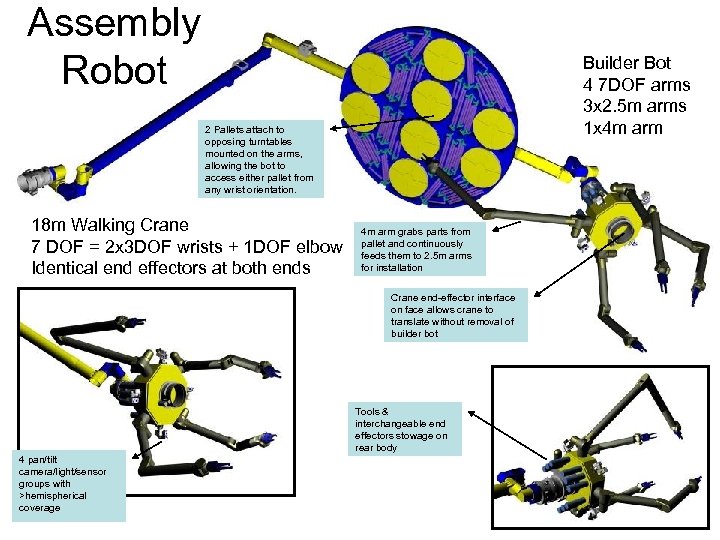

Assembly Robot Builder Bot 4 7 DOF arms 3 x 2. 5 m arms 1 x 4 m arm 2 Pallets attach to opposing turntables mounted on the arms, allowing the bot to access either pallet from any wrist orientation. 18 m Walking Crane 7 DOF = 2 x 3 DOF wrists + 1 DOF elbow Identical end effectors at both ends 4 m arm grabs parts from pallet and continuously feeds them to 2. 5 m arms for installation Crane end-effector interface on face allows crane to translate without removal of builder bot Tools & interchangeable end effectors stowage on rear body 4 pan/tilt camera/light/sensor groups with >hemispherical coverage

Assembly Robot Builder Bot 4 7 DOF arms 3 x 2. 5 m arms 1 x 4 m arm 2 Pallets attach to opposing turntables mounted on the arms, allowing the bot to access either pallet from any wrist orientation. 18 m Walking Crane 7 DOF = 2 x 3 DOF wrists + 1 DOF elbow Identical end effectors at both ends 4 m arm grabs parts from pallet and continuously feeds them to 2. 5 m arms for installation Crane end-effector interface on face allows crane to translate without removal of builder bot Tools & interchangeable end effectors stowage on rear body 4 pan/tilt camera/light/sensor groups with >hemispherical coverage

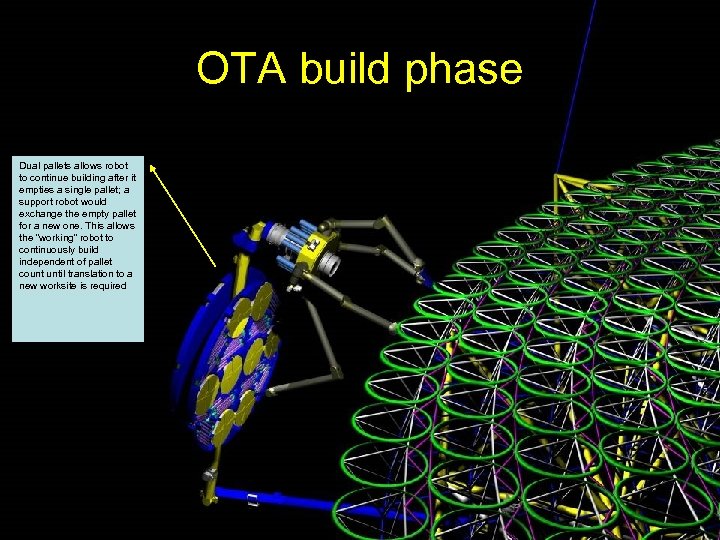

OTA build phase Dual pallets allows robot to continue building after it empties a single pallet; a support robot would exchange the empty pallet for a new one. This allows the “working” robot to continuously build independent of pallet count until translation to a new worksite is required

