ab2571157c6a5fe54f7a2abe5e35e28c.ppt

- Количество слайдов: 23

Thermal Comfort Control Based on Neural Network for HVAC Application Jian Liang and Ruxu Du Dept. of Automation and Computer-Aided Engineering The Chinese University of Hong Kong August 2005 1

Outline q Introduction q Design of thermal comfort Controller q Models of thermal comfort Controller q Design of the Neural Networks controller q Simulation of thermal comfort Controller q Conclusion and further research 2

Introduction q The Heating, Ventilating and Air Conditioning (HVAC) plays an important role in energy consumption Ø In China, it takes 15% of the building energy Ø In United States, it takes 44% q Development of air-conditioning control: Ø First generation: ON / OFF switch based on the sensation of the users Ø Second generation: ON / OFF control assisted by a temperature sensor Ø Third generation, digital control assisted by electronic thermostat, and humidity was also taken into consideration Ø Fourth generation: intelligent control (fuzzy control, adaptive control and etc. ) 3

Introduction q Background Ø Most of the HVAC systems still adopt the temperature / humidity controllers Ø Thermal comfort control is necessary for higher comfort level Ø Thermal comfort indices Ø Standard Effective Temperature (SET) (Gagge, 1971) Ø Predicted Mean Vote (PMV) (Fanger, 1970): predict the mean thermal sensation vote on a standard scale for a large group of persons Ø PMV have been adopted by ISO 7730 standard, and ISO recommends to maintain PMV at 0 with a tolerance of 0. 5 as the best thermal comfort Ø Thermal comfort concept: for long exposure to a constant thermal environment with a constant metabolic rate, a heat balance can be established for the human body and the bodily heat production is equal to its heat dissipation 4

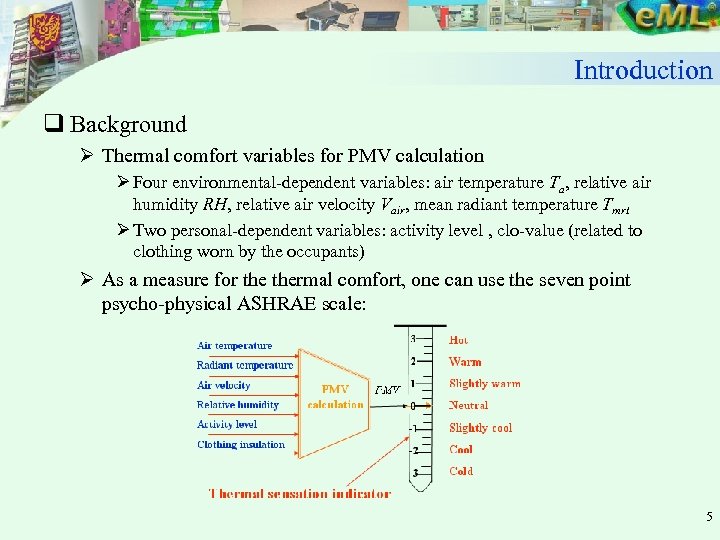

Introduction q Background Ø Thermal comfort variables for PMV calculation Ø Four environmental-dependent variables: air temperature Ta, relative air humidity RH, relative air velocity Vair, mean radiant temperature Tmrt Ø Two personal-dependent variables: activity level , clo-value (related to clothing worn by the occupants) Ø As a measure for thermal comfort, one can use the seven point psycho-physical ASHRAE scale: 5

Introduction q Air conditioning controller Ø Most of the AC controllers are air temperature regulator (ATR) These regulators control the indoor temperature / humidity. Since comfort level is determined by six variables, thus these regulators can’t provide high comfort level Ø Comfort index regulators were proposed (CIR) (Mac. Arthur, 1986; Scheatzle, 1991) These regulators are based on PMV / SET. The default reference input is 0 (neutral). Occupant serves as a supervisory controller by adjusting the reference value Ø User-adaptable comfort controller (UACC) (Federspiel and Asada, 1994 ) These controllers are based on a simplified PMV-like index proposed by Federspiel. It can tune the PMV model parameters by learning the specific occupant’s thermal sensation. Ø Some thermal comfort sensing systems were designed (J. Kang and S. Park, 2000) 6

