5fb128147c4f202064496d5b8f7f670b.ppt

- Количество слайдов: 39

“The Win – Win Solution to FSP Technology Development” National Science Foundation Industry / University Cooperative Research Center Multi-University I/UCRC Management Tools - A Case Study Mr. William Arbegast (AMP) Dr. Antonette Logar (MCS) Dr. Edward Corwin (MCS) Center for Friction Stir Processing South Dakota School of Mines and Technology January 11, 2008 IUCRC Annual Directors Meeting Washington, DC Page 1

“The Win – Win Solution to FSP Technology Development” National Science Foundation Industry / University Cooperative Research Center Multi-University I/UCRC Management Tools - A Case Study Mr. William Arbegast (AMP) Dr. Antonette Logar (MCS) Dr. Edward Corwin (MCS) Center for Friction Stir Processing South Dakota School of Mines and Technology January 11, 2008 IUCRC Annual Directors Meeting Washington, DC Page 1

Draft of the “Book” can be found at http: //ampcenter. sdsmt. edu CFSP IUCRC Management Tools Page 2

Draft of the “Book” can be found at http: //ampcenter. sdsmt. edu CFSP IUCRC Management Tools Page 2

Who is the South Dakota School of Mines? WSU SDSMT is a Small Engineering University Teamed with Larger Academic Institutions under the IUCRC Environment Page 3

Who is the South Dakota School of Mines? WSU SDSMT is a Small Engineering University Teamed with Larger Academic Institutions under the IUCRC Environment Page 3

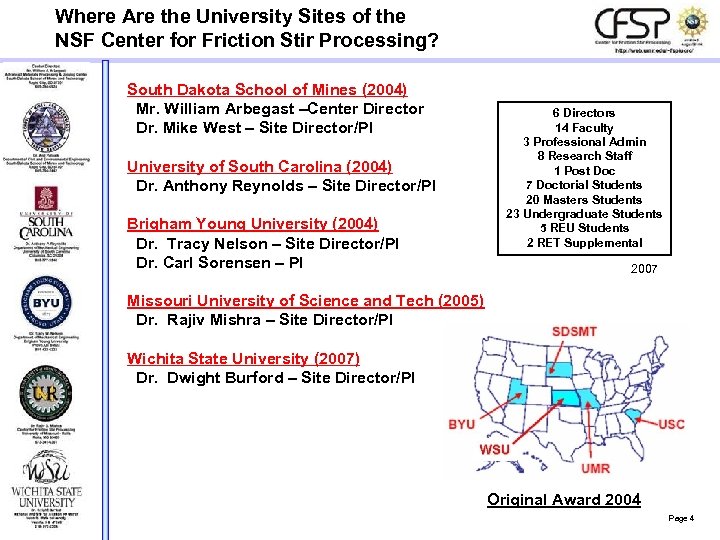

Where Are the University Sites of the NSF Center for Friction Stir Processing? South Dakota School of Mines (2004) Mr. William Arbegast –Center Director Dr. Mike West – Site Director/PI University of South Carolina (2004) Dr. Anthony Reynolds – Site Director/PI Brigham Young University (2004) Dr. Tracy Nelson – Site Director/PI Dr. Carl Sorensen – PI 6 Directors 14 Faculty 3 Professional Admin 8 Research Staff 1 Post Doc 7 Doctorial Students 20 Masters Students 23 Undergraduate Students 5 REU Students 2 RET Supplemental 2007 Missouri University of Science and Tech (2005) Dr. Rajiv Mishra – Site Director/PI Wichita State University (2007) Dr. Dwight Burford – Site Director/PI Original Award 2004 Page 4

Where Are the University Sites of the NSF Center for Friction Stir Processing? South Dakota School of Mines (2004) Mr. William Arbegast –Center Director Dr. Mike West – Site Director/PI University of South Carolina (2004) Dr. Anthony Reynolds – Site Director/PI Brigham Young University (2004) Dr. Tracy Nelson – Site Director/PI Dr. Carl Sorensen – PI 6 Directors 14 Faculty 3 Professional Admin 8 Research Staff 1 Post Doc 7 Doctorial Students 20 Masters Students 23 Undergraduate Students 5 REU Students 2 RET Supplemental 2007 Missouri University of Science and Tech (2005) Dr. Rajiv Mishra – Site Director/PI Wichita State University (2007) Dr. Dwight Burford – Site Director/PI Original Award 2004 Page 4

Setting the CFSP Vision and Mission--1. 1 CFSP Vision Statement • The Center for Friction Stir Processing (CFSP) vision is to provide the forum for industry/university cooperative research on the further development, validation, and industrial implementation of the emerging solid-state materials joining and processing technologies known as Friction Stir Welding (FSW) and Friction Stir Processing (FSP). 1. 2 CFSP Mission Statement The Mission of the NSF Center for Friction Stir Processing is: • To advance, develop and promote research into the principles and technology of Friction Stir Processing science and engineering through research, development, education, and technology exchange among academic, industry, and government entities; • To increase the quantity and quality of the professionals prepared to work in the area; • To involve the faculty of the University(s) in research in areas of common interest to Sponsors and the University(s); • To perform research that will allow industrial Friction Stir Processing facilities to be competitive in the world economy Page 5

Setting the CFSP Vision and Mission--1. 1 CFSP Vision Statement • The Center for Friction Stir Processing (CFSP) vision is to provide the forum for industry/university cooperative research on the further development, validation, and industrial implementation of the emerging solid-state materials joining and processing technologies known as Friction Stir Welding (FSW) and Friction Stir Processing (FSP). 1. 2 CFSP Mission Statement The Mission of the NSF Center for Friction Stir Processing is: • To advance, develop and promote research into the principles and technology of Friction Stir Processing science and engineering through research, development, education, and technology exchange among academic, industry, and government entities; • To increase the quantity and quality of the professionals prepared to work in the area; • To involve the faculty of the University(s) in research in areas of common interest to Sponsors and the University(s); • To perform research that will allow industrial Friction Stir Processing facilities to be competitive in the world economy Page 5