OTA build phase Dual pallets allows robot to continue building after it empties a single pallet; a support robot would exchange the empty pallet for a new one. This allows the “working” robot to continuously build independent of pallet count until translation to a new worksite is required

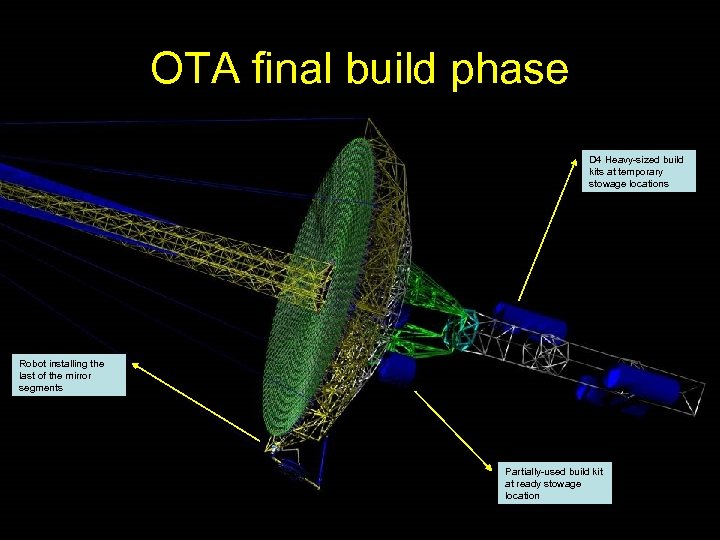

OTA final build phase D 4 Heavy-sized build kits at temporary stowage locations Robot installing the last of the mirror segments Partially-used build kit at ready stowage location

OTA final build phase D 4 Heavy-sized build kits at temporary stowage locations Robot installing the last of the mirror segments Partially-used build kit at ready stowage location