Introduction q Our objective: design an intelligent thermal comfort controller based on neural networks for HVAC application Ø High comfort level Learn the comfort zone from the user’s preference, and guarantee the high comfort level and good dynamic performance Ø Energy saving Combine thermal comfort control with a energy saving strategy Ø Air quality control Provide variable air volume (VAV) control, and adjust the fresh air and return air mix ratio to guarantee the required fresh air 7

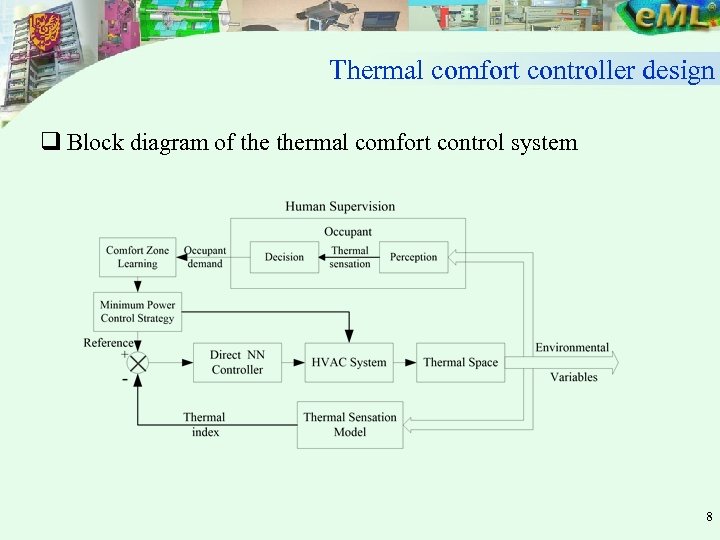

Thermal comfort controller design q Block diagram of thermal comfort control system 8

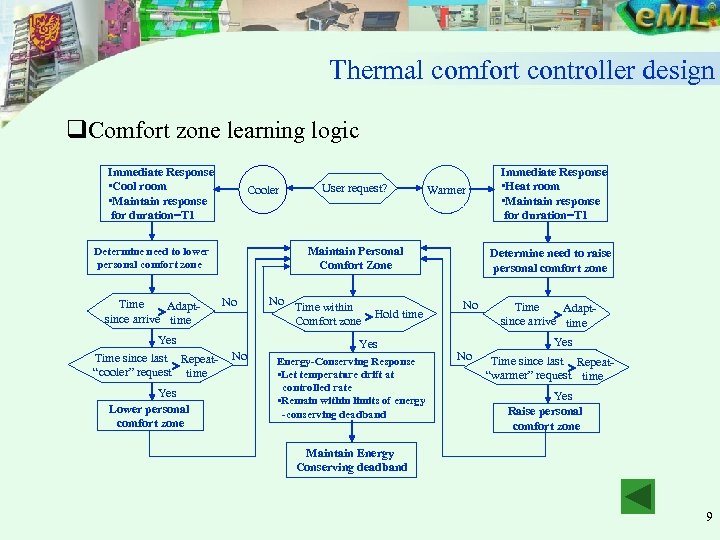

Thermal comfort controller design q. Comfort zone learning logic Immediate Response • Cool room • Maintain response for duration=T 1 Cooler No Yes Time since last Repeat“cooler” request> time Yes Lower personal comfort zone Warmer Maintain Personal Comfort Zone Determine need to lower personal comfort zone Time Adapt> since arrive time User request? No No Time within Hold time Comfort zone > Yes Energy-Conserving Response • Let temperature drift at controlled rate • Remain within limits of energy -conserving deadband Immediate Response • Heat room • Maintain response for duration=T 1 Determine need to raise personal comfort zone No Time Adapt> since arrive time Yes No Time since last Repeat> “warmer” request time Yes Raise personal comfort zone Maintain Energy Conserving deadband 9