Setting the CFSP Research Objectives--1. 3 CFSP Research Objectives The overall objective of the Center is to develop and deliver relevant scientific knowledge that will help its industrial members with future challenges. Center programs are designed to complement the members’ in-house research and development in the area of friction stir processing by bringing together theoretical, experimental and application experts from industry and academia. The specific objectives are focused on the following: • Friction Stir Joining: Process optimization (parameters, pin tool materials, pin tool designs); process modeling (thermal, forces, metal flow, residual stress, distortion, microstructure evolution); microstructural characterizations; property characterizations (tensile, fatigue, fracture, creep, corrosion); nondestructive evaluations; new alloy development. • Friction Stir Microstructural Modification: Induced superplasticity; grain refinement; sub-micron and nano particle injection; defect removal. • Friction Stir Post –Processing: Heat treatment; forming (stretch, spin, age, and creep); machining; finishing. • Friction Stir Structural Designs and Applications: replacement of fusion welds and rivets; static and dynamic response of structures; efficient design and analysis methodologies. • Friction Stir Intelligent Controllers and Efficient Tooling: Process sensors; logicbased controllers; reconfigurable tooling. • Friction Stir Cost Benefits Analysis: Business case development and environmental impact assessments. Page 6

Setting the CFSP Research Objectives--1. 3 CFSP Research Objectives The overall objective of the Center is to develop and deliver relevant scientific knowledge that will help its industrial members with future challenges. Center programs are designed to complement the members’ in-house research and development in the area of friction stir processing by bringing together theoretical, experimental and application experts from industry and academia. The specific objectives are focused on the following: • Friction Stir Joining: Process optimization (parameters, pin tool materials, pin tool designs); process modeling (thermal, forces, metal flow, residual stress, distortion, microstructure evolution); microstructural characterizations; property characterizations (tensile, fatigue, fracture, creep, corrosion); nondestructive evaluations; new alloy development. • Friction Stir Microstructural Modification: Induced superplasticity; grain refinement; sub-micron and nano particle injection; defect removal. • Friction Stir Post –Processing: Heat treatment; forming (stretch, spin, age, and creep); machining; finishing. • Friction Stir Structural Designs and Applications: replacement of fusion welds and rivets; static and dynamic response of structures; efficient design and analysis methodologies. • Friction Stir Intelligent Controllers and Efficient Tooling: Process sensors; logicbased controllers; reconfigurable tooling. • Friction Stir Cost Benefits Analysis: Business case development and environmental impact assessments. Page 6

Setting the CFSP Policies, Procedures and Practices (P 3)-1. 4 CFSP Policies Procedures and Practices (P 3) • Membership Policy • IAB Roles and Responsibilities • Selection of Research Projects • Selection of Project Investigators • Regular Reports Policy • Publications Policy • Patents Policy The Formal CSFP Policies, Procedures and Practices (P 3)are set forth in the Center Membership Agreement and Center Bylaws • Termination of Research Policy http: //ampcenter. sdsmt. edu CFSP IUCRC Members Agreement Bylaws Page 7

Setting the CFSP Policies, Procedures and Practices (P 3)-1. 4 CFSP Policies Procedures and Practices (P 3) • Membership Policy • IAB Roles and Responsibilities • Selection of Research Projects • Selection of Project Investigators • Regular Reports Policy • Publications Policy • Patents Policy The Formal CSFP Policies, Procedures and Practices (P 3)are set forth in the Center Membership Agreement and Center Bylaws • Termination of Research Policy http: //ampcenter. sdsmt. edu CFSP IUCRC Members Agreement Bylaws Page 7

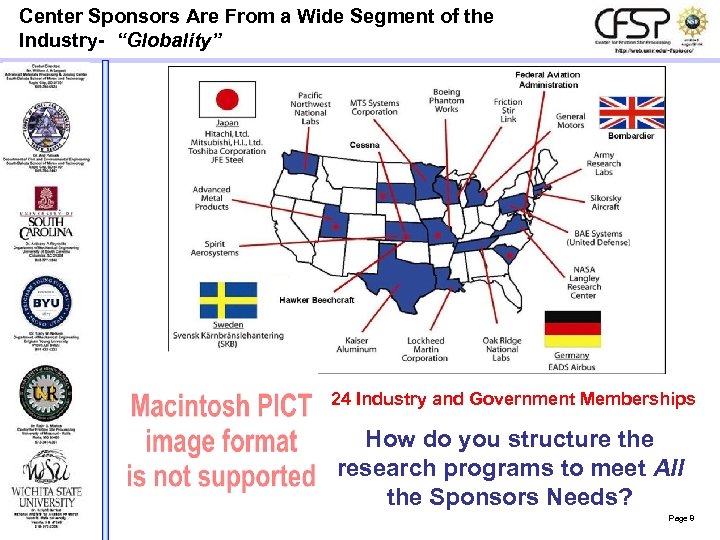

Center Sponsors Are From a Wide Segment of the Industry- “Globality” 24 Industry and Government Memberships How do you structure the research programs to meet All the Sponsors Needs? Page 8

Center Sponsors Are From a Wide Segment of the Industry- “Globality” 24 Industry and Government Memberships How do you structure the research programs to meet All the Sponsors Needs? Page 8