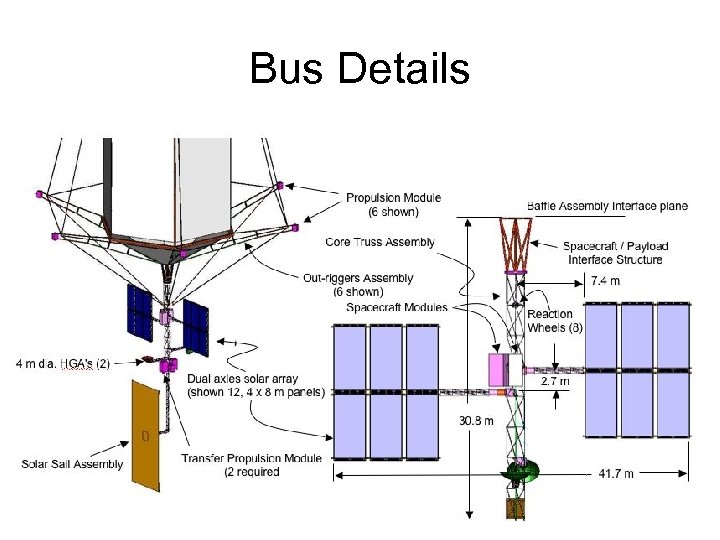

Bus Details

Bus Details

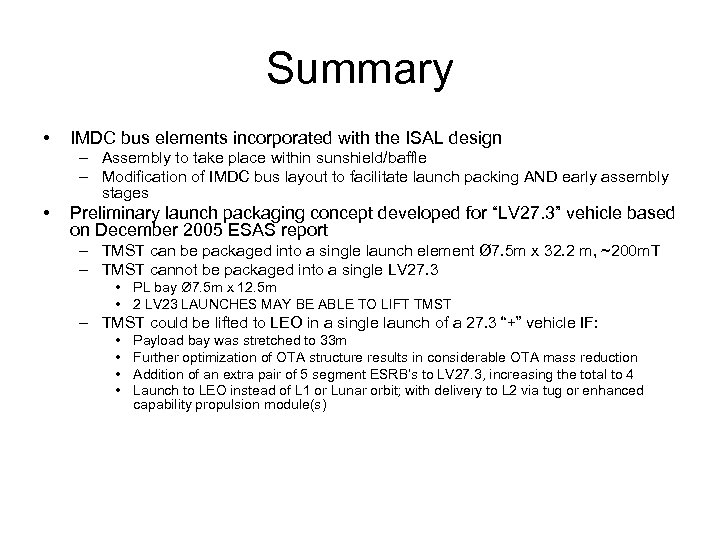

Summary • IMDC bus elements incorporated with the ISAL design – Assembly to take place within sunshield/baffle – Modification of IMDC bus layout to facilitate launch packing AND early assembly stages • Preliminary launch packaging concept developed for “LV 27. 3” vehicle based on December 2005 ESAS report – TMST can be packaged into a single launch element Ø 7. 5 m x 32. 2 m, ~200 m. T – TMST cannot be packaged into a single LV 27. 3 • PL bay Ø 7. 5 m x 12. 5 m • 2 LV 23 LAUNCHES MAY BE ABLE TO LIFT TMST – TMST could be lifted to LEO in a single launch of a 27. 3 “+” vehicle IF: • • Payload bay was stretched to 33 m Further optimization of OTA structure results in considerable OTA mass reduction Addition of an extra pair of 5 segment ESRB’s to LV 27. 3, increasing the total to 4 Launch to LEO instead of L 1 or Lunar orbit; with delivery to L 2 via tug or enhanced capability propulsion module(s)

Summary • IMDC bus elements incorporated with the ISAL design – Assembly to take place within sunshield/baffle – Modification of IMDC bus layout to facilitate launch packing AND early assembly stages • Preliminary launch packaging concept developed for “LV 27. 3” vehicle based on December 2005 ESAS report – TMST can be packaged into a single launch element Ø 7. 5 m x 32. 2 m, ~200 m. T – TMST cannot be packaged into a single LV 27. 3 • PL bay Ø 7. 5 m x 12. 5 m • 2 LV 23 LAUNCHES MAY BE ABLE TO LIFT TMST – TMST could be lifted to LEO in a single launch of a 27. 3 “+” vehicle IF: • • Payload bay was stretched to 33 m Further optimization of OTA structure results in considerable OTA mass reduction Addition of an extra pair of 5 segment ESRB’s to LV 27. 3, increasing the total to 4 Launch to LEO instead of L 1 or Lunar orbit; with delivery to L 2 via tug or enhanced capability propulsion module(s)

POST-IDC Concept • VSE ESAS LV 27. 3+ class packaging • “All-up” single launch in stretched fairing

POST-IDC Concept • VSE ESAS LV 27. 3+ class packaging • “All-up” single launch in stretched fairing