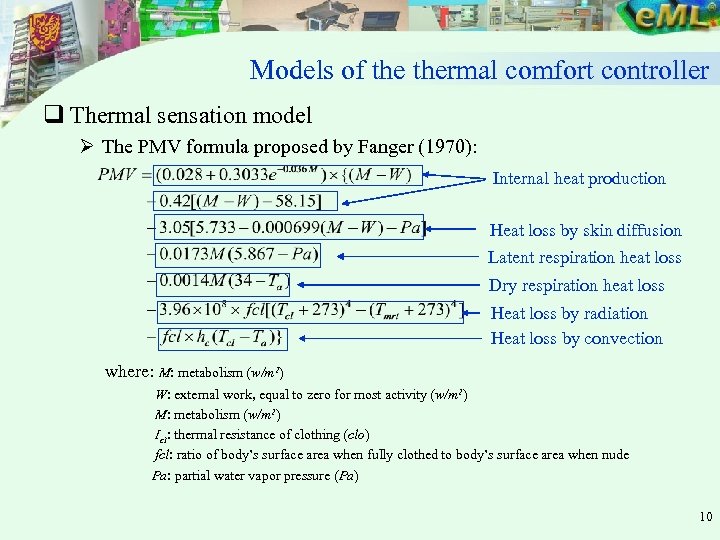

Models of thermal comfort controller q Thermal sensation model Ø The PMV formula proposed by Fanger (1970): Internal heat production Heat loss by skin diffusion Latent respiration heat loss Dry respiration heat loss Heat loss by radiation Heat loss by convection where: M: metabolism (w/m 2) W: external work, equal to zero for most activity (w/m 2) M: metabolism (w/m 2) Icl: thermal resistance of clothing (clo) fcl: ratio of body’s surface area when fully clothed to body’s surface area when nude Pa: partial water vapor pressure (Pa) 10

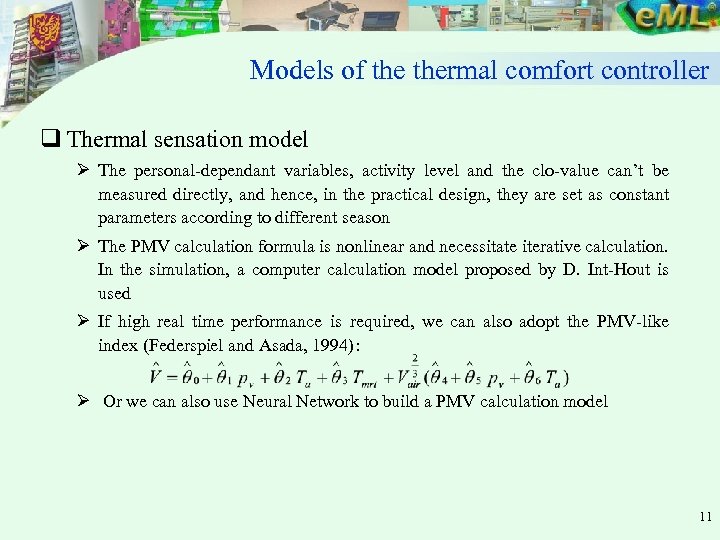

Models of thermal comfort controller q Thermal sensation model Ø The personal-dependant variables, activity level and the clo-value can’t be measured directly, and hence, in the practical design, they are set as constant parameters according to different season Ø The PMV calculation formula is nonlinear and necessitate iterative calculation. In the simulation, a computer calculation model proposed by D. Int-Hout is used Ø If high real time performance is required, we can also adopt the PMV-like index (Federspiel and Asada, 1994): Ø Or we can also use Neural Network to build a PMV calculation model 11