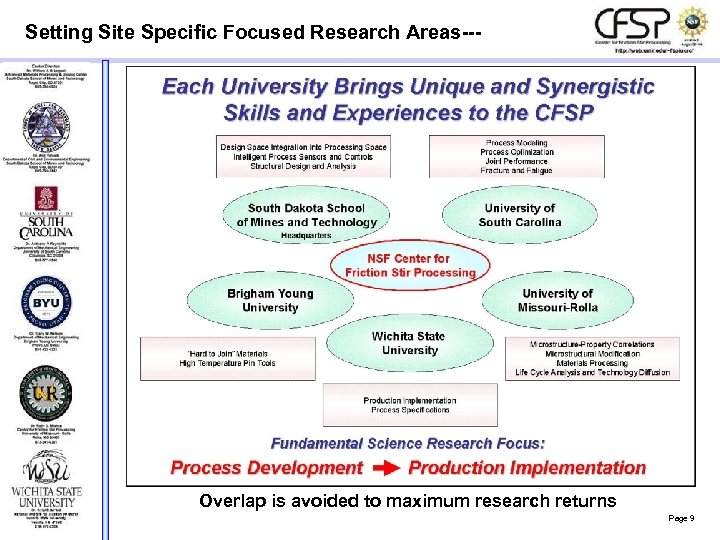

Setting Site Specific Focused Research Areas--- Overlap is avoided to maximum research returns Page 9

Setting Site Specific Focused Research Areas--- Overlap is avoided to maximum research returns Page 9

Setting the Research Needs of the IAB --- Color Coded To Track “SUCCESS” Page 10

Setting the Research Needs of the IAB --- Color Coded To Track “SUCCESS” Page 10

Preparing a Long Term Technology Development Roadmap The Over-Riding Issues are Identified and a Technology Development Roadmap is prepared Page 11

Preparing a Long Term Technology Development Roadmap The Over-Riding Issues are Identified and a Technology Development Roadmap is prepared Page 11

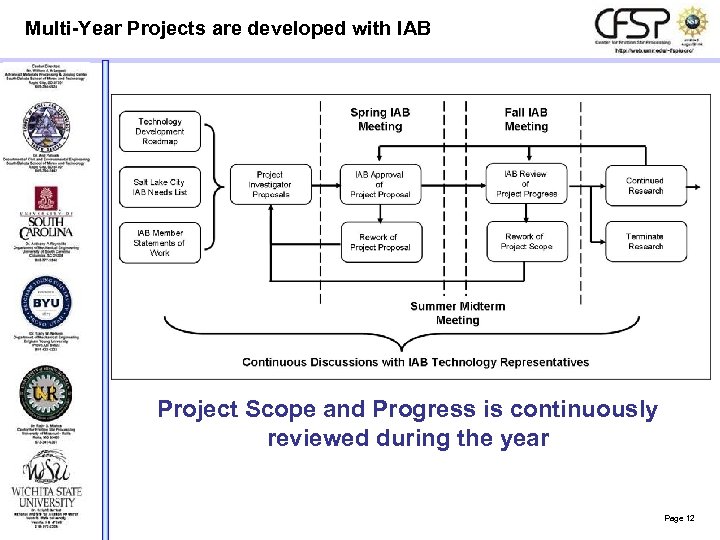

Multi-Year Projects are developed with IAB Project Scope and Progress is continuously reviewed during the year Page 12

Multi-Year Projects are developed with IAB Project Scope and Progress is continuously reviewed during the year Page 12

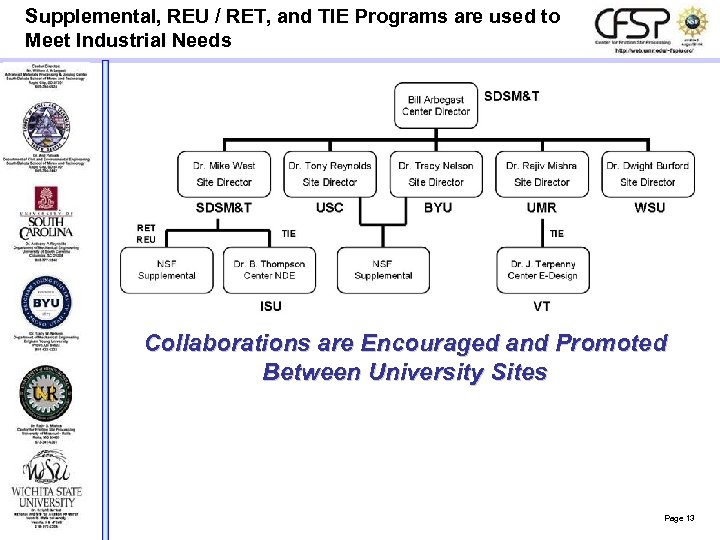

Supplemental, REU / RET, and TIE Programs are used to Meet Industrial Needs Collaborations are Encouraged and Promoted Between University Sites Page 13

Supplemental, REU / RET, and TIE Programs are used to Meet Industrial Needs Collaborations are Encouraged and Promoted Between University Sites Page 13

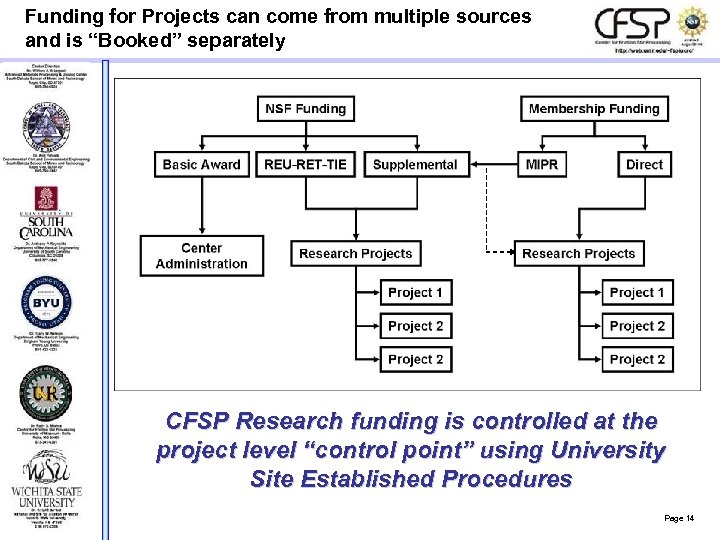

Funding for Projects can come from multiple sources and is “Booked” separately Collaborations are Encouraged and Promoted Between University Sites CFSP Research funding is controlled at the project level “control point” using University Site Established Procedures Page 14