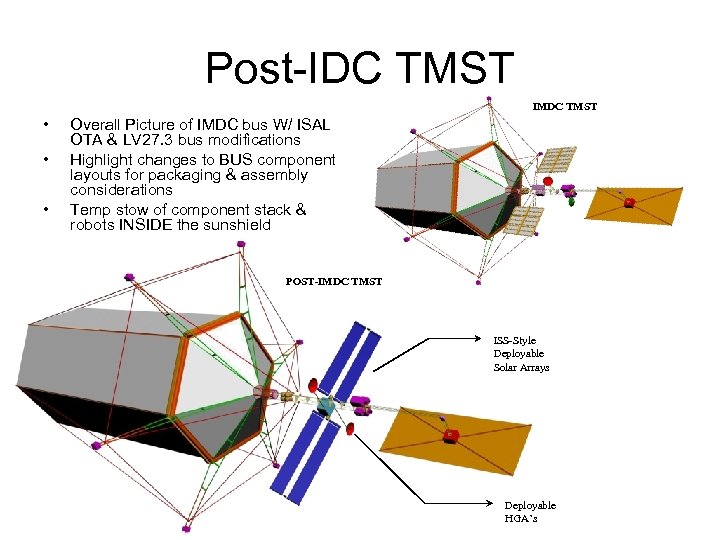

Post-IDC TMST IMDC TMST • • • Overall Picture of IMDC bus W/ ISAL OTA & LV 27. 3 bus modifications Highlight changes to BUS component layouts for packaging & assembly considerations Temp stow of component stack & robots INSIDE the sunshield POST-IMDC TMST ISS-Style Deployable Solar Arrays Deployable HGA’s

Post-IDC TMST IMDC TMST • • • Overall Picture of IMDC bus W/ ISAL OTA & LV 27. 3 bus modifications Highlight changes to BUS component layouts for packaging & assembly considerations Temp stow of component stack & robots INSIDE the sunshield POST-IMDC TMST ISS-Style Deployable Solar Arrays Deployable HGA’s

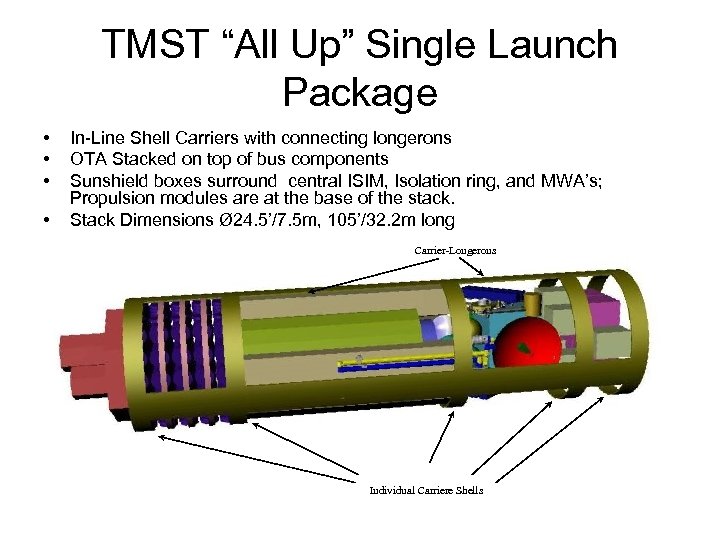

TMST “All Up” Single Launch Package • • In-Line Shell Carriers with connecting longerons OTA Stacked on top of bus components Sunshield boxes surround central ISIM, Isolation ring, and MWA’s; Propulsion modules are at the base of the stack. Stack Dimensions Ø 24. 5’/7. 5 m, 105’/32. 2 m long Carrier-Longerons Individual Carriere Shells

TMST “All Up” Single Launch Package • • In-Line Shell Carriers with connecting longerons OTA Stacked on top of bus components Sunshield boxes surround central ISIM, Isolation ring, and MWA’s; Propulsion modules are at the base of the stack. Stack Dimensions Ø 24. 5’/7. 5 m, 105’/32. 2 m long Carrier-Longerons Individual Carriere Shells