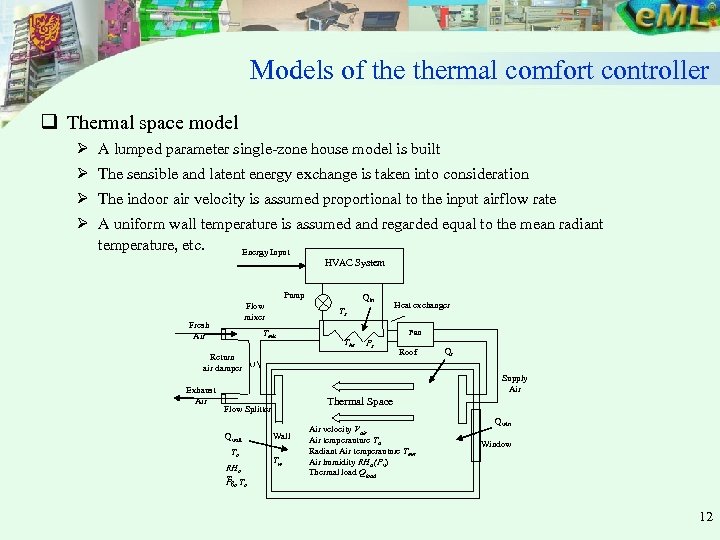

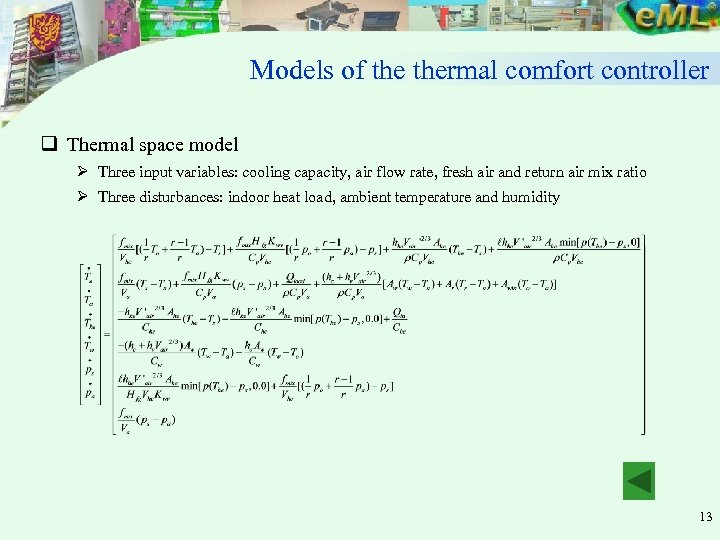

Models of thermal comfort controller q Thermal space model Ø A lumped parameter single-zone house model is built Ø The sensible and latent energy exchange is taken into consideration Ø The indoor air velocity is assumed proportional to the input airflow rate Ø A uniform wall temperature is assumed and regarded equal to the mean radiant temperature, etc. Energy Input HVAC System Pump Flow mixer Fresh Air Qin Ts Tmix Fan The Ps Return air damper Exhaust Air Heat exchanger Roof Qr Supply Air Thermal Space Flow Splitter Qwall Wall To RHo To T P vo Tw Air velocity Vair Air temperauture Ta Radiant Air temperauture Tmrt Air humidity RHa (Pv) Thermal load Qwin Window o 12

Models of thermal comfort controller q Thermal space model Ø Three input variables: cooling capacity, air flow rate, fresh air and return air mix ratio Ø Three disturbances: indoor heat load, ambient temperature and humidity 13

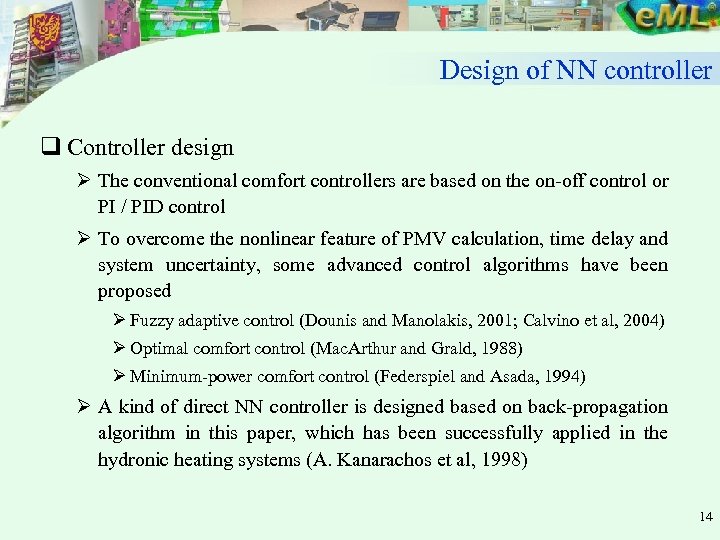

Design of NN controller q Controller design Ø The conventional comfort controllers are based on the on-off control or PI / PID control Ø To overcome the nonlinear feature of PMV calculation, time delay and system uncertainty, some advanced control algorithms have been proposed Ø Fuzzy adaptive control (Dounis and Manolakis, 2001; Calvino et al, 2004) Ø Optimal comfort control (Mac. Arthur and Grald, 1988) Ø Minimum-power comfort control (Federspiel and Asada, 1994) Ø A kind of direct NN controller is designed based on back-propagation algorithm in this paper, which has been successfully applied in the hydronic heating systems (A. Kanarachos et al, 1998) 14