Funding for Projects can come from multiple sources and is “Booked” separately Collaborations are Encouraged and Promoted Between University Sites CFSP Research funding is controlled at the project level “control point” using University Site Established Procedures Page 14

Specific Multi-Year Projects are Identified and added to the Program Master Schedule New Projects are Proposed at the Spring IAB Meeting Authorization to Proceed Obtained at the Fall IAB Meeting Unique Project Numbering System Used to ID Projects Page 15

Specific Multi-Year Projects are Identified and added to the Program Master Schedule New Projects are Proposed at the Spring IAB Meeting Authorization to Proceed Obtained at the Fall IAB Meeting Unique Project Numbering System Used to ID Projects Page 15

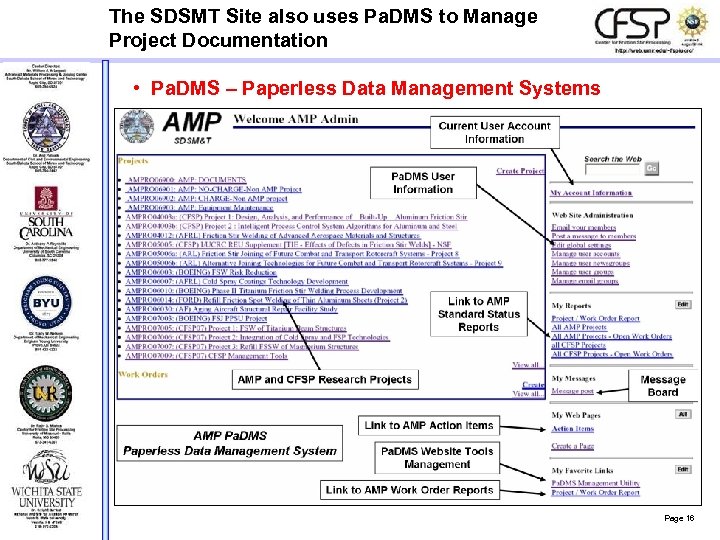

The SDSMT Site also uses Pa. DMS to Manage Project Documentation • Pa. DMS – Paperless Data Management Systems Page 16

The SDSMT Site also uses Pa. DMS to Manage Project Documentation • Pa. DMS – Paperless Data Management Systems Page 16

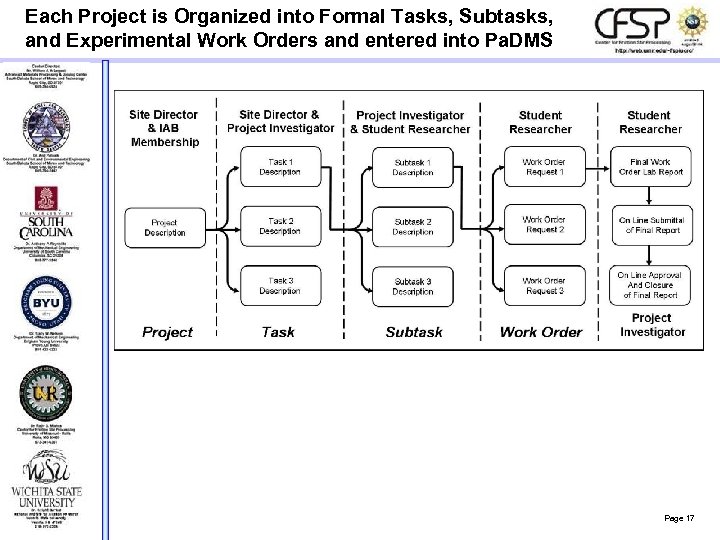

Each Project is Organized into Formal Tasks, Subtasks, and Experimental Work Orders and entered into Pa. DMS Page 17

Each Project is Organized into Formal Tasks, Subtasks, and Experimental Work Orders and entered into Pa. DMS Page 17

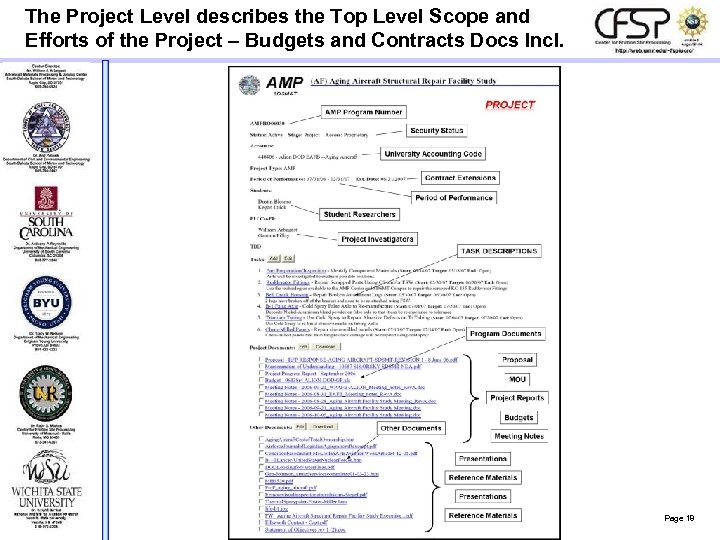

The Project Level describes the Top Level Scope and Efforts of the Project – Budgets and Contracts Docs Incl. Page 18

The Project Level describes the Top Level Scope and Efforts of the Project – Budgets and Contracts Docs Incl. Page 18