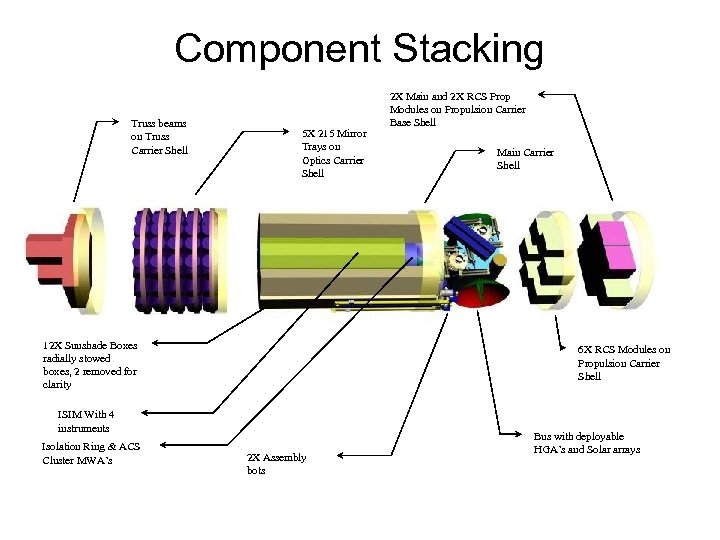

Component Stacking Truss beams on Truss Carrier Shell 5 X 215 Mirror Trays on Optics Carrier Shell 12 X Sunshade Boxes radially stowed boxes, 2 removed for clarity Main Carrier Shell 6 X RCS Modules on Propulsion Carrier Shell ISIM With 4 instruments Isolation Ring & ACS Cluster MWA’s 2 X Main and 2 X RCS Prop Modules on Propulsion Carrier Base Shell 2 X Assembly bots Bus with deployable HGA’s and Solar arrays

Component Stacking Truss beams on Truss Carrier Shell 5 X 215 Mirror Trays on Optics Carrier Shell 12 X Sunshade Boxes radially stowed boxes, 2 removed for clarity Main Carrier Shell 6 X RCS Modules on Propulsion Carrier Shell ISIM With 4 instruments Isolation Ring & ACS Cluster MWA’s 2 X Main and 2 X RCS Prop Modules on Propulsion Carrier Base Shell 2 X Assembly bots Bus with deployable HGA’s and Solar arrays

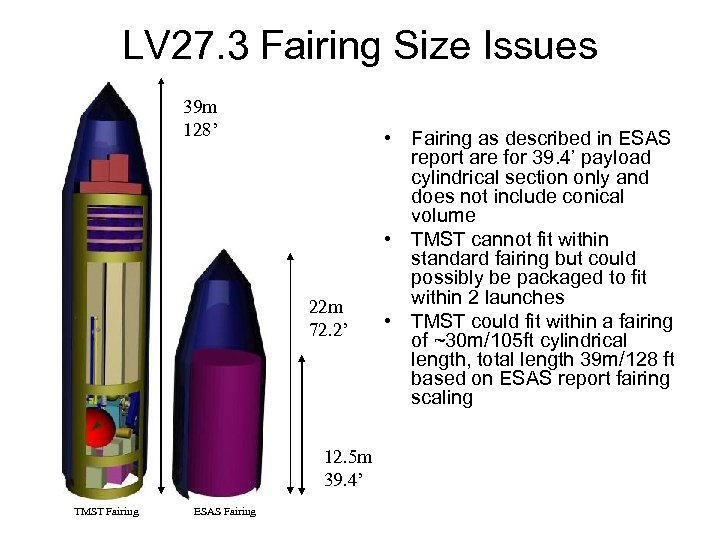

LV 27. 3 Fairing Size Issues 39 m 128’ 22 m 72. 2’ 12. 5 m 39. 4’ TMST Fairing ESAS Fairing • Fairing as described in ESAS report are for 39. 4’ payload cylindrical section only and does not include conical volume • TMST cannot fit within standard fairing but could possibly be packaged to fit within 2 launches • TMST could fit within a fairing of ~30 m/105 ft cylindrical length, total length 39 m/128 ft based on ESAS report fairing scaling

LV 27. 3 Fairing Size Issues 39 m 128’ 22 m 72. 2’ 12. 5 m 39. 4’ TMST Fairing ESAS Fairing • Fairing as described in ESAS report are for 39. 4’ payload cylindrical section only and does not include conical volume • TMST cannot fit within standard fairing but could possibly be packaged to fit within 2 launches • TMST could fit within a fairing of ~30 m/105 ft cylindrical length, total length 39 m/128 ft based on ESAS report fairing scaling