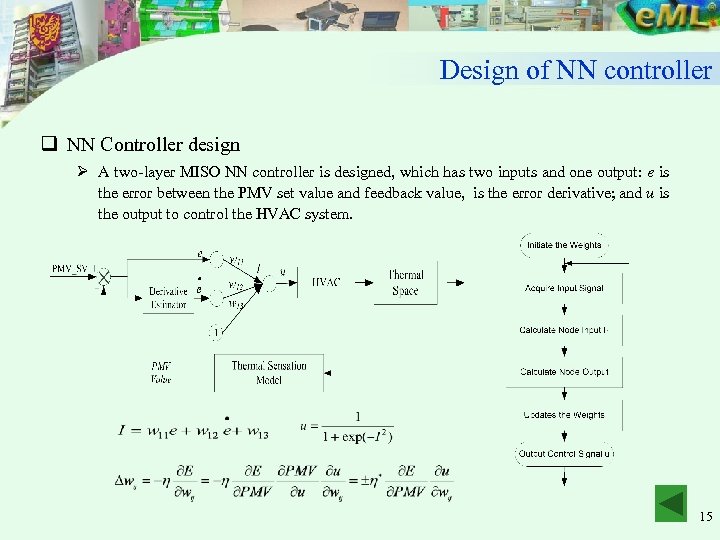

Design of NN controller q NN Controller design Ø A two-layer MISO NN controller is designed, which has two inputs and one output: e is the error between the PMV set value and feedback value, is the error derivative; and u is the output to control the HVAC system. 15

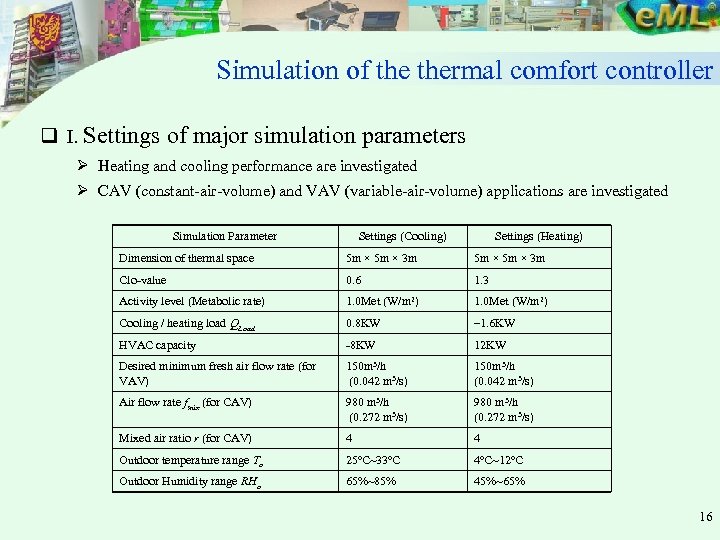

Simulation of thermal comfort controller q I. Settings of major simulation parameters Ø Heating and cooling performance are investigated Ø CAV (constant-air-volume) and VAV (variable-air-volume) applications are investigated Simulation Parameter Settings (Cooling) Settings (Heating) Dimension of thermal space 5 m × 3 m Clo-value 0. 6 1. 3 Activity level (Metabolic rate) 1. 0 Met (W/m 2) Cooling / heating load QLoad 0. 8 KW – 1. 6 KW HVAC capacity -8 KW 12 KW Desired minimum fresh air flow rate (for VAV) 150 m 3/h (0. 042 m 3/s) Air flow rate fmix (for CAV) 980 m 3/h (0. 272 m 3/s) Mixed air ratio r (for CAV) 4 4 Outdoor temperature range To 25 o. C~33 o. C 4 o. C~12 o. C Outdoor Humidity range RHo 65%~85% 45%~65% 16