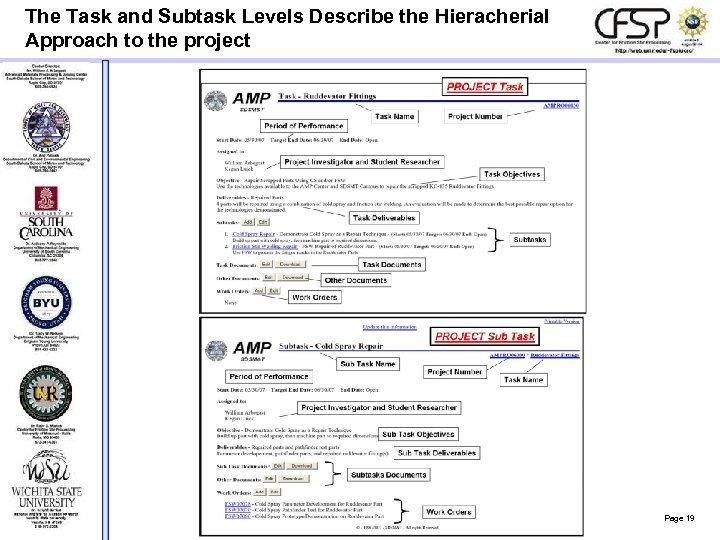

The Task and Subtask Levels Describe the Hieracherial Approach to the project Page 19

The Task and Subtask Levels Describe the Hieracherial Approach to the project Page 19

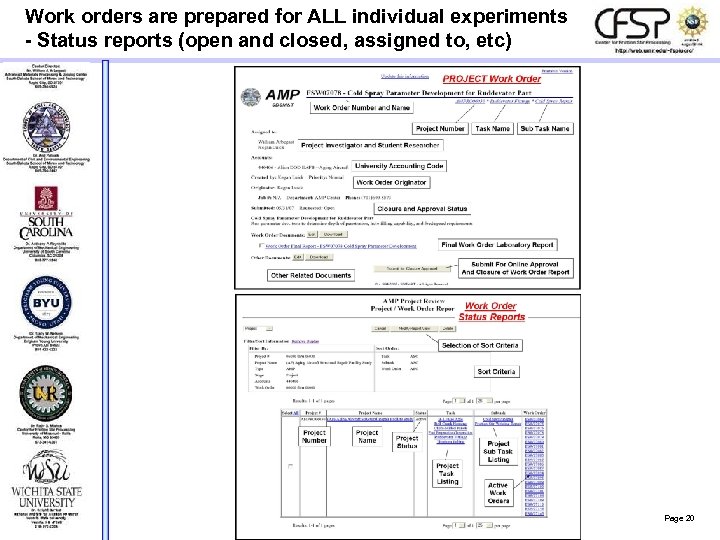

Work orders are prepared for ALL individual experiments - Status reports (open and closed, assigned to, etc) Page 20

Work orders are prepared for ALL individual experiments - Status reports (open and closed, assigned to, etc) Page 20

Each Work Order (Experiment) is Completed with a Formal Laboratory Report and electronically submitted Approved WO Are Closed … Rejected WO are sent back to student for rework and is electronically resubmitted to PI for approval Page 21

Each Work Order (Experiment) is Completed with a Formal Laboratory Report and electronically submitted Approved WO Are Closed … Rejected WO are sent back to student for rework and is electronically resubmitted to PI for approval Page 21

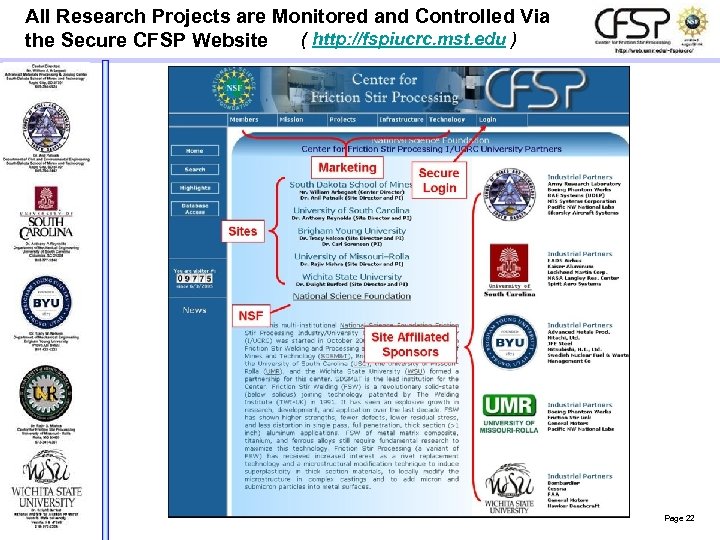

All Research Projects are Monitored and Controlled Via ( http: //fspiucrc. mst. edu ) the Secure CFSP Website Page 22

All Research Projects are Monitored and Controlled Via ( http: //fspiucrc. mst. edu ) the Secure CFSP Website Page 22