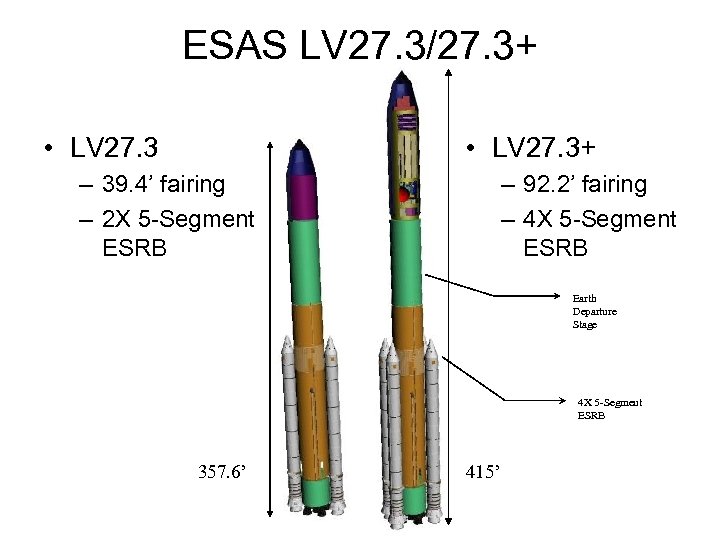

ESAS LV 27. 3/27. 3+ • LV 27. 3+ – 39. 4’ fairing – 2 X 5 -Segment ESRB – 92. 2’ fairing – 4 X 5 -Segment ESRB Earth Departure Stage 4 X 5 -Segment ESRB 357. 6’ 415’

ESAS LV 27. 3/27. 3+ • LV 27. 3+ – 39. 4’ fairing – 2 X 5 -Segment ESRB – 92. 2’ fairing – 4 X 5 -Segment ESRB Earth Departure Stage 4 X 5 -Segment ESRB 357. 6’ 415’