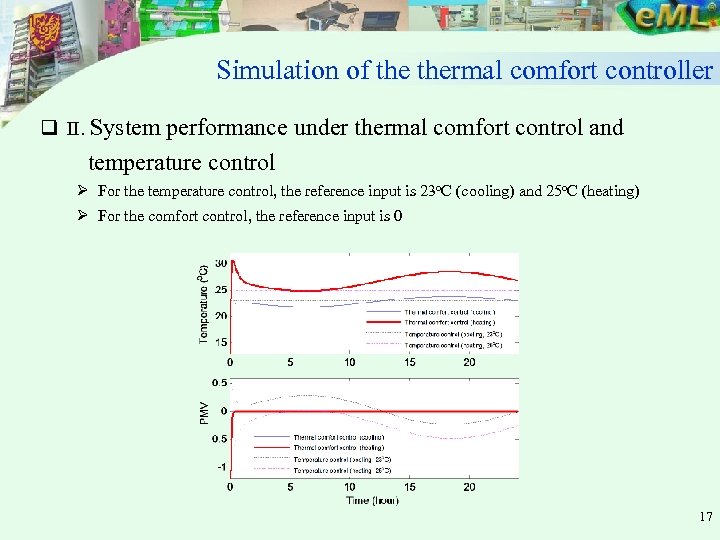

Simulation of thermal comfort controller q II. System performance under thermal comfort control and temperature control Ø For the temperature control, the reference input is 23 o. C (cooling) and 25 o. C (heating) Ø For the comfort control, the reference input is 0 17

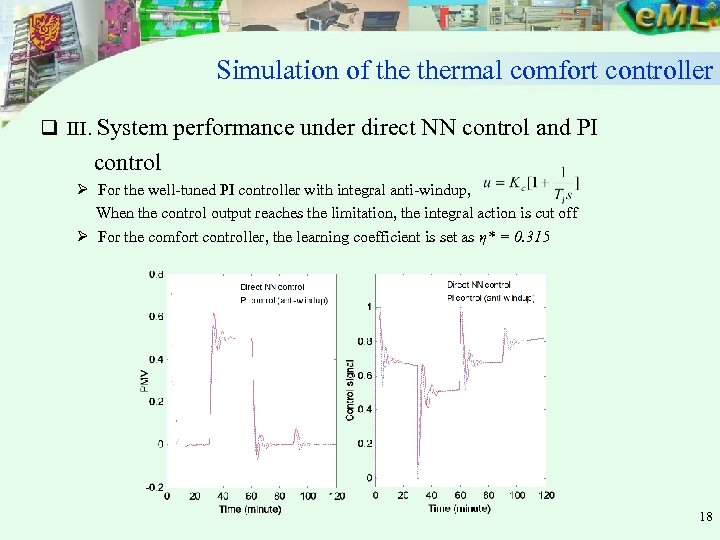

Simulation of thermal comfort controller q III. System performance under direct NN control and PI control Ø For the well-tuned PI controller with integral anti-windup, When the control output reaches the limitation, the integral action is cut off Ø For the comfort controller, the learning coefficient is set as η* = 0. 315 18

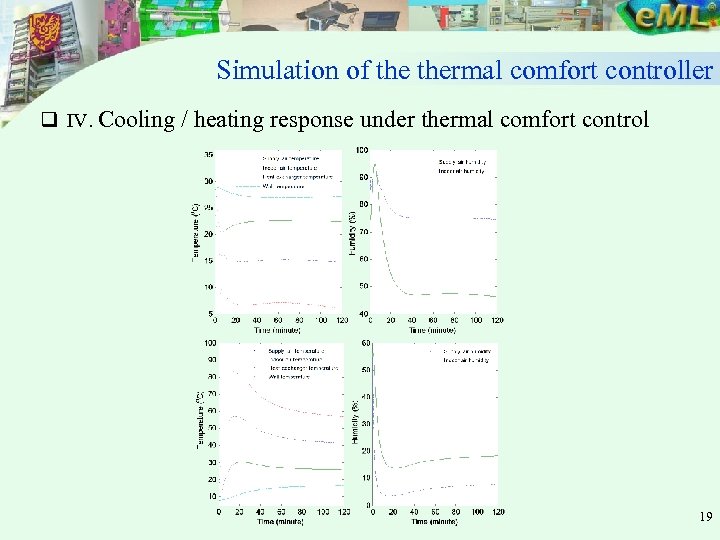

Simulation of thermal comfort controller q IV. Cooling / heating response under thermal comfort control 19