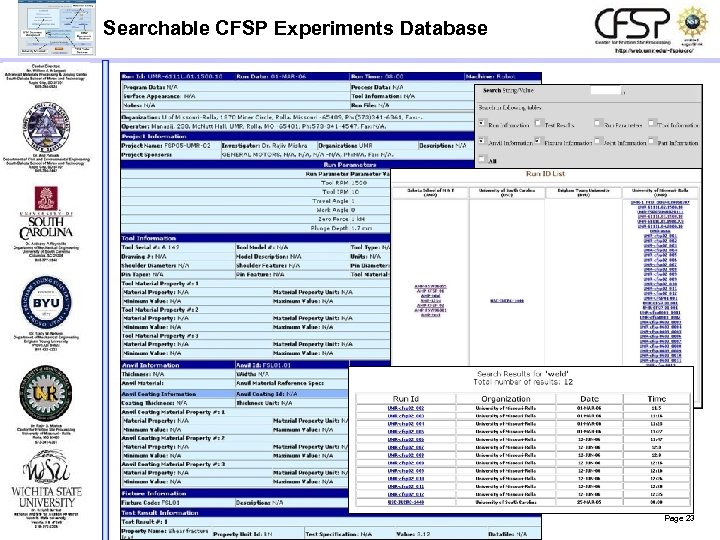

Searchable CFSP Experiments Database Page 23

Searchable CFSP Experiments Database Page 23

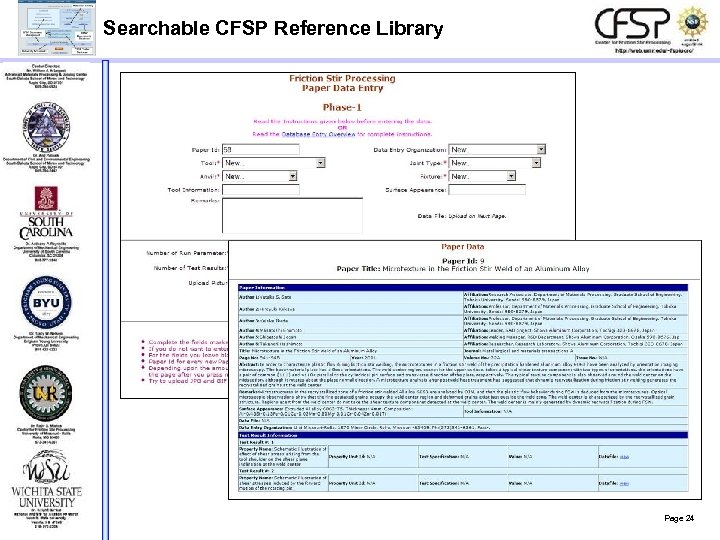

Searchable CFSP Reference Library Page 24

Searchable CFSP Reference Library Page 24

CFSP Reporting and Documentation are available on Website • CFSP Quarterly Reports are Posted on the Website for Member Reviews • CFSP Annual Members Reports is uploaded to website and hardcopies to be distributed after Final Revisions • CFSP NSF Annual Center Report has been submitted and should be available on the website soon (includes independent evaluators report) • Spring IAB Meeting Life Form Response and Action Items sent to members and uploaded to Website Page 25

CFSP Reporting and Documentation are available on Website • CFSP Quarterly Reports are Posted on the Website for Member Reviews • CFSP Annual Members Reports is uploaded to website and hardcopies to be distributed after Final Revisions • CFSP NSF Annual Center Report has been submitted and should be available on the website soon (includes independent evaluators report) • Spring IAB Meeting Life Form Response and Action Items sent to members and uploaded to Website Page 25

Quarterly Reports are Prepared For Each Project and Uploaded for Sponsor Review 1 Page Max Each Current Project has a QTR Report Prepared every 3 months Page 26

Quarterly Reports are Prepared For Each Project and Uploaded for Sponsor Review 1 Page Max Each Current Project has a QTR Report Prepared every 3 months Page 26

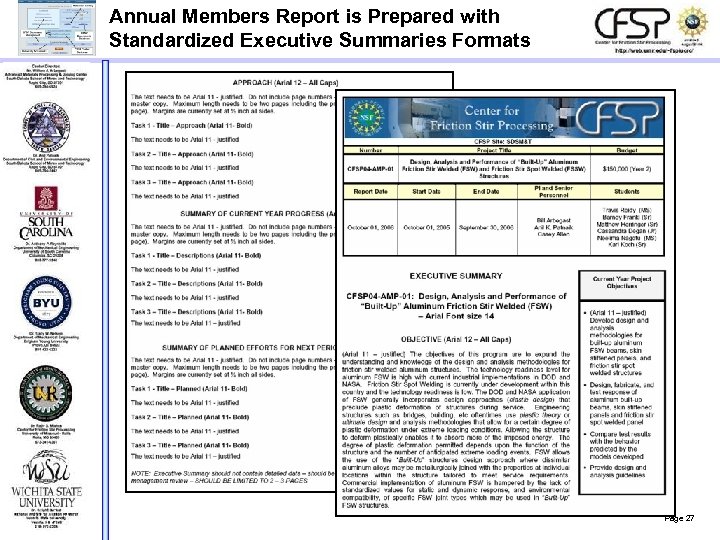

Annual Members Report is Prepared with Standardized Executive Summaries Formats Page 27

Annual Members Report is Prepared with Standardized Executive Summaries Formats Page 27

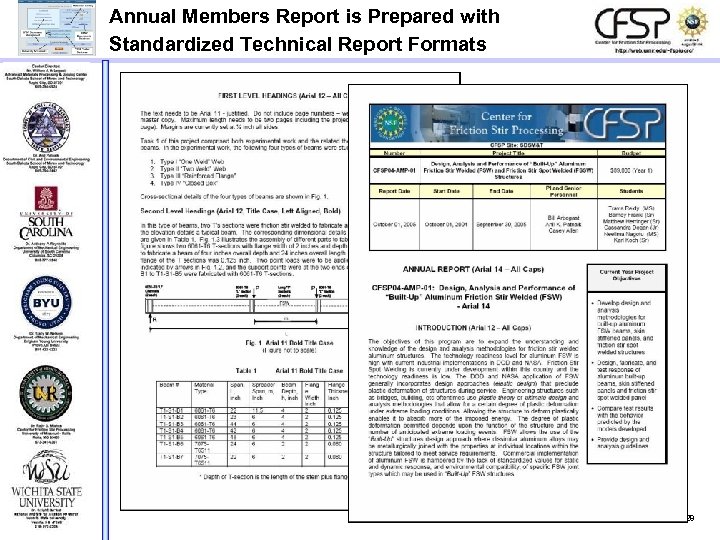

Annual Members Report is Prepared with Standardized Technical Report Formats Page 28