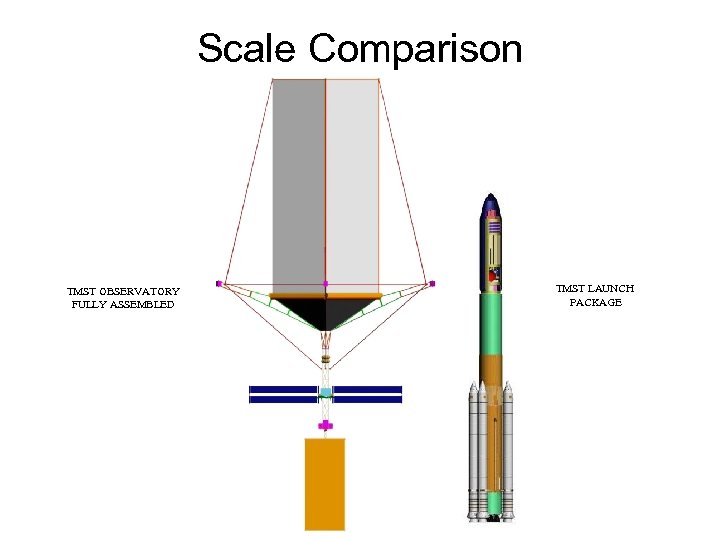

Scale Comparison TMST OBSERVATORY FULLY ASSEMBLED TMST LAUNCH PACKAGE

Scale Comparison TMST OBSERVATORY FULLY ASSEMBLED TMST LAUNCH PACKAGE

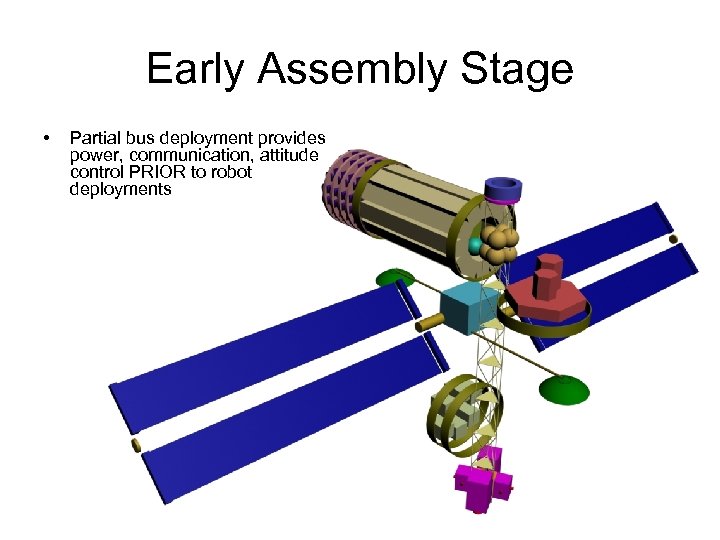

Early Assembly Stage • Partial bus deployment provides power, communication, attitude control PRIOR to robot deployments

Early Assembly Stage • Partial bus deployment provides power, communication, attitude control PRIOR to robot deployments