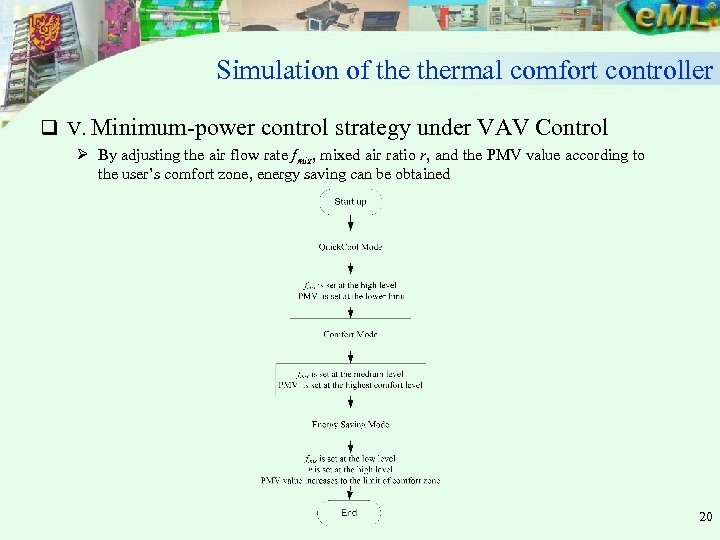

Simulation of thermal comfort controller q V. Minimum-power control strategy under VAV Control Ø By adjusting the air flow rate fmix, mixed air ratio r, and the PMV value according to the user’s comfort zone, energy saving can be obtained 20

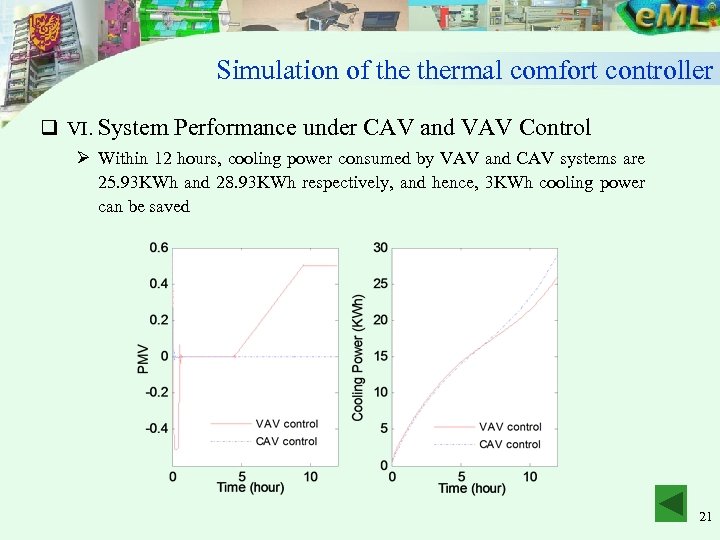

Simulation of thermal comfort controller q VI. System Performance under CAV and VAV Control Ø Within 12 hours, cooling power consumed by VAV and CAV systems are 25. 93 KWh and 28. 93 KWh respectively, and hence, 3 KWh cooling power can be saved 21

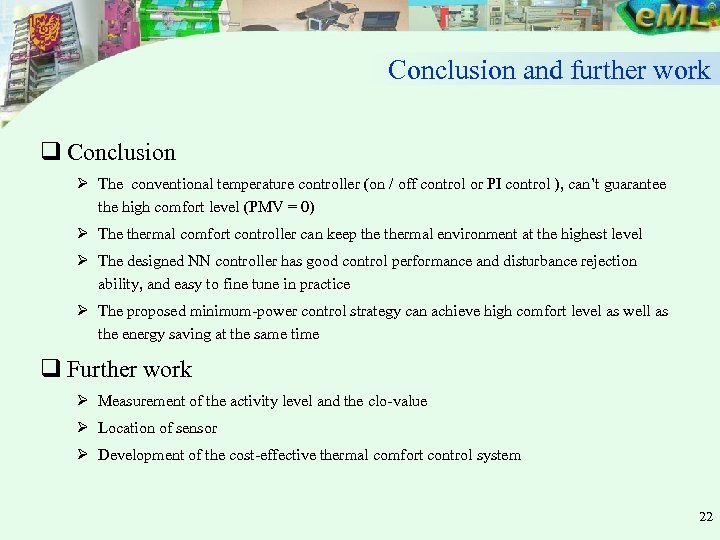

Conclusion and further work q Conclusion Ø The conventional temperature controller (on / off control or PI control ), can’t guarantee the high comfort level (PMV = 0) Ø The thermal comfort controller can keep thermal environment at the highest level Ø The designed NN controller has good control performance and disturbance rejection ability, and easy to fine tune in practice Ø The proposed minimum-power control strategy can achieve high comfort level as well as the energy saving at the same time q Further work Ø Measurement of the activity level and the clo-value Ø Location of sensor Ø Development of the cost-effective thermal comfort control system 22

23

ab2571157c6a5fe54f7a2abe5e35e28c.ppt