Annual Members Report is Prepared with Standardized Technical Report Formats Page 28

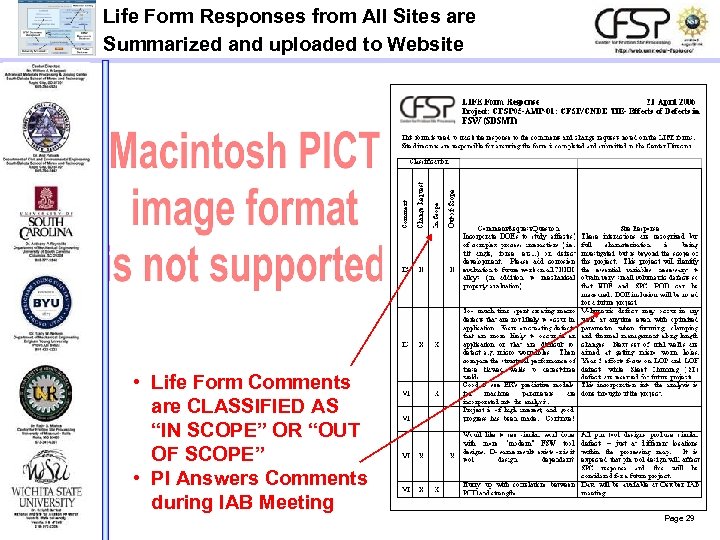

Life Form Responses from All Sites are Summarized and uploaded to Website • Life Form Comments are CLASSIFIED AS “IN SCOPE” OR “OUT OF SCOPE” • PI Answers Comments during IAB Meeting Page 29

Life Form Responses from All Sites are Summarized and uploaded to Website • Life Form Comments are CLASSIFIED AS “IN SCOPE” OR “OUT OF SCOPE” • PI Answers Comments during IAB Meeting Page 29

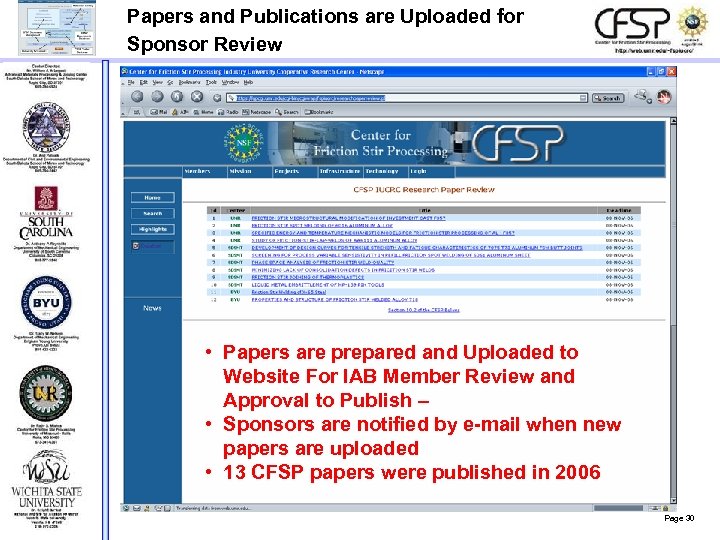

Papers and Publications are Uploaded for Sponsor Review • Papers are prepared and Uploaded to Website For IAB Member Review and Approval to Publish – • Sponsors are notified by e-mail when new papers are uploaded • 13 CFSP papers were published in 2006 Page 30

Papers and Publications are Uploaded for Sponsor Review • Papers are prepared and Uploaded to Website For IAB Member Review and Approval to Publish – • Sponsors are notified by e-mail when new papers are uploaded • 13 CFSP papers were published in 2006 Page 30

Action Items from IAB Meetings are Tracked and Controlled on the Website Page 31

Action Items from IAB Meetings are Tracked and Controlled on the Website Page 31

Center Performance Metrics Per NSF Best Practices are Tracked NSF IUCRC “Best Practices” Page 32

Center Performance Metrics Per NSF Best Practices are Tracked NSF IUCRC “Best Practices” Page 32

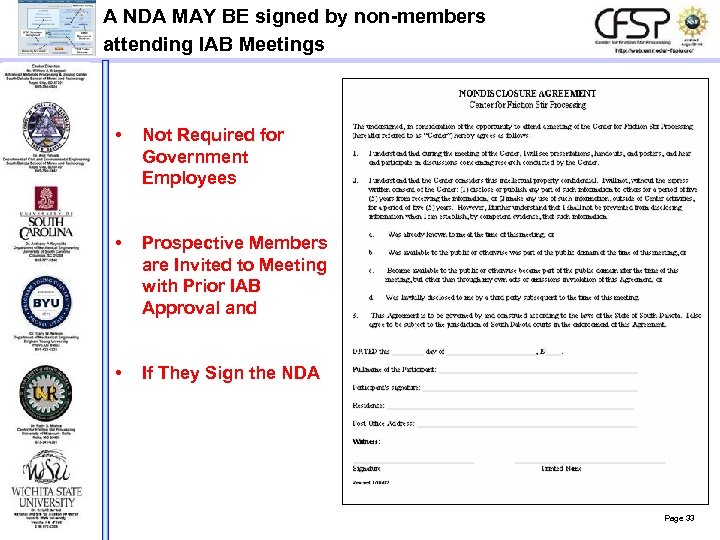

A NDA MAY BE signed by non-members attending IAB Meetings • Not Required for Government Employees • Prospective Members are Invited to Meeting with Prior IAB Approval and • If They Sign the NDA Page 33

A NDA MAY BE signed by non-members attending IAB Meetings • Not Required for Government Employees • Prospective Members are Invited to Meeting with Prior IAB Approval and • If They Sign the NDA Page 33