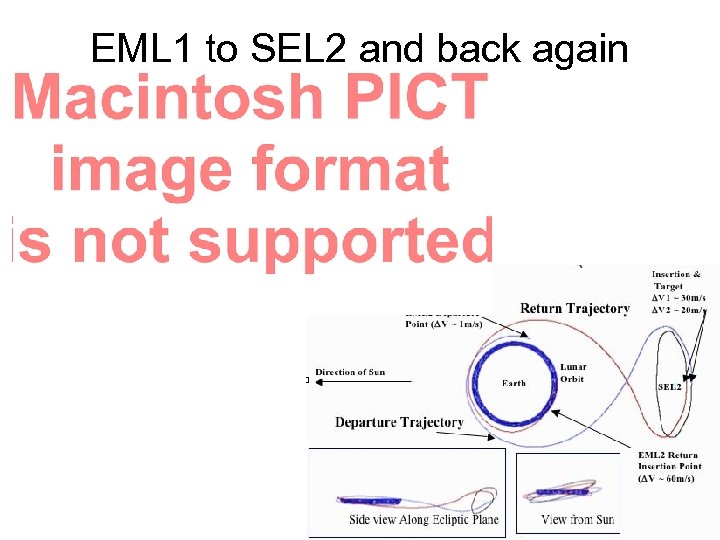

EML 1 to SEL 2 and back again

EML 1 to SEL 2 and back again

SPIE Concept • ESAS LV 27. 2 packaging • No special modifications

SPIE Concept • ESAS LV 27. 2 packaging • No special modifications

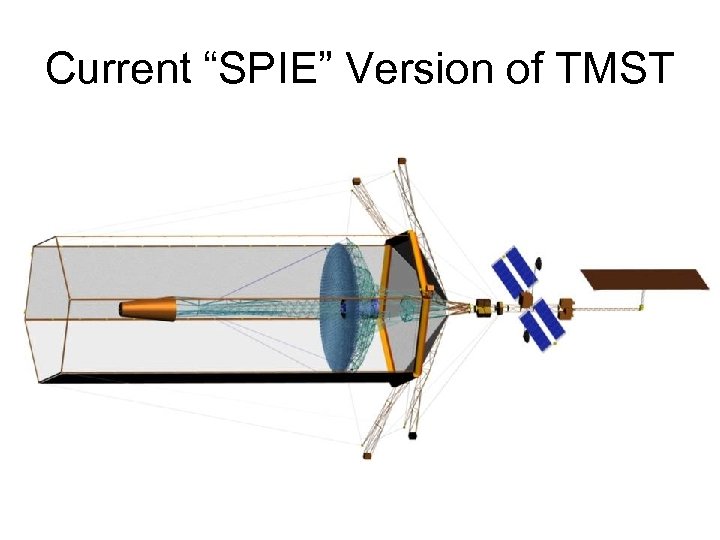

Current “SPIE” Version of TMST

Current “SPIE” Version of TMST

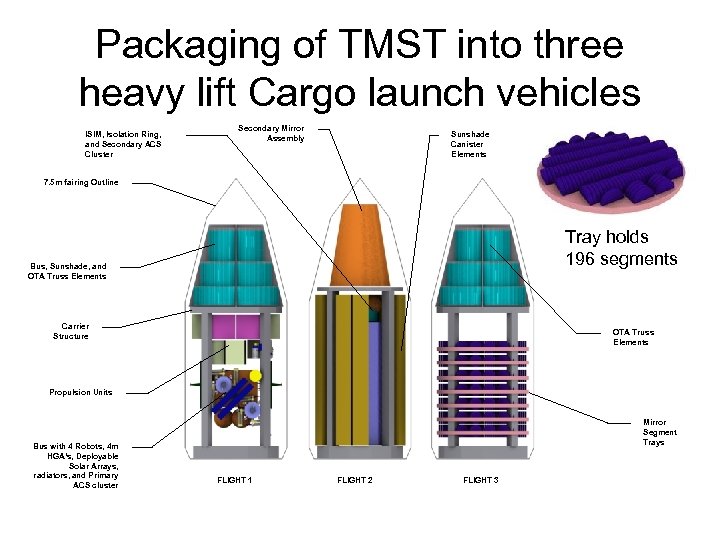

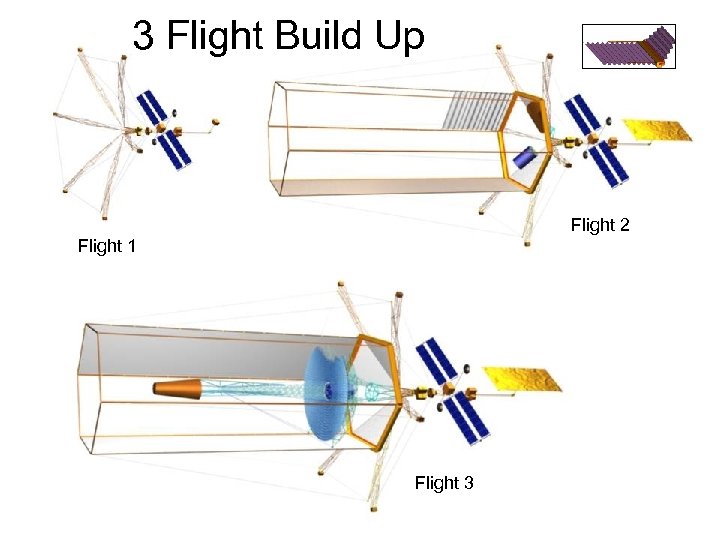

Packaging of TMST into three heavy lift Cargo launch vehicles ISIM, Isolation Ring, and Secondary ACS Cluster Secondary Mirror Assembly Sunshade Canister Elements 7. 5 m fairing Outline Tray holds 196 segments Bus, Sunshade, and OTA Truss Elements Carrier Structure OTA Truss Elements Propulsion Units Bus with 4 Robots, 4 m HGA’s, Deployable Solar Arrays, radiators, and Primary ACS cluster Mirror Segment Trays FLIGHT 1 FLIGHT 2 FLIGHT 3

Packaging of TMST into three heavy lift Cargo launch vehicles ISIM, Isolation Ring, and Secondary ACS Cluster Secondary Mirror Assembly Sunshade Canister Elements 7. 5 m fairing Outline Tray holds 196 segments Bus, Sunshade, and OTA Truss Elements Carrier Structure OTA Truss Elements Propulsion Units Bus with 4 Robots, 4 m HGA’s, Deployable Solar Arrays, radiators, and Primary ACS cluster Mirror Segment Trays FLIGHT 1 FLIGHT 2 FLIGHT 3

3 Flight Build Up Flight 2 Flight 1 Flight 3

3 Flight Build Up Flight 2 Flight 1 Flight 3