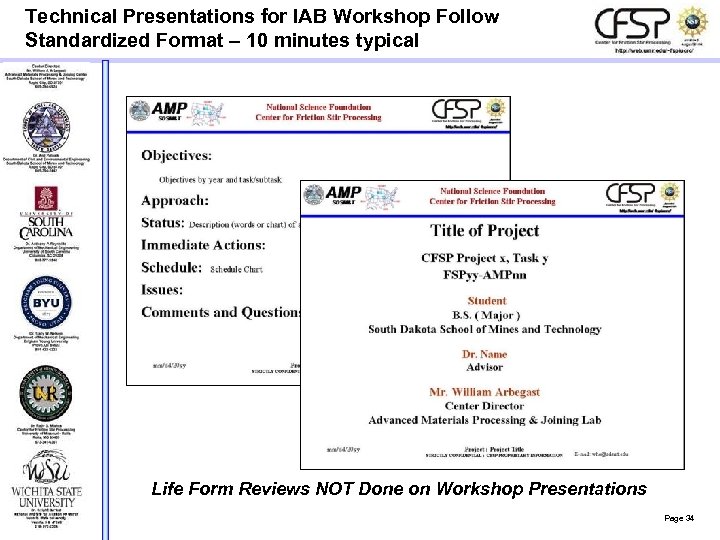

Technical Presentations for IAB Workshop Follow Standardized Format – 10 minutes typical Life Form Reviews NOT Done on Workshop Presentations Page 34

Technical Presentations for IAB Workshop Follow Standardized Format – 10 minutes typical Life Form Reviews NOT Done on Workshop Presentations Page 34

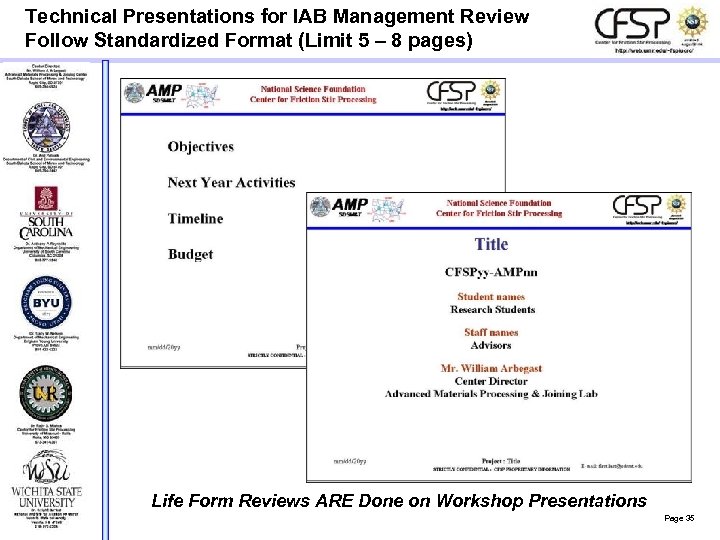

Technical Presentations for IAB Management Review Follow Standardized Format (Limit 5 – 8 pages) Life Form Reviews ARE Done on Workshop Presentations Page 35

Technical Presentations for IAB Management Review Follow Standardized Format (Limit 5 – 8 pages) Life Form Reviews ARE Done on Workshop Presentations Page 35

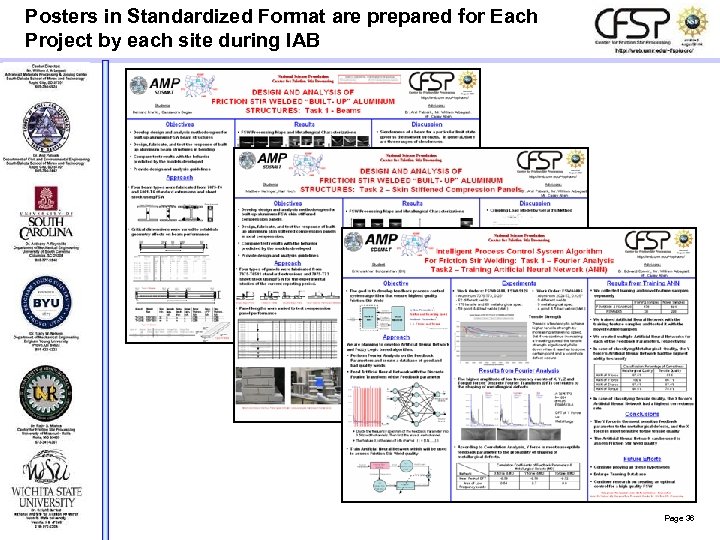

Posters in Standardized Format are prepared for Each Project by each site during IAB Page 36

Posters in Standardized Format are prepared for Each Project by each site during IAB Page 36

The CFSP hosts various activities to ensure student participation – and have FUN B-Day Parties Industrial Speakers Annual Picnics Native American Outreach AMP Stock Undergraduate Capstone Design More CFSP Picnics Page 37

The CFSP hosts various activities to ensure student participation – and have FUN B-Day Parties Industrial Speakers Annual Picnics Native American Outreach AMP Stock Undergraduate Capstone Design More CFSP Picnics Page 37

”Marketing -- hey- I got pictures- Wanna Join the CFSP ? ” Page 38

”Marketing -- hey- I got pictures- Wanna Join the CFSP ? ” Page 38

”Wait –there is more ---Under a IUCRC REU Supplement “Team Bob” is Automating the AMP and CFSP Website and Standardized Documents Forms and Reports– Matt will tell you more. . Matt Desenfants (Fr) Chris Cody (Soph) Jordan Ritz (Soph) Page 39

”Wait –there is more ---Under a IUCRC REU Supplement “Team Bob” is Automating the AMP and CFSP Website and Standardized Documents Forms and Reports– Matt will tell you more. . Matt Desenfants (Fr) Chris Cody (Soph) Jordan Ritz (Soph) Page 39